Choosing Your 40 Gallon Planter: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 40 gallon planter

In today’s rapidly evolving agricultural landscape, sourcing the right 40-gallon planter is a pivotal challenge for B2B buyers across the globe. The demand for large-capacity planters is surging as businesses look to optimize space, enhance plant growth, and improve operational efficiency. This comprehensive guide addresses the complexities of navigating the global market for 40-gallon planters, focusing on key aspects such as types, applications, supplier vetting, and cost considerations.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including Germany and Saudi Arabia—will find valuable insights tailored to their unique market dynamics. By exploring different materials, design features, and functionality, this guide empowers B2B purchasers to make informed decisions that align with their operational needs and sustainability goals.

Additionally, the guide highlights best practices for evaluating suppliers, ensuring that businesses engage with reliable partners who meet quality standards and regulatory requirements. With a focus on actionable insights and strategic sourcing, this resource is designed to facilitate successful procurement processes, ultimately driving growth and innovation in the horticultural sector.

Understanding 40 gallon planter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Plastic Container | Made from recycled polyethylene; lateral handles for easy transport | Nurseries, large-scale gardening, landscaping | Pros: Durable, lightweight, eco-friendly. Cons: Limited color options. |

| Self-Watering Planter | Integrated reservoir for consistent moisture; reduces labor costs | Urban gardening, commercial landscaping | Pros: Low maintenance, efficient water usage. Cons: Higher initial cost. |

| Nursery Pot | Designed for excellent drainage; robust construction | Plant nurseries, agricultural production | Pros: Good root growth, stackable. Cons: Bulky, requires LTL shipping. |

| Grow Bags | Made from breathable fabric; lightweight and flexible | Hydroponics, small-scale farming | Pros: Promotes healthy root systems, easy to store. Cons: Less durable than plastic. |

| Camo Grow Bag | Unique camouflage design; made from durable fabric | Specialty retail, outdoor applications | Pros: Aesthetic appeal, good for outdoor use. Cons: May be less common in supply chains. |

What are the Characteristics and Suitability of Heavy-Duty Plastic Containers?

Heavy-duty plastic containers are typically constructed from recycled polyethylene, making them both durable and eco-friendly. They often feature lateral handles for easy transport, which is advantageous for nurseries and landscaping businesses. When considering these containers, B2B buyers should assess their weight capacity and resistance to environmental factors, ensuring they meet the demands of their specific applications.

How Do Self-Watering Planters Enhance Efficiency in Commercial Gardening?

Self-watering planters are designed with an integrated reservoir that allows for consistent moisture levels, reducing the need for frequent watering. This feature is particularly beneficial for urban gardening and commercial landscaping, where labor costs can be significant. Buyers should evaluate the size of the reservoir and the materials used to ensure they align with their operational needs and climate conditions.

What Makes Nursery Pots a Reliable Choice for Plant Production?

Nursery pots are engineered for optimal drainage, which is crucial for preventing root rot and promoting healthy plant growth. Their robust construction allows for stacking, making them space-efficient for agricultural production. B2B buyers should consider the shipping logistics, as these pots are often bulky and may require less-than-truckload (LTL) shipping, impacting overall costs.

Why Choose Grow Bags for Small-Scale Farming?

Grow bags are made from breathable fabric, which encourages healthy root systems by allowing air circulation. They are lightweight and flexible, making them suitable for hydroponics and small-scale farming operations. Buyers should consider the longevity of the fabric and its resistance to environmental wear when selecting grow bags for their operations.

What Advantages Do Camo Grow Bags Offer for Outdoor Applications?

Camo grow bags feature a unique camouflage design, appealing to specialty retail and outdoor applications. Made from durable fabric, they provide functionality while enhancing aesthetic appeal. However, buyers should be aware that these may not be as commonly available in supply chains, which could affect procurement timelines.

Key Industrial Applications of 40 gallon planter

| Industry/Sector | Specific Application of 40 gallon planter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Hydroponic and aquaponic farming systems | Provides a controlled environment for optimal growth | Durability, UV resistance, and drainage capabilities are essential. |

| Landscaping | Urban landscaping projects, parks, and public spaces | Enhances aesthetic appeal while ensuring plant health | Sourcing should consider local climate adaptability and design. |

| Horticulture | Nursery production for large plants and trees | Supports healthy root development and reduces disease | Ensure containers are stackable and easy to transport. |

| Retail Gardening | Retail garden centers for showcasing plants | Attracts customers with visually appealing displays | Look for lightweight, portable options with good drainage. |

| Environmental Projects | Reforestation and ecological restoration initiatives | Contributes to environmental sustainability efforts | Sourcing should prioritize recycled materials and ecological impact. |

How is the 40 Gallon Planter Used in Agriculture?

In agriculture, the 40-gallon planter is pivotal for hydroponic and aquaponic farming systems. These planters create a controlled environment that optimizes plant growth by managing water and nutrient delivery. International buyers, particularly from regions like Africa and South America, often seek planters that are durable and UV resistant to withstand harsh climates. Additionally, proper drainage capabilities are crucial to prevent root diseases, making it essential for buyers to verify these specifications when sourcing.

What Role Does the 40 Gallon Planter Play in Landscaping?

The landscaping industry utilizes 40-gallon planters for urban projects, parks, and public spaces, enhancing aesthetic appeal while ensuring plant health. These planters allow for the strategic placement of plants that can thrive in urban settings. Buyers in Europe, especially in countries like Germany, should consider the adaptability of materials to local climates and the design of the planters to complement urban landscapes. Sourcing durable options that are visually appealing can significantly impact project success.

Why is the 40 Gallon Planter Important for Horticulture?

In horticulture, the 40-gallon planter is essential for nursery production, particularly for larger plants and trees. It supports healthy root development and minimizes the risk of disease, which is vital for maintaining plant quality. Buyers, especially those in the Middle East, need to ensure that the containers are stackable and easy to transport to optimize logistics and reduce costs. The ability to handle large volumes of soil while providing excellent drainage is another critical consideration.

How Can Retail Gardening Benefit from 40 Gallon Planters?

For retail gardening centers, 40-gallon planters serve as an effective way to showcase plants, attracting customers with visually appealing displays. These planters allow for a diverse range of plants to be exhibited, encouraging purchases. Buyers should prioritize lightweight and portable options with good drainage to facilitate easy movement and maintenance. Additionally, sourcing planters that align with customer preferences can enhance sales opportunities.

What is the Contribution of 40 Gallon Planters to Environmental Projects?

In environmental projects, such as reforestation and ecological restoration initiatives, 40-gallon planters play a crucial role. They enable organizations to cultivate young plants and trees in controlled conditions, contributing to sustainability efforts. Buyers should focus on sourcing planters made from recycled materials to align with ecological goals. It is also important to consider the planters’ environmental impact, ensuring they support the overall objectives of restoration projects.

3 Common User Pain Points for ’40 gallon planter’ & Their Solutions

Scenario 1: Difficulty in Transporting Large Planters

The Problem: B2B buyers often encounter challenges when transporting 40-gallon planters, especially in regions with limited infrastructure or when handling large quantities. The weight and size of these planters can lead to logistical issues, including damage during transit, increased shipping costs, or even worker injuries during loading and unloading. This is particularly concerning for buyers in developing markets, where road conditions can be unpredictable.

The Solution: To mitigate transportation issues, buyers should prioritize sourcing planters that come with integrated handles or are designed for easier handling. For instance, heavy-duty containers like the Gro Pro Heavy Duty Container feature built-in lateral handles that facilitate safe carrying and loading. Additionally, it’s essential to evaluate the material of the planters; opting for lightweight yet durable options can reduce shipping costs and ease transportation. When placing orders, consider consolidating shipments to maximize truck space and reduce costs per unit. Engaging with suppliers who offer palletized shipping can also enhance efficiency and minimize damage.

Scenario 2: Inconsistent Drainage and Plant Health Risks

The Problem: Another significant pain point for B2B buyers is ensuring adequate drainage in 40-gallon planters. Poor drainage can lead to root rot and other diseases, adversely affecting plant health and increasing the risk of crop failure. This issue is particularly critical in regions with high humidity or heavy rainfall, where water accumulation can quickly become a problem.

The Solution: To address drainage concerns, buyers should select planters specifically engineered with multiple drainage holes. For example, containers like the 45-gallon nursery pots are designed with strategically placed drain holes that optimize soil drainage and reduce the risk of standing water. When specifying orders, inquire about the drainage design of the planters and request samples to evaluate their performance. Implementing a soil mix that includes drainage-enhancing components, such as perlite or vermiculite, can further improve water management. It’s also advisable to monitor moisture levels regularly and adjust watering practices based on environmental conditions.

Scenario 3: Limited Customization Options for Planting Needs

The Problem: B2B buyers often face limitations in customizing 40-gallon planters to meet specific planting needs, such as the type of plants being cultivated or aesthetic requirements for commercial landscaping. This can lead to inefficiencies in planting strategies and dissatisfaction among clients or end-users who expect tailored solutions.

The Solution: To enhance customization, buyers should seek suppliers that offer a range of planter designs, colors, and materials. Engaging with manufacturers like Cherokee Manufacturing, which provides options for various styles and features, can help meet diverse client needs. Additionally, consider collaborating with suppliers that allow for bulk orders with custom branding or specific modifications. Implementing modular planting systems can also offer flexibility, allowing for different plant species to thrive in the same container. Buyers should communicate their unique requirements clearly to suppliers to explore potential customization opportunities that can enhance both functionality and aesthetic appeal.

Strategic Material Selection Guide for 40 gallon planter

What are the Key Materials for 40 Gallon Planters?

When selecting a 40-gallon planter, the choice of material is crucial for ensuring optimal performance, longevity, and suitability for various applications. Below is an analysis of four common materials used in manufacturing 40-gallon planters, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Polyethylene (PE) Perform in 40 Gallon Planters?

Polyethylene is a widely used plastic in the production of planters. It offers excellent resistance to moisture and UV radiation, making it suitable for outdoor use. The temperature tolerance of polyethylene ranges from -40°F to 180°F, which allows it to withstand various climates.

Pros: Polyethylene planters are lightweight, durable, and resistant to cracking. They are also cost-effective, making them a popular choice for large-scale agricultural applications.

Cons: While they are durable, polyethylene can degrade over time when exposed to extreme weather conditions, particularly UV light. Additionally, they may not provide the best insulation for roots compared to other materials.

Impact on Application: Polyethylene is compatible with various growing media, including soil and hydroponic systems. However, its drainage capabilities depend on the design of the planter.

International Considerations: Buyers from regions like Africa and the Middle East should ensure that the polyethylene used complies with local environmental regulations. In Europe, adherence to standards such as REACH and the Plastics Directive is essential.

What are the Benefits of Using Fiberglass for 40 Gallon Planters?

Fiberglass is another popular choice for planters due to its strength and aesthetic appeal. It is resistant to corrosion and can handle a wide range of temperatures, making it suitable for both hot and cold climates.

Pros: Fiberglass planters are extremely durable and can last for many years without significant wear. They are also lightweight and can be molded into various shapes and designs.

Cons: The initial cost of fiberglass planters is typically higher than that of plastic options. Additionally, they may require more complex manufacturing processes, which can affect lead times.

Impact on Application: Fiberglass planters can support a variety of soil types and are often used for decorative purposes in urban settings. Their insulation properties help maintain soil temperature, benefiting plant growth.

International Considerations: Buyers in Europe may prefer fiberglass planters due to their aesthetic qualities, while buyers in developing regions may be deterred by the higher price point. Compliance with local safety and environmental regulations is also crucial.

How Does Metal Compare for 40 Gallon Planters?

Metal planters, particularly those made from aluminum or galvanized steel, offer a robust option for large-scale planting. They have excellent durability and can withstand harsh weather conditions without degrading.

Pros: Metal planters are highly durable and resistant to pests and rot. They can also be recycled, making them an environmentally friendly option.

Cons: The thermal conductivity of metal can lead to overheating in hot climates, which may harm plant roots. Additionally, they can be heavier and more expensive than plastic alternatives.

Impact on Application: Metal planters are suitable for a variety of growing media, but their drainage design is critical to prevent waterlogging.

International Considerations: Buyers should be aware of local regulations regarding metal use and recycling. In regions like Germany, adherence to strict recycling standards is essential.

What Role Does Wood Play in 40 Gallon Planters?

Wooden planters, often treated for durability, provide a natural aesthetic and can be an excellent choice for landscaping.

Pros: Wooden planters are biodegradable and can blend well into natural environments. They provide good insulation for roots, helping to maintain soil temperature.

Cons: Wood is susceptible to rot and pests, requiring regular maintenance and treatment. The lifespan of wooden planters may be shorter than that of plastic or metal options.

Impact on Application: Wooden planters are ideal for soil-based growing media but may require additional drainage solutions to prevent water accumulation.

International Considerations: Buyers should ensure that the wood used is sourced sustainably and complies with local forestry regulations, particularly in Europe where environmental standards are stringent.

Summary Table of Material Selection for 40 Gallon Planters

| Material | Typical Use Case for 40 gallon planter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | General horticulture and agriculture | Lightweight and durable | UV degradation over time | Low |

| Fiberglass | Decorative urban landscaping | Long-lasting and aesthetic | Higher initial cost | High |

| Metal | Commercial landscaping and urban areas | Extremely durable | Can overheat in hot climates | Medium |

| Wood | Residential gardens and landscaping | Natural aesthetic and insulation | Susceptible to rot | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 40 gallon planter

What Are the Main Stages in the Manufacturing Process of 40 Gallon Planters?

The manufacturing process of 40-gallon planters involves several key stages that ensure both durability and functionality. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first stage involves selecting the right materials, which are often high-density polyethylene (HDPE) or recycled polyethylene (PE) plastics. These materials are chosen for their durability, UV resistance, and ability to withstand various environmental conditions. In some cases, additives are incorporated to enhance specific properties such as impact resistance and color stability.

-

Forming: After material preparation, the forming process begins. This is commonly done using blow molding or injection molding techniques. Blow molding is particularly favored for large planters, as it allows for the creation of hollow structures that are lightweight yet strong. The mold is heated, and air is blown into the plastic to form the desired shape of the planter.

-

Assembly: In the assembly phase, any additional components, such as drainage holes, handles, or water reservoirs, are integrated into the planter. For instance, built-in lateral handles can be added to enhance portability. The assembly process must ensure that all components are securely attached and meet design specifications.

-

Finishing: The final stage of manufacturing includes surface treatment and quality checks. This may involve adding UV stabilizers to prevent fading and increasing the planter’s lifespan. The planters are then inspected for any defects or inconsistencies before being packaged for distribution.

Which Key Techniques Are Employed in the Production of 40 Gallon Planters?

The production of 40-gallon planters employs several advanced techniques to ensure product quality and efficiency:

-

Blow Molding: This technique is essential for creating seamless, hollow planters. It allows manufacturers to produce large quantities with consistent quality and minimal waste.

-

Injection Molding: Used for smaller components or specialized features, this method allows for high precision and complex shapes that enhance the planter’s functionality.

-

Thermoforming: In some cases, thermoforming is used to shape the planters from sheets of plastic. This technique is cost-effective for producing various sizes and shapes.

How Are Quality Control Measures Integrated into the Manufacturing Process?

Quality control (QC) is a critical aspect of manufacturing 40-gallon planters. Adhering to international standards, such as ISO 9001, ensures that manufacturers maintain a high level of quality throughout the production process. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers must provide certificates of compliance to ensure that the materials meet specified quality standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to identify any deviations from quality standards. This includes monitoring temperatures during molding and ensuring that dimensions meet design specifications.

-

Final Quality Control (FQC): Before shipment, each planter undergoes a final inspection to check for defects, verify functionality (such as drainage), and confirm compliance with international standards.

What International Standards and Certifications Should B2B Buyers Look For?

B2B buyers should be aware of various international standards and certifications that can impact the quality and safety of 40-gallon planters. Key certifications include:

-

ISO 9001: This quality management standard ensures that manufacturers maintain consistent quality in their processes, leading to higher customer satisfaction.

-

CE Marking: For products sold in the European Union, CE marking indicates conformity with health, safety, and environmental protection standards.

-

API Standards: While primarily associated with the petroleum industry, certain API standards may be relevant for manufacturers producing planters that require specific material properties or safety features.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers adhere to stringent quality control processes, B2B buyers can take several steps:

-

Audits: Conducting on-site audits of manufacturing facilities can provide insight into the supplier’s production capabilities and adherence to quality standards. This allows buyers to assess the equipment, processes, and overall management systems in place.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s historical performance regarding defects, returns, and customer complaints. These reports should outline the supplier’s QC procedures and results from recent inspections.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s production processes. These inspections can occur at various stages of production, providing an additional layer of assurance.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following nuances in QC and certifications:

-

Regulatory Compliance: Different regions have specific regulations governing product safety and environmental impact. Buyers should ensure that suppliers are compliant with local laws, especially when importing products.

-

Cultural Differences: Understanding cultural attitudes towards quality and safety can be crucial in international trade. Buyers should communicate their quality expectations clearly and be aware of any regional standards that may differ from their own.

-

Logistics and Shipping: International shipping can introduce risks related to product damage and compliance with import regulations. Buyers should verify that suppliers have robust packaging and logistics strategies in place to mitigate these risks.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and choose suppliers that align with their quality standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’40 gallon planter’

To assist international B2B buyers in effectively sourcing a 40-gallon planter, this guide offers a structured checklist. Each step is designed to ensure that buyers make informed decisions, maximizing both product quality and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for your 40-gallon planter is essential to meet your project requirements. Consider factors such as material type (e.g., recycled polyethylene, BPA-free plastic), dimensions, and weight capacity. These specifications will help narrow down your options and ensure compatibility with your intended use.

Step 2: Research Market Trends and Requirements

Understanding market trends in your target regions can guide your purchasing decisions. For instance, in Africa and the Middle East, demand may lean towards durable, weather-resistant planters, while European buyers might prioritize eco-friendly materials. Stay updated on regional preferences to align your sourcing strategy with local market needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they can meet your demands. Request company profiles, certifications, and customer references. Additionally, consider their track record in your specific region, as this can influence delivery times and service reliability.

- What to Look For:

- Supplier’s experience in the industry.

- Availability of testimonials from similar clients.

Step 4: Assess Product Quality and Compliance

Quality assurance is vital when sourcing planters. Verify that the products meet international standards and are compliant with any local regulations, particularly concerning environmental impact. Request samples when possible to evaluate the product firsthand, focusing on durability, drainage capabilities, and ease of handling.

Step 5: Negotiate Pricing and Terms

Once you have shortlisted suppliers, enter negotiations to secure the best pricing and terms. Consider factors such as bulk discounts, payment terms, and shipping costs. Establishing clear agreements can prevent misunderstandings and help build a long-term relationship with your supplier.

Step 6: Plan for Logistics and Shipping

Effective logistics planning is crucial for international procurement. Ensure that your chosen supplier has reliable shipping options that comply with import/export regulations in your target market. Discuss delivery timelines and packaging requirements to avoid damage during transport.

- Key Considerations:

- Shipping methods and associated costs.

- Customs documentation and compliance.

Step 7: Establish a Feedback Loop

After procurement, maintain a feedback loop with your supplier. Provide insights on product performance and any issues encountered. This ongoing communication can foster improvements and strengthen your business relationship, paving the way for future collaborations.

By following these steps, B2B buyers can ensure a successful procurement process for 40-gallon planters, ultimately leading to enhanced operational efficiency and customer satisfaction.

Comprehensive Cost and Pricing Analysis for 40 gallon planter Sourcing

What Are the Key Cost Components for Sourcing a 40 Gallon Planter?

When sourcing 40-gallon planters, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the planter’s price. Common options like recycled polyethylene (PE) are often more cost-effective but may vary in quality. Higher-grade materials, such as those used in heavy-duty or self-watering planters, can lead to increased costs.

-

Labor: Labor costs can vary widely based on the manufacturing location. Regions with higher labor costs (e.g., parts of Europe) may yield higher prices for planters. Conversely, sourcing from regions with lower labor costs can enhance cost efficiency.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient production processes can help keep overhead low, impacting the final price.

-

Tooling: Custom tooling for specific planter designs can add to initial costs. However, this is often a one-time expense that can be amortized over larger production runs.

-

Quality Control (QC): Ensuring quality through rigorous QC processes may add to costs but is vital for maintaining product standards, especially for international markets that may require specific certifications.

-

Logistics: Shipping costs are a significant factor, particularly for large and heavy items like 40-gallon planters. Considerations include the mode of transport, distance, and any tariffs or duties applicable in the destination country.

-

Margin: Supplier margins can vary based on the competitive landscape and brand reputation. Understanding the typical margins in your target market can aid in negotiation.

How Do Price Influencers Affect the Cost of 40 Gallon Planters?

Several factors influence the pricing of 40-gallon planters, including:

-

Volume/MOQ: Suppliers often offer lower prices for larger orders. Understanding the minimum order quantity (MOQ) can help buyers negotiate better deals.

-

Specifications and Customization: Custom features, such as specific colors, sizes, or functionalities (like self-watering), typically increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: The quality of materials used can dictate the price. Planters with certifications for sustainability or safety may carry a premium.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge more due to their perceived value.

-

Incoterms: Understanding the agreed Incoterms is crucial for managing logistics and associated costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence the total cost of ownership.

What Are the Best Negotiation Tips for International Buyers of 40 Gallon Planters?

For international B2B buyers, effective negotiation and understanding the total cost of ownership are essential:

-

Leverage Volume: When possible, consolidate orders to reach higher volumes, which can unlock better pricing and terms.

-

Research Local Market Prices: Understanding prevailing market prices in your region can provide leverage during negotiations. This knowledge helps avoid overpaying.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but also shipping costs, potential tariffs, and maintenance expenses over the planter’s lifespan. This holistic view can lead to more informed purchasing decisions.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Trust and reliability often lead to more favorable negotiations.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations and their impact on pricing. Engage in currency hedging strategies if necessary to mitigate risks.

Conclusion

In summary, understanding the comprehensive cost structure and various price influencers is critical for international B2B buyers sourcing 40-gallon planters. By focusing on key components such as materials, labor, and logistics, as well as effective negotiation strategies, buyers can optimize their sourcing process and achieve cost efficiency. Always keep in mind that prices are indicative and subject to change based on market conditions and supplier factors.

Alternatives Analysis: Comparing 40 gallon planter With Other Solutions

Exploring Alternatives to the 40 Gallon Planter

When considering planting solutions, the 40-gallon planter is a popular choice for its capacity and versatility. However, various alternatives exist that may better suit specific needs, particularly in different geographical markets. This analysis will compare the 40-gallon planter with two viable alternatives: the 45-gallon nursery pot and self-watering planters. By evaluating performance, cost, ease of implementation, maintenance, and best use cases, international B2B buyers can make informed decisions.

| Comparison Aspect | 40 Gallon Planter | 45 Gallon Nursery Pot | Self-Watering Planter |

|---|---|---|---|

| Performance | Good for larger plants; ample space for root growth. | Excellent drainage; supports larger plant material. | Consistent moisture levels; reduces watering frequency. |

| Cost | $26.39 per unit | $13.63 – $18.00 per unit | Varies widely; typically higher initial cost. |

| Ease of Implementation | Requires manual handling; heavy. | Easy to handle with built-in grips. | Some models require assembly; generally straightforward. |

| Maintenance | Moderate; regular watering needed. | Low; designed for durability. | Low; self-watering feature minimizes effort. |

| Best Use Case | Ideal for large gardens or nurseries needing space. | Suitable for nurseries or commercial growers with larger plants. | Perfect for urban gardens or areas with water restrictions. |

In-Depth Analysis of Alternatives

45 Gallon Nursery Pot

The 45-gallon nursery pot offers a slightly larger capacity than the 40-gallon planter, which can be beneficial for specific plant types that require extensive root systems. Its design includes embedded carrying handles, making it easier to transport. Additionally, engineered drainage holes help prevent waterlogging, which is critical for plant health. While the cost is competitive, the pot’s bulkiness may pose challenges in logistics for international buyers, especially in regions with limited transport infrastructure.

Self-Watering Planter

Self-watering planters provide an innovative approach to maintaining plant hydration. This solution is particularly advantageous in regions where water scarcity is a concern. The built-in reservoir allows for consistent moisture levels, reducing the frequency of watering. However, the initial investment can be higher than traditional planters, and some models may require assembly. Despite these factors, the convenience and efficiency of self-watering systems make them appealing to urban gardeners and commercial operations focused on sustainability.

Making the Right Choice for Your Needs

Choosing the right planting solution involves understanding the specific requirements of your business. Consider factors such as the types of plants you intend to cultivate, your operational capacity for maintenance, and the geographical challenges you face. The 40-gallon planter remains a robust option for larger spaces, while alternatives like the 45-gallon nursery pot and self-watering planters can cater to specific needs. Ultimately, aligning your choice with your operational strategy will ensure optimal results and a better return on investment.

Essential Technical Properties and Trade Terminology for 40 gallon planter

What Are the Key Technical Properties of a 40 Gallon Planter?

When sourcing a 40-gallon planter, understanding its technical properties is crucial for ensuring it meets your agricultural or horticultural needs. Here are several critical specifications:

-

Material Grade

Most 40-gallon planters are constructed from high-density polyethylene (HDPE) or recycled polyethylene (PE). HDPE is known for its durability and resistance to UV rays and extreme weather conditions, making it ideal for outdoor use. For B2B buyers, selecting a planter made from high-quality materials can lead to longer product life and lower replacement costs. -

Weight Capacity

The weight capacity of a planter is essential for determining how many plants or how much soil it can hold without risking structural integrity. A typical 40-gallon planter can weigh approximately 9.8 lbs when empty, but once filled, it can significantly increase in weight. B2B buyers should consider weight for shipping and handling logistics, especially in regions where transport can be challenging. -

Drainage Design

Effective drainage is crucial for root health. A 40-gallon planter should feature strategically placed drainage holes to prevent water accumulation, which can lead to root rot. Understanding drainage design helps buyers ensure that the planter can support healthy plant growth, ultimately affecting yield and profitability. -

Dimensions

The dimensions of the planter (often around 32.3 inches in diameter and 23.1 inches in height) influence how much space it occupies and its suitability for various plant types. For B2B buyers, knowing the dimensions is key for optimizing space in nurseries or retail environments. -

Handle Design

Built-in lateral handles are a common feature in many 40-gallon planters, facilitating easier transportation. For businesses involved in logistics and plant sales, ergonomic design can reduce labor costs and improve efficiency during handling and shipping. -

Recyclability

With increasing emphasis on sustainability, many planters are made from recyclable materials. Understanding a planter’s recyclability can be a selling point for businesses focused on eco-friendly practices, appealing to environmentally conscious consumers.

What Are Common Trade Terms Associated with 40 Gallon Planters?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality products and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses, knowing the MOQ helps in budgeting and inventory planning, as it can affect cash flow and storage needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ is a strategic step to obtain competitive pricing and assess supplier capabilities. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with these terms ensures clarity in shipping, insurance, and customs duties, thus minimizing risks in cross-border transactions. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving it. Understanding lead times is critical for businesses planning their inventory cycles and ensuring timely product availability. -

Pallet Quantity

Pallet quantity indicates how many planters can be shipped on a standard pallet. This metric is important for logistics planning, as it affects shipping costs and warehouse storage efficiency.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 40-gallon planters, ensuring they choose products that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the 40 gallon planter Sector

What Are the Key Trends Influencing the 40 Gallon Planter Market?

The global market for 40-gallon planters is experiencing significant growth, driven by increasing urbanization, a rising demand for sustainable gardening solutions, and the need for efficient agricultural practices. International B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, are increasingly sourcing these planters to support both commercial and residential landscaping projects. The trend towards vertical gardening and urban farming is particularly pronounced, with 40-gallon planters offering a versatile solution for limited space environments.

Moreover, technological advancements in manufacturing are leading to the development of lightweight, durable materials such as recycled polyethylene (PE) and high-density polyethylene (HDPE). These materials not only enhance the planters’ longevity but also improve their aesthetic appeal. Emerging trends like self-watering systems and modular designs are gaining traction, as they provide added convenience and efficiency for users. Additionally, global supply chains are adapting to incorporate just-in-time inventory systems, facilitating quicker delivery times and reducing overhead costs for B2B buyers.

How Is Sustainability Shaping the Sourcing of 40 Gallon Planters?

Sustainability is at the forefront of sourcing strategies in the 40-gallon planter sector. As environmental concerns escalate, buyers are prioritizing products that are made from sustainable materials and manufactured through eco-friendly processes. Planters made from recycled plastics not only minimize waste but also align with the growing demand for circular economy practices.

Ethical sourcing practices are becoming increasingly important, with buyers scrutinizing supply chains for transparency and compliance with environmental regulations. Certifications such as ISO 14001 for environmental management and the Global Recycled Standard are key indicators of a supplier’s commitment to sustainability. Additionally, B2B buyers are exploring partnerships with manufacturers that prioritize low-carbon production methods and utilize renewable energy sources.

Moreover, the emphasis on sustainable practices is influencing consumer preferences as well, with end-users favoring products that contribute to greener living spaces. This trend creates a competitive advantage for suppliers who can demonstrate their commitment to environmental stewardship.

What Is the Historical Context of the 40 Gallon Planter Industry?

The 40-gallon planter segment has evolved significantly over the past few decades. Initially, large planters were primarily used in commercial horticulture and landscaping, with limited accessibility for individual consumers. However, as urban gardening became popularized in the late 20th century, the demand for larger, versatile planters surged.

Manufacturers began innovating with lightweight materials and improved drainage systems to enhance usability and plant health. The introduction of eco-friendly materials in the 21st century marked a significant shift, aligning product offerings with the growing emphasis on sustainability. Today, the 40-gallon planter is recognized not only for its practicality but also as a vital component in promoting sustainable practices in both urban and rural settings.

As the market continues to evolve, international B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with both their operational needs and the values of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of 40 gallon planter

-

How do I choose the right supplier for 40-gallon planters?

Selecting the right supplier involves evaluating their reputation, product quality, and compliance with international standards. Start by reviewing their certifications, such as ISO or other relevant quality assurance marks. Request samples to assess material durability and design. Additionally, check customer reviews and testimonials, focusing on reliability in delivery and customer service. It’s beneficial to establish direct communication with potential suppliers to gauge their responsiveness and willingness to accommodate your specific needs. -

What is the best material for a 40-gallon planter?

The best material for a 40-gallon planter typically includes recycled polyethylene (PE) or high-density polyethylene (HDPE). These materials are known for their durability, UV resistance, and ability to withstand varying weather conditions. For specialized applications, consider planters made from materials that offer enhanced drainage and aeration properties. Always evaluate the specific needs of your plants and the environmental conditions to determine the most suitable material. -

What customization options are available for 40-gallon planters?

Many manufacturers offer customization options such as color, size, drainage hole placement, and branding. Depending on your business needs, you can request specific features like reinforced handles for easier transport or unique drainage systems to promote healthy plant growth. Discuss your requirements with suppliers to explore the extent of their customization capabilities, ensuring that the final product meets your operational and aesthetic standards. -

What are the minimum order quantities (MOQs) for 40-gallon planters?

Minimum order quantities vary by supplier and can range from a few dozen to several hundred units. When sourcing internationally, consider suppliers that offer flexible MOQs to accommodate your inventory needs without overcommitting. It’s advisable to negotiate with suppliers to find a mutually agreeable MOQ, especially if you are testing the market or starting a new project. -

What payment terms should I expect when purchasing 40-gallon planters internationally?

Payment terms for international orders can include options like advance payment, letters of credit, or payment upon delivery. Commonly, suppliers may request a deposit upfront, typically around 30%, with the balance due before shipment or upon receipt. Always clarify payment terms before finalizing the order to avoid misunderstandings, and consider using secure payment methods to protect your transaction. -

How can I ensure quality assurance for my 40-gallon planter order?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Inquire if they perform regular inspections and testing for durability and compliance with industry standards. You may also consider hiring a third-party inspection service to verify product quality before shipment. Clear communication regarding your quality expectations will help prevent issues during the manufacturing and shipping processes. -

What logistics considerations should I keep in mind for shipping 40-gallon planters?

When shipping internationally, consider the logistics of freight options, shipping costs, and potential tariffs. Select a shipping method that balances cost and delivery speed, such as LTL (Less Than Truckload) for larger orders. Ensure your supplier can provide the necessary documentation for customs clearance and be prepared for any import regulations specific to your country. Collaborating with a logistics partner familiar with international trade can streamline this process. -

What are the typical lead times for ordering 40-gallon planters?

Lead times can vary significantly based on the supplier’s location, production capabilities, and order size. Generally, expect a lead time of 4 to 12 weeks for custom orders, while stock items may ship sooner. Discuss lead times upfront with your supplier and consider factors like peak seasons or holidays that may affect production schedules. Planning ahead will help you align your inventory needs with the supplier’s timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 40 Gallon Planter Manufacturers & Suppliers List

1. Vertical Crop Consultants – Gro Pro Heavy Duty Container

Domain: verticalcropconsultants.com

Registered: 2016 (9 years)

Introduction: {“name”:”Gro Pro Heavy Duty Container w/ handles 40 Gallon”,”price”:”$26.39″,”sku”:”VCC-725465″,”category”:”Pots and Containers”,”description”:”This heavy-duty pot is made with recycled polyethylene (PE) plastic. The best feature is the built-in lateral handles for easy carrying.”,”weight”:”9.8 lbs”,”dimensions”:”32.3 × 32.3 × 23.1 in”,”stock”:”67 in stock”}

2. Reach Supplies – 45 Gallon Nursery Pot

Domain: reachsupplies.com

Registered: 2015 (10 years)

Introduction: {“name”: “45 Gallon Nursery Pot”, “price_range”: “$13.63 – $18.00”, “features”: [“Carrying handles embedded into lip for easier carrying”, “Designed for good drainage with engineered drain holes to reduce risk of root rot and disease”, “Container walls and base resist crushing and warping”], “specifications”: {“Container Designation”: “HP4500”, “Trade Designation”: “45 Gallon”, “Diameter (inches)”…

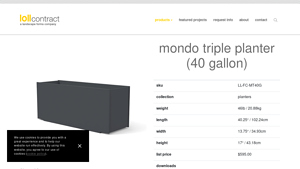

3. Loll – Mondo Triple Planter

Domain: lollcontract.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Mondo Triple Planter”, “capacity”: “40 Gallon”, “sku”: “LL-FC-MT40G”, “collection”: “planters”, “weight”: “46lb / 20.88kg”, “dimensions”: {“length”: “40.25\” / 102.24cm”, “width”: “13.75\” / 34.93cm”, “height”: “17\” / 43.18cm”}, “list_price”: “$595.00”, “available_colors”: [“Leaf Green”, “Charcoal Grey”, “Black”, “Apple Red”, “Sunset Orange”, “Navy Blue”, “Sky Blue”, “Cloud Whit…

4. Reddit – 40 Gallon Nursery Pots for Avocado Trees

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 40 gallon nursery pots for avocado trees; sought after by users in West LA; expensive shipping; checked local nurseries and hydroponics stores (GreenCoast LAX & Pacific Coast Hydroponics); suggestions include the flower district downtown and Garden View Nursery in Irwindale.

5. Growinbag – 40 Gallon Grow Bag

Domain: growinbag.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “40 Gallon Grow Bag”, “brand”: “Growinbag By GrowInnovate”, “price”: “$7.05 USD”, “pack_size”: “1 Bag”, “dimensions”: {“top_outer_diameter”: “23 5/8 Inches”, “height”: “21 1/4 Inches”}, “features”: [“Manufactured to suit all U.S.A climates”, “Promotes superior root growth & root pruning”, “Prevents root circling”, “Controls soil health and keeps it free from ground contaminants”, …

Strategic Sourcing Conclusion and Outlook for 40 gallon planter

As the demand for sustainable and efficient horticultural solutions continues to rise, the strategic sourcing of 40-gallon planters presents a significant opportunity for international B2B buyers. Key takeaways include the importance of selecting durable materials, such as recycled polyethylene, which not only enhances longevity but also promotes environmental responsibility. Furthermore, features like built-in handles and superior drainage systems are essential for operational efficiency and plant health.

Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers who offer robust logistics and competitive pricing. This is crucial for managing costs while ensuring timely delivery, especially for large orders that may require specialized shipping methods.

Looking ahead, the global market for planters is poised for growth, driven by increasing urbanization and a shift towards sustainable agricultural practices. Now is the time for businesses to evaluate their sourcing strategies and align with suppliers who can meet their specific needs. Engaging in strategic partnerships will not only enhance product offerings but also contribute to a more sustainable future in horticulture. Take the next step and explore reliable suppliers who can support your business goals in this expanding market.