Cckb Board: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for cckb board

In today’s competitive landscape, sourcing high-quality Clay Coated Kraft Back (CCKB) board can pose significant challenges for B2B buyers, particularly those operating across diverse markets such as Africa, South America, the Middle East, and Europe. With increasing demand for sustainable packaging solutions, businesses must navigate a myriad of options while ensuring compliance with varying international standards. This comprehensive guide addresses the complexities of sourcing CCKB board by covering essential topics, including the different types of CCKB board available, their wide-ranging applications in food and beverage packaging, and key considerations for supplier vetting.

Moreover, we delve into cost factors, helping buyers understand the pricing structures associated with CCKB board and how to negotiate effectively with suppliers. By consolidating critical insights and actionable strategies, this guide empowers international B2B buyers, enabling them to make informed purchasing decisions that align with their operational needs and sustainability goals. Whether you are based in Brazil, Saudi Arabia, or any other global market, the information presented here is tailored to support your specific requirements in securing the best quality CCKB board for your business endeavors.

Understanding cckb board Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CCKB 250g | White clay-coated front, brown kraft back, 250gsm thickness | Food packaging (e.g., takeout boxes, frozen food) | Pros: Cost-effective, FDA approved, eco-friendly. Cons: Limited to single-sided printing. |

| CCKB 300g | Thicker version with similar features to 250g, enhanced durability | Heavy-duty food packaging, retail boxes | Pros: Greater strength, suitable for heavier items. Cons: Higher cost compared to lighter variants. |

| CCKB 365g | Heaviest variant, robust construction, excellent moisture resistance | Industrial packaging, high-end food service | Pros: Exceptional protection, ideal for demanding applications. Cons: May be overkill for lightweight products. |

| CCKB Custom | Custom thickness options available, tailored to specific needs | Specialized packaging solutions | Pros: Flexibility in design and use, meets specific client requirements. Cons: Longer lead times for custom orders. |

| CCKB Eco | Made from 100% recycled materials, maintaining quality | Sustainable packaging for eco-conscious brands | Pros: Strong marketing appeal, supports sustainability initiatives. Cons: May have higher upfront costs. |

What Are the Characteristics of CCKB 250g Board?

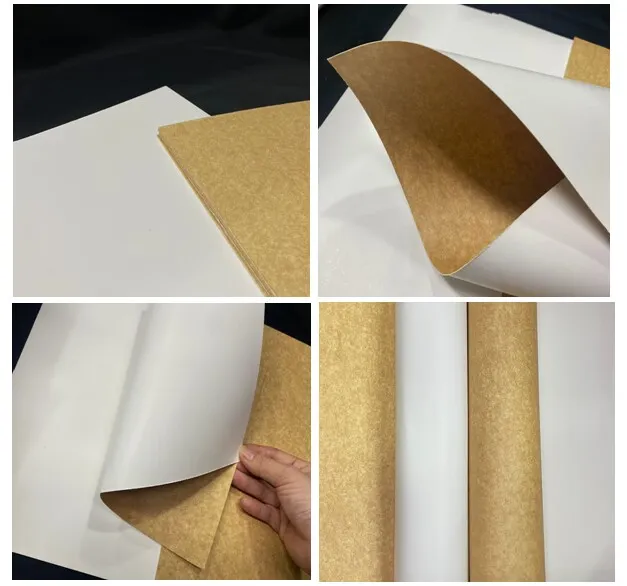

CCKB 250g board features a white clay-coated surface ideal for high-quality printing, paired with a natural brown kraft back. This lightweight option is particularly effective for food packaging, such as takeout boxes and frozen food containers. When purchasing, consider its FDA approval, which ensures compliance with food safety standards. Additionally, its cost-effectiveness makes it a popular choice for businesses looking to balance quality and budget.

How Does CCKB 300g Differ from Other Variants?

The CCKB 300g variant offers enhanced durability and strength compared to the 250g version, making it suitable for heavy-duty applications. Its thicker construction allows it to withstand more weight, which is beneficial for retail packaging and food service products. Buyers should evaluate their packaging needs carefully, as the increased strength comes at a higher price point, but it can ultimately save costs on damaged goods.

Why Choose CCKB 365g for Industrial Applications?

CCKB 365g is the heaviest option available, providing superior moisture resistance and structural integrity. This board is ideal for industrial packaging and high-end food service applications where product protection is paramount. Businesses must assess whether the additional strength justifies the cost, especially for lightweight items that may not require such robust materials.

What Are the Benefits of Custom CCKB Options?

Custom CCKB boards allow businesses to tailor thickness and specifications to meet unique packaging needs. This flexibility can be crucial for companies with specialized products or branding requirements. However, buyers should be prepared for longer lead times and potential higher costs associated with custom orders, making it essential to plan ahead for production schedules.

How Does CCKB Eco Support Sustainability Initiatives?

The CCKB Eco variant is produced from 100% recycled materials, appealing to businesses focused on sustainability. This option not only meets environmental goals but also enhances brand image among eco-conscious consumers. While the upfront costs may be higher, the long-term benefits of aligning with sustainability initiatives can outweigh initial investments, making it a wise choice for forward-thinking companies.

Key Industrial Applications of cckb board

| Industry/Sector | Specific Application of cckb board | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Take-out food containers and packaging | Eco-friendly, moisture-resistant, enhances branding | FDA approval, thickness options, and printing quality |

| Retail Packaging | Gift boxes and product packaging | Attractive presentation, durable for shipping | Custom sizes, print capabilities, and recyclability |

| E-commerce | Shipping boxes for various products | Lightweight, cost-effective, sustainable option | Sourcing from certified suppliers, international shipping |

| Personal Care Products | Packaging for soaps and cosmetics | Protects products, enhances brand image | Compliance with regulations, quality assurance, and design |

| Frozen Foods | Packaging for frozen meals and snacks | Maintains product integrity, high-quality printing | Temperature resistance, structural integrity, and bulk orders |

How is CCKB Board Used in the Food & Beverage Sector?

CCKB board is widely utilized for take-out food containers and packaging due to its eco-friendly properties and moisture resistance. This makes it an ideal choice for restaurants and food service providers who prioritize sustainability while ensuring product safety. The board’s FDA approval allows businesses to package food items directly without compromising safety. International buyers should focus on sourcing CCKB with the correct thickness options and printing capabilities to enhance branding and customer appeal.

What Role Does CCKB Board Play in Retail Packaging?

In the retail sector, CCKB board is often employed for creating gift boxes and product packaging. Its attractive white clay-coated surface allows for high-quality printing, which is crucial for branding and product display. This type of packaging not only enhances the visual appeal but also provides durability during shipping. Retailers must consider custom sizes and print capabilities when sourcing CCKB board to ensure it meets their specific marketing needs and sustainability goals.

How is CCKB Board Beneficial for E-commerce?

E-commerce businesses benefit from using CCKB board for shipping boxes, as it is lightweight yet sturdy, providing cost-effective shipping solutions. The recyclability of the board aligns with the growing consumer demand for sustainable packaging. When sourcing CCKB for e-commerce applications, businesses should prioritize suppliers that offer certified products, ensuring compliance with international shipping regulations and environmental standards.

In What Ways Does CCKB Board Support Personal Care Products?

The personal care industry frequently utilizes CCKB board for packaging soaps and cosmetics. The board’s ability to protect products while enhancing brand image through attractive printing is a significant advantage. Buyers in this sector need to ensure that their CCKB board complies with relevant regulations and quality assurance standards to avoid any issues related to product safety and consumer trust.

How is CCKB Board Applied in Frozen Foods Packaging?

For frozen foods, CCKB board provides a reliable solution for maintaining product integrity during storage and transport. Its moisture and tear resistance are critical for ensuring that frozen meals and snacks remain protected from external elements. Buyers looking for CCKB board for this application should focus on sourcing materials that can withstand temperature variations while maintaining structural integrity and print quality for branding purposes.

3 Common User Pain Points for ‘cckb board’ & Their Solutions

Scenario 1: Navigating Quality Assurance for Food Packaging

The Problem: When sourcing CCKB board for food packaging, B2B buyers often face challenges related to quality assurance and compliance with food safety standards. The risk of using subpar materials can lead to serious health implications, product recalls, and damage to brand reputation. Buyers may struggle to verify the certifications of suppliers, such as FDA approval and ISO standards, which are crucial for ensuring the safety and integrity of food products.

The Solution: To navigate these challenges, B2B buyers should prioritize sourcing from reputable suppliers with transparent quality assurance processes. Before placing orders, buyers should request documentation demonstrating compliance with food safety regulations, including FDA certifications. Establishing a relationship with suppliers that conduct multiple quality inspections at various stages of production can also mitigate risks. Additionally, buyers can conduct their own audits or assessments to verify the supplier’s practices and materials. Utilizing a sample order to evaluate the board’s performance in real-world conditions can further ensure it meets the necessary standards for food packaging.

Scenario 2: Balancing Cost and Sustainability in Material Selection

The Problem: Many businesses are committed to sustainable practices but often find themselves torn between cost-effectiveness and eco-friendliness when selecting packaging materials like CCKB board. B2B buyers may encounter higher costs associated with sustainable options, leading to concerns about maintaining profitability while fulfilling corporate social responsibility objectives.

The Solution: To strike a balance between cost and sustainability, buyers should conduct a comprehensive cost-benefit analysis that considers not only the initial price but also the long-term savings associated with using recyclable materials. Engaging with suppliers who offer competitive pricing for CCKB board without compromising on recycled content can help. Buyers can also explore bulk purchasing agreements or long-term contracts that may lead to discounts. Additionally, investing in marketing efforts that highlight the sustainability of CCKB board can enhance brand value and attract environmentally-conscious consumers, potentially offsetting higher material costs through increased sales.

Scenario 3: Ensuring Print Quality for Branding Needs

The Problem: For businesses reliant on high-quality branding and marketing, the print quality of packaging materials like CCKB board is paramount. B2B buyers may find that the board does not deliver the desired results in terms of color fidelity and graphic reproduction, which can lead to disappointing packaging that fails to resonate with consumers.

The Solution: To ensure optimal print quality, buyers should collaborate closely with their printing partners to select the right specifications for CCKB board. This involves understanding the board’s surface properties and how they interact with various printing techniques, such as offset or digital printing. Buyers should request samples and conduct test prints to evaluate the results before committing to larger orders. Additionally, working with suppliers who specialize in print-ready materials can provide valuable insights into the ideal board thickness and coatings that enhance printability. By maintaining open communication with both suppliers and printers, businesses can achieve the high-quality branding necessary to stand out in a competitive market.

Strategic Material Selection Guide for cckb board

What Are the Key Properties of Clay Coated Kraft Back (CCKB) Board?

Clay Coated Kraft Back (CCKB) board is primarily composed of recycled paper, featuring a white clay-coated surface on one side and a natural brown kraft back. This dual-layer structure provides excellent printability and durability. The clay coating enhances the board’s moisture and tear resistance, making it suitable for various applications, particularly in the food packaging sector. CCKB board typically exhibits a thickness range from 250 to 350 grams per square meter (gsm), allowing for versatility in packaging design.

What Are the Advantages and Disadvantages of Using CCKB Board?

Advantages:

1. Eco-Friendly: Made from 100% recycled materials, CCKB board aligns with sustainability goals, appealing to environmentally conscious businesses.

2. High Print Quality: The clay-coated surface allows for vibrant and detailed graphics, enhancing brand visibility on packaging.

3. Food Safety Compliance: Many CCKB boards are FDA-approved for direct food contact, making them ideal for packaging food items such as takeout meals and frozen products.

Disadvantages:

1. Limited One-Sided Printing: While the front side is optimized for printing, the kraft back may not be suitable for branding, limiting design options.

2. Cost Variability: Depending on the thickness and specific features, CCKB board can range from medium to high cost, which may affect budget-sensitive projects.

3. Manufacturing Complexity: The production process may involve additional steps to ensure the clay coating is applied uniformly, potentially leading to longer lead times.

How Does CCKB Board Impact Specific Applications?

CCKB board is particularly beneficial for applications requiring moisture and tear resistance, such as food packaging, where it protects the contents from external elements. Its high-quality printability makes it suitable for branding and promotional materials, ensuring that products stand out on the shelf. However, businesses should consider the board’s limitations in terms of one-sided printing when designing packaging solutions.

What Should International B2B Buyers Consider When Selecting CCKB Board?

When sourcing CCKB board, international buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local regulations. This includes ensuring that the materials meet standards such as ASTM, DIN, or JIS, depending on the region. Additionally, buyers should assess the board’s certifications, such as FDA approval for food contact, which is crucial in the food industry. Understanding local preferences for packaging materials can also influence purchasing decisions, as some markets may prioritize eco-friendly options over cost.

Summary of Material Selection for CCKB Board

| Material | Typical Use Case for cckb board | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clay Coated Kraft Back (CCKB) Board | Food packaging, takeout containers, frozen food packaging | Eco-friendly, high print quality, FDA-approved for food contact | Limited one-sided printing, cost variability | Medium to High |

| Clay Coated Recycled Board (CCNB) | High volume folding carton packaging for dry goods | Consistent quality, excellent printability | Less suitable for direct food contact | Medium |

| Heavy Duty Clay Coated Board | Packaging for heavy items, appliances | Superior durability and strength | Higher cost, may require specialized manufacturing | High |

| Lightweight Clay Coated Board | Packaging for lightweight products | Cost-effective, easy to handle | Less durable, not suitable for heavy items | Low to Medium |

This table provides a concise overview of various materials related to CCKB board, enabling B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for cckb board

What Are the Main Stages in the Manufacturing Process of CCKB Board?

The production of Clay Coated Kraft Back (CCKB) board involves several critical stages, each contributing to the final quality and performance of the product. Understanding these stages is vital for B2B buyers looking for reliable packaging solutions.

1. Material Preparation

The manufacturing process begins with sourcing the raw materials, primarily 100% recycled paper. This eco-friendly approach not only promotes sustainability but also aligns with the growing consumer demand for green products. The recycled paper is processed to remove impurities and ensure a consistent fiber quality.

Once the materials are prepared, they undergo a pulping process where they are mixed with water and chemicals to break down the fibers. This slurry is then screened and refined to achieve the desired consistency and strength.

2. Forming

In the forming stage, the prepared pulp is spread onto a moving wire mesh screen, allowing excess water to drain away. This process forms a wet sheet of paper that is then pressed to remove more moisture and enhance its density. The sheet is subsequently dried using heated rollers, which helps to solidify the structure and achieve the required thickness.

For CCKB, a clay coating is applied to the front side during the forming stage. This coating provides a smooth surface that is ideal for high-quality printing, making it particularly valuable for branding and packaging applications.

3. Assembly

Once the sheets are dried and coated, they are cut into specified sizes and weights according to customer requirements. This assembly stage may also involve additional processes such as laminating or embossing, depending on the end-use of the board. The versatility of CCKB allows for various applications, including food packaging, folding cartons, and more.

4. Finishing

The final stage of manufacturing is finishing, where the CCKB board undergoes quality checks and surface treatments. This may include treatments to enhance moisture resistance or to ensure the surface is suitable for printing. The finished boards are then packaged for shipment, ready to meet the demands of international buyers.

How Is Quality Assurance Implemented in CCKB Board Production?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the CCKB board meets international standards and customer expectations.

Relevant International Standards

To maintain high-quality production, manufacturers adhere to various international standards, such as ISO 9001, which focuses on quality management systems. Additionally, certifications like CE (Conformité Européenne) and FDA (Food and Drug Administration) approval are essential for food-grade packaging, particularly for clients in regions with strict regulatory requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process. These checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before they enter the production process. This ensures that only high-quality materials are used in the production of CCKB board.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are conducted to monitor the production process. This includes assessing the moisture content, thickness, and strength of the board at various stages to catch any issues early.

-

Final Quality Control (FQC): Once production is complete, the final product undergoes rigorous testing to ensure it meets all specifications and standards. This may include tests for printability, moisture resistance, and tear strength, among others.

What Testing Methods Are Commonly Used for CCKB Board?

Several testing methods are employed to evaluate the quality of CCKB board:

-

Physical Testing: This includes measuring thickness, weight, and tensile strength. Such tests help determine the board’s suitability for different packaging applications.

-

Chemical Testing: To ensure food safety, boards undergo chemical analysis to confirm they do not contain harmful substances. This is particularly important for products intended for food contact.

-

Printability Tests: As CCKB is often used for packaging requiring high-quality printing, tests are conducted to assess the adhesion and appearance of inks on the board’s surface.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality assurance systems. This firsthand assessment can help identify any gaps in compliance with international standards.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control measures, including IQC, IPQC, and FQC reports. These documents should detail the testing methods used and the results obtained.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control practices. Such agencies can conduct surprise inspections and quality assessments, ensuring compliance with international standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing CCKB board internationally, it’s important to understand the nuances of quality control and certification that may differ by region. For example:

-

Certification Requirements: Different regions have varying certification requirements for food packaging. Buyers from the EU may require CE certification, while those in the U.S. will look for FDA approval.

-

Cultural Expectations: Business practices and quality expectations can vary significantly across regions. Buyers should be aware of these differences and communicate their specific quality requirements clearly.

-

Logistical Considerations: Shipping and handling can impact product quality. Buyers should ensure that suppliers have robust logistics processes to minimize damage during transportation.

In conclusion, understanding the manufacturing processes and quality assurance practices for CCKB board is essential for B2B buyers seeking reliable and high-quality packaging solutions. By focusing on international standards, quality checkpoints, and effective supplier verification methods, businesses can make informed decisions that enhance their product offerings and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cckb board’

This guide serves as a practical resource for B2B buyers interested in sourcing Clay Coated Kraft Back (CCKB) board. By following the outlined steps, buyers can ensure they make informed decisions that align with their packaging needs while adhering to sustainability practices.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical when sourcing CCKB board. Consider factors such as thickness, grammage, and intended use (e.g., food packaging, durable boxes). This clarity helps in communicating your requirements to suppliers and ensures the final product meets your expectations.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers who specialize in CCKB board. Look for companies with a proven track record, positive reviews, and experience in your target market. Focus on suppliers that have certifications such as FDA and ISO, which indicate adherence to quality standards.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is essential to ensure compliance with international standards. Check for certifications relevant to your industry, such as FDA approval for food-grade packaging. This step safeguards your brand’s reputation and ensures your packaging meets regulatory requirements.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the CCKB board from potential suppliers. Assess the samples for printability, durability, and moisture resistance, which are critical for packaging performance. This hands-on evaluation allows you to make a more informed decision based on actual product quality.

Step 5: Inquire About Sustainability Practices

Given the growing emphasis on sustainability, it’s essential to inquire about the supplier’s sourcing and production practices. Look for suppliers that use 100% recycled materials and have eco-friendly certifications. This not only aligns with global sustainability goals but also enhances your brand’s image.

Step 6: Negotiate Pricing and Terms

Once you have narrowed down your options, engage in negotiations regarding pricing and payment terms. Be clear about your budget while discussing minimum order quantities and delivery timelines. A well-negotiated contract can lead to better pricing and favorable terms, benefiting your overall procurement strategy.

Step 7: Establish Communication Channels

Setting up effective communication channels with your chosen supplier is vital for ongoing collaboration. Ensure that there is a clear point of contact for order updates, quality issues, or logistical concerns. Strong communication fosters a productive relationship and can help mitigate potential challenges during the procurement process.

By following these steps, B2B buyers can navigate the complexities of sourcing CCKB board effectively, ensuring they select the right supplier to meet their packaging needs while also prioritizing quality and sustainability.

Comprehensive Cost and Pricing Analysis for cckb board Sourcing

What Are the Key Cost Components in CCKB Board Sourcing?

When sourcing Clay Coated Kraft Back (CCKB) boards, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The base cost for CCKB boards is influenced by the price of recycled paper and clay coatings. As these materials can fluctuate based on market demand and availability, it’s essential to monitor trends and negotiate pricing accordingly.

-

Labor: Labor costs encompass the wages paid to the workforce involved in the production process. This can vary significantly depending on the country of production, local labor laws, and skill levels of workers.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance of machinery, and factory operations. Efficient operations can lead to lower overhead costs, which is a critical factor for competitive pricing.

-

Tooling: For custom orders, tooling costs can be a significant factor. This includes the expense of creating molds or dies specific to the buyer’s requirements. Buyers should consider whether the initial tooling investment aligns with their volume needs.

-

Quality Control (QC): Ensuring that the CCKB boards meet specific standards involves rigorous quality control processes. This may increase costs but is essential for maintaining product integrity and compliance with regulations, especially for food-grade applications.

-

Logistics: Shipping costs can vary based on the origin of the product, destination, and chosen shipping method. Incoterms should be clearly defined to understand who bears the costs and risks during transportation.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on their market position and competitiveness. Understanding this margin can aid in negotiation.

How Do Pricing Influencers Affect CCKB Board Costs?

Several factors can influence the pricing of CCKB boards:

-

Volume/MOQ: Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) to achieve favorable pricing.

-

Specifications/Customization: Custom dimensions, thickness, or finishes can significantly affect costs. Clear communication of requirements can help in obtaining precise quotes.

-

Material Quality and Certifications: Boards that are FDA-approved or meet other international standards may command higher prices. Buyers should weigh the importance of certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer higher prices but can provide assurance of quality and timely delivery.

-

Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help in determining total landed costs and managing logistics effectively.

What Are the Best Buyer Tips for Negotiating CCKB Board Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Wisely: Engage in discussions about pricing, especially if you have competitive quotes from other suppliers. Leverage your volume needs to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, potential tariffs, and the longevity of the product. A higher upfront cost may yield savings in the long run.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations and local market conditions that can impact pricing. Establishing relationships with suppliers can provide insights into potential price changes.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can help avoid costly mistakes and ensure the product meets expectations.

-

Stay Informed: Regularly review market trends and material costs. Being informed can provide leverage in negotiations and help anticipate pricing shifts.

Disclaimer on Indicative Prices

Prices for CCKB boards can vary widely based on numerous factors, including market conditions, supplier capabilities, and specific buyer requirements. It is advisable to obtain detailed quotes from multiple suppliers and to conduct thorough due diligence to ensure the best value for your investment.

Alternatives Analysis: Comparing cckb board With Other Solutions

Understanding Alternatives to CCKB Board for Packaging Solutions

When evaluating packaging options, it’s essential for businesses to consider various materials that meet their operational needs while also aligning with sustainability goals. CCKB (Clay Coated Kraft Back) board is recognized for its high-quality printing surface and food-grade certification, making it a popular choice for food packaging. However, alternatives exist that may better suit specific requirements based on performance, cost, and application.

| Comparison Aspect | CCKB Board | Alternative 1: CCNB (Clay Coated News Back) | Alternative 2: SBS (Solid Bleached Sulfate) |

|---|---|---|---|

| Performance | High-quality printability, food-safe | Similar print quality, less moisture resistant | Excellent print quality, very durable |

| Cost | Moderate pricing | Generally lower cost than CCKB | Higher cost due to premium quality |

| Ease of Implementation | Easy to cut and shape | Similar ease of use | Requires specialized equipment for handling |

| Maintenance | Low maintenance | Low maintenance | Low maintenance, but can be heavier |

| Best Use Case | Food packaging, eco-friendly options | High volume folding cartons for dry goods | Premium packaging for luxury items |

In-Depth Look at Alternatives

Alternative 1: CCNB (Clay Coated News Back)

CCNB is a cost-effective alternative to CCKB, often utilized in high-volume folding carton applications for items such as cereals and pastas. While it features a similar glossy front surface that accommodates high-quality printing, its moisture resistance is not as robust as CCKB. This makes CCNB less ideal for direct food contact packaging, limiting its applications in the food industry. However, its lower cost and ease of use make it attractive for businesses focusing on non-perishable products.

Alternative 2: SBS (Solid Bleached Sulfate)

SBS is a premium paperboard option known for its superior print quality and durability. It offers a bright white surface suitable for high-end packaging applications, including luxury goods and cosmetics. While SBS is excellent for visual appeal and structural integrity, it typically comes at a higher price point. Additionally, SBS may require specialized equipment for processing and can be heavier than CCKB, which could affect shipping costs. Its sustainability profile may also vary, depending on the source of the pulp used.

Making the Right Choice for Your Business Needs

When selecting the most suitable packaging solution, B2B buyers should evaluate their specific needs, including product type, target market, and budget constraints. CCKB board excels in food-safe applications and eco-friendliness, making it a strong candidate for businesses focused on sustainable practices. In contrast, CCNB may be better suited for those seeking cost-effective solutions for dry goods, while SBS stands out for premium products requiring high-quality branding. By carefully considering the pros and cons of each option, businesses can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for cckb board

What Are the Key Technical Properties of CCKB Board?

-

Material Composition

CCKB (Clay Coated Kraft Back) board is primarily made from 100% recycled paper, which enhances its eco-friendliness. This property is crucial for B2B buyers who prioritize sustainability in their supply chains. The dual coating of clay on the front provides a smooth surface ideal for high-quality printing, making it suitable for branding and promotional packaging. -

Basis Weight and Thickness

CCKB board typically ranges from 250gsm to 350gsm, with thicknesses varying accordingly (e.g., 12pt to 18pt). The basis weight indicates the weight of the paper per unit area, which directly affects the board’s sturdiness and durability. For manufacturers in sectors such as food packaging, understanding these specifications is essential to ensure the material can withstand handling and transport without compromising product integrity. -

Moisture and Tear Resistance

The clay coating not only provides an excellent printing surface but also enhances moisture and tear resistance. This property is particularly important for packaging food products, as it helps maintain product quality and safety during storage and transport. B2B buyers in the food industry must ensure their packaging materials can protect against environmental factors. -

Printability

The white clay-coated front side of CCKB board allows for vibrant and detailed printing. This is a significant advantage for businesses looking to create visually appealing packaging that stands out on the shelf. High-quality printability can lead to better brand recognition and customer engagement, making it a key consideration for marketing teams. -

FDA Compliance

Many CCKB boards are FDA-approved for direct food contact, making them suitable for a variety of food packaging applications, such as takeout containers and frozen food boxes. For international buyers, particularly in regions with strict food safety regulations, this certification is vital for compliance and market access.

What Are Common Trade Terms Associated with CCKB Board?

-

OEM (Original Equipment Manufacturer)

In the context of CCKB board, OEM refers to companies that manufacture products based on the specifications provided by another company. This term is significant for B2B buyers who are looking to have custom packaging solutions tailored to their unique needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to produce or sell. For CCKB board, understanding the MOQ is crucial for businesses to manage inventory and budget constraints effectively. Higher MOQs may benefit larger operations, while smaller businesses need to negotiate favorable terms. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to request pricing information for specific products. In the context of CCKB board, an RFQ can help buyers compare costs and negotiate better deals, ensuring they get the best price for their packaging needs. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers, as they can significantly impact the total cost and logistics of acquiring CCKB board from suppliers in different countries. -

FSC Certification (Forest Stewardship Council)

FSC certification indicates that the paperboard comes from responsibly managed forests that provide environmental, social, and economic benefits. For businesses emphasizing sustainability, this certification is a vital aspect of their procurement strategy, ensuring that their packaging materials align with corporate social responsibility goals. -

Caliper

Caliper is the measurement of the thickness of the CCKB board, typically expressed in mils or microns. This specification is crucial for B2B buyers as it affects the board’s performance in terms of durability and handling, influencing decisions on packaging design and application.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and sustainability goals.

Navigating Market Dynamics and Sourcing Trends in the cckb board Sector

What are the Current Market Dynamics and Key Trends Affecting the CCKB Board Sector?

The global market for Clay Coated Kraft Back (CCKB) board is experiencing significant growth, driven by an increasing demand for sustainable packaging solutions across various industries, particularly in food service and retail. The rise of eco-conscious consumerism is a major driver, with buyers from regions such as Africa, South America, the Middle East, and Europe prioritizing recyclable and biodegradable materials. The CCKB board, made from 100% recycled paper, fits this demand perfectly, offering not only environmental benefits but also high-quality printability and durability.

Emerging trends in B2B sourcing are heavily influenced by technological advancements. Digital platforms are now facilitating more streamlined procurement processes, allowing international buyers to compare suppliers and products efficiently. Additionally, automation in manufacturing is enhancing production capabilities, resulting in consistent quality and faster turnaround times. As global supply chains become more interconnected, buyers in regions like Brazil and Saudi Arabia are increasingly looking for reliable suppliers who can meet their specific needs quickly and efficiently.

Furthermore, the push towards food safety regulations is shaping market dynamics. The CCKB board’s food-grade certifications, including FDA approval, make it an attractive option for companies involved in food packaging. With the ongoing rise of e-commerce, packaging solutions that are both visually appealing and functional are becoming essential for brand differentiation in a competitive market.

How Does Sustainability and Ethical Sourcing Impact B2B Purchases of CCKB Board?

Sustainability is a key consideration for B2B buyers, especially in today’s environmentally conscious market. The CCKB board stands out due to its eco-friendly properties, being fully recyclable and made from recycled materials. This not only helps companies reduce their carbon footprint but also aligns with the growing consumer preference for sustainable products. Buyers from Africa, South America, and the Middle East are increasingly integrating sustainability into their sourcing strategies, recognizing that eco-friendly packaging solutions can enhance brand reputation and consumer loyalty.

Ethical sourcing practices are also gaining traction. Buyers are prioritizing suppliers who adhere to ethical labor practices and environmental standards. Certifications such as FSC (Forest Stewardship Council) and ISO indicate a commitment to responsible sourcing, which can significantly influence purchasing decisions. The importance of transparency in supply chains cannot be overstated; buyers want assurance that their materials are sourced responsibly and sustainably, which is critical for maintaining brand integrity.

As the market evolves, the demand for ‘green’ certifications and materials will continue to rise, compelling suppliers to adopt sustainable practices. Companies that proactively engage in sustainable sourcing of CCKB boards not only meet regulatory requirements but also cater to the ethical considerations of their clients.

What is the Brief Evolution and History of CCKB Board in the B2B Context?

The evolution of CCKB board can be traced back to the early 20th century when the packaging industry began to prioritize innovative materials for food safety and branding. Initially, traditional paperboard was the standard; however, the introduction of clay coatings significantly improved print quality and durability. The transition to clay-coated recycled boards like CCKB reflects a broader shift towards sustainability, as manufacturers sought to minimize waste and utilize recycled materials.

In recent years, advancements in production technology have enhanced the quality and versatility of CCKB boards, making them suitable for a wide range of applications—from takeout food packaging to high-end retail boxes. The increased focus on environmental impact has further driven the adoption of CCKB boards in various sectors, establishing them as a preferred choice for businesses looking to balance functionality with sustainability. As the industry continues to evolve, CCKB boards are expected to play a pivotal role in shaping the future of sustainable packaging solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of cckb board

-

How do I choose the right thickness of CCKB board for my packaging needs?

Selecting the appropriate thickness for CCKB board depends on the type of product you plan to package. For lightweight items, a thickness of 250gsm may suffice, while heavier products may require 300gsm or more. Consider the weight, fragility, and moisture exposure of your items. Additionally, ensure that the chosen thickness aligns with your branding requirements, as thicker boards often provide a more premium feel and better print quality. -

What are the key benefits of using CCKB board for food packaging?

CCKB board is an excellent choice for food packaging due to its FDA-approved food-grade certification and moisture-resistant properties. The white clay-coated front allows for high-quality printing of branding and product information, while the kraft back provides a natural aesthetic. Its durability ensures that the packaging maintains its integrity during transportation and handling, making it suitable for takeout food, frozen items, and various beverages. -

What should I consider when vetting suppliers for CCKB board?

When evaluating suppliers for CCKB board, prioritize their certifications, such as ISO and FDA approvals, to ensure compliance with international standards. Request samples to assess the quality of the board and inquire about their production capacity and lead times. Additionally, check customer reviews and references to gauge their reliability and service quality. Establishing clear communication channels is crucial for addressing any concerns during the sourcing process. -

What is the minimum order quantity (MOQ) for CCKB board, and can it be customized?

The MOQ for CCKB board typically starts at 1 ton, but this can vary by supplier. Many manufacturers offer customization options, allowing you to specify thickness, size, and printing designs. Discuss your specific needs with potential suppliers to determine if they can accommodate your order volume and customization requirements. Keep in mind that larger orders may lead to better pricing and negotiation flexibility. -

What payment terms can I expect when purchasing CCKB board internationally?

Payment terms for international purchases of CCKB board can vary widely by supplier. Common options include T/T (telegraphic transfer), Western Union, and PayPal. Some suppliers may request a deposit upfront, with the balance due before shipment. Ensure that you clarify payment terms during negotiations to avoid misunderstandings and consider using escrow services for added security in international transactions. -

How do I ensure quality assurance when sourcing CCKB board?

To ensure quality assurance, request detailed information about the supplier’s quality control processes, including inspections at different production stages. Ask for certifications that demonstrate adherence to industry standards. It is also advisable to conduct third-party inspections, especially for large orders, to verify the quality before shipment. Establishing a clear agreement on quality expectations in your contract will help mitigate risks. -

What are the logistics considerations when importing CCKB board from international suppliers?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with importing packaging materials to help navigate customs clearance. Be aware of any tariffs or duties applicable to your imports, as these can impact overall costs. Communicate closely with your supplier regarding packaging and shipping arrangements to minimize delays and damages during transit. -

Can CCKB board be recycled, and what sustainability benefits does it offer?

Yes, CCKB board is recyclable, making it an environmentally friendly option for packaging. Its production from 100% recycled paper contributes to sustainability efforts by reducing waste and conserving natural resources. By choosing CCKB board, businesses can enhance their green credentials, appealing to eco-conscious consumers and meeting regulatory requirements in various regions. Consider promoting these sustainability benefits in your marketing materials to strengthen your brand image.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cckb Board Manufacturers & Suppliers List

1. PakFactory – Clay Coated Kraft Back (CCK) Paper

Domain: pakfactory.com

Registered: 2015 (10 years)

Introduction: Clay Coated Kraft Back (CCK) paper is a recyclable kraft paperboard material featuring a white clay coated front side for high quality printing and a natural brown color on the back side. It is moisture and tear-resistant, making it ideal for packaging take-out food, frozen food, and beverages. The clay coating provides a semi-gloss finish, better dimensional stability, and durability. Common thic…

2. Cefbox – Clay Coated Kraft Back Paper Board

Domain: cefbox.com

Registered: 2022 (3 years)

Introduction: {“product_name”: “Clay Coated Kraft Back Paper Board (CCK)”, “description”: “A popular type of kraft paperboard frequently employed for packaging takeout food, frozen food, and beverages. It features a white clay-coated front side for high-quality printing and a natural brown back side.”, “features”: {“tear_resistance”: “Excellent for extra protection”, “recyclable”: “Yes, making it a sustainable …

3. BMPAPER – CCKB Board 250g 300g Clay Coated Kraft Back Paper Board

Domain: bmpaper.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “CCKB Board 250g 300g Clay Coated Kraft Back Paper Board”, “Certification”: “FDA Approved”, “Place of Origin”: “China”, “Brand Name”: “BMPAPER”, “Model Number”: “BM 364”, “Thickness”: “250g – 300g”, “Material”: “Virgin Wood Pulp”, “Color”: “White surface, brown back”, “Coating”: “Single side clay coated”, “Application”: “Food grade packaging box”, “Minimum Order Quantity”: “1 ton”…

4. Graphic Packaging – Paperboard Materials

Domain: graphicpkg.com

Registered: 1997 (28 years)

Introduction: Paperboard Materials:

– Recycled Paperboard: Made from 100% recycled fiber, lightweight, ideal for consumer product folding cartons, excellent print results, supports sustainability initiatives.

– Unbleached Paperboard: Blend of wood and recycled fiber, includes coated and uncoated options, excellent strength and durability, ideal for beverage and frozen food applications.

– Bleached Paperboard…

5. Albert Paper Products – Tan Bending & SBS Solid Bleached Sulphate

Domain: albertpaperproducts.com

Registered: 2001 (24 years)

Introduction: 1. Tan Bending or Plain Chip TBC: Used in the semiconductor industry, made from 100% recycled fibers, provides thermal insulation, stress relief, electrical insulation, and chemical resistance. Allows for simple graphics printing. 2. SBS Solid Bleached Sulphate: White paperboard made from 100% virgin fibers, known for strength, durability, printability, and barrier properties. Suitable for food, h…

6. PaperIndex – CCKB Board

Domain: paperindex.com

Registered: 2004 (21 years)

Introduction: CCKB (Clay Coated Kraft Backed) Board; available in rolls, sheets, and reels; suppliers include distributors, merchants, and exporters from countries such as Belgium, China, Spain, and the United States; notable companies include Grace Paper and Board SRL, Hayani Trading, SL, Xiamen C&D Paper & Pulp Co., Ltd., and PALS International LLC; regions represented include East Asia, North America, Southe…

7. BMPaper – CCKB Food Grade Paperboard

Domain: m.bmpaper.com

Registered: 2015 (10 years)

Introduction: Product Name: CCKB Paperboard

Type: Food Grade CCKB Paperboard

Specifications:

– Material: Made from virgin fibres

– Paper Type: Coated Kraft board

– Paper Gram Weight: 200g, 235g, 250g, 270g, 300g, 325g, 365g

Size: 600 – 2000mm

Description: Clay coated recycled paperboard with kraft back for carton boxes.

Strategic Sourcing Conclusion and Outlook for cckb board

In the evolving landscape of packaging materials, the Clay Coated Kraft Back (CCKB) board stands out as a versatile and eco-friendly option. Its exceptional printability, moisture resistance, and tear strength make it an ideal choice for a variety of applications, particularly in the food industry. By leveraging CCKB’s unique properties, international B2B buyers can enhance their product presentation while also aligning with sustainable practices, a critical consideration for modern consumers.

Strategic sourcing of CCKB board not only optimizes supply chain efficiency but also opens avenues for cost-effective, high-quality packaging solutions. As businesses increasingly prioritize sustainability, sourcing from manufacturers that adhere to international certifications like FDA and ISO ensures compliance and builds trust with end-users.

Looking ahead, the demand for CCKB board is poised to grow, driven by rising awareness of environmental issues and the need for high-performance packaging. Buyers from Africa, South America, the Middle East, and Europe, such as Brazil and Saudi Arabia, are encouraged to explore partnerships with reputable suppliers to secure a reliable source of CCKB. By doing so, you can not only meet your packaging needs but also contribute to a greener future. Embrace the potential of CCKB board to elevate your packaging strategy today.