Carport Square Tubing Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for carport square tubing

In the evolving landscape of global construction and outdoor structures, sourcing high-quality carport square tubing presents a significant challenge for B2B buyers. With increasing demand across various markets, including Africa, South America, the Middle East, and Europe, understanding the nuances of this product is essential for making informed purchasing decisions. This guide delves into the diverse types of carport square tubing available, their specific applications, and the critical factors to consider when vetting suppliers.

Navigating the complexities of carport square tubing involves examining aspects such as material composition, length options, and corrosion resistance, which are vital for ensuring durability and longevity in various environments. Additionally, the guide addresses cost considerations, providing insights into pricing structures and potential financial implications for bulk orders. By equipping international buyers with comprehensive knowledge on these topics, this resource empowers them to select the most suitable products that meet their project requirements.

Furthermore, we will explore key strategies for identifying reputable suppliers, including certifications and manufacturing processes that guarantee product quality. Whether you are looking to enhance the value of a property, expand storage capabilities, or meet regulatory standards, this guide serves as a valuable tool for decision-makers in the carport industry. Dive into the details to streamline your sourcing efforts and ensure successful outcomes in your projects.

Understanding carport square tubing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Square Tubing | Corrosion-resistant, available in various sizes | Carports, outdoor structures | Pros: Durability, low maintenance; Cons: Higher upfront cost compared to non-galvanized options. |

| Electrogalvanized Tubing | Thin layer of zinc coating, smooth finish | Lightweight structures, indoor use | Pros: Cost-effective, good for indoor applications; Cons: Less corrosion resistance than hot-dipped. |

| Hot-Dipped Galvanized Tubing | Thick zinc coating, robust protection against corrosion | Heavy-duty outdoor applications | Pros: Superior corrosion resistance; Cons: Heavier and may require more robust support structures. |

| Structural Steel Tubing | High strength-to-weight ratio, versatile sizes | Industrial applications, carports | Pros: Strong and versatile; Cons: Prone to rust if not treated. |

| Stainless Steel Tubing | Excellent corrosion resistance, aesthetic appeal | Premium carports, architectural designs | Pros: Long-lasting, visually appealing; Cons: Higher cost and weight. |

What are the Characteristics of Galvanized Square Tubing?

Galvanized square tubing is known for its exceptional corrosion resistance, making it ideal for outdoor applications such as carports and other structures exposed to the elements. Available in various sizes and wall thicknesses, this type of tubing is often chosen for its durability and low maintenance requirements. B2B buyers should consider the upfront cost versus long-term benefits, as the initial investment is typically higher than non-galvanized alternatives.

How Does Electrogalvanized Tubing Differ from Other Types?

Electrogalvanized tubing features a thin layer of zinc coating applied through electrolysis, resulting in a smooth finish. This type of tubing is particularly suitable for lightweight structures and indoor applications where corrosion is less of a concern. Buyers in industries focused on cost-effectiveness may find electrogalvanized options appealing; however, they should be aware of its lower corrosion resistance compared to hot-dipped alternatives.

What Makes Hot-Dipped Galvanized Tubing a Preferred Choice?

Hot-dipped galvanized tubing undergoes a process where it is submerged in molten zinc, resulting in a thick, protective coating. This makes it the go-to choice for heavy-duty outdoor applications, offering superior resistance to rust and corrosion. While its robustness is an advantage, the increased weight may necessitate stronger support structures, which is an important consideration for B2B buyers planning large installations.

Why Choose Structural Steel Tubing for Industrial Applications?

Structural steel tubing is characterized by its high strength-to-weight ratio, making it versatile for a range of applications, including carports and industrial structures. While it offers excellent strength, it may be prone to rust if not properly treated. B2B buyers should weigh the benefits of its strength against the need for protective coatings and maintenance.

What are the Advantages of Using Stainless Steel Tubing?

Stainless steel tubing is renowned for its excellent corrosion resistance and aesthetic appeal, making it suitable for premium carports and architectural designs. Its longevity and low maintenance needs are significant advantages for B2B buyers looking for durability. However, the higher cost and weight of stainless steel may be a deterrent for some applications, necessitating careful consideration of project requirements and budget constraints.

Key Industrial Applications of carport square tubing

| Industry/Sector | Specific Application of carport square tubing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Carport structures for vehicle protection | Enhances vehicle longevity and reduces maintenance costs | Corrosion resistance, customizable lengths, and local availability |

| Agriculture | Storage shelters for equipment and livestock | Protects valuable assets from weather damage | Durability, load-bearing capacity, and ease of assembly |

| Construction | Framework for temporary or permanent structures | Supports diverse construction projects efficiently | Compliance with local building codes and structural integrity |

| Retail | Canopies for outdoor displays and customer areas | Increases customer engagement and product visibility | Aesthetic appeal, weather resistance, and adaptability to various designs |

| Renewable Energy | Support structures for solar panel installations | Maximizes energy efficiency and system longevity | Material quality, weight considerations, and environmental impact |

How is Carport Square Tubing Utilized in the Automotive Sector?

In the automotive industry, carport square tubing is primarily used to construct protective structures for vehicles, such as carports and garages. These structures shield vehicles from harsh weather conditions, thereby extending their lifespan and reducing maintenance costs. Buyers in this sector must consider corrosion-resistant materials, as well as the ability to customize lengths and designs to fit specific vehicle sizes. For international buyers, understanding local climate conditions can also influence the choice of tubing specifications.

What Role Does Carport Square Tubing Play in Agriculture?

In agricultural applications, carport square tubing is essential for creating storage shelters for equipment, machinery, and livestock. These structures protect valuable assets from the elements, ensuring that farmers can maintain their operations without incurring significant weather-related damages. Buyers should prioritize durability and load-bearing capacity, especially in regions prone to extreme weather. Additionally, ease of assembly and transportability are crucial factors for international buyers who may face logistical challenges.

How Does Carport Square Tubing Benefit Construction Projects?

Within the construction sector, carport square tubing serves as a versatile framework for both temporary and permanent structures, including storage units and workshops. Its strength and adaptability make it suitable for a wide range of construction projects, allowing builders to respond quickly to evolving site needs. Buyers should ensure that the sourced tubing complies with local building codes and standards, as well as assess its structural integrity to guarantee safety and durability.

In What Ways Can Retailers Use Carport Square Tubing?

Retail businesses frequently utilize carport square tubing to create canopies and awnings for outdoor displays and customer service areas. Such structures enhance customer engagement by providing protection from the elements while increasing product visibility. When sourcing for retail applications, considerations should include aesthetic appeal, weather resistance, and the ability to adapt to various design specifications to align with branding efforts.

How is Carport Square Tubing Essential for Renewable Energy Installations?

In the renewable energy sector, particularly for solar energy, carport square tubing is used to construct support structures for solar panels. These frameworks are vital for maximizing energy efficiency and ensuring the longevity of the solar installations. Buyers should focus on the quality of materials, weight considerations for stability, and the environmental impact of the tubing, especially in regions where sustainability is a priority. International buyers must also be aware of local regulations regarding renewable energy installations.

3 Common User Pain Points for ‘carport square tubing’ & Their Solutions

Scenario 1: Sourcing Reliable Suppliers for Carport Square Tubing

The Problem: B2B buyers often face challenges in identifying trustworthy suppliers for carport square tubing. In regions such as Africa and South America, the supply chain can be fragmented, leading to concerns about product quality, consistency, and delivery times. Buyers may experience delays in receiving materials or receive subpar tubing that does not meet their structural requirements, impacting their project timelines and budgets.

The Solution: To mitigate these challenges, buyers should focus on building relationships with established manufacturers who have a proven track record in the industry. Research potential suppliers by reviewing their certifications, customer testimonials, and the range of products they offer. It’s beneficial to request samples or small orders initially to evaluate the quality of the square tubing. Additionally, consider suppliers that provide comprehensive technical support and have a robust logistics network to ensure timely deliveries. Engaging in direct communication with sales representatives can help clarify specifications and lead times, enabling buyers to make informed decisions.

Scenario 2: Understanding Specifications and Standards for Carport Applications

The Problem: Many B2B buyers may struggle with understanding the specific specifications and standards required for carport applications, particularly in diverse markets. Different regions may have varying regulations regarding structural integrity, material properties, and corrosion resistance. This lack of clarity can lead to the purchase of inappropriate tubing that fails to comply with local codes, resulting in costly adjustments or project failures.

The Solution: Buyers should familiarize themselves with local building codes and industry standards relevant to carport constructions. Engaging with local construction professionals or industry associations can provide valuable insights into necessary specifications. When sourcing carport square tubing, opt for galvanized steel options, as they offer superior corrosion resistance, particularly in areas with extreme weather conditions. Ensure that the suppliers provide documentation certifying that their products meet applicable standards. This due diligence will not only enhance the durability of the carport but also ensure compliance with local regulations, safeguarding the investment.

Scenario 3: Addressing Cost Management and Budget Constraints

The Problem: Cost management is a significant concern for B2B buyers, especially when dealing with large projects involving carport square tubing. Fluctuating steel prices and additional costs associated with shipping and handling can strain budgets. Buyers may find themselves in a position where they need to make compromises on quality or project scope due to unexpected expenses.

The Solution: To manage costs effectively, buyers should engage in strategic sourcing practices. This includes negotiating bulk purchase agreements with suppliers to secure better pricing and minimize shipping costs. Additionally, buyers can explore local suppliers to reduce transportation expenses and lead times. Implementing a just-in-time inventory strategy can also help in maintaining cash flow while ensuring that materials are available as needed. Furthermore, conducting a thorough cost-benefit analysis on different tubing options—such as standard versus custom sizes—can help in making more informed purchasing decisions that align with both quality requirements and budget constraints.

Strategic Material Selection Guide for carport square tubing

What Are the Key Materials for Carport Square Tubing?

When selecting materials for carport square tubing, international B2B buyers must consider various factors including durability, cost, and compliance with local standards. Below are analyses of four common materials used in carport square tubing, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

How Does Galvanized Steel Perform in Carport Applications?

Galvanized steel is a popular choice for carport square tubing due to its excellent corrosion resistance, achieved through a protective zinc coating. This material can withstand harsh weather conditions, making it suitable for outdoor applications. Galvanized steel typically has a temperature rating that allows it to perform well in both high and low temperatures, ensuring structural integrity.

Pros: Its durability and resistance to rust make it ideal for long-term use. Additionally, galvanized steel is readily available and often cost-effective.

Cons: The manufacturing process can be complex, and the initial cost may be higher than non-galvanized options. Over time, the zinc coating can wear off, requiring maintenance.

Impact on Application: Galvanized steel is compatible with various environmental conditions, making it suitable for regions with high humidity or heavy rainfall.

Considerations for International Buyers: Compliance with standards such as ASTM A123 for hot-dip galvanizing is essential. Buyers should also consider local availability and shipping costs.

What Role Does Aluminum Play in Carport Square Tubing?

Aluminum is another viable option for carport square tubing, known for its lightweight and high strength-to-weight ratio. It is naturally corrosion-resistant and does not require additional coating, making it an attractive choice for buyers looking for low-maintenance solutions.

Pros: Aluminum is easy to work with and can be extruded into various shapes. Its lightweight nature reduces shipping costs and simplifies installation.

Cons: While aluminum is durable, it may not be as strong as steel for heavy-duty applications. It can also be more expensive than galvanized steel.

Impact on Application: Aluminum is suitable for areas with less extreme weather but may not hold up as well under heavy loads.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221 for aluminum extrusions and consider the implications of higher costs in their budgeting.

How Does Carbon Steel Compare for Carport Square Tubing?

Carbon steel is a strong and versatile material often used in carport applications. It offers good strength and can be treated for corrosion resistance, though it is not inherently resistant like galvanized steel or aluminum.

Pros: Carbon steel is generally less expensive than both aluminum and galvanized steel, making it an economical choice for large projects.

Cons: Without proper treatment, carbon steel is susceptible to rust and corrosion, which can lead to higher maintenance costs over time.

Impact on Application: Carbon steel is suitable for structural applications but may require protective coatings depending on the environment.

Considerations for International Buyers: Compliance with standards like ASTM A500 for structural tubing is necessary. Buyers should also evaluate the availability of protective coatings in their region.

What About Stainless Steel for Carport Square Tubing?

Stainless steel is renowned for its exceptional corrosion resistance and aesthetic appeal. It is often used in high-end applications where appearance and longevity are critical.

Pros: The durability and resistance to rust make stainless steel an excellent long-term investment. It also requires minimal maintenance.

Cons: The primary downside is the cost, as stainless steel is generally more expensive than other materials. Its weight can also complicate shipping and installation.

Impact on Application: Stainless steel is ideal for regions with high humidity or coastal environments where corrosion is a significant concern.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A554 for stainless steel tubing and consider the implications of higher costs on their overall project budgets.

Summary Table of Material Selection for Carport Square Tubing

| Material | Typical Use Case for carport square tubing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Outdoor carports in humid climates | Excellent corrosion resistance | Zinc coating may wear off over time | Medium |

| Aluminum | Lightweight carports | Low maintenance and easy to work with | Less strong than steel | High |

| Carbon Steel | Structural applications | Economical for large projects | Susceptible to rust without treatment | Low |

| Stainless Steel | High-end carports | Exceptional durability and aesthetics | Higher cost and weight | High |

This guide provides a comprehensive overview of the materials available for carport square tubing, helping international B2B buyers make informed decisions based on their specific project requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for carport square tubing

What Are the Main Stages of the Manufacturing Process for Carport Square Tubing?

The manufacturing process for carport square tubing typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the required strength, durability, and corrosion resistance needed for carport applications.

-

Material Preparation:

The process begins with selecting high-quality raw materials, primarily steel, which is often galvanized to enhance corrosion resistance. The steel is then cut into appropriate lengths and inspected for any defects or inconsistencies. This initial step ensures that only suitable materials are used in production, setting the foundation for quality. -

Forming:

The next stage involves shaping the steel into square tubing. This is typically achieved through a process called roll forming, where flat steel sheets are continuously fed through a series of rollers that gradually bend and shape the steel into the desired square profile. Advanced techniques, such as cold forming, can be employed to achieve precise dimensions and improve the mechanical properties of the steel. -

Assembly:

Following the forming stage, the square tubing may undergo additional processes such as welding or joining, particularly if multiple pieces are combined for larger structures. The assembly stage is critical for ensuring structural integrity, especially in applications where the tubing must support significant weight or withstand environmental stresses. -

Finishing:

The final stage of manufacturing involves applying protective coatings to enhance durability and aesthetics. Common finishing techniques include hot-dip galvanizing, which provides an additional layer of corrosion resistance, and powder coating, which can be used for decorative purposes. Quality control measures during this stage include visual inspections and adhesion tests to verify the effectiveness of the finishes applied.

How Is Quality Assurance Implemented in Carport Square Tubing Manufacturing?

Quality assurance (QA) is essential in the manufacturing of carport square tubing to ensure that products meet international standards and customer specifications. This process involves several checkpoints and adherence to recognized standards.

-

International Standards and Certifications:

Manufacturers often adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Compliance with these standards demonstrates a commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications may also be relevant. -

Quality Control Checkpoints:

Quality control is typically divided into three main checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery to ensure they meet specified standards before production begins. This can include material testing for chemical composition and mechanical properties.

-

In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted at different stages to monitor production quality. This can involve dimensional checks, visual inspections, and testing for weld integrity or coating adherence.

-

Final Quality Control (FQC): After the product is completed, a final inspection is performed to ensure it meets all specifications and quality standards. This may include functionality tests, load-bearing tests, and corrosion resistance evaluations.

- Common Testing Methods:

Various testing methods are utilized to ensure product quality, including:

- Tensile Testing: Measures the strength and ductility of the steel.

- Corrosion Testing: Assesses the resistance of coatings and materials to environmental factors.

- Visual Inspections: Checks for surface defects, proper dimensions, and overall finish quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensure product reliability and compliance with local regulations.

-

Supplier Audits:

Conducting on-site audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control practices. During an audit, buyers can assess compliance with international standards, review quality documentation, and observe production practices firsthand. -

Requesting Quality Reports:

Buyers should request detailed quality reports from suppliers, including documentation of inspections, test results, and certifications. These reports can help verify that the supplier adheres to the required quality standards and has a robust quality management system in place. -

Third-Party Inspections:

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can perform evaluations of manufacturing facilities, conduct testing, and verify compliance with international standards. This is particularly beneficial for buyers who may not have the resources to perform audits themselves.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific quality control nuances that can vary by region and industry. Understanding these differences is essential for ensuring product compliance and meeting local market demands.

-

Regional Standards and Regulations:

Different regions may have specific quality standards and regulations that must be adhered to. For instance, European buyers might require CE marking, while buyers in the Middle East may focus on compliance with local building codes and standards. Familiarity with these requirements can help prevent costly delays and ensure smooth market entry. -

Cultural Considerations:

When dealing with suppliers from diverse regions, cultural differences may influence communication and expectations around quality. Building strong relationships and ensuring clear communication about quality requirements can help mitigate misunderstandings and foster successful partnerships. -

Supply Chain Transparency:

As supply chains become increasingly globalized, ensuring transparency in sourcing and manufacturing processes is vital. Buyers should inquire about the origin of materials, production methods, and any subcontractors involved in the manufacturing process. This transparency can help buyers assess risks and maintain quality standards throughout the supply chain.

By understanding the manufacturing processes and quality assurance practices for carport square tubing, B2B buyers can make informed decisions and establish successful partnerships with suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘carport square tubing’

Introduction

Sourcing carport square tubing requires careful consideration to ensure that the materials meet your project’s specifications and quality standards. This guide provides a comprehensive checklist to assist international B2B buyers in making informed procurement decisions, focusing on critical factors such as material specifications, supplier reliability, and logistical considerations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Identify the dimensions, wall thickness, and grade of galvanized square tubing that meet your project requirements. Consider factors such as corrosion resistance and load-bearing capacity, which are crucial for the durability of carports.

- Common Sizes: Determine if you need standard lengths (e.g., 20 or 24 feet) or custom sizes.

- Material Standards: Specify whether you require hot-dipped or electro-galvanized tubing.

Step 2: Assess Supplier Capabilities

Evaluating potential suppliers is essential to ensure they can meet your specifications consistently. Look for suppliers who specialize in steel products and have a proven track record in the carport industry.

- Experience: Seek suppliers with extensive experience in manufacturing carport square tubing.

- Production Capacity: Ensure the supplier can handle your order volume and delivery timelines.

Step 3: Verify Supplier Certifications

It’s vital to ensure that your suppliers adhere to industry standards and regulations. Certifications can indicate a commitment to quality and safety.

- Quality Certifications: Look for suppliers with ISO certifications or similar quality management systems.

- Material Certifications: Request documentation that verifies the chemical and mechanical properties of the steel used.

Step 4: Request Samples for Quality Assurance

Before placing a large order, request samples to evaluate the quality of the square tubing. Inspect the samples for any defects or inconsistencies that could affect performance.

- Physical Inspection: Check for proper dimensions and surface finish.

- Testing: Consider third-party testing for corrosion resistance and structural integrity.

Step 5: Evaluate Pricing and Payment Terms

Understanding pricing structures and payment terms is crucial for budgeting and cash flow management. Compare quotes from multiple suppliers while considering the total cost of ownership.

- Transparent Pricing: Ensure that the quoted prices include all costs, such as shipping and handling.

- Payment Flexibility: Discuss payment terms and options, especially if you require extended payment periods.

Step 6: Consider Logistics and Shipping Options

Logistics play a significant role in the timely delivery of materials. Assess the supplier’s shipping capabilities and how they align with your project timelines.

- Shipping Methods: Confirm the shipping methods available (e.g., sea freight, air freight) and their respective timelines.

- Customs Regulations: Ensure the supplier is knowledgeable about customs requirements in your region, especially for international shipments.

Step 7: Establish a Communication Plan

Effective communication with your supplier is key to a smooth procurement process. Establish a clear communication plan to address any issues that may arise during production and delivery.

- Point of Contact: Designate a primary contact person for ongoing communication.

- Regular Updates: Agree on a schedule for regular updates regarding order status and any potential delays.

By following this checklist, you can streamline your sourcing process for carport square tubing, ensuring that you receive high-quality materials that meet your project’s requirements.

Comprehensive Cost and Pricing Analysis for carport square tubing Sourcing

What Are the Key Cost Components in Sourcing Carport Square Tubing?

When sourcing carport square tubing, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The type of steel used, such as galvanized or carbon steel, significantly impacts pricing. Galvanized steel, known for its corrosion resistance, typically commands a higher price due to its enhanced durability.

-

Labor: Labor costs can vary based on geographic location and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing, but it’s crucial to ensure quality standards are met.

-

Manufacturing Overhead: This encompasses costs related to facilities, equipment maintenance, and utilities. A well-managed manufacturing facility can lead to cost efficiencies, which can be passed on to buyers.

-

Tooling: Initial setup costs for tooling can be significant, especially for custom or specialized tubing. Buyers should consider these costs when evaluating quotes for tailored solutions.

-

Quality Control (QC): Ensuring that products meet specified standards incurs costs. Suppliers with robust QC measures may charge more, but this investment can prevent costly issues down the line.

-

Logistics: Transportation and shipping costs are critical, particularly for international buyers. Factors such as distance, mode of transport, and local regulations affect overall logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market rates and comparing multiple suppliers can help buyers negotiate better deals.

How Do Price Influencers Affect Carport Square Tubing Costs?

Several key factors influence the pricing of carport square tubing:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding the MOQ can help buyers plan their orders more efficiently to take advantage of lower prices.

-

Specifications and Customization: Custom specifications such as length, thickness, and coating can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher-grade materials and certifications (such as ISO) can lead to increased prices but often ensure better performance and reliability.

-

Supplier Factors: The reputation, location, and production capabilities of a supplier can impact pricing. Established suppliers may charge a premium for their reliability and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects shipping costs and responsibilities. Understanding these terms helps buyers calculate total costs accurately.

What Negotiation Strategies Can B2B Buyers Use for Cost Efficiency?

To maximize cost efficiency when sourcing carport square tubing, buyers should consider the following strategies:

-

Conduct Market Research: Understanding current market prices and trends can empower buyers during negotiations. Gathering quotes from multiple suppliers can provide leverage.

-

Emphasize Long-Term Partnerships: Suppliers are often willing to offer better pricing to buyers who commit to long-term contracts. This approach can lead to more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider factors like durability and maintenance. Investing in higher-quality tubing may reduce long-term expenses related to repairs and replacements.

-

Utilize Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can minimize logistics costs and reduce lead times.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions such as the Middle East and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Prices may vary due to exchange rate changes. It’s advisable to negotiate prices in a stable currency to mitigate risks.

-

Import Duties and Tariffs: Understanding local import regulations and associated costs is crucial. These expenses can significantly impact the total cost of sourcing.

-

Cultural Differences: Different regions may have varying negotiation styles and expectations. Being culturally aware can facilitate smoother transactions.

Disclaimer on Indicative Prices

Pricing for carport square tubing can vary widely based on the factors discussed. It is essential for buyers to conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing carport square tubing With Other Solutions

When considering solutions for constructing carports, buyers often seek alternatives to carport square tubing. Understanding these alternatives can provide insight into which method best suits their needs in terms of performance, cost, ease of implementation, maintenance, and intended use. Below, we compare carport square tubing with two viable alternatives: wood framing and pre-engineered metal carports.

| Comparison Aspect | Carport Square Tubing | Wood Framing | Pre-engineered Metal Carports |

|---|---|---|---|

| Performance | High durability and resistance to corrosion; suitable for various climates. | Generally lower durability; susceptible to rot and pests. | Excellent durability; designed for specific weather conditions. |

| Cost | Moderate initial investment; long-term savings due to durability. | Lower initial cost, but potential for higher long-term costs due to maintenance. | Higher upfront costs, but includes design and engineering, which can save costs in the long run. |

| Ease of Implementation | Requires specialized skills for welding and assembly; may need additional tools. | Easier to work with for those familiar with carpentry; tools are generally more common. | Quick installation as kits come pre-assembled; less skilled labor required. |

| Maintenance | Low maintenance; occasional inspections recommended. | Requires regular maintenance (e.g., painting, sealing) to prevent decay. | Minimal maintenance; typically designed for weather resistance. |

| Best Use Case | Ideal for custom designs and heavy-duty applications. | Suitable for residential projects or temporary structures. | Best for quick installations and standardized designs. |

What Are the Pros and Cons of Wood Framing as an Alternative?

Wood framing is a traditional method for constructing carports and offers a more familiar approach for many builders. Its primary advantage is the lower initial cost, making it an attractive option for budget-conscious projects. Additionally, wood is widely available and can be easier to work with for those skilled in carpentry. However, the downsides include susceptibility to rot, pests, and overall lower durability compared to metal options. Regular maintenance is required to keep wood structures in good condition, which may lead to higher long-term costs.

How Do Pre-engineered Metal Carports Compare?

Pre-engineered metal carports provide a modern alternative to traditional carport designs. These structures are manufactured to specific engineering standards, ensuring they perform well in various weather conditions. The installation process is typically faster than that of square tubing or wood framing, as these kits often come pre-assembled. However, the upfront costs can be higher, reflecting the engineering and design work involved. They also offer excellent durability and require minimal maintenance, making them a long-term investment for buyers looking for reliability.

Conclusion: How Can B2B Buyers Choose the Right Carport Solution?

Selecting the right carport solution depends on several factors, including budget, intended use, and required durability. Carport square tubing stands out for its performance and longevity, making it ideal for custom applications where strength is paramount. Wood framing may appeal to those looking for lower initial costs and easier construction methods but comes with higher maintenance demands. Pre-engineered metal carports offer a balance of quick installation and durability, suitable for buyers who prefer standardized designs. Ultimately, B2B buyers should assess their specific needs and project requirements to make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for carport square tubing

What Are the Key Technical Properties of Carport Square Tubing?

When selecting carport square tubing, understanding its technical specifications is crucial for ensuring durability, structural integrity, and compliance with local regulations. Here are some essential properties to consider:

-

Material Grade

Carport square tubing is typically made from galvanized steel, which enhances its corrosion resistance. Common material grades include ASTM A500 for structural tubing and ASTM A653 for galvanized products. The material grade affects the strength, weight, and corrosion resistance of the tubing, making it vital for meeting specific project requirements. -

Wall Thickness

The wall thickness of square tubing is a critical factor that influences its load-bearing capacity and overall strength. Wall thickness is measured in inches or millimeters, with common options ranging from 0.0625” to 0.125”. For B2B buyers, selecting the appropriate thickness is essential for ensuring that the tubing can withstand environmental stresses and loads without failure. -

Length and Tolerances

Standard lengths for carport square tubing typically range from 6 to 24 feet. Tolerances refer to the allowable variation in dimensions, which can affect how well the tubing fits with other components. Understanding tolerances is important for manufacturers and builders to ensure precise assembly and structural integrity. -

Corrosion Resistance

Galvanization provides a protective layer that enhances corrosion resistance. There are two primary methods of galvanization: hot-dip and electrogalvanization. Hot-dipped tubing generally offers superior protection against harsh environmental conditions, making it an ideal choice for outdoor applications in diverse climates. -

Weight per Foot

The weight per foot is an important specification that impacts shipping costs and handling. Heavier tubing may be more robust but could also lead to increased transportation costs. Understanding weight specifications allows buyers to calculate logistics and budget more effectively. -

Finish

The finish of the square tubing can vary, with options including mill finish, painted, or powder-coated. The type of finish affects aesthetics, corrosion resistance, and maintenance requirements. B2B buyers should select a finish that aligns with their project goals, especially in terms of visual appeal and longevity.

What Are Common Trade Terms Associated with Carport Square Tubing?

Navigating the procurement process for carport square tubing involves familiarizing oneself with industry jargon. Here are some common terms that are essential for effective communication:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that manufactures products that are then sold under another company’s brand name. In the context of carport square tubing, OEMs often produce components that are integrated into larger structures or systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers as it impacts inventory management and procurement strategies. Suppliers may set MOQs to ensure that production and shipping costs are covered. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. This process allows buyers to compare offerings and negotiate terms, making it an essential step in sourcing carport square tubing. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is vital for B2B transactions to avoid misunderstandings regarding shipping, delivery, and risk allocation. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is important for project planning and scheduling, particularly in regions where construction timelines are critical. -

Certification Standards

Certification standards, such as ISO or ASTM, indicate compliance with specific industry regulations and quality benchmarks. B2B buyers should ensure that suppliers meet relevant certification standards to guarantee product quality and safety.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing carport square tubing, ensuring they meet their project specifications and compliance requirements effectively.

Navigating Market Dynamics and Sourcing Trends in the carport square tubing Sector

What Are the Key Trends Driving the Carport Square Tubing Market?

The global carport square tubing market is witnessing significant growth, driven by an increasing demand for durable, weather-resistant structures across various sectors. Key factors propelling this trend include urbanization, the rise in automotive ownership, and a growing emphasis on outdoor living spaces. In regions like Africa and South America, where economic development is fostering more residential and commercial constructions, the demand for robust carport solutions is surging.

Emerging B2B technologies such as advanced manufacturing processes and real-time inventory management are reshaping sourcing strategies. Suppliers are increasingly adopting digital platforms to streamline procurement, allowing buyers to access a wider range of products and specifications with ease. Moreover, trends like customization are gaining traction, with clients seeking tailored solutions that meet specific project requirements. This trend is particularly relevant for international buyers from the Middle East and Europe, where architectural preferences vary significantly.

Understanding regional market dynamics is crucial. For instance, buyers in Saudi Arabia and Vietnam may prioritize corrosion-resistant materials due to their respective climates. Suppliers offering diverse sizes, wall thicknesses, and galvanization options can better cater to these varying needs, enhancing their competitive edge in the global market.

How Is Sustainability Influencing Sourcing Decisions for Carport Square Tubing?

Sustainability is becoming a cornerstone of B2B procurement strategies, particularly in the carport square tubing sector. As global awareness of environmental issues rises, businesses are increasingly focused on reducing their carbon footprints. This shift is leading buyers to prioritize suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or implementing energy-efficient manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with suppliers who can provide transparency regarding their sourcing practices and labor conditions. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential criteria for procurement decisions.

Moreover, the use of galvanized steel in carport applications is often highlighted for its longevity and resistance to corrosion, which translates into reduced maintenance and replacement costs over time. International buyers are encouraged to seek out suppliers who can offer these ‘green’ materials and demonstrate a commitment to ethical sourcing, ensuring that their investments align with broader sustainability goals.

What Is the Historical Context of Carport Square Tubing Production?

The evolution of carport square tubing can be traced back to the industrial revolution, which sparked significant advancements in steel manufacturing. Initially, steel was primarily used for heavy structural applications; however, as technology progressed, the versatility of steel became apparent, leading to its adoption in various consumer applications, including carports.

The introduction of galvanization processes in the mid-20th century further enhanced the appeal of steel for outdoor applications, providing improved resistance to environmental factors. Over the years, as the demand for carports surged, manufacturers began to focus on developing specialized products tailored for this market, resulting in a diverse range of square tubing sizes and specifications available today.

This historical context is vital for international buyers, as it underscores the importance of selecting suppliers with a proven track record and expertise in the carport sector. Understanding the evolution of materials and manufacturing processes can help buyers make informed decisions that align with their specific project requirements and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of carport square tubing

-

How do I determine the right size of carport square tubing for my project?

To select the appropriate size of carport square tubing, consider the specific requirements of your project, including the intended load, environmental factors, and design specifications. Generally, larger tubing can support more weight and provide greater durability, while smaller sizes may be suitable for less demanding applications. Consult with engineering guidelines or a structural engineer to ensure the chosen size meets safety and performance standards. Additionally, request samples from suppliers to evaluate the quality and suitability for your project. -

What is the best type of galvanized square tubing for carports?

The best type of galvanized square tubing for carports typically features hot-dipped galvanization, which offers superior corrosion resistance compared to electrogalvanized options. Hot-dipped galvanized tubing undergoes a thorough coating process that protects against rust and environmental wear, making it ideal for outdoor applications. When sourcing, check the manufacturer’s specifications for thickness and grade to ensure it aligns with your project’s structural requirements and local building codes. -

How can I verify the quality of carport square tubing from a supplier?

To ensure the quality of carport square tubing, request certifications from suppliers that validate their products meet industry standards, such as ASTM or ISO certifications. Additionally, inquire about their manufacturing processes, including the type of galvanization used and any quality assurance measures in place. If possible, ask for product samples or references from previous clients to assess the tubing’s durability and performance in real-world applications. -

What are the typical minimum order quantities (MOQ) for carport square tubing?

Minimum order quantities for carport square tubing can vary significantly among suppliers, generally ranging from a few hundred to several thousand units, depending on the size and specifications of the tubing. When negotiating with suppliers, it’s essential to discuss your project requirements and potential for bulk orders to secure favorable terms. Some suppliers may offer flexibility on MOQs for first-time buyers or special projects, so be sure to communicate your needs clearly. -

What payment terms should I expect when sourcing carport square tubing internationally?

Payment terms for international purchases of carport square tubing often include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, particularly for larger orders, with the balance due prior to shipment or upon delivery. It’s crucial to establish clear payment terms in your contract to avoid misunderstandings. Always verify the supplier’s payment history and credibility to mitigate risks associated with international transactions. -

How do shipping and logistics work for international orders of carport square tubing?

Shipping and logistics for international orders typically involve coordination between the supplier and a freight forwarder. The supplier will provide details on packaging, documentation, and any required customs forms. Depending on your location, you may choose sea freight for cost-effectiveness or air freight for faster delivery. Ensure you understand the incoterms (such as FOB, CIF) to clarify responsibilities for shipping costs, insurance, and risks during transit. -

Can I customize the specifications of carport square tubing?

Yes, many suppliers offer customization options for carport square tubing, including variations in size, wall thickness, and length. When discussing customization, provide detailed specifications, including any particular requirements for your project. Keep in mind that custom orders may have longer lead times and potentially higher costs. It’s beneficial to discuss your needs upfront to ensure the supplier can meet your expectations effectively. -

What should I consider regarding warranty and after-sales service for carport square tubing?

When sourcing carport square tubing, inquire about the warranty period and coverage provided by the supplier. A reputable supplier should offer a warranty that covers defects in material and workmanship, typically ranging from one to several years. Additionally, assess the supplier’s after-sales service, including their responsiveness to inquiries and support for installation or maintenance. Strong after-sales support can significantly enhance your experience and ensure long-term satisfaction with your purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Carport Square Tubing Manufacturers & Suppliers List

1. Steel Supply LP – Galvanized Square Tubing

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: Galvanized Square Tubing available in 20 and 24 foot lengths. Types include Electrogalvanized and Hot Dipped Galvanized. Wall thicknesses available: 11 GAUGE, 14 GAUGE, 16 GAUGE. Sizes include: .500-X-.500, .750-X-.750, 1.00-X-1.00, 1.25-X-1.25, 1.50-X-1.50, 2.00-X-2.00, 2.50-X-2.50, 3.00-X-3.00, 4.00-X-4.00. Custom cuts available with a processing time of 1-2 days. Tolerance on cut lengths may be…

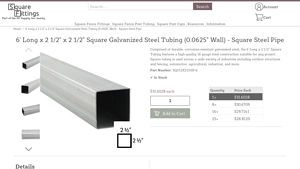

2. Square Fittings – 6′ Galvanized Steel Square Fitting

Domain: squarefittings.com

Registered: 2013 (12 years)

Introduction: {‘length’: “6′”, ‘size’: ‘2 1/2″ x 2 1/2″‘, ‘gauge’: ’16 Gauge’, ‘wall_thickness’: ‘0.0625″‘, ‘material’: ‘Galvanized Steel’, ‘part_number’: ‘SQ212X212GP-6’, ‘price_per_unit’: ‘$31.6028’, ‘common_uses’: ‘Outdoor structures, fencing, automotive, agricultural, industrial’, ‘features’: ‘Can be cut to any size, heavy-duty corrosion-resistant construction’}

3. Americas Elite – Galvanized Steel Carports

Domain: americaselitegaragesandcarports.com

Registered: 2019 (6 years)

Introduction: Materials: Galvanized Steel (100% galvanized) 14 Gauge: 2.5″x2.5″ rectangular tubing (standard) 12 Gauge: 2.25″x2.25″ rectangular tubing (20-Year Rust Through Warranty) Trusses/Bows: Single piece tubing bent for widths from 12 to 60 feet Base Rail: Foundation with welded sleeves 4ft to 5ft apart Sheet Panels: 29 gauge (standard) or 26 gauge upgrade, 3′ wide, lengths of 21′, 26′, 31′, 36′, 41′, lon…

4. Versatube – Frame Only Classic Carport

Domain: versatube.com

Registered: 1997 (28 years)

Introduction: Frame Only Classic Carport (2×2) – Dimensions: 10’W x 31.5’L x 7’H – Availability: In stock – Regular Price: $1,630 – Special Price: $1,600 – Price Drop: $30 – Frame ships in 5 business days – Made in the USA – Designed for horizontal sheet metal application – Steel Tubing Size: 2″ x 3″ – Steel Gauge: 14 Gauge – Warranty: 20 Year Product Pledge – Connections: Patented Slip Fit Connections – Ground…

5. Wheeler Metals – Bare Square Tubing

Domain: wheelermetals.com

Registered: 1999 (26 years)

Introduction: Bare Square Tubing options include: 1/2 X 16ga Sq Tube – $0.42, 3/4 X 16ga Sq Tube – $0.63, 3/4 X 14ga Sq Tube – $0.71, 1 X 16ga Sq Tube – $0.83, 1 X 14ga Sq Tube – $0.99, 1 X 11ga Sq Tube – $1.47, 1 1/4 X 16ga Sq Tube – $1.05, 1 1/4 X 14ga Sq Tube – $1.19, 1 1/4 X 11ga Sq Tube – $1.89, 1 1/2 X 16ga Sq Tube – $1.27, 1 1/2 X 14ga Sq Tube – $1.46, 1 1/2 X 11ga Sq Tube – $2.21, 1 1/2 X 3/16 Sq Tube -…

6. All American Metal Sales – Carports and Covers

Domain: allamericanmetalsales.com

Registered: 2018 (7 years)

Introduction: Carports and covers are available in various styles and sizes to protect vehicles and outdoor equipment from the elements. They are made from durable materials, ensuring longevity and resistance to weather conditions. Customization options are offered to meet specific needs, including color choices and dimensions. Installation services may be provided, and the products are designed to be cost-effe…

7. Your Custom Carport – Metal Tubing Features

Domain: yourcustomcarport.com

Registered: 2022 (3 years)

Introduction: Metal tubing is a versatile building material made from steel, aluminum, or other metals, available in round, square, and rectangular shapes. Key features include:

– Strength and Durability: Exceptional strength, able to withstand heavy loads and harsh conditions.

– Corrosion and Rust Resistance: Galvanized steel and aluminum resist rust and corrosion, ideal for outdoor use.

– Customization and Fl…

8. Midwest Steel – Steel Frame Gauge Options

Domain: midweststeelcarports.com

Registered: 2016 (9 years)

Introduction: Midwest Steel offers two steel frame gauge options: 14 gauge and 12 gauge.

14 Gauge:

– Standard option for steel buildings

– Economical choice

– 7-year warranty on rust through of frame

– Dimensions: 2 1/2″ x 2 1/2″ in diameter, .0747 inch thick

– Industry standard for carports

12 Gauge:

– Heavy duty option with high tensile strength

– Best for heavy snow loads and high winds

– 20-year warranty…

Strategic Sourcing Conclusion and Outlook for carport square tubing

Strategic sourcing for carport square tubing is critical for businesses aiming to enhance operational efficiency while ensuring product quality. By focusing on suppliers that offer galvanized options, companies can benefit from superior corrosion resistance and longevity, thus protecting their investments and enhancing property value. Moreover, understanding the specific needs of your market—whether it’s for residential carports in Africa or industrial applications in Europe—allows for tailored sourcing strategies that align with regional demands.

International buyers should prioritize suppliers with a proven track record of reliability and quick turnaround times, such as those with over a century of industry experience. This not only ensures a steady supply of quality materials but also fosters partnerships that can lead to innovation and cost savings. As demand for durable and versatile building materials continues to rise globally, now is the time to reassess your sourcing strategies.

Looking forward, businesses in regions like South America and the Middle East should actively seek opportunities to collaborate with reputable steel tubing manufacturers. By doing so, they can secure competitive advantages and position themselves for growth in an increasingly interconnected marketplace. Engage with suppliers today to explore customized solutions that meet your specific project requirements.