Ar500 Steel Price Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for ar500 steel price

In today’s competitive landscape, sourcing AR500 steel at the right price poses a significant challenge for international B2B buyers. This high-strength, low-alloy steel is renowned for its exceptional hardness and abrasion resistance, making it a preferred choice in industries ranging from defense to mining. However, navigating the global market for AR500 steel pricing can be complex, especially for buyers in diverse regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Vietnam.

This comprehensive guide offers valuable insights into the various types of AR500 steel products available, their specific applications, and effective strategies for supplier vetting. We delve into cost factors that influence pricing, such as material specifications, shipping logistics, and market demand. By equipping buyers with detailed knowledge and actionable insights, this guide empowers them to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you’re seeking to enhance your supply chain efficiency or optimize your procurement strategy, understanding the nuances of AR500 steel pricing is crucial. This guide serves as your essential resource for successfully navigating the complexities of the global market, ensuring you secure the best value for your investment in AR500 steel.

Understanding ar500 steel price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AR500 Steel Plate | High tensile strength, abrasion resistance, available in various thicknesses | Mining equipment, armored vehicles, industrial machinery | Pros: Durable, versatile; Cons: Higher cost compared to lower-grade steels. |

| AR500 Steel Sheet | Thinner than plates, customizable dimensions, often pre-cut | Fabrication, construction, target shooting | Pros: Lightweight, easy to work with; Cons: Less impact resistance than thicker plates. |

| AR500 Targets | Designed for shooting sports, often 1/2″ thickness, reusable | Shooting ranges, military training | Pros: Long-lasting, cost-effective for repeated use; Cons: Limited to specific applications. |

| AR550 Steel | Enhanced hardness compared to AR500, thicker options available | Heavy-duty applications, military armor | Pros: Greater durability; Cons: Increased weight may affect transport. |

| Custom AR500 Products | Tailored specifications, unique cuts, and sizes | Specialized applications, unique projects | Pros: Meets specific needs; Cons: Potentially longer lead times and higher costs. |

What Are the Key Characteristics of AR500 Steel Plate?

AR500 steel plates are known for their exceptional hardness and abrasion resistance, making them ideal for applications in mining and heavy machinery. Typically available in thicknesses ranging from 0.25″ to 1″, these plates withstand extreme wear and impact. B2B buyers should consider the specific thickness required for their application, as thicker plates offer greater durability but at a higher cost. Additionally, sourcing high-quality AR500 plates from reputable suppliers ensures longevity and performance.

How Does AR500 Steel Sheet Differ from Plates?

AR500 steel sheets are thinner and often customizable, making them suitable for various fabrication projects. They are commonly used in construction and lightweight applications where weight is a concern. While they provide good abrasion resistance, they may not withstand the same level of impact as thicker plates. Buyers should evaluate their specific needs, such as size and weight considerations, to determine if sheets are the right choice for their projects.

What Are the Benefits of Using AR500 Targets?

Designed specifically for shooting sports, AR500 targets are typically 1/2″ thick and can endure repeated impacts from firearms. These targets are reusable and cost-effective, making them a popular choice for shooting ranges and military training facilities. Buyers should assess the expected usage frequency and the type of firearms to ensure the chosen targets can withstand the required impact without deformation.

Why Choose AR550 Steel for Heavy-Duty Applications?

AR550 steel offers enhanced hardness compared to AR500, making it suitable for heavy-duty applications, including military armor and high-stress environments. While it provides superior durability, buyers should consider the added weight, which may impact transport and installation. AR550 is an excellent choice for those needing extra protection and longevity in demanding conditions.

What Are the Advantages of Custom AR500 Products?

Custom AR500 products allow B2B buyers to specify dimensions and features that meet unique project requirements. This flexibility is particularly beneficial for specialized applications where standard sizes may not suffice. However, buyers should be prepared for potentially longer lead times and higher costs associated with custom orders. Understanding the balance between customization and budget is crucial for effective procurement.

Key Industrial Applications of ar500 steel price

| Industry/Sector | Specific Application of ar500 steel price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Defense and Military | Armored vehicles and protective gear | Enhanced safety and durability against ballistic threats | Compliance with military standards and specifications |

| Mining | Wear plates for heavy equipment | Reduced maintenance costs and increased equipment lifespan | Sourcing thickness and hardness grade based on application needs |

| Construction | Structural components in high-wear areas | Improved structural integrity and longevity | Availability of custom cuts and sizes for specific projects |

| Manufacturing | Machinery parts exposed to high abrasion | Minimized downtime and repair costs | Ensuring quality certifications and traceability of materials |

| Sports and Recreation | Shooting targets and training equipment | High performance and safety for recreational use | Consideration of shipping logistics and local regulations |

How is AR500 Steel Used in the Defense and Military Sector?

AR500 steel is extensively utilized in the defense and military sectors for the production of armored vehicles and personal protective gear. Its exceptional hardness and impact resistance enable it to withstand ballistic threats effectively, ensuring the safety of personnel in combat situations. For international buyers, particularly in regions like the Middle East, compliance with specific military standards is crucial, necessitating thorough vetting of suppliers who can meet these stringent requirements.

What Role Does AR500 Steel Play in Mining Applications?

In the mining industry, AR500 steel is primarily used for wear plates on heavy machinery, such as excavators and haul trucks. Its high abrasion resistance significantly reduces wear and tear, thereby extending the lifespan of expensive equipment and minimizing maintenance costs. Buyers from resource-rich regions like South America should prioritize sourcing suppliers who can provide the appropriate thickness and hardness specifications tailored to their operational demands.

How is AR500 Steel Beneficial in Construction Projects?

AR500 steel finds application in construction, particularly in areas subjected to high wear, such as loading docks and industrial floors. Its robustness contributes to improved structural integrity, reducing the likelihood of failure or damage over time. Businesses in Europe looking to source AR500 steel should focus on suppliers that offer custom cuts and sizes to meet specific project requirements, ensuring seamless integration into existing structures.

In What Ways is AR500 Steel Utilized in Manufacturing?

Manufacturers leverage AR500 steel for components that endure significant abrasion, such as conveyor systems and processing machinery. The durability of AR500 minimizes downtime and repair costs, enhancing overall productivity. For international buyers, particularly from Africa, confirming the quality certifications and traceability of materials is essential to ensure compliance with industry standards and regulations.

Why is AR500 Steel Important for Sports and Recreation?

In the sports and recreation sector, AR500 steel is favored for shooting targets and training equipment due to its ability to withstand repeated impacts without deforming. This ensures safety and performance for users, whether in recreational shooting ranges or competitive environments. Buyers should consider local regulations regarding material use and shipping logistics to ensure compliance and timely delivery of their orders.

3 Common User Pain Points for ‘ar500 steel price’ & Their Solutions

Scenario 1: Navigating Fluctuating AR500 Steel Prices

The Problem: B2B buyers often face significant challenges when it comes to the fluctuating prices of AR500 steel. These price variations can be driven by numerous factors, including global market demand, raw material costs, and geopolitical influences. This unpredictability complicates budgeting and financial forecasting for companies that rely on AR500 steel for manufacturing armored vehicles, mining equipment, or construction materials. Buyers may find themselves facing unexpected price hikes, which can jeopardize contract agreements and strain customer relationships.

The Solution: To mitigate the impact of fluctuating prices, buyers should establish long-term relationships with multiple suppliers. This strategy allows for better negotiation leverage and access to competitive pricing. Additionally, consider utilizing forward contracts or price-lock agreements that can secure current prices for future purchases, thereby providing cost predictability. It’s also beneficial to closely monitor industry trends and economic indicators that can affect steel prices, allowing for more informed purchasing decisions. Regularly reviewing inventory needs and adjusting order quantities based on market insights can further help in optimizing costs.

Scenario 2: Understanding the Quality and Specifications of AR500 Steel

The Problem: A common pain point for B2B buyers is the challenge of understanding the quality specifications associated with AR500 steel. With various grades available, buyers often struggle to determine the right thickness and hardness required for their specific applications. Misunderstanding these specifications can lead to purchasing the wrong product, resulting in subpar performance, increased wear, and ultimately financial losses. This confusion is particularly prevalent among companies new to using AR500 steel.

The Solution: To address this issue, buyers should invest time in educating themselves about the different grades of AR500 steel and their respective properties. Engaging with suppliers who offer technical support can provide invaluable insights into the most suitable options for specific applications. Additionally, requesting material test reports (MTRs) can ensure the steel’s quality meets industry standards. It’s also advisable to conduct small-scale trials with different thicknesses to determine the optimal fit for the intended use, allowing buyers to make informed decisions before committing to larger orders.

Scenario 3: Managing Supply Chain Disruptions Affecting AR500 Steel Availability

The Problem: Global supply chain disruptions can severely affect the availability of AR500 steel, leaving B2B buyers in a lurch. Factors such as shipping delays, production halts due to labor shortages, or natural disasters can create significant hurdles, impacting project timelines and production schedules. This situation is particularly critical for businesses that operate in industries like defense or construction, where timing is crucial for contract fulfillment and operational efficiency.

The Solution: To navigate supply chain challenges, companies should diversify their sourcing strategies by working with multiple suppliers across different regions. This approach minimizes reliance on a single source and provides alternative options in case of disruptions. Implementing a just-in-time inventory system can also help reduce stockouts while optimizing storage costs. Moreover, building strong relationships with suppliers can facilitate better communication regarding potential delays, allowing businesses to proactively adjust their production schedules and manage client expectations. Establishing a contingency plan that includes alternative materials or suppliers can further enhance resilience against unexpected supply chain issues.

Strategic Material Selection Guide for ar500 steel price

What Are the Key Properties of AR500 Steel?

AR500 steel is a high-strength, low-alloy steel known for its exceptional hardness, typically reaching a hardness level of 500 BHN (Brinell Hardness Number). This material is designed to withstand extreme wear and impact, making it ideal for applications such as armored vehicles, mining equipment, and shooting targets. Its high carbon content and specific alloying elements contribute to its impressive abrasion resistance and toughness, allowing it to endure harsh conditions without fracturing. Additionally, AR500 steel exhibits good weldability and can be easily machined, making it versatile for various manufacturing processes.

What Are the Pros and Cons of Using AR500 Steel?

When considering AR500 steel for B2B applications, several advantages stand out. Its durability and wear resistance make it suitable for high-impact environments, reducing the need for frequent replacements. However, one key disadvantage is its cost; AR500 steel can be more expensive than lower-grade steels, which might deter budget-conscious buyers. Furthermore, its hardness can complicate machining processes, potentially increasing manufacturing complexity and costs. For international buyers, particularly in regions like Africa and South America, understanding the balance between performance and cost is crucial for making informed purchasing decisions.

How Does AR500 Steel Impact Specific Applications?

The application of AR500 steel significantly influences its performance in various industries. For example, in the defense sector, its use in armored vehicles ensures protection against ballistic threats, while in mining, it enhances the lifespan of equipment exposed to abrasive materials. However, buyers must consider the specific media compatibility; AR500 steel is not suitable for environments involving corrosive substances unless adequately protected. This necessitates a thorough assessment of the operational environment when selecting AR500 steel for a particular application.

What Should International B2B Buyers Consider When Sourcing AR500 Steel?

For international B2B buyers, particularly from the Middle East and Europe, compliance with local standards and regulations is paramount. Familiarity with common standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung) is essential to ensure product quality and compatibility. Additionally, understanding regional preferences and market conditions can aid in negotiating better terms and prices. Buyers should also be aware of logistical considerations, such as shipping costs and delivery times, which can vary significantly based on geographic location.

| Material | Typical Use Case for ar500 steel price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| AR500 Steel | Armored vehicles, mining equipment, shooting targets | Exceptional hardness and wear resistance | Higher cost compared to lower-grade steels | High |

| AR400 Steel | General wear applications, construction equipment | Good balance of hardness and cost | Less hardness than AR500, limiting certain applications | Medium |

| AR600 Steel | Extreme wear applications, heavy-duty armor | Superior hardness for high-impact use | More brittle, can fracture under certain conditions | High |

| Mild Steel | General fabrication, structural components | Cost-effective and easy to work with | Poor wear resistance compared to hardened steels | Low |

This analysis provides a comprehensive overview of AR500 steel and its alternatives, equipping international B2B buyers with the necessary insights to make informed purchasing decisions. Understanding the properties, advantages, and limitations of these materials will facilitate better alignment with specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for ar500 steel price

What Are the Key Stages in the Manufacturing Process of AR500 Steel?

The manufacturing process of AR500 steel involves several critical stages that ensure the production of high-quality, durable materials suitable for various industrial applications. Understanding these stages is essential for B2B buyers looking to procure AR500 steel at competitive prices.

-

Material Preparation

The first stage in the manufacturing process involves sourcing high-quality raw materials, typically high-carbon steel. The steel is melted in an electric arc furnace, where precise control over the chemical composition is maintained to achieve the desired hardness and toughness. After melting, the steel is cast into slabs or blooms, which are then cooled and prepared for further processing. -

Forming

Once the material is prepared, it undergoes forming processes such as hot rolling or cold rolling. Hot rolling involves heating the steel above its recrystallization temperature, allowing it to be shaped into plates or sheets. Cold rolling, on the other hand, is performed at room temperature, providing a finer finish and tighter tolerances. The choice between hot and cold rolling depends on the specific requirements of the final product. -

Heat Treatment

After forming, the steel undergoes heat treatment to enhance its hardness and mechanical properties. This typically involves quenching (rapid cooling) and tempering (reheating at lower temperatures) processes. These techniques improve the steel’s wear resistance and impact toughness, making it suitable for high-demand applications like armored vehicles and industrial machinery. -

Finishing

The final stage of manufacturing involves various finishing processes. This may include surface treatments such as shot blasting, grinding, or coating to enhance corrosion resistance and surface finish. Custom cut-to-size options are also offered to meet specific customer requirements, ensuring the final product is ready for immediate use.

How Is Quality Assurance Implemented in AR500 Steel Production?

Quality assurance is paramount in the production of AR500 steel, ensuring that the final product meets international and industry-specific standards. B2B buyers should be familiar with the following aspects of quality assurance:

-

International Standards Compliance

AR500 steel manufacturers often adhere to international quality management standards such as ISO 9001. This certification ensures that the manufacturing process is consistent and meets predefined quality benchmarks. Additionally, compliance with industry-specific standards such as CE marking for European markets or API standards for oil and gas applications can further enhance product credibility. -

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with several checkpoints established:

- Incoming Quality Control (IQC): This initial phase involves inspecting raw materials for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, processes are monitored to ensure they adhere to quality standards. This may involve real-time measurements of parameters such as temperature and thickness.

- Final Quality Control (FQC): After the product is completed, final inspections are conducted to assess the overall quality, including visual inspections and dimensional checks.

- Testing Methods for Quality Assurance

Various testing methods are employed to validate the mechanical and physical properties of AR500 steel. Common tests include:

- Hardness Testing: Typically measured using the Brinell or Rockwell scale, this test assesses the material’s hardness and wear resistance.

- Tensile Testing: This determines the yield strength, ultimate tensile strength, and elongation of the steel, critical for evaluating its performance under stress.

- Impact Testing: This assesses the toughness of the steel, particularly its ability to absorb energy during sudden impacts, which is vital for applications involving heavy machinery or armored vehicles.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several effective strategies:

-

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. Buyers should establish an audit schedule and evaluate suppliers based on their compliance with quality standards, production capabilities, and overall reliability. -

Request Quality Assurance Reports

Suppliers should be able to provide detailed quality assurance reports, including results from various testing methods and certifications. These documents should outline the specifications met during production and any deviations from standards. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing process, conduct tests, and verify compliance with international standards. This is particularly valuable when sourcing from new suppliers or regions with less established manufacturing practices. -

Understand Certification Nuances

Different regions may have specific certification requirements, and it is essential for buyers to understand these nuances. For instance, in Europe, CE certification is mandatory for many products, while in the Middle East, local regulations may dictate additional testing and certification. Being aware of these requirements helps buyers ensure that the AR500 steel they procure complies with local laws and industry standards.

What Are the Challenges and Considerations for International B2B Buyers?

International B2B buyers must navigate several challenges when sourcing AR500 steel, particularly regarding quality assurance. Key considerations include:

-

Cultural and Regulatory Differences

Understanding the cultural and regulatory landscape of the supplier’s country is vital. This includes knowledge of local quality standards, business practices, and potential language barriers that could affect communication regarding quality specifications. -

Supply Chain Reliability

Ensuring a reliable supply chain is critical for maintaining production schedules. Buyers should assess the supplier’s ability to deliver consistently high-quality products within agreed timelines, especially in regions prone to logistical challenges. -

Post-Purchase Support

Establishing clear channels for post-purchase support is essential for addressing any quality issues that may arise after procurement. Buyers should inquire about the supplier’s warranty policies and procedures for handling defective products or discrepancies.

In conclusion, the manufacturing processes and quality assurance measures associated with AR500 steel play a crucial role in ensuring that buyers receive high-quality, reliable products. By understanding these processes and implementing effective verification strategies, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ar500 steel price’

In the competitive landscape of industrial materials, AR500 steel stands out for its exceptional hardness and durability. For B2B buyers looking to procure AR500 steel, understanding the procurement process is essential to ensure quality, cost-effectiveness, and timely delivery. This guide provides a structured approach to sourcing AR500 steel, focusing on key actions that will help you navigate the complexities of the market.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline the technical requirements for your AR500 steel. Specify dimensions, thickness, and any industry standards that must be met. This clarity helps prevent miscommunication and ensures that the steel you receive meets your operational needs.

- Consider the specific applications for the steel, such as armor plates or industrial machinery, as these will influence your specifications.

- Document desired properties like hardness ratings (BHN) and any additional treatments or coatings required.

Step 2: Research Market Prices

Understanding the current market price for AR500 steel is critical for budget planning. Prices can fluctuate based on global supply and demand, so gather data from multiple suppliers to get a sense of the price range.

- Utilize online platforms and industry reports to track price trends.

- Consider factors that may affect pricing, such as geopolitical events or changes in raw material costs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your requirements. Look for companies with a proven track record in providing AR500 steel and request documentation of their certifications.

- Ask for case studies or references from clients in similar industries to assess reliability.

- Verify that suppliers comply with relevant standards and regulations, such as ISO certifications.

Step 4: Request Samples and Quotes

Once you have a shortlist of suppliers, request samples to evaluate the quality of their AR500 steel. Additionally, obtain detailed quotes that outline pricing, shipping costs, and lead times.

- Compare the quality of samples against your specifications to ensure they meet your needs.

- Be sure to clarify any additional costs that may arise during procurement, such as tariffs or handling fees.

Step 5: Negotiate Terms and Conditions

Effective negotiation can lead to better pricing and terms. Discuss payment options, delivery schedules, and return policies with your selected supplier.

- Ensure that the terms are clear and documented to avoid misunderstandings later.

- Consider including performance clauses to protect your interests, particularly for large orders.

Step 6: Finalize the Purchase Order

Once negotiations are complete, prepare and send a formal purchase order. This document should detail all agreed-upon terms, including pricing, delivery dates, and specifications.

- Double-check that all specifications are accurately represented to avoid disputes.

- Maintain open lines of communication with the supplier throughout the order fulfillment process.

Step 7: Plan for Quality Assurance Upon Delivery

Upon receiving the AR500 steel, conduct a thorough inspection to ensure it meets your specified criteria. Implement quality control measures to catch any discrepancies early.

- Utilize testing methods such as hardness tests to confirm that the steel matches the required standards.

- Document any issues and communicate with the supplier promptly to resolve any problems.

By following these steps, B2B buyers can streamline the sourcing process for AR500 steel, ensuring they acquire high-quality materials that meet their specific needs while maintaining budgetary control.

Comprehensive Cost and Pricing Analysis for ar500 steel price Sourcing

What Are the Key Cost Components in AR500 Steel Pricing?

Understanding the cost structure of AR500 steel is essential for B2B buyers looking to optimize their sourcing strategies. The primary cost components include:

-

Materials: The price of raw materials significantly influences the overall cost. AR500 steel, known for its high strength and abrasion resistance, requires a specific mix of high-carbon steel and alloys, which can fluctuate based on market conditions.

-

Labor: Labor costs encompass both direct and indirect labor involved in manufacturing AR500 steel. Factors such as regional wage levels and labor availability can affect these costs, particularly in countries with varying labor standards.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient production processes can help minimize overhead and thus reduce overall costs.

-

Tooling: Investment in high-quality tooling is necessary for the precise cutting and shaping of AR500 steel. The initial tooling cost can be substantial, but it is amortized over the production volume, impacting unit pricing.

-

Quality Control (QC): Ensuring that the steel meets rigorous standards for hardness and toughness involves QC processes, which also contribute to the cost. Certifications and testing can add to the expense but are critical for maintaining product integrity.

-

Logistics: Transportation costs can vary widely based on the distance between the supplier and the buyer, as well as the chosen shipping method. International buyers should account for customs duties, insurance, and potential delays in their logistics planning.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on market competition and demand. Understanding your supplier’s cost structure can aid in negotiations.

How Do Volume and Customization Affect AR500 Steel Prices?

Price influencers for AR500 steel are multifaceted. Volume or Minimum Order Quantity (MOQ) plays a significant role in pricing. Larger orders often qualify for bulk discounts, which can substantially reduce the per-unit cost. Conversely, smaller orders may incur higher prices due to the lack of economies of scale.

Specifications and Customization also impact pricing. Custom sizes or specific quality certifications may lead to increased costs. Suppliers may require additional processing time and resources for tailored orders, which can further elevate prices.

What Quality and Supplier Factors Should Buyers Consider?

Quality and certification are critical in the AR500 steel market. Buyers should look for suppliers who provide detailed certifications regarding the steel’s hardness, tensile strength, and other relevant properties. High-quality materials can lead to lower Total Cost of Ownership (TCO) in applications where durability and performance are paramount.

Supplier Factors include the supplier’s reputation, production capacity, and geographical location. Reliable suppliers with proven track records may command higher prices but can offer greater assurance of quality and timely delivery.

What Are Effective Negotiation Strategies for B2B Buyers?

For international buyers, especially in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings. Here are some tips:

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate with established clients.

-

Understand Total Cost of Ownership: Assess not just the purchase price but also the long-term costs associated with the steel, including maintenance, replacement, and potential downtime.

-

Explore Incoterms: Familiarize yourself with Incoterms, as they define the responsibilities of buyers and sellers in international transactions. Choosing favorable terms can significantly impact overall costs.

-

Timing of Purchase: Monitor market trends and purchase during periods of lower demand to secure better pricing.

What Are the Pricing Nuances for International B2B Buyers?

International buyers must navigate various pricing nuances, such as currency fluctuations and import tariffs, which can affect the final landed cost of AR500 steel. It is advisable to obtain multiple quotes from different suppliers to compare prices effectively. Additionally, being aware of local market conditions in the supplier’s country can provide leverage during negotiations.

Disclaimer on Indicative Prices

Prices for AR500 steel can fluctuate due to various factors, including raw material costs and market demand. It is essential for buyers to conduct thorough market research and obtain updated quotes to ensure accurate budgeting and cost management in their procurement process.

Alternatives Analysis: Comparing ar500 steel price With Other Solutions

Understanding Alternatives to AR500 Steel

In the pursuit of durable and high-performance materials for demanding applications, AR500 steel has carved a niche due to its exceptional hardness and impact resistance. However, businesses should consider alternative solutions that may offer similar benefits at different price points or with varying characteristics. This analysis will compare AR500 steel against two viable alternatives: AR550 steel and Polyethylene (UHMW) sheets, allowing B2B buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Ar500 Steel Price | AR550 Steel Price | Polyethylene (UHMW) Price |

|---|---|---|---|

| Performance | High hardness (534 BHN), abrasion-resistant | Higher hardness, better impact resistance | Lower hardness, good wear resistance |

| Cost | Moderate to high, varies by thickness | Higher than AR500 | Generally lower |

| Ease of Implementation | Requires cutting and welding | Similar to AR500, but may require specialized tools | Easy to handle and install |

| Maintenance | Low, but prone to rust without treatment | Low, similar to AR500 | Very low, resistant to chemicals |

| Best Use Case | Armor plates, industrial equipment | Armor applications, high-impact scenarios | Conveyor systems, wear strips |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of AR550 Steel?

AR550 steel is a direct competitor to AR500, boasting a higher hardness rating and improved impact resistance. This makes it particularly suitable for applications where more extreme conditions are expected, such as military or high-risk industrial environments. However, the cost of AR550 is generally higher than AR500, which may deter some buyers. While AR550’s performance is superior, businesses must weigh this against their budget constraints and the specific demands of their projects.

How Does Polyethylene (UHMW) Compare to AR500 Steel?

Polyethylene, specifically Ultra High Molecular Weight (UHMW) polyethylene, offers a lightweight alternative to steel. It provides excellent wear resistance and is often used in applications such as conveyor systems and lining for chutes. The primary advantage of UHMW is its lower cost and ease of installation, as it can be cut and shaped with standard tools. However, it lacks the hardness and impact resistance of AR500, making it less suitable for applications requiring high-strength materials. Buyers should consider the specific performance requirements of their projects when evaluating UHMW as an alternative.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right material involves evaluating multiple factors including performance, cost, and application requirements. B2B buyers should carefully analyze their specific use cases and budget constraints when considering alternatives to AR500 steel. While AR550 steel offers enhanced performance at a higher price, UHMW polyethylene presents a cost-effective, lightweight option for less demanding applications. Ultimately, the best choice will depend on balancing these considerations to align with operational goals and project specifications.

Essential Technical Properties and Trade Terminology for ar500 steel price

What Are the Key Technical Properties of AR500 Steel That Impact Pricing?

Understanding the technical specifications of AR500 steel is crucial for B2B buyers as these properties directly influence performance, pricing, and suitability for various applications. Here are some critical specifications to consider:

-

Material Grade: AR500 is classified as a high-strength, abrasion-resistant steel with a hardness of up to 534 BHN (Brinell Hardness Number). This high hardness makes it ideal for applications requiring exceptional wear resistance, such as armor plates and mining equipment. Buyers should evaluate the grade in relation to their specific needs, as higher grades may come at a premium price but offer greater durability.

-

Thickness: Available in various thicknesses (typically ranging from 0.119″ to 0.500″), the thickness of AR500 steel significantly affects its weight, strength, and price. Thicker plates provide better protection and durability but also increase shipping costs and may require specialized handling equipment. B2B buyers need to balance the required thickness with budget constraints and application demands.

-

Tolerances: Tolerance refers to the allowable deviation from specified dimensions. For AR500 steel, precise tolerances are critical in applications where fit and assembly are essential, such as in machinery and structural components. Buyers should inquire about the tolerances offered by suppliers, as tighter tolerances can lead to higher costs but may be necessary for optimal performance.

-

Impact Toughness: This property indicates the steel’s ability to withstand sudden forces or impacts without fracturing. AR500 steel is engineered to retain toughness even at high hardness levels, making it suitable for environments with high impact risks. Understanding the impact toughness can help buyers assess whether the material will perform adequately in their specific use cases.

-

Heat Treatment: Many AR500 products undergo heat treatment to enhance their hardness and toughness. The method of heat treatment can affect the material’s overall performance and cost. Buyers should consider whether they need heat-treated steel and how it might influence the overall pricing structure.

What Common Trade Terms Should B2B Buyers Understand When Discussing AR500 Steel?

Navigating the procurement process for AR500 steel requires familiarity with key trade terminology. Here are several essential terms that can aid decision-making:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that may be sold under another company’s brand. Understanding OEM relationships is important for B2B buyers, as it can impact the quality and availability of AR500 steel products.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. For AR500 steel, MOQs can vary significantly by supplier and product type. Buyers should clarify MOQs to avoid overcommitting resources or incurring higher costs due to low-volume orders.

-

RFQ (Request for Quotation): An RFQ is a formal process by which buyers request pricing and terms from suppliers. In the context of AR500 steel, submitting an RFQ can help buyers compare offers from multiple suppliers, ensuring they obtain the best value for their investment.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B transactions involving AR500 steel, as they can affect overall pricing and delivery timelines.

-

DFARS (Defense Federal Acquisition Regulation Supplement): This regulation applies to materials used in defense contracts. If your business is involved in defense-related projects, understanding DFARS compliance for AR500 steel can be vital for ensuring eligibility and avoiding legal issues.

-

MTR (Material Test Report): An MTR provides detailed information about the steel’s properties, including chemical composition and mechanical performance. Requesting MTRs can help buyers verify that the AR500 steel meets their specific requirements, adding a layer of confidence to the procurement process.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and budget constraints when sourcing AR500 steel.

Navigating Market Dynamics and Sourcing Trends in the ar500 steel price Sector

What Are the Current Market Dynamics and Key Trends Affecting AR500 Steel Pricing?

The AR500 steel market is experiencing significant transformations driven by global demand and technological advancements. The increase in industrial applications, particularly in defense, mining, and heavy machinery, is fueling the demand for high-strength, abrasion-resistant materials. Countries in Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Vietnam, are witnessing a surge in infrastructure projects and defense spending, which directly influences AR500 steel pricing.

Emerging B2B technologies, such as advanced sourcing platforms and real-time market analytics, are reshaping procurement strategies. Buyers are increasingly leveraging data-driven insights to negotiate better pricing and improve supply chain efficiencies. Additionally, the trend toward customization is on the rise; suppliers are offering tailored solutions, including cut-to-size AR500 steel sheets, to meet specific project requirements. This trend not only enhances product usability but also reduces waste, aligning with sustainability goals.

Another notable market dynamic is the fluctuation in raw material costs, influenced by geopolitical tensions and supply chain disruptions. International buyers must remain vigilant about these factors, as they can impact pricing and availability. Keeping abreast of these trends will empower B2B buyers to make informed purchasing decisions and negotiate favorable contracts.

How Important Is Sustainability and Ethical Sourcing in the AR500 Steel Sector?

Sustainability and ethical sourcing are becoming increasingly critical in the AR500 steel market. As businesses face mounting pressure from consumers and regulatory bodies to adopt environmentally responsible practices, the focus on reducing the carbon footprint of steel production is intensifying. AR500 steel, known for its durability, can contribute to sustainability by extending the lifespan of products, thereby reducing the need for frequent replacements.

Moreover, buyers are prioritizing suppliers who demonstrate a commitment to ethical supply chains. This includes ensuring fair labor practices, responsible sourcing of raw materials, and compliance with environmental regulations. Certifications such as ISO 14001 for environmental management and ethical sourcing certifications can serve as indicators of a supplier’s commitment to sustainability.

Investing in ‘green’ materials and processes not only enhances a company’s reputation but also aligns with global sustainability goals. B2B buyers should actively seek suppliers who can provide transparency regarding their sourcing practices and environmental impact. By doing so, they can contribute to a more sustainable future while also meeting the growing consumer demand for ethically produced products.

What Is the Brief History and Evolution of AR500 Steel in the B2B Market?

The evolution of AR500 steel dates back to its initial development in the mid-20th century, primarily for military applications. Over time, its unique properties—high hardness, excellent wear resistance, and impact toughness—made it a preferred choice in various industrial sectors, including mining, construction, and defense. As global industries expanded, the demand for AR500 steel grew, leading to innovations in production techniques and processing methods.

Today, AR500 steel is not only recognized for its performance but also for its adaptability in diverse applications, from armored vehicles to shooting targets. The historical significance of AR500 steel in military and industrial contexts has paved the way for its current status as a critical material in international supply chains, influencing pricing and sourcing strategies across the globe.

Understanding this evolution helps B2B buyers appreciate the material’s value and its role in modern applications, guiding their procurement decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of ar500 steel price

1. How can I determine the current market price of AR500 steel?

To determine the current market price of AR500 steel, start by researching reputable suppliers and manufacturers online. Websites specializing in metal products often provide real-time pricing. Additionally, consider contacting suppliers directly for quotes, as prices can fluctuate based on demand, region, and order volume. Keep in mind that international shipping costs and tariffs may also affect the final price for buyers in regions such as Africa or South America.

2. What factors influence the pricing of AR500 steel?

The pricing of AR500 steel is influenced by several factors, including raw material costs, market demand, thickness, and customization options. The geographical location of your supplier can also play a significant role, as shipping costs and import/export tariffs vary by region. Furthermore, fluctuations in steel prices on the global market, as well as any additional processing or treatment required for specific applications, can affect the final pricing.

3. Are there minimum order quantities (MOQ) for AR500 steel?

Most suppliers impose a minimum order quantity (MOQ) for AR500 steel to ensure cost-effectiveness in production and shipping. MOQs can vary significantly between suppliers, ranging from small quantities for custom cuts to larger bulk orders. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQ policies and negotiate terms that work for both parties, especially if you’re looking to source from different regions like Europe or the Middle East.

4. What customization options are available for AR500 steel?

AR500 steel can be customized in various ways, including thickness, dimensions, and surface treatments. Many suppliers offer cut-to-size options, allowing buyers to specify exact measurements for their projects. Additionally, you may find options for surface finishing to enhance durability or specific treatments tailored to unique applications, such as armor plating or industrial machinery. Always inquire about customization capabilities when reaching out to suppliers.

5. How can I verify the quality of AR500 steel?

To verify the quality of AR500 steel, request material test reports (MTRs) from your supplier. These documents provide essential information about the steel’s composition and mechanical properties. Reputable suppliers should be able to provide certifications that comply with international standards. Additionally, consider asking for samples before committing to larger orders, allowing you to assess the material’s quality firsthand.

6. What payment terms are typical for international B2B transactions involving AR500 steel?

Payment terms for international B2B transactions can vary widely depending on the supplier and the relationship established. Common terms include partial upfront payments, letters of credit, or payment upon delivery. It’s crucial to negotiate clear payment terms before finalizing any order, considering factors like currency fluctuations and banking fees. Be aware of any risks associated with international payments, particularly when dealing with suppliers from different continents.

7. What logistics considerations should I keep in mind when sourcing AR500 steel internationally?

When sourcing AR500 steel internationally, logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with your supplier’s country and your destination to facilitate smooth shipping. Additionally, factor in potential delays due to customs inspections or documentation requirements. Understanding incoterms (International Commercial Terms) is essential for clarifying responsibilities for shipping costs and risk during transit.

8. How do I vet suppliers of AR500 steel to ensure reliability?

To vet suppliers of AR500 steel, start by researching their reputation through online reviews and testimonials from other B2B buyers. Verify their business credentials and industry experience, and request references from past clients. Additionally, consider visiting their facilities if feasible, or conduct virtual meetings to assess their operations. Ensuring that suppliers comply with international quality standards and can provide necessary certifications will also help in confirming their reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Ar500 Steel Price Manufacturers & Suppliers List

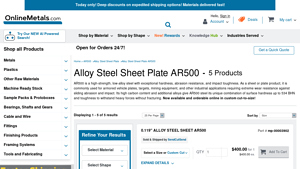

1. Online Metals – AR500 Steel Sheet/Plate

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: AR500 Steel Sheet/Plate – Pre-cut and cut to size pricing. High-strength, low-alloy steel with exceptional hardness, abrasion resistance, and impact toughness. Commonly used for armored vehicle plates, targets, mining equipment, and other industrial applications requiring extreme wear resistance. Surface hardness up to 534 BHN. Thickness: 0.119″. Ships in 2-3 business days. Custom cut-to-size avai…

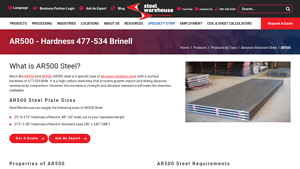

2. Steel Warehouse – AR500 Steel

Domain: steelwarehouse.com

Registered: 1997 (28 years)

Introduction: AR500 Steel is a type of abrasion resistant steel with a surface hardness of 477-534 BHN. It is a high-carbon steel alloy that offers greater impact and sliding abrasion resistance compared to other types of AR steel. AR500 steel is less malleable, making it less weldable and formable. Steel Warehouse supplies AR500 in thicknesses of .25″-2.00″ and widths of 48″-65″, with standard sizes of 96″ x 2…

3. DM Steel – AR500 Abrasion Resistant Plate

Domain: dmsteel.com

Introduction: Hot Rolled Abrasion Resistant AR500 Plate, Thickness: 3/8 inch, High hardness for wear resistance, Suitable for applications requiring high impact and abrasion resistance, Commonly used in mining, construction, and military applications.

4. Victor Steel – AR500 Steel Plate

Domain: victorsteel.net

Registered: 2014 (11 years)

Introduction: AR500 Steel Plate is a high carbon alloy steel plate known for its abrasion resistance and hardness. Key details include:

– Thickness: 3-200mm

– Width: 500-3000mm

– Length: 1000-12000mm

– Heat Treatment: N, Q+T

– Surface Finish Options: EP, PE, HDP, SMP, PVDF

– Average Price: Starts at Rs. 80 per KG

– Applications: Mining, dump trucks, hoppers, buckets, storage bins, military armor plates. …

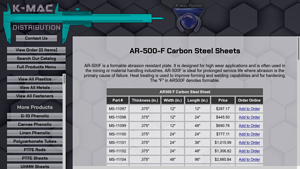

5. KMAC – AR500 Carbon Steel Plates

Domain: kmac-distribution.com

Registered: 2006 (19 years)

Introduction: AR500 Carbon Steel Plates and Sheets, thickness range from .187 to 1.00 inches. Designed for high wear applications, often used in mining or material handling industries. Heat treated for improved forming and welding capabilities. The “F” in AR500F denotes formable. Available sizes and prices include:

– .375″ thickness: 12″x12″ for $287.17, 12″x24″ for $445.50, 12″x48″ for $690.76, 24″x24″ for $7…

6. Reddit – AR500 Steel Pricing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: AR500 steel prices are reportedly over $5 per pound for 1/2″ plate.

Strategic Sourcing Conclusion and Outlook for ar500 steel price

What Are the Key Takeaways for Sourcing AR500 Steel?

In conclusion, the strategic sourcing of AR500 steel presents significant advantages for international B2B buyers, particularly those operating in sectors requiring high durability and wear resistance, such as defense, mining, and heavy equipment manufacturing. Understanding the current pricing trends and the factors influencing these prices—such as raw material costs, shipping logistics, and market demand—enables companies to make informed purchasing decisions. The ability to acquire AR500 steel in custom sizes further enhances flexibility, allowing businesses to optimize their production processes.

How Can Strategic Sourcing Impact Your Bottom Line?

Investing in strategic sourcing not only ensures competitive pricing but also fosters long-term relationships with suppliers, which can lead to better service and reliability. As the global market for AR500 steel continues to evolve, especially in regions like Africa, South America, the Middle East, and Europe, it is crucial for buyers to remain proactive. Engaging with suppliers who offer expedited shipping and tailored solutions can significantly reduce lead times and improve operational efficiency.

What Does the Future Hold for AR500 Steel Pricing?

Looking ahead, it is essential for B2B buyers to stay attuned to market fluctuations and emerging trends that could impact AR500 steel pricing. By establishing a robust sourcing strategy now, companies can position themselves favorably to capitalize on future opportunities. We encourage buyers to explore diverse supplier networks and consider the total cost of ownership in their procurement strategy. The future is ripe for those who act decisively in securing high-quality AR500 steel at competitive prices.