American Pacemaker Lathe Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for american pacemaker lathe

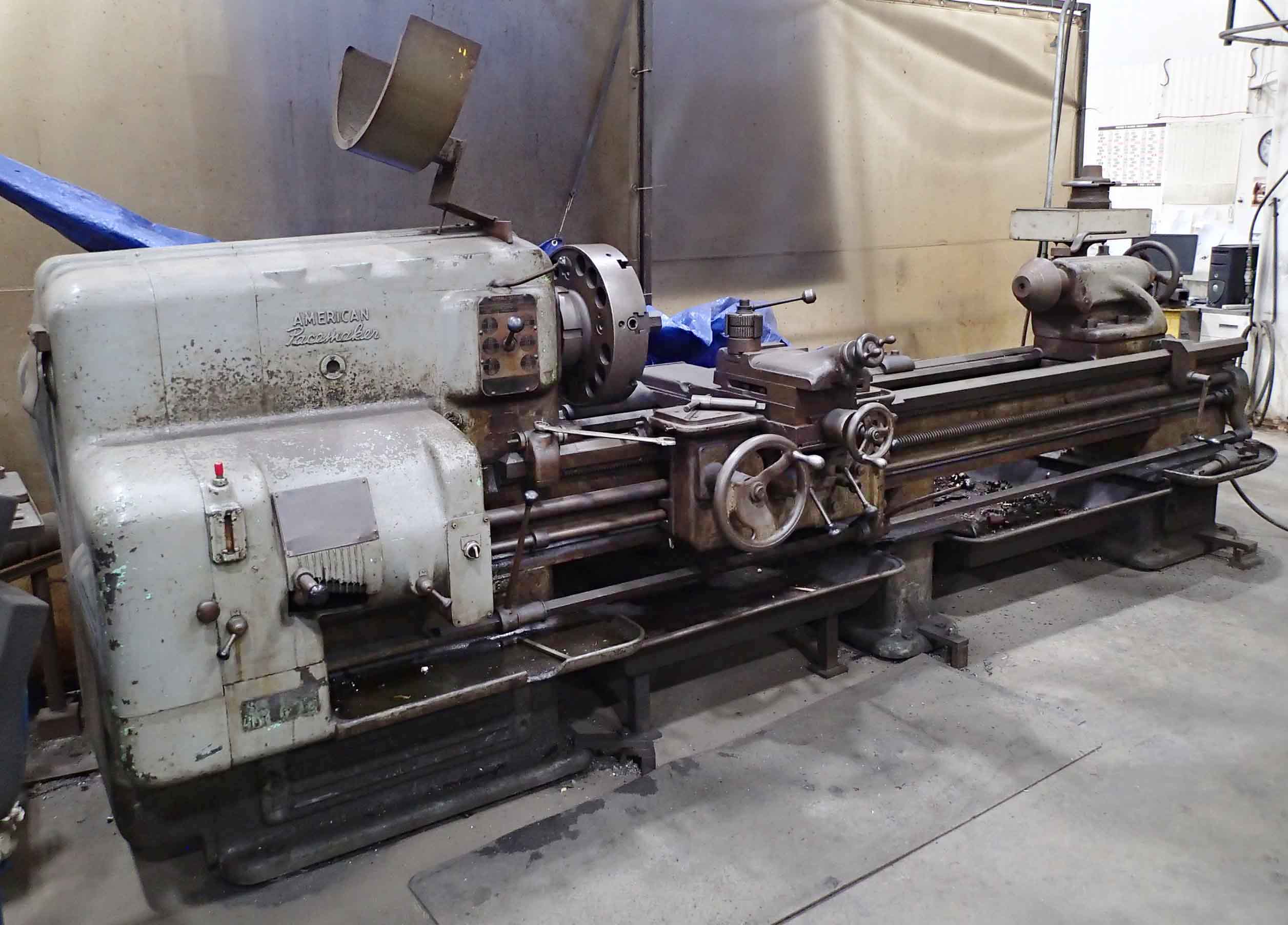

In an increasingly competitive global landscape, sourcing an American Pacemaker lathe can be a daunting challenge for international B2B buyers. These robust machines, renowned for their precision and durability, are essential for companies looking to enhance their manufacturing capabilities. However, navigating the complexities of procurement—ranging from identifying the right model to understanding the nuances of supplier vetting—requires a comprehensive strategy. This guide delves into various aspects of the American Pacemaker lathe, including its diverse types, applications across industries, and critical considerations for cost management.

Buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Nigeria, will find actionable insights tailored to their unique market conditions. The guide equips stakeholders with knowledge on evaluating supplier reliability, ensuring quality during inspections, and optimizing shipping logistics. With a focus on empowering informed purchasing decisions, this resource aims to streamline the acquisition process, helping businesses secure machinery that enhances operational efficiency and meets production demands. By understanding the full spectrum of factors influencing the purchase of an American Pacemaker lathe, you can confidently invest in machinery that drives your business forward.

Understanding american pacemaker lathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Style D Engine Lathe | 20″ swing, 78″ centers, 2″ spindle hole, 25-1500 RPM speeds | Precision machining, automotive parts | Pros: High durability, versatile speeds. Cons: Heavy, requires space. |

| 14-inch Pacemaker Lathe | Compact size, robust construction, versatile tooling options | Small batch production, tool making | Pros: Space-efficient, reliable. Cons: Limited capacity compared to larger models. |

| 20-inch Heavy Duty Lathe | Enhanced rigidity, high spindle speed (up to 2000 RPM) | Heavy machining, aerospace components | Pros: Exceptional cutting capacity. Cons: Higher investment cost. |

| 16-inch Medium Duty Lathe | Balanced design, suitable for a range of materials and operations | General engineering, prototype work | Pros: Good balance of performance and size. Cons: Limited by swing size. |

| Taper Attachment Lathe | Enhanced taper turning capabilities, integrated with existing models | Precision engineering, custom machining | Pros: Increases versatility for specialized tasks. Cons: Additional setup time required. |

The Style D Engine Lathe is one of the most recognized models, featuring a 20″ swing and a 78″ distance between centers. Its robust construction allows for a spindle speed range of 25 to 1500 RPM, making it ideal for a variety of precision machining applications. B2B buyers should consider its high durability and versatility, although its substantial weight may require more space and dedicated rigging for installation.

The 14-inch Pacemaker Lathe is a compact option that still offers robust construction and versatile tooling capabilities. Suitable for small batch production and tool making, it is an excellent choice for businesses with limited floor space. While it delivers reliability and efficiency, potential buyers should be aware of its limited capacity compared to larger models, which might restrict its application in high-volume settings.

For those requiring heavy machining capabilities, the 20-inch Heavy Duty Lathe stands out with its enhanced rigidity and high spindle speed, reaching up to 2000 RPM. This model is particularly suited for aerospace components and other industries requiring substantial cutting power. While it offers exceptional performance, the higher investment cost may be a consideration for budget-conscious buyers.

The 16-inch Medium Duty Lathe strikes a balance between performance and size, making it suitable for general engineering and prototype work. Its design allows for a range of materials and operations, appealing to businesses looking for versatility without compromising on quality. However, its swing size may limit its use for larger workpieces, which could be a drawback for some operations.

Lastly, the Taper Attachment Lathe enhances the capabilities of existing models by providing specialized taper turning functions. This attachment is particularly beneficial for precision engineering and custom machining tasks. While it increases versatility, buyers should factor in the additional setup time and training required to fully utilize this feature, especially in a fast-paced production environment.

Key Industrial Applications of american pacemaker lathe

| Industry/Sector | Specific Application of American Pacemaker Lathe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision manufacturing of aircraft components | High accuracy and durability for safety-critical parts | Availability of spare parts and service support |

| Automotive | Production of engine blocks and transmission parts | Enhanced machining capability for complex shapes | Compliance with industry standards and certifications |

| Oil & Gas | Fabrication of drilling tools and equipment | Robust construction for harsh environments | Energy efficiency and operational reliability |

| Heavy Machinery | Custom parts for machinery and equipment | Versatility in handling large workpieces | Machine size and capability to handle specific materials |

| Defense and Military | Manufacturing of weapon components | Reliability and precision for mission-critical applications | Historical performance and availability of reconditioned units |

How is the American Pacemaker Lathe Used in Aerospace Applications?

In the aerospace industry, the American Pacemaker lathe is utilized for the precision manufacturing of aircraft components such as engine mounts and landing gear parts. Its robust construction and high-speed capabilities allow manufacturers to achieve tight tolerances required for safety-critical applications. Buyers in this sector must ensure that the lathe meets stringent regulatory standards and can be serviced easily to maintain operational efficiency.

What Role Does the American Pacemaker Lathe Play in Automotive Manufacturing?

The automotive sector employs the American Pacemaker lathe for producing complex engine blocks and transmission components. Its ability to handle heavy cuts and maintain dimensional accuracy makes it ideal for high-volume production. Businesses looking to source this equipment should consider the machine’s adaptability to various materials and its compliance with automotive industry quality standards to ensure reliable performance.

How Does the American Pacemaker Lathe Benefit Oil & Gas Operations?

In the oil and gas industry, the American Pacemaker lathe is critical for fabricating drilling tools and equipment that must withstand extreme conditions. The machine’s durability and capability to produce large, heavy components provide a competitive edge in this demanding environment. International buyers should prioritize sourcing from suppliers who can guarantee machine reliability and offer efficient after-sales support to minimize downtime.

What Are the Applications of the American Pacemaker Lathe in Heavy Machinery?

Heavy machinery manufacturers utilize the American Pacemaker lathe for custom parts production, benefiting from its versatility in machining large workpieces. This capability is essential for creating components that meet specific operational requirements. Buyers should evaluate the lathe’s size and capabilities to ensure it aligns with their production needs, particularly for handling diverse materials used in heavy machinery.

How is the American Pacemaker Lathe Used in Defense and Military Manufacturing?

The defense and military sectors rely on the American Pacemaker lathe for the precise manufacturing of weapon components. Its historical reliability and precision are crucial for mission-critical applications where failure is not an option. Buyers in this sector should consider the availability of reconditioned units and the machine’s performance history to ensure they acquire equipment that meets their rigorous operational demands.

3 Common User Pain Points for ‘american pacemaker lathe’ & Their Solutions

Scenario 1: Sourcing Reliable Replacement Parts for American Pacemaker Lathe

The Problem:

B2B buyers often face challenges in sourcing reliable replacement parts for the American Pacemaker Lathe, especially when operating in regions with limited access to specialized machine tool suppliers. The wear and tear on critical components can lead to prolonged downtime, affecting production schedules and profitability. Buyers may find themselves in a situation where they have to settle for subpar parts that do not meet the stringent specifications required by these robust machines, leading to further complications down the line.

The Solution:

To effectively source high-quality replacement parts, buyers should establish relationships with reputable dealers who specialize in American Pacemaker machinery. It is advisable to look for suppliers who offer OEM (Original Equipment Manufacturer) parts or verified aftermarket components that meet the original specifications. Additionally, participating in online forums and industry-specific groups can provide insights into trusted vendors and user experiences. Buyers should also maintain a detailed inventory of the parts they frequently need, enabling them to order in bulk to save on costs and ensure quicker access to replacements when necessary. Engaging with local machine shops that may have experience with these lathes can also lead to valuable recommendations for sourcing parts.

Scenario 2: Managing Lathe Maintenance and Performance Issues

The Problem:

A common pain point for users of the American Pacemaker Lathe is the maintenance required to keep the machine operating at optimal performance. Over time, users may encounter issues such as decreased spindle speeds or poor surface finish quality due to inadequate lubrication, wear on the ways, or misalignment. These problems can lead to operational inefficiencies and increased costs, as frequent repairs may be necessary if not addressed promptly.

The Solution:

Implementing a robust maintenance schedule is crucial for maximizing the lifespan and performance of the American Pacemaker Lathe. Buyers should develop a routine that includes regular checks of lubrication levels, cleaning of the ways, and inspections for signs of wear or misalignment. Utilizing a preventative maintenance checklist can help ensure that all critical components are monitored. Additionally, investing in training for operators on proper usage and maintenance techniques can significantly mitigate issues. For example, operators should be taught how to properly adjust spindle bearings and how to use the machine’s built-in lubrication system effectively. This proactive approach not only enhances performance but can also reduce repair costs over time.

Scenario 3: Overcoming Technical Skills Gaps in Operator Training

The Problem:

Many organizations struggle with a skills gap when it comes to operating and maintaining complex machinery like the American Pacemaker Lathe. New operators may lack the technical knowledge required to leverage the machine’s capabilities fully, leading to suboptimal production outcomes and increased error rates. This gap can be particularly pronounced in regions where access to formal training programs is limited.

The Solution:

To address the technical skills gap, companies should invest in comprehensive training programs tailored to the specific functionalities of the American Pacemaker Lathe. This can include on-site training sessions led by experienced machinists who can provide hands-on guidance and share best practices. Additionally, creating a mentorship program where seasoned operators support newer staff can foster knowledge transfer and build confidence. For organizations unable to access local training, exploring online resources, instructional videos, and manuals can supplement knowledge. Investing in simulation software that mimics the lathe’s operations can also provide an interactive learning experience. By prioritizing operator training, companies can enhance productivity and ensure a higher standard of work output.

Strategic Material Selection Guide for american pacemaker lathe

What Are the Key Materials Used in American Pacemaker Lathes?

When considering the American Pacemaker lathe, the choice of materials is paramount for ensuring optimal performance and durability. Below are analyses of four common materials used in the construction of these lathes, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Cast Iron Contribute to Lathe Performance?

Cast iron is a primary material in the construction of American Pacemaker lathes, particularly in the bed and base. It offers excellent vibration dampening, which is crucial for precision machining. The tensile strength of cast iron typically ranges around 40,000 psi, making it robust enough to withstand heavy loads and cutting forces.

Pros: Cast iron is durable, relatively inexpensive, and easy to machine. Its inherent properties allow for high stability during operation, reducing wear and tear on moving parts.

Cons: However, cast iron is brittle and can crack under extreme stress or impact. Additionally, it is heavier than alternative materials, which can complicate transportation and installation.

Impact on Application: Cast iron is compatible with various machining processes, including turning and milling. Its resistance to deformation under load makes it suitable for high-precision applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards for material strength and durability. Cast iron is widely accepted, but understanding regional preferences for material sourcing is essential.

What Role Does Steel Play in Lathe Components?

Steel, particularly high-tensile alloy steel, is commonly used in critical components like spindles and gears. It offers superior strength and resistance to wear, making it ideal for high-performance applications.

Pros: Steel components can endure higher temperatures and pressures, making them suitable for demanding machining tasks. They also provide excellent fatigue resistance.

Cons: The manufacturing process for steel can be complex and costly, particularly when high precision is required. Additionally, steel components may require protective coatings to prevent corrosion.

Impact on Application: Steel’s compatibility with high-speed operations allows for efficient metal removal rates, enhancing productivity.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial when sourcing steel components. Buyers should also consider the availability of quality steel in their regions.

How Does Bronze Enhance Lathe Functionality?

Bronze is often used for bushings and bearings in American Pacemaker lathes due to its excellent wear resistance and self-lubricating properties.

Pros: Bronze reduces friction between moving parts, which leads to less wear and longer service life. It is also resistant to corrosion, making it suitable for various environments.

Cons: The cost of bronze can be higher than that of other materials, and it may not provide the same strength as steel in high-load applications.

Impact on Application: Bronze is particularly effective in applications where lubrication is challenging, as its self-lubricating properties help maintain performance.

Considerations for International Buyers: Buyers should verify that the bronze used meets international standards for quality and performance, especially in regions with varying industrial regulations.

Why Is Aluminum Used in Some Lathe Components?

Aluminum is sometimes used in non-structural components of American Pacemaker lathes due to its lightweight and corrosion-resistant properties.

Pros: Aluminum is easy to machine and can help reduce the overall weight of the lathe, making it easier to handle and transport.

Cons: However, aluminum lacks the strength and rigidity of steel and cast iron, which can limit its use in high-stress applications.

Impact on Application: Aluminum is suitable for components that do not require high load-bearing capacity but still need to withstand moderate wear.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards for strength and corrosion resistance, particularly in humid or corrosive environments.

Summary Table of Material Selection for American Pacemaker Lathe

| Material | Typical Use Case for American Pacemaker Lathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Bed and base components | Excellent vibration dampening | Brittle and heavy | Low |

| Steel | Spindles and gears | High strength and wear resistance | Complex and costly manufacturing | Medium |

| Bronze | Bushings and bearings | Self-lubricating and corrosion-resistant | Higher cost than other materials | High |

| Aluminum | Non-structural components | Lightweight and easy to machine | Lower strength compared to steel | Medium |

This guide provides a comprehensive overview of the materials used in American Pacemaker lathes, highlighting their properties and implications for international B2B buyers. Understanding these factors can aid in making informed purchasing decisions tailored to specific operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for american pacemaker lathe

What Are the Key Stages in the Manufacturing Process of the American Pacemaker Lathe?

The manufacturing process of the American Pacemaker Lathe involves several critical stages, each designed to ensure that the final product meets the high standards expected by users in various industries.

-

Material Preparation: The foundation of any quality lathe starts with the materials used. The American Pacemaker lathes are constructed from a cast-iron mixture, which includes approximately 40% steel scrap. This unique blend provides a tensile strength of around 40,000 pounds, ensuring durability and stability during operation. The raw materials undergo rigorous quality checks to confirm their compliance with the desired specifications before moving to the next stage.

-

Forming: Once the materials are prepared, they are formed into the required shapes. This involves casting and machining processes where the bed, ways, and other components are created. The V-ways, for instance, are made from solid tool-steel, hardened to achieve a Rockwell C hardness of approximately 60. This hardness is crucial for maintaining precision and longevity. Additionally, advanced methods such as cold treatment at extremely low temperatures are employed to prevent warping, ensuring that the components remain true to specification.

-

Assembly: After forming, the components are meticulously assembled. This stage requires skilled labor to ensure that each part fits perfectly, which is critical for the lathe’s operational efficiency. The assembly process includes the installation of the spindle, gears, and other moving parts, which are precisely aligned to minimize friction and wear during operation. The use of hardened spur gears and helical gears in the assembly further enhances the performance of the lathe.

-

Finishing: The final stage involves finishing processes that enhance the lathe’s appearance and functionality. This may include surface grinding, polishing, and applying protective coatings. The finishing touches not only improve the aesthetic appeal but also protect the lathe from environmental factors that could lead to rust or corrosion.

How Is Quality Assurance Integrated into the Manufacturing of American Pacemaker Lathes?

Quality assurance is a fundamental aspect of the manufacturing process for American Pacemaker lathes, ensuring that every unit meets international standards and customer expectations.

-

What Are the Relevant International Standards for Quality Assurance?

The manufacturing process adheres to several international quality standards, including ISO 9001, which focuses on quality management systems and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) standards may apply, especially for lathes intended for specific applications in different regions. -

What Are the Key Quality Control Checkpoints?

The quality assurance process includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet predetermined specifications.

– In-Process Quality Control (IPQC): During manufacturing, various tests are conducted to monitor the production process, ensuring that no defects occur as components are formed and assembled.

– Final Quality Control (FQC): After assembly, the finished lathe undergoes rigorous testing to verify its performance, accuracy, and safety features. This may include operational tests and checks for dimensional accuracy. -

What Testing Methods Are Commonly Used?

Various testing methods are employed throughout the manufacturing process. These may include:

– Dimensional Inspection: Using precision measuring instruments to ensure components meet specified tolerances.

– Functional Testing: Assessing the lathe’s operational capabilities, such as spindle speed ranges and stability under load.

– Performance Tests: Evaluating how well the lathe performs under simulated working conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial for ensuring the reliability of their purchases.

-

What Should Buyers Look for in Supplier Audits?

Buyers should request detailed audit reports from potential suppliers. These reports should outline the quality management systems in place, including adherence to international standards like ISO 9001. Additionally, buyers should inquire about the frequency and scope of these audits, as well as whether they are conducted by third-party organizations. -

How Can Buyers Use Third-Party Inspections?

Engaging third-party inspection services is an effective way for buyers to verify quality. These independent organizations can conduct pre-shipment inspections to ensure that the lathe meets the specified standards before it is shipped. This adds an extra layer of assurance, especially for international transactions where trust is paramount. -

What Are the Quality Certification Nuances for Different Regions?

B2B buyers should be aware that quality certifications may vary by region. For instance, European buyers might prioritize CE certification, while buyers from the Middle East may seek compliance with local industry standards. Understanding these nuances is essential for ensuring that the lathe will meet regulatory requirements in the buyer’s market.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

In summary, the manufacturing processes and quality assurance protocols for American Pacemaker lathes are designed to ensure the production of high-quality, reliable machinery. For B2B buyers, especially those operating in diverse international markets, understanding these processes can help in making informed purchasing decisions. By focusing on the details of manufacturing, quality control, and the verification of supplier practices, buyers can secure equipment that meets their operational needs and contributes to their business success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘american pacemaker lathe’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure the American Pacemaker lathe, a renowned machine tool known for its durability and precision. By following these steps, you can ensure that your sourcing process is efficient, aligns with your technical requirements, and mitigates risks associated with purchasing heavy machinery.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications you require from the American Pacemaker lathe. Consider factors such as swing over ways, distance between centers, spindle speeds, and power requirements. This clarity will help you identify models that best suit your operational needs and avoid unnecessary purchases.

Step 2: Research Available Models and Variants

Investigate the different models and variants of the American Pacemaker lathe. Models such as the Style D and others offer varying features, including spindle configurations and additional attachments. Understanding these differences will enable you to select a model that matches your specific machining tasks.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. Request detailed company profiles, case studies, and references from other buyers in your industry or region. Look for suppliers with a solid reputation and experience in dealing with heavy machinery, as this indicates reliability and expertise.

- Supplier Certifications: Ensure that suppliers have the necessary certifications, such as ISO 9001, which indicates a commitment to quality management systems.

- Customer Reviews: Read reviews or testimonials to gauge the supplier’s customer service and after-sales support.

Step 4: Inspect Equipment Condition

If possible, arrange for an inspection of the lathe before purchase. Assess the machine’s physical condition, including wear on the ways, operational parts, and the overall maintenance history. This step is crucial to ensure you are investing in a machine that will perform reliably and meet your production standards.

Step 5: Verify Availability of Spare Parts

Confirm that spare parts for the American Pacemaker lathe are readily available. The longevity of your investment depends on the ease of obtaining replacement parts and components as needed. Inquire about the supplier’s inventory of spare parts and their lead times for orders.

Step 6: Discuss Warranty and Support Options

Engage in discussions regarding warranty terms and post-purchase support. A robust warranty can safeguard your investment by covering unexpected repairs or malfunctions. Additionally, inquire about the supplier’s technical support services, as having access to expertise can be invaluable for maintenance and troubleshooting.

Step 7: Negotiate Terms and Finalize Purchase

Once you have identified a suitable model and supplier, negotiate the purchase terms. Discuss pricing, payment options, delivery timelines, and installation services. Ensure that all agreements are documented to avoid any misunderstandings in the future.

Following this checklist will help you navigate the complexities of sourcing an American Pacemaker lathe, ensuring that you make an informed and strategic purchase that aligns with your business needs.

Comprehensive Cost and Pricing Analysis for american pacemaker lathe Sourcing

What Are the Key Cost Components for Sourcing an American Pacemaker Lathe?

When considering the purchase of an American Pacemaker lathe, understanding the comprehensive cost structure is crucial. Key cost components include:

-

Materials: The primary material used in the construction of American Pacemaker lathes is a specialized cast iron mixture that incorporates steel scrap. This semi-steel offers a high tensile strength, which is essential for durability and performance. The quality of the materials directly affects the lathe’s longevity and operational efficiency.

-

Labor: Skilled labor is required for both manufacturing and assembly processes. The expertise involved in crafting high-precision components ensures that the lathe meets stringent performance standards, which can influence the overall labor cost.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate overhead costs, thereby affecting the final pricing of the lathe.

-

Tooling: The cost of tooling is significant, especially for custom configurations or specialized attachments that enhance the lathe’s functionality. Buyers should evaluate whether standard tooling will suffice or if investments in custom tools are necessary.

-

Quality Control (QC): Stringent QC measures ensure that each lathe meets high performance and safety standards. Investing in robust QC processes may increase upfront costs but can significantly reduce long-term operational issues.

-

Logistics: Shipping and handling costs are crucial, particularly for international buyers. The size and weight of the lathe necessitate careful planning regarding transportation, insurance, and potential tariffs or duties.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand, competition, and the uniqueness of the offering.

How Do Price Influencers Affect the Cost of American Pacemaker Lathes?

Several factors can influence the pricing of American Pacemaker lathes:

-

Volume/MOQ: Purchasing in larger quantities can lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) that align with their operational needs to benefit from economies of scale.

-

Specifications and Customization: Custom specifications, such as specific spindle speeds or additional attachments, can increase costs. Buyers should weigh the benefits of customization against the additional expense.

-

Materials and Quality Certifications: Higher-quality materials and certifications can enhance performance and reliability but will also increase costs. Buyers should assess their operational requirements to determine the necessary certifications.

-

Supplier Factors: Reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is vital for international buyers. These terms dictate who bears the cost and risk during shipping, impacting the overall cost structure.

What Buyer Tips Can Enhance Cost-Efficiency for American Pacemaker Lathes?

To maximize value when sourcing American Pacemaker lathes, consider the following tips:

-

Negotiation: Always negotiate pricing and terms. Suppliers may have room to adjust prices based on the buyer’s commitment or potential for future orders.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, maintenance, operation costs, and potential downtime. A lower initial price may not always result in long-term savings.

-

Pricing Nuances for International Buyers: Understand the specific economic conditions, currency exchange rates, and local market trends that may affect pricing in regions such as Africa, South America, the Middle East, and Europe.

-

Research and Compare: Take time to research various suppliers and compare their offerings. This diligence can uncover better deals and ensure that you are getting the best quality for your investment.

Disclaimer on Indicative Prices

Prices for American Pacemaker lathes can vary widely based on the factors discussed above. The indicative price of $8,950 for a 20″ x 78″ model serves as a baseline, but final costs may differ based on customization, logistics, and other variables. Always obtain detailed quotations from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing american pacemaker lathe With Other Solutions

Exploring Alternatives to the American Pacemaker Lathe

When selecting a lathe for industrial applications, it’s essential to consider various alternatives that may suit specific needs better than the American Pacemaker lathe. This section compares the Pacemaker with other viable solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | American Pacemaker Lathe | CNC Lathe | Manual Lathe |

|---|---|---|---|

| Performance | High rigidity and power, capable of heavy cuts (up to 1/4 inch) | High precision and automation for complex shapes | Good for simple, straightforward tasks |

| Cost | Moderate ($8,950) | High initial investment ($20,000+) | Low initial cost ($1,000 – $5,000) |

| Ease of Implementation | Requires skilled operators | Minimal operator skill needed, training for CNC software | Requires skilled operators for setup and operation |

| Maintenance | Regular lubrication and checks needed; robust construction | Less frequent maintenance; software updates required | Regular maintenance and manual adjustments needed |

| Best Use Case | Heavy-duty applications, military, and aerospace components | Precision machining, mass production | Hobbyist projects, simple machining tasks |

What are the Advantages and Disadvantages of CNC Lathes?

CNC lathes offer high precision and automation capabilities, making them suitable for complex designs and mass production. They can operate continuously with minimal human intervention, thus increasing productivity. However, the initial investment is significantly higher than that of traditional lathes, and they require specialized training to operate the software. This could be a barrier for smaller businesses or those in regions with limited access to skilled labor.

How Do Manual Lathes Compare to the American Pacemaker Lathe?

Manual lathes are generally more affordable and easier to find, making them an attractive option for small shops or hobbyists. They are well-suited for straightforward machining tasks where precision is not critical. However, they require skilled operators who can handle setup and adjustments manually. In contrast to the American Pacemaker, manual lathes may lack the rigidity and power required for heavy-duty applications, potentially leading to lower performance in demanding environments.

Conclusion: Which Lathe is Right for Your Business Needs?

Choosing the right lathe depends on your specific business requirements, including budget constraints, production volume, and the complexity of the tasks at hand. The American Pacemaker lathe excels in heavy-duty applications, providing robust performance for industries requiring high precision and durability. However, for businesses focused on mass production with intricate designs, CNC lathes may be more appropriate despite their higher costs. Conversely, manual lathes may serve well for smaller-scale operations or simpler projects. Assessing these factors will help international B2B buyers make informed decisions tailored to their operational needs.

Essential Technical Properties and Trade Terminology for american pacemaker lathe

What Are the Essential Technical Properties of the American Pacemaker Lathe?

Understanding the technical specifications of the American Pacemaker lathe is crucial for international buyers looking to enhance their machining capabilities. Here are several key properties that define this machine’s performance and reliability:

1. Swing Over Ways

The swing over ways refers to the maximum diameter of a workpiece that can be rotated on the lathe. For the American Pacemaker, this measurement is typically 20 inches. This specification is vital for buyers as it determines the size of the components that can be machined, impacting the lathe’s versatility in handling various projects.

2. Distance Between Centers

This measurement indicates the maximum length of the workpiece that can be accommodated on the lathe. The American Pacemaker generally offers a distance of 78 inches between centers. Buyers should consider this property to ensure that the lathe can handle the lengths of materials they intend to work with, especially in industries like automotive and aerospace.

3. Spindle Speed Range

The spindle speed range, which for the American Pacemaker is between 25 to 1500 RPM, is crucial for determining the type of materials that can be machined effectively. Different materials require different speeds for optimal cutting. Understanding this range helps buyers select a lathe that can handle both high-precision tasks and heavy-duty cutting operations.

4. Power Rating

The power rating, typically around 10 horsepower for the American Pacemaker, indicates the machine’s capability to handle heavy workloads. A higher power rating allows for more aggressive machining, which is essential for businesses that require efficient metal removal. This specification is particularly important for industries engaged in high-volume production.

5. Material Composition

The construction of the American Pacemaker lathe incorporates a unique blend of cast iron and steel, providing a tensile strength of approximately 40,000 pounds. This material choice ensures durability and stability, minimizing vibrations during operation. Buyers should prioritize this aspect when assessing a lathe’s longevity and performance under stress.

6. Taper Attachment

The inclusion of a taper attachment enhances the lathe’s functionality by allowing for the machining of conical shapes. This feature is vital for applications requiring precision in creating tapered components, making the machine more versatile for various industrial applications.

What Are Common Trade Terms Relevant to the American Pacemaker Lathe?

Familiarity with industry terminology can significantly streamline the procurement process for international buyers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify the source of components for replacement or upgrades, ensuring compatibility and quality in their machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage their inventory and budget effectively, especially when sourcing lathes and related equipment.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request quotes from suppliers for specific products or services. Understanding how to issue an RFQ can help buyers obtain competitive pricing and better terms from vendors, enhancing their purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is crucial for buyers to navigate the complexities of international shipping and ensure compliance with regulations.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for buyers to plan their production schedules and manage supply chain expectations effectively.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement. Knowledge of warranty terms helps buyers assess the risk associated with their purchase and ensures they are protected against defects.

By comprehensively understanding these technical properties and trade terminology, international buyers can make informed decisions when investing in an American Pacemaker lathe, ultimately enhancing their operational efficiency and competitiveness in the marketplace.

Navigating Market Dynamics and Sourcing Trends in the american pacemaker lathe Sector

What Are the Current Market Dynamics and Key Trends for American Pacemaker Lathes?

The American Pacemaker lathe market is experiencing significant shifts driven by global manufacturing demands and technological advancements. The demand for high-precision machining tools continues to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Industries such as automotive, aerospace, and heavy machinery are increasingly reliant on robust and reliable lathes, with the American Pacemaker being recognized for its durability and performance.

Key trends include the adoption of Industry 4.0 technologies, which enhance machine connectivity and data analytics, providing real-time insights into production efficiency. This trend is crucial for international B2B buyers seeking to optimize operations and minimize downtime. Additionally, there is a growing focus on refurbishing and maintaining existing machinery, particularly for vintage models like the American Pacemaker, which are valued for their craftsmanship and reliability. This has led to increased interest in sourcing parts and services that can extend the life of these machines.

Furthermore, the rise of e-commerce platforms is transforming the way buyers engage with suppliers. International buyers can now easily access a broader range of offerings, compare prices, and evaluate vendors based on their service reputation and product quality. This shift is particularly beneficial for buyers in regions like Nigeria and Saudi Arabia, where traditional sourcing methods may have been limited.

How Can Sustainability and Ethical Sourcing Impact the American Pacemaker Lathe Market?

Sustainability and ethical sourcing are becoming increasingly important considerations in the B2B landscape, especially in the manufacturing sector. The environmental impact of machining processes and the sourcing of materials for American Pacemaker lathes is under scrutiny. Buyers are now more inclined to partner with suppliers who prioritize sustainability, reducing their carbon footprint and promoting responsible manufacturing practices.

To align with these values, manufacturers are exploring eco-friendly materials and processes. For instance, sourcing recycled materials for the production of machine components not only reduces waste but also appeals to environmentally conscious buyers. Certifications such as ISO 14001 for environmental management systems can further assure international buyers of a supplier’s commitment to sustainability.

Moreover, the importance of ethical supply chains cannot be understated. Buyers are increasingly aware of the social implications of their sourcing decisions, including labor practices and community impacts. As such, suppliers who can demonstrate transparency in their supply chains and compliance with ethical standards are more likely to gain trust and loyalty from international customers.

What Is the Historical Significance of the American Pacemaker Lathe in the B2B Sector?

The American Pacemaker lathe has a rich history that underscores its significance in the B2B manufacturing sector. Developed by the American Tool Works Company in the mid-20th century, these lathes were designed to meet the evolving needs of precision machining during a time of rapid technological advancement. Known for their robust construction and high tensile strength, they became a staple in many workshops, especially in industries requiring reliable and powerful machinery.

The Pacemaker’s reputation was solidified during World War II when it was utilized for critical manufacturing tasks, including the production of military equipment. This historical context not only adds to the machine’s allure but also reflects a legacy of quality that many buyers still seek today. The ongoing interest in vintage and refurbished models speaks to their enduring value in modern manufacturing, making them a wise investment for B2B buyers aiming to combine tradition with contemporary efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of american pacemaker lathe

-

How do I evaluate the condition of an American Pacemaker lathe before purchasing?

When assessing the condition of an American Pacemaker lathe, start by examining its physical state for rust, wear, and any structural damage. Check the bed for wear and tear, particularly in the V-ways, as this impacts precision. Inspect the spindle and bearings for smooth operation and listen for unusual noises. Request maintenance records, if available, to understand its usage history. Additionally, if possible, conduct a test run to evaluate its performance and ensure all features, such as the taper attachment and steady rest, function correctly. -

What is the best way to source American Pacemaker lathes for my business?

To source American Pacemaker lathes effectively, begin by identifying reputable machinery dealers or auction sites specializing in industrial equipment. Utilize online marketplaces and forums where existing users discuss their experiences. Attend industry trade shows and expos to connect with suppliers directly. It’s also beneficial to network with other businesses in your region that use similar machinery to get recommendations on reliable vendors. Finally, consider contacting manufacturers directly if you seek new models or specific configurations. -

What customization options are available for American Pacemaker lathes?

Customization options for American Pacemaker lathes may include modifications to spindle speeds, additional tooling attachments, or enhanced electronic controls. Some suppliers offer tailored solutions based on specific production needs, such as increased horsepower or specialized chucks. Discuss your requirements with potential suppliers to understand the extent of available customizations and their associated costs. Ensure that any modifications do not compromise the machine’s integrity or warranty. -

What are the minimum order quantities (MOQ) for purchasing American Pacemaker lathes?

Minimum order quantities for American Pacemaker lathes can vary significantly based on the supplier and the specific model. Many dealers may sell individual machines, especially for used or refurbished units. However, if purchasing new equipment or through a distributor, there might be an MOQ requirement, often ranging from one to several units. It’s advisable to clarify these terms upfront during negotiations to align your purchasing plans with supplier capabilities. -

What payment terms should I expect when buying an American Pacemaker lathe?

Payment terms for purchasing an American Pacemaker lathe typically include options such as full payment upfront, a deposit followed by a final payment upon delivery, or financing arrangements. International buyers should inquire about payment methods accepted, including wire transfers, letters of credit, or payment through escrow services for added security. Ensure to discuss and agree on terms that protect both parties, particularly in terms of currency exchange rates and any potential taxes or duties applicable to international transactions. -

How can I ensure quality assurance when sourcing American Pacemaker lathes?

To ensure quality assurance when sourcing American Pacemaker lathes, request detailed inspection reports or certifications from the seller. If purchasing used machinery, consider hiring a third-party inspector to assess the lathe’s condition thoroughly. Look for warranties or guarantees offered by the supplier, which can provide additional assurance. Additionally, verify the supplier’s reputation through customer reviews and industry references, ensuring they have a history of delivering reliable equipment. -

What logistics considerations should I keep in mind when importing lathes?

When importing American Pacemaker lathes, consider logistics factors such as shipping methods, customs clearance, and insurance. Choose a reliable freight forwarder experienced in handling heavy machinery to navigate international shipping regulations. Understand the import duties and taxes applicable in your country, and prepare necessary documentation to avoid delays. Additionally, plan for the transportation from the port to your facility, ensuring that the equipment is handled safely to prevent damage during transit. -

What are the common maintenance practices for American Pacemaker lathes?

Common maintenance practices for American Pacemaker lathes include regular cleaning of the machine to prevent debris buildup, checking and replenishing lubrication levels, and inspecting belts and gears for wear. It’s crucial to regularly adjust the spindle bearings to maintain optimal performance and prevent excessive wear. Schedule periodic professional servicing to address any technical issues and ensure the machine operates at peak efficiency. Keeping detailed maintenance records will also help track performance and anticipate potential repairs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 American Pacemaker Lathe Manufacturers & Suppliers List

1. American Pacemaker – Lathe Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: American Pacemaker Lathe products for sale on eBay include various models and specifications. Key details extracted include:

– Machine Types: Engine Lathe, Precision Lathe

– Swing Over Bed Sizes: 14 in, 16 in, 18 in, 19 in, 20 in, 22 in, 23 in, 25 in, 32 in

– X-Axis Sizes: 16 in, 18 in, 32 in

– Distance Between Centers: 71 in – 80 in, 101 in – 120 in

– Model Years: 1961, 1968

– Condition: Ne…

2. American Tool Works – Pacemaker Lathes

Domain: lathes.co.uk

Registered: 1998 (27 years)

Introduction: American Pacemaker Lathes manufactured by American Tool Works Company, Cincinnati, Ohio, USA. Available sizes: 14-inch, 16-inch, 20-inch Medium Duty, and 20-inch Heavy Duty. Made from a cast-iron mixture with 40% steel scrap, tensile strength of approximately 40,000 pounds. Features detachable V-ways of solid tool-steel, hardened to approximately 60 Rockwell C. Four Vees for carriage and tailstock…

3. American Pacemaker – Heavy-Duty Lathe

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: American Pacemaker Lathe, heavy iron construction, used during WWII for manufacturing, capable of taking a quarter inch cut, generally well-regarded for its durability and performance, sold for $600, previously used in a municipal shop with low operational hours, has a big swing but limited distance between centers.

4. American – Engine Lathes for Sale

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: American Engine Lathes for Sale include various models such as PACEMAKER, 16X102, 20D-PACEMAKER, 20X150, 23 X 192 MDL PACEMAKER, and more. Key specifications for some models are as follows:

– 15″ x 96″ American #24 engine lathe, 3-Jaw 24″ chuck, Price: $9,950, Location: Thousand Oaks, CA.

– 16″ x 102″ American #16X102 engine lathe, 25-1500 RPM, 15″ 4-Jaw chuck, Price: $12,500, Location: Hugo, MN…

5. American Tool Works – Pacemaker Lathe

Domain: revelationmachinery.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “American Tool Works Pacemaker Lathe”, “Dimensions”: {“Swing”: “20 inches”, “Distance Between Centers”: “96 inches”, “Through Hole”: “2.25 inches”}, “Spindle Speeds”: “18 (20 – 1200 RPM)”, “Bed Length”: “10 feet”, “Equipped With”: [“18-inch 4-Jaw Chuck”, “12-inch 3-Jaw Chuck”, “Collet Chuck with Collets Set”, “Steady Rest”], “Condition”: “Solid vintage lathe in good, working condi…

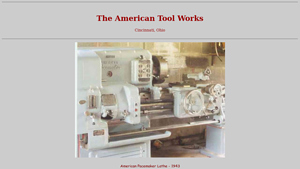

6. American Tool Works – American Pacemaker Lathe

Domain: pounceatron.dreamhosters.com

Introduction: Product Name: American Pacemaker Lathe

Manufacturer: American Tool Works Company

Location: Cincinnati, Ohio

Year of Manufacture: 1943

Model: Toolroom Lathe

Dimensions: 16 by 78 inches

Features:

– Power clutch engaged by lever near headstock or apron (not yet installed)

– Ball bearing taper attachment

– Power train for relieving attachment

– Spindle speed control with large lever (6 positions) and …

7. American Pacemaker Lathe – 14×54 Model

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: 1954 American Pacemaker Lathe, Size: 14×54, Lubrication requirements: Headstock and gearbox – high grade machine oil viscosity 275-290 seconds Saybolt at 100 degrees; Carriage and apron – Vactra oil #2; Power traverse cylinder oil – viscosity 155-165 at 210 degrees. The lathe has been unused for 15 years.

8. AMERICAN – PACEMAKER 18 X 54 ENGINE LATHE

Domain: assetexchangeinc.com

Registered: 2004 (21 years)

Introduction: {“Manufacturer”: “AMERICAN”, “Model”: “PACEMAKER 18 X 54 ENGINE LATHE”, “Year”: 1943, “Stock Number”: 61749, “Specifications”: {“Size”: “18 X 54”, “Swing Over Bed Ways”: “18” , “Swing Over Carriage”: “13”, “Distance Between Centers”: “54”, “Spindle Speeds”: “20 to 1200 RPM (18)”, “Main Drive Motor”: “8 HP”, “Threading Capacity”: “60TPI to 1TPI”, “Current Electrical Arrangement”: “240/3/60”}, “Equi…

Strategic Sourcing Conclusion and Outlook for american pacemaker lathe

Why Should B2B Buyers Consider the American Pacemaker Lathe?

In summary, the American Pacemaker Lathe stands out as a robust, high-performance machine tool that has been engineered to meet the rigorous demands of modern machining. Its substantial construction, combined with a versatile range of spindle speeds and advanced lubrication systems, ensures reliability and precision, making it an excellent investment for industries seeking to enhance productivity.

Strategic sourcing of the American Pacemaker not only provides access to a piece of machinery renowned for its durability and performance but also opens the door to a network of suppliers and services that can facilitate maintenance and support. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the long-term value of these lathes is essential.

As you explore procurement options, consider the operational advantages and cost-effectiveness of integrating the American Pacemaker into your manufacturing processes. Engage with trusted suppliers to ensure you’re getting the best deal and support. Embrace the opportunity to elevate your machining capabilities—your next strategic move could redefine your production efficiency and market competitiveness.