Alternator Scrap Price Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for alternator scrap price

In an increasingly interconnected world, understanding the fluctuating alternator scrap price is crucial for international B2B buyers looking to optimize their procurement strategies. As market dynamics evolve, buyers face the challenge of sourcing reliable suppliers while navigating the complexities of pricing variations across different regions, particularly in Africa, South America, the Middle East, and Europe. This comprehensive guide aims to demystify the intricacies of the alternator scrap market by providing in-depth insights into various types of alternators, their applications, and the factors influencing their value.

Throughout this guide, you will discover essential information on how to effectively vet suppliers and assess the quality of alternators for scrap. Additionally, we delve into current pricing trends, historical data, and market predictions, equipping you with the tools needed to make informed purchasing decisions. Whether you are a small business in Brazil seeking to maximize profit margins or a large-scale operation in Vietnam looking to streamline your supply chain, this resource is designed to empower you with actionable insights.

By leveraging this guide, international B2B buyers can confidently navigate the global market for alternator scrap, ensuring they capitalize on opportunities while mitigating risks associated with fluctuating prices and varying supplier reliability. Join us as we explore the essential components of this critical market and position your business for success in the ever-evolving landscape of scrap metal procurement.

Understanding alternator scrap price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alternators | Commonly found in vehicles; typically contain copper windings | Auto recycling, metal fabrication | Pros: Widely accepted; consistent pricing. Cons: Lower value compared to specialized types. |

| High-Grade Alternators | Higher copper content; often removed from luxury vehicles | High-value scrap markets | Pros: Better return on investment. Cons: Limited availability; may require sourcing from specific regions. |

| Industrial Alternators | Larger units used in heavy machinery; robust construction | Industrial recycling, equipment refurbishing | Pros: Higher weight yields more scrap value. Cons: Bulkier; requires specialized transport. |

| Refurbished Alternators | Repaired and resold units; often from reputable sources | Automotive parts supply, resale markets | Pros: Can offer warranty; potential for resale profit. Cons: Higher initial cost; may require additional inspection. |

| Specialty Alternators | Unique designs or materials; used in specific applications | Niche markets, custom machinery | Pros: Potentially high scrap value. Cons: Difficult to find; may require specialized knowledge to assess. |

What Are the Key Characteristics of Standard Alternators?

Standard alternators are the most common type found in vehicles, primarily due to their widespread use in everyday transportation. These units typically contain copper windings, making them valuable in the scrap metal market. B2B buyers can easily source these alternators from auto recyclers or scrap yards, ensuring a steady supply for recycling or refurbishing. However, their lower market value compared to specialized types means that buyers must consider volume to maximize profit.

How Do High-Grade Alternators Differ in Value?

High-grade alternators are characterized by their superior copper content, often sourced from luxury or high-performance vehicles. These units yield a higher scrap price due to their enhanced metal composition. B2B applications for high-grade alternators include high-value scrap markets and specialized recycling operations. While they offer better returns, their limited availability can pose challenges for buyers looking to maintain a consistent supply.

What Are the Benefits of Industrial Alternators?

Industrial alternators are larger units commonly found in heavy machinery and equipment. Their robust construction and higher weight make them particularly valuable in the scrap market. B2B buyers in industries such as manufacturing and construction can benefit from purchasing these units for recycling or refurbishing. However, their size may necessitate specialized transport solutions, which can add to overall costs.

Why Choose Refurbished Alternators for Resale?

Refurbished alternators are those that have been repaired and restored to working condition, often sourced from reputable suppliers. They are popular in the automotive parts supply chain due to the warranty and reliability they offer. For B2B buyers, these units can be a lucrative investment for resale in the aftermarket. However, the initial cost may be higher, and thorough inspections are recommended to ensure quality.

What Makes Specialty Alternators Unique?

Specialty alternators are designed for specific applications and may feature unique materials or configurations. These units can command high scrap prices, particularly in niche markets or custom machinery sectors. B2B buyers interested in specialty alternators should be prepared for a more complex sourcing process, as these units may not be as readily available. Understanding the specific requirements of the target market is essential for maximizing the value of these unique scrap materials.

Key Industrial Applications of alternator scrap price

| Industry/Sector | Specific Application of alternator scrap price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Recycling | Sourcing copper and steel for remanufacturing | Reduces costs by utilizing recycled materials, enhancing sustainability efforts. | Verify local regulations on scrap metal processing; assess quality and type of alternator scrap. |

| Electrical Manufacturing | Production of new electrical components | Lower raw material costs and reduced environmental impact through recycling. | Ensure consistent supply of high-quality alternator scrap; consider logistics for transport. |

| Renewable Energy | Manufacturing of components for wind turbines | Supports green initiatives by using recycled metals, lowering carbon footprint. | Evaluate the purity of metals; establish reliable suppliers to ensure consistent quality. |

| Construction and Heavy Machinery | Fabrication of machinery components | Cost savings on materials and enhanced durability of components made from recycled metals. | Assess the mechanical properties of the scrap; ensure compliance with industry standards. |

| Export and Trading | International trade of scrap metals | Opens new markets and revenue streams, particularly in regions with high demand for recycled materials. | Understand market demand in target regions; establish connections with local scrap yards. |

The automotive recycling sector plays a crucial role in utilizing alternator scrap price effectively. As vehicles reach the end of their lifecycle, alternators are dismantled for their copper and steel components. By sourcing these materials from scrap, businesses can significantly reduce costs and minimize waste, aligning with sustainability goals. International buyers should consider local regulations regarding the recycling process and the quality of the scrap to ensure compliance and effectiveness.

In the electrical manufacturing industry, alternator scrap is increasingly valued for its copper content, which is essential for producing new electrical components. By utilizing recycled materials, manufacturers can lower their raw material costs while promoting environmentally friendly practices. Buyers should focus on establishing a consistent supply of high-quality alternator scrap, as fluctuating prices and quality can impact production schedules.

The renewable energy sector is also tapping into the potential of alternator scrap. As the demand for wind turbines and other renewable energy solutions grows, manufacturers seek out recycled metals to fabricate components. This not only reduces costs but also supports green initiatives by lowering the carbon footprint associated with new metal production. Buyers must evaluate the purity and quality of the metals to ensure they meet the stringent requirements of renewable energy applications.

In construction and heavy machinery, alternator scrap is used to fabricate durable components. By sourcing these materials from scrap, companies can achieve significant cost savings while benefiting from the inherent strength of recycled metals. It is essential for buyers to assess the mechanical properties of the scrap and ensure compliance with industry standards to maintain safety and performance.

Finally, the export and trading of scrap metals, including alternators, presents lucrative opportunities for international businesses. With growing demand in regions like Africa and South America, establishing connections with local scrap yards can open new markets and revenue streams. Understanding market dynamics and demand in target regions is vital for successful trading operations.

3 Common User Pain Points for ‘alternator scrap price’ & Their Solutions

Scenario 1: Navigating Fluctuating Scrap Prices

The Problem: B2B buyers often face the challenge of fluctuating scrap prices for alternators, which can vary significantly across regions and over time. This volatility makes it difficult to budget and plan for procurement and sales strategies. Buyers may find themselves purchasing alternators at a high price only to see the market drop shortly after, impacting their margins. Additionally, inconsistent pricing can lead to trust issues between buyers and scrap yards, as buyers may feel uncertain about whether they are receiving a fair rate.

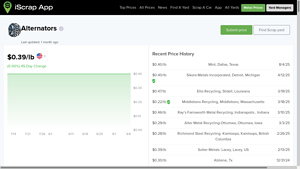

The Solution: To mitigate the impact of price fluctuations, B2B buyers should establish strong relationships with multiple local scrap yards and use tools like the iScrap App to monitor real-time market prices. Regularly updating themselves on market trends will help them make informed purchasing decisions. Moreover, buyers can negotiate fixed pricing agreements with reliable scrap yards that allow for predictable budgeting. Implementing a price alert system can also help buyers act quickly when prices dip, ensuring they maximize their profit margins on scrap sales.

Scenario 2: Limited Acceptance of Alternators at Scrap Yards

The Problem: A common pain point for B2B buyers is the variability in scrap yards regarding which types of alternators they accept. Some yards may not accept alternators at all or might impose strict conditions, such as requiring them to be completely intact or cleaned. This inconsistency can lead to wasted trips, lost time, and increased transportation costs, as buyers may haul alternators only to find out that their local yard won’t take them.

The Solution: To navigate this issue, buyers should create a comprehensive list of scrap yards in their region that accept alternators and their specific requirements for acceptance. Utilizing platforms that aggregate yard information, like the iScrap App, can help streamline this process. Buyers can also communicate directly with scrap yard operators to clarify acceptance policies before transporting materials. Establishing a network of reliable scrap yards can provide buyers with alternatives, ensuring they always have a destination for their scrap alternators.

Scenario 3: Understanding the Value of Alternator Scrap Components

The Problem: Many B2B buyers lack a clear understanding of the factors that influence the scrap price of alternators, particularly regarding the value of their individual components, such as copper windings and steel casings. This lack of knowledge can lead to buyers undervaluing their scrap or failing to recognize the potential for higher prices based on the quality and condition of the alternators they are selling.

The Solution: To overcome this challenge, buyers should invest time in learning about the specific components of alternators and their respective market values. Resources like industry reports, scrap metal pricing websites, and educational webinars can provide valuable insights into how to assess the quality of alternators and what aspects to highlight when selling them. Additionally, buyers should consider conducting a comparative analysis of prices offered by different yards for specific alternator types, allowing them to gauge the market value effectively. This informed approach will empower buyers to negotiate better prices and optimize their scrap sales.

Strategic Material Selection Guide for alternator scrap price

What Are the Key Materials Impacting Alternator Scrap Prices?

When evaluating the scrap value of alternators, several materials play a critical role in determining their market price. Here, we analyze four common materials found in alternators: copper, aluminum, steel, and plastic. Each material has unique properties, advantages, and limitations that can influence pricing and buyer decisions in the international market.

How Does Copper Affect Alternator Scrap Pricing?

Copper is one of the most valuable materials in alternators due to its excellent electrical conductivity and thermal performance. It typically has a high melting point (around 1,984°F or 1,085°C), making it suitable for high-temperature applications.

Pros: Copper’s high conductivity translates to better performance in electrical systems, which is crucial for alternator functionality. Additionally, copper has a significant resale value, often fetching higher prices in scrap markets.

Cons: The primary drawback of copper is its cost, which can be volatile depending on global market conditions. Furthermore, the extraction and processing of copper can be environmentally taxing, leading to regulatory concerns.

Impact on Application: Copper’s compatibility with various media ensures reliable performance in diverse environments, making it a preferred choice for manufacturers.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of compliance with local environmental regulations regarding copper sourcing. Standards such as ASTM B224 for copper wire may apply, influencing purchasing decisions.

What Role Does Aluminum Play in Alternator Scrap Value?

Aluminum is another significant component in alternators, known for its lightweight and corrosion-resistant properties. It typically has a melting point of about 1,221°F (660.3°C), which allows it to perform well under moderate temperatures.

Pros: Aluminum is less expensive than copper and is easier to work with, which can reduce manufacturing complexity. Its lightweight nature contributes to overall vehicle efficiency.

Cons: While aluminum is corrosion-resistant, it is not as strong as copper, which may impact durability in high-stress applications. Additionally, its lower conductivity compared to copper can affect performance.

Impact on Application: Aluminum’s compatibility with various automotive applications makes it suitable for use in alternators, but its mechanical properties may limit its use in high-performance scenarios.

Considerations for International Buyers: Buyers should consider the common standards for aluminum, such as ASTM B221, and ensure compliance with local regulations. The preference for aluminum over copper may vary by region, influenced by local market dynamics.

How Does Steel Contribute to Alternator Scrap Pricing?

Steel is often used in the casing and structural components of alternators. It is known for its strength and durability, with a melting point around 2,500°F (1,370°C).

Pros: Steel’s high strength and durability make it ideal for protective casings, which can withstand harsh environmental conditions. It is also generally more affordable than both copper and aluminum.

Cons: Steel is heavier than aluminum and copper, which can negatively impact vehicle efficiency. Additionally, it is more susceptible to corrosion unless treated, which can affect longevity.

Impact on Application: The robustness of steel allows for reliable protection of internal components, but its weight may be a concern for performance-oriented applications.

Considerations for International Buyers: Buyers should be aware of the relevant standards, such as ASTM A36 for structural steel, and ensure compliance with local regulations regarding steel sourcing and processing.

What Is the Importance of Plastic in Alternator Scrap Pricing?

Plastic components are often used in alternators for insulation and housing. While not as valuable as metals, they play a crucial role in overall functionality.

Pros: Plastic is lightweight, corrosion-resistant, and offers excellent electrical insulation properties. It helps reduce the overall weight of the alternator, contributing to vehicle efficiency.

Cons: The primary limitation of plastic is its lower durability compared to metals, making it more susceptible to damage under extreme conditions. Additionally, its scrap value is significantly lower than that of metals.

Impact on Application: Plastic’s insulating properties are essential for preventing electrical shorts, but its mechanical limitations may restrict its use in high-stress areas.

Considerations for International Buyers: Buyers should consider local regulations regarding plastic recycling and disposal, as well as compliance with standards such as ASTM D6400 for biodegradable plastics.

Summary Table of Materials Impacting Alternator Scrap Price

| Material | Typical Use Case for alternator scrap price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical windings and connectors | High conductivity and resale value | Volatile pricing and environmental concerns | High |

| Aluminum | Structural components and casings | Lightweight and corrosion-resistant | Lower strength and conductivity | Medium |

| Steel | Protective casings and structural parts | High strength and durability | Heavier and susceptible to corrosion | Low |

| Plastic | Insulation and housing | Lightweight and excellent insulation | Lower durability and scrap value | Low |

This guide aims to provide international B2B buyers with actionable insights into the materials influencing alternator scrap prices, ensuring informed decision-making in the global market.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator scrap price

What Are the Key Stages in the Manufacturing Process for Alternator Scrap?

The production of alternators typically involves several crucial stages that ensure the efficiency and quality of the final product. These stages are material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of raw materials, primarily copper wire and steel for the alternator casing. The copper wire is usually wound into coils, which are integral to the alternator’s function. Quality control at this stage involves checking the purity of the copper and the specifications of the steel to ensure they meet industry standards.

-

Forming: The next step is forming, where the prepared materials are shaped into their respective components. This may involve processes like stamping for the steel casing and winding for the copper coils. Advanced techniques such as CNC machining may also be employed to ensure precision. It is essential that the forming process adheres to strict tolerances to guarantee optimal performance.

-

Assembly: After forming, the individual components are assembled. This stage requires meticulous attention to detail, as the arrangement of parts directly impacts the alternator’s efficiency. Automated assembly lines are often used to enhance consistency and reduce human error. Quality checks at this stage include verifying the alignment of components and ensuring that connections are secure.

-

Finishing: The final stage involves finishing processes such as painting or coating to protect the alternator from corrosion and wear. This is where quality assurance measures are critical, as improper finishing can lead to premature failure. Testing for durability and resistance to environmental factors is also conducted during this stage.

How Is Quality Assurance Implemented in Alternator Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for alternators, particularly for international B2B buyers who require reliable products. Various international standards and industry-specific certifications guide QA practices.

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently meet customer requirements and enhance satisfaction. Additionally, CE marking may be required in Europe, indicating that products meet safety, health, and environmental protection standards.

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality before they enter the production process. This is vital for ensuring that only high-quality components are used.

– In-Process Quality Control (IPQC): During manufacturing, quality checks are performed to monitor the production processes. This may involve measuring dimensions, testing material properties, and verifying assembly integrity.

– Final Quality Control (FQC): After assembly, the finished alternators undergo rigorous testing to ensure they meet performance specifications. Common tests include electrical performance tests, thermal stability assessments, and mechanical durability tests.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure the quality and reliability of alternators. These methods can include:

- Electrical Testing: Ensures that the alternator produces the required voltage and current under various conditions. This may involve load testing and no-load testing.

- Thermal Testing: Assesses how the alternator performs under extreme temperatures, which is crucial for ensuring reliability in different environments.

- Mechanical Testing: Involves stress tests to evaluate the strength and durability of components, ensuring they can withstand operational stresses.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some methods to ensure that suppliers maintain high standards:

-

Supplier Audits: Conducting regular audits of suppliers can help verify that they adhere to quality standards. This includes reviewing their quality management systems, production processes, and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their QA processes and outcomes. These reports should outline testing results, defect rates, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These organizations can conduct independent assessments of the supplier’s manufacturing processes and quality control measures.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances can be challenging for international buyers. Here are several considerations:

- Cultural Differences: Understanding local manufacturing practices and cultural attitudes toward quality can impact supplier relationships. Open communication about quality expectations can help mitigate misunderstandings.

- Regulatory Compliance: Different regions may have unique regulations concerning quality standards. Buyers must ensure that their suppliers comply with both local and international regulations relevant to their market.

- Logistics and Supply Chain: Quality assurance does not end at manufacturing. It is crucial to monitor the supply chain and logistics processes to ensure that products remain compliant throughout transportation.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for alternators is vital for B2B buyers in global markets. By focusing on the main stages of production, adhering to international standards, and implementing thorough quality control measures, buyers can make informed decisions that enhance their supply chain reliability. This knowledge is particularly crucial for businesses in regions like Africa, South America, the Middle East, and Europe, where market dynamics can vary significantly.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator scrap price’

In the global scrap metal market, understanding how to source alternator scrap effectively can yield significant benefits for your business. This guide provides a step-by-step checklist to help B2B buyers navigate the intricacies of procuring alternator scrap at competitive prices.

Step 1: Research Current Market Prices

Before initiating any transactions, familiarize yourself with the current scrap prices for alternators. Prices can fluctuate based on various factors such as market demand and regional availability. Utilize platforms like iScrap App or local recycling yards to gather up-to-date pricing information and historical trends.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is crucial for ensuring quality and consistency in your scrap procurement. Look for suppliers with strong reputations in the industry, verified by reviews or recommendations. Consider reaching out to multiple suppliers to compare offerings and establish relationships.

- Tip: Attend local scrap metal expos or industry conferences to meet suppliers face-to-face and build rapport.

Step 3: Evaluate Quality Standards

Not all alternator scrap is created equal. Assess the quality of the scrap being offered by asking for detailed descriptions, including weight and copper content. High-quality alternator scrap typically contains more copper, which can increase its market value.

- Tip: Request samples if possible, to gauge the quality before committing to larger purchases.

Step 4: Understand Shipping and Logistics

Logistics can significantly impact your overall costs. Determine how the alternator scrap will be shipped, the associated costs, and delivery timelines. Establish whether the supplier offers freight services or if you need to arrange for transportation independently.

- Tip: Factor in customs regulations and duties if you are sourcing scrap from international suppliers, particularly from regions like Africa or South America.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and assessed their quality, engage in negotiations. Discuss bulk pricing, payment terms, and any discounts for larger orders. Clear communication can lead to better deals and long-term partnerships.

- Tip: Be prepared to walk away if the terms do not meet your expectations; the scrap metal market is competitive, and there are often alternative sources available.

Step 6: Verify Compliance with Local Regulations

Ensure that your suppliers comply with local and international regulations regarding scrap metal trading. This is particularly important for sustainable practices and environmental compliance. Request documentation that verifies their adherence to such regulations.

- Tip: Engage with suppliers who are certified by recognized industry bodies, as this can serve as an assurance of their legitimacy.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your suppliers can lead to better pricing and exclusive access to quality materials. Regular communication and feedback can enhance trust and ensure that both parties are aligned on expectations.

- Tip: Consider forming a partnership that includes regular orders, which can help secure more favorable terms and reliability in supply.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing alternator scrap and ensure they are making informed decisions that benefit their business operations.

Comprehensive Cost and Pricing Analysis for alternator scrap price Sourcing

What Are the Key Cost Components Influencing Alternator Scrap Pricing?

When sourcing alternator scrap, understanding the cost structure is crucial. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The main value of alternator scrap lies in the copper windings and steel casing. Prices for copper fluctuate based on global demand and supply dynamics. Buyers should monitor copper prices as they directly affect the scrap value.

-

Labor: Labor costs encompass the workforce involved in the collection, sorting, and processing of alternators. Regions with higher labor costs may see increased scrap prices, affecting the total cost for buyers.

-

Manufacturing Overhead: This includes the indirect costs of running a scrap yard or processing facility, such as utilities and maintenance. These expenses can vary significantly based on geographical location.

-

Tooling and QC: The equipment used for processing scrap and the standards for quality control can also influence prices. Advanced machinery and rigorous QC processes typically lead to higher operational costs, which may be reflected in the price of the scrap.

-

Logistics: Transportation costs play a significant role, especially for international buyers. Shipping fees, customs duties, and local taxes can add substantially to the overall expenditure.

-

Margin: Suppliers will typically include a profit margin on top of their costs. Understanding the average margin in your region can aid in negotiating better prices.

What Factors Influence Alternator Scrap Prices for International Buyers?

Several price influencers can impact the cost of alternator scrap, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger volumes often leads to better pricing. Suppliers are usually willing to negotiate lower rates for bulk orders, which can be advantageous for businesses looking to source scrap on a larger scale.

-

Specifications and Customization: Specific requirements regarding the quality and condition of the alternators can influence pricing. Buyers requesting customized specifications might face higher costs due to additional processing requirements.

-

Material Quality and Certifications: The quality of the scrap, including the copper yield and absence of contaminants, can significantly affect pricing. Certifications for recycling practices or material quality can also justify higher prices.

-

Supplier Factors: The reputation and reliability of suppliers matter. Established suppliers with a track record of quality and service may charge premium prices, but they often provide better guarantees and support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting the total landed cost.

How Can Buyers Optimize Costs When Sourcing Alternator Scrap?

Buyers looking to maximize value and minimize costs should consider the following tips:

-

Negotiation Strategies: Always negotiate prices. Research the market and be prepared to discuss alternatives or bulk purchases to secure better rates.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but all associated costs, including shipping, tariffs, and potential quality issues. A lower upfront price may not always lead to overall savings.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in scrap prices due to currency changes, geopolitical factors, and local market conditions. Establishing relationships with local suppliers can help mitigate risks associated with international sourcing.

-

Regular Price Monitoring: Stay informed about current scrap prices through platforms and apps that track market trends. Regular updates can help in making timely purchasing decisions.

Disclaimer on Indicative Prices

The prices mentioned in this analysis are indicative and subject to change based on market fluctuations. Buyers should verify current pricing with local scrap yards and recycling facilities to ensure accurate cost assessments before making sourcing decisions.

Alternatives Analysis: Comparing alternator scrap price With Other Solutions

Exploring Alternatives to Alternator Scrap Price

In the landscape of scrap metal, particularly for alternators, businesses often seek alternatives that may offer comparable benefits or cost efficiencies. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational goals and financial constraints.

Comparison Table

| Comparison Aspect | Alternator Scrap Price | Electric Motor Scrap Price | Copper Wire Scrap Price |

|---|---|---|---|

| Performance | $0.39/lb | $0.35/lb | $3.47/lb |

| Cost | Moderate | Low | High |

| Ease of Implementation | Easy | Moderate | Easy |

| Maintenance | Minimal | Low | Minimal |

| Best Use Case | Vehicle recycling | Household appliances | Electrical applications |

Detailed Breakdown of Alternatives

Electric Motor Scrap Price

Electric motors, similar to alternators, are common in various equipment, from household appliances to industrial machines. Priced at approximately $0.35/lb, they provide a slightly lower return than alternators but are more widely accepted by scrap yards. The ease of dismantling electric motors can vary, often requiring some technical skills to extract valuable copper windings. While the maintenance involved in handling electric motors is minimal, their overall utility may be limited to specific sectors such as manufacturing and appliance recycling.

Copper Wire Scrap Price

Copper wire is one of the most sought-after materials in the scrap metal industry, commanding prices around $3.47/lb. This high value reflects the metal’s extensive use in electrical systems, making it a favorite among recyclers. The process of collecting and selling copper wire is straightforward, allowing for quick turnaround times. However, the maintenance of quality (ensuring wires are stripped and clean) can require additional effort. For businesses focused on maximizing profitability, copper wire offers a lucrative alternative, though it may not serve the same niche as alternators.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the best scrap solution, B2B buyers must consider their specific operational needs, financial goals, and the nature of their scrap materials. For those dealing with vehicle components, alternator scrap prices may offer the most straightforward and relevant solution. However, if maximizing profit is a priority, exploring alternatives like copper wire or electric motors might yield better returns. Evaluating the ease of implementation and maintenance will also play a crucial role in making the right choice. Ultimately, understanding the market dynamics and aligning them with business objectives will lead to optimal decisions in the scrap metal landscape.

Essential Technical Properties and Trade Terminology for alternator scrap price

What Are the Key Technical Properties of Alternator Scrap?

Understanding the technical specifications of alternator scrap is crucial for B2B buyers looking to maximize their investment. Here are some critical properties to consider:

-

Material Composition

Alternators primarily consist of copper, aluminum, and steel. The copper windings are particularly valuable, as copper scrap commands higher prices in the market. Buyers should assess the copper content to determine the scrap’s potential value, as higher copper percentages typically lead to better returns. -

Weight and Size

The weight and dimensions of the alternator scrap significantly influence its price. Scrap yards often price based on weight (usually per pound or kilogram), making it essential for buyers to have accurate measurements. Understanding the size can also help in logistics planning, especially for international shipping. -

Condition of the Scrap

The condition—whether the alternators are clean, damaged, or mixed with other materials—affects their market value. Clean scrap, free from contaminants, generally receives a higher price than mixed or contaminated scrap. Buyers must evaluate the condition to ensure they receive the best price. -

Grade of the Scrap

Scrap metal is often categorized into grades, which can affect pricing. For alternators, they may be classified as “clean” or “dirty.” Clean scrap, which is unblemished and free of non-metal components, will typically yield a higher price than dirty scrap. Understanding these grades helps buyers negotiate better deals. -

Market Trends

The scrap metal market is volatile, with prices fluctuating based on demand, global trends, and economic conditions. Buyers should stay informed about current market rates and historical pricing trends to make informed purchasing decisions.

What Are Common Trade Terms in the Alternator Scrap Industry?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that originally manufactured the alternator. Understanding OEM specifications can help buyers determine the quality and potential resale value of the scrap. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of scrap that a supplier is willing to sell. Knowing the MOQ is critical for buyers to plan their purchases effectively and ensure they are getting the best deal without overcommitting. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quote for specific quantities and types of scrap. This helps buyers compare prices and terms from different suppliers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and rights in a transaction. -

Scrap Yard

This refers to a facility where scrap materials are collected, processed, and sold. Knowing the local scrap yards that accept alternators and their pricing policies can help buyers optimize their sourcing strategies. -

Bale Weight

This term pertains to the weight of compacted scrap material, often used for shipping purposes. Understanding bale weight is important for logistics and cost estimation in international transactions.

Conclusion

For international B2B buyers, comprehending the technical properties and trade terminology associated with alternator scrap is vital for making informed purchasing decisions. By grasping these concepts, buyers can enhance their negotiating power, optimize logistics, and ultimately maximize their return on investment in the scrap metal market.

Navigating Market Dynamics and Sourcing Trends in the alternator scrap price Sector

What are the Current Market Dynamics Influencing Alternator Scrap Prices?

The global alternator scrap market is shaped by several key drivers, including fluctuating demand for copper, advancements in recycling technologies, and regional economic conditions. As of September 2025, the price of alternator scrap has shown some volatility, with recent prices around $0.39 to $0.52 per pound depending on the region. This variation is often influenced by local market conditions, including the availability of scrap and operational costs at recycling facilities. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these fluctuations is critical for making informed sourcing decisions.

Emerging technologies in the recycling sector, such as automated sorting systems and enhanced metal extraction methods, are also transforming the landscape. These advancements not only improve efficiency but also reduce operational costs for scrap yards, potentially leading to more competitive pricing for buyers. Additionally, the increasing global emphasis on sustainability is pushing businesses to seek out reliable suppliers who can provide quality scrap materials with minimal environmental impact.

Buyers should also be aware of the geopolitical factors that can affect scrap metal prices, including trade tariffs and regulations that vary significantly by region. Engaging with local scrap yards and using platforms like the iScrap App can help buyers stay updated on pricing trends and market conditions.

How Can Sustainability and Ethical Sourcing Impact Your Business in the Alternator Scrap Sector?

Sustainability has become a cornerstone of modern business practices, especially in the scrap metal industry. The environmental impact of scrap metal recycling is significant, as it reduces the need for new materials, conserves energy, and minimizes waste. For B2B buyers in the alternator scrap sector, prioritizing suppliers with sustainable practices is not only a responsible choice but also a competitive advantage.

Ethical sourcing involves ensuring that the materials procured do not contribute to environmental degradation or human rights violations. Buyers should seek out suppliers who demonstrate compliance with environmental regulations and hold certifications for sustainable practices. Certifications such as ISO 14001 (Environmental Management) or those related to responsible sourcing can provide assurances about the integrity of the supply chain.

Moreover, as consumers and businesses increasingly favor ‘green’ products, companies that prioritize sustainability can enhance their brand reputation and customer loyalty. In markets like Europe and North America, where regulatory frameworks are more stringent, sourcing responsibly can also mitigate risks related to compliance and penalties.

What is the Historical Context of the Alternator Scrap Price Market?

The alternator scrap market has evolved significantly over the past few decades, driven by changes in automotive technology and recycling methodologies. Historically, alternators were seen primarily as waste at the end of a vehicle’s life cycle. However, as the demand for copper and other valuable metals increased, the perception shifted, and scrap alternators became recognized as a valuable resource.

In the early 2000s, the rise in global demand for copper, spurred by industrial growth in emerging markets, led to a significant increase in scrap metal prices, including those for alternators. This trend encouraged more organized recycling efforts and the establishment of specialized scrap yards. As technology advanced, the ability to efficiently process and extract metals from scrap alternators improved, further solidifying their position in the recycling economy.

Today, the market continues to adapt to global economic trends, technological advancements, and the growing importance of sustainable practices. For B2B buyers, understanding this historical context can provide valuable insights into current pricing dynamics and future market opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator scrap price

-

How do I determine the current market price for alternator scrap?

To determine the current market price for alternator scrap, you can refer to reputable scrap metal pricing websites and apps, such as iScrap App, which provide real-time data on scrap prices based on location. Additionally, contacting local scrap yards directly can give you insights into their pricing, as they may vary based on demand and regional market conditions. It’s also beneficial to monitor trends over time to understand price fluctuations and seasonal impacts on scrap value. -

What factors influence the pricing of alternator scrap?

The pricing of alternator scrap is influenced by several factors including the weight and condition of the alternators, the current demand for copper and steel, and regional market dynamics. Scrap yards may also consider the volume of material being sold; larger quantities may attract better pricing. Additionally, fluctuations in global metal prices can impact local pricing, making it essential to stay informed about international market trends. -

What should I consider when selecting a supplier for alternator scrap?

When selecting a supplier for alternator scrap, consider their reputation, reliability, and compliance with local regulations. It’s advisable to check reviews and testimonials from other B2B buyers. Verify their sourcing methods to ensure they comply with ethical and environmental standards. Also, discuss terms related to pricing, minimum order quantities, and payment methods to ensure they align with your business needs. -

Are there minimum order quantities (MOQ) for purchasing alternator scrap?

Yes, many scrap suppliers have minimum order quantities (MOQ) that must be met to process an order. This can vary significantly between suppliers, so it’s important to clarify this upfront. If your needs are smaller, some suppliers may still accommodate you but at potentially higher pricing. Always inquire about flexibility in MOQs if you are unsure of your requirements. -

What payment terms are typically offered for alternator scrap purchases?

Payment terms for alternator scrap purchases can vary among suppliers. Common terms include payment upon delivery, net 30 days, or even cash on delivery. It’s crucial to negotiate terms that suit your cash flow and operational needs. Additionally, consider discussing any potential discounts for early payments or bulk purchases, as these can enhance your profitability. -

How can I ensure quality assurance (QA) when buying alternator scrap?

To ensure quality assurance when buying alternator scrap, request detailed specifications and certifications from the supplier regarding the quality of the materials. Conducting a pre-purchase inspection, if feasible, can help confirm the condition and quality of the scrap. Additionally, establishing a clear return policy in case the materials do not meet agreed standards can safeguard your interests. -

What are the logistics considerations for importing alternator scrap?

When importing alternator scrap, consider logistics factors such as shipping costs, customs regulations, and the time required for transportation. Ensure that your supplier is familiar with international shipping and can provide necessary documentation for customs clearance. It’s also wise to evaluate potential tariffs and taxes that may apply to your import, as these can significantly affect the total cost. -

How can I track market trends for alternator scrap pricing?

Tracking market trends for alternator scrap pricing can be achieved by subscribing to industry newsletters, following scrap metal market reports, and utilizing digital tools like pricing apps. Engaging in industry forums and networking with other buyers can also provide insights into market shifts. Regularly reviewing historical pricing data will help you make informed purchasing decisions based on trends and forecasts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Alternator Scrap Price Manufacturers & Suppliers List

1. iScrapApp – Alternators Scrap Price

Domain: iscrapapp.com

Registered: 2010 (15 years)

Introduction: Alternators Scrap Price: $0.39/lb (0.00% change) as of September 9, 2025. Recent price history includes: $0.40/lb in Dallas, Texas (8/4/25), $0.40/lb in Detroit, Michigan (4/12/25), $0.47/lb in Slidell, Louisiana (3/19/25), $0.22/lb in Middleboro, Massachusetts (3/18/25), $0.46/lb in Indianapolis, Indiana (3/10/25), $0.29/lb in Ottumwa, Iowa (3/3/25), $0.28/lb in Kamloops, British Columbia (2/26/2…

2. Reddit – Alternators Bulk Load

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Load of alternators, estimated weight around 2500 lbs, potential scrap value approximately $1800 at a rate of $0.72 per pound.

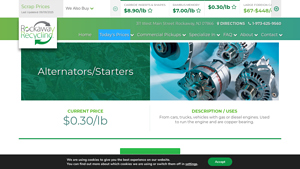

3. Rockaway Recycling – Copper Bearing Scrap

Domain: rockawayrecycling.com

Registered: 2007 (18 years)

Introduction: {“Current Price”:”$0.30/lb”,”Description”:”From cars, trucks, vehicles with gas or diesel engines. Used to run the engine and are copper bearing.”,”Location”:”311 West Main Street, Rockaway, NJ 07866″,”Contact”:”1-973-625-9560″,”Last Updated”:”09/09/2025″}

4. Ohio Drop Off – Scrap Metal Buying Services

Domain: ohiodropoff.com

Registered: 2005 (20 years)

Introduction: We buy scrap metal including aluminum, copper, brass, stainless steel, and more. We offer competitive pricing and convenient drop-off locations. Our services are available for both individuals and businesses.

5. DND Scrap Metal – Aluminum Products

Domain: dndscrapmetal.com

Registered: 2012 (13 years)

Introduction: Aluminum EC Wire, 1100 Aluminum, 3003 Aluminum Clips, 5052 Aluminum Clips, 6061 Sheet/Plate/Clip, 6061 Bare NP Extrusion, 6063 Bare Extrusion, 6063 Painted Aluminum, 6063 Breakage 95/5, MLC (no 2000/7000), Litho, Cast Aluminum, Painted Siding, MLC with Paint/Poly, Old Sheet/Road Signs, Alum Cans – Baled, Aluminum Radiators, Aluminum Radiators Breakage, ACSR (67%), ACSR (58%), Insulated Aluminum Wi…

6. Arrows Scrap – Copper Recycling

Domain: arrowscrap.com

Registered: 2003 (22 years)

Introduction: This company, Arrows Scrap – Copper Recycling, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Scrap Stop Metals – Alternators

Domain: myscrapstop.com

Registered: 2011 (14 years)

Introduction: Alternators are valued for their copper wire winding, with a typical scrap price of around 13 cents per pound. They have a steel casing similar to electric motors. Not all scrap yards accept alternators and starters, so it’s advisable to check local prices. Scrap Stop Metals offers fair prices and a quick service for scrapping these parts.

Strategic Sourcing Conclusion and Outlook for alternator scrap price

The fluctuating market for alternator scrap presents both challenges and opportunities for international buyers. With current prices averaging around $0.39 to $0.52 per pound, understanding regional price variations is crucial for maximizing profit margins. Buyers should prioritize establishing relationships with multiple scrap yards to ensure competitive pricing and to stay informed about market trends. Additionally, sourcing from regions with higher copper yields in alternators can further enhance profitability.

Strategic sourcing is essential in navigating the complexities of the scrap metal market. By leveraging data and insights on price fluctuations, buyers can make informed decisions that align with their procurement strategies. Furthermore, engaging with local scrap yards and utilizing technology, such as scrap price apps, can streamline the sourcing process.

Looking ahead, the demand for scrap metal, particularly from emerging markets in Africa, South America, and the Middle East, is expected to rise. Buyers are encouraged to take proactive steps in their sourcing strategies to capitalize on this growing demand. By doing so, they can secure advantageous positions in a competitive marketplace. Engage with local suppliers today to optimize your sourcing and ensure sustainability in your operations.