A Deep Dive into Where To Buy Resin Washed Stone Solution

Introduction: Navigating the Global Market for where to buy resin washed stone

In the ever-evolving landscape of construction and landscaping materials, sourcing high-quality resin washed stone presents a unique challenge for B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the need for durable, aesthetically pleasing, and environmentally sustainable surfacing solutions is paramount. This comprehensive guide serves as your definitive resource for identifying reputable suppliers, understanding the various types and applications of resin washed stone, and navigating the complexities of pricing and procurement.

Throughout this guide, we delve into critical aspects such as product specifications, supplier vetting processes, and cost considerations. You’ll gain insights into the performance characteristics that distinguish resin washed stone from other materials, including its permeability, durability, and aesthetic versatility. Additionally, we highlight best practices for installation and maintenance, ensuring that your investment yields long-lasting benefits.

By equipping international B2B buyers with actionable information and expert recommendations, this guide empowers you to make informed purchasing decisions that align with your project goals. Whether you’re looking to enhance outdoor spaces in urban environments or seeking sustainable options for residential developments, understanding where to buy resin washed stone can streamline your sourcing process and elevate your projects to new heights.

Understanding where to buy resin washed stone Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resin Bound Paving | Flexible, permeable surface; combines aggregate with resin | Driveways, pathways, public spaces | Pros: Durable, low maintenance; Cons: Initial cost can be high. |

| Resin Bonded Surfacing | Aggregate applied on top of resin layer; provides textured finish | Residential, commercial flooring | Pros: Aesthetic appeal, customizable; Cons: Less permeable than resin bound. |

| Epoxy Resin Flooring | High-strength, seamless finish; ideal for heavy-duty applications | Industrial, commercial spaces | Pros: Extremely durable; Cons: Can be slippery when wet. |

| Stone Carpet | Decorative surface of natural stone; DIY-friendly kits available | Patios, terraces, indoor flooring | Pros: Easy application, customizable; Cons: Requires proper weather for installation. |

| Glow-in-the-Dark Stones | Unique aesthetic with phosphorescent properties | Nighttime pathways, decorative installations | Pros: Eye-catching, enhances safety; Cons: Limited color options. |

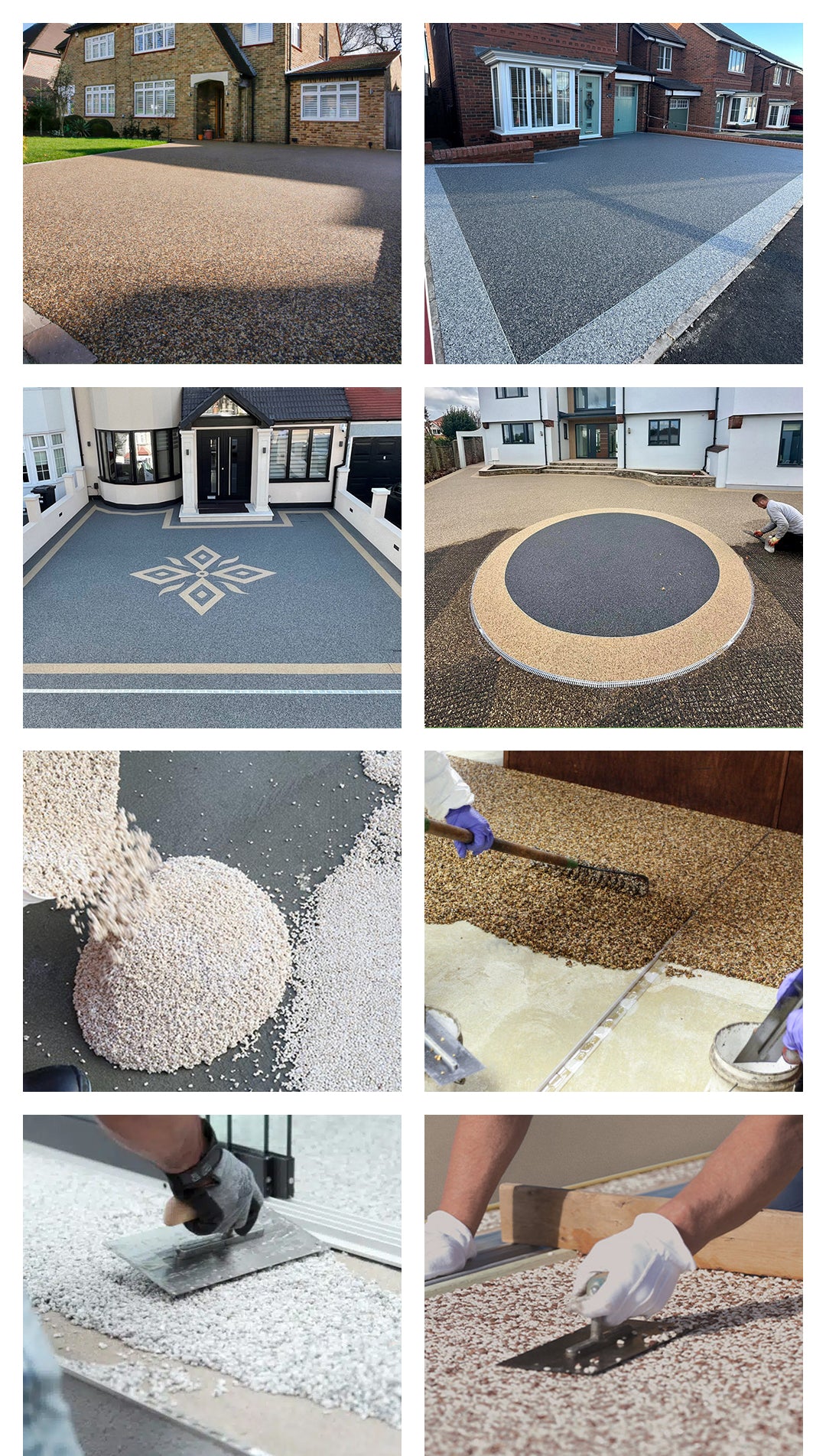

What are the Key Characteristics of Resin Bound Paving?

Resin bound paving is a popular choice for B2B buyers seeking a durable and aesthetically pleasing surface. This type combines natural aggregates with a clear resin binder, resulting in a flexible and permeable surface. It is particularly suitable for high-traffic areas such as driveways and public spaces due to its resilience and low maintenance requirements. Buyers should consider the initial investment, as the cost can be higher compared to traditional paving methods, but the long-term durability often justifies the expense.

How Does Resin Bonded Surfacing Differ from Resin Bound?

Resin bonded surfacing involves applying a layer of resin onto a prepared base, followed by scattering aggregates on top. This method provides a textured finish and is often used in residential and commercial flooring applications. It offers a high degree of customization in terms of color and texture, appealing to buyers looking for aesthetic enhancements. However, it is important to note that this type is less permeable compared to resin bound systems, which could be a consideration for areas prone to flooding.

What are the Benefits of Epoxy Resin Flooring in Industrial Applications?

Epoxy resin flooring is characterized by its seamless finish and exceptional strength, making it ideal for industrial and commercial environments where heavy machinery is used. This flooring type can withstand heavy loads and is resistant to chemical spills, which is crucial for manufacturing or warehouse settings. While it offers outstanding durability, buyers should be aware of its potential slipperiness when wet and consider applying anti-slip treatments for safety.

What Makes Stone Carpet an Attractive Option for Outdoor Spaces?

Stone carpet is a decorative and functional surface made from natural stones bound together with resin. This type is particularly appealing for patios and terraces, offering a DIY-friendly installation option. The customization potential allows buyers to create unique outdoor spaces that reflect their brand or aesthetic preferences. However, proper weather conditions are critical during installation, as the resin requires specific temperatures and dry conditions to cure effectively.

How Do Glow-in-the-Dark Stones Enhance Safety and Aesthetics?

Glow-in-the-dark stones are a unique variation that adds both safety and visual appeal to outdoor spaces. These stones absorb light during the day and emit a soft glow at night, making them ideal for pathways and decorative installations. While they can enhance nighttime visibility, buyers may find that the color options are somewhat limited. However, the distinctive look they provide can significantly enhance the overall ambiance of a space.

Key Industrial Applications of where to buy resin washed stone

| Industry/Sector | Specific Application of where to buy resin washed stone | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Landscaping | Decorative pathways and driveways | Enhances aesthetic appeal and property value | Local availability, durability under climate conditions |

| Retail & Hospitality | Outdoor flooring for commercial spaces | Creates inviting environments that attract customers | Slip resistance, easy maintenance, and design versatility |

| Infrastructure & Urban Development | Permeable paving for streets and public spaces | Improves drainage and reduces flooding risks | Compliance with local regulations, environmental sustainability |

| Residential Property | Pool surrounds and garden areas | Increases safety and enhances outdoor living spaces | UV stability, frost resistance, and design customization |

| Sports & Recreation | Surface for sports courts and recreational areas | Provides safe, durable surfaces for various activities | Impact resistance, maintenance requirements, and color options |

How is Resin Washed Stone Used in Construction and Landscaping Projects?

In the construction and landscaping sectors, resin washed stone is frequently utilized for creating decorative pathways and driveways. This application not only enhances the aesthetic appeal of residential and commercial properties but also increases their overall value. Buyers in these sectors should consider the local availability of materials and the stone’s durability against regional climate conditions, ensuring long-term performance and minimal maintenance.

What Role Does Resin Washed Stone Play in Retail and Hospitality?

For retail and hospitality industries, resin washed stone is an ideal choice for outdoor flooring in commercial spaces. It creates inviting environments that attract customers and enhance their experience. Key considerations for sourcing include ensuring the material has slip-resistant properties, is easy to maintain, and offers a variety of design options to align with branding and ambiance requirements.

How is Resin Washed Stone Beneficial in Infrastructure Development?

In infrastructure and urban development, resin washed stone is often used for permeable paving in streets and public spaces. This application significantly improves drainage and reduces flooding risks, which is critical in urban planning. Buyers must ensure compliance with local regulations and prioritize environmentally sustainable options, as these factors can influence project approval and success.

Why Choose Resin Washed Stone for Residential Properties?

Residential properties benefit from resin washed stone in applications such as pool surrounds and garden areas. This material increases safety by providing a non-slip surface and enhances the outdoor living experience. International buyers should focus on sourcing options that offer UV stability and frost resistance, as well as customization opportunities to suit personal design preferences.

How is Resin Washed Stone Used in Sports and Recreational Facilities?

In sports and recreation, resin washed stone serves as a surface for courts and recreational areas, offering durability and safety for various activities. When sourcing this material, businesses should consider its impact resistance, maintenance requirements, and the availability of color options to meet specific sporting needs. This ensures that the surface not only performs well but also meets aesthetic standards for the facility.

3 Common User Pain Points for ‘where to buy resin washed stone’ & Their Solutions

Scenario 1: Sourcing Quality Resin Washed Stone for Diverse Projects

The Problem: B2B buyers often struggle with sourcing high-quality resin washed stone that meets specific project requirements. Whether for landscaping, construction, or decorative purposes, the quality of stone can greatly impact the final product’s aesthetic and durability. Buyers may encounter issues with inconsistent quality, limited supplier options, or suppliers who do not meet their specific regional standards. This can lead to project delays, increased costs, and ultimately, dissatisfaction with the final result.

The Solution: To overcome these challenges, buyers should establish a robust vetting process for suppliers. Start by identifying reputable distributors known for their quality control standards. Engage in direct conversations to discuss product specifications, including stone size, color, and resin composition. Additionally, request samples before committing to large orders; this allows you to assess the material’s quality firsthand. Utilize online platforms and industry forums to gather feedback from other buyers about their experiences with suppliers. This proactive approach ensures that you source resin washed stone that aligns with your project needs, reducing the risk of costly mistakes.

Scenario 2: Navigating Import Regulations for Resin Washed Stone Purchases

The Problem: International buyers, particularly those from regions like Africa and South America, often face complex import regulations when purchasing resin washed stone. Different countries have varying standards for construction materials, including environmental regulations and quality certifications. Navigating this maze can be daunting, leading to potential delays in shipment, unexpected costs, and legal complications that can derail projects.

The Solution: To efficiently navigate these challenges, buyers should familiarize themselves with the import regulations specific to their country. This includes understanding necessary certifications, customs duties, and potential tariffs. Collaborating with a logistics expert or a freight forwarder experienced in handling construction materials can streamline the process. They can provide valuable insights into the required documentation and help ensure compliance with local regulations. Additionally, consider partnering with suppliers who have experience exporting to your region, as they can offer guidance on meeting local standards and expedite the importation process.

Scenario 3: Ensuring Effective Installation of Resin Washed Stone

The Problem: Even after successfully sourcing resin washed stone, B2B buyers may encounter installation issues that can compromise the integrity of the surface. Improper installation techniques or lack of trained personnel can lead to uneven surfaces, poor drainage, or premature wear. These issues can result in costly repairs and diminished customer satisfaction, particularly in competitive markets where quality and performance are paramount.

The Solution: To mitigate installation risks, it is essential to invest in training for your installation teams or partner with certified installers who specialize in resin washed stone. Many suppliers offer training programs or resources that provide detailed installation guidelines. Encourage your team to participate in these training sessions to ensure they are equipped with the latest techniques and best practices. Additionally, consider utilizing a resin binding product that is suited for your specific climate conditions, as this can enhance the longevity and performance of the installation. By prioritizing proper installation, you can significantly reduce long-term maintenance costs and improve customer satisfaction, solidifying your reputation in the market.

Strategic Material Selection Guide for where to buy resin washed stone

What Are the Key Materials for Buying Resin Washed Stone?

When considering where to buy resin washed stone, it’s crucial to evaluate the materials involved in its production. This analysis will focus on four common materials used in resin washed stone applications: natural stone aggregates, epoxy resins, polyurethane resins, and glass aggregates. Each material has unique properties, advantages, and limitations that can significantly impact the final product’s performance and suitability for various applications.

What Are the Key Properties of Natural Stone Aggregates?

Natural stone aggregates, such as granite, marble, and limestone, are often used in resin washed stone applications. These materials are known for their durability and aesthetic appeal. Key properties include high compressive strength and resistance to weathering, making them suitable for outdoor applications. However, natural stone can be heavy and may require specific handling and installation techniques.

Pros:

– Excellent durability and aesthetic quality.

– High resistance to weathering and UV exposure.

Cons:

– Higher transportation costs due to weight.

– Limited color options compared to synthetic aggregates.

For international buyers, it’s essential to consider local sourcing options to minimize costs and ensure compliance with regional standards. Many countries have specific regulations regarding the use of natural stone, which may affect sourcing decisions.

How Do Epoxy Resins Perform in Resin Washed Stone Applications?

Epoxy resins are a popular choice for binding aggregates in resin washed stone applications due to their excellent adhesion and chemical resistance. They provide a strong, durable finish that can withstand varying temperatures and environmental conditions.

Pros:

– Superior bonding strength and resistance to chemicals.

– Versatile application methods, including troweling and pouring.

Cons:

– Higher initial cost compared to other binders.

– Curing time can be affected by temperature and humidity.

For buyers in regions with extreme weather conditions, selecting a UV-stabilized epoxy resin is critical to ensure longevity and performance. Compliance with international standards like ASTM can also influence the choice of epoxy used.

What Are the Advantages of Polyurethane Resins?

Polyurethane resins are increasingly favored for their flexibility and durability. They offer excellent resistance to abrasion and can accommodate slight movements in the substrate, making them ideal for areas with variable temperatures.

Pros:

– High flexibility and impact resistance.

– Good UV stability and low maintenance requirements.

Cons:

– Generally more expensive than epoxy resins.

– Potential for yellowing over time if not properly formulated.

For international buyers, understanding local regulations regarding chemical use is vital. Polyurethane resins may require specific certifications in some regions, particularly in Europe and North America.

How Do Glass Aggregates Enhance Resin Washed Stone?

Glass aggregates, often used for decorative purposes, can add unique visual appeal to resin washed stone applications. They are available in various colors and sizes, allowing for customization.

Pros:

– Aesthetic versatility with a wide range of colors.

– Lightweight, reducing transportation costs.

Cons:

– Lower compressive strength compared to natural stone.

– Potentially higher cost due to processing.

International buyers should consider the availability of glass aggregates in their regions, as sourcing may vary significantly. Additionally, ensuring compliance with safety standards is crucial, especially in applications where slip resistance is a concern.

Summary Table of Material Selection for Resin Washed Stone

| Material | Typical Use Case for where to buy resin washed stone | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Stone Aggregates | Driveways, pathways, and outdoor landscaping | Excellent durability and aesthetic quality | Higher transportation costs | Medium |

| Epoxy Resins | Indoor and outdoor surfaces requiring strong bonds | Superior bonding strength | Higher initial cost | High |

| Polyurethane Resins | Areas with temperature fluctuations | High flexibility and impact resistance | Generally more expensive | High |

| Glass Aggregates | Decorative applications in landscaping and flooring | Aesthetic versatility | Lower compressive strength | Medium |

This strategic material selection guide provides essential insights for international B2B buyers looking to purchase resin washed stone. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for where to buy resin washed stone

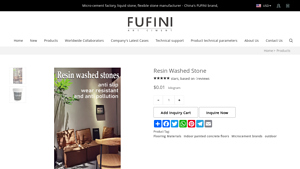

What Are the Key Stages in the Manufacturing Process of Resin Washed Stone?

The manufacturing process for resin washed stone typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the quality and durability of the final product, which is essential for B2B buyers looking for reliable supplies.

Material Preparation: This initial phase includes sourcing high-quality aggregates, such as natural stones, gravel, or glass. The selection of materials is vital, as it directly impacts the aesthetic and functional properties of the resin washed stone. Suppliers often perform tests to ensure the aggregates meet specific standards, including size, shape, and purity.

Forming: Once the materials are prepared, they are mixed with a high-performance resin. This mixture is crucial for achieving the desired texture and strength. Techniques such as wet mixing and dry mixing are employed, depending on the specific product requirements. For instance, wet mixing allows for a more uniform distribution of resin throughout the aggregates, enhancing the overall integrity of the stone.

Assembly: After forming, the mixture is applied to a substrate, typically using specialized equipment to ensure a consistent layer thickness. This step is essential for achieving the desired finish and ensuring the longevity of the surface. The application can be done manually or through automated systems, depending on the scale of production.

Finishing: The final phase involves curing the resin, which can take several hours to days, depending on the type of resin and environmental conditions. Proper curing is critical, as it affects the durability and performance of the resin washed stone. Additional finishing techniques may include polishing or sealing to enhance appearance and protect against environmental factors.

How Is Quality Assurance Implemented in Resin Washed Stone Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process for resin washed stone, ensuring that products meet international and industry-specific standards. B2B buyers must be aware of these quality control measures to make informed purchasing decisions.

Relevant International Standards: Manufacturers often adhere to ISO 9001, which outlines criteria for a quality management system. Compliance with this standard demonstrates a commitment to quality and continuous improvement. Additionally, certifications like CE mark indicate that products meet EU safety, health, and environmental protection standards, which can be particularly relevant for buyers in Europe.

Quality Control Checkpoints: Key checkpoints in the quality control process include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials upon arrival to ensure they meet specified requirements before production begins.

- IPQC monitors the manufacturing process in real-time, allowing for immediate corrections if issues arise.

- FQC assesses the final product to ensure it meets all quality standards before shipping.

What Common Testing Methods Are Used in Quality Assurance for Resin Washed Stone?

To ensure product integrity, manufacturers employ various testing methods throughout the production process. Common tests include:

- Compression Strength Tests: These tests evaluate the load-bearing capacity of the resin washed stone, essential for applications in high-traffic areas.

- Adhesion Tests: These assess the bond strength between the aggregates and resin, ensuring durability and resistance to delamination.

- Water Permeability Tests: Particularly important for permeable paving solutions, these tests determine how well the product allows water to pass through, impacting drainage and environmental sustainability.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify the quality control measures of suppliers. This can include:

- Audits: Conducting on-site audits of manufacturing facilities to assess compliance with quality standards and practices.

- Quality Reports: Requesting detailed quality reports that outline testing results and compliance with international standards.

- Third-Party Inspections: Engaging independent inspectors to evaluate manufacturing processes and product quality. This adds an extra layer of assurance, particularly for international transactions.

What Are the Quality Control Nuances for International B2B Buyers in Regions Like Africa, South America, the Middle East, and Europe?

International buyers often face unique challenges regarding quality control, especially when sourcing from different regions.

- Cultural Differences: Understanding local practices and standards is crucial. For example, suppliers in Africa may have different certifications than those in Europe, impacting product acceptance.

- Regulatory Compliance: Buyers must be aware of the regulatory landscape in their respective regions. Products must meet local building codes and environmental regulations, which can vary significantly.

- Logistics and Supply Chain Management: Ensuring that quality is maintained throughout the supply chain is essential. This includes verifying that transportation methods do not compromise product integrity.

Conclusion

For international B2B buyers, understanding the manufacturing processes and quality assurance measures associated with resin washed stone is critical. By familiarizing themselves with each stage of production and the relevant quality control standards, buyers can make informed decisions that ensure they receive high-quality products tailored to their specific needs. Investing time in verifying suppliers through audits, reports, and third-party inspections will further enhance buyer confidence in their sourcing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘where to buy resin washed stone’

In the world of construction and landscaping, sourcing resin washed stone efficiently is essential for ensuring project success. This guide serves as a practical checklist for B2B buyers looking to procure high-quality resin washed stone for various applications. By following these steps, you can streamline your sourcing process and make informed decisions.

Step 1: Define Your Project Requirements

Before you begin sourcing, clearly outline your project specifications. Consider the type of resin washed stone you need, including color, size, and texture. Understanding your project requirements helps narrow down potential suppliers and ensures you select materials that align with your design vision.

- Key Considerations:

- Intended use (e.g., pathways, driveways, decorative features).

- Environmental conditions (e.g., frost resistance, UV stability).

Step 2: Research Potential Suppliers

Thorough research is critical to finding reliable suppliers. Look for companies with a strong reputation in the industry, particularly those that specialize in resin washed stone. Utilize industry directories, online marketplaces, and trade shows to identify potential vendors.

- Tips for Research:

- Review online reviews and testimonials.

- Check for industry awards or recognitions.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and quality standards. A reputable supplier should have relevant certifications that demonstrate adherence to industry standards, such as ISO or environmental management certifications.

- What to Look For:

- Product safety certifications.

- Compliance with local and international regulations.

Step 4: Request Samples and Product Specifications

Once you have identified potential suppliers, request samples of their resin washed stone products. This allows you to assess the quality and suitability of the materials for your project. Additionally, obtain detailed product specifications, including technical data sheets.

- Important Aspects:

- Assess the aesthetic appeal and physical properties of samples.

- Confirm that specifications meet your project requirements.

Step 5: Compare Pricing and Terms

Price is a significant factor in procurement, but it should not be the only consideration. Request quotes from multiple suppliers and compare not only the pricing but also the terms of service, including delivery schedules and payment options.

- Considerations for Comparison:

- Bulk pricing discounts.

- Warranty and return policies.

Step 6: Assess Customer Service and Support

Reliable customer service can make a significant difference in your procurement experience. Evaluate how responsive and helpful potential suppliers are during your initial communications. A supplier that provides excellent support is likely to be more reliable throughout the project lifecycle.

- Key Indicators:

- Response times to inquiries.

- Availability of expert consultation for installation or application.

Step 7: Finalize the Order and Establish Communication Channels

After selecting a supplier, finalize your order with clear communication regarding delivery dates, payment terms, and any other expectations. Establish a point of contact for ongoing communication to address any issues that may arise during the procurement process.

- Communication Tips:

- Confirm order details in writing.

- Set up regular check-ins to monitor progress.

By following this checklist, B2B buyers can effectively navigate the sourcing process for resin washed stone, ensuring they secure high-quality materials that meet their project needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for where to buy resin washed stone Sourcing

What Are the Key Cost Components of Sourcing Resin Washed Stone?

When sourcing resin washed stone, understanding the cost structure is vital for effective budgeting. The primary cost components include:

-

Materials: The type of resin and stone used significantly influences cost. High-quality, UV-stabilized resins and premium natural stones may incur higher upfront costs but offer durability and aesthetic appeal.

-

Labor: Installation labor is a critical factor, especially for specialized applications like permeable paving or decorative surfacing. Skilled labor often commands higher wages, impacting overall project costs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can help mitigate these expenses.

-

Tooling: Initial investments in tools and equipment for installation can be substantial. However, these costs are often amortized over multiple projects.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to costs but is essential for maintaining standards and customer satisfaction.

-

Logistics: Transportation costs vary based on distance, shipping methods, and Incoterms. For international buyers, customs duties and import tariffs can also affect pricing.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margins, which can vary significantly based on market dynamics and competition.

How Do Price Influencers Affect the Cost of Resin Washed Stone?

Several factors can influence the pricing of resin washed stone, making it crucial for buyers to be aware of these dynamics:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Minimum order quantities can impact pricing, especially for smaller projects.

-

Specifications and Customization: Custom blends of stones or specific resin formulations can lead to increased costs. Buyers should define their requirements clearly to avoid unexpected price hikes.

-

Materials: The choice of stone and resin types can vary widely in price. Premium materials will increase costs but may offer better performance and longevity.

-

Quality and Certifications: Products with recognized quality certifications may carry a higher price tag but provide assurance of compliance with industry standards.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their experience and service levels.

-

Incoterms: Understanding shipping terms is essential. Different Incoterms (like FOB, CIF) affect who bears shipping costs, insurance, and responsibilities, influencing the total landed cost.

What Are the Best Buyer Tips for Cost-Efficiency in Resin Washed Stone Sourcing?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider several strategies for cost-efficient sourcing:

-

Negotiation: Engage in discussions with suppliers to explore pricing flexibility. Bulk purchases or long-term contracts can provide leverage for better terms.

-

Total Cost of Ownership (TCO): Evaluate the overall costs associated with the product, including installation, maintenance, and lifespan. A higher initial price may be offset by lower long-term maintenance costs.

-

Pricing Nuances for International Transactions: Be aware of currency fluctuations, shipping delays, and import regulations that can affect pricing. Establishing strong relationships with local distributors can mitigate some risks.

-

Market Research: Conduct thorough research to compare pricing and product offerings across different suppliers. This can help identify the best value for your specific needs.

Disclaimer for Indicative Prices

Prices for resin washed stone can vary widely based on the aforementioned factors. The figures provided are indicative and subject to change based on market conditions, supplier pricing strategies, and international shipping costs. Always request detailed quotes from multiple suppliers to ensure you receive the best possible pricing for your specific requirements.

Alternatives Analysis: Comparing where to buy resin washed stone With Other Solutions

Introduction: Exploring Alternatives to Resin Washed Stone

When considering the procurement of resin washed stone, B2B buyers should assess viable alternatives that may meet their specific project requirements more effectively or economically. This analysis evaluates resin washed stone against other surfacing solutions, helping buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Where To Buy Resin Washed Stone | Alternative 1: Resin Bound Paving | Alternative 2: Concrete Pavers |

|---|---|---|---|

| Performance | High durability and aesthetic appeal; weather-resistant | Highly durable; permeable surface that allows water drainage | Durable but less permeable; aesthetic variations available |

| Cost | Moderate to high; varies by supplier | Moderate; competitive pricing | Generally lower cost; varies with materials and design |

| Ease of Implementation | Requires professional installation; specific curing time needed | Can be DIY or professional; less curing time | Straightforward installation; DIY-friendly |

| Maintenance | Low maintenance; occasional cleaning needed | Low maintenance; some periodic re-sealing required | Moderate; may require joint filling and sealing |

| Best Use Case | High-end residential or commercial spaces requiring aesthetics | Commercial and residential areas with drainage needs | High-traffic areas needing robust surfaces |

Detailed Breakdown of Alternatives

Alternative 1: Resin Bound Paving

Resin bound paving is a popular choice among B2B buyers looking for a durable and aesthetically pleasing surface. This method involves combining resin with aggregates, creating a seamless and permeable surface that can manage water drainage effectively. Its performance is commendable, particularly in environments prone to heavy rainfall, making it ideal for commercial applications and public spaces. However, while it offers ease of installation, it may require periodic resealing to maintain its appearance and functionality.

Alternative 2: Concrete Pavers

Concrete pavers are a cost-effective alternative that provides versatility in design and durability. They are well-suited for high-traffic areas, making them an excellent option for commercial developments, pedestrian pathways, and driveways. The installation process is straightforward, allowing for DIY projects, which can reduce labor costs. However, while concrete pavers are durable, they may require more maintenance over time compared to resin-bound surfaces, especially regarding joint filling and sealing to prevent weed growth.

Conclusion: Making the Right Choice for Your Project

Selecting the right surfacing solution involves careful consideration of specific project needs, budget constraints, and desired aesthetics. Buyers should weigh the long-term performance and maintenance requirements of each option. For projects prioritizing aesthetics and permeability, resin washed stone or resin bound paving may be preferable. Conversely, for budget-conscious projects that require durability and ease of installation, concrete pavers present a viable alternative. Ultimately, understanding the unique advantages and disadvantages of each option will empower B2B buyers to make strategic decisions that align with their project objectives.

Essential Technical Properties and Trade Terminology for where to buy resin washed stone

What Are the Key Technical Properties of Resin Washed Stone?

Understanding the technical properties of resin washed stone is crucial for B2B buyers in order to make informed purchasing decisions. Here are some essential specifications:

-

Material Grade

Material grade refers to the quality and composition of the stones used in resin washed surfaces. High-grade materials ensure durability, aesthetics, and resistance to environmental factors. In B2B transactions, specifying material grade helps buyers ensure they receive products that meet their project requirements and longevity expectations. -

Tolerance Levels

Tolerance levels indicate the acceptable variations in size and shape of the stones. For instance, a tolerance of ±5mm ensures that the stones fit well together, which is critical for achieving a seamless finish. In the B2B context, understanding tolerance levels can help buyers assess the precision of the manufacturing process, affecting installation efficiency and overall project success. -

Permeability

This property measures how well water can pass through the resin washed surface. High permeability is essential for outdoor applications where drainage is necessary to prevent water pooling. Buyers should prioritize permeability ratings to ensure compliance with local regulations and environmental standards, especially in regions prone to heavy rainfall. -

UV Stability

UV stability refers to the material’s resistance to degradation from ultraviolet light exposure. This is particularly important for outdoor installations, as UV exposure can lead to fading and brittleness over time. B2B buyers must consider UV stability to ensure the longevity and aesthetic appeal of their projects, especially in sunny climates. -

Load-Bearing Capacity

This property defines how much weight the resin washed stone can support without deformation. It is crucial for applications such as driveways or pathways. Understanding load-bearing capacity helps buyers select the right products for specific uses, ensuring safety and durability. -

Weather Resistance

Weather resistance encompasses a range of factors, including frost resistance, moisture absorption, and temperature fluctuations. Products that can withstand various weather conditions are vital for outdoor applications. B2B buyers should inquire about weather resistance to ensure that the materials will perform reliably over time.

What Are Common Trade Terms in the Resin Washed Stone Industry?

Familiarity with industry jargon can significantly streamline B2B transactions. Here are some important terms:

-

OEM (Original Equipment Manufacturer)

In the context of resin washed stone, OEM refers to companies that produce components that can be branded by another company. Buyers should understand OEM relationships to ensure they are sourcing high-quality materials from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest amount of product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to plan their purchases effectively and avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific quantities of products. This is an essential step in the procurement process, allowing buyers to compare offers and make informed decisions. -

Incoterms

Incoterms are a series of international commercial terms that define the responsibilities of buyers and sellers in shipping agreements. Understanding these terms is vital for B2B buyers to clarify who is responsible for shipping costs, insurance, and risk during transportation. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the resin washed stone industry, lead times can vary significantly based on sourcing and production capabilities. Buyers should factor in lead times when planning project timelines. -

Sustainability Certification

This term refers to certifications that indicate a product meets specific environmental standards. For businesses focused on sustainability, understanding these certifications can influence purchasing decisions and enhance brand reputation.

By grasping these technical properties and industry terms, B2B buyers can navigate the resin washed stone market more effectively, ensuring they select the right products for their needs while fostering strong supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the where to buy resin washed stone Sector

What Are the Current Market Dynamics and Key Trends Influencing the Resin Washed Stone Sector?

The resin washed stone sector is experiencing notable growth, driven by a surge in demand for aesthetically pleasing and durable surfacing materials in both residential and commercial applications. Key global drivers include urbanization, increased construction activities, and a growing preference for sustainable landscaping solutions. Notably, regions like Africa and the Middle East are investing heavily in infrastructure, spurring demand for innovative surfacing options. In South America and Europe, the focus on eco-friendly products is reshaping purchasing decisions, making environmentally responsible sourcing a priority for B2B buyers.

Emerging B2B technology trends also play a significant role in shaping the market. The rise of e-commerce platforms has simplified the sourcing process, enabling buyers from various regions to access a broader range of suppliers and products. Additionally, advancements in supply chain management technologies, such as blockchain, are enhancing transparency and traceability in the procurement of resin washed stone. These technologies allow buyers to verify the authenticity and sustainability of materials, which is increasingly important in today’s market.

How Does Sustainability and Ethical Sourcing Impact the Purchase of Resin Washed Stone?

Sustainability and ethical sourcing are paramount considerations for B2B buyers in the resin washed stone sector. The environmental impact of materials used in construction and landscaping cannot be overlooked; thus, many companies are prioritizing the use of recycled and sustainably sourced materials. Buyers are increasingly seeking products that not only meet their aesthetic needs but also align with their corporate social responsibility goals.

The importance of ethical supply chains is underscored by the growing consumer demand for transparency. Buyers are now inclined to partner with suppliers who provide certifications indicating that their products meet sustainability standards. Certifications such as ISO 14001 for environmental management systems and various green building certifications (e.g., LEED) are becoming critical in the decision-making process. Furthermore, utilizing materials that are low in VOCs (volatile organic compounds) and other harmful substances ensures compliance with health and safety regulations, further bolstering a company’s reputation in the marketplace.

What Is the Evolution of Resin Washed Stone and Its Relevance to Today’s B2B Buyers?

The evolution of resin washed stone can be traced back to the increasing demand for durable yet visually appealing surfacing options in the late 20th century. Originally developed as a solution for enhancing the aesthetics of concrete surfaces, resin washed stone has gained popularity due to its versatility and adaptability in various applications, including driveways, patios, and commercial spaces.

As the market has matured, innovation in resin formulations and application techniques has led to the development of products that are not only more durable but also environmentally friendly. This evolution is particularly relevant for B2B buyers today, as they seek to invest in long-lasting materials that offer a competitive edge in both functionality and design. Understanding the historical context of resin washed stone helps buyers appreciate the advancements in technology and sustainability that define the sector today, making informed sourcing decisions that align with modern market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of where to buy resin washed stone

-

How do I find reliable suppliers of resin washed stone?

To find reliable suppliers of resin washed stone, start by conducting thorough online research using B2B marketplaces such as Alibaba, Global Sources, and Made-in-China. Look for suppliers with verified status, positive customer reviews, and a solid track record in international trade. Networking within industry-specific forums and attending trade shows can also yield valuable contacts. Finally, consider reaching out to industry associations for recommendations on reputable suppliers. -

What is the best type of resin washed stone for outdoor applications?

For outdoor applications, permeable resin washed stone is often the best choice due to its drainage capabilities, which prevent water pooling and reduce slip hazards. Look for products that are UV-stable and frost-resistant to ensure durability against various weather conditions. Additionally, consider the aesthetic appeal and color options available, as this can enhance the visual impact of your project. -

What customization options are available for resin washed stone?

Many suppliers offer customization options for resin washed stone, including color blends, stone sizes, and finishes. Some manufacturers allow you to create bespoke mixes tailored to your project requirements, enabling unique designs. Always inquire about the minimum order quantities (MOQs) for custom orders, as these can vary significantly between suppliers. -

What are the typical minimum order quantities (MOQs) for resin washed stone?

MOQs for resin washed stone can vary based on the supplier and the specific product. Generally, you can expect MOQs to range from 1 ton to several tons for standard products. For customized orders, MOQs may be higher due to the need for specific materials and production runs. Always clarify MOQs with your supplier before placing an order to ensure it aligns with your project needs. -

What payment terms should I expect when buying resin washed stone internationally?

Payment terms can vary by supplier and location, but common practices include upfront payments, 30% deposits with the balance due before shipping, or payment via letter of credit. It’s essential to negotiate payment terms that mitigate your financial risk while ensuring the supplier’s confidence in fulfilling the order. Always request a proforma invoice to outline terms clearly before proceeding with any transactions. -

How can I ensure quality assurance when sourcing resin washed stone?

To ensure quality assurance, request detailed product specifications, including material certifications and compliance with relevant standards. Many suppliers will provide samples for testing before you commit to larger orders. It’s also wise to conduct factory visits or hire third-party inspection services to verify product quality and manufacturing practices before shipping. -

What logistics considerations should I keep in mind when importing resin washed stone?

When importing resin washed stone, consider shipping methods, customs clearance, and potential tariffs or taxes. Choose a reliable freight forwarder who can handle the logistics, including packing, shipping, and delivery to your location. Understand the lead times involved, as resin washed stone may require specific handling during transport. Always ensure that your supplier provides the necessary documentation for customs clearance. -

How do I handle disputes with international suppliers of resin washed stone?

To handle disputes with international suppliers, it’s crucial to maintain clear communication and document all agreements in writing. If issues arise, address them promptly through direct discussions. Utilize mediation services if informal discussions do not resolve the matter. If necessary, refer to the terms outlined in your contract regarding dispute resolution, which may include arbitration or legal proceedings in a mutually agreed jurisdiction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Where To Buy Resin Washed Stone Manufacturers & Suppliers List

1. EPODEX – Stone Carpet DIY Kit

Domain: epodex.us

Registered: 2020 (5 years)

Introduction: EPODEX’s Stone Carpet – DIY kit for easy-to-apply outdoor natural stone flooring. Starting price: $27.99. Features: frost and weather-resistant, UV stabilized, odorless, BPA-free. Suitable materials: natural stones, glass, marble, granite, etc. Recommended application temperature: around 70°F, with no rain forecast for a week. Curing time: at least one day before use. Customer satisfaction: 4.78/5…

2. Paramount Materials – Gravel-Lok Stone Binder

Domain: paramountmaterials.com

Registered: 2017 (8 years)

Introduction: Gravel-Lok for Driveways and Walkways is a polyurethane-based stone binder designed to keep gravel in place, creating a strong, porous surface. It is available in two formulas: Clear and Amber, in sizes of 1 gallon, 5 gallons, and 50 gallons. The Clear formula is colorless or light yellow, ideal for white or light-colored stones, while the Amber formula may change the color of white stones. Benefi…

3. Accio – Resin Washed Stone Flooring Solutions

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Resin Washed Stone: Waterproof & Weather-Resistant Flooring Solutions; Manufacturer: Various including Guangdong Maydos Building Materials Limited Company, Hubei Greenway New Construction Material Technology Co., Ltd., Guangdong Huaren Chemical Industry Co., Ltd.; Price Range: $0.28 – $28; Minimum Order Quantities: 1 kilogram to 1000 kilograms; Reorder Rates: Ranging from 5% to 56%; Delivery Estim…

4. Fufini – Resin Washed Stone

Domain: fufini-microcement.com

Registered: 2024 (1 years)

Introduction: Product Name: Resin Washed Stone

Price: $0.01 per kilogram

Availability: 2147483647 items available

Key Features:

1. Simple Construction: Increases construction efficiency by about 40%, with an ordinary skilled worker completing about 120 square meters per day.

2. Anti-slip and Abrasion-resistant: Anti-slip coefficient above 0.7; withstands over 50,000 abrasion cycles.

3. Durable: Stable physical …

5. Annran – Resin-Washed Stone Pebble Stone

Domain: stonecontact.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Resin-Washed Stone Pebble Stone”, “Origin”: “China”, “Material Type”: “Gold – Sandstone”, “Grade”: “A”, “Size”: “2*8*3 cm”, “Surface Finish”: “Polished”, “Minimum Order”: “1000 Square Meters”, “FOB Price”: “$10-56/Square Meter”, “Supplier Name”: “Annran”, “Established”: “Jan 04, 2005”, “Main Products”: [“Volcanic Stone”, “Resin-washed Stone”, “Volcanic Stone Slabs”, “Iron Oxide P…

6. Stoneset – Stone & Resin Bound Paving Kits

Domain: stoneset.com.au

Introduction: Stone & Resin Bound Paving Kits are pre-weighed kits that include either 3mm or 6mm stone and a single part resin. The kits are designed for DIY use, allowing customers to mix and lay the product easily. Available stone colors include Ash, Beach, Evergreen, Glensanda, Kaikōura, Koonunga, Pearl, Pitch Black, Southern Value, Southern White, Sterling, Tan, Tarawera Yellow, and Sienna. Prices for the …

Strategic Sourcing Conclusion and Outlook for where to buy resin washed stone

In the quest for resin washed stone, strategic sourcing emerges as a pivotal element for international B2B buyers. By identifying reputable suppliers across various regions, such as North America and Europe, buyers can access high-quality materials that meet their specific project needs. Key factors to consider include product quality, supplier reliability, and the potential for long-term partnerships. Engaging with distributors who offer comprehensive support, training, and consultation can enhance the procurement process, ensuring that businesses are well-equipped to implement resin-bound solutions effectively.

Moreover, the shift towards environmentally sustainable materials has made sourcing from ethical suppliers increasingly important. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for innovative and durable surfacing options will only grow.

Looking ahead, B2B buyers are encouraged to explore diverse sourcing avenues and leverage emerging trends in the resin washed stone sector. By investing in strategic partnerships and staying informed about industry developments, businesses can position themselves for success in this dynamic market. Embrace the opportunity to enhance your projects with superior resin washed stone and unlock new possibilities for growth.