A Deep Dive into Hesco Barrier For Sale Solution

Introduction: Navigating the Global Market for hesco barrier for sale

In an increasingly volatile world, sourcing effective protective solutions like Hesco barriers for sale has become a critical challenge for international B2B buyers. Whether for military applications, humanitarian efforts, or infrastructure protection, the demand for reliable, robust, and quickly deployable barriers is at an all-time high. This comprehensive guide addresses the diverse types of Hesco barriers available, their various applications—from troop fortifications to flood control—and essential factors to consider when selecting a supplier.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in navigating this global market. Understanding local regulations, logistical concerns, and cost implications is essential for making informed purchasing decisions. This guide not only outlines the different specifications and customization options available but also offers insights into the vetting process for suppliers, ensuring that buyers can confidently identify the best partners for their needs.

By equipping B2B buyers with actionable information on pricing, quality assurance, and the latest innovations in barrier technology, this guide empowers them to make strategic decisions that protect their investments and enhance their operational capabilities. With a focus on practicality and reliability, readers will gain a clearer understanding of how to effectively navigate the complexities of sourcing Hesco barriers in today’s dynamic marketplace.

Understanding hesco barrier for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mil Series | Military-grade, collapsible design; various sizes available | Military, humanitarian, disaster response | Pros: High durability, rapid deployment. Cons: Higher cost compared to civilian options. |

| Flood Barrier | Specifically designed to resist water; deployable in minutes | Flood control, disaster management | Pros: Effective in water management. Cons: Limited use in non-flood scenarios. |

| Guard Post | Provides protection from blasts and ballistic threats | Security installations, military bases | Pros: Enhanced safety for personnel. Cons: Requires more space for installation. |

| Accommodation Bunker | Offers overhead blast protection; modular design | Military housing, emergency shelters | Pros: Safe living quarters in conflict zones. Cons: Higher logistical requirements. |

| Custom Solutions | Tailored sizes and materials based on project needs | Specialized defense, unique applications | Pros: Fully adaptable to specific needs. Cons: Longer lead times for production. |

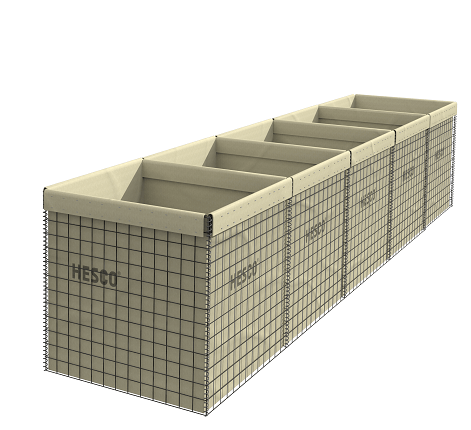

What are the Key Features and Applications of the Mil Series Hesco Barriers?

The Mil Series Hesco barriers are designed for military and defense applications, characterized by their collapsible wire mesh structure that can be filled with soil or gravel. They are available in various sizes, allowing for flexibility in deployment based on operational requirements. This series is particularly suitable for military bases and humanitarian efforts where rapid assembly and high durability are critical. Buyers should consider the initial investment, as these barriers tend to be pricier than civilian-grade options, but their longevity and effectiveness justify the cost.

How Do Flood Barriers Differ in Functionality and Use Cases?

Flood barriers are engineered specifically to combat water-related threats, making them indispensable in flood-prone areas. They can be deployed quickly, typically within minutes, which is essential during emergency situations. These barriers are primarily used in disaster management and flood control efforts. While they excel in water management, their design limits their effectiveness in other contexts, which buyers should keep in mind when considering their investment.

What Advantages Do Guard Posts Offer for Security Applications?

Guard posts made from Hesco barriers provide robust protection against both blasts and ballistic threats, making them ideal for security installations and military bases. Their design allows personnel to safely monitor and control entry points, enhancing overall security. However, their installation may require more space and logistical planning, which buyers must factor into their operational strategies. The investment in guard posts can significantly improve safety for personnel in high-risk environments.

Why Are Accommodation Bunkers Important for Military and Emergency Situations?

Accommodation bunkers are designed to offer overhead blast protection while providing safe living conditions for personnel in conflict zones. Their modular design allows for quick assembly and adaptability to different environments, making them suitable for military housing and emergency shelters. While they provide essential safety, buyers should be aware of the logistical complexities involved in transporting and setting up these structures, which may increase overall costs and timeframes.

How Can Custom Solutions Enhance the Effectiveness of Hesco Barriers?

Custom solutions for Hesco barriers offer tailored sizes and materials that align precisely with specific project needs, whether for military, humanitarian, or industrial applications. This adaptability allows organizations to address unique challenges effectively. However, buyers should be prepared for potentially longer lead times as customization often requires additional design and manufacturing processes. The investment in custom solutions can yield significant benefits in terms of operational efficiency and effectiveness.

Key Industrial Applications of hesco barrier for sale

| Industry/Sector | Specific Application of hesco barrier for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Defense & Military | Troop Fortifications | Provides rapid deployment and protection for personnel | Ensure compliance with military standards and specifications |

| Disaster Management | Flood Control Systems | Effective barrier against floodwaters, protecting assets | Consider local environmental conditions and required sizes |

| Oil & Gas | Critical Infrastructure Protection | Safeguards facilities from blast and vehicle threats | Evaluate barrier specifications based on site-specific risks |

| Construction | Erosion Control and Site Security | Stabilizes sites and enhances safety during construction | Assess custom sizes and materials for specific project needs |

| Humanitarian Aid | Temporary Shelters for Refugees | Quick setup for safe living conditions in crisis zones | Ensure lightweight and easy-to-transport options are available |

How are HESCO Barriers Used in Defense & Military Applications?

In defense and military sectors, HESCO barriers are primarily utilized for troop fortifications. These barriers provide a robust protective solution that can be rapidly deployed to safeguard personnel and equipment from various threats, including explosions and small arms fire. For international buyers, particularly in regions like the Middle East and Africa, it is essential to ensure that the barriers meet specific military standards and can be quickly assembled in challenging environments.

What Role Do HESCO Barriers Play in Disaster Management?

HESCO barriers serve as effective flood control systems, particularly in areas prone to flooding. These barriers can be filled with local materials such as sand or gravel, allowing for quick installation to protect critical infrastructure and communities. For buyers in South America, where flooding can be a significant issue, sourcing barriers that are adaptable to local environmental conditions is crucial to ensure their effectiveness.

How Are HESCO Barriers Critical for Oil & Gas Sector Protection?

In the oil and gas industry, HESCO barriers are employed to protect critical infrastructure from potential threats such as blasts or vehicle attacks. Their ability to form a protective perimeter around facilities enhances security and minimizes risks. Companies sourcing these barriers should focus on evaluating the specifications based on site-specific risks, especially in politically sensitive regions like Nigeria and Saudi Arabia.

Why Are HESCO Barriers Important for Construction Site Security?

During construction projects, HESCO barriers are used for erosion control and enhancing site security. They stabilize the ground and protect ongoing work from environmental factors while also deterring unauthorized access. Buyers should assess custom sizes and materials to fit the unique requirements of their construction projects, ensuring compliance with local regulations.

How Do HESCO Barriers Support Humanitarian Efforts?

HESCO barriers are invaluable in humanitarian aid efforts, providing temporary shelters for refugees and displaced persons. Their quick setup capability allows for the establishment of safe living conditions in crisis zones, making them a vital resource in emergency situations. For international buyers, particularly NGOs in Europe and Africa, it is important to prioritize lightweight and easy-to-transport options to facilitate rapid deployment in affected areas.

3 Common User Pain Points for ‘hesco barrier for sale’ & Their Solutions

Scenario 1: Sourcing Hesco Barriers Efficiently

The Problem: B2B buyers, particularly those in regions with unstable supply chains like parts of Africa and South America, often struggle to source Hesco barriers in a timely manner. Delays in procurement can lead to project setbacks, affecting critical infrastructure projects or humanitarian operations. Moreover, buyers may face challenges in verifying the quality and specifications of the products offered by different suppliers, leading to concerns about the durability and performance of the barriers in real-world applications.

The Solution: To ensure timely sourcing of high-quality Hesco barriers, buyers should establish relationships with reputable manufacturers who have a proven track record in producing these barriers. Conduct thorough research to identify suppliers with certifications such as ISO9001 and compliance with international standards. Request detailed product specifications and samples before placing bulk orders. Additionally, leveraging local suppliers or manufacturers who understand regional logistics can minimize delays. By implementing a structured procurement process that includes quality checks and clear communication with suppliers, buyers can significantly reduce the risks associated with sourcing Hesco barriers.

Scenario 2: Customization to Meet Specific Project Needs

The Problem: Projects requiring Hesco barriers often have unique specifications based on their intended use, such as flood control or military applications. Buyers may find it challenging to procure barriers that meet these specific requirements, leading to either over-specification, which increases costs, or under-specification, which compromises safety and effectiveness. This can be particularly problematic in regions like the Middle East and Europe, where environmental conditions and regulatory requirements vary widely.

The Solution: To address customization needs, buyers should engage directly with manufacturers that offer tailored solutions. This includes discussing project specifics such as dimensions, materials, and desired protective features. It’s beneficial to consult with experts who can provide insights into the most effective barrier configurations for specific applications. Buyers should also consider suppliers that provide detailed customization options, including varying wire mesh specifications and surface treatments, ensuring that the final product aligns perfectly with their project needs. Utilizing advanced simulation tools during the design phase can also help in visualizing the performance of customized barriers before production.

Scenario 3: Cost Management and Budget Constraints

The Problem: In many cases, especially in developing regions, budget constraints can significantly impact the procurement of Hesco barriers. Buyers may struggle to balance the need for high-quality protective solutions with the realities of limited financial resources. Fluctuations in material costs and shipping fees can further complicate budget planning, leading to potential overspending or project compromises.

The Solution: To effectively manage costs, buyers should conduct a comprehensive cost analysis that includes not only the price of the barriers but also associated expenses such as shipping, handling, and installation. Engaging with multiple suppliers to obtain quotes can help identify competitive pricing. Consider options for bulk purchasing or long-term contracts, which can often yield discounts. Additionally, buyers can explore financing options or government grants available for infrastructure projects that can alleviate upfront costs. Regularly reviewing and adjusting procurement strategies in line with market trends can also help in maintaining budgetary control without compromising on quality.

Strategic Material Selection Guide for hesco barrier for sale

What Are the Key Materials Used in Hesco Barriers?

When selecting materials for Hesco barriers, it’s essential to consider their properties, performance, and suitability for specific applications. Below, we analyze four common materials used in the construction of Hesco barriers: galvanized steel, high-strength polyethylene, geotextile fabric, and concrete.

How Does Galvanized Steel Perform in Hesco Barriers?

Galvanized steel is a popular choice due to its excellent strength and corrosion resistance. The galvanization process involves coating steel with a layer of zinc, which protects it from rust and environmental degradation. This material can withstand high pressures and is suitable for various climates, making it ideal for military and humanitarian applications.

Pros: Durability is one of the key advantages of galvanized steel, as it can endure harsh conditions and impacts. Its manufacturing process is well-established, ensuring consistent quality.

Cons: The primary limitation is weight; galvanized steel barriers can be heavy and may require more manpower for installation. Additionally, while the initial cost is moderate, long-term maintenance can be a consideration if the coating wears off.

Impact on Application: Galvanized steel is compatible with various fill materials, including soil and sand, and is particularly effective in military fortifications.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN for material specifications and durability tests.

What Role Does High-Strength Polyethylene Play in Hesco Barriers?

High-strength polyethylene (PE) is increasingly used for its lightweight and flexible properties. This material is resistant to UV radiation, chemicals, and moisture, making it suitable for diverse environmental conditions.

Pros: The lightweight nature of PE allows for easier transport and faster deployment. It is also resistant to corrosion and does not require additional coatings, reducing long-term maintenance costs.

Cons: However, high-strength polyethylene may not provide the same level of ballistic protection as steel, making it less suitable for high-threat environments. Its performance can also be affected by extreme temperatures.

Impact on Application: Polyethylene barriers are often used in flood control and erosion prevention, where flexibility and rapid deployment are crucial.

Considerations for International Buyers: Buyers should verify that the polyethylene used meets international standards for environmental impact and safety, particularly in regions with stringent regulations.

How Does Geotextile Fabric Enhance Hesco Barriers?

Geotextile fabric is often used as a lining for Hesco barriers, providing additional filtration and drainage capabilities. This material is designed to be permeable, allowing water to pass through while retaining soil or other fill materials.

Pros: Geotextile fabric enhances the overall stability of the barrier and prevents erosion of fill materials. It is lightweight and easy to handle, contributing to quicker installation.

Cons: The main limitation is its vulnerability to punctures and tears, which can compromise the barrier’s integrity. Additionally, geotextile fabric may require replacement over time, adding to maintenance costs.

Impact on Application: This material is particularly effective in flood control applications, where drainage is essential to prevent water buildup.

Considerations for International Buyers: Buyers should ensure that the geotextile fabric meets specific international standards for filtration and durability, especially in regions prone to heavy rainfall or flooding.

What Are the Benefits of Using Concrete in Hesco Barriers?

Concrete is sometimes used in Hesco barriers, particularly for permanent installations. It offers exceptional strength and durability, making it suitable for long-term applications.

Pros: Concrete barriers provide robust protection against blasts and projectiles, making them ideal for high-security areas. They also require minimal maintenance once installed.

Cons: The primary drawback is the high cost and complexity of installation, as concrete barriers are heavy and require specialized equipment for placement.

Impact on Application: Concrete is well-suited for critical infrastructure protection and military installations where long-term durability is paramount.

Considerations for International Buyers: Buyers should consider local regulations regarding concrete use, including environmental impact assessments and compliance with construction standards.

Summary Table of Material Selection for Hesco Barriers

| Material | Typical Use Case for hesco barrier for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Military fortifications | High durability and corrosion resistance | Heavy and requires more manpower | Medium |

| High-Strength Polyethylene | Flood control and erosion prevention | Lightweight and easy to deploy | Less ballistic protection | Medium |

| Geotextile Fabric | Flood control applications | Enhances stability and drainage | Vulnerable to punctures | Low |

| Concrete | Permanent installations for critical infrastructure | Exceptional strength and durability | High cost and complex installation | High |

This strategic material selection guide provides international B2B buyers with crucial insights into the various materials used in Hesco barriers, enabling informed decision-making based on application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hesco barrier for sale

What Are the Key Stages in the Manufacturing Process of Hesco Barriers?

The manufacturing process of Hesco barriers involves several critical stages, ensuring that each product meets the stringent requirements for safety and durability. Here’s a breakdown of the main stages:

Material Preparation: What Materials Are Used in Hesco Barriers?

Hesco barriers are primarily made from high-strength wire mesh and heavy-duty geotextile fabric. The wire mesh, often galvanized or coated for enhanced corrosion resistance, provides the structural integrity necessary to withstand external forces. The geotextile fabric, which lines the interior of the mesh containers, serves to hold fill materials like soil, sand, or gravel, contributing to the barrier’s overall strength.

Before production begins, raw materials undergo rigorous inspections to ensure they meet specified standards. This includes checking the wire diameter, mesh size, and fabric quality, which are vital for the barrier’s performance.

How Are Hesco Barriers Formed and Assembled?

Once materials are prepared, the next step involves forming the wire mesh into the desired shape. This process typically includes:

- Cutting: The wire mesh is cut into specific dimensions based on the product requirements.

- Welding: Pieces are welded together to create a robust framework. Advanced welding techniques, such as robotic welding, may be employed to ensure uniformity and strength.

- Shaping: The welded mesh is shaped into collapsible containers, which are designed to be easily transported and deployed.

Assembly involves attaching the geotextile fabric to the interior of the wire mesh. This step is crucial for ensuring that the fill material remains contained, enhancing the barrier’s effectiveness.

What Finishing Techniques Are Employed to Ensure Quality?

Finishing touches are applied to enhance the barrier’s durability and performance. This may include additional coatings for corrosion resistance, quality checks for structural integrity, and ensuring that the seams of the geotextile fabric are properly sealed. The finished products are then packaged for shipping, ensuring they are easy to handle and deploy in various environments.

How Is Quality Assurance Integrated into the Production of Hesco Barriers?

Quality assurance is paramount in the manufacturing of Hesco barriers, given their critical role in safety and security. Manufacturers often adhere to international and industry-specific standards to ensure the highest quality.

What International Standards Are Relevant to Hesco Barrier Production?

The ISO 9001:2015 certification is a critical international standard that governs quality management systems. This certification ensures that manufacturers have established processes to monitor and improve quality consistently. Additionally, certifications such as CE mark and API (American Petroleum Institute) standards may be applicable, especially for barriers used in specific industries such as oil and gas.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch any defects early:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections occur during manufacturing to monitor adherence to quality standards.

- Final Quality Control (FQC): The completed barriers undergo a final inspection to verify that they meet all specifications before packaging.

What Testing Methods Are Commonly Used to Ensure Product Reliability?

Testing methods play a vital role in verifying the performance of Hesco barriers. Common tests include:

- Load Testing: Assessing the barrier’s ability to withstand various loads, including blast and ballistic impacts.

- Durability Testing: Evaluating the resistance of materials to environmental factors such as moisture and corrosion.

- Field Testing: Deploying barriers in controlled environments to assess their performance under real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing Hesco barriers, B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Here are several strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request and review supplier quality audits, which may include:

- ISO Certification Documentation: Proof of adherence to international standards.

- Quality Assurance Reports: Documentation of testing and inspection results.

- Customer Testimonials: Feedback from previous clients can provide insight into the reliability of the supplier.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can be conducted at various stages of production, offering additional assurance that products meet specified standards before shipment.

What Nuances Should International Buyers Be Aware Of When Sourcing Hesco Barriers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

- Regulatory Compliance: Different regions may have unique regulatory requirements for defense and safety products. Understanding these can prevent potential legal issues.

- Shipping and Logistics: Buyers should consider the logistics involved in transporting heavy materials, including customs regulations and potential tariffs.

- Cultural Considerations: Building relationships with suppliers can be crucial in international markets. Understanding cultural differences can enhance negotiations and foster long-term partnerships.

By understanding the manufacturing processes and quality assurance protocols associated with Hesco barriers, B2B buyers can make informed purchasing decisions, ensuring they select reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hesco barrier for sale’

Introduction

When sourcing HESCO barriers for sale, a structured approach is essential to ensure that you acquire the right product for your specific needs. This guide provides a step-by-step checklist tailored for international B2B buyers in diverse regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and make informed decisions that align with your operational requirements.

1. Identify Your Specific Requirements

Before you begin searching for suppliers, clearly define your project requirements. Consider factors such as the intended use of the barriers (e.g., military, flood control, or perimeter security), the environmental conditions they’ll face, and the size specifications that best fit your project. This step is crucial to ensure that the barriers you source will meet your operational needs effectively.

2. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies with a proven track record in manufacturing HESCO barriers and positive reviews from previous clients. Utilize online platforms, industry trade shows, and recommendations from peers to compile a list of potential suppliers that meet your criteria.

3. Verify Supplier Certifications

Ensure that the suppliers you consider hold relevant certifications that demonstrate their compliance with industry standards. Look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications indicate a commitment to quality and safety, which is vital for products designed to protect lives and infrastructure.

4. Request Samples and Technical Specifications

Before making a bulk purchase, request samples of the HESCO barriers. This will allow you to assess the quality, durability, and suitability of the materials used. Additionally, obtaining detailed technical specifications will help you understand the product’s features, such as fill material requirements and assembly instructions, ensuring they align with your operational expectations.

5. Evaluate Pricing and Payment Terms

Request detailed quotes from your shortlisted suppliers, considering not only the price per unit but also shipping costs and any additional fees. Compare the pricing structures while paying attention to minimum order quantities and payment terms. This step is crucial for budget management and ensuring that you receive the best value for your investment.

6. Check Delivery and Lead Times

Inquire about the expected delivery times for the barriers. Understanding lead times is essential for planning your project timeline effectively. A reliable supplier should provide clear information on production and shipping durations, allowing you to coordinate the deployment of the barriers with your operational schedule.

7. Establish Communication Channels

Finally, set up clear communication channels with your chosen supplier. This includes defining points of contact for any inquiries or issues that may arise during the procurement process. Effective communication is key to resolving potential challenges and ensuring a smooth transaction, ultimately leading to a successful partnership.

By following this checklist, B2B buyers can enhance their sourcing process for HESCO barriers, ensuring that they choose the right products from reputable suppliers while effectively managing costs and timelines.

Comprehensive Cost and Pricing Analysis for hesco barrier for sale Sourcing

What Are the Key Cost Components for Sourcing Hesco Barriers?

When evaluating the cost structure for sourcing Hesco barriers, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The primary cost driver is the high-strength wire mesh and heavy-duty fabric used in the construction of Hesco barriers. The quality of these materials significantly affects the price, with options ranging from standard galvanized steel to advanced coatings that enhance durability and resistance to environmental factors.

-

Labor: Labor costs encompass the workforce involved in manufacturing and assembling the barriers. Efficient production processes and skilled labor can reduce these costs, making it essential for suppliers to maintain a balanced workforce.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and factory space costs. A well-managed production facility can minimize these overheads, directly impacting the final pricing.

-

Tooling: Initial investments in tooling and equipment are necessary for producing customized or specialized barrier sizes. These costs are often amortized over larger production runs, allowing for lower prices per unit with higher volume orders.

-

Quality Control: Rigorous QC processes are vital for ensuring product integrity and safety, particularly for military and humanitarian applications. This aspect can add to the cost but is crucial for maintaining high standards.

-

Logistics: Transporting the barriers to the buyer’s location, especially for international shipments, can significantly influence pricing. Factors such as shipping distance, mode of transport, and local tariffs play a pivotal role.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and demand. Understanding these margins helps buyers negotiate better deals.

How Do Price Influencers Affect Hesco Barrier Costs?

Several factors can influence the pricing of Hesco barriers beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes can lead to significant price reductions due to economies of scale. Many suppliers offer tiered pricing models that reward bulk purchases.

-

Specifications and Customization: Custom specifications, such as size and material treatment, can lead to higher costs. Suppliers may charge more for tailored solutions, so it’s advisable to determine the necessary specifications upfront.

-

Quality and Certifications: Barriers that meet international safety and quality standards (e.g., ISO certifications) may command higher prices. Buyers should consider these certifications as part of their procurement strategy.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and location can all impact pricing. Established suppliers with a strong track record may offer more reliable products, but at a premium.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential for budgeting total costs. These terms define who bears shipping and insurance costs, which can significantly alter the final price.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Hesco Barriers?

To maximize value when sourcing Hesco barriers, consider the following tips:

-

Negotiate Terms: Engage suppliers in discussions about pricing, especially for large orders. Negotiating terms such as payment schedules or delivery times can also yield cost benefits.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like durability, maintenance, and potential resale value to assess the true cost over the product’s life.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, local tariffs, and import duties that may affect pricing. Understanding these factors can lead to more informed purchasing decisions.

-

Research Multiple Suppliers: Gathering quotes from various suppliers can provide insight into competitive pricing and help identify the best options for your needs.

-

Consider Long-Term Partnerships: Establishing ongoing relationships with suppliers can lead to better pricing and service over time, as suppliers may prioritize repeat customers for favorable terms.

Disclaimer on Indicative Prices

While indicative pricing for a single set of Hesco barriers can range from $9.50 to $29, actual prices may vary based on the aforementioned factors. Buyers are encouraged to obtain tailored quotes that reflect their specific requirements and circumstances.

Alternatives Analysis: Comparing hesco barrier for sale With Other Solutions

Exploring Alternatives to Hesco Barriers

In the realm of security and defense solutions, it is essential for B2B buyers to evaluate multiple options before making a purchase. Hesco barriers are widely recognized for their effectiveness in providing protective measures against various threats, but there are alternative solutions that may also meet specific operational needs. This section compares Hesco barriers with two viable alternatives: concrete barriers and portable fencing systems.

| Comparison Aspect | Hesco Barrier For Sale | Concrete Barriers | Portable Fencing Systems |

|---|---|---|---|

| Performance | High resistance to blasts and projectiles | Excellent for static protection | Moderate, primarily for perimeter control |

| Cost | $9.5 – $29 per unit | $50 – $150 per unit | $2 – $10 per linear foot |

| Ease of Implementation | Quick setup (under 5 minutes for extensive lengths) | Requires heavy machinery and labor | Simple assembly; no machinery needed |

| Maintenance | Low, primarily weatherproofing | Moderate; can crack or chip | Low; regular checks needed for stability |

| Best Use Case | Military and humanitarian applications | Long-term, permanent installations | Temporary events, crowd control |

Detailed Breakdown of Alternatives

Concrete Barriers

Concrete barriers are a traditional choice for securing sensitive areas. They offer excellent protection against vehicle threats and are often used in urban environments. Their robust design ensures durability and effectiveness, especially in high-threat scenarios. However, the significant drawbacks include high costs and the need for specialized equipment for installation and removal. Additionally, once placed, they are not easily movable, limiting flexibility in changing security needs.

Portable Fencing Systems

Portable fencing systems provide a lightweight, cost-effective solution for temporary security needs. Ideal for events, crowd control, or construction sites, these systems can be quickly deployed and require no heavy machinery for setup. However, their performance in terms of ballistic resistance and overall security is moderate compared to Hesco barriers or concrete barriers. As such, they are better suited for low-risk environments where flexibility and rapid deployment are prioritized over high-level protection.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating security solutions, B2B buyers must carefully consider their specific requirements. Hesco barriers offer superior protection for military and humanitarian applications, particularly where rapid deployment is crucial. Conversely, concrete barriers may be more suitable for permanent installations requiring robust defense against vehicles. For temporary or less critical scenarios, portable fencing systems provide a flexible and cost-effective alternative. Ultimately, the choice should align with the operational context, budget constraints, and desired level of security.

Essential Technical Properties and Trade Terminology for hesco barrier for sale

What Are the Key Technical Properties of Hesco Barriers That Buyers Should Consider?

Understanding the essential specifications of Hesco barriers is crucial for international B2B buyers, especially those involved in defense, construction, or emergency management. Here are several critical technical properties:

-

Material Grade

Hesco barriers are typically constructed from high-strength galvanized steel wire mesh, which is designed to resist corrosion and maintain structural integrity. The material grade affects durability and performance, making it essential for applications in harsh environments. Buyers should prioritize barriers with appropriate certifications that ensure quality and safety standards. -

Cell Dimensions

The size of the cells within a Hesco barrier unit can vary significantly. Common configurations include Mil 1 through Mil 10, with dimensions ranging from 1.06m to 2.21m in height and varying lengths. Understanding cell dimensions is vital for determining how many units are required for a specific project, ensuring proper coverage and protection. -

Fill Material Compatibility

Hesco barriers are designed to be filled with a variety of materials, including soil, sand, and gravel. The choice of fill material can impact the barrier’s effectiveness against blasts and projectiles. Buyers should consider the availability of fill materials in their region and the intended use of the barrier to optimize performance. -

Weight and Portability

The weight of the assembled barrier can influence transportation and deployment logistics. Lighter units may be easier to handle and deploy quickly, making them suitable for emergency response situations. It’s essential for buyers to assess their specific needs in terms of mobility and rapid deployment capabilities. -

Assembly Time

The ease of assembly is another critical factor. Some Hesco barriers come as flat-packed units that can be quickly assembled with minimal manpower. This feature is particularly valuable in urgent situations where time is of the essence, making it a key consideration for procurement decisions.

Which Trade Terms Are Commonly Used in the Hesco Barrier Market?

Navigating the Hesco barrier market requires familiarity with specific trade terminology. Here are several important terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Hesco barriers, understanding OEM relationships can help buyers identify reliable suppliers and ensure product authenticity. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For Hesco barriers, MOQs can vary widely; being aware of these can help buyers optimize their inventory and budget management. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other terms for specific products. Buyers should prepare detailed RFQs for Hesco barriers to ensure they receive accurate quotes that meet their project specifications. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing shipping costs and risk during the procurement of Hesco barriers. -

Lead Time

This refers to the time taken from placing an order to the delivery of the product. Knowing the lead time for Hesco barriers is essential for project planning, especially in scenarios requiring rapid deployment. -

Custom Solutions

Many suppliers offer custom solutions tailored to specific project needs, such as size, design, and material specifications. Buyers should inquire about customization options to ensure the barriers meet their unique requirements effectively.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when sourcing Hesco barriers, ensuring they choose the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the hesco barrier for sale Sector

What Are the Current Market Dynamics and Key Trends in the Hesco Barrier Sector?

The global market for Hesco barriers is experiencing robust growth, driven by increasing concerns over security and disaster management across various regions. Key factors propelling this trend include rising geopolitical tensions, the need for enhanced military infrastructure, and an uptick in natural disasters that necessitate effective flood control measures. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly sourcing Hesco barriers for applications ranging from military fortifications to humanitarian efforts.

Emerging technologies are reshaping the sourcing landscape. The integration of digital platforms for procurement processes, such as e-commerce solutions and real-time inventory management systems, is streamlining transactions and improving accessibility for buyers. Moreover, manufacturers are leveraging advanced materials and innovative designs to enhance the durability and effectiveness of Hesco barriers, catering to diverse requirements from various sectors. For instance, rapid deployment models are gaining traction, allowing military and emergency response teams to establish defenses quickly and efficiently.

The competitive landscape is also evolving, with manufacturers focusing on customization options to meet specific client needs. Buyers are encouraged to engage with suppliers that offer tailored solutions and expert consultations, ensuring that they receive products that align with their operational requirements. This trend toward customization is vital for international buyers, who may face unique environmental and logistical challenges in their respective regions.

How Is Sustainability and Ethical Sourcing Shaping the Hesco Barrier Market?

Sustainability is becoming a critical consideration in the sourcing of Hesco barriers. The environmental impact of manufacturing processes and the materials used is increasingly under scrutiny. Buyers are now more inclined to partner with suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste during production.

Ethical sourcing is equally important, especially in regions where supply chain transparency can significantly affect community relations and brand reputation. Companies that adhere to international standards and obtain certifications such as ISO 14001 for environmental management systems are viewed favorably by buyers. Moreover, the use of “green” materials, including eco-friendly geotextiles and non-toxic coatings, is becoming a standard expectation among discerning B2B clients.

In addition to enhancing brand loyalty, adopting sustainable and ethical practices can also lead to cost savings in the long run, as companies can benefit from reduced material costs and potential tax incentives for using eco-friendly products. Buyers are advised to prioritize suppliers who not only fulfill their immediate needs but also align with their long-term sustainability goals.

What Is the Brief Evolution of the Hesco Barrier Industry?

The Hesco barrier industry has evolved significantly since its inception in the late 1980s, originally designed for military applications to provide quick and effective defensive structures. Over the years, the versatility of Hesco barriers has been recognized, leading to their adoption in various sectors, including disaster relief, flood control, and infrastructure protection.

Technological advancements have played a crucial role in this evolution, with innovations in materials and designs enhancing the barriers’ efficacy and ease of deployment. Today, Hesco barriers are not only synonymous with military fortifications but are also integral to emergency management strategies across the globe. As international markets continue to expand, the focus on customization, sustainability, and rapid deployment will shape the future trajectory of the industry, making it an essential component of modern security solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of hesco barrier for sale

-

How do I determine the right type of HESCO barrier for my project?

Selecting the appropriate HESCO barrier depends on your specific needs, including the environment, purpose, and size requirements. Consider factors such as the barrier’s intended use (e.g., military defense, flood control, or temporary security) and the expected threat level. Consulting with suppliers who can provide expert guidance based on your project’s parameters is essential. Most suppliers offer a range of standard sizes, such as Mil 1 to Mil 10, and customization options to fit unique specifications. -

What are the standard sizes available for HESCO barriers?

HESCO barriers come in various standard sizes, commonly identified by their “Mil” classification. For instance, Mil 1 measures approximately 4’6” x 3’6” x 32’ while Mil 10 is about 7’ x 5’ x 95’. It is vital to match the size to your project needs, whether for troop fortifications or flood control. Many manufacturers also offer customization for specific dimensions or configurations based on client requirements. -

What customization options are available for HESCO barriers?

Many suppliers provide extensive customization options for HESCO barriers. Customizations can include size, mesh specifications, wire diameter, and surface treatments like galvanization. Additionally, you can specify the type of fill material required for the barriers, depending on their intended use. Engaging with manufacturers who can tailor solutions to your project’s unique needs can enhance performance and effectiveness. -

What is the minimum order quantity (MOQ) for purchasing HESCO barriers?

The MOQ for HESCO barriers can vary by supplier, but many manufacturers typically set a minimum order of around 100 sets. This allows for flexibility in supply while ensuring that production and shipping processes are efficient. When negotiating orders, consider discussing potential reductions in MOQ based on your needs and the supplier’s capabilities. -

How can I vet suppliers when sourcing HESCO barriers internationally?

Vetting suppliers involves several key steps: check for certifications such as ISO standards to ensure quality control, review customer testimonials, and assess their production capabilities. Additionally, inquire about their experience in international shipping and handling logistics specific to your region. Engaging in direct communication with potential suppliers can provide insights into their reliability and responsiveness. -

What payment terms should I expect when purchasing HESCO barriers?

Payment terms can vary significantly among suppliers. Common practices include upfront payments, partial payments during production, or payment upon delivery. It’s advisable to clarify payment terms upfront and ensure they align with your financial policies. Utilizing secure payment methods can also help mitigate risks associated with international transactions. -

What quality assurance processes should I look for in HESCO barrier suppliers?

Quality assurance is critical in ensuring that HESCO barriers meet safety and performance standards. Look for suppliers who implement rigorous quality control measures, including multiple inspections during production and final testing of the barriers. Certifications such as ISO 9001 can indicate adherence to quality management systems, providing further assurance of the product’s reliability. -

What logistics considerations should I be aware of when sourcing HESCO barriers?

Logistics play a crucial role in the procurement of HESCO barriers, especially for international buyers. Consider factors such as shipping costs, lead times, and customs regulations in your country. Collaborating with suppliers who have experience in international shipping can facilitate smoother transactions. Additionally, ensure that the supplier can provide appropriate documentation for customs clearance to avoid delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Hesco Barrier For Sale Manufacturers & Suppliers List

1. HESCO – Rapid Defences Solutions

Domain: hesco.com

Registered: 2000 (25 years)

Introduction: HESCO offers a range of products designed for protection and defense, including: 1. RAPID DEFENCES MIL – Innovative design for safeguarding personnel, vehicles, and critical assets. 2. RAPID DEFENCES R – Flat packed units that can be assembled quickly with minimal manpower. 3. RAPID DEFENCES RAID – Deploys over 1,000 feet of defensive barriers in under 5 minutes. 4. HESCO® ARMOR 800 SERIES – Milit…

2. Shengsen – Hesco Barrier Walls

Domain: shengsengabion.com

Registered: 2022 (3 years)

Introduction: Hesco Barrier Wall Wholesale at Factory Price – Shengsen

Key Product Details:

– Professional manufacturing for Hesco barrier bastion and on-demand sizes.

– Daily production output: 260+ tons.

– Quality inspection: 3 times throughout production.

– Served over 70 countries and regions.

– Certifications: ISO9001:2015, ISO14001:2015, ISO45001:2015, TüVRheinland Verified.

Applications:

– Used as a ba…

3. Metalfencetech – Heavy-Duty Hesco Barrier

Domain: metalfencetech.com

Registered: 2016 (9 years)

Introduction: Heavy-Duty Hesco Barrier for Defense, Flood Control, and Environmental Protection. Designed for military, environmental, and emergency scenarios. Features durable zinc-coated steel welded mesh and non-woven geotextile lining. Quick deployment, robust performance, and adaptability. Specifications include: Steel Wire Composition: 0.1% carbon max steel; Wire Thickness: 3.5mm to 5.0mm; Wire Tensile St…

4. TLWY – Sand Color Welded Mesh Hesco Barrier Wall

Domain: fence-global.com

Registered: 2010 (15 years)

Introduction: Hesco Barrier Wall

– Price: $29.00-50.00

– MOQ: 5 sets

– Brand Name: TLWY

– Material: Galvanized Iron Wire

– Wire Gauge: 2.0-4.0mm

– Type: Welded Mesh

Sand Color Welded Mesh Military Hesco Barrier Wall 24 Inches

– Price: $29.00-50.00

– MOQ: 5 sets

– Brand Name: TLWY

– Material: Galvanized Iron Wire

– Wire Gauge: 2.0-4.0mm

– Type: Welded Mesh

4mm Security Welded Gabion Baskets Flood Control Barri…

5. Hesco – Temporary Fortification Barriers

Domain: ar15.com

Registered: 1997 (28 years)

Introduction: Hesco barriers are temporary fortification products that are not very permanent or cheap. They are designed to be filled rapidly using front-end loaders, unlike sandbags which must be filled individually. Surplus or used Hesco barriers may be difficult to find as they tend to get torn up and are not serviceable after use. They are available for purchase on platforms like Amazon, GovPlanet, and Ali…

6. Hesco – Bastion Barriers

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Hesco Bastion Barriers for sale in New Mexico

Strategic Sourcing Conclusion and Outlook for hesco barrier for sale

As international B2B buyers seek robust solutions for security and infrastructure protection, the value of strategic sourcing for HESCO barriers cannot be overstated. These innovative, collapsible barriers provide unparalleled protection for personnel and assets against a range of threats, making them indispensable in military, humanitarian, and civil applications. By leveraging the advanced capabilities of HESCO products, businesses can optimize their defensive strategies while ensuring safety and compliance with international standards.

In sourcing HESCO barriers, buyers should consider not only the specifications and pricing but also the reliability of the supplier and their ability to customize products to meet specific needs. With manufacturers offering options for customization, fast deployment, and substantial production capacities, organizations can secure the right solutions that align with their operational requirements.

Looking ahead, the demand for HESCO barriers will continue to grow, particularly in regions like Africa, South America, the Middle East, and Europe. As geopolitical tensions rise and climate-related challenges persist, investing in high-quality barriers will be vital for safeguarding critical infrastructure. Now is the time for international buyers to engage with trusted suppliers to enhance their defensive capabilities and ensure the safety of their operations.