A Deep Dive into Fob Exw Solution

Introduction: Navigating the Global Market for fob exw

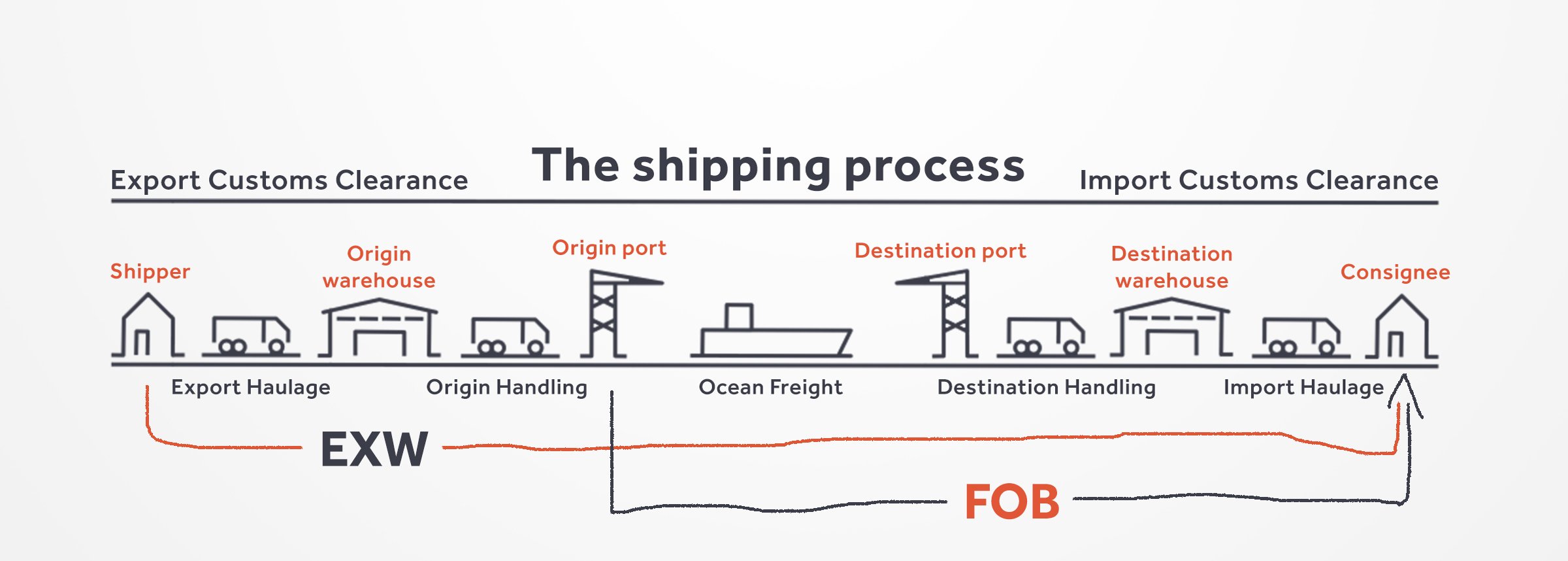

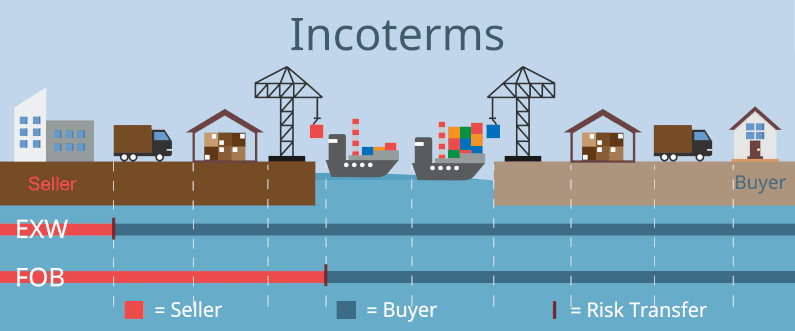

In the complex world of international trade, navigating the intricacies of shipping terms such as Free on Board (FOB) and Ex Works (EXW) can pose significant challenges for B2B buyers. Understanding these Incoterms is crucial when sourcing products from global suppliers, as they dictate the responsibilities and costs associated with shipping. This guide aims to demystify FOB and EXW, providing insights into their applications, advantages, and best practices for effective supplier vetting. By equipping international buyers, particularly those from Africa, South America, the Middle East, and Europe, with the knowledge to make informed decisions, we empower them to optimize their procurement processes and mitigate risks.

Throughout this comprehensive guide, readers will explore the key differences between FOB and EXW, helping them determine which term aligns best with their business goals and logistical capabilities. We will delve into various scenarios, highlighting how each Incoterm can affect overall shipping costs and responsibilities. Additionally, the guide will provide actionable tips for evaluating suppliers, ensuring that buyers not only secure the best prices but also maintain high standards of quality and reliability. By the end of this guide, B2B buyers will be better equipped to navigate the global market, fostering successful international partnerships that drive growth and innovation.

Understanding fob exw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| FOB Origin | Seller is responsible until goods are loaded onto the vessel. | Bulk commodities, industrial goods | Pros: Lower shipping costs; Cons: More risk until loading. |

| FOB Destination | Seller covers costs until goods reach the buyer’s location. | Retail goods, high-value items | Pros: Reduced risk for buyers; Cons: Higher overall costs. |

| EXW Factory | Seller’s responsibility ends at the factory; buyer handles all. | Custom manufacturing, machinery | Pros: Lower initial price; Cons: High responsibility on buyer. |

| EXW Warehouse | Goods available at seller’s warehouse; buyer manages logistics. | Local suppliers, small shipments | Pros: Flexibility for buyers; Cons: Requires logistical knowledge. |

| EXW Port | Goods ready for pickup at the port; buyer arranges transport. | Exporters, importers | Pros: Control over shipping; Cons: Potential for unexpected fees. |

What are the Characteristics of FOB Origin and Its Suitability for B2B Buyers?

FOB Origin is characterized by the seller’s responsibility for the goods until they are loaded onto the shipping vessel. This term is particularly suitable for bulk commodities and industrial goods, where the buyer has a good understanding of logistics and can manage further transportation. Buyers benefit from potentially lower shipping costs but must be aware of the risks involved until the goods are loaded. Effective communication with the seller is essential to ensure smooth logistics.

How Does FOB Destination Benefit Buyers in B2B Transactions?

FOB Destination shifts the risk and responsibility to the seller until the goods arrive at the buyer’s specified location. This arrangement is ideal for retail goods and high-value items, as it minimizes the buyer’s risk throughout the shipping process. While buyers enjoy peace of mind and reduced liability, they should be prepared for higher overall costs. Understanding the seller’s shipping capabilities is crucial to ensure timely delivery.

What Makes EXW Factory a Viable Option for Custom Manufacturing?

EXW Factory indicates that the seller’s responsibility ends once the goods are available at their factory. This term is commonly used in custom manufacturing and machinery procurement, where buyers often have specific requirements. While this option can lead to lower initial prices, it places the onus of logistics entirely on the buyer, necessitating a robust understanding of international shipping. Buyers must assess their logistical capabilities before choosing this term.

Why Choose EXW Warehouse for Local Suppliers and Small Shipments?

EXW Warehouse allows buyers to pick up goods directly from the seller’s warehouse, giving them control over the logistics. This term is particularly beneficial for local suppliers and small shipments, where flexibility is paramount. However, buyers need to be knowledgeable about transportation arrangements and potential costs involved. This arrangement can lead to cost savings if managed well, but it requires careful planning to avoid unexpected challenges.

What Are the Implications of EXW Port for Exporters and Importers?

EXW Port designates that goods are ready for pickup at the port, with the buyer responsible for arranging transport. This term is advantageous for exporters and importers who want control over their shipping processes. However, buyers must be cautious about potential unexpected fees and should have a clear understanding of port operations. This option provides autonomy in logistics but requires a proactive approach to manage costs effectively.

Key Industrial Applications of fob exw

| Industry/Sector | Specific Application of fob exw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Sourcing raw materials for production | Reduces upfront costs and allows buyers to control logistics | Supplier reliability, local transportation options, and customs expertise |

| Agriculture | Exporting agricultural products | Enhances market access and reduces seller responsibilities | Harvest timing, quality control, and compliance with import regulations |

| Electronics | Importing electronic components | Minimizes costs and allows for flexibility in logistics | Supplier’s ability to package and store goods, local transport options |

| Automotive | Sourcing parts for assembly | Streamlines supply chain and reduces overall shipping expenses | Supplier’s location, shipping documentation, and customs clearance |

| Textiles | Importing fabric and materials | Lowers purchase prices and allows for customized shipping plans | Quality assurance, supplier certifications, and local shipping knowledge |

How is FOB EXW Applied in Manufacturing and What Problems Does it Solve?

In the manufacturing sector, FOB EXW is often utilized for sourcing raw materials from international suppliers. This arrangement allows buyers to minimize upfront costs by assuming responsibility for transportation and logistics. Manufacturers benefit from having control over their supply chain while reducing the seller’s liabilities, which can lead to more competitive pricing. Buyers must ensure that suppliers are reliable and can provide necessary documentation for customs clearance to avoid delays.

What Are the Applications of FOB EXW in Agriculture?

In agriculture, FOB EXW is frequently employed for exporting products such as fruits, vegetables, and grains. This arrangement offers farmers and exporters enhanced market access while shifting the burden of logistics onto the buyer. By leveraging FOB EXW, agricultural businesses can avoid potential losses associated with shipping delays or damages, as they are not responsible for goods once they are made available for pickup. Buyers should focus on harvest timing and ensure compliance with the importing country’s regulations for smooth transactions.

How Do Electronics Companies Benefit from FOB EXW?

Electronics companies often rely on FOB EXW for importing components like circuit boards and semiconductors. This arrangement allows them to minimize shipping costs while maintaining flexibility in logistics. By taking on the responsibility for transportation, buyers can select the most cost-effective shipping methods and schedules. However, it is crucial for buyers to assess the supplier’s ability to package and store sensitive electronic components properly, as well as their knowledge of local transport options to mitigate risks.

What Are the Key Considerations for Automotive Parts Sourcing with FOB EXW?

In the automotive industry, FOB EXW is used extensively for sourcing parts required for assembly. This arrangement streamlines the supply chain by allowing buyers to manage logistics and reduce overall shipping expenses. By shifting the responsibility for transportation to the buyer, manufacturers can negotiate better rates and timelines. However, it is essential to verify the supplier’s location and ensure they can provide accurate shipping documentation to facilitate customs clearance and avoid delays in production.

How is FOB EXW Used in the Textiles Sector?

In the textiles industry, FOB EXW is beneficial for importing fabrics and materials from international suppliers. This arrangement helps businesses lower purchase prices by transferring logistics responsibilities to the buyer. Importers can customize their shipping plans based on their specific needs, allowing for greater flexibility. However, buyers must prioritize quality assurance and verify supplier certifications to ensure that the materials meet their standards, alongside having knowledge of local shipping regulations to avoid compliance issues.

3 Common User Pain Points for ‘fob exw’ & Their Solutions

Scenario 1: Navigating Unexpected Costs in EXW Transactions

The Problem: When dealing with Ex Works (EXW) shipping terms, B2B buyers often face the challenge of unexpected additional costs. Since the seller’s responsibility ends once the goods are made available at their premises, the buyer assumes full responsibility for all logistics. This can include transportation, customs clearance, and any unforeseen charges, such as demurrage fees or unexpected tariffs. For buyers unfamiliar with the seller’s local logistics environment, these costs can quickly escalate, impacting the overall budget and profitability of the transaction.

The Solution: To mitigate unexpected costs, B2B buyers should conduct thorough due diligence before entering an EXW agreement. This involves understanding the complete logistics landscape in the seller’s country. Buyers should establish relationships with local freight forwarders who can provide insights into typical costs associated with transporting goods from the seller’s location. Additionally, buyers should request detailed quotes from multiple logistics providers to identify the best rates and services. Clearly specifying the logistics expectations in the contract can also help manage costs—detailing who is responsible for customs duties, insurance, and any other fees will ensure there are no surprises down the line.

Scenario 2: Lack of Control Over Shipping and Delivery Timelines with FOB

The Problem: B2B buyers opting for Free on Board (FOB) shipping terms may find themselves at the mercy of the seller’s ability to manage the shipping process. Once the goods are loaded onto the vessel, the responsibility shifts to the buyer. If the seller delays loading or fails to adhere to agreed timelines, it can result in significant delays in delivery. This lack of control can disrupt the buyer’s supply chain, leading to missed deadlines and potentially damaging business relationships.

The Solution: To maintain control over shipping and delivery timelines in FOB transactions, buyers should establish clear timelines and performance metrics within their contracts. This includes setting deadlines for when goods must be loaded and specifying penalties for delays. Buyers should also maintain open lines of communication with sellers, regularly checking in on the status of shipments. Utilizing tracking technology can provide real-time updates, allowing buyers to make adjustments to their logistics plans if delays arise. Furthermore, engaging a reliable freight forwarder can help coordinate the shipping process and manage any potential disruptions, ensuring a smoother delivery experience.

Scenario 3: Complexity in Documentation and Compliance for International Shipping

The Problem: International shipping under EXW or FOB terms can involve complex documentation and compliance requirements, which can be overwhelming for B2B buyers, especially those new to global trade. Inaccuracies or missing documents can lead to customs delays, fines, or even the confiscation of goods. This complexity is compounded for buyers in regions with less familiarity with international shipping regulations, such as those from Africa or South America.

The Solution: To navigate the complexities of documentation and compliance effectively, B2B buyers should invest in education and resources. Familiarizing themselves with Incoterms and relevant regulations is essential; many online resources and workshops can provide this knowledge. Additionally, buyers should consider working with a customs broker or trade compliance expert who can guide them through the necessary paperwork and ensure adherence to local and international regulations. Creating a checklist of required documents, such as invoices, packing lists, and bills of lading, can streamline the process and reduce the risk of errors. By prioritizing proper documentation, buyers can facilitate smoother customs processes and avoid costly delays.

Strategic Material Selection Guide for fob exw

What Are the Key Properties of Common Materials Used in FOB EXW Transactions?

When engaging in international trade under FOB or EXW terms, selecting the right materials is crucial for ensuring product performance and compliance with various standards. Below are analyses of four common materials, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Steel Perform in FOB EXW Applications?

Key Properties: Steel is renowned for its high tensile strength, durability, and corrosion resistance, particularly when treated with coatings like galvanization. It can withstand significant pressure and temperature variations, making it suitable for various applications, from construction to manufacturing.

Pros & Cons: Steel’s durability ensures longevity in products, but it can be heavy and may involve higher shipping costs. While generally more affordable, the manufacturing complexity increases with specialized treatments, which can raise costs. Its suitability for heavy-duty applications is a significant advantage.

Impact on Application: Steel is compatible with a range of media, including water and chemicals, depending on the alloy used. However, buyers must ensure that the specific type of steel meets the necessary standards for their intended application.

Considerations for International Buyers: Compliance with international standards like ASTM for the U.S. or DIN for Germany is essential. Buyers from regions like Africa and South America should also consider local regulations regarding steel imports.

What Are the Advantages of Using Plastic Materials in FOB EXW Transactions?

Key Properties: Plastics offer excellent corrosion resistance, lightweight characteristics, and versatility in manufacturing. They can be engineered to withstand various temperatures and pressures, making them suitable for diverse applications.

Pros & Cons: The primary advantage of plastic is its low weight, which reduces shipping costs. However, certain plastics may lack the durability of metals and can be more susceptible to environmental degradation. The manufacturing complexity varies widely, with some plastics requiring specialized processes.

Impact on Application: Plastics are often used in applications where corrosion resistance is critical, such as in chemical handling. However, compatibility with specific media must be assessed to avoid degradation.

Considerations for International Buyers: Buyers should be aware of common standards like ISO for plastics and ensure compliance with local regulations in their respective regions. For instance, European buyers may need to adhere to REACH regulations concerning chemical safety.

How Do Composite Materials Compare in FOB EXW Transactions?

Key Properties: Composite materials, such as fiberglass or carbon fiber, combine different materials to achieve superior strength-to-weight ratios and enhanced corrosion resistance. They can be tailored for specific performance requirements, including thermal and electrical insulation.

Pros & Cons: The significant advantage of composites is their lightweight nature and high strength, making them ideal for aerospace and automotive applications. However, they often come with higher manufacturing costs and complexity, which can deter some buyers.

Impact on Application: Composites are particularly suited for applications requiring high performance under extreme conditions, such as in aerospace or marine environments. Buyers must ensure that the composite materials meet the required specifications for their applications.

Considerations for International Buyers: Compliance with industry-specific standards, such as ASTM D3039 for tensile properties, is critical. Buyers in regions like the Middle East should also consider the availability of local suppliers who can provide compliant materials.

What Are the Benefits and Limitations of Using Aluminum in FOB EXW Transactions?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It performs well under a range of temperatures and is often used in applications where weight is a critical factor.

Pros & Cons: The lightweight nature of aluminum reduces shipping costs, making it an attractive option for international buyers. However, it can be more expensive than steel and may require additional treatments to enhance its strength.

Impact on Application: Aluminum is suitable for various media, including water and some chemicals, but buyers should verify compatibility for specific applications. Its use in industries like automotive and aerospace is prevalent due to its favorable properties.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. Additionally, understanding local market preferences and regulations in regions like Europe and South America can aid in successful sourcing.

Summary Table of Material Selection for FOB EXW

| Material | Typical Use Case for fob exw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, manufacturing | High durability and strength | Heavy, potential high shipping costs | Medium |

| Plastic | Chemical handling, packaging | Lightweight, corrosion-resistant | Less durable than metals | Low |

| Composite | Aerospace, automotive | Superior strength-to-weight ratio | High manufacturing cost | High |

| Aluminum | Automotive, electronics | Lightweight, good thermal conductivity | Higher cost than steel | Medium |

This strategic material selection guide aims to provide international B2B buyers with actionable insights into material properties and considerations when engaging in FOB and EXW transactions. Understanding these factors can lead to more informed purchasing decisions and successful international trade relationships.

In-depth Look: Manufacturing Processes and Quality Assurance for fob exw

What Are the Main Stages of the Manufacturing Process in FOB EXW Transactions?

Understanding the manufacturing process is crucial for B2B buyers, especially when engaging in FOB (Free on Board) and EXW (Ex Works) transactions. These terms dictate the responsibilities of buyers and sellers in international shipping, and knowing how products are made can help buyers make informed decisions.

What Are the Key Stages of Manufacturing?

-

Material Preparation

– This initial stage involves sourcing and preparing raw materials for production. Buyers should inquire about suppliers’ material sources and their compliance with international standards. For instance, ensuring materials are sourced sustainably can add value to the final product.

– Techniques such as cutting, shaping, or treating materials are employed to make them ready for the next manufacturing stages. -

Forming

– Forming techniques vary widely depending on the type of product being manufactured. Common methods include molding, casting, and machining. Buyers should assess whether the techniques align with the desired quality and specifications.

– It’s essential for buyers to understand how forming techniques can impact the product’s durability and overall quality. -

Assembly

– In this stage, the prepared components are assembled to create the final product. Quality control is critical here, as this is where defects can arise due to improper assembly.

– Buyers should inquire about the assembly processes, including labor training, to ensure skilled workers are handling the products. -

Finishing

– The finishing stage enhances the product’s appearance and protects it from environmental factors. Techniques include painting, coating, and polishing. Buyers should request information on the finishing processes and materials used to ensure compliance with safety and quality standards.

How Is Quality Assurance Implemented in FOB EXW Transactions?

Quality assurance is vital in manufacturing, especially for international B2B transactions. Buyers need to ensure that the products they receive meet specific standards and regulations.

Which International Standards Should B2B Buyers Be Aware Of?

- ISO 9001: This is a globally recognized standard for quality management systems. Suppliers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- Industry-Specific Certifications: Depending on the product, buyers may also look for certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas products. These certifications assure compliance with specific industry standards.

What Are the Key Quality Control Checkpoints?

Effective quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC)

– This checkpoint occurs when raw materials arrive at the manufacturing facility. Suppliers should have processes in place to inspect materials for defects or deviations from specifications. -

In-Process Quality Control (IPQC)

– During the manufacturing process, ongoing inspections are conducted to identify defects early. This proactive approach helps reduce waste and ensures that quality is maintained throughout production. -

Final Quality Control (FQC)

– Before products are shipped, a final inspection ensures they meet all specifications and quality standards. Buyers should ask suppliers about their FQC processes and criteria.

What Common Testing Methods Are Used in Quality Control?

Several testing methods can be employed to ensure product quality:

- Visual Inspection: Basic yet effective, visual inspections can identify obvious defects in products.

- Functional Testing: This involves testing the product under simulated conditions to ensure it performs as intended.

- Destructive Testing: For critical components, destructive testing may be employed to determine the product’s limits and capabilities.

- Non-Destructive Testing (NDT): Techniques like ultrasound or X-ray are used to inspect materials without causing damage, ensuring structural integrity.

How Can B2B Buyers Verify Supplier Quality Control?

Verification of a supplier’s quality control processes is essential for building trust and ensuring product quality. Here are some strategies for B2B buyers:

-

Supplier Audits

– Conducting audits allows buyers to assess a supplier’s manufacturing processes and quality control measures firsthand. It provides insight into their operational capabilities and adherence to standards. -

Requesting Quality Control Reports

– Buyers should ask for documentation that outlines the quality control measures in place, including IQC, IPQC, and FQC procedures. These reports can reveal the thoroughness of the supplier’s quality management system. -

Third-Party Inspections

– Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and product quality. This is particularly valuable for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances when dealing with suppliers:

- Cultural Differences: Understanding cultural norms can influence communication and negotiation styles. Building rapport is essential for effective collaboration.

- Regulatory Compliance: Buyers must ensure that suppliers comply with both local and international regulations, which can vary significantly across regions.

- Language Barriers: Clear communication is vital. Buyers should consider hiring translators or using bilingual representatives to avoid misunderstandings during negotiations and inspections.

Conclusion

For B2B buyers engaging in FOB and EXW transactions, understanding the manufacturing processes and quality assurance practices is essential for ensuring product quality. By familiarizing themselves with key manufacturing stages, international standards, quality control checkpoints, and verification methods, buyers can make informed decisions that contribute to successful international trade relationships. These insights not only help mitigate risks but also enhance the overall value derived from cross-border transactions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fob exw’

In the dynamic landscape of international trade, understanding the intricacies of shipping terms like Free on Board (FOB) and Ex Works (EXW) is essential for B2B buyers. This practical sourcing guide offers a step-by-step checklist for effectively procuring goods under these Incoterms, ensuring that buyers are well-equipped to navigate the complexities of global logistics.

Step 1: Understand the Key Differences Between FOB and EXW

Before engaging with suppliers, familiarize yourself with the distinctions between FOB and EXW. This understanding will help you determine which term best suits your operational capabilities. EXW places the minimum responsibility on the seller, while FOB requires the seller to manage costs and risks until the goods are loaded on the vessel.

Step 2: Assess Your Shipping Capability

Evaluate your company’s logistics infrastructure and shipping expertise. If you have limited experience with international shipping, opting for FOB may mitigate risks, as the seller will handle more responsibilities. Conversely, if you are well-versed in logistics and customs in the seller’s country, EXW could offer cost savings.

Step 3: Define Your Technical Specifications

Clearly outline the specifications of the goods you intend to procure. This includes dimensions, weight, materials, and any quality standards that must be met. Providing detailed specifications helps suppliers understand your requirements and minimizes the risk of receiving incorrect or subpar products.

Step 4: Verify Supplier Credentials

Conduct thorough due diligence on potential suppliers. Check for certifications, past performance records, and customer reviews to ensure they are reputable and capable of fulfilling your order. Engaging with suppliers with a solid track record can significantly reduce the risks associated with international procurement.

Step 5: Request Detailed Quotes

When you identify potential suppliers, request comprehensive quotes that include all costs associated with the shipment, such as transportation, insurance, and any applicable duties. This transparency will help you compare offers effectively and make informed decisions regarding cost versus service.

Step 6: Negotiate Terms Clearly

Once you receive quotes, engage in discussions to negotiate favorable terms. Ensure that both parties clearly understand the responsibilities associated with FOB and EXW. This includes confirming the pickup location, shipping arrangements, and who will handle customs clearance to avoid any misunderstandings later.

Step 7: Draft a Comprehensive Contract

Finalize the procurement process by drafting a detailed contract that specifies all agreed-upon terms, including delivery timelines, payment terms, and liability clauses. A well-structured contract protects both parties and provides a clear framework for resolving disputes should they arise.

By following this checklist, B2B buyers can navigate the complexities of international shipping with greater confidence and efficiency, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for fob exw Sourcing

What Are the Key Cost Components in FOB and EXW Sourcing?

When sourcing products under FOB (Free on Board) and EXW (Ex Works) terms, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The raw materials used in production directly impact the final price. Buyers should consider the quality and sourcing of these materials, as premium options may increase costs significantly.

-

Labor: Labor costs vary by region and can affect pricing. In regions with higher labor costs, manufacturers may charge more, impacting the total cost for buyers.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. A transparent breakdown of these costs can help buyers negotiate better.

-

Tooling: If custom tooling is required for specific products, this can add to the initial cost. Buyers should assess whether the investment in tooling aligns with their volume needs.

-

Quality Control (QC): Implementing rigorous QC measures can incur additional costs. Buyers should weigh the importance of quality assurance against potential savings from lower-quality alternatives.

-

Logistics: Under FOB terms, the seller is responsible for logistics until the goods are loaded onto the shipping vessel. In contrast, EXW places this responsibility on the buyer, who must arrange and pay for transportation from the seller’s location. This can significantly affect the total cost depending on the distance and method of shipping.

-

Margin: The supplier’s profit margin will also influence pricing. Understanding industry standards for margins can aid buyers in evaluating if prices are competitive.

What Factors Influence Pricing for FOB and EXW Agreements?

Several factors play a crucial role in determining pricing in FOB and EXW agreements:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced unit prices due to economies of scale. Negotiating MOQs can enhance cost efficiency.

-

Specifications and Customization: Custom products typically incur higher costs. Buyers should be clear about their specifications to avoid unexpected expenses.

-

Quality and Certifications: Higher quality standards and certifications (e.g., ISO, CE) can increase costs but often lead to better reliability and performance.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can affect pricing. Building long-term relationships can lead to better pricing through loyalty and trust.

-

Incoterms: The choice between FOB and EXW significantly influences pricing and risk. FOB may involve higher upfront costs for the seller, while EXW shifts more responsibility (and potential costs) to the buyer.

How Can Buyers Optimize Costs and Pricing in FOB and EXW Sourcing?

To ensure cost-effectiveness in sourcing under FOB or EXW terms, consider the following tips:

-

Negotiate Effectively: Leverage volume and long-term purchasing agreements to negotiate better pricing. Be clear about your expectations and seek transparency in pricing components.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider all associated costs, including transportation, customs duties, and potential tariffs, particularly for international shipments.

-

Understand Pricing Nuances: International buyers should be aware of regional pricing differences and logistics costs. Factors such as currency fluctuations, tariffs, and local supply chain dynamics can impact overall costs.

-

Conduct Thorough Supplier Research: Vet suppliers thoroughly, considering their pricing structures, delivery times, and service levels. Engaging with suppliers who understand the specific challenges of your region can result in more favorable terms.

Disclaimer on Indicative Prices

Pricing in international trade can vary significantly based on numerous factors, including market conditions, supplier negotiations, and regional economic conditions. Therefore, the prices discussed in this analysis are indicative and should be verified with suppliers to obtain accurate quotes tailored to your specific needs.

Alternatives Analysis: Comparing fob exw With Other Solutions

When navigating international shipping, understanding the various Incoterms is essential for optimizing logistics and costs. While Free on Board (FOB) and Ex Works (EXW) are popular options, there are alternative methods that may better suit specific business needs. This section will compare FOB and EXW with two viable alternatives: Delivered Duty Paid (DDP) and Cost, Insurance, and Freight (CIF).

Comparison Table

| Comparison Aspect | Fob Exw | Delivered Duty Paid (DDP) | Cost, Insurance, and Freight (CIF) |

|---|---|---|---|

| Performance | Moderate | High | High |

| Cost | Generally lower | Higher due to inclusivity | Moderate, depending on terms |

| Ease of Implementation | Moderate complexity | Low, as seller handles most | Moderate, requires understanding of logistics |

| Maintenance | Low | Moderate, requires oversight | Moderate, requires insurance management |

| Best Use Case | Buyers with logistics knowledge | Buyers wanting a hassle-free process | Buyers needing cost predictability |

Understanding Delivered Duty Paid (DDP)

Delivered Duty Paid (DDP) is an Incoterm that places maximum responsibility on the seller. The seller is responsible for all costs, including shipping, insurance, and customs duties, until the goods reach the buyer’s location. This arrangement is advantageous for buyers who prefer a simplified process, as it eliminates the complexities of customs and logistics management. However, DDP can lead to higher costs as the seller incorporates all expenses into the price. It is best suited for buyers who prioritize convenience over cost and may not have the expertise or resources to manage shipping logistics.

Exploring Cost, Insurance, and Freight (CIF)

Cost, Insurance, and Freight (CIF) is another alternative that combines shipping and insurance costs into a single price. The seller is responsible for delivering the goods to the port of destination and covering the insurance during transit. This option offers a balance between cost and protection, making it suitable for buyers who want to mitigate risks while keeping transportation costs manageable. However, buyers need to be aware that they assume responsibility for the goods once they reach the destination port, which requires familiarity with local logistics. CIF is ideal for buyers looking for a middle ground between FOB and DDP.

Conclusion: How to Choose the Right Shipping Solution

Selecting the best shipping method depends on various factors, including cost, risk tolerance, and logistical expertise. Buyers who have established relationships with suppliers and are familiar with local shipping regulations may benefit from EXW or FOB due to lower costs. Conversely, those seeking a hassle-free experience with minimal involvement in logistics may find DDP more appealing, while CIF provides a balanced approach with some level of risk management. By carefully assessing their operational capabilities and priorities, B2B buyers can make informed decisions that align with their specific needs and enhance their international trade efficiency.

Essential Technical Properties and Trade Terminology for fob exw

What Are the Key Technical Properties Related to FOB and EXW?

Understanding the technical specifications associated with FOB (Free on Board) and EXW (Ex Works) is crucial for international B2B transactions. Here are some critical properties that buyers should consider:

-

Shipping Point: The shipping point is the location where the seller hands over the goods to the buyer’s designated carrier. For FOB agreements, this point is typically the port of shipment. Understanding the shipping point is vital for determining cost responsibilities and risk transfer.

-

Loading Responsibilities: Under FOB, the seller is responsible for loading the goods onto the buyer’s chosen vessel, while in EXW, the seller only needs to make the goods available for pickup. This distinction affects logistics planning and cost allocation, making it essential for buyers to clarify loading terms upfront.

-

Risk Transfer Point: In a FOB agreement, risk transfers from the seller to the buyer once the goods are loaded onto the vessel. In contrast, with EXW, the buyer assumes risk as soon as they take possession of the goods. Knowing when risk transfers helps buyers manage insurance and liability effectively.

-

Customs Clearance: FOB includes the responsibility for export customs clearance as part of the seller’s obligations, whereas EXW requires the buyer to handle all customs procedures. This difference can significantly impact the time and cost associated with international shipping.

-

Freight Charges: For FOB, the seller incurs costs up to the loading point, while the buyer takes on all transportation costs thereafter. In EXW, all transport expenses fall on the buyer from the moment they pick up the goods. This knowledge is essential for budgeting and financial planning.

-

Incoterms Compliance: Both FOB and EXW are defined under the Incoterms published by the International Chamber of Commerce (ICC). Understanding these terms ensures that both parties adhere to internationally recognized shipping standards, reducing potential disputes.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential trade terms related to FOB and EXW:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing quality products and negotiating prices.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity a supplier is willing to sell. This term is crucial for buyers to know, as it impacts inventory management and purchasing strategies.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request price and other terms for specific goods or services. This process is essential for B2B buyers to obtain competitive pricing and terms before making purchasing decisions.

-

Incoterms: These are standardized shipping terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps buyers understand their obligations and manage risks associated with shipping.

-

Bill of Lading: A bill of lading is a legal document between the shipper and carrier that details the type, quantity, and destination of the goods being transported. It serves as a receipt and can be critical for claims in case of loss or damage during transit.

-

Freight Forwarder: This is a third-party logistics provider that arranges the shipment of goods on behalf of the buyer. Utilizing a freight forwarder can simplify the shipping process, especially for buyers unfamiliar with international logistics.

In conclusion, grasping the essential technical properties and trade terminology associated with FOB and EXW is vital for B2B buyers engaging in international trade. This knowledge not only facilitates effective negotiations but also helps in managing logistics and costs more efficiently.

Navigating Market Dynamics and Sourcing Trends in the fob exw Sector

What Are the Current Global Drivers Impacting FOB and EXW Trade?

The FOB and EXW sectors are currently shaped by several global drivers that significantly influence international B2B trade, particularly for buyers from Africa, South America, the Middle East, and Europe. The rise of e-commerce has increased demand for flexible shipping options, prompting suppliers to offer varied Incoterms, including FOB and EXW. Furthermore, advancements in logistics technology, such as real-time tracking systems and automated customs clearance, are streamlining operations, making it easier for buyers to manage their supply chains.

Emerging markets are becoming vital players in the FOB and EXW space, as countries like Vietnam and regions in Africa and South America seek to enhance their export capabilities. This shift is also driven by geopolitical factors, such as trade agreements and tariffs, which impact shipping costs and responsibilities. For example, buyers must weigh the risks and benefits of EXW, where they assume more responsibility, against the more balanced risk-sharing in FOB arrangements.

As the global landscape evolves, international buyers need to stay updated on these trends to make informed decisions. Adopting a strategic approach to sourcing—factoring in cost, risk, and logistics capabilities—will be essential for maintaining competitiveness in a dynamic market.

How Can Sustainability and Ethical Sourcing Be Integrated into FOB and EXW Procurement?

Sustainability and ethical sourcing have become increasingly important in the FOB and EXW sectors, as B2B buyers are now more conscious of the environmental impact of their supply chains. The use of sustainable materials and practices not only aligns with corporate social responsibility goals but also meets the growing demand from consumers for eco-friendly products.

Buyers should prioritize suppliers who adhere to environmental standards and possess certifications such as ISO 14001 or Fair Trade. These certifications signal a commitment to sustainability and ethical practices, which can enhance a buyer’s brand reputation and appeal to environmentally conscious consumers. Moreover, integrating green logistics practices—such as optimizing transportation routes and using energy-efficient shipping methods—can reduce the carbon footprint associated with FOB and EXW shipments.

As international buyers navigate their sourcing strategies, it is crucial to evaluate the entire supply chain for sustainability. By collaborating with suppliers who share similar values, buyers can foster ethical supply chains that not only meet regulatory requirements but also contribute positively to the environment.

What Is the Historical Context of FOB and EXW in B2B Trade?

The historical context of FOB and EXW can be traced back to the establishment of Incoterms by the International Chamber of Commerce (ICC) in the early 20th century. These terms were designed to create a standardized framework for international trade, helping to clarify responsibilities and reduce disputes between buyers and sellers.

Initially, the focus was on facilitating maritime trade, with terms like Free on Board (FOB) gaining prominence as global shipping routes expanded. As trade evolved, the need for a term like Ex Works (EXW) emerged, reflecting a shift towards more buyer-centric logistics arrangements. This evolution has allowed businesses to tailor their shipping strategies to meet specific needs, accommodating diverse market dynamics and buyer preferences.

In today’s interconnected economy, understanding the historical significance of these terms helps B2B buyers appreciate the nuances of their contracts. By leveraging this knowledge, they can make more strategic decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of fob exw

-

How do I choose between FOB and EXW for my international shipments?

Choosing between FOB (Free on Board) and EXW (Ex Works) depends on your specific needs and logistics capabilities. If you have experience in handling shipments and logistics in the supplier’s country, EXW may be advantageous as it often results in lower costs. However, if you prefer the seller to manage the loading and initial transportation, FOB is better as it reduces your risk until the goods are loaded onto the vessel. Consider your familiarity with the shipping process, cost implications, and the level of control you wish to maintain over the shipment. -

What are the key differences between FOB and EXW in international trade?

The primary difference between FOB and EXW lies in the responsibilities assigned to the seller and the buyer. Under EXW, the seller’s obligation is minimal, only requiring them to make the goods available for pickup at their location. The buyer assumes all costs and risks from that point forward. In contrast, FOB requires the seller to load the goods onto the buyer’s designated transport, retaining responsibility for costs and risks until the goods are onboard. Understanding these distinctions is crucial for managing your supply chain effectively. -

What should I consider when vetting suppliers for FOB or EXW agreements?

When vetting suppliers, evaluate their reliability, experience in international trade, and understanding of the Incoterms you plan to use. Check references and reviews from other buyers to gauge their performance. It’s also important to assess their ability to meet quality standards, production timelines, and responsiveness to inquiries. Ensure they have experience with the shipping and customs processes relevant to your destination, particularly if you opt for EXW, where you assume more logistical responsibility. -

What are typical payment terms for FOB and EXW transactions?

Payment terms can vary widely depending on the supplier and the agreement. For FOB transactions, it’s common to negotiate a deposit upfront, with the balance due upon shipment or delivery. In EXW agreements, since the buyer takes on more responsibilities, suppliers may request full payment in advance or at least a significant deposit before the goods are made available. Always clarify payment terms in your contract to avoid misunderstandings and ensure smooth transactions. -

How can I ensure product quality when sourcing under FOB or EXW terms?

To ensure product quality, establish clear quality assurance (QA) standards and communicate them to your supplier before production begins. Consider arranging for third-party inspections at various production stages, especially for EXW shipments where you may not have direct oversight. Additionally, request samples or conduct factory audits to assess the supplier’s capabilities. A well-defined quality agreement can help mitigate risks associated with product defects in both FOB and EXW arrangements. -

What are the logistics implications of choosing FOB versus EXW?

The logistics implications differ significantly between FOB and EXW. With FOB, the seller manages logistics until the goods are loaded onto the vessel, simplifying the process for the buyer. Conversely, with EXW, the buyer must coordinate all logistics, including transportation and customs clearance, which can be challenging if unfamiliar with local practices. Evaluate your logistics capabilities and the potential for delays or issues in the destination country when deciding between these terms. -

What are the minimum order quantities (MOQ) typically associated with FOB and EXW?

Minimum order quantities (MOQ) can vary by supplier and product type, but generally, they may be higher for FOB agreements due to the seller’s investment in logistics. For EXW, MOQs might be lower since the buyer assumes responsibility for transport. However, suppliers may set MOQs based on production costs and capacity. Always discuss MOQs upfront to ensure they align with your purchasing goals and budget. -

What are the risks involved with FOB and EXW shipping terms?

With FOB, the primary risk for the buyer is that responsibility shifts once the goods are loaded; any damage or loss during transit is their liability. Conversely, EXW places almost all risk on the buyer from the moment the goods are made available, including transport and customs clearance. Understanding these risks is crucial for effective risk management; consider purchasing insurance or using freight forwarders to mitigate potential losses in both scenarios.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Fob Exw Manufacturers & Suppliers List

1. Investopedia – EXW vs. FOB Explained

Domain: investopedia.com

Registered: 1999 (26 years)

Introduction: Ex Works (EXW) and Free on Board (FOB) are international shipping terms (Incoterms) that dictate the responsibilities of buyers and sellers in shipping goods. EXW requires the seller to make products available at a designated location, with the buyer incurring transportation costs and risks. FOB obligates the seller to load goods onto the buyer’s transport at the shipping point, retaining responsi…

2. Unicargo – Key Incoterms Guide

Domain: unicargo.com

Registered: 1997 (28 years)

Introduction: FOB (Free On Board) and EXW (Ex Works) are two Incoterms used in international shipping. FOB requires the seller to load goods onto the buyer’s chosen ship, covering costs and risks until that point. The buyer then assumes responsibility for transportation and associated costs. EXW places minimal responsibility on the seller, who only needs to make goods available for pickup at a specified locatio…

3. Ship4WD – EXW and FOB Explained

Domain: ship4wd.com

Registered: 2020 (5 years)

Introduction: EXW (Ex Works) and FOB (Free On Board) are Incoterms used in international shipping. EXW signifies that the seller’s responsibility ends when goods are made available at their premises, with the buyer assuming all costs and risks from that point. Advantages of EXW for buyers include cost control, flexibility, and transparency, while disadvantages include increased responsibility and potential extr…

4. CargoFlip – Essential Shipping Terms

Domain: cargoflip.com

Registered: 2019 (6 years)

Introduction: Ex Works (EXW) and Free on Board (FOB) are two essential trade terms in international shipping. EXW signifies the seller’s minimum obligation, where the buyer assumes all responsibilities for transportation, loading, and insurance once the goods are made available at the seller’s premises. FOB indicates the point at which the buyer assumes responsibility for the goods, with two arrangements: FOB o…

5. Global Unity Logistics – Comprehensive Shipping Solutions

Domain: gul-llc.com

Registered: 2024 (1 years)

Introduction: Global Unity Logistics offers a range of logistics services including: Ocean Freight, Air Freight, Ground Transportation, Express Shipping, and Door-to-Door Shipping. They provide shipping solutions from China to the USA, Hong Kong to the USA, China to Canada, China to Germany, China to Australia, Korea to the USA, Europe to Australia, and Germany to the USA. Their services also include DDP shippi…

6. PROSENSO™ – Nitrile and Latex Gloves

Domain: ewmedico.com

Registered: 2020 (5 years)

Introduction: PROSENSO™ BLUE NITRILE GLOVES, PROSENSO™ BLUE FEATHER NITRILE GLOVES, PROSENSO™ BLACK NITRILE GLOVES, PROSENSO™ WHITE NITRILE GLOVES, PROSENSO™ PEARL LATEX GLOVES, PROSENSO™ BIODEGRADABLE GLOVES, PROSENSO™ SURGICAL PPE

7. China Division – Shipping Terms Explained

Domain: chinadivision.com

Registered: 2015 (10 years)

Introduction: FCA (Free Carrier): Seller delivers goods to carrier designated by buyer at a designated location; applies to all transport modes; seller responsible for export customs clearance; buyer assumes responsibility once goods are handed over.

FOB (Free On Board): Seller responsible for transporting goods to port of departure, loading them, and handling export procedures; risk passes to buyer when goods…

8. LinkedIn – Key International Trade Terms

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: The article discusses six key international trade terms: EXW (Ex Works), FOB (Free On Board), CFR (Cost and Freight), CIF (Cost, Insurance, and Freight), DDU (Delivered Duty Unpaid), and DDP (Delivered Duty Paid). Each term defines the responsibilities and risks of buyers and sellers in cross-border transactions. EXW places minimal obligation on the seller, while DDP offers maximum convenience for…

Strategic Sourcing Conclusion and Outlook for fob exw

What Are the Key Takeaways for B2B Buyers Considering FOB and EXW?

In navigating the complexities of international trade, understanding the distinctions between Free on Board (FOB) and Ex Works (EXW) is crucial for B2B buyers. FOB places more responsibility on sellers, ensuring that goods are loaded and transported to a specified point before the risk transfers to the buyer. This can be advantageous for those unfamiliar with local logistics, as it simplifies the shipping process. Conversely, EXW minimizes seller obligations, shifting maximum responsibility to the buyer. This can lead to cost savings but requires a robust understanding of logistics and potential risks.

How Can Strategic Sourcing Enhance Your Shipping Decisions?

Strategic sourcing is not just about reducing costs; it’s about optimizing supply chains and building strong partnerships. By carefully evaluating FOB and EXW terms, buyers can align their sourcing strategies with their operational capabilities and market conditions. This alignment is particularly important for buyers in Africa, South America, the Middle East, and Europe, where diverse logistics landscapes can impact costs and delivery timelines.

What Should International Buyers Do Next?

As you move forward, consider your operational strengths and the nature of your goods when selecting shipping terms. Engage with suppliers who can provide clarity on Incoterms and logistics, and leverage technology to streamline your sourcing processes. By making informed decisions today, you position your business for sustainable growth and success in the global marketplace.