A Deep Dive into Fiberglass Sheets 4X8 Price Solution

Introduction: Navigating the Global Market for fiberglass sheets 4×8 price

In the ever-evolving landscape of construction and manufacturing, sourcing quality fiberglass sheets, particularly the 4×8 size, presents a unique challenge for international B2B buyers. With fluctuating prices and varying quality across suppliers, making informed purchasing decisions can feel overwhelming. This comprehensive guide addresses these challenges head-on by offering valuable insights into the pricing dynamics of fiberglass sheets, their diverse applications, and effective supplier vetting strategies.

The guide delves into the various types of fiberglass sheets available in the market, from clear and fire-rated options to reinforced wall panels, ensuring that buyers can find the right fit for their specific needs. Additionally, we explore the factors influencing pricing, helping businesses understand how to navigate the complexities of international trade and shipping logistics.

By equipping B2B buyers from Africa, South America, the Middle East, and Europe—such as Germany and Vietnam—with actionable insights, this guide empowers them to make well-informed decisions. Whether you are looking to enhance your product offerings or seeking reliable suppliers, understanding the global market for fiberglass sheets is crucial. Together, we will navigate the intricacies of sourcing, ensuring that your procurement process is both efficient and effective, ultimately leading to successful project outcomes.

Understanding fiberglass sheets 4×8 price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat Fiberglass Sheets | Smooth surface, available in various thicknesses | Wall panels, roofing, and insulation | Pros: Lightweight, easy to install. Cons: May require edge finishing. |

| Fiberglass Reinforced Panels (FRP) | High strength, impact-resistant, available in textured finishes | Industrial walls, ceilings, and partitions | Pros: Durable, low maintenance. Cons: Higher initial cost. |

| Gel-Coated Fiberglass Sheets | Smooth, glossy finish, UV-resistant | Marine applications, outdoor structures | Pros: Aesthetic appeal, long-lasting. Cons: More expensive than standard sheets. |

| Fire-Rated Fiberglass Sheets | Compliant with fire safety standards, available in various colors | Commercial buildings, factories | Pros: Enhanced safety, regulatory compliance. Cons: Limited design options. |

| Transparent Fiberglass Sheets | Translucent, allows natural light, available in various thicknesses | Skylights, greenhouses, and light panels | Pros: Energy-efficient, aesthetically pleasing. Cons: Can be more prone to scratching. |

What are the Characteristics and Suitability of Flat Fiberglass Sheets?

Flat fiberglass sheets are characterized by their smooth surface and availability in various thicknesses, typically ranging from 1/16″ to 1/2″. They are widely used in wall paneling and roofing applications due to their lightweight nature and ease of installation. B2B buyers should consider the specific thickness and surface finish required for their projects, as these factors can impact durability and aesthetic appeal. Cost-effectiveness is a significant advantage, but edge finishing may be necessary to prevent chipping.

How Do Fiberglass Reinforced Panels (FRP) Stand Out in B2B Applications?

Fiberglass Reinforced Panels (FRP) are known for their high strength and impact resistance, making them ideal for industrial applications such as walls, ceilings, and partitions. Their textured finishes enhance grip and aesthetic appeal, which is beneficial in commercial settings. Buyers should evaluate the initial cost against the long-term savings from reduced maintenance and durability. While FRP panels are more expensive upfront, their longevity and low upkeep can justify the investment.

What Makes Gel-Coated Fiberglass Sheets Ideal for Marine Applications?

Gel-coated fiberglass sheets feature a smooth, glossy finish that is not only aesthetically pleasing but also UV-resistant, making them suitable for marine and outdoor applications. These sheets can withstand harsh environmental conditions, making them perfect for boats and outdoor structures. B2B buyers should weigh the benefits of longevity and appearance against the higher costs associated with gel-coated options. This type is ideal for businesses looking to enhance their product’s visual appeal while ensuring durability.

Why Choose Fire-Rated Fiberglass Sheets for Commercial Buildings?

Fire-rated fiberglass sheets are designed to meet stringent fire safety standards, making them a crucial choice for commercial buildings and factories. Available in various colors, these sheets provide both safety and design flexibility. B2B buyers must consider compliance with local regulations when selecting these products. While they may offer fewer design options compared to standard sheets, the enhanced safety features can significantly reduce liability risks.

What are the Advantages of Transparent Fiberglass Sheets for Energy Efficiency?

Transparent fiberglass sheets allow natural light to permeate spaces, making them an excellent choice for applications like skylights and greenhouses. Their energy-efficient properties can help reduce lighting costs in commercial buildings. Buyers should be aware that while these sheets offer aesthetic and energy-saving benefits, they can be more susceptible to scratching. Evaluating the balance between visibility, energy efficiency, and durability is essential for businesses considering transparent options.

Key Industrial Applications of fiberglass sheets 4×8 price

| Industry/Sector | Specific Application of fiberglass sheets 4×8 price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Wall and Ceiling Panels | Lightweight, durable, and resistant to moisture and mold | Ensure compliance with local building codes and standards. |

| Transportation | Truck Body and Trailer Panels | Corrosion resistance and reduced weight for fuel efficiency | Check for fire ratings and suitability for specific vehicle types. |

| Marine | Boat Hulls and Decking | Enhanced strength-to-weight ratio and resistance to marine environments | Verify UV resistance and compliance with maritime regulations. |

| Agriculture | Greenhouse Panels | Improved light transmission and thermal insulation | Consider climate conditions and the need for UV protection. |

| Industrial Manufacturing | Protective Barriers and Equipment Covers | Chemical resistance and durability under harsh conditions | Assess compatibility with chemicals used in the facility. |

How Are Fiberglass Sheets Used in Construction and Building Applications?

In the construction industry, fiberglass sheets measuring 4×8 are frequently utilized as wall and ceiling panels. Their lightweight yet durable nature makes them ideal for environments prone to moisture, such as bathrooms and kitchens. Additionally, these panels resist mold and mildew, which is crucial for maintaining indoor air quality. For international buyers, it is essential to ensure that the sheets comply with local building codes and standards, especially in regions with stringent regulations.

What Role Do Fiberglass Sheets Play in Transportation?

In the transportation sector, fiberglass sheets are commonly employed in the manufacturing of truck bodies and trailer panels. Their corrosion resistance and lightweight properties contribute significantly to fuel efficiency, making them a preferred choice among manufacturers. When sourcing these materials, businesses should verify the fire ratings and ensure that the fiberglass sheets meet the specific requirements for different vehicle types to ensure safety and compliance.

How Are Fiberglass Sheets Beneficial in Marine Applications?

Fiberglass sheets are extensively used in marine applications, particularly for boat hulls and decking. Their exceptional strength-to-weight ratio allows for enhanced performance and fuel efficiency while navigating water. Furthermore, these sheets are designed to withstand harsh marine environments, providing long-lasting durability. International buyers must verify the UV resistance and compliance with maritime regulations to ensure that the materials are suitable for their specific needs.

What Advantages Do Fiberglass Sheets Offer in Agriculture?

In the agricultural sector, 4×8 fiberglass sheets are utilized as greenhouse panels. Their ability to transmit light while providing thermal insulation is vital for promoting plant growth. These sheets also offer protection against UV rays, ensuring that crops are shielded from harmful sunlight. Buyers from regions with varying climate conditions should consider the specific requirements for UV protection and thermal performance to optimize their greenhouse environments.

How Are Fiberglass Sheets Used in Industrial Manufacturing?

Fiberglass sheets find significant applications in industrial manufacturing as protective barriers and equipment covers. Their chemical resistance and durability under harsh conditions make them ideal for safeguarding equipment and personnel from exposure to hazardous materials. When sourcing these sheets, businesses should assess their compatibility with the chemicals used in their facilities to ensure optimal performance and safety.

3 Common User Pain Points for ‘fiberglass sheets 4×8 price’ & Their Solutions

Scenario 1: Navigating Price Variability in Global Markets

The Problem: B2B buyers often face significant challenges when sourcing fiberglass sheets due to fluctuating prices that vary by region and supplier. This can lead to unpredictability in budgeting, complicating project costs, and affecting overall profitability. For instance, a manufacturer in South America may find that the cost of fiberglass sheets sourced from Europe is considerably higher due to import tariffs and shipping costs, leading to discrepancies in project planning and execution.

The Solution: To navigate price variability effectively, buyers should establish relationships with multiple suppliers across different regions. This diversification allows for better comparisons and the ability to leverage competitive pricing. Additionally, consider negotiating bulk purchasing agreements or long-term contracts to lock in prices, particularly if your project timeline is extended. Utilize online platforms to monitor price trends and stay informed about local market conditions. Implementing a price tracking system can also help anticipate fluctuations and adjust budgets accordingly, ensuring financial stability throughout the project lifecycle.

Scenario 2: Quality Assurance in Fiberglass Sheets

The Problem: Quality concerns are prevalent among B2B buyers, especially when dealing with fiberglass sheets. Poor quality materials can lead to structural failures, increased maintenance costs, and project delays. For example, a construction firm in Africa may receive a shipment of fiberglass sheets that do not meet the required specifications, compromising the integrity of the build and resulting in costly rework.

The Solution: To mitigate quality risks, buyers should prioritize sourcing from reputable suppliers with established track records. Conduct thorough due diligence, including requesting samples and certifications that verify the material’s compliance with industry standards. Consider engaging third-party quality assurance services to inspect materials before shipment. Additionally, implementing a standardized checklist for quality evaluation can streamline the procurement process and ensure that only high-quality fiberglass sheets are used. Establishing clear communication with suppliers about quality expectations will further enhance the reliability of the materials sourced.

Scenario 3: Understanding the Specifications and Applications

The Problem: Many B2B buyers struggle to understand the technical specifications and appropriate applications for different types of fiberglass sheets. This lack of knowledge can lead to purchasing errors, such as selecting the wrong thickness or type of sheet for a specific application, which can result in project delays and wasted resources. For instance, a company in the Middle East might purchase sheets that are too thin for outdoor applications, leading to premature degradation.

The Solution: Buyers should invest time in educating themselves about the various types of fiberglass sheets and their specific applications. This can be achieved through online courses, supplier webinars, and industry workshops. Additionally, collaborating with suppliers who provide technical support and guidance can be invaluable. Create a detailed project requirement document outlining the intended use, environmental conditions, and load-bearing needs, and share this with your supplier to receive tailored recommendations. Leveraging resources such as technical datasheets and application guides will also aid in making informed decisions, ensuring that the selected fiberglass sheets meet the project requirements and perform optimally in their intended environments.

Strategic Material Selection Guide for fiberglass sheets 4×8 price

What Are the Key Properties of Common Fiberglass Sheet Materials?

When selecting fiberglass sheets, particularly the 4×8 size, it is essential to consider the material composition, as it directly influences product performance and suitability for various applications. Below are analyses of four common materials used in fiberglass sheets.

Polyester Fiberglass Sheets

Polyester fiberglass sheets are among the most widely used types due to their cost-effectiveness and versatility. These sheets typically feature a temperature rating of up to 120°C and exhibit good corrosion resistance against a variety of chemicals, making them suitable for applications in construction and automotive sectors.

Pros: Polyester sheets are lightweight, relatively inexpensive, and easy to manufacture. They provide good mechanical strength and can be molded into various shapes, enhancing their application range.

Cons: However, they may not perform well under extreme temperatures or in highly corrosive environments, which can limit their use in specific industrial applications.

Impact on Application: Polyester sheets are often used in wall panels, roofing, and decorative applications. They are compatible with most common construction materials, making them a popular choice in both residential and commercial projects.

Considerations for International Buyers: Compliance with local standards such as ASTM in the U.S. or DIN in Germany is crucial. Buyers should also consider the specific environmental conditions in their regions, as polyester may not be suitable for extreme climates.

Vinyl Ester Fiberglass Sheets

Vinyl ester fiberglass sheets offer enhanced resistance to corrosion and heat, with a temperature rating that can exceed 150°C. This material is particularly favored in chemical processing and marine applications due to its superior durability.

Pros: The key advantage of vinyl ester is its excellent resistance to a wider range of chemicals compared to polyester, making it ideal for harsh environments. It also offers better mechanical properties.

Cons: The manufacturing process for vinyl ester sheets is more complex and costly, which can lead to higher prices compared to polyester options.

Impact on Application: These sheets are often used in environments where chemical exposure is a concern, such as in wastewater treatment facilities or chemical storage tanks.

Considerations for International Buyers: Buyers should ensure that vinyl ester sheets meet international standards for chemical resistance and fire safety, particularly in regions with stringent regulations.

Epoxy Fiberglass Sheets

Epoxy fiberglass sheets are known for their exceptional strength and thermal resistance, with capabilities to withstand temperatures up to 200°C. They are often used in aerospace and high-performance applications due to their superior mechanical properties.

Pros: The primary advantage of epoxy sheets is their high strength-to-weight ratio and excellent adhesion properties, making them suitable for structural applications.

Cons: The cost of epoxy sheets is generally higher than other fiberglass materials, and they can be more challenging to work with due to their rigidity.

Impact on Application: Epoxy sheets are ideal for applications requiring high strength and thermal stability, such as in the aerospace, automotive, and marine industries.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for aerospace applications, and ensure compliance with international standards.

Fire-Retardant Fiberglass Sheets

Fire-retardant fiberglass sheets are specifically designed to meet fire safety standards, making them suitable for use in commercial buildings and public spaces. They typically have a temperature rating of around 120°C.

Pros: These sheets provide excellent fire resistance, making them a safe choice for applications where fire safety is a priority.

Cons: The inclusion of fire-retardant additives can increase the cost and may slightly affect the mechanical properties compared to standard fiberglass sheets.

Impact on Application: Fire-retardant sheets are commonly used in wall panels, ceilings, and other areas where fire safety regulations are stringent.

Considerations for International Buyers: Compliance with local fire safety standards is crucial, and buyers should verify that the sheets meet the required certifications for their specific applications.

Summary Table of Fiberglass Sheet Materials

| Material | Typical Use Case for fiberglass sheets 4×8 price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Wall panels, roofing, decorative applications | Cost-effective and versatile | Limited performance in extreme conditions | Low |

| Vinyl Ester | Chemical processing, marine applications | Superior chemical and heat resistance | Higher manufacturing complexity and cost | High |

| Epoxy | Aerospace, high-performance applications | Exceptional strength and thermal stability | Higher cost and rigidity | High |

| Fire-Retardant | Commercial buildings, public spaces | Excellent fire resistance | Increased cost and potential mechanical trade-offs | Medium |

This guide provides a comprehensive overview of the different types of fiberglass sheets available in the 4×8 size, highlighting their properties, advantages, and considerations for international buyers. Understanding these factors will enable B2B buyers to make informed decisions that align with their specific application needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fiberglass sheets 4×8 price

What Are the Key Stages in the Manufacturing Process of Fiberglass Sheets?

The manufacturing process for fiberglass sheets, particularly the 4×8 size, involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages can help B2B buyers assess the value and reliability of their suppliers.

Material Preparation: What Goes into Making Fiberglass Sheets?

The first step in manufacturing fiberglass sheets is material preparation. This typically involves selecting high-quality fiberglass strands, resin, and any additional additives that may enhance the properties of the sheet. Fiberglass strands are usually made from silica sand, limestone, and other raw materials that are melted and drawn into thin fibers. These fibers are then combined with a resin, which serves as the binder, providing structural integrity to the sheet.

During this stage, suppliers may also incorporate various additives to improve characteristics such as fire resistance, UV stability, and color. This careful selection and preparation of materials is crucial, as it directly influences the durability and performance of the finished fiberglass sheets.

How Are Fiberglass Sheets Formed and Assembled?

The next stage is forming and assembling the fiberglass sheets. This is achieved through a process called lay-up, where layers of fiberglass strands are arranged in a mold and saturated with resin. There are different techniques for this, including hand lay-up, spray-up, and automated processes, each offering varying degrees of precision and efficiency.

Once the fiberglass and resin are layered, the mixture is subjected to a curing process, which can involve heat or ambient conditions, allowing the resin to harden and bond the fibers together. This stage is vital for ensuring that the sheets achieve the desired thickness and mechanical properties.

What Finishing Techniques Are Commonly Used in Fiberglass Sheet Production?

After the sheets have cured, they undergo finishing processes, which may include trimming, sanding, and surface treatment. Trimming ensures that the sheets meet the standard dimensions, while sanding provides a smooth surface that is essential for aesthetic purposes and further applications. Surface treatments may involve applying a gel coat or other protective layers to enhance UV resistance, reduce maintenance, and improve the overall appearance.

The finishing stage is where manufacturers can add unique features, such as textures or colors, making the sheets more appealing for various applications, including construction, automotive, and marine uses.

What Quality Assurance Measures Are Implemented in Fiberglass Sheet Production?

Quality assurance (QA) is an integral part of the manufacturing process for fiberglass sheets. Implementing strict QA measures not only ensures compliance with international standards but also builds trust with B2B buyers who rely on the durability and performance of these materials.

Which International Standards Are Relevant to Fiberglass Manufacturing?

Manufacturers of fiberglass sheets often adhere to several international standards, such as ISO 9001, which focuses on quality management systems, and specific industry certifications like CE marking for European markets. These standards help ensure that products meet customer and regulatory requirements, promoting safety and reliability.

In addition to these, certain industry-specific standards, such as those set by the American Petroleum Institute (API) for oil and gas applications, may also apply. Compliance with these standards is essential for suppliers aiming to operate in diverse markets, including Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) during the manufacturing process is typically segmented into several checkpoints:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials for compliance with specifications before production begins. It ensures that only high-quality materials are used in manufacturing.

-

In-Process Quality Control (IPQC): This phase includes monitoring the manufacturing process itself. Techniques such as visual inspections, dimensional checks, and process parameter monitoring are employed to ensure that the product is being manufactured according to established standards.

-

Final Quality Control (FQC): Once the sheets are completed, a final inspection is conducted. This involves testing the sheets for physical properties, such as tensile strength, flexibility, and surface finish. Various testing methods, including tensile tests and impact resistance tests, are utilized to validate the product’s performance.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should be proactive in verifying the quality control measures of their suppliers. Here are several ways to ensure that a supplier adheres to high-quality standards:

-

Conduct Supplier Audits: Periodic audits of suppliers can provide insight into their manufacturing processes, quality control measures, and adherence to international standards. These audits can be conducted by the buyer or through third-party inspection agencies.

-

Request Quality Assurance Reports: Suppliers should be willing to provide documentation detailing their quality control processes, certifications, and testing results. This transparency can help buyers assess reliability.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing practices and product quality. This is particularly important for international buyers who may face challenges in directly monitoring overseas suppliers.

What Are the Unique QC Considerations for International B2B Buyers?

For international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Differences in regulatory standards, material specifications, and market expectations can impact the quality and suitability of fiberglass sheets.

Buyers should familiarize themselves with the specific certifications required in their target markets. For instance, European buyers may prioritize CE marking, while buyers in other regions might have different compliance requirements.

Additionally, language barriers and cultural differences can affect communication regarding quality expectations. Therefore, establishing clear specifications and maintaining open lines of communication with suppliers can help mitigate potential misunderstandings.

Conclusion

The manufacturing processes and quality assurance measures for fiberglass sheets are critical components that influence the final product’s price and performance. By understanding these processes, B2B buyers can make informed decisions, ensuring they procure high-quality materials that meet their specific needs. Establishing strong relationships with reliable suppliers who adhere to international standards and rigorous quality control protocols is essential for success in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiberglass sheets 4×8 price’

When sourcing fiberglass sheets (4×8), it’s essential to follow a structured approach to ensure you make informed purchasing decisions. This guide provides a step-by-step checklist designed for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the desired thickness, type of fiberglass (e.g., polyester, fire-rated), and any specific performance characteristics, such as corrosion resistance or insulation properties. Having well-defined specifications helps streamline communication with suppliers and ensures that the products meet your project needs.

Step 2: Research Market Prices

Conduct thorough market research to understand the price range for 4×8 fiberglass sheets. Prices can vary significantly based on material, thickness, and supplier location. Utilize online platforms and local distributors to gather pricing data. This step is crucial for budgeting and allows you to identify competitive offers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to vet them thoroughly. Look for their company profile, product certifications, and customer reviews. Request case studies or references from buyers in similar industries or regions to assess their reliability and quality of service. This due diligence minimizes risks associated with procurement.

Step 4: Request Samples

Once you’ve shortlisted suppliers, request samples of the fiberglass sheets. Evaluating physical samples allows you to assess the quality, thickness, and finish before making a bulk order. This step is particularly important in industries where material performance is critical, ensuring that the product meets your expectations.

Step 5: Negotiate Terms and Conditions

Engage in negotiations regarding pricing, payment terms, and delivery schedules. Discussing these details upfront can prevent misunderstandings later on. Additionally, inquire about bulk purchase discounts or long-term partnership agreements, which could provide cost savings and enhance supply chain stability.

Step 6: Verify Shipping and Logistics

Confirm the shipping options and logistics arrangements with your chosen supplier. This includes understanding shipping costs, delivery timelines, and any customs duties that may apply when importing materials into your region. Clear communication about logistics ensures timely delivery and helps avoid unexpected delays.

Step 7: Finalize the Purchase Agreement

After confirming all details, finalize the purchase agreement. Ensure that the contract includes all negotiated terms, including specifications, pricing, payment terms, and delivery dates. Having a formal agreement protects both parties and provides a clear reference point should any issues arise during the transaction.

By following this checklist, you can effectively navigate the procurement process for fiberglass sheets, ensuring that you secure high-quality materials at competitive prices while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for fiberglass sheets 4×8 price Sourcing

Analyzing the cost structure and pricing of fiberglass sheets, specifically the 4×8 size, is essential for international B2B buyers looking to source these materials efficiently. Understanding the components of cost and the factors that influence pricing can lead to better purchasing decisions and enhanced negotiation strategies.

What Are the Key Cost Components for Fiberglass Sheets?

The cost of fiberglass sheets encompasses several components:

-

Materials: The primary cost driver is the raw materials, which include fiberglass fibers and resins. The quality and source of these materials can significantly affect the price. For instance, higher-grade resins may enhance durability but increase costs.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs, such as parts of Asia and South America, can offer more competitive pricing. However, this might also impact quality control.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities, rent, and equipment maintenance. Efficient factories with streamlined processes can reduce these overheads, leading to more competitive pricing.

-

Tooling: Initial setup costs for molds and machinery can be substantial, especially for custom sizes or specifications. These costs are usually amortized over production runs, impacting the per-unit price.

-

Quality Control (QC): Implementing rigorous QC processes ensures product consistency and safety, but it also adds to costs. Certifications (e.g., ISO) may be required in specific markets, further influencing pricing.

-

Logistics: Transportation and shipping fees play a crucial role in the total cost, particularly for international buyers. Factors such as distance, mode of transport, and customs duties can significantly affect the final price.

-

Margin: Suppliers will add their profit margin to the cost structure. This can vary widely based on market conditions and competition.

What Influences the Pricing of Fiberglass Sheets?

Several factors influence the pricing of fiberglass sheets, particularly for B2B buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQ) often dictate pricing. Higher volumes usually lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to optimize their purchase.

-

Specifications and Customization: Custom specifications (e.g., thickness, color, fire rating) can increase costs. Standard products are typically cheaper, so buyers should assess whether customization is necessary for their applications.

-

Materials and Quality: The quality of materials directly impacts price. High-quality fiberglass sheets are more durable and may offer better performance, making them a worthwhile investment despite a higher initial cost.

-

Supplier Factors: The reputation, location, and reliability of suppliers can affect pricing. Established suppliers with a proven track record may charge a premium but can provide better quality assurance.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial for cost management. They define responsibilities and risks in shipping, which can influence total costs.

What Are Effective Buyer Tips for Cost-Efficiency?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, can implement several strategies to enhance cost-efficiency:

-

Negotiate Effectively: Leverage volume purchasing and long-term contracts to negotiate better pricing. Building relationships with suppliers can also yield better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also factors like maintenance, durability, and shipping costs. A lower upfront cost may not always equate to overall savings.

-

Understand Pricing Nuances: Be aware that pricing can vary significantly based on local market conditions, currency fluctuations, and geopolitical factors. Conducting thorough market research can help buyers identify the best sourcing options.

Disclaimer

Prices for fiberglass sheets can fluctuate based on market dynamics, material availability, and supplier pricing strategies. The figures presented in this analysis are indicative and should be verified with suppliers for accuracy at the time of purchase.

Alternatives Analysis: Comparing fiberglass sheets 4×8 price With Other Solutions

Exploring Alternatives to Fiberglass Sheets 4×8

When considering materials for construction or manufacturing, it’s essential to evaluate alternatives that can meet specific project requirements while potentially offering cost savings or improved performance. This section compares the pricing and value propositions of fiberglass sheets (4×8) against other viable options such as PVC sheets and plywood.

Comparison Table

| Comparison Aspect | Fiberglass Sheets 4X8 Price | PVC Sheets | Plywood |

|---|---|---|---|

| Performance | High durability, corrosion-resistant | Moderate durability, resistant to moisture | Good strength, but susceptible to water damage |

| Cost | $255.11 | $200 – $300 | $50 – $150 |

| Ease of Implementation | Moderate; requires special tools | Easy; can be cut with standard tools | Easy; standard woodworking tools suffice |

| Maintenance | Low; requires minimal upkeep | Low; easy to clean | Moderate; may require sealing |

| Best Use Case | Industrial applications, chemical environments | Decorative panels, moisture-prone areas | General construction, furniture |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of PVC Sheets?

PVC sheets are a popular alternative due to their versatility and resistance to moisture. They are lighter than fiberglass and can be easily cut and shaped with standard tools, making them user-friendly for various applications. The cost of PVC sheets typically ranges from $200 to $300, providing a competitive option for projects requiring water resistance. However, while PVC is durable, it may not withstand high temperatures or harsh chemicals as effectively as fiberglass, which limits its use in certain industrial settings.

How Does Plywood Compare as a Building Material?

Plywood is one of the most cost-effective options, with prices ranging from $50 to $150 for a 4×8 sheet. It offers excellent structural strength and is widely used in general construction and furniture manufacturing. The ease of working with plywood is notable, as it can be cut with standard woodworking tools. However, plywood is vulnerable to moisture and may require sealing to prevent warping or decay, making it less suitable for environments exposed to water or chemicals. While it is a good choice for many applications, its durability and longevity may not match that of fiberglass.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right material for your project involves balancing performance, cost, and specific use cases. For industrial applications where durability and resistance to harsh conditions are paramount, fiberglass sheets (4×8) are an excellent choice despite their higher price point. On the other hand, if budget constraints are a priority and the application is less demanding, PVC sheets or plywood could serve as viable alternatives. B2B buyers should assess their unique requirements—such as environmental exposure, desired longevity, and installation conditions—before making a decision, ensuring that the selected material aligns with both project goals and financial considerations.

Essential Technical Properties and Trade Terminology for fiberglass sheets 4×8 price

What Are the Key Technical Properties of Fiberglass Sheets 4×8?

1. Material Grade

Material grade indicates the quality and type of resin used in fiberglass sheets, commonly either polyester or epoxy. Polyester is typically more cost-effective, while epoxy provides superior strength and chemical resistance. Understanding material grades is crucial for buyers as it directly affects the durability and application suitability of the sheets.

2. Thickness

Fiberglass sheets are available in various thicknesses, often ranging from 1/16 inch to 1/2 inch. The thickness impacts the sheet’s strength, weight, and insulation properties. For B2B buyers, selecting the appropriate thickness is essential to meet specific project requirements, such as load-bearing capacity and thermal insulation.

3. Surface Finish

The surface finish of fiberglass sheets can be smooth, textured, or embossed. A smooth finish is ideal for applications requiring easy cleaning and aesthetic appeal, while textured surfaces may provide additional grip or aesthetic value. This property influences both functionality and the visual aspect of installations, making it important for buyers to consider in their specifications.

4. Fire Rating

Fire ratings indicate the material’s resistance to fire and heat. Fiberglass sheets can be manufactured to meet various fire safety standards, which is particularly important in construction and manufacturing environments. B2B buyers must ensure that the fiberglass sheets meet local fire safety regulations to minimize risks and liability.

5. Chemical Resistance

Fiberglass sheets exhibit varying levels of resistance to chemicals, which is critical for industries such as food processing, pharmaceuticals, and chemical manufacturing. Buyers should evaluate chemical resistance properties to ensure that the selected sheets can withstand specific environmental conditions and substances, thus prolonging their lifespan.

Which Trade Terms Are Important for Understanding Fiberglass Sheets 4×8 Pricing?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of fiberglass sheets, understanding OEM relationships can help buyers identify reliable suppliers and ensure that they receive high-quality products that meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for fiberglass sheets can help buyers plan their purchasing strategies, especially when dealing with international suppliers. This term is essential for managing inventory and budgeting effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products. Crafting a detailed RFQ for fiberglass sheets can help buyers receive accurate quotes and compare options across different suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for B2B buyers, as they dictate who is responsible for shipping, insurance, and tariffs. This knowledge can significantly impact the total cost of procurement and the logistics involved in importing fiberglass sheets.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. For B2B buyers, understanding lead times for fiberglass sheets is crucial for project planning and ensuring that materials are available when needed. Delays in lead time can disrupt timelines and increase costs, making it essential to factor this into procurement strategies.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions regarding the procurement of fiberglass sheets, ensuring that they select the best products for their specific needs while navigating the complexities of global trade.

Navigating Market Dynamics and Sourcing Trends in the fiberglass sheets 4×8 price Sector

What Are the Current Market Dynamics Influencing Fiberglass Sheets 4×8 Prices?

The global market for fiberglass sheets, particularly the 4×8 variant, is experiencing significant changes driven by several factors. The construction and building materials sector is increasingly adopting fiberglass due to its lightweight, corrosion-resistant, and versatile nature. Emerging economies in Africa and South America are witnessing a surge in infrastructure development, which is boosting demand for fiberglass sheets. Additionally, technological advancements in manufacturing processes are reducing production costs, which may lead to more competitive pricing.

Internationally, B2B buyers should be aware of the impact of fluctuating raw material costs, particularly resin and fiberglass reinforcements, which can significantly affect pricing. The market is also experiencing a shift toward online procurement platforms, enhancing transparency and efficiency in sourcing. As buyers become more tech-savvy, they are leveraging digital tools for price comparison and supplier evaluations, ensuring they obtain the best deals.

Moreover, sustainability is becoming a key driver in sourcing decisions. Companies are increasingly looking for suppliers that prioritize eco-friendly practices and materials, which can influence pricing structures. The ongoing geopolitical tensions and supply chain disruptions due to the pandemic have also prompted buyers to diversify their supplier base, ensuring resilience in their procurement strategies.

How Is Sustainability Shaping the Sourcing of Fiberglass Sheets?

Sustainability has emerged as a critical consideration for B2B buyers in the fiberglass sheets market. The environmental impact of manufacturing processes and the lifecycle of fiberglass products is under scrutiny, prompting buyers to seek suppliers that adhere to sustainable practices. Certifications such as ISO 14001 for environmental management systems and LEED (Leadership in Energy and Environmental Design) are becoming essential for suppliers targeting international markets.

Moreover, the demand for “green” materials is rising. Buyers are encouraged to look for fiberglass sheets made from recycled materials or those that utilize low-emission production techniques. This shift not only helps in minimizing the carbon footprint but also aligns with the growing consumer preference for eco-friendly products, particularly in regions like Europe where regulations around sustainability are stringent.

Ethical sourcing is another significant aspect. Buyers are increasingly concerned about the labor practices of their suppliers, particularly in developing regions. Ensuring that suppliers adhere to fair labor practices is not only a moral obligation but also a strategic advantage in enhancing brand reputation and customer trust.

What Is the Evolution of Fiberglass Sheets in the B2B Market?

The evolution of fiberglass sheets has been marked by significant technological advancements since their inception. Initially, fiberglass was primarily used in niche applications due to its high cost and limited availability. However, as manufacturing processes improved and production scaled, the material became more accessible and affordable.

In the 1980s and 1990s, fiberglass gained popularity in construction and industrial applications due to its strength-to-weight ratio and durability. The introduction of new formulations and composites enhanced its performance, making it suitable for a broader range of applications, including wall panels, roofing, and insulation.

Today, the fiberglass sheets market is characterized by innovation, with manufacturers continuously exploring new materials and production methods. This evolution has led to the development of specialized products such as fire-rated fiberglass sheets and those designed for specific environmental conditions, catering to the diverse needs of international B2B buyers. As the market continues to evolve, the focus on sustainability and ethical sourcing is expected to shape future trends, making it imperative for buyers to stay informed and adaptable.

Frequently Asked Questions (FAQs) for B2B Buyers of fiberglass sheets 4×8 price

-

How do I find reliable suppliers for fiberglass sheets in international markets?

To find reliable suppliers for fiberglass sheets, start by researching manufacturers and distributors in your target regions. Utilize platforms such as Alibaba, Global Sources, or trade directories specific to your area. Assess supplier credibility by checking reviews, certifications, and their history of exports. It’s beneficial to request samples and evaluate their quality before committing to larger orders. Engage in direct communication to clarify any doubts regarding production capabilities and timelines, ensuring they align with your project requirements. -

What factors influence the price of 4×8 fiberglass sheets?

The price of 4×8 fiberglass sheets is influenced by various factors, including the thickness of the sheet, material composition, and specific reinforcement features. Additionally, market demand, shipping costs, and currency fluctuations can affect pricing, especially in international transactions. Customization requests, such as specific colors or finishes, can also lead to variations in cost. It’s advisable to obtain quotes from multiple suppliers to compare and negotiate better pricing based on your purchase volume. -

What are the minimum order quantities (MOQ) for fiberglass sheets?

Minimum order quantities (MOQ) for fiberglass sheets can vary significantly by supplier and product type. Typically, MOQs range from 50 to 200 square meters, depending on the manufacturer’s production capacity and inventory policies. For international buyers, establishing a good relationship with suppliers may allow for lower MOQs, especially for first-time orders. Always inquire about flexibility in MOQs, as some suppliers may accommodate smaller orders or provide samples for evaluation. -

What payment terms should I expect when ordering fiberglass sheets?

Payment terms for fiberglass sheet orders often vary by supplier and region. Common practices include a 30% deposit with the order and the balance before shipment, or net 30 to 60 days after delivery. For international transactions, consider using secure payment methods such as letters of credit, PayPal, or escrow services to protect your investment. Always clarify terms in advance and ensure they are documented in the purchase agreement to avoid misunderstandings. -

How can I ensure the quality of fiberglass sheets before purchasing?

To ensure quality, request samples from potential suppliers before placing a bulk order. Examine the samples for consistency in thickness, surface finish, and material properties. Additionally, ask for certifications that verify compliance with international standards, such as ISO or ASTM. It’s also prudent to inquire about the supplier’s quality assurance processes and whether they conduct regular product testing. Establishing a clear quality inspection protocol can help mitigate risks associated with subpar materials. -

What should I consider regarding logistics when importing fiberglass sheets?

When importing fiberglass sheets, consider logistics factors such as shipping methods, freight costs, and lead times. Choose between air freight for faster delivery or sea freight for cost-effective bulk shipments. Be aware of customs regulations in your country and ensure all documentation is accurate to avoid delays. Collaborating with a freight forwarder can streamline the process, helping you navigate international shipping complexities and ensuring compliance with local import laws. -

Can fiberglass sheets be customized for specific applications?

Yes, fiberglass sheets can be customized to suit various applications. Many manufacturers offer options for different thicknesses, colors, and surface finishes based on customer requirements. Additionally, you can specify unique properties such as fire resistance or UV protection for outdoor applications. When discussing customization, provide detailed specifications to ensure that the final product meets your project needs. Always confirm the supplier’s capabilities to avoid unexpected limitations. -

What are the best practices for storing fiberglass sheets after purchase?

To maintain the integrity of fiberglass sheets post-purchase, store them in a dry, temperature-controlled environment, away from direct sunlight to prevent degradation. Ideally, keep sheets flat and avoid stacking them in a way that could cause warping. If possible, cover them with protective sheeting to shield against dust and moisture. Establishing an organized storage system will help you access materials easily while preserving their quality for future use.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Fiberglass Sheets 4X8 Price Manufacturers & Suppliers List

1. Eplastics – Flat Clear Fiberglass Sheet 1/16 x 48 x 96

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: 1/16″ x 48″ x 96″ Flat Clear Fiberglass Sheet

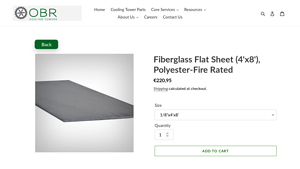

2. OBR Cooling Towers – Fiberglass Flat Sheet

Domain: obrcoolingtowers.com

Registered: 1998 (27 years)

Introduction: Fiberglass Flat Sheet Polyester Fire Rated

3. Dinuofrp – 4×8 Fiberglass Sheets

Domain: dinuofrp.com

Registered: 2019 (6 years)

Introduction: 4×8 Fiberglass Sheets, MOQ: 200 square meters, durable and shatter resistant, above 90% moisture resistant, thermal shock and chemical resistant, easy to clean, extensive color options, easy installation, high impact strength, low maintenance. Applications include concrete form panels, temporary shelters, offshore living quarters, work stations, outdoor signs, and safe rooms. OEM and ODM available…

4. Runfeng – 4 By 8 Fiberglass Sheets

Domain: frpexpert.com

Registered: 2021 (4 years)

Introduction: Product Name: 4 By 8 Fiberglass Sheets

Supplier: Runfeng

Key Features:

– Lightweight

– Non-magnetic

– Corrosion resistant

– Mechanical properties similar to steel, aluminum, and concrete

– Versatile applications including warehouse walls, roofing, hospital walls, and prefabricated house panels

– Anti-aging film on surface for improved performance

– UV absorbers added to raw materials to reduce de…

5. Roofing4Us – 8 Oz Clear Corrugated Fiberglass Sheet

Domain: roofing4us.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “8 Oz Clear Corrugated Fiberglass Sheet”, “SKU”: “FRPCORR800CLR26X96”, “thickness”: “0.060” (1/16″ +-10%)”, “color”: “Clear”, “available_sizes”: [“26″ X 96″”, “26” X 144″”, “52” X 96″”], “delivery_estimate”: “between 6th Feb and 12th Feb”, “shipping_info”: {“note”: “Customer must have means of offloading material at time of delivery”, “cancellation_policy”: “Orders cancelled withi…

Strategic Sourcing Conclusion and Outlook for fiberglass sheets 4×8 price

In conclusion, the price landscape for 4×8 fiberglass sheets is influenced by various factors including material quality, regional demand, and supplier reliability. For B2B buyers, strategic sourcing is essential; it not only ensures the procurement of high-quality materials but also fosters relationships with suppliers that can lead to better pricing and terms. By leveraging bulk purchasing and negotiating contracts, companies can maximize their ROI while ensuring a consistent supply chain.

As international markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must stay informed about price fluctuations and emerging suppliers. This proactive approach allows companies to adapt to changing market conditions and capitalize on opportunities for cost savings.

Looking ahead, the demand for fiberglass sheets is expected to grow, driven by their versatility and durability in various applications. B2B buyers are encouraged to engage with multiple suppliers, explore new partnerships, and consider local manufacturers to enhance their supply chains. By doing so, organizations can not only secure favorable pricing but also strengthen their competitive edge in the market.