A Deep Dive into Best Oil Burner Pipe Solution

Introduction: Navigating the Global Market for best oil burner pipe

In the ever-evolving landscape of the global market, sourcing the best oil burner pipe presents a unique challenge for international B2B buyers. With a plethora of options available, from traditional glass pipes to innovative unbreakable designs, understanding the nuances of quality, durability, and cost-effectiveness is crucial. This guide serves as an essential resource, meticulously outlining the various types of oil burner pipes, their applications across different industries, and strategies for effective supplier vetting.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—will find actionable insights tailored to their specific needs. The guide delves into critical aspects such as pricing trends, material specifications, and maintenance considerations, empowering buyers to make informed decisions that align with their operational requirements.

By equipping businesses with the knowledge to navigate the complexities of sourcing oil burner pipes, this comprehensive guide aims to streamline purchasing processes, reduce costs, and enhance product reliability. Whether you are looking to expand your product line or ensure the longevity of your supply chain, understanding the best oil burner pipe options is key to staying competitive in today’s global market.

Understanding best oil burner pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Glass Oil Burner | Made from standard glass; often fragile | Retail shops, local markets | Pros: Cost-effective, widely available. Cons: Prone to breakage, requires frequent replacements. |

| Unbreakable Oil Burner Pipe | Constructed from reinforced, high-quality materials | Specialty stores, online retailers | Pros: Durable, long-lasting, aesthetically appealing. Cons: Higher upfront cost compared to traditional options. |

| Oil Burner Bubbler Pipe | Features a bubbler design for smoother hits | Smoke shops, online distributors | Pros: Enhanced filtration, better user experience. Cons: Slightly bulkier, may require more maintenance. |

| Quartz Oil Burner Pipe | Made from quartz glass; excellent heat resistance | High-end retailers, specialty shops | Pros: Superior thermal stability, easy to clean. Cons: More expensive, less common than glass variants. |

| Portable Silicone Oil Burner | Flexible and lightweight; designed for on-the-go use | Travel retailers, convenience stores | Pros: Highly durable, easy to transport. Cons: May lack the aesthetic appeal of glass options. |

What are the Characteristics of Traditional Glass Oil Burner Pipes?

Traditional glass oil burner pipes are the most common type found in the market. They are generally made from standard glass, which makes them affordable and widely accessible. However, their fragility can lead to frequent replacements, which can be a significant cost for businesses. Buyers should consider the volume of sales and the likelihood of breakage when stocking these items, as they may need to maintain a higher inventory to account for damages.

Why Choose Unbreakable Oil Burner Pipes for B2B Purchases?

Unbreakable oil burner pipes are manufactured using advanced materials that provide exceptional durability and heat resistance. These pipes are ideal for retailers looking to offer high-quality products that appeal to discerning customers. While the initial investment is higher, the long lifespan and reduced replacement costs make them a financially sound choice for businesses aiming to enhance customer satisfaction and loyalty.

How Do Oil Burner Bubbler Pipes Enhance User Experience?

Oil burner bubbler pipes incorporate a water filtration system that provides a smoother smoking experience. This feature is particularly attractive to customers who prioritize comfort and quality. For B2B buyers, stocking these pipes can help differentiate their product offerings in a competitive market, appealing to consumers looking for enhanced functionality. However, it’s essential to consider the additional maintenance these pipes may require.

What are the Advantages of Quartz Oil Burner Pipes?

Quartz oil burner pipes are known for their excellent heat resistance and thermal stability. This makes them a preferred choice for high-end consumers and specialty retailers. Although they come at a higher price point, their ease of cleaning and durability can justify the cost for B2B buyers targeting premium markets. Retailers should evaluate their customer base to determine if the investment aligns with their business strategy.

Why Consider Portable Silicone Oil Burner Pipes?

Portable silicone oil burner pipes are designed for convenience and durability, making them perfect for on-the-go consumers. They are lightweight and flexible, catering to a niche market focused on travel and outdoor activities. For businesses, these pipes can offer a unique selling proposition, especially in convenience stores or travel shops. However, buyers should weigh the aesthetic appeal against practicality when considering their inventory.

Key Industrial Applications of best oil burner pipe

| Industry/Sector | Specific Application of best oil burner pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Used in extraction and refining processes | Enhances efficiency and reduces downtime due to breakage | Ensure high-temperature resistance and durability |

| Manufacturing | Employed in industrial heating systems | Provides consistent heating, improving product quality | Look for bulk purchasing options for cost efficiency |

| Cannabis Production | Utilized for vaporization of oils and concentrates | Increases yield and enhances flavor profile of products | Focus on compliance with local regulations and safety |

| Food Processing | Applied in extraction of essential oils | Maximizes extraction efficiency, leading to better yields | Assess materials for food safety standards |

| Research & Development | Used in laboratory settings for material testing | Offers precise heating control, improving experimental accuracy | Source from reputable suppliers with proven quality control |

How is the Best Oil Burner Pipe Used in the Oil & Gas Industry?

In the oil and gas sector, the best oil burner pipes are integral to extraction and refining processes. They are engineered to withstand extreme temperatures and pressures, ensuring safe and efficient operation. By utilizing unbreakable pipes, companies can minimize downtime caused by frequent replacements, thus enhancing overall productivity. Buyers in this sector should prioritize sourcing pipes that meet industry standards for durability and heat resistance, especially in regions with varying environmental conditions, such as Africa and the Middle East.

What Role Does the Best Oil Burner Pipe Play in Manufacturing?

Manufacturing facilities often rely on oil burner pipes for industrial heating systems. These pipes facilitate consistent and controlled heating, which is crucial for maintaining product quality and process efficiency. By investing in high-quality, durable pipes, manufacturers can reduce the frequency of maintenance and replacements, leading to significant cost savings. B2B buyers should consider bulk purchasing options to optimize their supply chain and ensure they have a reliable stock of pipes that meet their operational needs.

How is the Best Oil Burner Pipe Beneficial in Cannabis Production?

In the cannabis industry, oil burner pipes are essential for vaporizing oils and concentrates. The best pipes enhance the flavor profile of products while maximizing yield, which is critical for competitive pricing and customer satisfaction. Given the regulatory landscape surrounding cannabis production, international buyers must ensure that the pipes comply with local safety standards. Additionally, sourcing from reputable suppliers who specialize in cannabis equipment can help mitigate risks associated with product quality and legality.

Why is the Best Oil Burner Pipe Important in Food Processing?

In food processing, oil burner pipes are used for extracting essential oils from various plants. Their design allows for efficient heat application, maximizing oil yield and quality. Businesses in this sector must prioritize food-safe materials to meet regulatory requirements and consumer safety expectations. As international buyers, understanding local health regulations and sourcing pipes that are certified for food use will be crucial for maintaining compliance and product integrity.

How Does the Best Oil Burner Pipe Facilitate Research & Development?

In research and development environments, the best oil burner pipes are utilized for precise heating in material testing and experimentation. Their reliability and durability are essential for achieving accurate results, which can significantly impact research outcomes. Buyers in this sector should focus on suppliers with a strong track record of quality control and customer support to ensure they receive pipes that meet their specific research needs. Additionally, considering the availability of replacement parts and accessories can enhance operational efficiency in laboratories.

3 Common User Pain Points for ‘best oil burner pipe’ & Their Solutions

Scenario 1: Fragility of Traditional Oil Burner Pipes

The Problem: Many B2B buyers face the constant headache of dealing with fragile oil burner pipes that easily break during transport or regular use. For retailers and distributors, this not only leads to increased costs from frequent replacements but also affects customer satisfaction. The frustration mounts when fragile glass pipes shatter, leading to delays in delivery and diminished brand trust, especially in markets where reliable performance is paramount.

The Solution: To overcome this challenge, buyers should consider sourcing unbreakable oil burner pipes made from reinforced materials, such as high-quality Pyrex glass. These advanced pipes are designed to withstand everyday wear and tear, reducing the risk of breakage significantly. When specifying products for your inventory, prioritize suppliers who offer warranties on their products and highlight their durability features. Additionally, implementing better packaging solutions during shipping can further protect these pipes, ensuring they arrive intact and ready for sale.

Scenario 2: Difficulty in Maintenance and Cleaning

The Problem: A common pain point for B2B buyers is the difficulty associated with maintaining oil burner pipes. Many traditional pipes accumulate residue and tar, making them challenging to clean. This not only affects the product’s longevity but also the quality of the user experience. Retailers often receive complaints from end-users about the inconvenience of cleaning, which can lead to returns and a negative reputation for the brand.

The Solution: To address this issue, buyers should focus on sourcing oil burner pipes designed for easy maintenance. Look for products that feature smooth surfaces and detachable components, which facilitate thorough cleaning. Moreover, consider providing end-users with cleaning kits or guides that include effective cleaning solutions specifically formulated for glass pipes. By educating customers on proper maintenance techniques and offering supportive resources, businesses can enhance user satisfaction and reduce return rates.

Scenario 3: Limited Variety in Product Selection

The Problem: B2B buyers often encounter a limited selection of oil burner pipes that do not meet the diverse preferences of their customer base. This lack of variety can hinder sales, as consumers increasingly seek unique designs and functionalities that cater to their specific needs. Retailers may find themselves unable to differentiate their offerings in a competitive market, leading to lost sales opportunities.

The Solution: To combat this limitation, buyers should actively seek suppliers that offer a wide range of oil burner pipe styles, sizes, and functionalities. Look for manufacturers that provide customization options or unique designs that appeal to different market segments. Additionally, consider attending trade shows or industry expos to discover emerging trends and innovative products. By expanding the product range to include various styles—from traditional to modern designs—and emphasizing unique features, businesses can attract a broader customer base and enhance their competitive edge.

Strategic Material Selection Guide for best oil burner pipe

What Are the Key Materials Used in the Best Oil Burner Pipes?

When selecting the best oil burner pipes, understanding the materials used is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials: glass, quartz, silicone, and metal, each offering unique properties and advantages.

How Does Glass Perform as a Material for Oil Burner Pipes?

Glass is a traditional choice for oil burner pipes due to its aesthetic appeal and relatively low cost. High-quality borosilicate glass is often used, which can withstand high temperatures and thermal shock. The key properties of glass include a temperature rating of up to 500°F and excellent clarity, allowing users to observe the burning process.

Pros: Glass pipes are visually appealing and provide a clean taste. They are easy to clean and maintain, which is a significant advantage for frequent users.

Cons: However, glass is inherently fragile, making it susceptible to breakage from drops or impacts. This fragility can lead to higher replacement costs over time, particularly in environments where durability is essential.

Impact on Application: Glass pipes are suitable for use with various oils and concentrates but may not be ideal for high-pressure applications.

Considerations for International Buyers: Compliance with safety standards like ASTM is critical, especially in regions like Europe where regulations are stringent. Buyers should also consider the availability of replacement parts and local suppliers for maintenance.

What Advantages Does Quartz Offer for Oil Burner Pipes?

Quartz is increasingly popular for oil burner pipes due to its superior thermal resistance and durability. With a temperature rating of up to 1,000°F, quartz can handle intense heat without degrading. Its non-porous nature also prevents residue buildup.

Pros: Quartz pipes provide a purer flavor and are less likely to break compared to glass. They are ideal for high-temperature applications and are easy to clean.

Cons: The main drawback is the higher cost associated with quartz compared to traditional glass. Additionally, while quartz is more durable than glass, it can still shatter under extreme impact.

Impact on Application: Quartz is particularly effective for high-viscosity oils, making it a preferred choice for serious enthusiasts and commercial applications.

Considerations for International Buyers: Buyers must ensure that quartz pipes meet local regulations and standards. In regions like South America, where the market may be less mature, sourcing high-quality quartz can be a challenge.

Why Choose Silicone for Oil Burner Pipes?

Silicone has emerged as a versatile alternative for oil burner pipes, especially in markets where durability is a priority. Silicone pipes can withstand temperatures up to 600°F and are resistant to breakage, making them ideal for active environments.

Pros: The flexibility of silicone allows for unique designs and portability. They are lightweight, easy to clean, and can be produced at a lower cost.

Cons: However, silicone may impart a slight taste to the oil, which can be a concern for purists. Additionally, while durable, silicone may not withstand extreme heat as effectively as glass or quartz.

Impact on Application: Silicone pipes are suitable for casual use and are often favored by beginners or those who prioritize portability.

Considerations for International Buyers: Buyers should verify that silicone pipes are made from food-grade materials and comply with safety standards. In regions like Africa, where regulations may vary, ensuring quality is essential.

What Role Does Metal Play in Oil Burner Pipe Construction?

Metal pipes, often made from stainless steel or aluminum, offer exceptional durability and heat resistance. These materials can withstand high temperatures and pressures, making them suitable for industrial applications.

Pros: Metal pipes are virtually indestructible, making them ideal for environments where breakage is a concern. They are also easy to clean and maintain.

Cons: The primary downside is the potential for corrosion if not properly coated or treated. Additionally, metal pipes can impart a metallic taste to the oil, which may not be desirable for all users.

Impact on Application: Metal pipes are best suited for heavy-duty applications and can handle a variety of oils, including those used in industrial settings.

Considerations for International Buyers: Compliance with industry standards, such as DIN in Europe, is critical. Buyers should also consider the availability of specialized cleaning solutions to maintain metal pipes.

Summary of Material Properties for Oil Burner Pipes

| Material | Typical Use Case for best oil burner pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Casual use, home setups | Aesthetic appeal, clean taste | Fragile, prone to breakage | Medium |

| Quartz | High-temperature applications | Superior thermal resistance | Higher cost, can shatter | High |

| Silicone | Portable, casual use | Flexible, lightweight | May impart taste, lower heat resistance | Low |

| Metal | Industrial applications | Indestructible, easy to clean | Potential for corrosion, metallic taste | Medium |

This comprehensive analysis provides B2B buyers with the insights needed to make informed decisions about the best oil burner pipes based on material properties, advantages, and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for best oil burner pipe

What Are the Key Stages in the Manufacturing Process of Oil Burner Pipes?

The manufacturing process for oil burner pipes involves several critical stages that ensure the final product is durable, efficient, and aesthetically pleasing. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials, often glass or reinforced composites. Manufacturers prioritize materials that can withstand high temperatures and resist breakage. Rigorous quality checks are conducted on incoming materials to ensure they meet industry standards.

-

Forming: This stage involves shaping the raw materials into the desired pipe structure. Techniques such as molding or blowing are commonly used for glass pipes. Advanced technologies like CNC machining may also be employed for precision in design and consistent quality.

-

Assembly: After forming, pipes are assembled, particularly if they incorporate additional features like a bubbler or water filtration systems. This stage may involve welding or bonding components, ensuring a seamless connection that enhances durability.

-

Finishing: The finishing stage includes polishing, coating, and sometimes additional decorative elements. This not only improves aesthetics but also adds protective layers that can enhance durability and ease of cleaning.

What International Standards Should B2B Buyers Consider for Quality Assurance?

Quality assurance in the manufacturing of oil burner pipes is paramount, especially for international B2B buyers. Familiarity with relevant international standards can significantly impact purchasing decisions.

-

ISO 9001: This is a globally recognized standard that outlines criteria for a quality management system (QMS). Companies certified under ISO 9001 demonstrate their commitment to quality control and continuous improvement, making them more reliable suppliers.

-

CE Marking: In the European market, CE marking indicates compliance with health, safety, and environmental protection standards. For oil burner pipes, this is crucial as it assures buyers that the products meet EU regulations.

-

API Standards: For suppliers targeting regions with oil industry applications, adherence to API (American Petroleum Institute) standards is essential. These standards focus on the safety, efficiency, and reliability of products used in oil and gas applications.

What Are the Key Quality Control Checkpoints in Oil Burner Pipe Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that oil burner pipes meet the required standards throughout the manufacturing process.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers should provide documentation proving that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular checks ensure that each process adheres to quality standards. This can include monitoring temperature controls during forming and ensuring precise assembly techniques.

-

Final Quality Control (FQC): After the completion of the manufacturing process, a final inspection is conducted. This includes visual inspections for defects, functional testing (e.g., pressure tests), and confirmation of compliance with international standards.

What Common Testing Methods Are Employed in Quality Assurance for Oil Burner Pipes?

Testing methods are essential for verifying the durability and safety of oil burner pipes. Common practices include:

-

Stress Testing: Pipes are subjected to high-pressure conditions to assess their durability and resistance to breakage. This simulates real-world usage and ensures the product can withstand operational stresses.

-

Thermal Cycling Tests: These tests evaluate how the material responds to rapid temperature changes, which is critical for oil burner pipes exposed to varying heat levels.

-

Visual Inspections: Trained inspectors perform thorough examinations to identify any surface flaws or imperfections that may affect performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of a supplier’s quality control practices is crucial for B2B buyers, especially those operating in diverse international markets. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can include reviewing documentation and interviewing personnel about their QC practices.

-

Requesting Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC. This transparency can help build trust between the buyer and supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance measures. These organizations often have the expertise to evaluate compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances that can differ by region:

-

Regulatory Compliance: Buyers in Europe must ensure that products comply with CE marking standards, while those in the Middle East may need to adhere to local regulations specific to their markets.

-

Cultural Expectations: Understanding cultural differences in quality expectations can influence purchasing decisions. For instance, buyers in Germany may prioritize precision and engineering excellence, while those in Brazil may focus more on cost-effectiveness.

-

Supply Chain Considerations: The complexity of international supply chains can introduce risks related to quality. Buyers should consider the entire supply chain, from raw material sourcing to final delivery, to ensure consistent quality.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing oil burner pipes, ultimately leading to better product performance and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best oil burner pipe’

When sourcing the best oil burner pipes for your business, it’s essential to approach the process methodically. This guide provides a comprehensive checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select high-quality products that meet your business needs while also optimizing your investment.

1. Define Your Technical Specifications

Before you begin contacting suppliers, clarify the specifications for the oil burner pipes you need. Consider factors such as size, material (e.g., Pyrex glass vs. silicone), and design features (like durability and ease of cleaning). This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational requirements.

2. Research Market Trends and Innovations

Stay informed about the latest trends in the oil burner pipe market. Innovations such as unbreakable glass pipes are gaining popularity due to their durability and aesthetic appeal. Understanding these trends will help you identify products that offer better value and performance, ensuring you remain competitive in your market.

3. Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product samples, and references from previous clients, especially those in your region or industry. This step is crucial to ensure that the supplier can deliver quality products and has a reputation for reliability.

- Check Certifications: Verify if the supplier holds relevant certifications for quality and safety standards.

- Assess Production Capacity: Ensure they can meet your order volume within your required timeframe.

4. Request Samples for Testing

Always request samples of the oil burner pipes you are considering. Testing samples can help you evaluate the quality, durability, and functionality of the products. This hands-on approach allows you to make informed decisions and ensures that the pipes meet your specifications before placing a larger order.

5. Compare Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. Look for transparency in pricing and ensure that there are no hidden costs. Additionally, consider the payment options available, such as upfront payments or credit terms, which can impact your cash flow.

6. Review Shipping and Delivery Options

Assess the shipping and delivery terms offered by suppliers. Reliable and timely delivery is crucial for maintaining your inventory levels and meeting customer demand. Inquire about shipping costs, delivery timelines, and the ability to handle international logistics, especially if you’re sourcing from overseas.

7. Establish a Communication Plan

After selecting your supplier, establish a clear communication plan. Regular updates on order status, potential delays, and product availability are vital for maintaining a smooth supply chain. Effective communication fosters a strong relationship with your supplier, leading to better service and support in the long run.

By following this checklist, B2B buyers can ensure that they make informed decisions when sourcing the best oil burner pipes, leading to enhanced product offerings and improved customer satisfaction.

Comprehensive Cost and Pricing Analysis for best oil burner pipe Sourcing

What Are the Key Cost Components in Sourcing Oil Burner Pipes?

When considering the sourcing of oil burner pipes, understanding the cost structure is critical for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts the price. High-quality glass, such as reinforced Pyrex or quartz, is often used for its durability and heat resistance. Lower-grade materials may reduce upfront costs but can lead to higher replacement rates and lower customer satisfaction in the long term.

-

Labor: Labor costs vary by region and can influence the overall pricing. In countries with higher labor costs, such as Germany, manufacturers may charge more compared to those in regions like South America or parts of Africa where labor is cheaper.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities and facility expenses. Efficient manufacturing processes can help mitigate these costs, allowing suppliers to offer competitive pricing.

-

Tooling: Initial tooling costs can be substantial, especially for customized designs. Buyers should consider whether they require unique specifications, as this can significantly affect the overall cost.

-

Quality Control (QC): Investing in robust QC processes ensures product consistency and reliability. While it may increase costs, it can also reduce the total cost of ownership by minimizing returns and replacements.

-

Logistics: Shipping costs, particularly for international orders, can be significant. Factors such as distance, shipping method, and the chosen Incoterms will impact logistics costs. Buyers should factor these into their budget when sourcing from overseas.

-

Margin: Suppliers will include a margin that reflects their operational costs and profit goals. This can vary widely based on market demand, competition, and the supplier’s position in the supply chain.

How Do Price Influencers Affect the Cost of Oil Burner Pipes?

Several factors influence the pricing of oil burner pipes in the B2B marketplace.

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to volume discounts, which can lower the per-unit price.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials and Quality Certifications: Pipes made from premium materials or those that meet certain quality certifications (e.g., ISO standards) may come at a higher price but offer better durability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but provide greater assurance of product performance.

-

Incoterms: Understanding Incoterms is essential for international buyers. They dictate the responsibilities of buyers and sellers in shipping, which can affect overall costs, including insurance, tariffs, and transportation.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Oil Burner Pipes?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, implementing strategic sourcing practices can enhance cost-efficiency.

-

Negotiate Effectively: Always negotiate pricing and terms with suppliers. Discuss volume discounts, payment terms, and possible cost-sharing on logistics to achieve better deals.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, replacement rates, and shipping costs. Investing in higher-quality pipes may reduce long-term costs associated with replacements and repairs.

-

Research Local Suppliers: Exploring local suppliers can reduce shipping costs and lead times. It may also provide more flexibility in terms of order sizes and customization options.

-

Understand Pricing Nuances: Be aware of regional pricing trends and market demands. For instance, European suppliers may have higher costs due to stringent regulations and quality standards.

Conclusion: Navigating the Complexities of Oil Burner Pipe Sourcing

Sourcing the best oil burner pipes involves understanding a multifaceted cost structure and recognizing the various price influencers at play. By leveraging negotiation strategies and considering the total cost of ownership, B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that prices can vary, and it’s essential to seek multiple quotes and conduct thorough research before finalizing a supplier.

Alternatives Analysis: Comparing best oil burner pipe With Other Solutions

Introduction: Understanding Alternative Solutions to Oil Burner Pipes

In the world of oil consumption and vaporization, oil burner pipes have established themselves as a popular choice due to their effectiveness and reliability. However, there are alternative methods and devices available that may cater to specific needs and preferences. This section explores how the best oil burner pipes compare to other viable options, helping B2B buyers make informed decisions based on performance, cost, and ease of use.

Comparison Table

| Comparison Aspect | Best Oil Burner Pipe | Alternative 1: Vaporizer Pen | Alternative 2: Dabbing Rig |

|---|---|---|---|

| Performance | High efficiency in vaporization | Portable with decent vapor quality | Excellent flavor and potency |

| Cost | Moderate, varies by design | Generally affordable | Higher initial investment |

| Ease of Implementation | Simple setup and usage | User-friendly, ready-to-use | Requires more setup and accessories |

| Maintenance | Easy to clean and maintain | Minimal maintenance required | Moderate, requires cleaning tools |

| Best Use Case | Suitable for home and casual use | Ideal for on-the-go vaporization | Best for concentrated extracts |

Detailed Breakdown of Alternatives

Alternative 1: Vaporizer Pen

Vaporizer pens are compact devices designed for discreet and efficient vaporization of oils. They offer a portable solution that appeals to users who prioritize convenience. The performance of vaporizer pens is generally satisfactory, producing decent vapor quality suitable for casual use. One of the main advantages is their affordability, making them accessible for various budget ranges. However, they may not deliver the same level of potency or flavor as oil burner pipes, making them less ideal for users seeking a robust experience.

Alternative 2: Dabbing Rig

Dabbing rigs have gained popularity for their ability to vaporize concentrates, providing a highly potent and flavorful experience. These devices excel in performance, delivering superior vapor quality compared to traditional oil burner pipes. However, they come with a higher initial investment due to the need for additional accessories like a torch and specialized tools. The setup can be more complex, requiring users to have some knowledge of the process. Maintenance is also moderate, as cleaning is necessary to ensure optimal performance. Dabbing rigs are best suited for enthusiasts focused on high-quality concentrates rather than casual oil users.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right oil consumption solution depends on specific user needs and preferences. For B2B buyers, understanding the performance, cost, and maintenance requirements of each option is crucial. The best oil burner pipe remains a reliable choice for those seeking durability and ease of use. In contrast, vaporizer pens offer portability for on-the-go users, while dabbing rigs provide an unmatched experience for concentrate enthusiasts. Evaluating these aspects will help buyers determine the most suitable solution for their target market, ensuring they meet customer demands effectively.

Essential Technical Properties and Trade Terminology for best oil burner pipe

What Are the Key Technical Properties of the Best Oil Burner Pipe?

When sourcing oil burner pipes for your business, understanding the technical properties is crucial for making informed decisions. Here are some essential specifications to consider:

1. Material Grade

Oil burner pipes are commonly made from materials such as borosilicate glass, quartz, or reinforced glass. Borosilicate glass is highly resistant to thermal shock, making it ideal for high-temperature applications. Quartz is known for its superior heat resistance and durability. Selecting the right material grade ensures that the pipes can withstand operational stresses without compromising performance.

2. Diameter and Length Tolerances

The diameter and length of oil burner pipes can significantly affect their performance. Standard diameters typically range from 10mm to 25mm, while lengths can vary between 4 inches to over 12 inches. Tolerances in these dimensions are critical for ensuring compatibility with other equipment and achieving optimal airflow. Manufacturers often provide specific tolerance levels, which help maintain quality and consistency during production.

3. Heat Resistance

Heat resistance is a vital property for oil burner pipes as they are exposed to high temperatures during operation. Pipes with higher heat resistance can maintain their integrity and performance, reducing the likelihood of breakage or deformation. This is particularly important in industrial applications where reliability is paramount.

4. Wall Thickness

The wall thickness of an oil burner pipe affects its durability and overall lifespan. Thicker walls provide better resistance to impacts and thermal stress, making them less prone to cracking. For B2B buyers, understanding the wall thickness specifications helps assess the long-term value and performance reliability of the pipes being sourced.

5. Design Features

Innovative design features such as bubbler mechanisms or built-in filtration systems can enhance the functionality of oil burner pipes. These features improve airflow and filtration, leading to a smoother smoking experience. When evaluating products, consider how design impacts usability and customer satisfaction.

What Are Common Trade Terms Related to Oil Burner Pipes?

Navigating the procurement process for oil burner pipes involves understanding industry-specific terminology. Here are some key terms to be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that may be marketed by another manufacturer. In the context of oil burner pipes, sourcing from an OEM can ensure high-quality materials and adherence to specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This is a critical consideration for B2B buyers, as it can affect inventory management and cash flow. Understanding MOQ helps businesses plan their purchasing strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing oil burner pipes, submitting an RFQ allows buyers to compare offers and negotiate better deals, ensuring they receive the best value.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and delivery obligations, which are crucial for importing oil burner pipes from global suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for inventory planning and ensuring that supply meets demand, particularly in industries with fluctuating needs.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing the best oil burner pipes, ensuring they meet their operational requirements while maximizing value.

Navigating Market Dynamics and Sourcing Trends in the best oil burner pipe Sector

What Are the Current Market Dynamics and Key Trends in the Best Oil Burner Pipe Sector?

The global market for oil burner pipes is evolving rapidly, driven by technological advancements and changing consumer preferences. Key trends include the emergence of unbreakable materials that enhance durability, reducing the frequency of replacements. Such innovations are particularly appealing to international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where product longevity is paramount due to logistical challenges and the cost of imports.

Additionally, the rise of e-commerce platforms has transformed sourcing strategies, allowing buyers to access a broader range of products and suppliers. This trend is complemented by the increasing demand for customized solutions tailored to specific market needs. For instance, buyers can now easily source pipes with unique designs or functionalities, such as multi-use capabilities, enhancing their value proposition.

Another significant market dynamic is the growing emphasis on price competitiveness without compromising quality. B2B buyers are increasingly looking for suppliers that offer bulk discounts and flexible pricing structures. The focus on affordability is particularly pronounced in developing markets, where cost sensitivity is a crucial factor in procurement decisions.

Lastly, the integration of sustainability into the sourcing process is becoming a significant driver. Suppliers that can demonstrate eco-friendly practices and materials are likely to gain a competitive edge, appealing to buyers who prioritize sustainability in their purchasing decisions.

How Is Sustainability and Ethical Sourcing Impacting the Oil Burner Pipe Sector?

Sustainability and ethical sourcing are increasingly shaping the oil burner pipe market. The environmental impact of production processes has come under scrutiny, leading to a demand for suppliers who prioritize sustainable practices. This includes using materials that minimize ecological footprints, such as recycled glass or biodegradable components in packaging.

Moreover, ethical supply chains are critical for B2B buyers seeking to align with global sustainability goals. Buyers are encouraged to partner with suppliers who can provide certifications that verify their commitment to environmentally friendly practices. Certifications such as ISO 14001 or the Global Recycled Standard not only enhance credibility but also assure buyers of the product’s sustainability.

In addition, consumers are increasingly aware of the socio-economic impacts of their purchases. As a result, suppliers who engage in fair labor practices and ensure safe working conditions are more likely to attract business from conscientious buyers. This trend is particularly relevant in regions like Europe and North America, where ethical sourcing is becoming a key determinant in purchasing decisions.

How Has the Oil Burner Pipe Sector Evolved Over Time?

The evolution of the oil burner pipe sector has been marked by significant technological advancements and shifting consumer preferences. Initially dominated by fragile glass designs, the market has transitioned toward more durable materials that cater to the needs of both casual users and serious enthusiasts. The introduction of reinforced glass and innovative designs, such as the unbreakable oil burner pipe, reflects a response to the common frustrations associated with traditional products.

As the market matured, there was also a noticeable shift towards customization and personalization. B2B buyers now seek unique designs and functionalities that cater to specific demographic needs. This evolution has been further accelerated by the rise of online marketplaces, allowing for easier access to diverse product offerings.

Overall, the oil burner pipe sector has transformed from a niche market into a dynamic industry characterized by innovation, sustainability, and a focus on consumer satisfaction. As it continues to evolve, B2B buyers must stay informed about emerging trends to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of best oil burner pipe

-

How do I choose the right oil burner pipe for my business needs?

Choosing the right oil burner pipe involves considering several factors: durability, material, and design. Look for pipes made from reinforced materials such as Pyrex glass, which offer greater resistance to breakage. Evaluate the size and design options available, as these can affect functionality and user experience. Additionally, consider your target market’s preferences and aesthetic values, ensuring that the product aligns with their expectations. Lastly, assess the supplier’s reputation and their ability to meet your specific requirements. -

What is the best type of oil burner pipe for international shipping?

The best type of oil burner pipe for international shipping is one that is both durable and lightweight. Unbreakable pipes made from high-quality materials, such as reinforced glass, are ideal since they minimize the risk of damage during transit. Opt for designs that can be easily packed without taking up excessive space. Additionally, check if the supplier provides protective packaging to further safeguard the products during shipping. Collaborate with logistics partners familiar with customs regulations in your destination countries to streamline the shipping process. -

What are the minimum order quantities (MOQ) for oil burner pipes?

Minimum order quantities (MOQ) for oil burner pipes can vary widely depending on the manufacturer or supplier. Typically, MOQs range from 50 to several hundred units. It’s crucial to discuss MOQs with potential suppliers early in the negotiation process, as some may offer flexibility based on your business needs or long-term partnership potential. Additionally, consider how MOQs align with your inventory management and market demand to ensure that you can effectively meet customer needs without overstocking. -

How can I ensure the quality of oil burner pipes from suppliers?

To ensure the quality of oil burner pipes from suppliers, request samples before placing a bulk order. Evaluate the materials, craftsmanship, and design to verify that they meet your standards. Additionally, inquire about the supplier’s quality assurance processes and certifications. Look for suppliers with a proven track record and positive reviews from other B2B clients. Establish clear quality metrics and conduct periodic audits to maintain consistent quality in your supply chain. -

What customization options are available for oil burner pipes?

Customization options for oil burner pipes often include variations in size, color, and design features, such as engravings or unique shapes. Many suppliers are willing to collaborate on creating bespoke products that align with your brand identity or market demands. When discussing customization, ensure that you clarify the lead times and additional costs associated with these options. This can help you gauge the feasibility of offering unique products that differentiate your business in the market. -

What payment terms should I expect when sourcing oil burner pipes internationally?

Payment terms for international orders of oil burner pipes can vary based on the supplier’s policies and your negotiation. Common terms include a deposit upfront (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer credit terms, allowing for payment after a specified period. It’s essential to establish clear payment timelines and methods (e.g., wire transfer, letter of credit) to avoid any misunderstandings. Always ensure that payment terms are documented in the purchase agreement. -

How do I handle logistics for importing oil burner pipes?

Handling logistics for importing oil burner pipes involves coordinating with freight forwarders and understanding customs regulations in both the exporting and importing countries. Start by obtaining quotes from logistics providers and comparing their services. Ensure that all shipping documents, such as invoices and packing lists, are accurate and complete to avoid delays. Familiarize yourself with import tariffs, duties, and compliance requirements to ensure a smooth customs clearance process. -

What are the potential risks when sourcing oil burner pipes from international suppliers?

Sourcing oil burner pipes from international suppliers comes with risks, including quality inconsistencies, shipping delays, and compliance issues with local regulations. To mitigate these risks, conduct thorough due diligence on potential suppliers, including checking references and reviewing their business history. Establish clear contracts that outline quality standards, delivery timelines, and penalties for non-compliance. Additionally, consider diversifying your supplier base to reduce dependency on a single source and enhance supply chain resilience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Best Oil Burner Pipe Manufacturers & Suppliers List

1. SmokeMega – Unbreakable Oil Burner Pipe

Domain: smokemega.com

Registered: 2023 (2 years)

Introduction: The unbreakable oil burner pipe is designed for durability and performance, made from high-quality, reinforced Pyrex glass that resists cracks and breakage. It combines exceptional strength with a sleek design, ensuring a long-lasting and hassle-free experience. The pipes are engineered for easy cleaning and maintenance, available in various sizes and styles, including jumbo, bubbler, and compact …

2. Smoking Cats – Oil Burner Pipes

Domain: smokingcats.com

Registered: 2018 (7 years)

Introduction: Oil Burner Pipe – Free & Discreet Shipping from Texas. Available products include: Glass Pyrex Oil Burner Pipes, Color Change Oil Burner Pipes, Jumbo Oil Burner Pipes, Oil Burner Bubbler Pipes, Water Dog Oil Burner Pipes, and glowing in the dark Oil Burner Pipes. Prices range from $12.99 to $59.99. Featured products include: 5.5″ Quartz Glass Oil Burner Pipe ($18.99), Striped Glass Oil Burner Pipe…

3. GRAV – Orbis Borocca Water Pipe

Domain: headshop.com

Registered: 1997 (28 years)

Introduction: This company, GRAV – Orbis Borocca Water Pipe, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

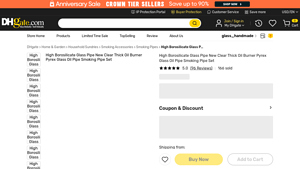

4. DHgate – Thick Pyrex Glass Oil Burner Pipe Set

Domain: dhgate.com

Registered: 2004 (21 years)

Introduction: Thick Pyrex Glass Oil Burner Pipe Set High Borosilicate, Clear & Durable Smoking Pipe. Price: $1.25 per piece (MOQ: 10 pieces). Material: High borosilicate glass. Size: 10cm. Color: Clear. Features: Factory direct sales, durable and tough. Package options: 10/20/50 glass pipes available. Shipping restrictions: Cannot be shipped to Romania. Customer reviews highlight fast shipping, good quality, an…

5. Bargzny – Oil Burner Pipes

Domain: bargzny.com

Registered: 2022 (3 years)

Introduction: Oil burner pipes are designed to vaporize essential oils for inhalation, providing a consistent and flavorful experience. They come in various forms including traditional hand pipes, bubblers, and water pipes, made from materials such as glass, silicone, and metal. Key types include: 1. Glass Oil Burner Pipes: Made from high-quality borosilicate glass, known for durability and heat resistance, fea…

6. msglasspipe – Oil Burner Pipe

Domain: msglasspipe.com

Registered: 2023 (2 years)

Introduction: Oil Burner Pipe: A smoking tool designed for vaporizing concentrates, typically made of glass. Key features include:

– Strong Portability: Compact and lightweight for easy transport.

– Simple Structure: User-friendly design, ideal for beginners.

– Affordable: Cost-effective compared to dab rigs and nectar collectors.

– Flexible Operation: Heats up quickly for immediate use.

Types of Oil Burner Pip…

7. Simple Glass Pipe – Oil Burner Pipe

Domain: simpleglasspipe.com

Registered: 2013 (12 years)

Introduction: Oil Burner Pipe – Free Discreet Shipping – SimpleGlassPipe.com

– Made in USA

– High-quality glass construction

– Available in various sizes: 4″ and 6″

– Compact and convenient for on-the-go use

– Designed to enhance the flavor of smoking oils

– Bulk discounts available

– Clear and durable options

– Oil Burner Pipe attachment for Water Pipe available (14mm/18.8mm)

– Transform your water pipe into a…

8. Reddit – Glass Water Dog Oil Burner Pipes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Glass Water Dog Oil Burner Pipes, 3 Chambers, 8 inch, Quantity Discounts

Strategic Sourcing Conclusion and Outlook for best oil burner pipe

In the competitive landscape of oil burner pipes, strategic sourcing remains paramount for international buyers seeking quality and durability. The introduction of unbreakable oil burner pipes has revolutionized the market, providing a robust solution to the common issue of fragility associated with traditional glass pipes. By opting for products made from advanced, reinforced materials, businesses can significantly reduce replacement costs and enhance user satisfaction.

Furthermore, the combination of aesthetic appeal and functional design in these modern pipes caters to a diverse clientele. Buyers can now procure high-quality products that not only perform well but also enhance their brand image through stylish offerings. As the demand for durable and cost-effective solutions grows, it is crucial for B2B buyers from regions such as Africa, South America, the Middle East, and Europe to remain vigilant and informed about market innovations.

Embrace the future of oil burner pipes by investing in unbreakable options that promise longevity and reliability. By making informed purchasing decisions, businesses can position themselves as leaders in their respective markets. Explore the latest offerings and secure your supply chain to ensure your operations thrive in this evolving industry.