A Deep Dive into 8 Foot Diameter Culvert Pipe Price Solution

Introduction: Navigating the Global Market for 8 foot diameter culvert pipe price

In the ever-evolving landscape of infrastructure development, sourcing an 8-foot diameter culvert pipe presents unique challenges for international B2B buyers. With varying specifications, fluctuating prices, and diverse applications across regions, understanding the nuances of culvert pipe procurement is essential for making informed investment decisions. This comprehensive guide aims to illuminate the complexities surrounding the pricing and availability of 8-foot diameter culvert pipes, providing crucial insights into types, applications, and supplier vetting processes.

The guide will delve into the various materials available—ranging from galvanized steel to polymer-coated options—each with its own cost implications and suitability for different environmental conditions. It will also address logistical considerations, including shipping and customs clearance, which are particularly relevant for buyers in Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil.

By equipping decision-makers with actionable intelligence on current market trends and pricing structures, this guide empowers B2B buyers to navigate the global market confidently. Whether you’re involved in large-scale construction projects, municipal infrastructure upgrades, or agricultural applications, understanding the factors that influence culvert pipe pricing will enable you to optimize your procurement strategy and achieve cost-effective solutions for your organization.

Understanding 8 foot diameter culvert pipe price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Corrugated Metal Pipe (CMP) | Lightweight, durable, and available in various gauges | Road construction, drainage systems, agriculture | Pros: Cost-effective, easy installation. Cons: Susceptible to corrosion if not coated. |

| Concrete Pipe | High strength, longevity, and low maintenance | Heavy-duty drainage, stormwater management | Pros: Very durable, resistant to heavy loads. Cons: Higher initial cost, requires heavy machinery for installation. |

| Plastic Pipe (HDPE) | Lightweight, flexible, and resistant to chemicals | Irrigation, residential drainage, industrial uses | Pros: Corrosion-resistant, easy handling. Cons: Less structurally robust than metal or concrete. |

| Tank Car Culvert | Made from solid steel plate, high weight capacity | Heavy traffic areas, industrial applications | Pros: Extremely durable, suitable for extreme loads. Cons: High cost, challenging to transport and install. |

| Spiral Corrugated Pipe | Helical design for enhanced strength and flow efficiency | Stormwater management, road drainage | Pros: High hydraulic efficiency, flexible installation. Cons: Can be more expensive than standard CMP. |

What are the Characteristics and Suitability of Corrugated Metal Pipe (CMP)?

Corrugated Metal Pipes (CMP) are known for their lightweight yet robust design, making them a popular choice in various applications. They are available in multiple gauges, allowing for customization based on project requirements. CMP is particularly suitable for road construction and agricultural drainage systems due to its cost-effectiveness and ease of installation. However, potential buyers should consider that untreated CMP can be prone to corrosion, necessitating protective coatings for longevity.

How Does Concrete Pipe Stand Out in the Market?

Concrete pipes are recognized for their exceptional strength and durability, making them ideal for heavy-duty drainage solutions and stormwater management. Their longevity and low maintenance requirements appeal to B2B buyers focused on long-term investments. However, the initial costs are higher compared to other options, and installation can be complex, requiring heavy machinery. It is crucial for buyers to evaluate their project needs against these factors.

What are the Advantages of Using Plastic Pipe (HDPE)?

High-Density Polyethylene (HDPE) pipes are lightweight, flexible, and highly resistant to chemicals, making them suitable for a wide range of applications, including irrigation and industrial drainage. Their ease of handling and installation can significantly reduce labor costs. However, while HDPE pipes offer corrosion resistance, they may not withstand heavy loads as effectively as metal or concrete options. Buyers should assess the specific environmental conditions and load requirements before selecting HDPE.

When Should You Consider Tank Car Culverts?

Tank Car Culverts are designed for heavy traffic areas and industrial applications, constructed from solid steel plates that provide outstanding weight capacity. They are perfect for projects requiring durability under extreme loads, such as highways and industrial sites. However, they come with a higher price tag and can be challenging to transport and install, making them less suitable for smaller projects. Buyers should weigh the benefits against logistics and budget constraints.

Why Choose Spiral Corrugated Pipe for Your Projects?

Spiral Corrugated Pipes are engineered with a helical design that enhances both strength and hydraulic efficiency. This makes them particularly effective for stormwater management and road drainage. They offer flexibility in installation and can adapt to various site conditions. However, they may be priced higher than standard corrugated options, so it is essential for buyers to consider the long-term benefits of improved flow efficiency against initial costs.

Key Industrial Applications of 8 foot diameter culvert pipe price

| Industry/Sector | Specific Application of 8 foot diameter culvert pipe price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Use in highway and road drainage systems | Enhances road longevity and safety by preventing flooding | Consider local regulations for road construction and drainage systems. |

| Agriculture | Irrigation and drainage in large farming operations | Optimizes water management and increases crop yield | Assess compatibility with existing irrigation systems and local soil conditions. |

| Construction | Foundation drainage for large commercial buildings | Reduces water accumulation, protecting structural integrity | Evaluate the need for permits and ensure compliance with local building codes. |

| Mining | Water management in open-pit and underground mines | Prevents water damage and operational disruptions | Ensure robust materials to withstand heavy loads and harsh environments. |

| Municipal Projects | Stormwater management in urban areas | Mitigates flooding risks and enhances public safety | Focus on sourcing from suppliers with proven reliability and delivery capabilities. |

How is 8 Foot Diameter Culvert Pipe Used in Transportation Projects?

In the transportation sector, 8-foot diameter culvert pipes are critical for effective drainage systems along highways and roads. They help manage surface water runoff, thereby preventing flooding and erosion that can damage road infrastructure. For international buyers, understanding local regulations regarding drainage and road construction is essential, as these can vary significantly by region. Additionally, sourcing from suppliers with a strong inventory and reliable shipping options can facilitate timely project execution.

What Role Does 8 Foot Diameter Culvert Pipe Play in Agriculture?

In agriculture, these culverts are employed for irrigation and drainage, particularly in large farming operations. They help optimize water management by directing excess water away from fields while ensuring adequate irrigation supply. For buyers in regions with diverse soil conditions, it’s crucial to assess how the culvert will integrate with existing irrigation systems. This is particularly relevant in areas like South America, where agricultural practices may vary widely.

How is 8 Foot Diameter Culvert Pipe Utilized in Construction?

In construction, 8-foot diameter culvert pipes are used for foundation drainage in large commercial buildings. Proper drainage is vital to prevent water accumulation, which can compromise the structural integrity of buildings. Buyers must consider local building codes and potential permit requirements when sourcing these pipes. Ensuring that the culverts meet specific durability standards is also crucial, especially in regions with extreme weather conditions.

What Importance Does 8 Foot Diameter Culvert Pipe Have in Mining Operations?

For the mining industry, these culverts are essential for effective water management in both open-pit and underground mines. They help prevent water damage and operational disruptions caused by flooding. Buyers should prioritize sourcing robust materials that can withstand heavy loads and harsh environmental conditions. Additionally, understanding local mining regulations and environmental guidelines is critical for compliance and project success.

How is 8 Foot Diameter Culvert Pipe Applied in Municipal Projects?

In municipal projects, 8-foot diameter culvert pipes are vital for stormwater management in urban areas. They play a key role in mitigating flooding risks, thereby enhancing public safety and infrastructure reliability. For international B2B buyers, focusing on suppliers with a proven track record in municipal projects can ensure the necessary quality and timely delivery. Additionally, understanding the specific drainage needs of the urban area will aid in making informed sourcing decisions.

3 Common User Pain Points for ‘8 foot diameter culvert pipe price’ & Their Solutions

Scenario 1: Struggling with Accurate Pricing Estimates for 8-Foot Diameter Culvert Pipes

The Problem:

B2B buyers often encounter challenges in obtaining accurate and up-to-date pricing for 8-foot diameter culvert pipes. This can stem from fluctuating material costs, variations in supplier pricing, and different shipping fees. For instance, a construction project manager in Brazil may receive a quote from one supplier, only to find that another vendor offers a significantly different price for the same product. This inconsistency complicates budgeting and can lead to costly delays if the right supplier isn’t chosen in time.

The Solution:

To effectively navigate pricing discrepancies, it is crucial to establish relationships with multiple suppliers and request detailed quotes that break down costs by material, shipping, and potential discounts for bulk purchases. Utilize tools like price comparison websites or industry-specific platforms that aggregate pricing data. Additionally, consider engaging in direct negotiations with suppliers to clarify pricing structures and explore flexible payment options or financing solutions. For instance, leveraging financing options can help manage cash flow while ensuring timely procurement of culvert pipes. Always ask for a written quote with validity periods to safeguard against sudden price increases.

Scenario 2: Navigating Supply Chain Disruptions for Timely Delivery of Culvert Pipes

The Problem:

In many regions, especially in Africa and South America, supply chain disruptions can severely impact the availability and delivery timelines of 8-foot diameter culvert pipes. Delays caused by transportation issues or sourcing raw materials can lead to project setbacks. A civil engineering firm might find itself in a bind when a critical culvert delivery is delayed, jeopardizing project deadlines and incurring additional costs.

The Solution:

To mitigate supply chain risks, B2B buyers should proactively plan their procurement schedules and place orders well in advance. Establishing contracts with suppliers that include clauses for timely delivery can provide additional assurance. It is also advisable to incorporate contingency plans, such as identifying alternative suppliers or considering local manufacturers who may have shorter lead times. Engaging with suppliers who offer real-time tracking and updates can also improve communication and transparency regarding delivery status. Furthermore, exploring different shipping options or logistical partners can enhance flexibility and responsiveness to potential disruptions.

Scenario 3: Understanding Technical Specifications and Compliance for Culvert Pipe Selection

The Problem:

B2B buyers often face confusion regarding the technical specifications and compliance standards required for 8-foot diameter culvert pipes. This is particularly true for industries governed by stringent regulations, such as construction and infrastructure. A procurement officer may struggle to ensure that the selected pipes meet local regulations, leading to potential legal issues and project delays.

The Solution:

To address this challenge, it is essential to conduct thorough research on local regulations and industry standards related to culvert pipe installation. Buyers should work closely with engineers or technical consultants to accurately specify the required dimensions, materials, and performance characteristics. When sourcing pipes, request certifications and compliance documentation from suppliers to ensure that products meet all necessary regulations. Additionally, participating in industry forums and trade shows can provide valuable insights into best practices and innovations in culvert pipe technology. Establishing a checklist for compliance requirements can streamline the selection process and prevent costly mistakes in procurement.

Strategic Material Selection Guide for 8 foot diameter culvert pipe price

What Are the Key Materials for 8 Foot Diameter Culvert Pipes?

When selecting an 8-foot diameter culvert pipe, the choice of material significantly impacts performance, durability, and cost. Below, we analyze four common materials used in the manufacturing of culvert pipes: corrugated metal, reinforced concrete, high-density polyethylene (HDPE), and fiberglass-reinforced plastic (FRP). Each material has unique properties that cater to different applications and environmental conditions.

How Does Corrugated Metal Perform in Culvert Applications?

Corrugated metal pipes (CMP) are widely used for their strength and cost-effectiveness. Typically made from galvanized steel or aluminum, these pipes exhibit excellent structural integrity and can handle high load capacities. They are resistant to deformation under pressure and are suitable for various soil conditions. However, they are prone to corrosion if not properly coated or maintained, especially in acidic or saline environments.

Pros:

– High strength-to-weight ratio.

– Cost-effective for large projects.

– Quick installation due to lightweight.

Cons:

– Susceptible to corrosion without protective coatings.

– Limited lifespan in harsh environments.

Impact on Application: CMP is ideal for drainage and stormwater management but may not be suitable for areas with aggressive soil chemistry.

International Considerations: Buyers should ensure compliance with local standards such as ASTM in the U.S. or DIN in Germany. Availability of protective coatings is also crucial for regions with high humidity or saline conditions.

What Are the Benefits of Using Reinforced Concrete for Culverts?

Reinforced concrete pipes (RCP) are known for their robustness and longevity. They can withstand heavy loads and are resistant to various environmental conditions. RCP is particularly effective in areas with heavy traffic or where soil stability is a concern. However, the weight of concrete makes transportation and installation more complex and costly.

Pros:

– Exceptional durability and load-bearing capacity.

– Resistant to corrosion and chemical attacks.

Cons:

– Higher initial cost and installation effort.

– Heavier, requiring specialized equipment for transport.

Impact on Application: RCP is suitable for permanent installations in high-traffic areas, but its weight may limit its use in remote locations.

International Considerations: Compliance with local construction codes and standards is essential, and buyers should verify the availability of skilled labor for installation.

How Does High-Density Polyethylene (HDPE) Compare for Culvert Use?

HDPE pipes are gaining popularity due to their lightweight, flexibility, and resistance to corrosion. They can handle a wide range of temperatures and are less likely to crack under stress. HDPE is particularly advantageous in environments where soil movement is expected. However, they may not be suitable for high-load applications without additional support.

Pros:

– Lightweight and easy to transport.

– Excellent chemical resistance.

Cons:

– Lower load-bearing capacity compared to metal or concrete.

– Potential for deformation under extreme conditions.

Impact on Application: HDPE is ideal for agricultural and drainage applications, especially in regions with fluctuating temperatures.

International Considerations: Ensure compliance with international standards such as ASTM F2306 and check for local availability, as HDPE may not be as commonly stocked in some regions.

What Are the Advantages of Fiberglass-Reinforced Plastic (FRP) Culverts?

FRP pipes are known for their high strength-to-weight ratio and resistance to corrosion. They are particularly effective in environments where chemical exposure is a concern. FRP can be molded into various shapes, allowing for customized designs. However, they can be more expensive than traditional materials and may require specialized installation techniques.

Pros:

– Lightweight and easy to install.

– Highly resistant to chemicals and corrosion.

Cons:

– Higher cost compared to traditional materials.

– Requires skilled labor for proper installation.

Impact on Application: FRP is suitable for industrial applications and corrosive environments but may not be cost-effective for all projects.

International Considerations: Buyers should check for compliance with standards such as ASTM D3754 and ensure that installation teams are trained in handling FRP materials.

Summary Table of Material Selection for 8 Foot Diameter Culvert Pipes

| Material | Typical Use Case for 8 foot diameter culvert pipe price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Corrugated Metal | Drainage and stormwater management | Cost-effective and strong | Susceptible to corrosion | Medium |

| Reinforced Concrete | High-traffic and permanent installations | Exceptional durability | Heavy and complex installation | High |

| High-Density Polyethylene | Agricultural and drainage applications | Lightweight and flexible | Lower load-bearing capacity | Medium |

| Fiberglass-Reinforced Plastic | Industrial and corrosive environments | Highly resistant to chemicals | Higher cost and specialized labor | High |

This analysis provides international B2B buyers with a comprehensive understanding of material options for 8-foot diameter culvert pipes, enabling informed purchasing decisions based on specific project requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 8 foot diameter culvert pipe price

What Are the Main Stages in the Manufacturing Process of 8 Foot Diameter Culvert Pipes?

The manufacturing of 8-foot diameter culvert pipes involves several key stages that ensure the final product meets both functional and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary materials used for culvert pipes include galvanized steel, plastic, and concrete. In this stage, raw materials are sourced and inspected for quality. Steel sheets, for instance, are cut to specified dimensions and treated to resist corrosion. The choice of material significantly affects the durability and performance of the culvert.

-

Forming: This stage involves shaping the prepared materials into the desired culvert pipe profile. For metal pipes, techniques such as roll forming or spiral corrugation are employed. Roll forming shapes the steel into a continuous profile, while spiral corrugated methods enhance strength and hydraulic efficiency. In the case of plastic pipes, extrusion techniques are often utilized to create the pipe’s structure.

-

Assembly: Depending on the design requirements, culvert pipes may be manufactured as single pieces or assembled from multiple segments. For large diameter pipes, such as those exceeding 8 feet, sections are often bolted together to facilitate transport and installation. This stage may also involve the addition of fittings, end sections, and other components.

-

Finishing: The final stage includes applying protective coatings, such as zinc galvanization or polymer coatings, to enhance corrosion resistance. The pipes undergo surface finishing processes to ensure smoothness, which is essential for efficient water flow. This stage may also involve marking the pipes with relevant specifications and compliance certifications.

Which Key Techniques Are Used in the Manufacturing of Culvert Pipes?

Various techniques are utilized in the manufacturing of culvert pipes, each contributing to the overall strength, durability, and performance of the final product.

-

Roll Forming: This technique is widely used for creating corrugated metal pipes. It involves feeding flat metal sheets through rollers that gradually shape the metal into a desired profile, ensuring uniformity and strength.

-

Extrusion: For plastic culverts, the extrusion method is prevalent. Plastic pellets are heated and forced through a die to create long sections of pipe. This process allows for continuous production and can accommodate various diameters.

-

Welding: In cases where pipes are assembled from segments, welding techniques are employed to ensure strong joints that can withstand pressure and environmental factors.

-

Curing: For concrete culverts, the curing process is essential. It involves maintaining adequate moisture and temperature conditions to ensure that the concrete reaches its designed strength.

What Quality Control Measures Are Relevant for Culvert Pipe Manufacturing?

Quality control (QC) is crucial in ensuring that culvert pipes meet international and industry-specific standards. Here are some key aspects of QC in this context:

-

International Standards: Compliance with standards such as ISO 9001 ensures that manufacturers follow a systematic approach to quality management. This includes maintaining consistent quality in processes and products.

-

Industry-Specific Standards: For culvert pipes, certifications like CE marking (for European markets) and API standards (for oil and gas applications) may be relevant. These certifications indicate that the products meet specific safety and performance criteria.

-

Quality Control Checkpoints:

- Incoming Quality Control (IQC): Materials received from suppliers are inspected for compliance with specifications before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, various checks are conducted to ensure that processes adhere to defined standards. This includes monitoring dimensions, weld quality, and surface treatment.

- Final Quality Control (FQC): Once the culvert pipes are completed, final inspections are performed to verify that they meet all specifications and standards before they are shipped to customers.

What Common Testing Methods Are Employed in Culvert Pipe Quality Assurance?

Several testing methods are utilized to ensure the quality and reliability of culvert pipes:

-

Hydraulic Testing: This method involves filling the culvert with water to check for leaks and ensure structural integrity under pressure.

-

Dimensional Inspection: Measurement tools are used to verify that the dimensions of the culvert pipes meet specified tolerances. This is critical for ensuring proper fit during installation.

-

Corrosion Resistance Testing: For metal pipes, tests may be conducted to assess the effectiveness of protective coatings against corrosion.

-

Load Testing: This evaluates the pipe’s performance under expected load conditions, simulating real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to verify the quality control measures of suppliers:

-

Conduct Audits: Buyers can perform on-site audits of manufacturing facilities to assess adherence to quality standards. This allows for firsthand evaluation of processes and equipment.

-

Request Documentation: Suppliers should provide documentation of their quality management system, including certifications, inspection reports, and testing results.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and final products. This is particularly important for international transactions where trust is essential.

-

Customer References: Asking for references from other clients can provide insight into the supplier’s reliability and product quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should consider specific nuances related to quality control and certification:

-

Understanding Local Standards: Different regions may have specific regulations and standards that apply to culvert pipes. Buyers should familiarize themselves with these to ensure compliance.

-

Language and Documentation: Ensure that all quality-related documentation is available in a language that is understood by the buyer. Miscommunication can lead to misunderstandings regarding specifications and requirements.

-

Cultural Considerations: Understanding cultural differences in business practices can enhance communication and collaboration with suppliers.

-

Logistical Challenges: Buyers should be aware of the logistical aspects of shipping large items like culvert pipes, including customs regulations and potential delays.

In conclusion, understanding the manufacturing processes and quality assurance measures for 8-foot diameter culvert pipes is vital for international B2B buyers. By focusing on key manufacturing stages, techniques, and quality control standards, buyers can make informed decisions and ensure they partner with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘8 foot diameter culvert pipe price’

In the competitive landscape of B2B procurement, sourcing an 8-foot diameter culvert pipe requires careful consideration and strategic planning. This guide serves as a practical checklist for international buyers, ensuring you make informed decisions while navigating the complexities of pricing and supplier selection.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the culvert pipe meets your project’s requirements. Consider factors such as material (e.g., corrugated metal, steel, or plastic), thickness, length, and load-bearing capacity. Providing these details to potential suppliers helps in receiving accurate quotes and reduces the risk of procurement errors.

Step 2: Research Market Prices and Variants

Understanding the market price range for 8-foot diameter culvert pipes is crucial. Prices can vary significantly based on material, gauge, and supplier. For instance, corrugated metal pipes may start around $7500 plus freight for basic models, while custom specifications can lead to higher costs. Use this knowledge to compare offers and negotiate effectively.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a strong track record in large culvert production and delivery to ensure reliability. Additionally, verify their certifications and compliance with local regulations to mitigate risks.

Step 4: Request Detailed Quotes

Once you’ve shortlisted suppliers, request detailed quotes that include pricing, delivery timelines, and terms. Ensure that quotes specify additional costs such as freight, handling, and any necessary permits. This transparency allows for better comparison and helps avoid unexpected expenses.

Step 5: Assess Freight and Delivery Options

Consider the logistics of transporting the culvert pipe to your location. Some suppliers may offer free freight within specific distances, while others might charge significant fees for shipping. Evaluate the total cost of delivery, including potential customs duties for international shipments, to determine the most cost-effective option.

Step 6: Understand Lead Times and Availability

Inquire about lead times for production and delivery of the culvert pipes. Depending on the size and specifications, lead times can range from a few days to several weeks. Understanding these timelines is essential for project planning and avoiding delays in construction or infrastructure projects.

Step 7: Negotiate Payment Terms and Financing Options

Discuss payment terms with your chosen supplier. Some may offer flexible financing options, which can be beneficial for larger purchases. Ensure that you understand the terms of payment, such as deposits, milestones, and any financing arrangements, to manage your cash flow effectively.

By following this checklist, B2B buyers can navigate the procurement process for 8-foot diameter culvert pipes with confidence, ensuring that they secure the best possible product at a competitive price while minimizing risks associated with sourcing.

Comprehensive Cost and Pricing Analysis for 8 foot diameter culvert pipe price Sourcing

What Are the Key Cost Components Influencing 8 Foot Diameter Culvert Pipe Prices?

When sourcing 8-foot diameter culvert pipes, understanding the cost structure is crucial for effective budget management. The primary cost components include:

-

Materials: The type of material significantly affects the price. Common options include galvanized steel, polymer-coated steel, and plastic. For instance, corrugated metal pipes (CMP) are often less expensive than high-density polyethylene (HDPE) pipes but may not provide the same longevity or performance in corrosive environments.

-

Labor: Labor costs encompass the expenses related to manufacturing, assembling, and possibly installing the culvert pipes. The complexity of the manufacturing process and the geographic location of the supplier can influence labor costs.

-

Manufacturing Overhead: This includes expenses related to running the manufacturing facility, such as utilities, maintenance, and administrative costs. Suppliers with advanced manufacturing technologies may have higher overheads but could offer superior product quality.

-

Tooling: Customization often requires specific tooling, which can increase initial costs. Suppliers may amortize these costs over larger orders, making it essential to consider the volume of your purchase.

-

Quality Control (QC): Ensuring the culvert meets regulatory standards involves QC processes that add to the overall cost. Certifications and compliance with international standards can also affect pricing.

-

Logistics: Freight costs play a significant role, especially for international buyers. Factors such as distance, shipping method, and customs duties can significantly impact total expenses.

-

Margin: Supplier margins can vary, influencing the final pricing. Established suppliers with a strong market presence might have slightly higher prices due to brand reputation and reliability.

What Factors Influence the Pricing of 8 Foot Diameter Culvert Pipes?

Several key factors can influence the pricing of culvert pipes:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Understanding the MOQ can help in negotiating better pricing.

-

Specifications and Customization: Custom specifications, such as specific dimensions, materials, or coatings, typically incur additional costs. Be prepared to discuss your exact requirements with suppliers.

-

Quality and Certifications: Pipes that meet higher quality standards or come with certifications (like ISO or DOT compliance) may be priced higher due to the assurance of durability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more for their experience and track record.

-

Incoterms: The agreed-upon delivery terms can impact the overall cost, particularly regarding who bears the shipping costs and responsibilities. Familiarizing yourself with Incoterms can prevent unexpected expenses.

What Buyer Tips Can Help Negotiate Better Prices for Culvert Pipes?

Navigating the procurement of culvert pipes requires strategic approaches to ensure cost-efficiency:

-

Negotiate Wisely: Always ask for quotes from multiple suppliers. Use competitive pricing to negotiate better terms and discounts.

-

Consider Total Cost of Ownership (TCO): Factor in not just the purchase price but also installation, maintenance, and potential replacement costs over the culvert’s lifespan. A higher upfront cost may lead to savings in the long run if the product is more durable.

-

Understand Pricing Nuances for International Buyers: When purchasing from suppliers in different regions, be aware of currency fluctuations, import taxes, and additional tariffs that can affect the overall price.

-

Leverage Volume Discounts: If your project allows, consider consolidating orders with other projects or companies to meet MOQ thresholds for discounts.

Disclaimer on Indicative Prices for 8 Foot Diameter Culvert Pipes

Pricing for 8-foot diameter culvert pipes can vary significantly based on the aforementioned factors and market conditions. While indicative prices may be available, it is essential to contact suppliers directly for accurate quotes tailored to your specific needs and circumstances. Always account for potential fluctuations in material costs and other variables when budgeting for your project.

Alternatives Analysis: Comparing 8 foot diameter culvert pipe price With Other Solutions

Introduction: Understanding Alternatives in Culvert Solutions

When considering drainage solutions, particularly for large-scale projects, it’s essential to evaluate various options beyond the standard 8-foot diameter culvert pipe. This analysis aims to compare the price and practicality of traditional culvert pipes against alternative solutions, such as tank car culverts and spiral corrugated pipes. Each alternative presents unique characteristics that may better suit specific project requirements, depending on factors like performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | 8 Foot Diameter Culvert Pipe Price | Tank Car Culvert | Spiral Corrugated Pipe |

|---|---|---|---|

| Performance | High hydraulic capacity, durable | Very strong, ideal for heavy loads | Good hydraulic efficiency, less weight |

| Cost | Approx. $6,000 – $7,500 (plus freight) | Starting at $7,500 (plus freight) | Varies, generally lower than metal pipes |

| Ease of Implementation | Requires heavy machinery, permits for large sizes | Heavy, needs special equipment for installation | Easier to handle, can be installed with less equipment |

| Maintenance | Moderate, periodic inspections needed | Low, very durable | Moderate, depends on material quality |

| Best Use Case | Large drainage systems, roadways | Heavy-duty applications, rail crossings | Residential and light commercial drainage |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Tank Car Culverts?

Tank car culverts are robust solutions made from solid steel plates, ranging in thickness from ½ inch to ¾ inch. They are ideal for applications requiring high load-bearing capacity, such as roads and rail crossings. The price starts at approximately $7,500, which is on the higher end compared to standard culverts. Although they are durable and require minimal maintenance, the installation process can be cumbersome due to their weight and size, often necessitating specialized machinery.

How Do Spiral Corrugated Pipes Compare?

Spiral corrugated pipes offer a lightweight alternative, making them easier to handle and install compared to traditional culverts. These pipes utilize advanced manufacturing techniques to achieve strength and hydraulic efficiency, making them suitable for various drainage applications. Their costs can be lower than metal pipes, providing a cost-effective solution for projects with budget constraints. However, the performance may not match the heavy-duty capabilities of tank car culverts or standard culverts in high-load scenarios, and the maintenance requirements can vary based on the material quality.

Conclusion: Choosing the Right Culvert Solution for Your Needs

Selecting the right culvert solution involves weighing the specific needs of your project against the strengths and weaknesses of each option. For projects demanding high load capacities and durability, tank car culverts may be the most appropriate choice despite their higher price and installation challenges. Conversely, if cost and ease of installation are primary concerns, spiral corrugated pipes offer a practical alternative, albeit with some limitations in load-bearing capabilities. Ultimately, understanding the nuances of each solution will empower B2B buyers to make informed decisions tailored to their unique project specifications.

Essential Technical Properties and Trade Terminology for 8 foot diameter culvert pipe price

What Are the Key Technical Properties of 8 Foot Diameter Culvert Pipes?

When evaluating 8-foot diameter culvert pipes, several technical specifications are crucial for ensuring the suitability and performance of the product. Understanding these properties can help B2B buyers make informed purchasing decisions.

1. Material Grade

The material used in culvert pipe construction typically includes galvanized steel, corrugated metal, or high-density polyethylene (HDPE). For instance, galvanized steel pipes are often specified in gauges such as 10g, 12g, or 14g. The grade of material affects the pipe’s durability, resistance to corrosion, and overall lifespan. In regions with harsh weather or soil conditions, selecting a higher-grade material can reduce long-term maintenance costs.

2. Wall Thickness

Wall thickness is a critical property that impacts the strength and load-bearing capacity of the culvert pipe. For example, an 8-foot diameter pipe might have wall thicknesses ranging from 0.079 inches to 0.5 inches or more, depending on the application. A thicker wall generally means higher resistance to deformation and collapse under heavy loads, making it essential for projects involving vehicular traffic or heavy soil loads.

3. Length and Tolerance

Culvert pipes are usually available in standard lengths, such as 10, 20, 30, and 40 feet. Tolerance refers to the allowable variation in the pipe’s dimensions. For instance, a tolerance of ±0.5 inches is common. Accurate lengths and tolerances are crucial for ensuring a proper fit during installation, minimizing additional costs related to modifications or reordering.

4. Weight

The weight of the culvert pipe affects transportation and installation logistics. An 8-foot diameter steel culvert can weigh significantly, with options ranging from approximately 18,000 lbs to over 32,000 lbs, depending on the wall thickness and material. Understanding the weight is vital for planning transportation methods, securing permits for oversized loads, and ensuring the installation site can accommodate the pipe’s weight.

5. Hydraulic Capacity

Hydraulic capacity is a measure of how well a culvert pipe can handle water flow without causing flooding or erosion. This property is influenced by the pipe’s diameter, length, and material. For B2B buyers, calculating the hydraulic capacity is essential to ensure compliance with local regulations and to avoid costly infrastructure failures.

What Are Common Trade Terms Related to 8 Foot Diameter Culvert Pipe Pricing?

Familiarity with industry jargon is essential for effective communication and negotiation in the culvert pipe market. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of culvert pipes, an OEM might supply specific components or custom solutions tailored to the needs of a project, enhancing the value of the purchase.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers, as it can affect overall project costs and inventory management. For large-scale projects, negotiating a favorable MOQ can lead to significant savings.

3. RFQ (Request for Quotation)

An RFQ is a formal document that solicits price quotes from suppliers for specific products or services. Issuing an RFQ for culvert pipes can help buyers compare prices, terms, and conditions from different suppliers, ensuring they secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to clarify shipping, insurance, and delivery obligations in their agreements.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. For culvert pipes, lead times can vary significantly based on the size, material, and customization required. Knowing the lead time helps buyers plan their projects and manage timelines effectively.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing 8-foot diameter culvert pipes more effectively, ultimately leading to better project outcomes and cost efficiencies.

Navigating Market Dynamics and Sourcing Trends in the 8 foot diameter culvert pipe price Sector

What Are the Current Market Dynamics Influencing 8 Foot Diameter Culvert Pipe Prices?

The global market for culvert pipes, particularly the 8-foot diameter segment, is experiencing notable shifts driven by several factors. Infrastructure development remains a primary driver, especially in emerging markets across Africa, South America, and the Middle East. These regions are investing heavily in transportation and water management systems, leading to increased demand for durable drainage solutions. Additionally, advancements in manufacturing technologies, such as spiral corrugated and polymer-coated pipes, are enhancing product performance and longevity, thereby influencing pricing dynamics.

Emerging B2B technologies are also reshaping sourcing trends. Digital platforms are becoming vital for buyers seeking competitive pricing and supplier transparency. This trend is particularly significant in regions where traditional sourcing methods have dominated. Buyers are leveraging e-commerce solutions to compare prices and specifications, streamlining the procurement process. Furthermore, the growing emphasis on local sourcing due to logistics challenges and tariffs is prompting businesses to explore regional suppliers, impacting pricing strategies.

Market dynamics are also influenced by fluctuating raw material costs and geopolitical factors. Steel prices, which directly affect the cost of metal culverts, can vary significantly based on global supply chain issues and trade policies. Therefore, buyers must stay informed about market conditions and supplier capabilities to navigate these complexities effectively.

How Is Sustainability and Ethical Sourcing Shaping the 8 Foot Diameter Culvert Pipe Market?

Sustainability is becoming a crucial consideration in the procurement of culvert pipes. The environmental impact of construction materials is under scrutiny, with buyers increasingly favoring products that minimize ecological footprints. For instance, the use of recycled materials in the production of culvert pipes not only reduces waste but can also lead to cost savings.

Moreover, ethical sourcing practices are gaining traction. Buyers are encouraged to engage with suppliers who prioritize transparency in their supply chains, ensuring that materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and products made from sustainably sourced materials are becoming essential for companies aiming to enhance their green credentials.

In the context of the 8-foot diameter culvert pipe, opting for environmentally friendly options can also influence pricing. While initial costs for sustainable products may be higher, long-term benefits, including reduced maintenance and environmental compliance costs, can offer significant savings. Consequently, B2B buyers are advised to consider the total cost of ownership rather than just upfront prices when evaluating culvert pipe options.

What Is the Historical Context Behind the Development of 8 Foot Diameter Culvert Pipes?

The evolution of culvert pipes dates back to ancient civilizations, where basic drainage systems were implemented to manage water flow. However, the modern era of culvert pipe development began in the mid-20th century with the introduction of corrugated metal pipes (CMP). These pipes offered enhanced durability and flexibility, making them a preferred choice for various applications, including road and bridge construction.

As infrastructure demands grew, the industry saw innovations in materials and manufacturing processes. The introduction of polymer coatings and advanced corrugation techniques has significantly improved the performance of culvert pipes, making them more resistant to corrosion and wear. Today, the 8-foot diameter culvert pipe is a standard solution in large-scale drainage projects, reflecting a blend of historical engineering principles and contemporary manufacturing technology.

In conclusion, understanding the market dynamics, sustainability considerations, and historical context of 8-foot diameter culvert pipes equips international B2B buyers with the insights needed to make informed purchasing decisions. This knowledge not only aids in navigating current trends but also prepares buyers for future developments in this essential infrastructure sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 8 foot diameter culvert pipe price

-

1. How do I determine the right specifications for an 8-foot diameter culvert pipe?

To select the appropriate specifications for an 8-foot diameter culvert pipe, consider factors such as the intended use, environmental conditions, and local regulations. Assess the load requirements, drainage capacity, and materials (like steel or plastic) suitable for your project. Collaborating with a qualified engineer can help ensure that your specifications meet industry standards and local codes. Additionally, consult with suppliers for their recommendations based on similar projects, as they can provide valuable insights and potential cost implications. -

2. What is the average price range for an 8-foot diameter culvert pipe?

The price for an 8-foot diameter culvert pipe varies significantly based on materials, length, and supplier location. Generally, you can expect prices to range from approximately $7500 to over $12,000, depending on specifications like thickness and type (e.g., corrugated metal or solid steel). It’s advisable to request quotes from multiple suppliers to ensure competitive pricing and consider additional costs such as freight and installation. Keep in mind that bulk purchases may lead to discounts, so inquire about minimum order quantities (MOQs). -

3. What factors influence the shipping costs of an 8-foot diameter culvert pipe?

Shipping costs for an 8-foot diameter culvert pipe are influenced by several factors, including the pipe’s weight, dimensions, distance to the delivery location, and any special handling requirements. Additionally, the choice of shipping method (e.g., ground vs. freight) and whether permits are needed for oversized loads will affect the overall cost. To minimize expenses, consider suppliers that offer free freight options within a certain radius or inquire about consolidated shipping arrangements with other orders. -

4. How can I vet suppliers for 8-foot diameter culvert pipes?

When vetting suppliers, check their reputation by reviewing customer testimonials and industry references. Ensure they have relevant certifications and adhere to quality standards such as ISO. Request samples or specifications for previous projects similar to yours to assess their production capabilities. Additionally, inquire about their delivery timelines and after-sales support. A reliable supplier should be transparent about pricing, terms, and any potential delays in the supply chain. -

5. Are customization options available for 8-foot diameter culvert pipes?

Yes, many suppliers offer customization options for 8-foot diameter culvert pipes, including variations in length, material thickness, and coatings (such as polymer or galvanized finishes). Custom solutions can cater to specific project requirements, such as increased load-bearing capacity or resistance to corrosion. It’s essential to communicate your project specifications clearly and work closely with the supplier to ensure that the customized product meets your expectations and regulatory requirements. -

6. What payment terms should I expect when purchasing culvert pipes internationally?

Payment terms for international purchases can vary widely among suppliers. Common arrangements include upfront payments, partial payments upon order confirmation, and the balance due before shipment. Ensure to discuss payment methods that accommodate international transactions, such as wire transfers or letters of credit. Additionally, confirm the supplier’s policy on currency exchange rates and any potential fees that may apply to the transaction to avoid unexpected costs. -

7. How do I ensure quality assurance for culvert pipes?

To ensure quality assurance, request documentation of the manufacturing process, including certifications and compliance with international standards. Suppliers should provide test reports and warranties for their products. Conducting a factory inspection or third-party quality checks can also be beneficial, particularly for large orders. Establish clear communication with the supplier regarding expectations for quality and performance, and ensure they have a return or replacement policy for defective items. -

8. What logistics considerations should I keep in mind for importing culvert pipes?

When importing culvert pipes, consider logistics factors such as customs regulations, tariffs, and import duties in your country. Ensure you have all necessary documentation, including commercial invoices and certificates of origin, to facilitate smooth customs clearance. Engage a freight forwarder experienced in handling oversized shipments to navigate potential challenges. Additionally, plan for potential delays due to inspections or transportation issues, and maintain open communication with your supplier regarding shipment tracking and delivery schedules.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 8 Foot Diameter Culvert Pipe Price Manufacturers & Suppliers List

1. Large Culvert – Corrugated Metal Pipe

Domain: largeculvert.com

Registered: 2016 (9 years)

Introduction: FOR SALE: Large Culverts and Large Valve Cans. Manufacturer with ample stock of corrugated metal pipe (CMP) and custom diameter culverts. Sizes range from 36″ to 180″ in diameter, lengths from 10′ to 70′. Current prices (as of 9-2-2025) include: 144″ x 10ga. at $950/ft, 120″ x 10ga. at $806/ft, 120″ x 12ga. at $632/ft, 120″ x 8ga. at custom pricing, 108″ x 12ga. at $554/ft, 96″ x 12ga. at $376/ft,…

2. Coble’s Agway – 8 x 20ft Culvert Steel

Domain: online.cobleskillagway.com

Registered: 2011 (14 years)

Introduction: Culvert Steel, 8″ x 20ft

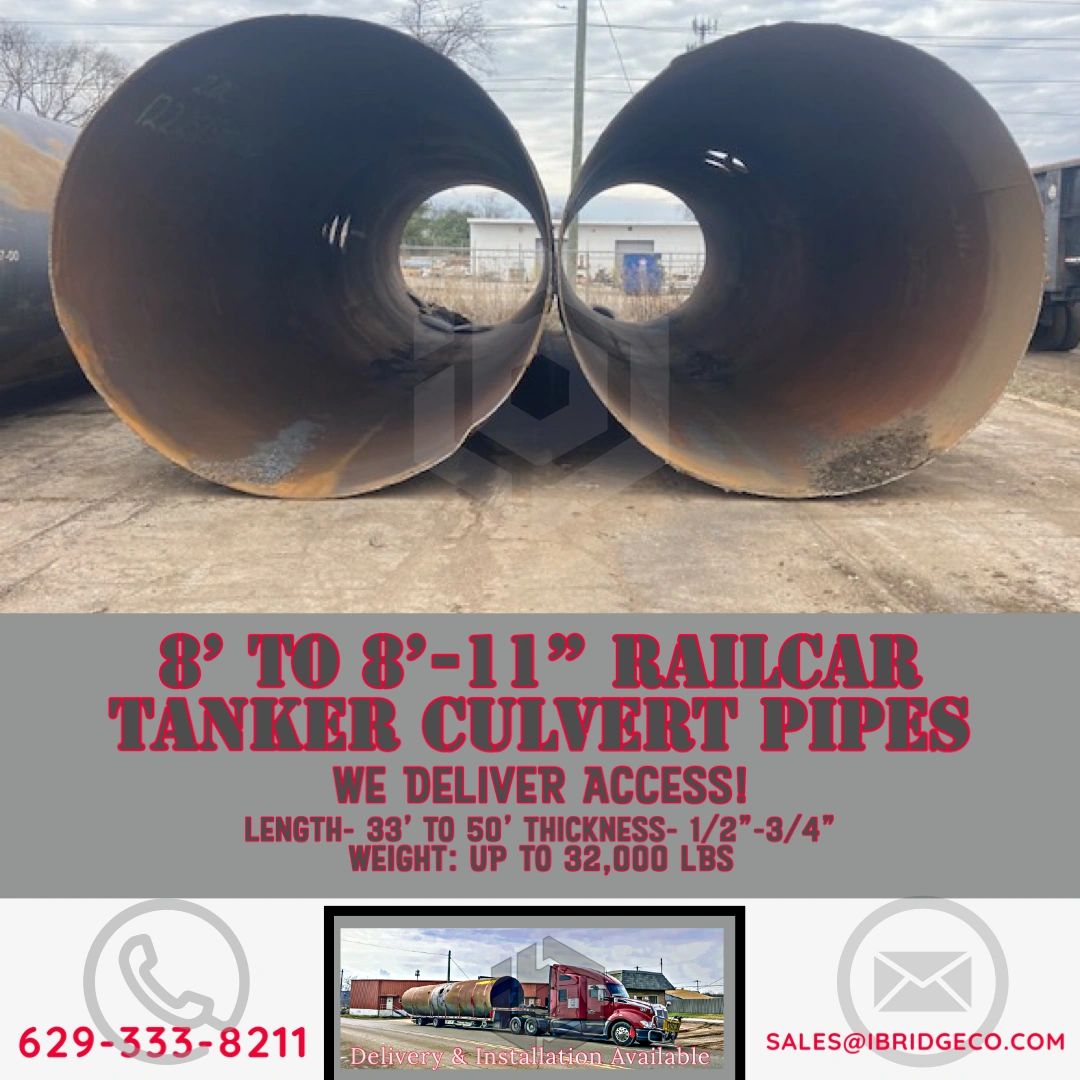

3. iBridgeCo – Tank Car Culvert Pipes

Domain: ibridgeco.com

Registered: 2020 (5 years)

Introduction: Tank Car Culvert Pipes 8′ to 8′-11″\n- Diameter: 8′ to 8′-11″\n- Length: Up to 60’\n- Material: Solid steel plate\n- Thickness: 1/2″ to 3/4″\n- Weight: 18,000 lbs – 32,000 lbs\n- Price: Starting at $7,500.00 plus freight\n\nTank Car Culvert Pipes 9′ to 9′-11″\n- Diameter: 9′ to 9′-11″\n- Length: Up to 60’\n- Material: Solid steel plate\n- Thickness: 1/2″ to 3/4″\n- Weight: 20,000 lbs – 38,000 lbs\…

4. Facebook – Culvert Pipe 100ft 8-10in

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: culvert pipe, 100 feet, 8-10 inches in diameter

5. ETA – 12 X 8′ GALV. 16GA CULVERT

Domain: shop.feldmans-fh.com

Registered: 2003 (22 years)

Introduction: {“product_name”:”12″ X 8′ GALV. 16GA CULVERT”,”price”:”$186.99 / EA”,”core_part_number”:”9240332″,”UPC”:””,”manufacturer”:”METAL CULVERTS CONTECH”,”brand”:”ETA”,”quantity_available”:”In Stock at Feldmans Blue Springs, Bonner Springs, Liberty”,”description”:”With its low cost, a wide variety of diameters, layout configurations, and materials, no other material can match CMPs versatility and flexibi…

6. Corrugated Metal Pipe – Spiral Corrugated Pipe

Domain: corrugatedmetalpipe.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “Spiral Corrugated Pipe”, “Diameter Range”: “12” to 144″”, “Material”: “Galvanized corrugated sheet”, “Manufacturing Technology”: “Advanced German manufacturing technology”, “Coating”: “Heavy zinc coating no less than 600g/m²”, “Weight”: “1/10 to 1/15 time the weight of traditional concrete pipe”, “Pipe Length”: “Any custom length available”, “Pipe Inside Diameter”: “0.3m to 3.6m”…

7. Corrugated Steel Culverts – Diameter & Pricing Comparison

Domain: corrugatedsteelculvert.com

Registered: 2015 (10 years)

Introduction: Comparing 12 ft, 10 ft, 8 ft, and 6 ft diameter corrugated steel culvert pipes. Pricing varies by size, gauge, and coating. Key prices per foot (USD) as of August 2025: 6 ft – $280, 8 ft – $376, 10 ft (12 ga) – $560, 10 ft (10 ga) – $700, 12 ft – $800. Material grades used are Q235B and Q345B. Coatings include hot-dip galvanizing and optional bitumen. Monthly supply scale is about 1,500 tons. Appl…

Strategic Sourcing Conclusion and Outlook for 8 foot diameter culvert pipe price

In navigating the complexities of sourcing 8-foot diameter culvert pipes, international B2B buyers should prioritize strategic sourcing to optimize costs and ensure timely delivery. The price range for these culverts varies significantly, influenced by factors such as material type, manufacturing processes, and geographic location. For example, steel options can start at approximately $7500, while custom specifications may incur additional costs. Understanding local regulations, especially regarding transport permits for oversized loads, is crucial for seamless procurement.

Investing in strong supplier relationships can yield advantages such as bulk pricing and flexible payment terms, which are essential for managing budgets effectively. Additionally, leveraging technology for real-time inventory checks can enhance decision-making, allowing buyers to respond swiftly to market fluctuations.

Looking ahead, the demand for large-diameter culvert pipes is likely to grow, driven by infrastructure projects across Africa, South America, the Middle East, and Europe. Buyers are encouraged to engage with suppliers early in their project planning phases to secure the best pricing and lead times. By embracing strategic sourcing practices, companies can not only meet their current needs but also position themselves for future growth in this vital sector.