A Deep Dive into 1.5 Gallon Water Jug Solution

Introduction: Navigating the Global Market for 1.5 gallon water jug

In today’s global marketplace, sourcing the right 1.5 gallon water jug can pose significant challenges for B2B buyers, particularly in diverse regions such as Africa, South America, the Middle East, and Europe. The need for reliable hydration solutions is paramount, whether for outdoor activities, emergency preparedness, or corporate events. This guide is designed to navigate the complexities of selecting the ideal water jug, offering insights into various types, their applications, and critical supplier vetting strategies.

From insulated models that maintain beverage temperatures for extended periods to durable, BPA-free options suitable for rugged environments, our comprehensive scope addresses the diverse needs of international buyers. We delve into the cost implications, warranty considerations, and materials that ensure safety and longevity, empowering businesses to make informed purchasing decisions.

By equipping B2B buyers with actionable insights and a thorough understanding of the market, this guide aims to simplify the sourcing process. Whether you’re operating in Nigeria’s bustling markets or Germany’s meticulous supply chains, our resource will enhance your procurement strategy, ensuring you choose products that meet both quality and performance standards. With the right knowledge at your fingertips, you can confidently invest in water jugs that cater to your operational needs while fostering sustainable business practices.

Understanding 1.5 gallon water jug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Insulated Water Jug | Double-walled vacuum insulation, keeps drinks cold for up to 48 hours | Outdoor events, camping, fieldwork | Pros: Excellent temperature retention, durable. Cons: Higher price point. |

| Rotomolded Water Container | Robust construction, leak-proof design, various mounting options | Off-road vehicles, industrial use | Pros: Extremely durable, customizable. Cons: Heavier than other types. |

| Standard Plastic Jug | Lightweight, cost-effective, basic design | General use, sports events, home use | Pros: Affordable, easy to carry. Cons: Less durable, limited insulation. |

| BPA-Free Water Jug | Made from food-grade materials, safe for long-term use | Health-conscious businesses, schools | Pros: Safe for consumption, eco-friendly. Cons: May lack insulation. |

| Multi-Spout Water Jug | Multiple dispensing options, easy to share | Large gatherings, festivals, camps | Pros: Convenient for group use, versatile. Cons: More complex design may require maintenance. |

What Are Insulated Water Jugs and Their Benefits for B2B Buyers?

Insulated water jugs are designed to maintain the temperature of beverages for extended periods. They typically feature double-walled vacuum insulation, making them ideal for outdoor events, camping, and fieldwork. B2B buyers should consider the durability and performance of these jugs, especially in demanding environments. While they come at a higher price, their longevity and effectiveness can justify the investment.

How Do Rotomolded Water Containers Differ from Other Types?

Rotomolded water containers stand out due to their robust construction and leak-proof design. These containers are available with various mounting options, making them suitable for off-road vehicles and industrial applications. For B2B buyers, their durability is a significant advantage, particularly in rugged environments. However, they tend to be heavier than other options, which may affect portability.

What Advantages Do Standard Plastic Jugs Offer?

Standard plastic jugs are lightweight and cost-effective, making them a popular choice for general use, sports events, and home applications. Their affordability makes them accessible for businesses looking to provide hydration solutions without significant investment. However, buyers should be aware that these jugs typically offer less durability and insulation compared to other options, which may lead to more frequent replacements.

Why Choose BPA-Free Water Jugs for Health-Conscious Businesses?

BPA-free water jugs are constructed from food-grade materials, ensuring safety for long-term use. They are particularly appealing to health-conscious businesses, schools, and organizations focused on eco-friendliness. While these jugs may lack insulation features found in other types, their safety and sustainability make them a worthwhile consideration for buyers prioritizing health and environmental impact.

What Makes Multi-Spout Water Jugs Ideal for Group Settings?

Multi-spout water jugs offer versatile dispensing options, making them convenient for large gatherings, festivals, and camps. Their design allows for easy sharing among multiple users, enhancing the experience at events. However, the complexity of their design may require more maintenance and care, which is an important consideration for B2B buyers looking for practical solutions for high-traffic environments.

Key Industrial Applications of 1.5 gallon water jug

| Industry/Sector | Specific Application of 1.5 Gallon Water Jug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | On-site hydration for workers | Ensures worker hydration and safety, improving productivity and morale | Durability, insulation properties, and ease of transport |

| Outdoor Events | Beverage station for festivals and gatherings | Facilitates high-volume hydration, enhancing guest experience and satisfaction | Portability, ease of cleaning, and aesthetic appeal |

| Emergency Services | Water supply for disaster relief operations | Provides essential hydration in crisis situations, supporting quick response efforts | BPA-free materials, leak-proof design, and capacity |

| Agriculture | Water supply for farm workers during shifts | Improves worker efficiency and health, reducing heat-related illnesses | Robust construction, ease of use, and thermal retention |

| Sports and Recreation | Hydration for teams during training and events | Promotes optimal performance and recovery for athletes | Lightweight, insulated design, and easy dispensing features |

How is the 1.5 Gallon Water Jug Used in the Construction Industry?

In the construction sector, a 1.5-gallon water jug serves as a vital hydration solution for workers exposed to harsh conditions. With long hours spent outdoors, ensuring that workers remain hydrated is crucial for safety and productivity. These jugs are designed for durability, often featuring insulated materials that maintain the temperature of the water for extended periods. Buyers in this sector should prioritize rugged construction and easy portability to facilitate frequent transport to various job sites.

What Role Does the 1.5 Gallon Water Jug Play at Outdoor Events?

For outdoor events such as festivals and community gatherings, the 1.5-gallon water jug acts as a central hydration station. By providing a large volume of water, it helps manage high demand during peak attendance, enhancing the overall guest experience. The ease of access and refilling capabilities allow for seamless service. When sourcing these jugs, event organizers should consider aesthetics, portability, and ease of cleaning to ensure they complement the event’s environment.

How is the 1.5 Gallon Water Jug Beneficial for Emergency Services?

In emergency services, the 1.5-gallon water jug is critical during disaster relief efforts, providing essential hydration to both responders and affected individuals. Its ability to hold a substantial amount of water ensures that teams can operate effectively in crisis situations without frequent resupply. Buyers should focus on jugs made from BPA-free materials with a leak-proof design to guarantee safety and reliability in high-stress environments.

Why is the 1.5 Gallon Water Jug Important in Agriculture?

In agriculture, the 1.5-gallon water jug supports farm workers by providing a readily available water supply during long shifts. This not only boosts productivity but also helps prevent heat-related illnesses, contributing to a healthier workforce. When selecting jugs for agricultural use, it’s essential to look for robust construction that can withstand outdoor conditions, as well as features that facilitate easy use and dispensing.

How Does the 1.5 Gallon Water Jug Enhance Sports and Recreation?

For sports teams and recreational activities, the 1.5-gallon water jug is a convenient hydration solution that promotes optimal performance. It allows teams to hydrate efficiently during training sessions or games, supporting athlete recovery. Sourcing considerations should include lightweight materials for easy transport and insulated designs to keep beverages at the desired temperature, ensuring athletes have access to refreshing water when they need it most.

3 Common User Pain Points for ‘1.5 gallon water jug’ & Their Solutions

Scenario 1: Difficulty in Maintaining Temperature for Extended Periods

The Problem: B2B buyers often face challenges in ensuring that beverages maintain their desired temperatures over long periods, especially in regions with extreme weather conditions like Africa or the Middle East. For instance, outdoor events or construction sites can lead to rapid temperature fluctuations, making it difficult to keep water cold or coffee hot, which can affect employee performance and satisfaction.

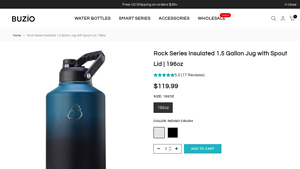

The Solution: When sourcing 1.5-gallon water jugs, prioritize models with advanced insulation technology, such as double-walled vacuum insulation. Products like the Buzio 1.5 Gallon Jug feature ThermoArmour technology that keeps drinks cold for up to 48 hours and hot for 24 hours. Additionally, look for jugs with a wide-mouth opening to facilitate easy filling with ice and pouring, ensuring that beverages remain at the desired temperature throughout the workday. For best results, educate your team on the optimal use of these jugs, including pre-chilling or pre-heating before filling them, which can enhance temperature retention.

Scenario 2: Concerns About Material Safety and Durability

The Problem: With increasing awareness of health and safety, B2B buyers are often concerned about the materials used in water jugs. The use of BPA and other harmful substances can deter potential buyers, especially in markets where health regulations are stringent. This concern is exacerbated when considering the longevity and durability of the product, which is crucial for cost-effective purchasing decisions.

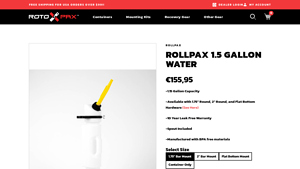

The Solution: To address these concerns, choose 1.5-gallon jugs made from high-quality, food-grade stainless steel that are BPA-free and lead-free. Products like the RollpaX Water Storage Container offer a 10-year leak-free warranty, ensuring that the jug will withstand harsh conditions without compromising safety. When sourcing, ask suppliers for certifications and material safety data sheets to verify the absence of harmful chemicals. Additionally, consider purchasing from brands that provide a warranty or guarantee, as this indicates confidence in their product’s durability and safety.

Scenario 3: Inconvenience in Portability and Usage

The Problem: In many business contexts, particularly in outdoor settings or remote locations, the portability of water jugs is a significant concern. Heavy or awkwardly shaped jugs can be cumbersome to transport, leading to spills or injuries. This inconvenience can deter employees from staying hydrated during long hours, negatively impacting productivity and health.

The Solution: When selecting a 1.5-gallon water jug, focus on ergonomic design features. Look for jugs with wide, comfortable handles and lightweight materials that make them easy to carry, even when full. The Buzio jug, for example, includes a one-inch wide handle designed for comfort and portability. It’s also beneficial to choose jugs with integrated spouts or pouring mechanisms to minimize spills during use. Educate employees on best practices for transporting and using these jugs, such as ensuring they are securely closed before moving and using a stable surface when pouring. This training can significantly enhance the user experience and ensure that hydration remains a priority in the workplace.

Strategic Material Selection Guide for 1.5 gallon water jug

What Are the Key Materials Used for 1.5 Gallon Water Jugs?

When selecting materials for 1.5-gallon water jugs, several options are commonly utilized in the industry. Each material has unique properties that influence performance, manufacturing complexity, and suitability for specific applications. Below is an analysis of four prevalent materials: stainless steel, high-density polyethylene (HDPE), glass, and aluminum.

How Does Stainless Steel Perform in 1.5 Gallon Water Jugs?

Stainless steel is a popular choice for 1.5-gallon water jugs due to its excellent durability and resistance to corrosion. It can withstand high temperatures and pressures, making it suitable for both hot and cold beverages. The material is also non-reactive, ensuring that the taste of the water remains unaffected.

Pros: Stainless steel offers high durability, resistance to rust and corrosion, and ease of cleaning. It is also recyclable, which appeals to environmentally conscious buyers.

Cons: The primary disadvantages include a higher manufacturing cost and weight compared to plastic options. Additionally, stainless steel jugs can be more expensive to ship due to their weight.

Impact on Application: Stainless steel is compatible with a wide range of liquids, including acidic beverages, without risk of leaching harmful substances.

International Considerations: Buyers in regions like Germany and Nigeria should ensure compliance with food safety standards such as EU regulations or local health codes. Stainless steel products often meet ASTM standards, providing assurance of quality.

What Are the Benefits of High-Density Polyethylene (HDPE)?

HDPE is another common material for water jugs, known for its lightweight and cost-effectiveness. It is resistant to impact and can handle a variety of temperatures, though it may not maintain temperatures as effectively as stainless steel.

Pros: HDPE is low-cost, lightweight, and easy to manufacture. It offers good chemical resistance, making it suitable for storing various liquids.

Cons: The main limitations include lower durability compared to stainless steel and potential for warping under extreme heat. HDPE may also degrade over time when exposed to UV light.

Impact on Application: HDPE is generally suitable for storing water and non-acidic beverages. However, it is not recommended for hot liquids due to the risk of deformation.

International Considerations: Compliance with standards like FDA regulations for food contact materials is essential. In regions like South America, buyers should verify local regulations regarding plastic materials.

How Does Glass Compare for 1.5 Gallon Water Jugs?

Glass is a premium option for water jugs, known for its aesthetic appeal and non-reactive properties. It does not leach chemicals and is easy to clean, making it a safe choice for water storage.

Pros: Glass is highly durable against chemical reactions and does not impart any flavors to the liquid. It is also recyclable and environmentally friendly.

Cons: The primary drawback is its fragility; glass can break easily, making it less suitable for outdoor or rugged use. Additionally, glass jugs are heavier and more expensive to produce and ship.

Impact on Application: Glass is ideal for storing pure water and beverages that require high-quality storage. However, it is not suitable for environments where breakage is a concern.

International Considerations: Buyers should ensure compliance with safety standards, especially in regions like the Middle East, where glass safety regulations may vary.

What Are the Advantages of Aluminum for Water Jugs?

Aluminum is another viable material for 1.5-gallon water jugs, known for its lightweight and strength. It can be treated to resist corrosion and is often used in outdoor applications.

Pros: Aluminum is lightweight, making it easy to transport. It also has good thermal conductivity, which can help maintain beverage temperatures.

Cons: Aluminum jugs may require a protective lining to prevent leaching, which adds to manufacturing complexity. They can also be less durable than stainless steel.

Impact on Application: Aluminum is suitable for cold beverages and can be used in outdoor settings, but care must be taken with acidic liquids.

International Considerations: Compliance with local regulations regarding aluminum food contact materials is crucial. In Europe, for instance, adherence to EU food safety standards is necessary.

Summary Table of Material Selection for 1.5 Gallon Water Jugs

| Material | Typical Use Case for 1.5 Gallon Water Jug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Hot and cold beverages | High durability and corrosion resistance | Higher cost and weight | High |

| High-Density Polyethylene (HDPE) | General water storage | Low cost and lightweight | Lower durability and UV degradation | Low |

| Glass | Premium water storage | Non-reactive and recyclable | Fragile and heavier | Med |

| Aluminum | Outdoor and cold beverage storage | Lightweight and good thermal conductivity | Requires protective lining | Med |

This strategic material selection guide provides insights for B2B buyers in various regions, helping them make informed decisions based on the specific needs and regulatory requirements of their markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 1.5 gallon water jug

What Are the Key Stages in the Manufacturing Process of a 1.5 Gallon Water Jug?

The manufacturing of a 1.5-gallon water jug involves several critical stages, each designed to ensure the final product meets quality and performance standards. Here’s a breakdown of the main processes involved:

Material Preparation: What Materials Are Used for 1.5 Gallon Water Jugs?

The primary materials for manufacturing 1.5-gallon water jugs typically include food-grade plastics (such as HDPE or PET) or stainless steel for insulated models. The selection of materials is crucial, as they must comply with health and safety regulations. This stage often involves sourcing raw materials that are BPA-free and lead-free to ensure consumer safety.

Forming: How Are 1.5 Gallon Water Jugs Shaped?

The forming process varies based on the material used. For plastic jugs, techniques such as blow molding or injection molding are common. Blow molding involves inflating heated plastic to form the desired shape, while injection molding uses high pressure to inject molten plastic into a mold. For stainless steel jugs, processes like deep drawing and welding are utilized to achieve the final shape. Each method has its advantages, influencing durability, weight, and cost.

Assembly: What Assembly Techniques Are Commonly Used?

After forming, the assembly stage involves attaching components such as lids, spouts, and handles. This may include processes like ultrasonic welding for plastic components or mechanical fastening for metal jugs. The assembly must ensure a secure fit to prevent leaks and facilitate ease of use. Additionally, ergonomic design considerations are crucial, particularly for jugs intended for outdoor or active use.

Finishing: How Is the Final Product Enhanced?

The finishing stage includes surface treatment processes to enhance durability and aesthetics. For plastic jugs, this might involve applying UV-resistant coatings to prevent degradation from sunlight. For stainless steel models, a powder coating or polishing may be applied to improve resistance to scratches and corrosion. Quality checks at this stage ensure that the jug meets both functional and visual standards.

What Are the Quality Assurance Practices in 1.5 Gallon Water Jug Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that every jug produced meets international standards and customer expectations.

What International Standards Apply to Water Jug Manufacturing?

Manufacturers often adhere to international quality management standards such as ISO 9001, which provides a framework for consistent quality assurance. Additionally, specific certifications like CE (for products sold in Europe) and FDA approval (for food-grade materials) may be necessary, depending on the target market. These certifications demonstrate compliance with safety and environmental regulations.

How Are Quality Checkpoints Structured in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This initial stage verifies the quality of raw materials before they enter production. Suppliers must provide documentation proving compliance with safety standards.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs to detect any deviations from standards. This may involve visual inspections, measurements, and testing of random samples.

-

Final Quality Control (FQC): Once the jugs are assembled, a final inspection ensures that all products meet specifications. This includes functionality tests, leak tests, and aesthetic evaluations.

What Common Testing Methods Are Employed for Water Jugs?

Testing methods vary based on material and design but generally include:

-

Leak Testing: Ensures that the jug can hold liquid without leaking, which is critical for customer satisfaction.

-

Thermal Insulation Tests: For insulated models, manufacturers assess the jug’s ability to maintain temperature, verifying claims of keeping drinks cold or hot for extended periods.

-

Drop Tests: Evaluating the durability of the jug under stress helps determine how well it can withstand impact during transportation or outdoor use.

-

Chemical Resistance Testing: For plastic jugs, tests determine how well the material holds up against various substances, ensuring it won’t degrade or leach harmful chemicals.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should conduct thorough due diligence to ensure their suppliers adhere to stringent quality control measures. Here are several actionable steps:

What Should Buyers Look for in Supplier Audits and Reports?

Requesting copies of quality assurance reports, including certifications and audit results, is essential. Buyers should look for documentation that demonstrates compliance with international standards like ISO 9001. Additionally, understanding the supplier’s quality management system can provide insights into their commitment to quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can further validate the quality of products. These independent organizations can conduct thorough inspections and tests, providing an unbiased assessment of the manufacturing process and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various regulations and standards that may differ significantly by region. For instance, European markets may require CE certification, while buyers in Africa or South America might have different regulatory requirements. Understanding these nuances is crucial for compliance and successful market entry.

How Can Buyers Stay Informed About Regulatory Changes?

Staying abreast of changes in regulations and standards is vital. Buyers can subscribe to industry newsletters, participate in trade associations, and attend international trade fairs to keep updated on best practices and compliance requirements.

In conclusion, the manufacturing processes and quality assurance protocols for 1.5-gallon water jugs are complex but vital for ensuring product reliability and safety. By understanding these processes and engaging in diligent supplier evaluation, B2B buyers can make informed decisions that support their business needs and consumer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1.5 gallon water jug’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure 1.5-gallon water jugs. Understanding the nuances of this product category is essential to ensure you select the right supplier and product that meets your needs for quality, durability, and functionality, particularly for international markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clarify your technical requirements. This includes determining the desired materials, insulation properties, and capacity. For instance, if you need jugs for outdoor activities, consider insulated options that keep beverages cold or hot for extended periods.

- Material: Look for food-grade, BPA-free materials to ensure safety and compliance with international health standards.

- Insulation: Double-wall vacuum insulation is preferable for maintaining temperature.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Utilize online platforms, industry directories, and trade shows to find reputable manufacturers.

- Supplier Reputation: Check reviews and ratings from other B2B clients to gauge reliability.

- Industry Experience: Prefer suppliers with a proven track record in producing durable water jugs.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications. This step ensures that the products meet international quality and safety standards.

- Certifications to Look For: ISO certification, FDA approval for food contact materials, and any local regulatory compliance relevant to your region.

- Sustainability Practices: Inquire about eco-friendly practices, which can enhance your brand’s reputation.

Step 4: Request Samples for Quality Assessment

Before placing bulk orders, request samples from shortlisted suppliers. This allows you to assess the quality of the product firsthand.

- Testing: Check for durability, insulation effectiveness, and ease of use (like spout functionality).

- Feedback Loop: Share samples with team members or stakeholders to gather input before making a decision.

Step 5: Negotiate Pricing and Terms

Once you’ve narrowed down your suppliers, initiate negotiations. Focus on getting the best value while ensuring quality is not compromised.

- Bulk Discounts: Inquire about pricing tiers based on order quantities.

- Payment Terms: Understand payment conditions and delivery timelines to avoid future complications.

Step 6: Establish Clear Communication Channels

Set up effective communication channels with your chosen supplier. Clear communication is vital for addressing queries and ensuring smooth transaction processes.

- Point of Contact: Designate a primary contact person from both sides for streamlined communication.

- Language Considerations: Ensure both parties are comfortable with the language used for discussions to avoid misunderstandings.

Step 7: Finalize Logistics and Shipping Arrangements

Plan the logistics for transporting the water jugs from the supplier to your location. This includes understanding shipping options, costs, and delivery timelines.

- Shipping Methods: Evaluate air vs. sea freight based on urgency and budget.

- Customs Clearance: Be aware of import regulations in your country to prevent delays.

By following this checklist, you can navigate the sourcing process for 1.5-gallon water jugs with confidence, ensuring that you secure a reliable product that meets your business needs.

Comprehensive Cost and Pricing Analysis for 1.5 gallon water jug Sourcing

What Are the Key Cost Components in Sourcing 1.5 Gallon Water Jugs?

When sourcing 1.5-gallon water jugs, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common options include food-grade stainless steel, plastic, or BPA-free materials. Stainless steel is generally more expensive but offers durability and insulation properties, making it suitable for high-quality products.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs, such as parts of Asia or Eastern Europe, may offer competitive pricing, while suppliers in countries like Germany may charge more due to higher wage standards.

-

Manufacturing Overhead: This encompasses facility costs, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, allowing suppliers to offer better pricing.

-

Tooling: Initial tooling costs can be substantial, especially for customized jugs. Buyers should consider whether the supplier can accommodate their design needs without excessive tooling expenses.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes can add to costs, but it also protects buyers from potential returns and dissatisfaction, particularly in markets with strict regulations.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and weight. Factors like Incoterms will dictate who bears these costs and risks, affecting the overall pricing structure.

-

Margin: Suppliers will include a margin to cover their risks and profit. Understanding the typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of 1.5 Gallon Water Jugs?

Several factors influence the final pricing of 1.5-gallon water jugs:

-

Volume/MOQ: Minimum order quantities (MOQs) significantly affect pricing. Larger orders often lead to lower per-unit costs. Buyers should assess their needs carefully to determine the best order size.

-

Specifications and Customization: Unique specifications or custom branding can increase costs. Buyers should evaluate the importance of customization against their budget constraints.

-

Materials: Higher-quality materials typically result in higher prices. Understanding the trade-offs between cost and quality is crucial for making informed purchasing decisions.

-

Quality Certifications: Products with certifications (e.g., FDA-approved, ISO) may have higher prices due to the costs associated with compliance. However, these certifications can enhance marketability and customer trust.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge a premium for their reputation and reliability.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) affect shipping costs and responsibilities. Buyers should be clear about who handles various logistics aspects to avoid unexpected charges.

What Are the Best Tips for Buyers in Negotiating Prices for 1.5 Gallon Water Jugs?

Negotiating prices requires a strategic approach:

-

Leverage Volume Discounts: Buyers should consider consolidating orders to leverage volume discounts. This can significantly reduce per-unit costs.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider the TCO, which includes logistics, maintenance, and potential disposal costs. A higher upfront cost may lead to lower long-term expenses with quality products.

-

Research Market Prices: Familiarizing oneself with market prices can provide leverage in negotiations. Online resources and trade shows can provide insight into average pricing and competitor offerings.

-

Be Open to Alternative Suppliers: Exploring multiple suppliers can reveal varying prices and terms. This competition can be advantageous during negotiations.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing locally can reduce logistics costs and lead times, potentially providing a more favorable overall cost structure.

Conclusion

In summary, the pricing of 1.5-gallon water jugs involves a complex interplay of various cost components and influencing factors. B2B buyers must conduct thorough research and engage in strategic negotiations to ensure they achieve the best value for their investment. Understanding the nuances of international trade, particularly in regions like Africa, South America, the Middle East, and Europe, is crucial for optimizing sourcing strategies. Prices can fluctuate based on market conditions, so staying informed is essential for making sound purchasing decisions.

Alternatives Analysis: Comparing 1.5 gallon water jug With Other Solutions

When evaluating hydration solutions for business needs, it is essential to consider various alternatives to the 1.5-gallon water jug. Different products can fulfill similar requirements while offering unique advantages and limitations. Below, we compare the 1.5-gallon water jug against two viable alternatives: the 5-gallon water cooler and the portable water filtration system.

| Comparison Aspect | 1.5 Gallon Water Jug | 5-Gallon Water Cooler | Portable Water Filtration System |

|---|---|---|---|

| Performance | Excellent insulation; keeps beverages cold for 48 hours. | Provides chilled water on-demand; ideal for high usage. | Filters water on-the-go; suitable for various water sources. |

| Cost | Typically ranges from $100-$120. | Generally costs $50-$150 plus recurring costs for water refills. | Initial cost varies; filters can be $20-$100 depending on the model. |

| Ease of Implementation | Simple to use; fill and transport. | Requires electrical outlet; regular maintenance needed. | Easy setup; requires access to water sources. |

| Maintenance | Minimal; occasional cleaning. | Regular cleaning and filter changes required. | Filters need replacement periodically based on usage. |

| Best Use Case | Ideal for outdoor activities, camping, or small group events. | Best for offices or high-traffic areas needing frequent access to water. | Perfect for hiking, traveling, or emergency preparedness. |

What Are the Benefits and Drawbacks of Using a 5-Gallon Water Cooler?

The 5-gallon water cooler is a popular alternative for businesses requiring a steady supply of chilled water. This solution can quickly dispense water, making it ideal for environments with high consumption, such as offices or workshops. However, the dependency on electrical outlets and the need for regular maintenance and water deliveries can be cumbersome. While the upfront costs may be lower, the ongoing expenses for water refills can add up, making it less cost-effective in the long run for companies with limited budgets.

How Does a Portable Water Filtration System Compare?

Portable water filtration systems offer an innovative approach to water sourcing, especially for businesses that operate in remote areas or have access to natural water sources. These systems can filter water from lakes, rivers, or tap sources, providing a sustainable hydration solution. The main advantages include portability and the ability to utilize available water sources, reducing dependency on bottled water. However, the performance can vary based on water quality, and the need for regular filter replacements can lead to ongoing costs that should be factored into overall budgeting.

Conclusion: How Can B2B Buyers Choose the Right Hydration Solution?

Selecting the appropriate hydration solution hinges on understanding specific business needs, such as consumption patterns, operational environments, and budget constraints. The 1.5-gallon water jug excels in portability and insulation, making it suitable for outdoor events or smaller groups. In contrast, the 5-gallon water cooler is ideal for high-traffic areas but involves more complex logistics. The portable water filtration system is best for those prioritizing sustainability and versatility but may require more upkeep. By weighing the performance, cost, ease of use, and maintenance of each option, B2B buyers can make informed decisions that align with their operational goals and hydration needs.

Essential Technical Properties and Trade Terminology for 1.5 gallon water jug

What Are the Key Technical Properties of a 1.5 Gallon Water Jug That B2B Buyers Should Consider?

When evaluating a 1.5 gallon water jug for bulk purchase or distribution, understanding its technical specifications is crucial for making informed decisions. Here are the key properties to consider:

1. Material Grade

Most high-quality water jugs are made from food-grade materials such as 18/8 stainless steel or BPA-free plastics. Stainless steel offers durability, resistance to corrosion, and is easy to clean. In contrast, BPA-free plastics are lightweight and can be more cost-effective. The choice of material affects the jug’s safety, longevity, and performance, making it essential for buyers to ensure compliance with health and safety regulations in their regions.

2. Insulation Technology

Double-walled vacuum insulation is a common feature in premium 1.5 gallon water jugs. This technology maintains temperature, keeping beverages cold for up to 48 hours or hot for 24 hours. For B2B buyers, this property is particularly important for ensuring customer satisfaction in outdoor or high-temperature environments, making the product more appealing to consumers who prioritize hydration during activities.

3. Capacity and Size Specifications

The capacity of a water jug is typically measured in ounces or gallons, with a standard 1.5 gallon jug holding approximately 192 ounces. Understanding the dimensions, such as mouth diameter and total height, is also important for storage and transportation logistics. Buyers should consider how the size impacts shipping costs and shelf space, as well as whether it fits the needs of end-users, such as families or outdoor enthusiasts.

4. Weight and Portability

The weight of a filled jug can significantly influence its usability. A typical 1.5 gallon water jug may weigh around 5.29 lbs when empty. For B2B buyers, it’s crucial to consider how weight affects transportation and the end-user experience. Features such as ergonomic handles and wide-mouth openings can enhance portability and usability, making the product more attractive in competitive markets.

5. Warranty and Durability

A warranty, such as a lifetime warranty against manufacturing defects, indicates the manufacturer’s confidence in the product’s durability. This is a vital consideration for B2B buyers, as it can minimize long-term costs associated with returns or replacements. Understanding warranty terms can also enhance brand reputation and foster trust with end-users.

6. Environmental Considerations

With increasing consumer awareness of environmental issues, the recyclability of materials used in water jugs is becoming a vital factor. Products made from recyclable materials may appeal more to environmentally conscious consumers. B2B buyers should consider sourcing options that emphasize sustainability, as this can lead to a competitive advantage in the market.

What Are the Common Trade Terms Related to 1.5 Gallon Water Jugs?

Understanding industry terminology is essential for smooth transactions and negotiations. Here are some common trade terms relevant to 1.5 gallon water jugs:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are sold under another company’s brand name. For B2B buyers, partnering with an OEM can help ensure quality and reliability, as well as potentially lower costs through bulk manufacturing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is crucial for B2B buyers to understand, as it affects inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases effectively and avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to submit price quotes for specific products or services. This is a critical step in the procurement process, allowing buyers to compare costs and negotiate terms before making a commitment.

4. Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border trade, as they dictate shipping costs, risk, and delivery obligations.

5. Lead Time

This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for B2B buyers as it impacts inventory levels and customer fulfillment. Effective supply chain management often hinges on accurately predicting and managing lead times.

6. Freight Forwarding

Freight forwarding involves the coordination and shipment of goods from one destination to another via a single or multiple carriers. B2B buyers should understand freight forwarding to ensure efficient logistics and cost management in the transportation of water jugs, especially when importing from international suppliers.

By grasping these technical properties and trade terms, B2B buyers can make strategic decisions that align with their business objectives and customer needs.

Navigating Market Dynamics and Sourcing Trends in the 1.5 gallon water jug Sector

What Are the Key Market Dynamics and Trends Affecting the 1.5 Gallon Water Jug Sector?

The 1.5-gallon water jug sector is witnessing a surge driven by several global trends, particularly the rising demand for hydration solutions in various sectors such as outdoor recreation, emergency preparedness, and health-conscious lifestyles. As urbanization increases in regions like Africa and South America, access to clean drinking water remains a pressing concern, leading to heightened interest in large-capacity water containers. Additionally, the COVID-19 pandemic has accelerated the shift towards personal hydration solutions, with consumers opting for reusable water jugs to minimize reliance on single-use plastic bottles.

Emerging technologies in manufacturing and material sourcing are also reshaping this market. Innovations such as double-walled vacuum insulation technology have enhanced the functionality of water jugs, enabling them to keep beverages cold or hot for extended periods. This feature is particularly appealing to B2B buyers in sectors like hospitality and outdoor events, where maintaining beverage temperature is crucial. Furthermore, the integration of smart technology—like built-in hydration tracking—has begun to emerge, offering a competitive edge for brands that adopt these advancements.

International buyers, particularly from regions like the Middle East and Europe, are increasingly looking for suppliers who can offer durable, high-quality products with features that cater to specific needs. This trend emphasizes the importance of understanding local market demands and preferences when sourcing 1.5-gallon water jugs.

How Is Sustainability and Ethical Sourcing Influencing the 1.5 Gallon Water Jug Market?

Sustainability is becoming a critical factor in the decision-making process for B2B buyers of 1.5-gallon water jugs. The environmental impact of plastic waste has led to a growing preference for products made from sustainable materials. Buyers are increasingly seeking out jugs constructed from BPA-free, food-grade stainless steel and other eco-friendly materials that reduce their carbon footprint.

Ethical sourcing practices are also gaining traction, as businesses aim to align their operations with global sustainability goals. Companies that can demonstrate responsible supply chain management—such as fair labor practices and minimal environmental impact—are likely to attract more buyers. Certifications like ISO 14001 for environmental management and the use of recycled materials can further enhance a brand’s appeal in the eyes of conscientious buyers.

In addition, the rise of the circular economy is influencing product design, with an emphasis on durability and the potential for recycling at the end of the product’s life cycle. This shift not only meets consumer demand for sustainability but also fosters brand loyalty among environmentally-conscious customers.

What Is the Historical Context of the 1.5 Gallon Water Jug Market?

The evolution of the 1.5-gallon water jug market has been closely tied to the broader trends in consumer behavior and environmental awareness. Initially, water jugs were primarily utilitarian, designed to serve basic hydration needs. However, as outdoor activities gained popularity in the late 20th century, manufacturers began to innovate, introducing features such as insulation and ergonomic designs to enhance functionality.

The turn of the 21st century marked a significant shift as concerns about plastic pollution began to rise. This prompted manufacturers to explore alternative materials and sustainable practices, leading to the development of eco-friendly jugs that appealed to a more environmentally-conscious consumer base. Today, the 1.5-gallon water jug is not just a functional item; it represents a commitment to health, sustainability, and an active lifestyle, making it a staple for both individual consumers and B2B buyers across various sectors.

In summary, understanding the market dynamics, sustainability trends, and historical context surrounding the 1.5-gallon water jug sector is essential for B2B buyers aiming to make informed sourcing decisions that align with their organizational values and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of 1.5 gallon water jug

-

How do I choose the right supplier for 1.5 gallon water jugs?

When selecting a supplier for 1.5 gallon water jugs, consider their manufacturing capabilities, quality certifications, and reputation in the industry. It’s crucial to review customer testimonials and request product samples to evaluate quality firsthand. Additionally, assess their ability to meet your demand in terms of Minimum Order Quantities (MOQ) and delivery timelines. Engaging in direct communication about your requirements and expectations can also help gauge their responsiveness and reliability. -

What are the typical payment terms when sourcing 1.5 gallon water jugs internationally?

Payment terms can vary widely depending on the supplier and region. Common terms include a 30% deposit upfront with the balance due before shipment, or net 30 to net 90 days after delivery. It’s advisable to negotiate terms that provide adequate security for both parties. Ensure that you are familiar with payment methods accepted, such as wire transfers, letters of credit, or online payment platforms, to facilitate a smooth transaction. -

What quality assurance measures should I look for in 1.5 gallon water jugs?

When sourcing water jugs, look for suppliers that have established quality assurance protocols, such as ISO certifications or adherence to specific industry standards. Inquire about their testing procedures for durability, insulation effectiveness, and safety compliance (e.g., BPA-free materials). Additionally, consider requesting third-party inspection services to verify product quality before shipment, especially for large orders. -

What customization options are available for 1.5 gallon water jugs?

Many suppliers offer customization options, including branding, color variations, and specialized lids or spouts. When discussing customization, clarify your specific requirements, such as logo placement or design elements. Be aware that customized orders may have higher MOQs and longer lead times, so factor these into your planning. It’s also beneficial to request mock-ups or prototypes to ensure the final product meets your expectations. -

What are the shipping logistics for importing 1.5 gallon water jugs?

Shipping logistics can significantly impact your overall costs and timelines. Determine whether your supplier can handle shipping arrangements or if you need to engage a freight forwarder. Understand the shipping methods available, such as sea freight for larger orders or air freight for urgent needs. Additionally, factor in customs clearance procedures and potential tariffs or duties that may apply upon arrival in your country. -

How do I handle potential quality issues with my order of 1.5 gallon water jugs?

Establish a clear process for addressing quality issues before placing an order. This should include defining acceptable quality standards and an inspection protocol upon receipt. If issues arise, promptly communicate with your supplier to resolve them, referencing the warranty or return policy if applicable. Documenting all communications can help facilitate a smoother resolution process and maintain a good relationship with your supplier. -

What are the environmental considerations when sourcing 1.5 gallon water jugs?

Sustainability is increasingly important in international sourcing. Look for suppliers that utilize eco-friendly materials and practices, such as BPA-free plastics or recyclable packaging. Inquire about their production processes and waste management strategies. Choosing environmentally responsible products not only enhances your brand image but also aligns with global trends towards sustainability, which can be a selling point in your market. -

How can I ensure timely delivery of 1.5 gallon water jugs?

To ensure timely delivery, maintain regular communication with your supplier regarding production schedules and shipping timelines. Discuss any potential delays upfront and consider establishing buffer periods in your inventory planning. Utilize tracking services to monitor the shipping process and stay informed about any issues that may arise during transit. Building a strong relationship with your supplier can also facilitate better responsiveness and reliability in meeting deadlines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 1.5 Gallon Water Jug Manufacturers & Suppliers List

1. Buzio – 1.5 Gallon Vacuum Insulated Jug

Domain: buziolife.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Buzio 1.5 Gallon Vacuum Insulated Gallon Jug”, “capacity”: “196 oz”, “colors_available”: [“Indigo Crush”, “Black”], “price”: “$119.99”, “insulation_technology”: “BUZIO ThermoArmour technology double-walled vacuum insulation”, “cold_duration”: “up to 48 hours”, “hot_duration”: “up to 24 hours”, “handle”: “1 inch wide handle for comfort and portability”, “lid”: “wide-mouth 3.58-inc…

2. Rotopax – RollpaX 1.5 Gallon Water Storage Container

Domain: rotopax.com

Registered: 2008 (17 years)

Introduction: {“name”:”RollpaX 1.5 Gallon Water Storage Container”,”price”:”$179.99″,”capacity”:”1.5 Gallon”,”dimensions”:”24\” x 5\” x 5 1/2\””,”features”:[“10 Year Leak Free Warranty”,”Spout Included”,”Manufactured with BPA free materials”],”mounting_options”:[“1.75\” Round”,”2\” Round”,”Flat Bottom”],”description”:”RollpaX is an ideal solution for carrying extra fuel or water on any roll bar or flat surface….

3. Igloo – Trailmate® 54 Oz Hybrid Jug

Domain: igloocoolers.com

Registered: 1997 (28 years)

Introduction: Water Jugs from Igloo are fully insulated and designed for various activities such as practice, game day, or picnics. They keep drinks cold, off the ground, and clean, making hydration easy during long days. Key products include:

– Trailmate® 54 Oz Hybrid Jug – $39.99

– Rival 1 Qt Jug – $16.99

– Rival Half Gallon Jug – $21.99

– Sale 54 Oz Hybrid Sports Jug – $22.99 (originally $29.99)

– Made …

4. Sears – Vintage Green Insulated Water Jug

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Title”:”Vintage Sears Metal Handle Green Insulated Gallon Water Jug 1.5 Gallon”,”Condition”:”Used”,”Price”:”US $34.99″,”Shipping”:”US $11.90 USPS Priority Mail”,”Location”:”Hammond, Indiana, United States”,”Delivery Estimate”:”Between Thu, Sep 11 and Tue, Sep 16 to 08054″,”Returns”:”Seller does not accept returns”,”Brand”:”Sears”,”Type”:”Water Jug Cooler”,”Color”:”Green”,”Features”:”Portable”,”M…

5. Airtec – 1.5 Gallon & 5 Gallon Reusable Water Jugs

Domain: airtec.com

Registered: 1994 (31 years)

Introduction: 1.5 Gallon Water Jug Reusable 5 Gallon Water Jug Plug

6. RTIC – Outback Jug

Domain: rticoutdoors.com

Registered: 2016 (9 years)

Introduction: RTIC Outback Jug, available in One Gallon and Half Gallon sizes.

7. WaterBottle – Insulated Stainless Steel Water Jug

Domain: waterbottle.tech

Registered: 2018 (7 years)

Introduction: Product Name: Insulated Stainless Steel Water Jug 1.5L 2.5L Big Bottle with Handle 50oz 85oz Gallon Capacity

Model Number / SKU: S11150051

Capacity / Size: 85 oz (2.5 L), 50 oz (1.5L)

Bottle Diameter: 86mm

Height (w/o cap): Not specified

Bottle Material: 18/8 food grade stainless steel (SUS304 stainless steel)

Lid Material: PP + Silicone

Surface Decoration Technical: Powder coating

Insulation Perf…

8. Ubuy – 1.5 Gallon Insulated Water Jug

Domain: ubuy.com.pr

Registered: 2019 (6 years)

Introduction: 1.5 Gallon Water Jug with Wide Mouth, 192oz capacity, insulated to keep cold for 24 hours and hot for 12 hours, features an ergonomic handle, includes two double-walled 16oz cups, made of 18/8 stainless steel.

Strategic Sourcing Conclusion and Outlook for 1.5 gallon water jug

As international B2B buyers consider sourcing 1.5-gallon water jugs, several critical factors emerge that can enhance procurement strategies. The demand for larger, insulated water containers reflects a growing preference for durability and functionality, especially in regions where hydration is crucial for outdoor activities and event management. Products like the Buzio and RollpaX offer innovative features such as double-wall vacuum insulation and versatile mounting options, catering to various market needs across Africa, South America, the Middle East, and Europe.

Strategic sourcing is vital in this context, allowing businesses to leverage competitive pricing and ensure product quality. Understanding the unique requirements of different markets can help buyers make informed decisions, fostering long-term supplier relationships and optimizing supply chain efficiency.

Looking ahead, the market for 1.5-gallon water jugs is poised for growth as consumer awareness of hydration needs increases. Buyers are encouraged to explore diverse suppliers and invest in high-quality products that align with their operational demands. By prioritizing strategic sourcing, companies can not only meet the hydration needs of their customers but also enhance their brand reputation in a competitive landscape.