A B2B Buyer’s Guide to Shipping Containers Under $1000: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for shipping containers under $1000

Sourcing shipping containers under $1000 can be a daunting challenge for international B2B buyers, especially when local market options are limited or overpriced. As global trade dynamics shift and budget constraints tighten, businesses from Africa, South America, the Middle East, and Europe must navigate a complex landscape to find reliable and cost-effective solutions for their shipping needs. This guide aims to equip you with comprehensive insights into the various types of containers available, their diverse applications, and strategies for effective supplier vetting.

Within these pages, you will discover practical advice on identifying the most suitable container options, whether you require 20ft or 40ft models for storage or transportation purposes. We will delve into the nuances of pricing, helping you understand what constitutes a fair market rate, and how to leverage online marketplaces to your advantage. Additionally, we will explore the importance of thorough vetting processes, ensuring that you partner with reputable sellers who can deliver high-quality containers without hidden costs.

By empowering you with these essential tools and knowledge, this guide will enhance your purchasing decisions, ultimately driving efficiency and profitability in your operations. Whether you’re a seasoned buyer or new to the shipping container market, the insights provided here will be invaluable in successfully navigating the global landscape for affordable shipping containers.

Understanding shipping containers under $1000 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 20ft Used Container | Compact size; typically cargo-worthy; lower cost | Storage, transportation, temporary offices | Pros: Affordable, versatile; Cons: Limited space |

| 40ft Used Container | Larger capacity; durable construction; versatile usage | Construction sites, storage, retail space | Pros: More storage, cost-effective; Cons: Higher delivery costs |

| High Cube Container | Extra height compared to standard containers | Warehousing, manufacturing, equipment storage | Pros: More vertical space; Cons: May be pricier |

| Reefer Container | Temperature-controlled; insulated design | Food transport, pharmaceuticals, perishables | Pros: Maintains temperature; Cons: Higher maintenance costs |

| Modified Container | Custom features (windows, insulation) | Pop-up shops, offices, living spaces | Pros: Tailored solutions; Cons: Additional costs for modifications |

What are the characteristics and suitability of the 20ft Used Container for B2B buyers?

The 20ft used container is a popular choice for businesses needing compact storage or transport solutions. Its cargo-worthy status ensures that it meets industry standards for structural integrity and can safely transport goods. Ideal for smaller operations, this container type is often found at prices under $1,000, making it accessible for startups or businesses with budget constraints. B2B buyers should consider the container’s condition and any potential additional costs for transport or modifications.

How does the 40ft Used Container cater to diverse B2B applications?

The 40ft used container offers significant storage capacity, making it suitable for a wide range of applications from construction sites to retail storage. Its durability and portability are key advantages, allowing businesses to store large volumes of goods securely. While typically priced just above the 20ft variant, it remains a cost-effective option for companies needing extra space. Buyers should evaluate delivery logistics and the container’s condition to ensure it meets their specific needs.

Why might B2B buyers choose a High Cube Container?

High cube containers provide additional vertical space, which can be beneficial for businesses that require storage for bulky items or need to optimize space utilization. Commonly used in warehousing and manufacturing, these containers can accommodate a variety of goods. While they may come at a higher price point than standard containers, the extra height can justify the investment for businesses focused on maximizing storage efficiency. Buyers should assess their specific height requirements and potential modification needs before purchasing.

What are the benefits and considerations for using Reefer Containers in B2B operations?

Reefer containers are equipped with temperature control systems, making them essential for businesses that transport perishable goods such as food or pharmaceuticals. Their insulated design ensures that products remain fresh during transit, which is critical for maintaining quality. However, the higher maintenance and operational costs associated with these containers can be a consideration for B2B buyers. It is crucial to evaluate the specific temperature requirements of the goods being transported to ensure compliance and efficiency.

How do Modified Containers provide tailored solutions for businesses?

Modified containers are customized to meet specific business needs, such as adding windows, insulation, or electrical systems. These containers are ideal for businesses looking to create pop-up shops, temporary offices, or even living spaces. While they offer flexibility and a unique solution, the additional costs for modifications can increase the overall investment. B2B buyers should carefully consider their intended use and budget for potential modifications to ensure they achieve the desired functionality.

Key Industrial Applications of shipping containers under $1000

| Industry/Sector | Specific Application of shipping containers under $1000 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | On-site storage for tools and materials | Reduces theft risk and keeps equipment organized | Ensure containers are weatherproof and secure |

| Agriculture | Mobile storage for equipment and produce | Enhances efficiency in managing farm supplies | Look for containers with ventilation for perishable goods |

| Retail | Pop-up shops or mobile retail outlets | Cost-effective way to enter new markets quickly | Consider customization options for branding |

| Disaster Relief | Temporary shelters or storage units | Provides immediate support during emergencies | Focus on local sourcing to reduce logistics costs |

| Mining | Equipment storage and site offices | Increases operational efficiency and safety | Verify container durability for harsh environments |

How Can Shipping Containers Under $1000 Be Utilized in Construction?

In the construction industry, shipping containers under $1000 serve as on-site storage solutions for tools, machinery, and materials. By providing a secure environment, these containers mitigate the risk of theft and damage, ensuring that essential equipment is organized and easily accessible. For international buyers, especially in regions like Africa and South America, sourcing containers that are weatherproof and equipped with secure locking mechanisms is crucial to protect valuable assets from environmental and security threats.

What Are the Benefits of Using Shipping Containers in Agriculture?

Agricultural businesses can leverage shipping containers under $1000 as mobile storage units for equipment and produce. This flexibility allows farmers to manage their supplies efficiently, especially during harvest seasons. Containers can also be modified to include ventilation for perishable goods. Buyers from the Middle East and Africa should prioritize sourcing containers that can withstand local climate conditions, ensuring that their agricultural products remain safe and fresh.

How Do Retailers Use Shipping Containers for Pop-Up Shops?

Retailers are increasingly turning to shipping containers under $1000 to create pop-up shops or mobile retail outlets. This innovative approach allows businesses to enter new markets with lower overhead costs and increased flexibility. For European buyers, particularly in Germany, sourcing containers that can be easily customized for branding and customer engagement is essential. Ensuring compliance with local regulations regarding mobile retail operations is also a key consideration.

In What Ways Are Shipping Containers Beneficial for Disaster Relief?

In disaster relief scenarios, shipping containers under $1000 can be transformed into temporary shelters or storage units for essential supplies. Their sturdy construction provides immediate support during emergencies, making them invaluable assets for humanitarian organizations. For international buyers, especially in regions prone to natural disasters, local sourcing can reduce logistics costs and ensure rapid deployment in crisis situations.

How Are Shipping Containers Used in the Mining Industry?

The mining sector utilizes shipping containers under $1000 for equipment storage and as site offices. Their durability and portability enhance operational efficiency and safety in remote locations. For B2B buyers in South America and Africa, it’s important to verify that the containers can withstand harsh environmental conditions, ensuring that they provide a reliable solution in challenging terrains.

3 Common User Pain Points for ‘shipping containers under $1000’ & Their Solutions

Scenario 1: Struggling to Find Quality Containers at Affordable Prices

The Problem: B2B buyers often face a daunting challenge when searching for shipping containers under $1000. Traditional methods, such as local suppliers or brokers, may not yield the best options, as they can lack both inventory and competitive pricing. This is particularly pressing for international buyers from regions like Africa or South America, where local markets may not have a robust selection of affordable containers. Additionally, concerns about the quality of used containers can lead to hesitation, as buyers fear investing in containers that may not meet their needs or could require costly repairs.

The Solution: To effectively navigate this challenge, buyers should leverage online container marketplaces like Container xChange. These platforms offer access to a wide range of containers at various price points, allowing buyers to filter their search specifically for containers under $1000. By using these platforms, buyers can directly connect with vetted sellers worldwide, ensuring not only competitive pricing but also the assurance of quality. It’s crucial to review seller ratings and container condition reports before making a purchase. Additionally, buyers should consider factors such as delivery costs and local regulations to better understand the total expenditure involved.

Scenario 2: Concerns Over Delivery Costs and Logistics

The Problem: For many B2B buyers, especially those operating in emerging markets, the cost of shipping and logistics can significantly inflate the final price of shipping containers. Buyers might find a great deal on a container priced under $1000, only to discover that delivery fees and logistical challenges push the total cost beyond their budget. This often results in frustration, as they must balance the initial container cost against the hidden expenses associated with transportation and local infrastructure limitations.

The Solution: To mitigate these challenges, buyers should conduct thorough research into delivery options before finalizing their container purchase. When using online marketplaces, buyers can often get quotes for delivery upfront, allowing for better budgeting. Additionally, it may be beneficial to collaborate with local logistics providers who understand the intricacies of transporting containers in specific regions. Establishing a relationship with a reliable freight forwarder can lead to negotiated rates and smoother logistics processes. Buyers should also consider purchasing containers from suppliers located closer to their operations to reduce shipping costs and transit times.

Scenario 3: Uncertainty About Container Specifications and Modifications

The Problem: Another significant pain point for B2B buyers involves uncertainty around the specifications and potential modifications of shipping containers. Many buyers may require specific features, such as insulation or ventilation, for their intended use—be it storage, office space, or a temporary structure. The lack of clear information about available modifications can lead to buyer confusion and ultimately deter them from making a purchase, especially when they’re unsure if a standard container will meet their needs.

The Solution: Buyers should proactively seek suppliers that provide detailed information about container specifications and available modifications. Before making a purchase, it’s essential to clarify the intended use of the container and discuss it with the seller. Some online platforms allow for direct communication with sellers, where buyers can inquire about customization options. If modifications are necessary, buyers can consult with local container modification specialists who can provide quotes and timelines for the work needed. This proactive approach not only ensures that the container meets specific requirements but also helps buyers avoid costly mistakes and ensures their investment aligns with their operational needs.

Strategic Material Selection Guide for shipping containers under $1000

What Are the Common Materials Used in Shipping Containers Under $1000?

When selecting shipping containers under $1000, understanding the materials used in their construction is crucial for B2B buyers. Here, we analyze four common materials: steel, aluminum, fiberglass, and wood. Each material has distinct properties, advantages, and limitations that can significantly impact their suitability for various applications.

How Does Steel Perform in Shipping Containers?

Steel is the most prevalent material used in shipping containers due to its strength and durability. It typically has a high tensile strength, allowing it to withstand high pressure and extreme temperatures. Steel containers are also resistant to corrosion when treated with appropriate coatings, making them suitable for maritime environments.

Pros: Steel containers are highly durable and can endure harsh weather conditions. They offer excellent security due to their robust construction and are generally available at lower costs compared to other materials.

Cons: Steel is heavier than other materials, which can increase shipping costs. It is also susceptible to rust if not properly maintained, which can lead to structural integrity issues over time.

Impact on Application: Steel containers are ideal for transporting heavy goods and can handle various media, including liquids and gases. However, buyers should consider corrosion resistance when shipping sensitive materials.

Considerations for International Buyers: Compliance with international shipping standards (such as ISO 668) is essential. Buyers from regions like Africa and South America should ensure that the containers meet local regulations regarding safety and environmental impact.

What Role Does Aluminum Play in Shipping Containers?

Aluminum containers are gaining popularity due to their lightweight nature and corrosion resistance. They are often used in specialized applications where weight savings are critical, such as in air freight.

Pros: Aluminum containers are lightweight, which reduces transportation costs. They are naturally resistant to corrosion and do not require additional treatment, making them low-maintenance.

Cons: The cost of aluminum is typically higher than steel, which can be a limiting factor for budget-conscious buyers. Additionally, aluminum is less durable under heavy loads compared to steel.

Impact on Application: Aluminum containers are suitable for transporting sensitive goods that require protection from moisture and corrosion. Their lightweight nature makes them ideal for air transport, but they may not be the best choice for heavy cargo.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific standards for aluminum containers, such as EN 12079, which governs the design and performance of offshore containers.

How Do Fiberglass Containers Compare?

Fiberglass containers are less common but are valued for their excellent insulation properties and resistance to chemicals. They are often used in specialized applications, such as transporting hazardous materials.

Pros: Fiberglass is lightweight and offers superior insulation, making it suitable for temperature-sensitive goods. It is also resistant to corrosion and chemicals, providing a longer lifespan.

Cons: Fiberglass containers can be more expensive to manufacture and repair. They are also less structurally robust than steel or aluminum, limiting their use for heavy loads.

Impact on Application: These containers are best suited for transporting chemicals or temperature-sensitive products. However, their lower load-bearing capacity may restrict their use in general cargo transport.

Considerations for International Buyers: Buyers should ensure compliance with chemical transport regulations, such as those outlined by the UN’s Globally Harmonized System (GHS), especially in regions like Africa and South America where regulations may vary.

What About Wood as a Material for Shipping Containers?

Wooden containers are often used for specific applications, such as temporary storage or shipping fragile items. They provide a natural aesthetic and can be less expensive than metal containers.

Pros: Wooden containers are generally cost-effective and can be easily modified or repaired. They provide good insulation and are suitable for transporting delicate items.

Cons: Wood is susceptible to pests and rot, which can compromise the integrity of the container. Additionally, they lack the security features of metal containers, making them less suitable for high-value goods.

Impact on Application: Wooden containers are ideal for transporting fragile items or for short-term storage solutions. However, they may not be suitable for long-distance shipping or for transporting heavy or valuable goods.

Considerations for International Buyers: Compliance with international phytosanitary standards (ISPM 15) is crucial to prevent pest infestations, particularly for buyers in Europe and the Middle East.

Summary Table of Material Selection for Shipping Containers Under $1000

| Material | Typical Use Case for shipping containers under $1000 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General cargo transport, heavy goods | High durability and security | Susceptible to rust without treatment | Low |

| Aluminum | Air freight, sensitive goods | Lightweight and corrosion-resistant | Higher cost, less durable under load | Medium |

| Fiberglass | Hazardous materials, temperature-sensitive products | Excellent insulation and chemical resistance | Higher manufacturing costs | Medium |

| Wood | Temporary storage, fragile items | Cost-effective and easily modifiable | Susceptible to pests and rot | Low |

This analysis provides B2B buyers with essential insights into material selection for shipping containers under $1000, helping them make informed decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for shipping containers under $1000

What Are the Main Stages in the Manufacturing Process of Affordable Shipping Containers?

The manufacturing process of shipping containers under $1,000 involves several key stages, each critical to ensuring the final product meets quality and safety standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the right materials, typically high-strength corten steel, known for its durability and resistance to corrosion. The steel is cut into specified dimensions using precision cutting tools, ensuring uniformity. This stage may also involve pre-treatment processes like sandblasting to remove impurities and enhance adhesion for coatings applied later.

-

Forming: In this stage, the cut steel sheets are shaped into the various components of the container. Techniques such as roll forming and press braking are commonly employed to create the walls, floor, and roof panels. Advanced machinery ensures that the dimensions and angles meet the strict specifications necessary for structural integrity.

-

Assembly: Once the components are formed, they are assembled. This involves welding the walls, floor, and roof together to create a rigid structure. Spot welding is often used for its speed and efficiency, while continuous welding provides additional strength. During assembly, it’s crucial to check for alignment and fit, as any discrepancies can affect the container’s performance.

-

Finishing: The final stage involves applying protective coatings to prevent rust and corrosion. This often includes priming and painting with marine-grade paints. Quality control checks are performed to ensure that the coating is even and adheres properly. Additionally, features such as doors, locks, and ventilation systems are installed at this stage.

How Is Quality Assurance Implemented in Shipping Container Manufacturing?

Quality assurance (QA) is vital in the manufacturing of shipping containers, especially for those priced under $1,000. The implementation of QA processes involves adherence to international standards, checkpoints throughout production, and rigorous testing methods.

-

International Standards: Manufacturers often comply with ISO 9001 standards, which provide a framework for quality management systems. This certification ensures that processes meet customer and regulatory requirements consistently. Additionally, compliance with industry-specific standards such as CE (European Conformity) and API (American Petroleum Institute) may be necessary depending on the intended use of the container.

-

Quality Control Checkpoints: Quality control is integrated into the manufacturing process through various checkpoints:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages to catch defects early.

– Final Quality Control (FQC): The completed containers undergo a thorough inspection to verify structural integrity and compliance with specifications.

What Common Testing Methods Are Used to Ensure Shipping Container Quality?

Testing methods are essential for verifying the quality and safety of shipping containers. Common practices include:

- Visual Inspection: This initial check ensures that there are no visible defects, such as dents, rust, or improper welding.

- Leak Testing: Containers may undergo pressure tests to ensure they are watertight, especially for those intended for transport of sensitive goods.

- Structural Testing: Load tests simulate the weight and stress the container will experience during shipping. This helps to confirm that the container can withstand external pressures.

- Corrosion Resistance Testing: Manufacturers may apply accelerated aging tests to evaluate how well the protective coatings resist corrosion over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is critical. Here are actionable steps:

-

Conduct Supplier Audits: Regular audits can provide insights into the manufacturing processes and quality control measures in place. Audits should evaluate compliance with ISO standards and other relevant certifications.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation detailing their QA processes, inspection results, and compliance with international standards. This transparency is vital for building trust.

-

Engage Third-Party Inspectors: Hiring independent inspectors to evaluate the manufacturing facility and the final products can provide an unbiased assessment of quality. These professionals can conduct thorough inspections and offer detailed reports.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be challenging for international buyers. Here are some nuances to consider:

-

Understanding Regional Standards: Different regions may have specific standards and regulations governing shipping containers. It is essential to understand these local requirements to ensure compliance.

-

Language Barriers: Communication can pose a challenge when dealing with suppliers in different regions. It is advisable to have a translator or a liaison familiar with both languages to facilitate clear communication regarding quality standards.

-

Cultural Differences: Business practices may vary significantly across cultures. Understanding these differences can help in negotiations and in establishing a good working relationship with suppliers.

-

Documentation and Compliance: Ensure that all necessary documentation, such as certificates of compliance and quality assurance reports, are in order before finalizing any purchases. This reduces the risk of legal issues and ensures that the containers meet all required standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for shipping containers under $1,000 is vital for B2B buyers. By focusing on these aspects, businesses can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shipping containers under $1000’

Introduction

In today’s competitive market, finding affordable shipping containers under $1,000 can be a challenging yet essential task for businesses looking to optimize logistics and storage solutions. This step-by-step checklist is designed to guide international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, through the practicalities of sourcing containers efficiently and effectively.

Step 1: Define Your Technical Specifications

Before you begin your search, it’s vital to determine your specific requirements for the shipping container. Consider factors such as size (20ft vs. 40ft), condition (new or used), and intended use (storage, modification, or transport). Defining these parameters will help streamline your search and ensure you find the right fit for your needs.

Step 2: Research Market Prices

Understanding the prevailing market rates for shipping containers is crucial for making informed decisions. Look for price trends in your target regions and compare various suppliers to gauge the average costs. Pay attention to factors such as container age, condition, and location, as these can significantly influence pricing.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet your potential suppliers. Request company profiles, customer testimonials, and case studies from buyers in similar industries or regions. Ensure that suppliers have a solid track record and positive reviews to mitigate risks associated with quality and reliability.

- Check Certifications: Verify any industry certifications or memberships that indicate a reputable supplier.

- Direct Communication: Engage in direct conversations with suppliers to assess their responsiveness and transparency.

Step 4: Utilize Online Marketplaces

Leverage online platforms like Container xChange to simplify your search. These marketplaces allow you to filter your search by price, location, and container type, providing access to a vast inventory of containers under $1,000. This approach not only saves time but also connects you directly with vetted sellers, eliminating broker fees.

Step 5: Inspect Containers Thoroughly

Once you’ve shortlisted potential containers, arrange for a physical inspection. A thorough examination is essential to assess the container’s condition, including checking for rust, structural integrity, and any signs of leaks. If inspection is not feasible, request detailed photos and condition reports from the seller.

Step 6: Understand Delivery and Logistics Costs

Before finalizing your purchase, factor in delivery costs and logistics. Depending on the seller’s location, shipping fees can vary significantly. Additionally, confirm whether the seller offers delivery or if you need to arrange transportation yourself, as this can impact overall budgeting.

Step 7: Finalize Payment and Secure Documentation

Once you’ve agreed on a price and logistics, ensure that the payment method is secure. Use platforms that offer escrow services or other secure payment options to protect your investment. Additionally, obtain all necessary documentation, including a bill of sale and any warranty information, to formalize the transaction.

By following these steps, B2B buyers can navigate the complexities of sourcing shipping containers under $1,000 while ensuring quality and value for their investment.

Comprehensive Cost and Pricing Analysis for shipping containers under $1000 Sourcing

What Are the Key Cost Components for Shipping Containers Under $1000?

When sourcing shipping containers priced under $1000, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials used in the construction of the container significantly impact the price. Standard ISO containers are typically made of Corten steel, known for its durability and corrosion resistance. However, variations in material quality can lead to price fluctuations.

-

Labor: Labor costs can vary depending on the region of production. In countries with lower labor costs, the overall price of containers may be more competitive. However, labor quality, especially in terms of assembly and finishing, can affect the longevity and usability of the containers.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including factory maintenance, utilities, and administrative expenses. Efficient manufacturing processes can reduce these overheads, contributing to lower prices for buyers.

-

Tooling: Specialized equipment and tooling required for container production can incur significant costs. While these are often factored into the price, buyers should inquire about the production methods to assess their impact on pricing.

-

Quality Control (QC): Quality assurance processes ensure that containers meet specific standards. Containers that undergo rigorous QC may carry a higher price tag but offer better durability and reliability, which can translate to long-term savings.

-

Logistics: Transportation costs, including shipping and handling, play a critical role in the final pricing. Factors such as distance from the seller, shipping methods, and local port fees can all influence the total logistics costs.

-

Margin: The profit margin expected by sellers can vary widely. Established suppliers with a strong market presence may have higher margins, while emerging sellers might offer lower prices to gain market share.

How Do Price Influencers Affect the Cost of Shipping Containers?

Several factors can influence the price of shipping containers, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Buying in bulk can lead to significant discounts. Suppliers often have tiered pricing structures that reward larger purchases, making it more cost-effective for businesses that require multiple units.

-

Specifications and Customization: Custom features, such as insulation, ventilation, or modifications for specific uses, can increase costs. Buyers should evaluate whether these customizations are necessary for their intended use to avoid unnecessary expenses.

-

Materials and Quality Certifications: Containers that meet international quality standards or certifications may cost more. However, investing in certified containers can reduce maintenance costs and improve safety.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a good track record may charge a premium, but they often provide better service and support.

-

Incoterms: Understanding Incoterms is crucial for international transactions. The chosen terms dictate responsibility for shipping, insurance, and tariffs, which can significantly impact the total cost of ownership.

What Are the Best Tips for Buyers to Optimize Costs?

B2B buyers, especially those from Africa, South America, the Middle East, and Europe, can employ several strategies to ensure cost efficiency when sourcing containers:

-

Negotiate Wisely: Don’t hesitate to negotiate prices with suppliers. Understanding the market rates and being aware of the seller’s cost structure can provide leverage during negotiations.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate ongoing costs such as maintenance, insurance, and potential modifications. This broader perspective can help identify the most cost-effective options.

-

Research Market Trends: Staying informed about market trends, geopolitical factors, and seasonal price fluctuations can aid in making timely purchasing decisions. For instance, container prices may rise due to geopolitical tensions or economic shifts.

-

Utilize Online Marketplaces: Leveraging platforms that connect buyers directly with sellers can reduce brokerage fees and provide better price transparency. These platforms often allow buyers to filter by price, location, and specifications, simplifying the sourcing process.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local demand and supply dynamics. Understanding these nuances can help buyers make informed decisions and avoid overpaying.

Conclusion

Navigating the cost and pricing landscape for shipping containers under $1000 requires careful consideration of various components and influencers. By understanding the cost structure, leveraging negotiation strategies, and being mindful of total ownership costs, international B2B buyers can optimize their purchasing decisions, ensuring they acquire quality containers that meet their needs within budget.

Alternatives Analysis: Comparing shipping containers under $1000 With Other Solutions

Introduction: Exploring Alternatives to Shipping Containers Under $1000

When sourcing storage and transport solutions, businesses often consider various options based on cost, performance, and specific needs. Shipping containers priced under $1000 are a popular choice for many, offering a balance of affordability and versatility. However, several alternatives may also meet a company’s logistical or storage requirements, each with its own advantages and drawbacks. This section compares shipping containers under $1000 with portable storage units and modular storage solutions.

Comparison Table

| Comparison Aspect | Shipping Containers Under $1000 | Portable Storage Units | Modular Storage Solutions |

|---|---|---|---|

| Performance | High durability; weather-resistant; ideal for long-term storage | Good for temporary use; limited weather resistance | Highly customizable; designed for specific needs |

| Cost | Generally $700 – $1000 per unit | Ranges from $100 – $500 monthly rental | Initial investment can exceed $1000; additional costs for customization |

| Ease of Implementation | Requires transportation logistics; may need site prep | Quick delivery and setup; minimal site prep | Requires planning and permits; longer setup time |

| Maintenance | Low; occasional rust treatment may be needed | Moderate; regular checks for structural integrity | Varies widely; depends on materials used and customization |

| Best Use Case | Long-term storage, shipping, and conversion projects | Short-term projects, on-site storage for events | Permanent installations, tailored for specific commercial needs |

Detailed Breakdown of Alternatives

1. Portable Storage Units

Portable storage units offer a practical alternative for businesses needing flexible storage solutions. These units are delivered directly to the site and can be rented for short durations, making them ideal for temporary projects, such as construction sites or events. They typically come in various sizes and are designed for easy transport. However, they may not provide the same level of durability as shipping containers, particularly in harsh weather conditions, and ongoing rental costs can add up over time.

2. Modular Storage Solutions

Modular storage solutions represent a more customizable option for businesses that require tailored storage or workspace. These structures can be designed to meet specific operational needs, from office space to secure storage. However, they often involve a higher initial investment and may require building permits and site preparation, which can complicate the implementation process. While they can be more expensive than containers under $1000, their flexibility and adaptability can make them a worthwhile investment for companies looking to create long-term infrastructure.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the appropriate storage or shipping solution ultimately depends on your business’s specific requirements, budget constraints, and intended use. Shipping containers under $1000 provide an effective balance of durability, cost-efficiency, and versatility, making them suitable for various applications. However, if your needs are more temporary or require customization, considering portable storage units or modular solutions may better serve your objectives. Evaluate the performance, costs, and logistical implications of each option to make an informed decision that aligns with your operational goals.

Essential Technical Properties and Trade Terminology for shipping containers under $1000

What Are the Key Technical Properties of Shipping Containers Under $1000?

When considering the purchase of shipping containers under $1000, it is essential to understand the technical specifications that define their quality and suitability for various applications. Here are some critical properties:

1. Material Grade

Shipping containers are primarily constructed from corten steel, known for its high strength and corrosion resistance. This material is crucial for durability, especially in harsh weather conditions. For B2B buyers, selecting containers made from high-grade materials ensures longevity and reduces the need for frequent replacements.

2. Tolerance

Tolerance refers to the allowable variation in the dimensions of the container. Standard containers are built to ISO specifications, which means they should have specific tolerances for length, width, and height. This is vital for businesses that require containers to fit into specific logistical or storage configurations. Ensuring precise tolerances can enhance operational efficiency, particularly in crowded or restricted spaces.

3. Load Capacity

The load capacity indicates the maximum weight a container can safely carry. Typically, a 20-foot container can hold up to 22,000 pounds, while a 40-foot container can handle around 30,000 pounds. For international buyers, understanding load capacities is crucial for compliance with shipping regulations and for optimizing transport costs.

4. Condition Ratings

Shipping containers are often categorized by their condition: new, cargo-worthy, or wind and watertight. A cargo-worthy container may have cosmetic wear but is still structurally sound for shipping. Understanding these ratings helps buyers assess the value and suitability of containers for their specific needs, especially when budget constraints are a factor.

5. Dimensions

Standard shipping containers come in various sizes, with the most common being 20-foot and 40-foot options. The choice of dimensions impacts storage space and shipping logistics. Businesses must consider their specific requirements to optimize both storage and transportation costs.

What Are Common Trade Terms Used in the Shipping Container Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common trade terms relevant to shipping containers:

1. OEM (Original Equipment Manufacturer)

In the context of shipping containers, an OEM refers to a company that produces containers to be sold under another brand name. Understanding this term helps buyers identify the origin of their containers and ensures they are purchasing from reputable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of containers a supplier is willing to sell. This term is crucial for businesses planning bulk purchases, as it can affect overall costs and inventory management. Knowing the MOQ can help in negotiating better deals or finding alternative suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer solicits price quotes from suppliers for specific products. For B2B buyers, issuing an RFQ for shipping containers can streamline the purchasing process and ensure competitive pricing from multiple vendors.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping agreements. Familiarity with these terms is essential for understanding shipping costs, risk management, and insurance responsibilities. They play a significant role in international transactions involving shipping containers.

5. Wind and Watertight

This term describes a container that is sealed against wind and water, making it suitable for storage and transport in adverse weather conditions. Understanding this specification is vital for businesses needing reliable protection for their goods during transit.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing shipping containers under $1000, ultimately enhancing their operational efficiency and cost management.

Navigating Market Dynamics and Sourcing Trends in the shipping containers under $1000 Sector

What Are the Key Market Dynamics and Trends Influencing Shipping Containers Under $1000?

The shipping container market, particularly for containers priced under $1000, is shaped by a variety of global drivers and emerging trends. One significant factor is the increasing demand for affordable storage and transportation solutions across industries, including retail, construction, and agriculture. As international trade expands, businesses in regions like Africa, South America, the Middle East, and Europe are seeking cost-effective ways to manage logistics and supply chains. Notably, the rise of online marketplaces, such as Container xChange, has revolutionized sourcing practices, allowing buyers to connect directly with sellers, eliminating intermediaries and associated costs.

Another emerging trend is the shift towards digital sourcing tools that facilitate transparency and accessibility. Buyers can now leverage technology to filter containers by price, location, and condition, significantly enhancing their procurement process. Additionally, geopolitical tensions and fluctuating trade policies have created a volatile pricing environment, making it essential for buyers to stay informed about global market conditions. This volatility often results in price variations, which can affect sourcing strategies, particularly for buyers in economically diverse regions.

How Can Sustainability and Ethical Sourcing Impact Decisions for Shipping Containers Under $1000?

Sustainability and ethical sourcing are increasingly becoming crucial considerations for businesses sourcing shipping containers. The environmental impact of container production and transportation is significant; thus, many companies are focusing on reducing their carbon footprints by opting for used containers rather than new ones. This not only lowers costs but also promotes recycling and waste reduction.

Moreover, ethical supply chains are essential in today’s business landscape. Buyers should prioritize suppliers who adhere to sustainable practices, such as using eco-friendly materials or obtaining certifications that confirm their commitment to environmental stewardship. Look for suppliers that offer containers with green certifications, ensuring that the products meet specific environmental standards. This not only enhances a company’s brand reputation but also resonates with consumers and partners who value corporate responsibility.

What Is the Historical Context Behind the Growth of the Shipping Containers Under $1000 Market?

Historically, the shipping container industry has evolved dramatically since its inception in the mid-20th century. Initially, containers were primarily used for international shipping, but over time, their applications have expanded significantly. The introduction of standard container sizes allowed for streamlined logistics and cost-effective shipping solutions.

As globalization intensified, the demand for affordable storage options surged, paving the way for the market for used containers, especially those under $1000. This evolution is particularly relevant for emerging markets in Africa and South America, where businesses often seek economical solutions for storage and transport. The growing acceptance of used containers in various sectors—ranging from construction to retail—has further solidified their role as a versatile asset in modern supply chains. Today, the accessibility of used containers has opened new avenues for businesses to optimize their logistics and operational efficiency while maintaining budget constraints.

Frequently Asked Questions (FAQs) for B2B Buyers of shipping containers under $1000

-

How do I find reliable suppliers for shipping containers under $1000?

Finding reliable suppliers requires thorough research and vetting. Start by utilizing online marketplaces that specialize in shipping containers, where you can filter options based on price and location. Look for platforms that verify their sellers and offer reviews from previous buyers. Additionally, consider contacting local shipping container companies and asking for references. Engage in direct communication with potential suppliers to gauge their responsiveness and professionalism, and always request documentation to confirm their legitimacy. -

What are the key factors to consider when buying a shipping container?

When purchasing a shipping container, consider factors such as size, condition, and intended use. For containers under $1000, focus on used options, ensuring they are cargo-worthy and free from significant damage. Evaluate the shipping costs to your location, as these can vary widely. Furthermore, check if modifications are necessary for your purpose and whether the supplier offers such services. Lastly, confirm the payment terms and warranty, as these can significantly impact your investment security. -

What types of shipping containers are available for under $1000?

Typically, you can find 20ft and 40ft used shipping containers for under $1000. The 20ft containers are ideal for smaller storage needs, while the 40ft containers offer double the space for a slightly higher price. Both types are versatile and can be used for various applications, including storage, shipping, and even conversion into living or working spaces. Always ensure the containers are inspected for quality and functionality before purchase. -

Are there customization options for shipping containers under $1000?

Customization options for containers under $1000 may be limited, especially for used units. However, many suppliers allow basic modifications such as adding doors, windows, or ventilation. If you require extensive customization, it’s advisable to discuss this with the supplier upfront, as these modifications may increase the overall cost. Always factor in additional time and costs for custom work when planning your purchase. -

What are the typical payment terms for international shipping container purchases?

Payment terms can vary by supplier, but most will require a deposit upfront, typically ranging from 10% to 50% of the total price. The balance is often due upon delivery or before shipping, depending on the agreement. For international transactions, consider using secure payment methods that offer buyer protection. Always clarify terms related to refunds, cancellations, and any additional fees before finalizing the deal to ensure transparency. -

How can I ensure the quality of a shipping container before buying?

To ensure quality, always conduct a thorough inspection of the shipping container before purchase. Look for structural integrity, signs of rust, leaks, and any damage to doors or locks. If possible, request a professional inspection or certification from the supplier. Additionally, reputable suppliers often provide detailed photos and descriptions of their containers. It’s also wise to check reviews and ratings from previous customers to gauge the supplier’s reliability. -

What logistics should I consider when purchasing shipping containers internationally?

When purchasing internationally, consider logistics such as shipping costs, delivery times, and customs regulations in your country. Determine if the supplier can handle shipping arrangements or if you need to engage a freight forwarder. Be aware of any import duties or tariffs that may apply to your shipment, as these can significantly impact your total cost. Ensure that the shipping container is compliant with local regulations to avoid any legal issues upon arrival. -

What are the common uses for shipping containers in emerging markets?

In emerging markets, shipping containers are often repurposed for various applications, including temporary housing, storage facilities, and mobile offices. They are increasingly used in construction for site storage or as part of modular building projects. Additionally, businesses utilize containers for retail spaces or food stalls due to their portability and durability. The versatility of shipping containers makes them an attractive solution for diverse needs across different sectors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Shipping Containers Under $1000 Manufacturers & Suppliers List

1. GovPlanet – Military Shipping Containers

Domain: govplanet.com

Registered: 2007 (18 years)

Introduction: Military Shipping Containers & Storage available at GovPlanet. Types include Shipping Containers and Storage Containers. Brands include AAR Mobility Systems, Keco, Plastics Research, Wel-Fab, and more. Total containers for sale: 163. Miscellaneous Container Equipment: 18. Storage Containers: 145. Buying formats include Auction (71), Online Auction (70), Sealed Auction (1), Buy Now (82), Make Offer…

2. Eveon Containers – Used 40ft Shipping Container

Domain: eveoncontainers.com

Registered: 2020 (5 years)

Introduction: Used 40ft Shipping Container

– Delivery in 3 to 5 business days

– Wind and watertight

– Color selection not possible

– Dimensions: Length: 40 feet (12.19 meters), Width: 8 feet (2.44 meters), Height: 8.5 feet (2.59 meters)

– Tare Weight: Around 8,200 to 8,500 lbs (empty)

– Maximum Cargo Weight: Roughly 67,000 lbs

– Storage Capacity: Approximately 2,700 cubic ft

– Cost-effective compared to new con…

3. Onsite Storage – Shipping Containers

Domain: onsitestorage.com

Registered: 2003 (22 years)

Introduction: Buy shipping containers starting at $1,350.00. Rent shipping containers for as low as $95.00 a month. Rent-To-Own shipping containers starting at $79.99 a month. Options include standard shipping containers and refrigerated shipping containers. Delivery available nationwide. No credit check required for rent-to-own options. Considerations when buying include container condition, delivery costs, an…

4. Container Xchange – Shipping Containers for Sale

Domain: container-xchange.com

Registered: 2017 (8 years)

Introduction: Shipping Containers for Sale in Houston, TX – New & Used Products. Pricing starts from $650/unit. Container types available include 20ft and 40ft containers, with prices ranging from $1,000 to $4,500 depending on condition and size. Features include a money-back guarantee, brokerage-free transactions, and the ability to negotiate prices. Key details include Year of Manufacture (YOM), forklift comp…

5. Used Shipping Container – $800.00

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “Shipping container”,”price”: “$800.00″,”condition”: “Used”,”quantity”: “1 available”,”item_number”: “326430298738”,”category”: “Business & Industrial > Material Handling > Shipping Containers”,”description”: “An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store re…

6. Conexwest – Storage Containers for Sale

Domain: conexwest.com

Registered: 2014 (11 years)

Introduction: Storage Containers for Sale: 20ft Shipping Container starting at $1,250.00, 40ft Shipping Container starting at $1,675, 40ft Refrigerated Container starting at $9,995, 30ft Storage Container with Roll-Up Door, 20ft Ground Level Office Container Rent $1350, 40ft Storage Container Rent $139.00, 20ft Storage Container Rent $119.00, 20ft Ground Level Office Container Rent $279.00, 40ft Ground Level Of…

7. Baytown Shipping Containers – 20ft & 40ft for Sale

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Baytown Shipping Containers – 20ft & 40ft for Sale, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

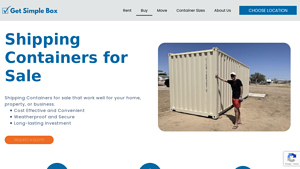

8. SimpleBox – Shipping Containers for Sale

Domain: getsimplebox.com

Registered: 2012 (13 years)

Introduction: New and Used Shipping Containers for Sale in 10ft, 20ft, and 40ft sizes. Cost-effective and convenient options for home, property, or business use. Containers are weatherproof, secure, and durable. 20ft containers are the most popular size, ideal for moving and job site storage. 40ft containers are made from high-quality steel, watertight, and weather-resistant. Options for customization available…

9. AirTec – Affordable Shipping Containers Guide

Domain: airtec.com

Registered: 1994 (31 years)

Introduction: This company, AirTec – Affordable Shipping Containers Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for shipping containers under $1000

In today’s competitive landscape, securing shipping containers under $1,000 is not only achievable but also essential for businesses looking to optimize their logistics and storage solutions. Strategic sourcing plays a pivotal role in this process, enabling buyers to navigate the complexities of the market effectively. By leveraging platforms like Container xChange, international B2B buyers can access a vast network of vetted sellers, ensuring quality and reliability while eliminating unnecessary brokerage fees.

Key takeaways for buyers include understanding the benefits of both 20ft and 40ft containers, considering factors such as condition and delivery costs, and being aware of the potential for modifications to meet specific needs. As demand continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, staying informed about market trends and pricing fluctuations will empower businesses to make strategic purchasing decisions.

Looking ahead, the landscape of shipping containers is expected to evolve with ongoing global trade dynamics. Now is the time for international buyers to act decisively and capitalize on the opportunities presented by sourcing containers under $1,000. Explore your options today and secure the best solutions for your business needs.