A B2B Buyer’s Guide to Northstar Air Compressor Parts: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for northstar air compressor parts

In the competitive landscape of industrial equipment, sourcing high-quality Northstar air compressor parts can be a daunting task for international B2B buyers. With diverse applications ranging from manufacturing to construction, the reliability of these components directly impacts operational efficiency. This guide is designed to navigate the complexities of the global market for Northstar air compressor parts, providing insights into various types of components, their applications, and best practices for supplier vetting.

As you explore this comprehensive resource, you’ll find detailed information on essential parts such as air filters, pressure switches, and unloader valves, along with tips on how to assess quality and compatibility. Understanding the cost implications and logistics involved in procuring these parts is crucial, especially for businesses operating in regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Vietnam.

By arming yourself with this knowledge, you will be empowered to make informed purchasing decisions that enhance your operational capabilities and reduce downtime. Whether you are looking to maintain existing equipment or expand your operations, this guide serves as a vital tool in ensuring that you secure the right Northstar air compressor parts at the best value.

Understanding northstar air compressor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air Filter Assembly | Essential for filtering contaminants from air | Manufacturing, automotive, construction | Pros: Increases efficiency, protects equipment. Cons: Requires regular replacement. |

| Unloader Valve | Controls airflow and pressure in the system | Industrial air systems | Pros: Reduces wear on components, enhances safety. Cons: May require precise installation. |

| Pressure Switch Kit | Regulates compressor operation based on pressure | HVAC, pneumatic tools | Pros: Ensures optimal pressure levels, prevents overload. Cons: Potential compatibility issues with different models. |

| Gasket Kit | Seals components to prevent leaks | General maintenance and repairs | Pros: Cost-effective, easy to replace. Cons: Quality can vary by manufacturer. |

| Electric Motor | Powers the compressor, available in various HP | Heavy-duty applications, manufacturing | Pros: High efficiency, various power options. Cons: Higher upfront cost for premium models. |

What Are the Key Features of Air Filter Assemblies for Northstar Compressors?

Air filter assemblies are critical components designed to remove dust, dirt, and other particulates from the air before it enters the compressor. This is particularly important in industries such as manufacturing and automotive, where air quality can directly impact equipment performance and longevity. When sourcing air filter assemblies, buyers should consider the frequency of maintenance and the specific requirements of their compressor model to ensure compatibility.

How Do Unloader Valves Enhance Compressor Performance?

Unloader valves play a vital role in managing airflow and pressure within air compressors. They release pressure from the compressor when it is not in use, thereby reducing wear and tear on the machine. These valves are essential in industrial air systems where consistent pressure is crucial for operations. Buyers should assess the specifications of their compressors to select the right unloader valve, as improper selection can lead to inefficiencies or equipment damage.

Why Are Pressure Switch Kits Important for Northstar Air Compressors?

Pressure switch kits are indispensable for regulating the operation of air compressors based on the pressure levels detected within the system. They ensure that compressors do not exceed their maximum pressure ratings, which is vital in HVAC and pneumatic tool applications. When purchasing pressure switch kits, businesses should verify compatibility with their existing systems to avoid potential operational disruptions.

What Should Buyers Consider When Choosing Gasket Kits?

Gasket kits are essential for sealing various components in air compressors to prevent air and oil leaks. They are particularly useful in maintenance and repair scenarios. Buyers should consider the material quality and manufacturer reputation when selecting gasket kits, as these factors can significantly affect durability and reliability. Regular inspections and timely replacements are crucial to maintaining optimal compressor performance.

How Do Electric Motors Impact the Efficiency of Northstar Compressors?

Electric motors are the driving force behind Northstar air compressors, available in various horsepower ratings to suit different operational needs. They are particularly beneficial in heavy-duty applications, providing high efficiency and reliability. When selecting an electric motor, businesses should evaluate the specific power requirements of their compressors and consider the long-term energy costs associated with different motor types. Investing in a high-quality motor can lead to significant operational savings over time.

Key Industrial Applications of northstar air compressor parts

| Industry/Sector | Specific Application of northstar air compressor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pneumatic Tools Operation | Enhanced efficiency and productivity in assembly lines | Quality assurance, compatibility with existing systems |

| Automotive Repair | Tire Inflation and Vehicle Diagnostics | Improved service speed and accuracy for customer satisfaction | Availability of replacement parts and maintenance support |

| Construction | Powering Air-Driven Equipment | Increased operational uptime and reliability on job sites | Durability of parts in harsh conditions, local supply chains |

| Agriculture | Crop Spraying and Irrigation Systems | Optimized resource usage and reduced operational costs | Adaptability to local climates and equipment standards |

| Mining | Compressed Air for Drilling and Blasting | Enhanced safety and efficiency in extraction processes | Compliance with local regulations and environmental standards |

How Are Northstar Air Compressor Parts Used in Manufacturing?

In the manufacturing sector, Northstar air compressor parts are critical for powering pneumatic tools used in assembly lines. Components like air filters and pressure switches ensure that tools operate efficiently and reliably, thus boosting productivity. International buyers, especially from regions such as Africa and South America, must consider compatibility with existing systems and the availability of high-quality parts to avoid downtime due to equipment failure.

What Role Do Northstar Air Compressor Parts Play in Automotive Repair?

In automotive repair shops, Northstar air compressor parts are essential for tire inflation and vehicle diagnostics. With the integration of unloader valves and pressure switches, these parts enhance the accuracy and speed of services offered. For B2B buyers in Europe and the Middle East, sourcing durable components that ensure long-term performance is vital, as it directly impacts customer satisfaction and service delivery.

How Are Northstar Air Compressor Parts Beneficial in Construction?

Construction sites rely heavily on air-driven equipment, which necessitates robust Northstar air compressor parts. Items such as safety relief valves and air intake manifolds contribute to the operational efficiency and safety of machinery used for heavy lifting and drilling. Buyers from regions with challenging environments, like Nigeria and Vietnam, should prioritize sourcing parts that can withstand harsh conditions while ensuring reliable performance.

How Do Northstar Air Compressor Parts Enhance Agricultural Operations?

In agriculture, Northstar air compressor parts are employed in crop spraying and irrigation systems. These parts optimize resource usage, leading to reduced costs and improved yield. Buyers in developing regions must focus on the adaptability of these components to local agricultural practices and climatic conditions, ensuring that they can effectively meet the demands of modern farming.

Why Are Northstar Air Compressor Parts Critical in Mining?

Mining operations utilize compressed air for drilling and blasting, making Northstar air compressor parts indispensable. Parts like unloader valves and pressure switches enhance safety and operational efficiency, which is crucial in high-stakes environments. International buyers should consider compliance with local regulations and the environmental impact of their equipment, ensuring that they source parts that meet stringent industry standards.

3 Common User Pain Points for ‘northstar air compressor parts’ & Their Solutions

Scenario 1: Sourcing Compatible Northstar Air Compressor Parts

The Problem:

B2B buyers often face challenges when sourcing compatible parts for Northstar air compressors. With various models and specifications available, it can be overwhelming to identify the exact parts needed for a specific machine. Misidentifying parts can lead to extended downtimes, increased costs, and frustration. For instance, a company in Nigeria may require a replacement pump but struggle to find the correct model number, leading to delays in production and negatively impacting their bottom line.

The Solution:

To effectively source the right parts, buyers should first familiarize themselves with the specific model and serial numbers of their Northstar air compressors. This information is typically found on the data tag of the machine. Once identified, buyers can utilize online catalogs and parts diagrams, such as those available on specialized websites, to cross-reference their needs. It is also beneficial to engage with reputable suppliers who can provide detailed specifications and compatibility information. Establishing a relationship with a trusted distributor can facilitate quicker access to parts and enhance overall supply chain reliability.

Scenario 2: Managing High Replacement Costs for Air Compressor Parts

The Problem:

One of the significant concerns for B2B buyers is the high cost associated with replacing parts for Northstar air compressors. For businesses in regions like South America, where import tariffs and shipping fees can inflate prices, sourcing affordable yet quality parts becomes a crucial issue. Companies may find themselves facing unplanned expenses that disrupt budget forecasts, causing strain on financial resources and project timelines.

The Solution:

To mitigate replacement costs, buyers should consider implementing a proactive maintenance strategy that includes regular inspections and part replacements before failures occur. This approach helps in extending the lifespan of existing parts and reducing the need for urgent replacements, which are often more expensive. Additionally, exploring bulk purchasing options or long-term contracts with suppliers can lead to significant discounts. Organizations can also benefit from investing in high-quality aftermarket parts, which are often more cost-effective while still meeting or exceeding OEM specifications.

Scenario 3: Ensuring Proper Installation and Maintenance of Air Compressor Parts

The Problem:

Even after successfully sourcing the correct parts, B2B buyers frequently encounter difficulties during the installation and maintenance processes. Improper installation can lead to operational inefficiencies, safety hazards, and premature part failures. For example, a manufacturing facility in the Middle East may face production downtime if technicians are not adequately trained in handling Northstar air compressor components, leading to costly delays.

The Solution:

To ensure proper installation and maintenance, companies should invest in training programs for their technicians. This training should cover best practices for installing Northstar parts and understanding the intricacies of air compressor operation. Additionally, suppliers often provide installation guides and support, which can be invaluable resources. Establishing a routine maintenance schedule that includes checking for wear and tear, replacing filters, and conducting system diagnostics will help maintain optimal performance. Utilizing technology, such as predictive maintenance software, can further assist in identifying potential issues before they escalate into costly problems.

Strategic Material Selection Guide for northstar air compressor parts

What Are the Key Materials Used in Northstar Air Compressor Parts?

When selecting materials for Northstar air compressor parts, it is essential to consider various factors, including performance, durability, and cost. Below, we analyze four common materials used in these components, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Aluminum Benefit Northstar Air Compressor Parts?

Aluminum is frequently used in air compressor parts due to its excellent strength-to-weight ratio and corrosion resistance. It typically withstands temperatures up to 150°C and pressures around 200 psi, making it suitable for various applications.

Pros: Aluminum is lightweight, which reduces the overall weight of the compressor, enhancing portability. It also resists corrosion, which is crucial in humid or corrosive environments.

Cons: While aluminum is durable, it can be less robust than steel under high-stress conditions. Additionally, its cost can be higher than some other materials, particularly for high-grade alloys.

Impact on Application: Aluminum’s lightweight nature makes it ideal for portable compressors used in construction or fieldwork, where mobility is essential.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards for aluminum quality, such as ASTM or JIS. Additionally, understanding the availability and cost of aluminum in their region is vital for budgeting.

What Role Does Steel Play in Northstar Air Compressor Parts?

Steel is another common material, particularly for parts requiring high strength and durability, such as frames and pressure vessels. Steel can handle high temperatures (up to 250°C) and pressures (up to 300 psi), making it an excellent choice for heavy-duty applications.

Pros: Steel is incredibly strong and offers excellent wear resistance, making it suitable for high-stress components. It is also relatively cost-effective compared to other metals.

Cons: Steel is heavier than aluminum, which can affect portability. Additionally, it is susceptible to corrosion if not properly treated or coated.

Impact on Application: Steel is ideal for stationary compressors used in industrial settings where durability and strength are paramount.

Considerations for International Buyers: Buyers should be aware of the specific grades of steel that meet local regulations and standards, such as DIN or ASTM. Corrosion resistance treatments may also be necessary in humid regions.

Why Is Brass Used in Northstar Air Compressor Parts?

Brass is often utilized for fittings and valves due to its excellent machinability and corrosion resistance. It can withstand temperatures up to 200°C and pressures around 150 psi, making it suitable for various applications.

Pros: Brass is easy to machine, allowing for precise component manufacturing. Its corrosion resistance is beneficial in humid environments.

Cons: Brass can be more expensive than aluminum and steel, and it may not be as strong under high-stress conditions.

Impact on Application: Brass is commonly used in fittings and connectors where precision and resistance to corrosion are critical.

Considerations for International Buyers: Buyers should verify the brass alloy standards that comply with local regulations. Understanding the cost implications of brass in their region is also essential for effective budgeting.

How Does Plastic Contribute to Northstar Air Compressor Parts?

Plastic is increasingly used in non-structural components, such as covers and housings, due to its lightweight and cost-effectiveness. It can handle temperatures up to 80°C and pressures around 100 psi.

Pros: Plastic is lightweight and cost-effective, making it suitable for various applications. It also offers good insulation properties.

Cons: Plastic is less durable than metals and may not withstand high temperatures or pressures, limiting its use in critical components.

Impact on Application: Plastic is ideal for non-critical components where weight savings and cost reduction are essential.

Considerations for International Buyers: Buyers should ensure that the plastic used meets local safety and quality standards, as well as understand the implications of using plastic in terms of durability and performance in their specific environment.

Summary of Material Selection for Northstar Air Compressor Parts

| Material | Typical Use Case for Northstar Air Compressor Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable compressor components | Lightweight and corrosion-resistant | Less robust under high stress | Medium |

| Steel | Frames and pressure vessels | High strength and durability | Heavier and susceptible to corrosion | Low |

| Brass | Fittings and valves | Excellent machinability and corrosion resistance | More expensive and less strong | High |

| Plastic | Non-structural components | Lightweight and cost-effective | Less durable and limited temperature resistance | Low |

This analysis provides a comprehensive overview of materials used in Northstar air compressor parts, offering valuable insights for international B2B buyers. Understanding these materials helps in making informed purchasing decisions that align with specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for northstar air compressor parts

What Are the Main Stages in the Manufacturing Process of Northstar Air Compressor Parts?

The manufacturing process for Northstar air compressor parts is a multi-stage operation that emphasizes precision and quality. It typically includes the following main stages:

Material Preparation

The first step involves selecting high-grade materials that meet specific performance and durability requirements. Common materials include various grades of steel, aluminum, and specialized composites designed to withstand high pressure and temperature conditions. Prior to fabrication, materials undergo rigorous inspection to ensure compliance with international standards, such as ASTM or ISO specifications.

Forming Techniques

Once the materials are prepared, they are subjected to forming techniques such as casting, machining, and stamping. For instance, components like the cylinder heads and crankcases may be cast using precision molds, while other parts, such as valves and fittings, are machined to exact tolerances. Advanced CNC (Computer Numerical Control) machines are often employed to enhance accuracy and repeatability in the shaping process.

Assembly Process

The assembly stage is critical for ensuring that all components fit and function together seamlessly. This process may involve manual assembly or automated techniques, depending on the complexity of the part. Skilled technicians carefully align and fasten components, often using torque specifications to prevent failures under operational stress. During assembly, parts such as gaskets and seals are installed to ensure airtight and leak-proof connections, which is vital for compressor efficiency.

Finishing Techniques

Finishing processes, including surface treatment and coating, are applied to enhance the durability and aesthetic appeal of the parts. Techniques such as anodizing, powder coating, and galvanization are commonly used to protect against corrosion and wear. These finishing touches not only improve longevity but also contribute to the overall performance of the air compressors.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for Northstar air compressor parts. It ensures that products meet both internal and external quality standards before they reach the market.

What International Standards Are Applicable?

Northstar air compressor parts manufacturers typically adhere to several international quality standards, including ISO 9001, which focuses on quality management systems. Compliance with CE marking regulations is also essential for parts sold in European markets, ensuring they meet health, safety, and environmental protection standards. Additionally, industry-specific standards such as API (American Petroleum Institute) may apply, particularly for components used in oil and gas applications.

What Are the Key Quality Control Checkpoints?

To maintain high-quality production, manufacturers implement a series of quality control checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components as they arrive at the facility to ensure they meet required specifications.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor processes and identify any deviations from quality standards. This can include measuring tolerances and conducting functional tests on critical components.

-

Final Quality Control (FQC): Once the parts are fully assembled, a comprehensive final inspection takes place. This may involve performance testing, dimensional checks, and visual inspections to ensure that every part meets the established criteria.

What Common Testing Methods Are Used for Quality Assurance?

Manufacturers utilize various testing methods to validate the quality and performance of Northstar air compressor parts:

-

Hydraulic Testing: This method checks the integrity of pressure-containing components by subjecting them to high-pressure water tests, ensuring they can withstand operational pressures without leaks.

-

Functional Testing: This involves running the assembled air compressors to verify operational performance, including airflow, pressure output, and noise levels.

-

Dimensional Inspection: Precision measuring tools are used to ensure that all parts conform to specified dimensions, critical for ensuring proper fit and function.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable steps:

Conduct Supplier Audits

Performing on-site audits can provide insights into a supplier’s manufacturing capabilities and quality control systems. During an audit, buyers should assess the cleanliness of the facility, the condition of manufacturing equipment, and the presence of quality management certifications.

Request Quality Assurance Documentation

Buyers should ask for documentation such as quality control reports, inspection certificates, and compliance certificates for relevant international standards. This paperwork serves as proof of adherence to quality protocols.

Engage Third-Party Inspection Services

Utilizing third-party inspection services can offer an independent verification of quality control measures. These services can conduct inspections at various stages of the manufacturing process, ensuring that parts meet required specifications before shipment.

What Are the Quality Control Considerations for International Markets?

For B2B buyers in international markets, several nuances regarding quality control must be understood:

-

Cultural Differences: Quality expectations can vary significantly across regions. Buyers should communicate their specific quality requirements clearly to avoid misunderstandings.

-

Regulatory Compliance: Each market may have its own set of regulations and certifications. Buyers must ensure that suppliers are compliant with local laws regarding safety and environmental impact.

-

Logistics and Supply Chain Considerations: Quality control doesn’t end with manufacturing. Buyers should consider the entire supply chain, including packaging, shipping, and handling processes, which can impact the final quality of the products received.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing Northstar air compressor parts, ensuring they invest in high-quality components that will perform reliably in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘northstar air compressor parts’

In the dynamic world of industrial procurement, sourcing the right components is crucial for operational efficiency and cost-effectiveness. This practical sourcing guide serves as a checklist for B2B buyers looking to procure Northstar air compressor parts, ensuring a streamlined process that minimizes risk and maximizes value.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the Northstar air compressor parts you require. This includes understanding the model numbers, part numbers, and any specific performance criteria such as pressure ratings and compatibility with existing equipment. Having precise specifications allows you to communicate effectively with suppliers and ensures that the parts meet your operational needs.

Step 2: Research Reliable Suppliers

Identify potential suppliers who specialize in Northstar air compressor parts. Look for vendors with a strong reputation and extensive experience in the industry. Utilize online directories, trade shows, and recommendations from industry peers to compile a list of candidates. Pay attention to customer reviews and feedback to gauge their reliability and service quality.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify the certifications and compliance of your potential suppliers. This includes checking for ISO certifications, quality management systems, and adherence to international standards relevant to your industry. Suppliers with recognized certifications are more likely to provide high-quality parts and reliable service.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations for the specific parts you need. Ensure that the quotes include pricing, lead times, shipping costs, and warranty information. Comparing multiple quotations helps you identify the best value for money while ensuring transparency in pricing.

Step 5: Assess Inventory and Availability

Confirm the supplier’s inventory levels and availability of the required Northstar parts. Delays in sourcing can lead to operational disruptions, so it is essential to ensure that your supplier can meet your timelines. Inquire about their ability to handle urgent requests or backorders if necessary.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to establish favorable terms and conditions. This includes payment terms, delivery schedules, and return policies. A well-negotiated agreement can provide cost savings and protect your business interests in case of any issues with the supplied parts.

Step 7: Finalize Purchase and Confirm Order

Once you have agreed on the terms, finalize the purchase by placing the order and confirming all details in writing. Ensure that both parties have a clear understanding of the order specifics, including quantities, part numbers, and delivery expectations. Follow up with the supplier to confirm receipt of the order and anticipated delivery dates.

By following this checklist, B2B buyers can navigate the complexities of sourcing Northstar air compressor parts effectively, ensuring that they secure the right components for their operations while minimizing potential risks.

Comprehensive Cost and Pricing Analysis for northstar air compressor parts Sourcing

When sourcing Northstar air compressor parts, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This section provides insights into the various cost components, price influencers, and practical tips for negotiating favorable terms.

What Are the Key Cost Components of Northstar Air Compressor Parts?

The cost structure for Northstar air compressor parts typically comprises several essential components:

- Materials: The quality and type of materials used significantly affect the pricing. High-grade metals and specialized components (like gaskets and filters) may incur higher costs but ensure durability and performance.

- Labor: Labor costs vary depending on the manufacturing location. Regions with higher labor costs can increase the overall price of parts.

- Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs, which can vary widely among manufacturers.

- Tooling: Initial tooling costs for custom parts can be substantial, especially for unique designs or specifications. Buyers should consider these costs when evaluating quotes.

- Quality Control (QC): Rigorous quality assurance processes ensure that parts meet industry standards. Enhanced QC measures can raise costs but are essential for reliability.

- Logistics: Shipping and handling expenses, including freight charges and import duties, are critical. These costs can vary significantly based on the destination, particularly for buyers in Africa, South America, and the Middle East.

- Margin: Suppliers typically apply a markup to cover their costs and profit. Understanding the expected margin can help buyers negotiate better pricing.

What Influences Pricing for Northstar Air Compressor Parts?

Several factors can influence the pricing of Northstar air compressor parts:

- Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to discounted pricing. Suppliers may provide better rates for bulk purchases, which can be advantageous for businesses looking to stock parts.

- Specifications and Customization: Customized parts or those with specific specifications usually come at a premium. Buyers should weigh the necessity of customization against potential cost increases.

- Materials and Quality Certifications: The certification of materials can also impact pricing. Parts that meet international quality standards may be more expensive but provide peace of mind regarding performance and reliability.

- Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better quality assurance and customer service.

- Incoterms: The chosen Incoterms (International Commercial Terms) can significantly influence overall costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, affecting the total expenditure.

How Can International B2B Buyers Optimize Costs When Sourcing?

For international buyers, particularly from regions like Africa, South America, and the Middle East, here are practical tips to optimize costs:

- Negotiate Effectively: Always engage in negotiations. Understand the supplier’s cost structure to argue for better prices, especially if you are a repeat customer or can guarantee higher volumes.

- Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, durability, and potential downtime costs. Investing in higher-quality parts can reduce long-term expenses.

- Research and Compare Suppliers: Don’t settle for the first quote. Compare multiple suppliers and seek references or reviews to ensure you are getting the best deal.

- Stay Informed About Market Trends: Keeping abreast of material costs and market conditions can provide leverage in negotiations. Economic fluctuations can impact pricing, and being informed allows for strategic purchasing decisions.

- Understand Shipping and Import Regulations: Familiarize yourself with local import duties, taxes, and shipping costs. This knowledge can help avoid unexpected expenses and inform your sourcing strategy.

Disclaimer on Indicative Prices

Please note that the prices listed for Northstar air compressor parts can fluctuate based on market conditions, supplier negotiations, and regional factors. It is advisable to obtain current quotes and confirm pricing directly with suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing northstar air compressor parts With Other Solutions

Introduction: Exploring Alternatives for Air Compressor Parts

In the competitive landscape of industrial equipment, B2B buyers often seek reliable and efficient solutions for their air compressor needs. While Northstar air compressor parts are well-regarded for their performance and compatibility, it’s essential to evaluate alternative options. This analysis will compare Northstar parts against two viable alternatives: Ingersoll Rand air compressor parts and generic aftermarket compressor components. Understanding the strengths and weaknesses of these options will help businesses make informed decisions that align with their operational requirements.

Comparison Table

| Comparison Aspect | Northstar Air Compressor Parts | Ingersoll Rand Air Compressor Parts | Generic Aftermarket Compressor Components |

|---|---|---|---|

| Performance | High reliability; designed for optimal performance in various models | Excellent durability and efficiency; widely trusted in industrial applications | Variable quality; performance can vary significantly based on manufacturer |

| Cost | Moderate pricing; parts like unloader valves range from $70 to $100 | Generally higher price point; premium parts often over $100 | Cost-effective; typically lower than brand-name parts, but quality varies |

| Ease of Implementation | Straightforward installation; well-documented parts | Installation can be complex; may require specific tools | Installation ease varies; some parts may require adjustments |

| Maintenance | Requires regular maintenance; easily accessible parts | Low maintenance; high-quality components reduce failure rates | Maintenance needs vary widely; some parts may not be durable |

| Best Use Case | Ideal for businesses already using Northstar compressors seeking reliable replacements | Best for industries prioritizing performance and longevity | Suitable for budget-conscious businesses or older compressor models |

Detailed Breakdown of Alternatives

Ingersoll Rand Air Compressor Parts

Ingersoll Rand parts are synonymous with quality and reliability in the air compressor market. Their components are designed for high performance and long life, making them suitable for industries that demand heavy-duty operation. However, the trade-off is a higher price point, which may not align with every business’s budget. Installation can also be more complex, sometimes necessitating specialized tools or training. Despite these challenges, their reputation for durability and efficiency makes them an excellent choice for critical applications.

Generic Aftermarket Compressor Components

Generic aftermarket parts offer an attractive alternative for businesses seeking cost savings. These parts are often significantly cheaper than branded options, making them appealing for budget-conscious buyers. However, the quality of these components can be inconsistent, leading to potential performance issues or shorter lifespans. For businesses operating older models or those in less critical environments, generic parts may be a viable solution. It is crucial to research suppliers and verify the quality to avoid costly repairs down the line.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting air compressor parts, B2B buyers must consider their specific operational needs, budget constraints, and the importance of reliability in their applications. Northstar air compressor parts are an excellent choice for businesses already invested in that brand, providing a balance of performance and cost. In contrast, Ingersoll Rand parts may be better suited for those prioritizing durability and efficiency, despite the higher cost. For those on a tighter budget, generic aftermarket components can serve as a stopgap, provided due diligence is performed to ensure quality. Ultimately, the decision should reflect the buyer’s unique operational context and long-term maintenance strategy.

Essential Technical Properties and Trade Terminology for northstar air compressor parts

What Are the Key Technical Properties of Northstar Air Compressor Parts?

Understanding the technical specifications of Northstar air compressor parts is vital for B2B buyers, particularly when sourcing equipment for operational efficiency. Here are several critical properties to consider:

-

Material Grade: The material used in air compressor parts significantly impacts durability and performance. For instance, parts made from high-grade aluminum or steel offer better resistance to wear and corrosion, ensuring longevity in demanding environments. B2B buyers should prioritize suppliers that provide detailed material specifications to ensure compatibility with their operational needs.

-

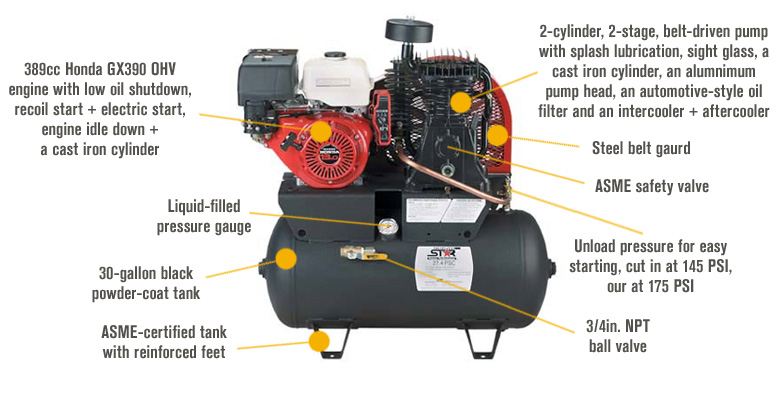

Pressure Rating: This specification indicates the maximum pressure the part can withstand, typically measured in pounds per square inch (PSI). For example, certain Northstar pumps may have a pressure rating of 175 PSI. Understanding pressure ratings is crucial for ensuring that all components within a compressor system can handle the operational pressure without failure, which can lead to costly downtime.

-

CFM (Cubic Feet per Minute): This measurement refers to the airflow capacity of the compressor. Higher CFM values indicate a more powerful compressor, which can significantly affect productivity in industrial applications. Buyers should assess the CFM requirements based on their specific applications to ensure they select parts that support their operational demands.

-

Thread Size and Type: Parts such as air filters and fittings often come with specific thread sizes, such as 1/2″ or 1″ NPT (National Pipe Thread). Proper thread specifications ensure secure connections and prevent leaks. Buyers must verify thread compatibility to avoid installation issues and ensure optimal performance.

-

Gasket and Seal Specifications: Gaskets and seals are critical for maintaining pressure and preventing leaks. Knowing the type and material of gaskets, such as rubber or silicone, can influence the reliability of the compressor. Buyers should consider the environmental conditions where the compressor will operate to select appropriate sealing materials.

-

Motor Power Rating: The power rating of the motor, measured in horsepower (HP), determines the overall efficiency and capability of the compressor. Motors rated at 2.0 HP or higher, for instance, can support more demanding applications. Buyers must align motor specifications with their operational requirements to ensure adequate performance.

What Are Common Trade Terms in the Northstar Air Compressor Parts Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts that are used in the manufacturing of another company’s product. For buyers, purchasing OEM parts ensures compatibility and quality assurance, as they are designed specifically for the equipment they will be used with.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers as it impacts inventory management and cost. Buyers should negotiate MOQs that align with their purchasing capabilities and inventory turnover rates.

-

RFQ (Request for Quotation): An RFQ is a formal request from buyers to suppliers to provide pricing and terms for specific products. This process helps buyers compare options and negotiate better deals. Providing detailed specifications in an RFQ can lead to more accurate quotes and better supplier relationships.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international contracts to define responsibilities regarding shipping, insurance, and tariffs. Understanding Incoterms helps buyers clarify shipping responsibilities and costs, which is especially important for international transactions.

-

Lead Time: This refers to the time it takes from placing an order to receiving the product. Knowing lead times can help buyers plan their operations and avoid delays. Clear communication with suppliers about expected lead times can mitigate risks associated with production schedules.

-

Warranty Period: This term indicates the duration for which a manufacturer guarantees the performance of their parts. A comprehensive warranty period can provide buyers with peace of mind regarding the quality and durability of their investment.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure the longevity of their equipment.

Navigating Market Dynamics and Sourcing Trends in the northstar air compressor parts Sector

What Are the Key Market Dynamics and Trends Affecting Northstar Air Compressor Parts?

The Northstar air compressor parts market is experiencing significant shifts driven by globalization, technological advancements, and changing buyer behaviors. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for reliable and efficient sourcing solutions. One key driver is the rise in industrial activities and infrastructure projects in emerging markets, which has led to a heightened demand for air compressors and their parts. Furthermore, the integration of IoT (Internet of Things) technologies into manufacturing processes is enabling real-time monitoring and predictive maintenance, thus enhancing the operational efficiency of air compressors.

Emerging trends indicate a growing preference for online sourcing platforms, which facilitate easier access to a wide array of Northstar parts. This trend is particularly pronounced in regions with developing economies, where traditional procurement processes may be less efficient. Additionally, buyers are focusing on suppliers who can offer not just parts but comprehensive support services, including technical assistance and after-sales service. This shift is prompting manufacturers and distributors to adapt their strategies to meet the evolving needs of international buyers.

How Are Sustainability and Ethical Sourcing Influencing the Northstar Air Compressor Parts Market?

Sustainability and ethical sourcing are becoming increasingly vital considerations for B2B buyers in the Northstar air compressor parts sector. The environmental impact of manufacturing processes has led to a demand for greener alternatives, pushing suppliers to adopt sustainable practices. This includes using environmentally friendly materials and reducing waste throughout the production cycle. Buyers are looking for suppliers who prioritize sustainability, as it not only aligns with their corporate social responsibility goals but also enhances their brand image in a competitive marketplace.

Moreover, certifications that verify ethical sourcing practices are gaining traction. Buyers are more inclined to work with suppliers who possess certifications such as ISO 14001 for environmental management and other ‘green’ labels. This trend is particularly relevant in regions like Europe, where regulatory frameworks are increasingly stringent regarding environmental standards. For international buyers from Africa and South America, aligning with sustainable suppliers can also open doors to new markets and customer segments that prioritize eco-friendly products.

What Is the Historical Context of Northstar Air Compressor Parts Development?

The Northstar brand has a rich history rooted in innovation and reliability within the air compressor market. Established to meet the growing demand for high-quality air compressor parts, Northstar has evolved by integrating advanced manufacturing techniques and robust design principles. Over the years, the brand has expanded its product line to include a variety of parts, catering to diverse applications across different industries. This historical commitment to quality and innovation has positioned Northstar as a trusted name among international B2B buyers seeking durable and efficient air compressor components.

In conclusion, the Northstar air compressor parts sector is influenced by dynamic market trends, a growing emphasis on sustainability, and a legacy of innovation. International buyers must stay informed about these factors to make strategic sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of northstar air compressor parts

-

How do I solve compatibility issues with Northstar air compressor parts?

To resolve compatibility issues, it’s essential to identify the specific model and part number of your Northstar air compressor. Refer to the data tag located on your machine, which provides vital information about the exact components required. If you’re uncertain, consult with your supplier or manufacturer for guidance. Additionally, consider cross-referencing part numbers across different suppliers to ensure you’re purchasing the correct parts that meet your operational needs. -

What is the best way to source Northstar air compressor parts internationally?

The best approach to sourcing Northstar air compressor parts internationally involves thorough research and supplier vetting. Start by identifying reputable suppliers with experience in your region, especially those familiar with international shipping and customs regulations. Platforms like trade directories and industry-specific forums can be useful for finding qualified suppliers. Additionally, ensure that the suppliers provide detailed product specifications and have positive reviews from other international buyers. -

What are the minimum order quantities (MOQs) for Northstar air compressor parts?

Minimum order quantities (MOQs) can vary significantly among suppliers, often depending on the type of part and the supplier’s policies. Typically, suppliers may have MOQs ranging from a few units to several dozen, especially for specialized components. To get the best deal, consider negotiating with your supplier if you plan to order in bulk or establish a long-term purchasing relationship. Always clarify MOQs before placing an order to avoid unexpected costs. -

What payment terms should I expect when ordering Northstar air compressor parts?

Payment terms for international orders can vary widely based on the supplier and the buyer’s location. Common terms include payment in full upfront, partial payments, or letters of credit for larger transactions. Be sure to discuss and agree on payment terms before finalizing any order to ensure mutual understanding. Additionally, inquire about any available discounts for bulk orders or early payments, which can help optimize your procurement budget. -

How can I ensure the quality of Northstar air compressor parts?

To ensure the quality of Northstar air compressor parts, work with suppliers who provide warranties or guarantees on their products. Request samples or certifications that demonstrate compliance with relevant industry standards. Additionally, consider performing due diligence by checking references and reading reviews from other buyers. Regularly inspect the parts upon receipt, and establish a quality assurance process to address any potential defects before they impact your operations. -

What logistics considerations should I keep in mind when importing Northstar air compressor parts?

When importing Northstar air compressor parts, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with your region to navigate these challenges efficiently. Ensure that all documentation, including invoices and packing lists, is accurate to avoid delays at customs. It’s also wise to factor in potential tariffs or duties that may apply to your shipments to budget accordingly. -

Can I customize Northstar air compressor parts to fit my specific needs?

Yes, customization of Northstar air compressor parts is often possible depending on the supplier’s capabilities. If you have specific requirements, discuss these with your supplier to determine available options for modifications or tailored solutions. Custom parts may incur additional costs and longer lead times, so it’s crucial to clearly communicate your needs early in the procurement process to avoid delays. -

What should I do if I receive the wrong Northstar air compressor parts?

If you receive the wrong Northstar air compressor parts, promptly contact your supplier to report the issue. Provide detailed information, including order numbers and photographs of the incorrect items. Most reputable suppliers will have a return policy in place for such situations, allowing you to exchange or return the parts. Ensure to document all communications for clarity and maintain a record of the issue to prevent similar occurrences in future orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Northstar Air Compressor Parts Manufacturers & Suppliers List

1. Northstar – Air Compressor Parts

Domain: arkansas-outdoor-power-equipment.myshopify.com

Introduction: This company, Northstar – Air Compressor Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Northstar – Key Parts for Model 459212B

Domain: jackssmallengines.com

Registered: 1997 (28 years)

Introduction: Northstar 459212B Parts Diagrams, 728 parts used by this model. Key parts include: 789354 Air Filter ($18.38), 789355 Filter Element Ck30 Ct40 Ea ($4.44), 789384 Magnetic Drain Plug ($3.50), 788880 Oil Sight Gauge ($14.63), 789386 Oil Filling Plug ($1.63), 788882 Breathing Cover ($4.00), 789349 Pulley CK30 Balanced Ac ($85.00), 789352 Exhaust Tube Set (34) ($19.44), 789524 Nut Wing M6-1.0 ($0.56).

3. Powermate – NorthStar Air Compressor Maintenance Kit

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: NorthStar Air Compressor Maintenance Kit, Condition: New, Brand: Powermate, Item number: 326247587230, Kit SKU: 84504, Part #: NS165-0343, Fits compressor SKU: 75710, Price: $50.00 or Best Offer, Shipping: $18.60, Estimated delivery: Mon, Sep 8 – Sat, Sep 13, Quantity available: 1, 1-year accident protection plan available for $5.99.

4. NorthStar – Equipment & Parts

Domain: gnedi.com

Registered: 2000 (25 years)

Introduction: NorthStar @ Great Northern Equipment offers a wide range of products including agricultural, construction, and turf equipment, as well as various parts and accessories. Key product categories include: 1. Seats and Parts: Bucket seats, golf cart seats, instructional buddy seats, restoration seats, seat components, and suspension seats. 2. Lighting: LED lights for agricultural, ATV, UTV, constructio…

5. NorthStar – Portable Quiet Electric Air Compressor

Domain: aamdcenter.com

Registered: 2024 (1 years)

Introduction: NORTHSTAR PORTABLE QUIET Electric Air Compressor, 1.5 HP, 26

Strategic Sourcing Conclusion and Outlook for northstar air compressor parts

In the competitive landscape of industrial equipment, the strategic sourcing of Northstar air compressor parts stands as a pivotal element for international buyers, particularly those from Africa, South America, the Middle East, and Europe. Understanding the diverse range of components available—from air filters to pressure switches—enables businesses to optimize their operations while ensuring longevity and reliability in their equipment.

Emphasizing the importance of quality and compatibility, sourcing genuine Northstar parts can significantly reduce downtime and maintenance costs. Buyers should leverage established suppliers that offer comprehensive catalogs and support services to streamline their procurement processes.

Looking ahead, the global demand for efficient air compressor systems is set to rise, driven by industrial growth and technological advancements. International buyers are encouraged to engage with suppliers who not only provide parts but also offer insights into the latest innovations and best practices in maintenance. By fostering strong partnerships and investing in quality components, businesses can enhance their operational efficiency and position themselves competitively in the market. Now is the time to explore your options and secure the best parts for your air compressor needs.