A B2B Buyer’s Guide to Millermatic Passport Plus: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for millermatic passport plus

In today’s global marketplace, sourcing the right equipment can be a daunting challenge, especially for B2B buyers seeking the versatile Millermatic Passport Plus welder. This compact MIG welder stands out due to its unique ability to operate on both 115V and 230V power, catering to a wide range of welding needs while maintaining portability. In this comprehensive guide, we will delve into the various types of Millermatic Passport Plus welders, their diverse applications across industries, and essential tips for vetting suppliers. Additionally, we will cover crucial aspects such as cost considerations and maintenance requirements.

International buyers from regions like Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Germany—will find this guide particularly beneficial. It empowers decision-makers by providing actionable insights and practical strategies for making informed purchasing choices. By understanding the unique features and advantages of the Millermatic Passport Plus, as well as navigating the complexities of international sourcing, businesses can ensure they invest in equipment that meets their operational needs and enhances productivity.

Whether you are a motorsport team, a fabricator, or involved in maintenance work, this guide will help you maximize the value of your investment in welding technology, ensuring your operations are efficient and effective in today’s competitive landscape.

Understanding millermatic passport plus Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Millermatic Passport Plus | Dual voltage (115V/230V), lightweight, portable | Automotive repair, construction | Pros: Portable, versatile, smooth arc; Cons: Limited duty cycle, small wire spool capacity |

| Millermatic Passport Plus 230V | Higher amperage output, suitable for thicker materials | Industrial fabrication, heavy-duty welding | Pros: Increased power for heavier tasks; Cons: Requires 230V supply, less portable |

| Millermatic Passport Plus with CO2 Cylinder | Self-contained CO2 supply for MIG welding | Mobile welding services, motorsports | Pros: Low spatter, easy to refill; Cons: Limited to short runs due to duty cycle |

| Millermatic Passport Plus with Flux Core Capability | Compatible with flux core wire for outdoor use | Maintenance, repair in adverse conditions | Pros: Versatile in various environments; Cons: Can produce more spatter than MIG |

| Millermatic Passport Plus for Hobbyists | Compact design, user-friendly controls | DIY projects, home workshops | Pros: Ideal for beginners, easy to transport; Cons: Not suitable for continuous heavy-duty use |

What are the Key Characteristics of the Millermatic Passport Plus Welder?

The Millermatic Passport Plus is designed for versatility and portability, making it ideal for B2B applications like automotive repair and construction. Its dual voltage capability allows it to operate on both standard 115V household power and 230V shop power, which is a significant advantage for businesses with varying power availability. Weighing approximately 45 pounds, it is compact enough for easy transportation, making it a popular choice for mobile welding services.

How Does the Millermatic Passport Plus 230V Differ from Other Variants?

The Millermatic Passport Plus 230V variant provides a higher amperage output, making it suitable for welding thicker materials in industrial fabrication settings. This model is best for businesses that require more power for heavy-duty tasks. However, it is less portable than the standard model since it requires a 230V power supply, which may limit its usability in some field applications.

Why Choose the Millermatic Passport Plus with CO2 Cylinder?

This version of the Passport Plus features a self-contained CO2 cylinder, allowing for MIG welding without the need for bulky external gas supplies. This is particularly beneficial for mobile welding services and motorsports applications, where low spatter and ease of refilling are essential. However, its duty cycle limits its use to shorter welding runs, which businesses need to consider when planning projects.

What Advantages Does the Millermatic Passport Plus Offer with Flux Core Capability?

The flux core capability expands the Passport Plus’s versatility, enabling it to handle outdoor welding tasks in adverse conditions. This feature is particularly beneficial for maintenance and repair work, where portability and adaptability are key. However, businesses should be aware that using flux core wire can lead to increased spatter compared to traditional MIG welding.

Is the Millermatic Passport Plus Suitable for Hobbyists and DIY Enthusiasts?

The Millermatic Passport Plus is an excellent choice for hobbyists and DIY enthusiasts due to its user-friendly controls and compact design. It is particularly suitable for small-scale projects in home workshops. However, its limited duty cycle makes it unsuitable for continuous heavy-duty use, which is a crucial consideration for businesses planning to invest in a welder for more extensive applications.

Key Industrial Applications of millermatic passport plus

| Industry/Sector | Specific Application of millermatic passport plus | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Mobile welding for vehicle frame repairs | Enhances service efficiency and customer satisfaction | Availability of local suppliers for consumables |

| Construction | On-site fabrication of metal structures | Reduces project timelines and labor costs | Compliance with local regulations and certifications |

| Agriculture | Repairing farming equipment and implements | Minimizes downtime and operational disruptions | Access to reliable power sources in remote areas |

| Maintenance Services | Routine maintenance of industrial machinery | Increases equipment lifespan and reliability | Support for diverse voltage options for various sites |

| Marine Industry | Welding on boats and marine structures | Ensures structural integrity and safety compliance | Durability against harsh environmental conditions |

How is the Millermatic Passport Plus Used in Automotive Repair?

In the automotive repair industry, the Millermatic Passport Plus is ideal for mobile welding applications, particularly for vehicle frame repairs. Its lightweight and portable design allow technicians to easily transport the welder to different job sites, enhancing efficiency and reducing turnaround times. The ability to operate on both 115V and 230V power sources makes it versatile, accommodating various workshop environments. For international buyers, especially in regions like Africa and South America, sourcing consumables locally can be a critical consideration to ensure uninterrupted service.

What Are the Applications in Construction?

In the construction sector, the Millermatic Passport Plus is employed for on-site fabrication of metal structures, such as beams and supports. Its compact nature allows for easy transport to job sites, where quick repairs and fabrications can significantly reduce project timelines. The welder’s capability to produce high-quality, low-spatter welds ensures that structural integrity is maintained, which is crucial for safety compliance. Buyers in Europe and the Middle East should consider the availability of local regulatory certifications when sourcing this equipment.

How Does It Benefit Agriculture?

For the agriculture industry, the Passport Plus proves invaluable in repairing farming equipment and implements. The ability to perform quick repairs on-site minimizes equipment downtime, which is critical during peak seasons. With its self-contained CO2 gas cylinder, the welder can operate effectively in remote locations without the need for cumbersome gas supplies. Buyers in regions with limited access to power should ensure that the welder’s dual voltage capability aligns with their local electrical infrastructure.

What Role Does It Play in Maintenance Services?

In maintenance services, the Millermatic Passport Plus is used for routine maintenance of industrial machinery, allowing technicians to perform repairs without significant disruptions to operations. Its portability and ease of use enable quick setups in various environments, ensuring that machinery remains operational and efficient. Businesses should look for local support and service agreements to facilitate maintenance and repairs of the welder itself.

How is it Utilized in the Marine Industry?

The marine industry benefits from the Millermatic Passport Plus for welding on boats and marine structures. Its ability to handle challenging environments while providing reliable, high-quality welds is essential for ensuring structural integrity and safety compliance in marine applications. Buyers should consider the welder’s resistance to corrosion and its performance in diverse weather conditions, which are critical for longevity in marine environments.

3 Common User Pain Points for ‘millermatic passport plus’ & Their Solutions

Scenario 1: Portability for On-Site Projects

The Problem: Many B2B buyers in industries such as construction, automotive, and maintenance often face challenges with the portability of welding equipment. The need to transport welding machines to various job sites can be cumbersome, especially if the equipment is heavy and lacks versatile power options. For instance, a contractor working in remote areas may struggle with the weight of traditional welders, limiting their ability to work efficiently.

The Solution: The Millermatic Passport Plus is designed with portability in mind, weighing only 45 pounds and being the size of a carry-on suitcase. To optimize its use, buyers should take advantage of its dual-voltage capability, allowing for easy plug-and-play functionality with both 115V and 230V power sources. Before heading to a job site, ensure you have the necessary adapters for different voltage options, which can enhance flexibility when working in various environments. Additionally, consider investing in a durable, wheeled case to protect the welder during transport and make moving it between sites easier.

Scenario 2: Managing Gas Supply and Quality

The Problem: Another common pain point for businesses using the Millermatic Passport Plus is managing the gas supply. Many users find that switching between gas types can lead to confusion, particularly when working with different materials or weld types. This can result in subpar weld quality, increased spatter, and wasted time on adjustments, ultimately affecting project timelines and costs.

The Solution: To streamline gas management, it is essential to familiarize yourself with the welder’s built-in CO2 supply system. The Passport Plus utilizes a self-contained CO2 paintball gun bottle, which simplifies gas usage. For those needing to switch to an external mixed gas cylinder, ensure you have a clear understanding of the switch mechanism and the specific gas requirements for your welding tasks. It’s advisable to keep a stock of both CO2 and argon/CO2 mixtures on hand to accommodate different projects. Regularly check the gas levels and maintain a log of usage to prevent unexpected shortages during critical work periods.

Scenario 3: Duty Cycle Limitations During Heavy Use

The Problem: Businesses that rely on the Millermatic Passport Plus for continuous welding operations may encounter issues with its duty cycle, which is 20% at 150 amps when using 230V. This limitation can lead to frustration during high-demand projects, such as fabricating large structures or undertaking extensive repairs, as the welder may overheat and require downtime to cool.

The Solution: To effectively manage the duty cycle limitations, consider implementing a strategic work schedule that incorporates breaks to allow the welder to cool down. Use the Passport Plus for shorter runs while reserving heavier tasks for more robust welding equipment. Additionally, leverage the welder’s dual-voltage functionality by utilizing 230V power when available to maximize its performance. Investing in a secondary welder can also provide backup during peak workloads, ensuring that project deadlines are met without sacrificing quality. Finally, educating the team on optimal welding practices and the importance of duty cycle awareness can lead to more efficient use of the equipment, minimizing downtime and enhancing overall productivity.

Strategic Material Selection Guide for millermatic passport plus

What Are the Key Materials for the Millermatic Passport Plus Welder?

The Millermatic Passport Plus is a versatile MIG welder designed for both portability and performance. When selecting materials for welding applications using this machine, it is essential to consider the properties, advantages, and limitations of various materials. Below are analyses of four common materials that are frequently welded with the Millermatic Passport Plus.

How Does Aluminum Perform in Welding Applications?

Aluminum is a lightweight and corrosion-resistant material widely used in automotive, aerospace, and construction applications. Its low density and excellent thermal conductivity make it suitable for various welding tasks. However, aluminum requires specific welding techniques due to its high thermal expansion and low melting point.

Pros: Aluminum is durable and resistant to corrosion, making it ideal for outdoor applications. It is also relatively easy to weld with the right settings on the Passport Plus.

Cons: The cost of aluminum can be higher than steel, and its welding can be complex due to the need for proper cleaning and pre-weld preparation.

Impact on Application: Aluminum is compatible with various media, including water and chemicals, making it versatile for multiple industries.

Considerations for International Buyers: Compliance with standards such as ASTM B209 for aluminum alloys is crucial. Buyers in regions like Europe may prefer materials that align with DIN standards, while those in the Middle East might focus on local certifications.

What Are the Advantages of Using Stainless Steel?

Stainless steel is renowned for its strength and corrosion resistance, making it a preferred choice in industries such as food processing, pharmaceuticals, and construction. The Millermatic Passport Plus can effectively weld various stainless steel grades, providing high-quality joints.

Pros: Stainless steel’s durability and aesthetic appeal make it suitable for both functional and decorative applications. It also offers excellent resistance to heat and corrosion.

Cons: The cost of stainless steel is typically higher than that of carbon steel, and its welding can produce more spatter, requiring additional cleanup.

Impact on Application: Stainless steel is compatible with a wide range of media, including acids and bases, making it ideal for specialized applications.

Considerations for International Buyers: Compliance with ASTM A240 for stainless steel is essential. Buyers in Germany may look for materials meeting DIN EN 10088 standards, while those in Africa might prioritize local availability and pricing.

How Does Carbon Steel Compare in Terms of Welding?

Carbon steel is one of the most commonly welded materials due to its strength, versatility, and cost-effectiveness. The Millermatic Passport Plus excels in welding carbon steel, making it a go-to choice for general fabrication and construction.

Pros: Carbon steel is widely available and relatively inexpensive, making it an economical choice for many applications. It also provides excellent weldability.

Cons: While durable, carbon steel is prone to rust and corrosion if not properly treated, which can limit its longevity in certain environments.

Impact on Application: Carbon steel is suitable for a wide range of media, including water and oil, but may require protective coatings for outdoor use.

Considerations for International Buyers: Compliance with ASTM A36 for structural steel is important. Buyers in South America may prioritize local standards, while those in the Middle East may focus on compliance with regional specifications.

What Role Does Copper Play in Welding Applications?

Copper is a highly conductive material often used in electrical applications and plumbing. While not as common for structural welding, it can be welded using the Millermatic Passport Plus for specific applications.

Pros: Copper offers excellent electrical and thermal conductivity, making it ideal for electrical connections and heat exchangers.

Cons: Welding copper can be challenging due to its high thermal conductivity, which can lead to warping and distortion if not managed properly.

Impact on Application: Copper is compatible with various media, including water and gases, making it suitable for plumbing and electrical applications.

Considerations for International Buyers: Compliance with ASTM B75 for copper tubing is essential. Buyers in Europe may prefer materials that meet EN standards, while those in Africa may focus on local sourcing.

Summary Table of Material Selection for Millermatic Passport Plus

| Material | Typical Use Case for millermatic passport plus | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and aerospace applications | Lightweight and corrosion-resistant | Higher cost and complex welding | Medium |

| Stainless Steel | Food processing and pharmaceutical industries | Durable and heat-resistant | Higher cost and more spatter | High |

| Carbon Steel | General fabrication and construction | Economical and widely available | Prone to rust without treatment | Low |

| Copper | Electrical connections and plumbing | Excellent conductivity | Challenging to weld due to distortion | Medium |

This guide provides a comprehensive overview of key materials for the Millermatic Passport Plus, enabling B2B buyers to make informed decisions based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for millermatic passport plus

What Are the Key Stages in the Manufacturing Process of the Millermatic Passport Plus?

The manufacturing process of the Millermatic Passport Plus involves several critical stages that ensure the final product meets both performance and quality standards.

Material Preparation: Selecting High-Quality Components

The process begins with material preparation, where high-grade metals and components are sourced. The choice of materials is crucial, as they directly affect the welder’s durability, weight, and performance. Components such as the inverter circuitry, gas delivery systems, and housing materials are selected based on rigorous specifications. Suppliers are often vetted for compliance with international standards, ensuring that materials are not only reliable but also sustainable.

Forming: Precision Engineering Techniques

Following material selection, the forming stage utilizes advanced manufacturing techniques such as CNC machining and laser cutting. These processes are essential for shaping components with high precision. For example, the welder’s chassis is typically formed from robust metal to withstand harsh working conditions while remaining lightweight for portability. The use of such precise engineering techniques minimizes material waste and maximizes product quality.

Assembly: Integrating Components with Care

Once the components are formed, they move to the assembly stage. Here, skilled technicians integrate the various parts, including the inverter, control panel, and gas delivery system. The assembly process is often performed in a clean environment to prevent contamination and ensure the integrity of electronic components. Each unit undergoes a series of assembly checkpoints where technicians verify that components are correctly installed and functioning as intended.

Finishing: Ensuring Aesthetic and Functional Quality

The final stage of manufacturing involves finishing processes such as painting, powder coating, and surface treatment. These processes not only enhance the aesthetic appeal of the Millermatic Passport Plus but also provide a protective layer against corrosion and wear. The finishing stage is critical, particularly for international markets, as it can affect shipping and long-term usability.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance (QA) is a cornerstone of the manufacturing process for the Millermatic Passport Plus. It encompasses various international standards and industry-specific regulations to ensure that the product meets both safety and performance criteria.

What International Standards Are Relevant for Quality Assurance?

To maintain high-quality standards, the manufacturing process adheres to ISO 9001, which outlines criteria for a quality management system. This certification is recognized globally and is essential for manufacturers aiming to export their products. Additionally, compliance with other standards such as CE for European markets and API for industry-specific applications ensures that the product meets regional safety and quality regulations.

What Are the Key Quality Control Checkpoints?

Quality control is integrated into the manufacturing process at several checkpoints:

-

Incoming Quality Control (IQC): This checkpoint ensures that all raw materials and components meet predefined specifications before they enter the production line. Suppliers are often required to provide certificates of compliance with material standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspectors conduct regular checks to ensure that each assembly stage meets quality standards. This may involve visual inspections and functional tests to catch any defects early.

-

Final Quality Control (FQC): Once the product is fully assembled, it undergoes a comprehensive final inspection. This includes testing the welder’s performance under various conditions to ensure it operates as intended.

What Testing Methods Are Commonly Used in Quality Assurance?

A variety of testing methods are employed to validate the performance and safety of the Millermatic Passport Plus:

-

Functional Testing: Each unit is subjected to functional tests to verify that all operational features work correctly. This includes testing the welding capabilities under different power settings.

-

Durability Testing: The welder is tested for its ability to withstand rigorous use in various environments. This may involve simulating extended periods of operation to assess the thermal stability and mechanical integrity.

-

Safety Testing: Compliance with safety standards is ensured through rigorous testing for electrical safety, gas leakage, and user interface ergonomics.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers must exercise due diligence when selecting suppliers for the Millermatic Passport Plus. Here are several strategies to verify quality control practices:

-

Supplier Audits: Conducting audits of the manufacturing facility can provide insights into the quality management systems in place. Buyers should look for evidence of compliance with international standards.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation related to quality control processes, including IQC, IPQC, and FQC reports. This transparency is vital for establishing trust.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing processes and product quality. This is particularly important for buyers from regions with stringent import regulations, such as Europe and Saudi Arabia.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, must be aware of specific quality control nuances:

-

Regional Compliance: Each region may have unique compliance requirements, such as specific certifications or testing protocols. Understanding these can help buyers avoid costly delays or rejections at customs.

-

Cultural Considerations: Different regions may have varying expectations regarding communication and transparency. Building a strong relationship with suppliers can facilitate smoother transactions and quality assurance processes.

-

Logistics and Supply Chain: Quality control does not end with manufacturing; it extends to shipping and handling. Buyers should inquire about the measures suppliers take to ensure that products arrive in good condition, including packaging standards and shipping practices.

By understanding the manufacturing processes and quality assurance measures behind the Millermatic Passport Plus, B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘millermatic passport plus’

In this guide, we will outline a practical step-by-step checklist for B2B buyers looking to procure the Millermatic Passport Plus welder. This versatile MIG welder is designed for portability and efficiency, making it a valuable asset for various industries. Follow these steps to ensure a successful purchasing experience.

Step 1: Define Your Technical Specifications

Understanding your technical needs is the first step in sourcing the right equipment. The Millermatic Passport Plus operates on both 115V and 230V, allowing flexibility in power source options. Identify the materials you will be welding, required amperage, and duty cycle to ensure this model meets your operational demands.

Step 2: Research Supplier Credentials

Before making a purchase, vet potential suppliers thoroughly. Confirm that they are authorized distributors of Miller products to guarantee the authenticity and warranty of the welder. Look for certifications or memberships in industry associations that indicate reliability and professionalism.

Step 3: Evaluate Potential Suppliers

Once you have identified potential suppliers, evaluate them based on their reputation and customer feedback. Request case studies, testimonials, and references from clients in similar industries or regions. This insight will help you gauge their reliability and the quality of after-sales support.

Step 4: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures. Ensure you understand the total cost, including shipping, taxes, and potential import duties if sourcing internationally. Look for flexible payment terms and warranties that can protect your investment.

Step 5: Assess Availability of Spare Parts and Accessories

Ensure that the supplier provides easy access to spare parts and compatible accessories for the Millermatic Passport Plus. This welder uses a self-contained CO2 cylinder and has a limited spool capacity, so check for availability of consumables like wire spools and gas cylinders. This will minimize downtime in case of repairs or maintenance.

Step 6: Understand Shipping and Delivery Options

Evaluate the shipping options available from your chosen supplier. Confirm estimated delivery times and costs, especially if you are importing from a different region. Consider suppliers that offer reliable logistics solutions to ensure timely delivery of the welder.

Step 7: Finalize Your Purchase and Document Everything

Once you’ve selected a supplier, finalize your purchase while ensuring all terms are documented in a formal agreement. Keep records of your order, warranty information, and any communications with the supplier. This documentation will be vital for future reference, especially regarding service and support.

By following this checklist, B2B buyers can effectively navigate the procurement process for the Millermatic Passport Plus, ensuring they invest in a quality product that meets their operational needs.

Comprehensive Cost and Pricing Analysis for millermatic passport plus Sourcing

What Are the Key Cost Components for the Millermatic Passport Plus?

When evaluating the cost structure of the Millermatic Passport Plus MIG welder, several components contribute to the overall pricing. These include:

-

Materials: The primary materials used in manufacturing the Passport Plus include high-quality metals for the body and components, specialized wiring, and the internal gas supply system. The use of durable materials ensures longevity and reliability, which can affect the initial pricing.

-

Labor: Skilled labor is essential in the assembly of the Passport Plus. The complexity of the welding machine requires workers who are trained in precision engineering and quality assurance.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Investment in tooling is necessary for the production of various components of the welder. Custom tools may be required for specific parts, which can influence the overall pricing strategy.

-

Quality Control (QC): Rigorous QC processes ensure that each unit meets safety and performance standards. The costs associated with testing and certification can be significant, reflecting in the price.

-

Logistics: Transportation and warehousing costs play a role in pricing, especially for international buyers. The shipping method, distance, and import duties can all influence the final cost to the buyer.

-

Margin: Suppliers typically build a profit margin into the price, which can vary based on market demand and competitive positioning.

How Do Price Influencers Impact the Cost of the Millermatic Passport Plus?

Several factors can influence the pricing of the Millermatic Passport Plus, particularly for international B2B buyers:

-

Volume/MOQ: Buying in bulk can lead to significant discounts. Suppliers often have Minimum Order Quantities (MOQs) that can affect pricing tiers, making it advantageous for larger buyers.

-

Specifications and Customization: Custom features or specifications may incur additional costs. Buyers should consider whether the standard model meets their needs or if customizations are necessary.

-

Materials and Quality Certifications: The choice of materials can affect both cost and performance. Additionally, obtaining quality certifications (like ISO) may add to the price but can enhance the product’s marketability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may command higher prices due to their brand value and customer service.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial. They dictate who bears the shipping costs and risks, which can significantly influence the total cost.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing the Millermatic Passport Plus?

International B2B buyers should consider several strategies to enhance cost-efficiency when sourcing the Millermatic Passport Plus:

-

Negotiation: Engage suppliers in negotiations to explore better pricing or additional benefits, such as extended warranties or free shipping. Building a good rapport can lead to favorable terms.

-

Total Cost of Ownership (TCO): Look beyond the purchase price to understand the TCO, which includes maintenance, potential repairs, and operational costs over the welder’s lifespan. A more expensive unit may offer lower TCO due to its durability and efficiency.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international tariffs that can impact the final cost. Understanding local market conditions in regions such as Africa, South America, the Middle East, and Europe (e.g., Germany, Saudi Arabia) can provide insights into competitive pricing.

-

Comparison Shopping: Evaluate multiple suppliers to identify the best value. Differences in pricing can be significant, so thorough research is essential.

-

Consider Local Suppliers: In some regions, local suppliers may offer competitive pricing due to reduced shipping costs and faster delivery times. This can be particularly beneficial for urgent projects.

Conclusion

While the Millermatic Passport Plus is a versatile and compact welding solution, understanding the comprehensive cost structure and pricing influencers is vital for making informed purchasing decisions. By leveraging negotiation strategies and being mindful of total cost considerations, international B2B buyers can optimize their sourcing process and ensure they receive the best value for their investment.

Alternatives Analysis: Comparing millermatic passport plus With Other Solutions

Introduction: Exploring Alternative Solutions to the Millermatic Passport Plus

For B2B buyers in the welding industry, selecting the right welder is crucial for optimizing operational efficiency and meeting project requirements. While the Millermatic Passport Plus is a versatile and portable MIG welder, there are several alternatives that may better suit specific needs, particularly for businesses operating in diverse environments. This analysis compares the Passport Plus against other leading options, helping buyers make informed decisions.

Comparison Table

| Comparison Aspect | Millermatic Passport Plus | Hobart Trek 180 | Lincoln Electric Power MIG 210 MP |

|---|---|---|---|

| Performance | Dual voltage (115V/230V), 150 amps, 20% duty cycle | Battery-powered, up to 180 amps | Dual voltage (120V/240V), 210 amps, 30% duty cycle |

| Cost | Moderate ($1,000 – $1,200) | Moderate ($1,200 – $1,400) | Higher ($1,500 – $1,800) |

| Ease of Implementation | Compact, easy to transport; requires gas cylinder | Cordless option available; easy to set up | Slightly heavier; versatile features but requires more setup |

| Maintenance | Low; easy to replace parts | Moderate; battery management required | Moderate; regular maintenance needed for optimal performance |

| Best Use Case | Hobbyists, light automotive work | Fieldwork, remote applications | Industrial applications, heavier fabrication work |

Detailed Breakdown of Alternatives

Hobart Trek 180

The Hobart Trek 180 is a unique battery-powered MIG welder that provides true portability, making it suitable for fieldwork and remote applications. One of its standout features is the ability to weld without being tethered to a power source, which is beneficial for operations in areas lacking electricity. However, while the Hobart Trek offers great flexibility, it has a lower maximum output compared to the Passport Plus and may not be as effective for heavier fabrication tasks. Additionally, the battery life can limit the duration of use before requiring a recharge.

Lincoln Electric Power MIG 210 MP

The Lincoln Electric Power MIG 210 MP is a robust welder designed for a wide range of applications, from light to heavy industrial tasks. It offers a higher amperage output, making it suitable for more demanding welding projects. The dual-voltage capability allows it to operate on both 120V and 240V power sources, enhancing its versatility. However, the higher initial investment and greater weight compared to the Passport Plus may deter some buyers, especially those focused on portability. Regular maintenance is also necessary to ensure optimal performance, which could add to operational costs.

Conclusion: How to Choose the Right Welding Solution

Choosing the right welding solution involves assessing various factors, including performance requirements, cost constraints, and specific application needs. For businesses operating in remote locations or requiring maximum portability, the Hobart Trek 180 may be the best choice despite its lower power output. Conversely, for companies needing a more powerful machine for heavier tasks, the Lincoln Electric Power MIG 210 MP is a strong contender despite its higher cost. Ultimately, B2B buyers should align their choice with their operational priorities, budget, and the specific welding scenarios they encounter in their industries.

Essential Technical Properties and Trade Terminology for millermatic passport plus

What Are the Key Technical Properties of the Millermatic Passport Plus?

The Millermatic Passport Plus is designed to meet the needs of diverse welding applications, making it a valuable asset for B2B buyers. Here are several essential technical specifications that are crucial for informed purchasing decisions:

-

Weight and Portability

At approximately 45 pounds, the Passport Plus is lightweight and compact, comparable to a large suitcase. This feature is especially beneficial for industries requiring mobility, such as automotive repair and construction. The ability to easily transport the welder to job sites can significantly reduce downtime and labor costs. -

Voltage Flexibility

The Passport Plus is equipped with a Multi-Voltage Plug (MVP) that allows users to switch between 115V and 230V power sources. This flexibility is crucial for international buyers who may encounter varying electrical standards. It ensures that the welder can be utilized in diverse environments, maximizing operational efficiency. -

Duty Cycle

The welder has a 20% duty cycle at 150 amps when using 230V power. This indicates the amount of time the machine can operate before it needs to cool down. For businesses focusing on short welding runs, this duty cycle is adequate; however, high-volume fabricators may need to consider other options. -

Wire Capacity

The unit supports a 2-pound wire spool, which is sufficient for occasional use but may require frequent reloading during larger projects. Understanding this capacity is vital for businesses planning extensive welding tasks, as it could impact productivity and workflow. -

Gas Supply Options

The Passport Plus can utilize a self-contained CO2 cylinder, allowing for low-spatter, high-quality welds. This feature is particularly advantageous for industries that require clean welding processes, such as aerospace and automotive manufacturing. The option to switch to a full-size external gas cylinder enhances versatility. -

Arc Control Technology

The advanced circuitry of the Passport Plus optimizes the welding arc, delivering smooth and consistent performance. This technology is crucial for maintaining quality in welding applications, reducing the likelihood of defects and rework.

What Trade Terminology Should Buyers Understand for the Millermatic Passport Plus?

Familiarity with industry-specific terminology is essential for B2B buyers to navigate the procurement process effectively. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, purchasing from an OEM ensures that they are receiving authentic, high-quality products that meet industry standards. -

MOQ (Minimum Order Quantity)

This is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is critical for budgeting and inventory management, as it affects the overall cost and logistics of acquiring the Passport Plus. -

RFQ (Request for Quotation)

A formal process where buyers request price quotes from suppliers. This is an important step in the procurement process, allowing buyers to compare pricing and terms before making a purchasing decision. -

Incoterms (International Commercial Terms)

A set of rules that define the responsibilities of buyers and sellers for the delivery of goods. Understanding Incoterms is vital for international transactions, as they clarify who bears the costs and risks during shipping. -

Lead Time

The amount of time it takes from placing an order to receiving the product. For buyers, knowing the lead time is essential for project planning and ensuring that the necessary equipment is available when needed. -

Warranty and Service Agreements

Terms that outline the support and maintenance provided by the manufacturer. Understanding these agreements is crucial for buyers to ensure they have access to repairs and replacements, which can minimize downtime and costs in the long run.

In summary, grasping the technical properties and trade terminology associated with the Millermatic Passport Plus can significantly enhance purchasing decisions for international B2B buyers, ensuring they invest in the right equipment for their specific welding needs.

Navigating Market Dynamics and Sourcing Trends in the millermatic passport plus Sector

What Are the Current Market Dynamics for the Millermatic Passport Plus?

The global welding equipment market is experiencing significant growth, driven by increased demand across various sectors, including construction, automotive, and manufacturing. The Millermatic Passport Plus, recognized for its portability and versatility, aligns well with emerging trends that prioritize efficiency and adaptability. B2B buyers in regions such as Africa, South America, the Middle East, and Europe, especially in markets like Saudi Arabia and Germany, are increasingly seeking equipment that can perform reliably in diverse environments.

One key trend is the shift towards multifunctional devices that cater to both professional and hobbyist needs. The Passport Plus, with its dual-voltage capabilities (115V and 230V), makes it an attractive option for businesses operating in varied settings. Additionally, the incorporation of advanced technologies, such as Miller’s MVP (multi-voltage plug) and low-spatter arc control, enhances the welding experience, making it easier for users to achieve high-quality results with minimal downtime.

Moreover, the rise of e-commerce platforms has transformed the sourcing landscape, enabling international buyers to access products like the Millermatic Passport Plus more easily. This shift has also encouraged manufacturers to adopt more transparent supply chains and improve their logistics to meet the growing demand for quick delivery and excellent customer service.

How Is Sustainability Influencing the Sourcing of the Millermatic Passport Plus?

Sustainability is becoming a crucial consideration for B2B buyers, particularly in the welding sector, where environmental impact and ethical sourcing are increasingly prioritized. The Millermatic Passport Plus offers features that align with these sustainability goals. For instance, the ability to use a self-contained CO2 bottle reduces waste associated with traditional gas cylinders, promoting a more efficient use of resources.

Buyers are also focusing on suppliers that demonstrate commitment to sustainable practices, such as using eco-friendly materials and ensuring responsible manufacturing processes. Certifications that highlight green practices can influence purchasing decisions, as businesses strive to enhance their corporate social responsibility (CSR) profiles.

Incorporating sustainability into sourcing strategies not only fulfills ethical obligations but can also lead to cost savings over time. For example, energy-efficient welding equipment can result in lower operational costs, which is particularly appealing for businesses operating in competitive markets. As B2B buyers become more environmentally conscious, the demand for products like the Millermatic Passport Plus, which meet these expectations, is likely to grow.

What Is the Evolution of the Millermatic Passport Plus in the Welding Industry?

The Millermatic Passport Plus has undergone significant evolution since its introduction, reflecting the changing needs of the welding industry. Initially designed for portability, it has evolved into a multifunctional tool that meets the demands of both professional welders and hobbyists. Its lightweight design, akin to that of a carry-on suitcase, allows users to transport it easily, which is especially beneficial in markets with diverse operational landscapes.

Over the years, Miller has integrated advanced features into the Passport Plus, such as the innovative MVP plug system and sophisticated arc control technology, which has enhanced its usability and performance. This evolution is indicative of a broader trend in the welding industry, where adaptability and technological advancement are key drivers of product development.

As the market continues to evolve, the Millermatic Passport Plus stands out as a versatile solution that meets the diverse needs of international buyers, particularly those in rapidly developing regions. Its ability to combine convenience, efficiency, and performance positions it as a competitive choice in the global welding equipment market.

Frequently Asked Questions (FAQs) for B2B Buyers of millermatic passport plus

-

How can I determine if the Millermatic Passport Plus is suitable for my business needs?

To evaluate the Millermatic Passport Plus for your business, consider the specific welding applications you intend to use it for. This welder is highly versatile, operating on both 115V and 230V, making it ideal for various environments. Assess its duty cycle of 20% at 150 amps; while it caters well to hobbyists, it may not meet the demands of high-volume fabrication. Conduct a cost-benefit analysis based on your expected usage frequency and project requirements to ensure it aligns with your operational goals. -

What are the key features of the Millermatic Passport Plus that differentiate it from competitors?

The Millermatic Passport Plus stands out due to its portability, weighing only 45 pounds, making it easy to transport. Its dual-voltage capability allows seamless switching between 115V and 230V power sources, enhancing flexibility. The unique self-contained CO2 cylinder minimizes spatter while maintaining high-quality welds. Additionally, its advanced arc control technology ensures a smooth and stable arc, which is crucial for achieving professional results in various welding projects. -

What is the warranty coverage for the Millermatic Passport Plus, and how does it benefit B2B buyers?

Miller typically offers a three-year warranty on the Millermatic Passport Plus, covering defects in materials and workmanship. This warranty is beneficial for B2B buyers as it provides assurance regarding the durability and reliability of the welder. It helps mitigate risks associated with equipment failure, ensuring that your investment is protected. Always confirm the warranty specifics with your supplier, as terms may vary by region. -

What are the available payment terms when purchasing the Millermatic Passport Plus internationally?

Payment terms for the Millermatic Passport Plus can vary by supplier and region. Common options include upfront payment, partial payment with the balance due upon delivery, and financing arrangements. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always negotiate terms upfront and ensure clarity on currency exchange rates and potential tariffs that may apply. -

How can I verify the credibility of suppliers offering the Millermatic Passport Plus?

To verify supplier credibility, conduct thorough research, including checking business licenses, customer reviews, and industry certifications. Request references from previous clients to gauge their reliability and service quality. Additionally, consider suppliers who are authorized distributors of Miller products, as they are more likely to provide genuine equipment and reliable after-sales support. Utilizing platforms like Alibaba or industry-specific trade shows can also help connect with reputable suppliers. -

What logistics considerations should I keep in mind when importing the Millermatic Passport Plus?

When importing the Millermatic Passport Plus, consider shipping methods, customs duties, and import regulations in your country. Select a logistics partner experienced in handling welding equipment to ensure safe and timely delivery. Additionally, factor in potential delays due to customs clearance, and confirm that all necessary documentation, such as invoices and shipping manifests, is in order to avoid complications. -

Can the Millermatic Passport Plus be customized for specific welding applications?

While the Millermatic Passport Plus is designed for versatility, customization options may be limited. However, you can enhance its functionality by selecting appropriate welding wires, tips, and gas mixtures tailored to your specific projects. Consult with your supplier regarding any available accessories or modifications that could better suit your welding needs. This approach can optimize performance based on the materials and techniques you plan to use. -

What quality assurance measures should I expect when purchasing the Millermatic Passport Plus?

Reputable suppliers should provide quality assurance measures such as pre-shipment inspections and certifications that confirm the welder meets industry standards. Look for suppliers who can guarantee compliance with international safety and quality regulations. Additionally, inquire about the testing procedures used by the manufacturer to ensure each unit performs reliably. This information will help you ensure that you are investing in a product that meets high-quality standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Millermatic Passport Plus Manufacturers & Suppliers List

1. Miller – Passport Mig Welder

Domain: weldingtipsandtricks.com

Registered: 2007 (18 years)

Introduction: Miller Passport Mig Welder

– Type: Dual voltage inverter welder

– Voltage: 115V and 230V (with plug adapter)

– Special Feature: Self-contained CO2 paintball gun bottle

– Arc Quality: Considered one of the smoothest arcs in the Miller product line

– Popular Use: Especially favored by motorsports teams

– Portability: Designed for short runs with a certain level of portability

– Duty Cycle: Low duty …

2. Miller Welding – Passport Plus

Domain: forum.millerwelds.com

Registered: 1996 (29 years)

Introduction: Passport Plus is now considered obsolete as it has been removed from the product page of the Miller Welding website and was not included in the 2013 catalog. Users have expressed disappointment over its discontinuation, noting that the Passport Plus was known for its durability and ability to withstand tough conditions. The discussion also mentions the Multimatic as a potential replacement, but th…

3. Miller – Repair Kit for Millermatic Passport Plus

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: REPAIR KIT for Millermatic Passport Plus 274419 274419M won’t turn on; Condition: New; Price: $32.99; Shipping: $3.99; Estimated delivery: Thu, Sep 11 – Wed, Sep 17; Quantity: 1 available; Non-Domestic Product: No; Brand: Miller; Seller: M-TRONICZ (99.2% positive feedback); Item number: 156367090657.

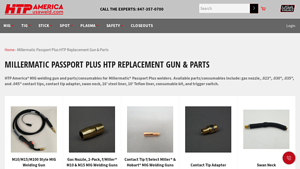

4. HTP America – Millermatic Passport Plus MIG Gun & Parts

Domain: usaweld.com

Registered: 1999 (26 years)

Introduction: Millermatic Passport Plus HTP Replacement Gun & Parts – HTP America Inc. MIG welding gun and parts/consumables for Millermatic Passport Plus welders. Available parts/consumables include: gas nozzle, .023″, .030″, .035″, and .045″ contact tips, contact tip adapter, swan neck, 16′ steel liner, 10′ Teflon liner, consumable kit, and trigger switch. M10/M15/M100 Style MIG Welding Gun on sale from $149….

Strategic Sourcing Conclusion and Outlook for millermatic passport plus

The Millermatic Passport Plus stands out as a versatile and portable MIG welder, ideal for diverse applications across various industries. Its compact design, dual voltage capability, and integrated CO2 gas cylinder make it an attractive option for businesses requiring mobility without sacrificing performance. The Passport Plus is particularly beneficial for sectors such as automotive, maintenance, and fabrication, where short runs and quick setups are common.

For B2B buyers in Africa, South America, the Middle East, and Europe, strategic sourcing of the Millermatic Passport Plus can enhance operational efficiency and reduce downtime. This welder not only meets the demands of hobbyists but can also serve as a reliable tool for professional settings, thus providing excellent return on investment.

As the industry continues to evolve, staying ahead of technological advancements is crucial. Investing in the Millermatic Passport Plus positions your business favorably for future challenges in welding applications. We encourage international buyers to consider this innovative solution to enhance their capabilities. Explore procurement options today to leverage the Passport Plus’s unique advantages and elevate your operational effectiveness.