A B2B Buyer’s Guide to 1/4 Inch Plexiglass 4X8 Sheet: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for 1/4 inch plexiglass 4×8 sheet

Sourcing high-quality 1/4 inch plexiglass 4×8 sheets can be a daunting challenge for international B2B buyers, particularly given the diverse applications and varying quality standards across different markets. This comprehensive guide aims to demystify the global market for plexiglass sheets, providing vital insights into types, applications, supplier vetting, and pricing strategies. Whether you are in the manufacturing sector, construction, or retail display, understanding the nuances of sourcing plexiglass is essential for optimizing your procurement processes.

In this guide, you’ll discover the various grades of plexiglass, from cast to extruded sheets, and their specific applications—ranging from protective barriers in medical facilities to display cases in retail environments. We’ll also delve into effective supplier evaluation methods, enabling you to identify reliable partners who can meet your quality and delivery expectations. Additionally, our analysis of cost factors will help you make informed budget decisions while maximizing value.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, this guide empowers you with the knowledge needed to navigate the complexities of the plexiglass market. By equipping you with actionable insights, we aim to facilitate informed purchasing decisions that support your business goals and enhance your competitive edge in a rapidly evolving marketplace.

Understanding 1/4 inch plexiglass 4×8 sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Cast Acrylic | High optical clarity, excellent impact resistance | Glazing, displays, sneeze guards | Pros: Lightweight, easy to fabricate; Cons: More expensive than extruded variants. |

| Extruded Acrylic | More affordable, lower molecular weight | Signage, DIY projects, protective barriers | Pros: Cost-effective; Cons: Lower impact strength than cast. |

| UV-Resistant Acrylic | Enhanced UV resistance, ideal for outdoor applications | Outdoor displays, greenhouses, signage | Pros: Long-lasting color stability; Cons: Slightly higher cost. |

| Colored Acrylic | Available in various colors, adds aesthetic value | Retail displays, architectural features | Pros: Customizable; Cons: Limited transparency compared to clear options. |

| Anti-Static Acrylic | Reduces static electricity, preventing dust attraction | Electronics packaging, cleanrooms | Pros: Ideal for sensitive environments; Cons: Limited availability. |

What Are the Characteristics of Clear Cast Acrylic Sheets?

Clear cast acrylic sheets are renowned for their exceptional optical clarity and high impact resistance, making them an ideal choice for applications requiring transparency and durability. They are often used in environments where glass is typically employed, such as glazing and protective barriers. B2B buyers should consider their manufacturing processes, as clear cast sheets can be easily fabricated and machined, allowing for customized solutions tailored to specific project needs. However, they are generally priced higher than extruded acrylic, which may be a key consideration for budget-conscious businesses.

How Does Extruded Acrylic Differ from Other Types?

Extruded acrylic sheets are more affordable and possess a lower molecular weight compared to cast acrylic. This makes them easier to handle but less durable in high-impact scenarios. They are primarily used for signage, DIY projects, and protective barriers. B2B buyers may find extruded acrylic appealing due to its cost-effectiveness, especially for large-volume orders. However, it is crucial to assess the application requirements, as its lower strength may not be suitable for all uses.

Why Choose UV-Resistant Acrylic for Outdoor Applications?

UV-resistant acrylic sheets are specifically designed to withstand outdoor conditions, offering enhanced resistance to yellowing and degradation from sun exposure. This makes them ideal for outdoor displays, greenhouses, and signage. B2B buyers focusing on longevity and performance in harsh environments should prioritize this type. While they come at a slightly higher price point, the investment can lead to significant savings over time by reducing replacement frequency.

What Are the Benefits of Colored Acrylic Sheets?

Colored acrylic sheets provide aesthetic versatility and can enhance the visual appeal of products or spaces. They are commonly used in retail displays and architectural features. For B2B buyers, the ability to customize colors allows for branding opportunities and creative design solutions. However, it is important to note that colored sheets may offer limited transparency compared to clear options, which could impact their suitability for certain applications.

How Do Anti-Static Acrylic Sheets Serve Specialized Needs?

Anti-static acrylic sheets are engineered to minimize static electricity, making them essential for environments such as electronics packaging and cleanrooms. They help prevent dust accumulation and protect sensitive components. B2B buyers in industries such as electronics manufacturing should consider these sheets for their specific applications. While they may be less commonly available, the benefits they provide in terms of product safety and cleanliness can outweigh the challenges of sourcing.

Key Industrial Applications of 1/4 inch plexiglass 4×8 sheet

| Industry/Sector | Specific Application of 1/4 inch plexiglass 4×8 sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Window Glazing and Protective Barriers | Enhanced safety and energy efficiency in building designs | Durability, UV resistance, and compliance with local building codes |

| Retail Displays | Point-of-Purchase (POP) Displays | Increased product visibility and customer engagement | Customization options, ease of fabrication, and weight considerations |

| Automotive | Interior Panels and Window Replacements | Lightweight and impact-resistant alternatives to glass | Compatibility with vehicle specifications and durability under various conditions |

| Healthcare | Sneeze Guards and Protective Barriers | Improved safety for staff and customers in medical settings | Clarity, ease of cleaning, and compliance with health regulations |

| Manufacturing | Machine Guards and Safety Shields | Enhanced safety for workers and equipment protection | Thickness specifications, impact resistance, and ease of installation |

How is 1/4 inch plexiglass 4×8 sheet used in construction and architecture?

In the construction industry, 1/4 inch plexiglass 4×8 sheets are frequently utilized for window glazing and protective barriers. These sheets offer a lightweight, shatter-resistant alternative to traditional glass, enhancing both safety and energy efficiency. For international buyers, particularly in regions with varying climates, sourcing options should consider UV resistance and compliance with local building codes to ensure longevity and performance.

What role does 1/4 inch plexiglass play in retail displays?

Retail environments utilize 1/4 inch plexiglass sheets to create eye-catching point-of-purchase (POP) displays. The clarity and durability of plexiglass enhance product visibility, driving customer engagement and sales. For businesses in Africa and South America, customization options and ease of fabrication are crucial factors, as they allow for tailored solutions that fit specific branding needs while maintaining lightweight properties for easy transport and installation.

How is 1/4 inch plexiglass applied in the automotive industry?

In the automotive sector, 1/4 inch plexiglass sheets serve as effective interior panels and window replacements. Their lightweight nature contributes to improved fuel efficiency, while their impact resistance offers enhanced safety. Buyers, especially in the Middle East and Europe, must consider compatibility with vehicle specifications and the sheets’ performance under varying weather conditions to ensure they meet industry standards.

What benefits does 1/4 inch plexiglass provide in healthcare settings?

Healthcare facilities utilize 1/4 inch plexiglass sheets for sneeze guards and protective barriers to enhance safety for both staff and patients. The material’s clarity allows for visibility while providing a physical barrier against airborne contaminants. Buyers in this sector should prioritize sheets that are easy to clean and comply with health regulations, ensuring they maintain a sterile environment.

In what ways does 1/4 inch plexiglass enhance safety in manufacturing?

In manufacturing, 1/4 inch plexiglass sheets are often used for machine guards and safety shields. These applications protect workers from potential hazards while allowing visibility of operations. For international buyers in regions like Vietnam and Nigeria, sourcing considerations should include the thickness of the sheets for optimal protection, impact resistance, and ease of installation to align with safety standards and operational efficiency.

3 Common User Pain Points for ‘1/4 inch plexiglass 4×8 sheet’ & Their Solutions

Scenario 1: Sizing and Customization Issues When Ordering Plexiglass Sheets

The Problem:

B2B buyers often face challenges when it comes to ordering plexiglass sheets of the right size and specifications. Many suppliers provide standard dimensions, but projects frequently require custom cuts or specific thicknesses. This can lead to significant delays in production timelines, increased costs, and wasted materials when buyers receive sheets that do not meet their needs. For instance, a construction company looking to use 1/4 inch plexiglass for a large display may inadvertently order the wrong size, resulting in project delays and added expenses for reordering.

The Solution:

To mitigate sizing and customization issues, B2B buyers should prioritize suppliers that offer precise cut-to-size options. When placing an order, it’s crucial to provide detailed dimensions and specifications, ensuring that the supplier can deliver a product that meets exact project requirements. Additionally, buyers should inquire about the supplier’s capabilities for custom cuts, the tools they use, and their accuracy in manufacturing. Utilizing online calculators or templates to determine the required dimensions can also help avoid mistakes. Furthermore, consider suppliers with a robust return policy that allows for exchanges if the dimensions do not meet project needs.

Scenario 2: High Shipping Costs and Delivery Delays

The Problem:

International buyers often encounter exorbitant shipping costs and unpredictable delivery times when ordering 1/4 inch plexiglass sheets. This is particularly true for larger orders that require pallet shipping, which can lead to additional charges and logistical headaches. Delays in delivery can disrupt project timelines, especially in industries like construction or manufacturing where timing is critical.

The Solution:

To address shipping challenges, B2B buyers should explore suppliers that offer competitive shipping rates or free shipping options on larger orders. It’s advisable to compare shipping policies among different suppliers before making a decision. Additionally, consolidating orders can minimize shipping costs—buyers should consider ordering in bulk to take advantage of lower per-unit shipping rates. Collaborating with suppliers who have established logistics partnerships can also enhance reliability and speed in delivery. Clear communication about shipping timelines and tracking options can further alleviate concerns about delays.

Scenario 3: Quality Assurance and Product Specifications

The Problem:

Another significant pain point for B2B buyers is ensuring that the quality of the 1/4 inch plexiglass meets their project standards. Inconsistent quality can lead to issues such as warping, scratching, or poor optical clarity, which can compromise the integrity of the final product. Buyers may struggle to find reliable suppliers that consistently provide high-quality materials, which can lead to costly rework or project failures.

The Solution:

To ensure quality assurance, buyers should conduct thorough research on potential suppliers. Requesting samples prior to placing large orders can help assess the quality of the plexiglass. Buyers should also inquire about the manufacturing process, including whether the sheets are cast or extruded, as this can impact strength and clarity. Certifications and compliance with industry standards can also serve as indicators of product quality. Establishing a relationship with a reputable supplier who understands the specific needs of the industry can result in consistent quality and reliability in future orders. Regular feedback and open lines of communication with the supplier can help maintain high standards throughout the procurement process.

Strategic Material Selection Guide for 1/4 inch plexiglass 4×8 sheet

What Are the Key Properties of 1/4 Inch Plexiglass 4×8 Sheets?

1/4 inch plexiglass sheets, also known as acrylic sheets, are widely used in various applications due to their unique properties. These sheets are lightweight yet incredibly strong, offering a high impact resistance that is approximately 17 times stronger than glass. They also provide excellent optical clarity, making them suitable for applications where visibility is crucial, such as display cases and protective barriers. Additionally, they are UV resistant, which helps prevent yellowing over time, making them ideal for outdoor applications.

What Are the Pros and Cons of Using 1/4 Inch Plexiglass?

When considering the use of 1/4 inch plexiglass sheets, several advantages and disadvantages come into play.

Pros:

– Durability: Plexiglass is significantly more durable than glass, reducing the risk of breakage and making it a safer option in high-traffic areas.

– Cost-Effectiveness: While the initial investment may be higher than some alternatives, the long-term savings on maintenance and replacement can be substantial.

– Ease of Fabrication: Plexiglass can be easily cut, shaped, and fabricated using common tools, making it suitable for custom projects.

Cons:

– Scratching: Although plexiglass is strong, it is prone to scratching, which can affect its appearance over time.

– Chemical Sensitivity: Certain solvents and chemicals can damage plexiglass, which may limit its use in specific industrial applications.

How Does Material Selection Impact Application?

The choice of material for 1/4 inch plexiglass sheets directly influences the performance and suitability for various applications. For instance, the high impact resistance makes it ideal for use in environments where safety is a concern, such as in schools or hospitals. Conversely, its susceptibility to scratching may not make it the best choice for surfaces that require a pristine finish, such as high-end retail displays.

What Should International B2B Buyers Consider When Sourcing Plexiglass?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of several factors when sourcing plexiglass sheets. Compliance with local and international standards, such as ASTM, DIN, or JIS, is crucial to ensure product quality and safety. Additionally, understanding the regional preferences for material characteristics, such as UV resistance for areas with high sun exposure or impact resistance for high-traffic environments, can guide purchasing decisions. Lastly, considering logistics and shipping costs is essential, especially for larger orders that may require special handling.

Summary Table of Material Selection for 1/4 Inch Plexiglass 4×8 Sheets

| Material | Typical Use Case for 1/4 inch plexiglass 4×8 sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clear Cast Acrylic | Display cases, sneeze guards, protective barriers | High impact resistance | Prone to scratching | Medium |

| Extruded Acrylic | Signage, interior partitions, hobby projects | Cost-effective, lightweight | Lower optical clarity than cast | Low |

| Polycarbonate | Security glazing, bullet-resistant applications | Superior impact resistance | Higher cost compared to acrylic | High |

| Glass | Windows, high-end displays | Excellent optical clarity | Heavy, prone to breakage | High |

This guide provides a comprehensive overview of the strategic material selection for 1/4 inch plexiglass 4×8 sheets, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 1/4 inch plexiglass 4×8 sheet

What Are the Main Stages in the Manufacturing Process of 1/4 Inch Plexiglass 4×8 Sheets?

The manufacturing process for 1/4 inch plexiglass sheets, particularly those sized 4×8 feet, typically involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, primarily methyl methacrylate (MMA), which is the primary monomer used in producing acrylic sheets. The quality of the MMA directly impacts the final product’s clarity, strength, and durability. Manufacturers often utilize advanced techniques to purify the MMA to remove impurities that could affect the optical quality of the sheets.

-

Forming: The preparation of the material leads to the forming stage, where the MMA is polymerized. This can be achieved through a casting process, where the liquid MMA is poured into molds and allowed to cure at controlled temperatures. Alternatively, extrusion methods may be employed, although cast acrylic generally offers superior optical clarity and impact resistance. The choice of method significantly affects the final product’s characteristics.

-

Assembly: Once the sheets are formed, they may require cutting to specific dimensions. For B2B buyers, custom sizes are often available, which can include precise cuts for unique applications. Manufacturers utilize advanced cutting tools to ensure clean edges and prevent chipping, which is critical for maintaining the aesthetic and functional integrity of the sheets.

-

Finishing: The final stage includes polishing and surface treatments to enhance clarity and remove any imperfections. Techniques such as flame polishing are commonly used to achieve a high-gloss finish. Additionally, protective films may be applied to prevent scratches during handling and shipping.

How is Quality Assurance Implemented in the Manufacturing of Plexiglass Sheets?

Quality assurance (QA) is paramount in plexiglass manufacturing, especially for B2B transactions where specifications must be met with high precision. Manufacturers often adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. This ensures consistent quality and customer satisfaction.

-

International Standards Compliance: Many manufacturers seek certifications such as CE marking for European markets or API for specific industrial applications. Compliance with these standards demonstrates adherence to safety, health, and environmental protection regulations, which is crucial for international buyers.

-

Quality Control Checkpoints: Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during production to identify and rectify any deviations from standards in real-time.

– Final Quality Control (FQC): Finished products undergo rigorous testing for optical clarity, thickness, and impact resistance before they are packaged for shipment. -

Common Testing Methods: Various testing methods are employed to verify the quality of the plexiglass sheets. These include:

– Optical Testing: To ensure clarity and check for any distortions.

– Mechanical Testing: Assessing impact resistance and tensile strength through standardized tests.

– Thermal Testing: Evaluating the material’s behavior under temperature variations, crucial for applications in diverse climates.

What Should B2B Buyers Consider When Verifying Supplier Quality Control?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks and ensure product reliability.

-

Conducting Supplier Audits: Engaging in regular audits of potential suppliers can provide insights into their manufacturing processes and quality management systems. Buyers should request access to audit reports that detail compliance with international standards and any corrective actions taken.

-

Requesting Quality Assurance Reports: Buyers should insist on obtaining comprehensive QA reports that outline testing methods and results for the specific batches of plexiglass sheets being purchased. This documentation serves as evidence of the supplier’s commitment to quality.

-

Utilizing Third-Party Inspections: To further ensure product quality, buyers can engage third-party inspection services. These independent entities can perform on-site inspections and quality assessments, providing an unbiased evaluation of the supplier’s capabilities.

What Are the Specific Quality Control Nuances for International Buyers?

When dealing with international suppliers, B2B buyers should be aware of certain nuances that may affect quality control processes:

-

Cultural and Regulatory Differences: Different regions may have varying regulations regarding manufacturing and quality standards. Understanding these differences is crucial for compliance and quality assurance.

-

Language Barriers: Communication can sometimes be a challenge. Buyers should ensure that specifications and quality requirements are clearly articulated and documented in a language both parties understand.

-

Time Zone Challenges: Coordinating with suppliers across different time zones can lead to delays in communication. Establishing clear timelines for responses and updates is essential for maintaining the flow of information.

-

Logistical Considerations: The shipping and handling processes can also impact product quality. Buyers should ensure that suppliers have robust logistics in place to minimize damage during transportation, particularly for large sheets that may be susceptible to breakage.

Conclusion

Understanding the manufacturing processes and quality assurance practices for 1/4 inch plexiglass 4×8 sheets is crucial for international B2B buyers. By focusing on the manufacturing stages, compliance with international standards, and effective quality control measures, buyers can make informed decisions and establish reliable partnerships with suppliers. Ensuring thorough verification processes further enhances the likelihood of obtaining high-quality products that meet specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘1/4 inch plexiglass 4×8 sheet’

To successfully procure a 1/4 inch plexiglass 4×8 sheet, B2B buyers should follow this comprehensive sourcing guide. This checklist will help ensure that you make informed decisions, select reliable suppliers, and receive high-quality materials suitable for your specific applications.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for the plexiglass sheets, including thickness, dimensions, and any specific features like UV resistance or optical clarity. This step is essential to ensure that the material meets your operational needs, whether for display cases, protective barriers, or other applications. Specify if you need custom cutting or fabrication services as well.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in plexiglass products. Look for companies with a solid reputation, positive customer reviews, and a strong online presence. Utilize resources like industry directories, trade shows, and professional networks to gather a list of potential candidates.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications and standards that suppliers adhere to. Look for ISO certifications or compliance with local and international quality standards. This step is crucial as it reflects the supplier’s commitment to maintaining high-quality production processes and materials.

Step 4: Request Samples and Specifications

Always request samples of the plexiglass sheets before placing a large order. This allows you to assess the material’s quality, clarity, and durability firsthand. Additionally, ask for detailed product specifications, including any technical data sheets that outline the material’s properties and performance.

Step 5: Compare Pricing Structures

Analyze the pricing offered by different suppliers, considering both the base price per sheet and any additional costs such as cutting and shipping fees. Look for bulk purchase discounts, as many suppliers offer lower prices for larger orders. This step helps in ensuring that you receive competitive pricing while not compromising on quality.

Step 6: Discuss Shipping and Handling Options

Inquire about shipping methods and handling charges, especially for larger orders that may require palletized shipping. Understanding the logistics will help you manage costs and delivery timelines effectively. Ensure the supplier can accommodate your preferred delivery schedule to avoid project delays.

Step 7: Finalize Terms and Place Your Order

Once you’ve evaluated suppliers and selected one that meets your criteria, finalize the terms of your order. This includes payment terms, delivery schedules, and return policies. Ensure that you have a written agreement outlining all details to avoid misunderstandings later.

By following this structured checklist, B2B buyers can streamline the procurement process for 1/4 inch plexiglass 4×8 sheets, ensuring that they source high-quality materials that meet their business needs efficiently.

Comprehensive Cost and Pricing Analysis for 1/4 inch plexiglass 4×8 sheet Sourcing

What Are the Key Cost Components for 1/4 Inch Plexiglass 4×8 Sheets?

When sourcing 1/4 inch plexiglass sheets, understanding the cost structure is essential for effective budgeting and procurement strategy. The primary cost components include:

-

Materials: The base cost of the plexiglass is influenced by the quality of the acrylic resin used. Clear cast acrylic tends to be more expensive than extruded types due to its superior clarity and strength.

-

Labor: This encompasses the workforce involved in manufacturing, cutting, and processing the sheets. Labor costs may vary based on the region and the complexity of the manufacturing process.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, equipment maintenance, and salaries of administrative staff. These costs are typically calculated as a percentage of total production costs.

-

Tooling: Custom tooling for specific sheet sizes or shapes can significantly impact costs. If a buyer requires unique dimensions or features, these additional costs must be factored in.

-

Quality Control (QC): Ensuring that the plexiglass meets specific standards involves inspections and testing, which can add to the overall cost.

-

Logistics: Shipping costs depend on the distance, mode of transportation, and the final destination’s accessibility. International buyers should also consider customs duties and taxes.

-

Margin: Suppliers will add a profit margin, which can vary based on market conditions, demand, and competition.

How Do Price Influencers Affect the Cost of 1/4 Inch Plexiglass Sheets?

Several factors can influence the pricing of 1/4 inch plexiglass sheets:

-

Volume/MOQ: Purchasing in bulk typically results in lower per-unit prices due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize costs.

-

Specifications and Customization: Custom dimensions, thicknesses, or features will increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice between cast and extruded acrylic affects pricing. Cast acrylic generally commands a higher price but offers better performance in certain applications.

-

Quality and Certifications: Higher-quality sheets with certifications (e.g., UV resistance, impact resistance) may be priced higher but can provide long-term savings through durability and reduced replacement frequency.

-

Supplier Factors: Different suppliers have varying pricing strategies, based on their production capabilities, reputation, and market positioning. Conducting supplier research can yield cost-effective options.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial for calculating total landed costs, especially for international buyers.

What Negotiation and Cost-Efficiency Tips Should B2B Buyers Consider?

To ensure the best value for 1/4 inch plexiglass sheets, B2B buyers should adopt strategic approaches:

-

Leverage Volume Discounts: When feasible, consolidate orders to meet volume thresholds that unlock discounts. This can significantly reduce the overall expenditure.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the initial purchase price but also long-term factors such as durability, maintenance, and potential replacements. Investing in higher-quality materials may yield better long-term savings.

-

Negotiate Payment Terms: Flexible payment options can alleviate cash flow concerns. Discussing terms such as net 30 or net 60 can provide financial relief for buyers.

-

Research and Compare Suppliers: Utilize platforms that provide insights into various suppliers’ offerings and pricing. Request quotes from multiple suppliers to compare costs and negotiate better terms.

-

Understand Pricing Nuances for International Transactions: Buyers from regions such as Africa, South America, the Middle East, and Europe should account for currency fluctuations, import duties, and local market conditions that can affect pricing.

Conclusion

Sourcing 1/4 inch plexiglass sheets involves careful consideration of multiple cost components and price influencers. By employing strategic negotiation tactics and understanding the total cost of ownership, B2B buyers can optimize their purchasing decisions and secure favorable terms. Always remember that prices may vary based on market conditions, and it’s advisable to seek multiple quotes for an accurate assessment.

Alternatives Analysis: Comparing 1/4 inch plexiglass 4×8 sheet With Other Solutions

Exploring Alternatives to the 1/4 Inch Plexiglass 4×8 Sheet

When considering material options for applications that require transparency, impact resistance, and versatility, it’s essential to evaluate alternatives to the 1/4 inch plexiglass 4×8 sheet. This section compares the plexiglass sheet against two viable alternatives: Polycarbonate Sheets and Glass Panels. Each material has its unique characteristics, benefits, and drawbacks, influencing purchasing decisions for B2B buyers.

| Comparison Aspect | 1/4 Inch Plexiglass 4×8 Sheet | Polycarbonate Sheets | Glass Panels |

|---|---|---|---|

| Performance | High impact resistance, lightweight, good optical clarity | Extremely high impact resistance, lightweight, UV resistant | Excellent optical clarity, rigid, heavy |

| Cost | Moderate ($134.95 per sheet) | Higher ($150 – $250 per sheet) | Higher ($200 – $400 per sheet) |

| Ease of Implementation | Easy to cut and shape with standard tools | Requires special tools for cutting | Requires professional installation |

| Maintenance | Low maintenance, easy to clean | Low maintenance, resistant to scratches | Requires regular cleaning, prone to breakage |

| Best Use Case | Indoor displays, sneeze guards, hobby projects | Security applications, outdoor displays, greenhouses | Windows, high-end displays, architectural applications |

In-Depth Analysis of Alternatives

What Are the Benefits and Drawbacks of Polycarbonate Sheets?

Polycarbonate sheets are renowned for their exceptional impact resistance—up to 200 times stronger than glass. They are also lightweight and can be UV resistant, making them suitable for outdoor applications. However, their higher cost and the need for specialized tools for cutting can be a drawback for some buyers. Polycarbonate sheets are ideal for security applications, such as protective barriers in retail environments, or for greenhouse structures where durability is paramount.

How Do Glass Panels Compare in Performance and Cost?

Glass panels offer unmatched optical clarity and rigidity, making them a preferred choice for applications where aesthetics are critical. However, they are significantly heavier and more fragile than plexiglass or polycarbonate options, necessitating professional installation to ensure safety and compliance. Although they provide an elegant look for architectural projects or high-end displays, the cost can be prohibitive, and the maintenance involved in keeping glass clean and intact can deter some buyers.

Making the Right Choice: How Should B2B Buyers Decide?

When selecting the best material for specific applications, B2B buyers should consider various factors, including performance requirements, budget constraints, and installation capabilities. For projects that require lightweight materials with decent impact resistance and ease of installation, the 1/4 inch plexiglass sheet may be the most suitable option. However, if the application demands superior durability and security, polycarbonate sheets might be more appropriate despite the higher cost. Glass panels, while aesthetically pleasing and offering high clarity, may be best reserved for applications where appearance trumps practicality. Ultimately, understanding the unique advantages and limitations of each material will guide buyers in making informed decisions tailored to their needs.

Essential Technical Properties and Trade Terminology for 1/4 inch plexiglass 4×8 sheet

What Are the Key Technical Properties of a 1/4 Inch Plexiglass 4×8 Sheet?

When considering the procurement of 1/4 inch plexiglass (also known as acrylic) sheets, understanding their technical specifications is vital for ensuring they meet your business needs. Here are some critical properties to consider:

-

Material Grade: Plexiglass comes in various grades, including cast and extruded. Cast acrylic is generally more durable and offers better optical clarity, making it ideal for applications requiring high transparency and strength. For B2B buyers, selecting the right material grade can impact the longevity and appearance of the final product.

-

Thickness: The standard thickness for the sheets in question is 1/4 inch (approximately 6.35 mm). This thickness provides a balance between strength and weight, making it suitable for various applications, such as signage, displays, and protective barriers. Understanding thickness is essential for determining the appropriate handling and installation methods.

-

Impact Resistance: Plexiglass is known for being significantly more impact-resistant than glass—up to 17 times stronger in some cases. This characteristic is crucial for industries where safety and durability are priorities, such as in construction, automotive, and retail environments.

-

Optical Clarity: High optical clarity ensures that the sheets remain transparent without distortion. This property is vital for applications like display cases and windows where visibility is paramount. B2B buyers should assess clarity levels to ensure they meet their specific aesthetic and functional requirements.

-

UV Resistance: Many plexiglass sheets come with UV protection, which prevents yellowing and degradation over time. This feature is particularly important for outdoor applications or environments with high sunlight exposure. Understanding UV resistance can aid in making long-term investments that enhance product durability.

-

Moisture Resistance: Plexiglass is inherently moisture-resistant, making it suitable for environments where exposure to water is a concern. This property is especially beneficial for applications like aquariums or outdoor signage, where moisture can compromise material integrity.

Which Trade Terms Are Essential for Buying 1/4 Inch Plexiglass 4×8 Sheets?

Navigating the trade landscape involves familiarizing yourself with key terminology. Here are several important terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers who provide quality materials suited for specific applications.

-

MOQ (Minimum Order Quantity): This term indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and ensuring that your order meets the supplier’s requirements, especially for bulk purchases.

-

RFQ (Request for Quotation): An RFQ is a document that solicits price proposals from suppliers. B2B buyers often use RFQs to compare prices and terms before making purchasing decisions, ensuring they get the best deal.

-

Incoterms (International Commercial Terms): These are standardized shipping and freight terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for managing logistics, shipping costs, and risk during international trade.

-

Cut-to-Size: This term refers to sheets that are customized to specific dimensions based on customer requirements. Understanding cut-to-size options can help businesses minimize waste and ensure that their materials fit perfectly in their intended applications.

-

Lead Time: This is the amount of time it takes from placing an order to receiving the goods. Knowing the lead time is vital for planning and inventory management, allowing businesses to align their supply chain with project timelines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the 1/4 inch plexiglass 4×8 sheet Sector

What Are the Key Market Trends Influencing the 1/4 Inch Plexiglass 4×8 Sheet Sector?

The global market for 1/4 inch plexiglass 4×8 sheets is experiencing significant growth driven by various factors, including the increasing demand for lightweight, durable, and versatile materials across multiple industries. Notably, sectors such as construction, automotive, and retail are adopting acrylic sheets as replacements for traditional glass due to their superior impact resistance and lower weight. In emerging markets in Africa, South America, the Middle East, and parts of Europe, the need for affordable and sustainable building materials is further propelling the demand for plexiglass.

Technological advancements in manufacturing processes, such as improved cutting and shaping techniques, are enabling suppliers to offer customized solutions that meet specific buyer requirements. Additionally, the rise of e-commerce platforms is transforming sourcing dynamics, allowing international buyers to access a broader range of suppliers and products more efficiently. The emphasis on transparency in the supply chain and the digitalization of procurement processes are also becoming critical for B2B buyers, as they seek reliable partners who can provide quality products with traceable origins.

How Is Sustainability Impacting the Sourcing of 1/4 Inch Plexiglass 4×8 Sheets?

Sustainability is increasingly becoming a cornerstone in the decision-making process for B2B buyers sourcing 1/4 inch plexiglass 4×8 sheets. The environmental impact of materials is now a key consideration, with buyers looking for suppliers who prioritize eco-friendly practices. Acrylic sheets, particularly those that are recyclable, are gaining traction as they offer a lower carbon footprint compared to traditional glass.

Ethical sourcing is equally important. Buyers are now more informed and concerned about the conditions under which materials are produced. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for suppliers aiming to establish credibility in the market. By opting for ‘green’ certified materials, buyers not only align with global sustainability goals but also enhance their own brand reputation among environmentally conscious consumers.

What Is the Historical Context of 1/4 Inch Plexiglass in B2B Markets?

The evolution of plexiglass, or acrylic, dates back to the early 20th century when it was first developed as a lightweight alternative to glass. Initially used in applications such as aircraft canopies during World War II, its versatility quickly led to widespread adoption in various industries. Over the decades, advancements in manufacturing technology have improved the quality and range of plexiglass products available, making it a staple in modern construction, signage, and display applications.

As global awareness of sustainability grew in the late 20th and early 21st centuries, the focus shifted towards sourcing materials that minimize environmental impact. This shift has fostered innovations in the plexiglass sector, including the development of recyclable and eco-friendly acrylic options, which are now increasingly sought after by B2B buyers looking to enhance their product offerings while adhering to sustainable practices.

In summary, understanding the current market dynamics, sustainability trends, and the historical context of 1/4 inch plexiglass is crucial for international B2B buyers navigating this evolving sector. By aligning sourcing strategies with these insights, buyers can make informed decisions that meet both their operational needs and corporate social responsibility goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 1/4 inch plexiglass 4×8 sheet

-

How do I choose the right supplier for 1/4 inch plexiglass 4×8 sheets?

When selecting a supplier for 1/4 inch plexiglass sheets, assess their reputation, industry experience, and product quality. Look for reviews and testimonials from previous B2B clients. It’s also essential to inquire about their certifications and compliance with international standards. Request samples to evaluate the material’s quality firsthand. Additionally, consider their capacity for customization, lead times, and customer service responsiveness to ensure they can meet your specific needs. -

What are the typical applications for 1/4 inch plexiglass sheets?

1/4 inch plexiglass sheets are versatile and commonly used in various applications, including protective barriers in retail and medical environments, window glazing, and display cases. They are also suitable for crafting, aquariums, and furniture design. Their lightweight nature and high impact resistance make them an excellent alternative to glass, particularly in settings where safety and visibility are paramount. -

What customization options are available for plexiglass sheets?

Many suppliers offer customization options for 1/4 inch plexiglass sheets, including cut-to-size services, edge finishing, and drilling holes for mounting. You can request specific dimensions, shapes, and even color tints if needed. When discussing your requirements, ensure you communicate your intended application clearly, as this will help the supplier recommend the best solutions for your needs. -

What are the minimum order quantities (MOQs) for plexiglass sheets?

Minimum order quantities for 1/4 inch plexiglass sheets can vary widely among suppliers. Some may offer flexible MOQs for smaller businesses, while others might require larger orders to optimize production costs. It’s advisable to inquire about MOQs before placing an order, especially if you’re considering purchasing for a specific project or if you require ongoing supplies. -

What payment terms should I expect when sourcing plexiglass sheets internationally?

Payment terms can differ significantly among suppliers. Common options include upfront payment, 30-day net terms, or payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms and any potential additional charges for customs or shipping to avoid unexpected costs. -

How do I ensure quality assurance for my plexiglass order?

To ensure quality assurance, request documentation such as material safety data sheets (MSDS) and certificates of compliance with industry standards. Many suppliers also provide quality inspection reports. If possible, establish a quality control plan that includes on-site inspections or third-party audits. This will help ensure that the plexiglass sheets meet your specifications and industry requirements. -

What shipping options are available for international orders of plexiglass sheets?

Shipping options for international orders typically include air freight, sea freight, and courier services, depending on urgency and cost considerations. Discuss with your supplier to determine the best shipping method based on your timeline and budget. Be sure to clarify who is responsible for customs duties and taxes, as these can add to the overall cost of your order. -

How can I address potential issues with my plexiglass order?

If you encounter issues with your plexiglass order, such as incorrect dimensions or defects, immediately contact your supplier with detailed documentation, including photographs. Most reputable suppliers will have a return or replacement policy in place. Establishing clear communication and understanding the supplier’s policies beforehand can facilitate smoother resolutions in case of discrepancies or quality concerns.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 1/4 Inch Plexiglass 4X8 Sheet Manufacturers & Suppliers List

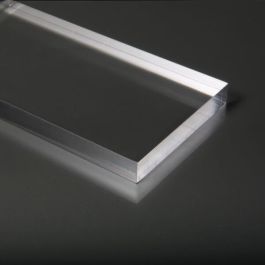

1. Shapes Plastics – 1/4 Clear Cast Acrylic Sheet

Domain: shapesplastics.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “1/4″ Clear Cast Acrylic Sheet”, “dimensions”: “48” x 96″”, “price”: “$134.95”, “bulk_pricing”: [{“quantity”: 2, “price”: “$128.20”}, {“quantity”: 5, “price”: “$121.46”}, {“quantity”: 10, “price”: “$114.71”}], “material_type”: “Acrylic/Plexiglass”, “features”: [“lightweight”, “impact-resistant”, “transparent”, “high impact strength”], “applications”: [“storm windows”, “garage door…

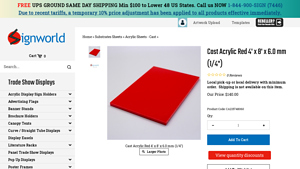

2. Display Wholesale – Cast Acrylic Red 4′ x 8′ x 6.0 mm (1/4)

Domain: display-wholesale.com

Registered: 2008 (17 years)

Introduction: {“Product Name”: “Cast Acrylic Red 4′ x 8′ x 6.0 mm (1/4)” , “Price”: “$140.00”, “Product Code”: “CA215748060”, “Dimensions”: “4′ x 8′ x 6.0 mm (1/4)”, “Color”: “Red”, “Shipping”: “FREE UPS GROUND SAME DAY SHIPPING Min $100 to Lower 48 US States”, “Local Delivery”: “Free local delivery available within 50 miles from California office”, “Features”: [“Optical Characteristic”, “Low Internal Stress Le…

Strategic Sourcing Conclusion and Outlook for 1/4 inch plexiglass 4×8 sheet

In today’s competitive landscape, strategic sourcing of 1/4 inch plexiglass 4×8 sheets is essential for businesses looking to maximize value while ensuring quality. Key takeaways include understanding the diverse applications of plexiglass, from window glazing to crafting sneeze guards, which highlight its versatility and durability. The cost-effectiveness of sourcing in bulk, coupled with the potential for custom fabrication, can significantly enhance operational efficiency and reduce overall expenditure.

International buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize establishing strong relationships with reliable suppliers. Leveraging competitive pricing and exploring volume discounts can lead to substantial savings, while also ensuring timely delivery and quality assurance. It is crucial to consider suppliers that offer customization options to meet specific project requirements, thereby enhancing the final product’s functionality.

Looking ahead, the demand for 1/4 inch plexiglass is expected to grow, driven by trends in sustainability and increased use in various sectors. By adopting a proactive sourcing strategy, businesses can position themselves advantageously in the market. Engage with suppliers today to explore innovative solutions and secure your competitive edge in the evolving landscape of plexiglass applications.