Brown Porcelain Insulator Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for brown porcelain insulator

Navigating the complex landscape of sourcing brown porcelain insulators can pose significant challenges for international B2B buyers. With the increasing demand for reliable electrical components across various industries, understanding the nuances of this market is crucial. This guide delves into the diverse types of brown porcelain insulators, their applications in electrical transmission and telecommunications, and the critical factors to consider when vetting suppliers. From analyzing production standards to estimating costs, we aim to equip you with the knowledge necessary to make informed purchasing decisions.

For buyers in Africa, South America, the Middle East, and Europe, particularly in regions like Germany and Nigeria, the procurement process involves not only identifying quality products but also ensuring compliance with regional standards and regulations. This guide empowers you to navigate these complexities by providing actionable insights into market trends, supplier reputation, and product specifications. By leveraging this comprehensive resource, you can mitigate risks and enhance your sourcing strategy, ultimately driving efficiency and reliability in your operations. Whether you’re a seasoned buyer or new to the field, our guide is designed to be your essential companion in the global marketplace for brown porcelain insulators.

Understanding brown porcelain insulator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Brown Insulator | Uniform chocolate brown glaze, common in modern designs | Electrical transmission lines | Pros: Widely available, cost-effective. Cons: Less desirable for collectors. |

| Mottled Brown Insulator | Unique patterns and color variations, often vintage | Decorative applications, vintage collectors | Pros: High aesthetic value, collectible. Cons: May be harder to source. |

| Pumpkin Brown Insulator | Characteristic uniform pumpkin orange/brown color | Utility poles, outdoor applications | Pros: Durable, weather-resistant. Cons: Limited styles available. |

| Dark and Mottled Brown Insulator | Rich, dark tones with mottling, often vintage | Specialized electrical applications | Pros: High resistance to environmental factors. Cons: Premium pricing for rare types. |

| Chocolate Brown Insulator | Commonly produced, modern design with chocolate hue | General electrical applications | Pros: Readily available, versatile. Cons: Less unique aesthetic appeal. |

What are the Characteristics of Standard Brown Insulators?

Standard brown insulators are characterized by their uniform chocolate brown glaze, commonly found in modern production. They are primarily used in electrical transmission lines due to their cost-effectiveness and wide availability. For B2B buyers, these insulators present a practical choice, although they may lack the appeal for collectors due to their uniformity.

How Do Mottled Brown Insulators Differ in Aesthetic and Application?

Mottled brown insulators feature unique patterns and color variations, making them particularly desirable for decorative applications and among vintage collectors. Their aesthetic value often outweighs their functional utility, which may lead to higher prices in the market. B2B buyers should consider the rarity and sourcing challenges associated with these insulators, as they may not be as readily available as standard types.

Why Choose Pumpkin Brown Insulators for Utility Applications?

Pumpkin brown insulators are recognized for their distinctive uniform color and durability, making them suitable for utility poles and outdoor applications. Their weather resistance is a significant advantage for B2B buyers in regions with harsh climates. However, the limited styles available may restrict options, necessitating careful consideration of specific project requirements.

What Are the Advantages of Dark and Mottled Brown Insulators?

Dark and mottled brown insulators are known for their rich tones and distinctive patterns, often found in vintage applications. They offer high resistance to environmental factors, making them suitable for specialized electrical applications. However, their rarity can lead to premium pricing, which B2B buyers should factor into their budget and sourcing strategies.

How Does the Chocolate Brown Insulator Fit into General Electrical Applications?

Chocolate brown insulators are a common choice in modern designs, offering versatility for general electrical applications. Their availability and affordability make them an attractive option for B2B buyers looking for reliable insulators. However, their less unique aesthetic may not appeal to buyers seeking specialized or vintage pieces, potentially limiting their market reach.

Key Industrial Applications of brown porcelain insulator

| Industry/Sector | Specific Application of brown porcelain insulator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Generation | High-voltage transmission lines | Enhanced electrical insulation and durability | Compliance with international standards and local regulations |

| Telecommunications | Communication towers and relay stations | Reliable signal transmission with minimal interference | Proven track record in performance under extreme weather conditions |

| Rail Transportation | Electrified rail systems | Improved safety and reliability of electrical systems | Compatibility with existing rail infrastructure |

| Renewable Energy | Wind turbine electrical systems | Resistance to environmental stressors | Availability of localized suppliers for timely delivery |

| Utilities Management | Utility poles for electricity and telecommunications | Long lifespan and reduced maintenance costs | Assessment of local sourcing options to ensure quality |

How Are Brown Porcelain Insulators Used in Power Generation?

In the power generation sector, brown porcelain insulators are crucial for high-voltage transmission lines. They provide excellent electrical insulation, preventing energy loss and ensuring safety. These insulators can withstand extreme weather conditions, making them ideal for diverse climates found in Africa and South America. Buyers in this sector must ensure that their suppliers comply with international safety standards and local regulations to avoid costly downtimes and enhance operational efficiency.

What Role Do Brown Porcelain Insulators Play in Telecommunications?

In telecommunications, brown porcelain insulators are used in communication towers and relay stations. Their durability and ability to insulate against electrical interference ensure reliable signal transmission, which is vital for maintaining service quality. For businesses in regions like the Middle East and Europe, sourcing insulators that have demonstrated performance under varying environmental stressors is critical. Buyers should prioritize suppliers with a proven history in providing high-quality insulators that meet rigorous performance standards.

How Are Brown Porcelain Insulators Critical for Rail Transportation?

Rail transportation systems utilize brown porcelain insulators in electrified rail systems to enhance safety and reliability. These insulators support the electrical infrastructure necessary for trains to operate efficiently. For buyers in this sector, particularly in regions like Nigeria, it is essential to source insulators that can withstand heavy loads and harsh conditions. Compatibility with existing rail infrastructure is a key consideration, as it ensures seamless integration and reduces installation costs.

In What Ways Do Brown Porcelain Insulators Support Renewable Energy Initiatives?

In the renewable energy sector, particularly in wind turbine systems, brown porcelain insulators are employed to protect electrical components from environmental stressors such as moisture and temperature fluctuations. Their resilience contributes to the longevity of the electrical systems in wind energy applications. Buyers in Europe focusing on renewable energy must consider localized suppliers who can provide timely delivery and support, ensuring that projects stay on schedule and within budget.

Why Are Brown Porcelain Insulators Important for Utilities Management?

Utilities management relies on brown porcelain insulators for utility poles that support both electricity and telecommunications. These insulators offer a long lifespan and significantly reduce maintenance costs, making them an economical choice for utility providers. For businesses in regions like South America, assessing local sourcing options is vital to guarantee quality and compliance with regional standards. This strategic sourcing approach can enhance service reliability and operational efficiency in utility management.

3 Common User Pain Points for ‘brown porcelain insulator’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: A common challenge faced by B2B buyers sourcing brown porcelain insulators is the inconsistency in quality and specifications among different suppliers. This inconsistency can lead to significant operational disruptions, especially in regions where reliability is paramount. For instance, a buyer in Nigeria might find that insulators sourced from one supplier fail to meet the required standards, resulting in increased maintenance costs and potential downtime in utility services. This not only affects project timelines but also erodes trust between suppliers and buyers.

The Solution: To mitigate this issue, buyers should implement a rigorous vendor qualification process. This includes requesting samples from multiple suppliers to evaluate the physical properties and manufacturing quality of the insulators. Buyers can also establish clear specifications and performance criteria upfront, ensuring that all potential suppliers understand the exact requirements. Conducting factory audits or utilizing third-party inspection services can further enhance quality assurance. Additionally, maintaining open communication with suppliers to discuss quality expectations and potential issues can foster better relationships and ensure consistent product delivery.

Scenario 2: Limited Availability of Specific Designs

The Problem: B2B buyers often encounter difficulties in finding specific designs or colors of brown porcelain insulators that meet their unique project requirements. For example, a utility company in Germany may require insulators with specific markings or colors to match existing infrastructure or comply with local regulations. Limited availability can lead to delays in project execution, forcing companies to either settle for subpar alternatives or extend project timelines while searching for the right products.

The Solution: Buyers should establish strong relationships with multiple manufacturers and distributors to widen their sourcing options. Engaging with suppliers who specialize in custom insulator designs can also be beneficial. Buyers can communicate their specific needs early in the procurement process, allowing suppliers to allocate resources accordingly. Utilizing online platforms that aggregate various suppliers and their product offerings can streamline the search for specific designs. Additionally, considering alternative solutions, such as utilizing insulators with compatible design features or collaborating with manufacturers to create bespoke products, can also meet unique project demands.

Scenario 3: High Shipping Costs and Delays

The Problem: International buyers frequently struggle with high shipping costs and long lead times when importing brown porcelain insulators, particularly from regions like South America or Europe. These logistical challenges can inflate project budgets and lead to unexpected delays, which can be detrimental to businesses that rely on timely installation for their operations. For instance, a construction company in Africa might find that shipping delays push back critical milestones, affecting overall project timelines and profitability.

The Solution: To address shipping challenges, buyers should consider consolidating orders to maximize shipping efficiency and reduce per-unit costs. Working with logistics companies that specialize in international shipping can also help negotiate better rates and expedite transit times. Additionally, buyers can explore local suppliers or regional distributors who may offer competitive pricing and shorter shipping durations. Leveraging technology, such as supply chain management software, can provide real-time visibility into shipping processes, allowing buyers to make informed decisions and adjust timelines proactively. Establishing agreements with reliable freight forwarders who understand the nuances of shipping porcelain insulators can further streamline the process and mitigate delays.

Strategic Material Selection Guide for brown porcelain insulator

What Are the Key Materials Used in Brown Porcelain Insulators?

Brown porcelain insulators are primarily made from several key materials, each offering unique properties and performance characteristics that influence their suitability for various applications. Understanding these materials is essential for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, where specific standards and environmental conditions may apply.

How Does Alumina Silicate Impact Insulator Performance?

Alumina silicate is a common material used in the production of brown porcelain insulators. This ceramic material exhibits excellent thermal stability, withstanding high temperatures (up to 1,200°C) without significant degradation. Its low thermal expansion coefficient minimizes the risk of cracking under thermal stress, making it suitable for high-voltage applications.

Pros: Alumina silicate is highly durable, resistant to thermal shock, and exhibits excellent electrical insulation properties. It is also relatively cost-effective due to its widespread availability.

Cons: The manufacturing process can be complex, requiring precise control over the sintering temperature and time. Additionally, while it offers good corrosion resistance, it may not be suitable for environments with extreme chemical exposure.

Impact on Application: Alumina silicate insulators are particularly effective in high-voltage transmission lines and substations, where they can withstand harsh environmental conditions.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial, especially in regions like Europe and the Middle East. Buyers should also consider local manufacturing capabilities and supply chains to ensure timely delivery.

What Role Does Feldspar Play in Insulator Manufacturing?

Feldspar is another key ingredient in the composition of brown porcelain insulators. It acts as a flux, lowering the melting temperature of the ceramic mixture and facilitating the formation of a glassy phase during firing.

Pros: Feldspar enhances the mechanical strength and durability of the insulator while improving its aesthetic appeal with a smooth, glossy finish. It also contributes to the insulator’s resistance to weathering.

Cons: The presence of feldspar can make the insulator more susceptible to thermal shock if not properly formulated. Additionally, variations in feldspar quality can lead to inconsistencies in the final product.

Impact on Application: Insulators containing feldspar are well-suited for outdoor applications, where they face exposure to moisture and temperature fluctuations.

Considerations for International Buyers: Buyers should verify that the feldspar used meets regional quality standards to ensure product reliability, especially in markets like Africa and South America, where climatic conditions can be extreme.

How Does Kaolin Influence Electrical Insulation Properties?

Kaolin, a type of clay, is often included in the formulation of brown porcelain insulators. It provides excellent plasticity during the manufacturing process and contributes to the insulator’s overall dielectric strength.

Pros: Kaolin enhances the insulator’s electrical insulation properties, making it ideal for high-voltage applications. It also provides good resistance to chemical attack.

Cons: While kaolin improves the insulator’s performance, it can increase production costs due to its processing requirements. Additionally, excessive amounts can lead to brittleness.

Impact on Application: Insulators with kaolin are particularly effective in environments with high electrical stress, such as power generation and distribution systems.

Considerations for International Buyers: Compliance with local electrical safety standards is critical, particularly in Europe, where regulations are stringent. Buyers should also consider the sourcing of kaolin to ensure it meets quality benchmarks.

Summary of Material Selection for Brown Porcelain Insulators

| Material | Typical Use Case for brown porcelain insulator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina Silicate | High-voltage transmission lines | Excellent thermal stability | Complex manufacturing process | Medium |

| Feldspar | Outdoor insulators | Enhances mechanical strength and aesthetics | Susceptible to thermal shock if not formulated | Medium |

| Kaolin | High-voltage applications | Superior electrical insulation properties | Increased production costs | High |

This analysis provides a comprehensive overview of the materials used in brown porcelain insulators, emphasizing their properties, advantages, and considerations for international buyers. Understanding these factors is crucial for making informed purchasing decisions in the global market.

In-depth Look: Manufacturing Processes and Quality Assurance for brown porcelain insulator

What Are the Key Stages in the Manufacturing Process of Brown Porcelain Insulators?

The manufacturing of brown porcelain insulators involves several critical stages, each contributing to the final product’s durability and effectiveness. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Is Involved in Creating Quality Insulators?

The initial stage involves sourcing high-quality raw materials, primarily kaolin, feldspar, and quartz. These materials are blended to achieve the desired consistency and properties. The preparation often includes drying and grinding the raw materials to a fine powder, ensuring uniformity in the mixture. This step is crucial because inconsistencies can lead to defects in the final product.

How Are Brown Porcelain Insulators Formed?

Once the materials are prepared, the next step is forming. This can be done through various methods, including:

-

Press Molding: The powdered mixture is placed into molds and subjected to high pressure. This method allows for precise shapes and sizes.

-

Slip Casting: A slurry of the prepared mixture is poured into plaster molds, allowing the moisture to absorb and form the insulator shape. This method is particularly useful for complex designs.

After forming, the insulators are typically air-dried to remove moisture before firing.

What Techniques Are Used During Assembly and Finishing?

The assembly stage often involves adding any required hardware, such as pins or fittings, before the insulators undergo their first firing. This initial firing, or bisque firing, occurs at high temperatures, usually between 1,200°C and 1,400°C, which vitrifies the porcelain and enhances its strength.

Following the initial firing, the insulators are glazed, often using a brown glaze to enhance their aesthetic appeal and protect against environmental factors. A second firing is then conducted to set the glaze, ensuring durability and resistance to wear.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the manufacturing of porcelain insulators, especially when considering international standards and industry-specific regulations. Buyers should be familiar with the following:

Which International Quality Standards Apply to Brown Porcelain Insulators?

-

ISO 9001: This is a widely recognized standard that outlines criteria for a quality management system. Manufacturers certified under ISO 9001 are often more reliable, as they adhere to systematic processes that ensure product quality.

-

CE Marking: In Europe, CE marking signifies that products meet EU safety, health, and environmental protection standards. Insulators marked with CE are often more desirable for buyers in the European market.

-

API Standards: For insulators used in oil and gas applications, adherence to American Petroleum Institute (API) standards may also be relevant.

How Is Quality Control Implemented During Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that the insulators meet required specifications.

What Are the Key QC Checkpoints in the Manufacturing Process?

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery. Suppliers should provide certificates of analysis to confirm material quality.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, random samples are tested to ensure that they meet design specifications. This can include visual inspections and dimensional checks.

-

Final Quality Control (FQC): Before packaging, a final inspection is conducted to ensure that the finished insulators meet all quality standards. This may involve testing for electrical insulation properties and mechanical strength.

What Testing Methods Are Commonly Used for Quality Assurance?

Testing methods play a vital role in validating the quality of brown porcelain insulators. Common methods include:

-

Electrical Testing: Insulators are subjected to high voltage to ensure they can withstand operational stresses without failure.

-

Mechanical Testing: This includes tensile tests and impact tests to assess the insulator’s strength and durability under stress.

-

Thermal Shock Testing: Insulators are exposed to rapid temperature changes to evaluate their ability to withstand thermal stress.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are some strategies:

What Steps Can Buyers Take to Ensure Supplier Compliance with QC Standards?

-

Conduct Supplier Audits: Regular audits can help assess the supplier’s adherence to quality standards. Buyers should consider requesting an audit report or conducting an on-site visit.

-

Request Quality Assurance Documentation: Suppliers should provide documentation detailing their quality assurance processes, including test results and certifications.

-

Engage Third-Party Inspection Services: Utilizing third-party inspectors can provide an unbiased evaluation of the supplier’s manufacturing processes and products.

-

Monitor Compliance with Local Regulations: Buyers should be aware of the specific regulations in their region regarding electrical components, as compliance can vary significantly.

What Nuances Should International Buyers Consider Regarding QC and Certification?

International buyers must navigate various certification requirements and standards that can differ by region. For instance, while CE marking is crucial in Europe, other regions may have different certifications. Understanding these nuances can prevent delays in customs and ensure that the products meet local market requirements.

Additionally, buyers should consider the reputation of the supplier within their respective markets. Engaging with other businesses that have sourced from the same suppliers can provide insights into their reliability and product quality.

Conclusion

Understanding the manufacturing processes and quality assurance standards associated with brown porcelain insulators is essential for B2B buyers. By being aware of the key stages in production, relevant international standards, and effective QC practices, buyers can make informed decisions that lead to successful procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown porcelain insulator’

The procurement of brown porcelain insulators requires careful consideration and a strategic approach. This guide serves as a comprehensive checklist to assist international B2B buyers in sourcing high-quality insulators that meet their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the insulators you procure meet your operational requirements. Consider factors such as voltage ratings, environmental conditions, and mechanical strength. Be specific about the dimensions and color variations you prefer, especially since brown insulators can come in different shades and finishes.

Step 2: Research the Market

Conduct thorough market research to identify potential suppliers of brown porcelain insulators. Utilize industry reports, trade publications, and online marketplaces to gather information about leading manufacturers and their product offerings. Pay attention to regional suppliers, particularly those in Europe, Africa, and South America, as they may offer competitive pricing and shipping options.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record of delivering quality products and excellent customer service. This step helps mitigate risks associated with poor-quality insulators that could lead to operational failures.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications and compliance with international standards. Look for certifications related to quality management systems, such as ISO 9001, as well as any industry-specific standards. Verified certifications provide assurance of the supplier’s commitment to maintaining high-quality manufacturing processes.

Step 5: Request Samples

Before finalizing your order, request samples of the brown porcelain insulators you are considering. This allows you to assess the quality, finish, and overall suitability of the products for your application. Pay attention to any color variations and physical defects that may not be apparent in product images.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier and evaluated the samples, enter into negotiations regarding pricing, delivery schedules, and payment terms. Be clear about your expectations and ensure that all agreed-upon terms are documented in a formal contract. This protects both parties and establishes a clear framework for the transaction.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in shipping the brown porcelain insulators to your location. Evaluate the supplier’s shipping options and timelines, and plan for potential customs and import regulations that may apply in your country. Effective logistics planning ensures that your insulators arrive on time and in good condition.

By following these steps, B2B buyers can make informed decisions when sourcing brown porcelain insulators, ensuring they secure the best products for their needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for brown porcelain insulator Sourcing

What Are the Key Cost Components for Sourcing Brown Porcelain Insulators?

When evaluating the cost structure of brown porcelain insulators, it’s essential to consider several critical components:

-

Materials: The primary raw materials used in the production of porcelain insulators include kaolin, feldspar, and quartz. The quality and source of these materials can significantly impact pricing. For instance, sourcing high-grade kaolin may increase costs but also enhance the final product’s durability.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but this may come at the expense of quality and craftsmanship. Skilled labor is crucial for ensuring that insulators meet safety and performance standards.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, maintenance, and facility costs. Efficient manufacturing processes can help minimize overhead, thus affecting the overall pricing.

-

Tooling: The initial investment in molds and machinery for producing specific designs or custom insulators can be substantial. Tooling costs are amortized over production runs, which means larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Implementing rigorous QC measures is essential to ensure product reliability. The costs associated with testing and inspection can influence pricing, especially for insulators that require compliance with international standards.

-

Logistics: Transportation and shipping costs play a significant role in the final pricing of porcelain insulators. Factors such as distance, mode of transport, and tariffs can add to the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. The margin can vary based on supplier reputation, market demand, and customer relationships.

How Do Price Influencers Impact the Cost of Brown Porcelain Insulators?

Several factors can influence the pricing of brown porcelain insulators:

-

Volume and Minimum Order Quantity (MOQ): Larger orders generally result in lower per-unit pricing. Suppliers often set a MOQ to ensure that production and logistics costs are covered.

-

Specifications and Customization: Custom designs or specific technical requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Insulators that meet higher quality standards or specific certifications (such as ISO or IEC) typically come at a premium. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven track record and the assurance of quality.

-

Incoterms: The chosen Incoterms can affect the total cost of ownership. For example, ‘CIF’ (Cost, Insurance, and Freight) includes shipping costs, while ‘EXW’ (Ex Works) requires the buyer to cover all transportation, which could lead to varied pricing strategies.

What Buyer Tips Can Help Optimize Costs and Pricing for Brown Porcelain Insulators?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-effectiveness:

-

Negotiation: Building a strong relationship with suppliers can lead to better pricing. Consider discussing long-term contracts or bulk purchase agreements to secure favorable terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and performance. Investing in higher-quality insulators may save costs over time.

-

Understand Pricing Nuances: Be aware of regional market trends that can affect pricing. For instance, demand fluctuations during peak seasons can lead to price hikes.

-

Conduct Market Research: Regularly analyze market conditions and competitor pricing. This knowledge can empower buyers during negotiations and help identify the best sourcing options.

-

Evaluate Logistics Options: Assess different shipping methods and routes to find cost-effective solutions. Collaborating with logistics partners can help in managing shipping expenses effectively.

Disclaimer

The pricing information provided is indicative and may vary based on market conditions, regional differences, and specific buyer requirements. Always conduct thorough due diligence and engage in direct discussions with suppliers to obtain accurate pricing.

Alternatives Analysis: Comparing brown porcelain insulator With Other Solutions

Understanding Alternatives to Brown Porcelain Insulators

In the realm of electrical insulation, brown porcelain insulators have long been a popular choice due to their durability and aesthetic appeal. However, as technology evolves, several alternatives have emerged that may better suit certain applications. This analysis aims to provide B2B buyers with a clear comparison of brown porcelain insulators against viable alternatives, allowing for informed decision-making based on specific project requirements.

| Comparison Aspect | Brown Porcelain Insulator | Composite Insulator | Glass Insulator |

|---|---|---|---|

| Performance | Excellent dielectric strength and thermal resistance; suitable for high-voltage applications. | Good performance with lower weight; effective in polluted environments. | High dielectric strength; can withstand extreme temperatures but may be more fragile. |

| Cost | Moderate initial cost; long lifespan offsets expenses. | Generally higher upfront cost but reduced installation costs due to lightweight. | Lower initial cost; however, may require more frequent replacements. |

| Ease of Implementation | Standard installation procedures; heavier, requiring careful handling. | Lightweight, easier to install, especially in remote locations. | Simple installation; however, requires careful handling to avoid breakage. |

| Maintenance | Low maintenance; resistant to environmental degradation. | Low maintenance but may require inspections in harsh conditions. | Requires more frequent inspections and potential replacements. |

| Best Use Case | Ideal for traditional overhead power lines and aesthetic applications. | Best suited for modern applications in urban environments or areas with high pollution. | Suitable for older systems or where aesthetics are not a concern. |

What Are the Advantages and Disadvantages of Composite Insulators?

Composite insulators are increasingly favored in environments with high pollution levels due to their hydrophobic properties, which prevent contamination build-up. They are lightweight, making them easier to handle and install, especially in challenging locations. However, they typically come at a higher initial cost compared to brown porcelain insulators. While they require less frequent maintenance, they may need closer inspection in extremely harsh conditions to ensure integrity and performance.

How Do Glass Insulators Compare to Brown Porcelain Insulators?

Glass insulators are known for their high dielectric strength and excellent temperature resistance, making them suitable for a variety of applications. They generally come at a lower initial cost, appealing for projects with budget constraints. However, their fragility can be a significant drawback, as they are more prone to breakage during installation or under stress. Additionally, glass insulators may require more frequent replacements, leading to higher long-term costs, especially in high-vibration environments.

Conclusion: How to Choose the Right Insulation Solution for Your Needs

When selecting the appropriate insulation solution, B2B buyers should consider various factors including application requirements, environmental conditions, and budget constraints. Brown porcelain insulators offer durability and aesthetic appeal, making them ideal for traditional applications. In contrast, composite and glass insulators may provide advantages in specific contexts, such as urban areas or cost-sensitive projects. Ultimately, a thorough assessment of project needs and an understanding of the characteristics of each option will guide buyers toward the most effective insulation solution for their specific applications.

Essential Technical Properties and Trade Terminology for brown porcelain insulator

What Are the Key Technical Properties of Brown Porcelain Insulators?

Brown porcelain insulators are essential components in electrical systems, providing reliable insulation and support for overhead power lines. Understanding their technical properties can significantly influence purchasing decisions.

-

Material Grade

The primary material used in brown porcelain insulators is high-quality ceramic porcelain, chosen for its excellent electrical insulating properties and durability. The material’s grade affects its resistance to environmental factors, such as moisture and UV exposure, which is crucial for outdoor applications. A higher-grade porcelain typically indicates better performance and longevity, making it a preferred choice for utility companies. -

Voltage Rating

This specification indicates the maximum voltage the insulator can safely handle without breaking down. Voltage ratings for brown porcelain insulators can vary widely, often ranging from 1 kV to over 100 kV. For B2B buyers, selecting the appropriate voltage rating is critical to ensure the insulator meets the operational demands of their electrical systems and avoids potential failures. -

Mechanical Strength

Mechanical strength refers to the insulator’s ability to withstand physical stresses, including tension and compression. This property is particularly important in areas prone to high winds or heavy ice loads. Insulators with higher mechanical strength ratings are less likely to break under stress, ensuring reliability and reducing maintenance costs over time. -

Surface Quality

The surface finish of brown porcelain insulators can impact their performance in outdoor environments. A smooth surface reduces the accumulation of dirt and moisture, which can lead to electrical tracking and failure. Insulators with high surface quality are essential for maintaining efficiency and reliability in harsh conditions, making them a preferred choice for infrastructure projects. -

Thermal Resistance

Thermal resistance indicates how well an insulator can withstand temperature variations without degrading. This property is crucial in regions with extreme weather conditions, where insulators may be exposed to high heat or cold. A higher thermal resistance ensures that the insulator remains functional and safe under varying environmental conditions.

Which Trade Terms Are Commonly Used in the Brown Porcelain Insulator Industry?

Navigating the procurement process for brown porcelain insulators requires familiarity with specific trade terminology that can impact purchasing decisions.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of brown porcelain insulators, sourcing from OEMs can ensure that the insulators meet specific industry standards and quality requirements. This term is vital for buyers looking for reliable and tested components. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers to gauge their budget and inventory needs. Suppliers with lower MOQs can be beneficial for smaller businesses or projects with limited scope, while larger enterprises may benefit from bulk purchasing to reduce costs. -

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. For buyers, issuing an RFQ for brown porcelain insulators allows for comparison of pricing, terms, and conditions, ensuring that they receive the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping, specifying who bears the costs and risks at various stages of the transportation process. Familiarity with these terms is essential for B2B buyers to understand shipping logistics and ensure that their orders are delivered efficiently and without unexpected costs. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Understanding lead times is critical for project planning and inventory management, enabling buyers to synchronize their supply chains effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and ensure the reliability of their electrical systems.

Navigating Market Dynamics and Sourcing Trends in the brown porcelain insulator Sector

What are the Key Market Drivers and Trends Influencing the Brown Porcelain Insulator Sector?

The global market for brown porcelain insulators is currently experiencing notable growth, driven by increasing demand from various industries, including telecommunications and electrical utilities. As countries across Africa, South America, the Middle East, and Europe continue to invest in infrastructure development, the need for reliable insulation solutions has surged. Emerging technologies, such as smart grid systems and renewable energy sources, are pushing the demand for high-quality insulators that can withstand extreme weather conditions and provide long-term durability.

In addition to traditional applications, the rise of digitalization has led to the adoption of advanced manufacturing techniques, such as 3D printing and automation, which enhance the efficiency of production processes. This shift allows manufacturers to offer customizable solutions that meet specific client requirements, thereby appealing to international B2B buyers seeking tailored products. Furthermore, the market is witnessing a trend towards vintage and collectible insulators, particularly among enthusiasts and collectors, which may open new avenues for niche market development.

How are Sustainability and Ethical Sourcing Practices Shaping the Brown Porcelain Insulator Industry?

The environmental impact of manufacturing processes is becoming increasingly important to B2B buyers in the brown porcelain insulator sector. Companies are now prioritizing sustainability by sourcing raw materials responsibly and minimizing waste during production. The use of eco-friendly materials and processes not only reduces the carbon footprint but also enhances the brand image among environmentally conscious consumers.

Ethical supply chains are gaining traction as businesses recognize the importance of transparency and social responsibility. Certifications such as ISO 14001 for environmental management and Fair Trade practices are becoming vital for suppliers aiming to appeal to international buyers. These certifications assure customers that the products they source are made with consideration for environmental and social governance. As such, suppliers who prioritize sustainability are more likely to gain a competitive edge in the market.

What Historical Context Should B2B Buyers Consider in the Brown Porcelain Insulator Market?

The evolution of brown porcelain insulators dates back to the late 19th century when their unique properties, such as resistance to high voltages and durability, made them essential in the electrical industry. Initially, insulators were predominantly white or light-colored; however, the introduction of brown glazes was a strategic shift aimed at reducing vandalism and increasing the longevity of installations. The early 20th century saw significant advancements in manufacturing techniques, which allowed for mass production and standardization of these insulators, making them more accessible to utility companies worldwide.

As the market has evolved, so too have the designs and applications of brown porcelain insulators, which now cater to both functional and aesthetic needs. Today, collectors and businesses alike value unique characteristics, such as color variations and historical markings, further influencing market dynamics. Understanding this historical context can provide B2B buyers with insights into product quality, market value, and potential sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of brown porcelain insulator

-

How do I select the right brown porcelain insulator for my project?

Choosing the right brown porcelain insulator involves understanding your specific application needs, such as voltage requirements, environmental conditions, and mechanical strength. Look for insulators that meet or exceed industry standards for electrical insulation and mechanical performance. Additionally, consider the insulator’s design features, such as shape and size, to ensure compatibility with your existing infrastructure. Consulting with manufacturers or industry experts can provide insights into the best options available based on your geographical and operational context. -

What are the key benefits of using brown porcelain insulators in electrical applications?

Brown porcelain insulators offer several advantages, including excellent electrical insulation properties, high mechanical strength, and resistance to environmental factors such as UV radiation and moisture. Their durability makes them suitable for outdoor applications, ensuring long-lasting performance even in harsh conditions. The brown color also helps reduce visibility against the backdrop of utility poles, which can deter vandalism and improve aesthetics. Furthermore, porcelain is less prone to degradation compared to other materials, providing a reliable solution for electrical systems. -

What should I consider when vetting suppliers for brown porcelain insulators?

When vetting suppliers, assess their industry experience, reputation, and certification standards. Look for manufacturers with ISO certifications or compliance with relevant international quality standards. Request samples to evaluate product quality and consistency. Additionally, consider their production capacity, lead times, and ability to meet your specific requirements. Checking customer reviews and testimonials can also provide insights into their reliability and service quality. Establishing clear communication channels is essential for a successful partnership. -

What is the minimum order quantity (MOQ) for brown porcelain insulators?

Minimum order quantities for brown porcelain insulators can vary significantly based on the supplier and the specifics of your order. Some manufacturers may have a MOQ of as low as 100 units for standard products, while custom or specialized insulators may require higher quantities. It’s essential to discuss your needs with potential suppliers to understand their MOQ policies and negotiate terms that fit your project requirements. Keep in mind that larger orders can often lead to better pricing and reduced shipping costs. -

Can I customize brown porcelain insulators for my specific needs?

Yes, many manufacturers offer customization options for brown porcelain insulators. Customizations can include variations in size, shape, color, and marking options. When seeking customized solutions, provide detailed specifications and discuss your requirements with the supplier’s engineering team. They can guide you through the design process and ensure that the final product meets your operational needs. Custom orders may have longer lead times, so plan accordingly to avoid project delays. -

What payment terms should I expect when ordering brown porcelain insulators internationally?

Payment terms for international orders can vary widely depending on the supplier and the specific terms of your agreement. Common payment methods include bank transfers, letters of credit, or payment through secure online platforms. Many suppliers may require a deposit upfront, typically ranging from 30% to 50%, with the balance due before shipment. Always ensure that the payment terms are clearly defined in the purchase agreement to avoid misunderstandings. Consider discussing terms that offer protection for both parties, especially for larger orders. -

How do I ensure quality assurance for my brown porcelain insulator order?

To ensure quality assurance, request detailed product specifications and compliance certifications from your supplier. It’s advisable to conduct factory audits or inspections, if possible, to evaluate the manufacturing processes and quality control measures in place. Additionally, ask for samples prior to placing a bulk order to assess the quality of the insulators. Establishing a clear agreement on quality standards and testing methods can also help mitigate risks and ensure that the final products meet your expectations. -

What logistics considerations should I keep in mind when importing brown porcelain insulators?

When importing brown porcelain insulators, consider factors such as shipping methods, customs regulations, and import duties. Choose a reliable logistics partner experienced in handling industrial goods to ensure timely delivery. Understand the shipping costs associated with your order, including freight, insurance, and handling fees. Additionally, ensure that your supplier provides all necessary documentation for customs clearance. Being proactive in planning logistics will help prevent delays and additional costs during the import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Brown Porcelain Insulator Manufacturers & Suppliers List

1. Etsy – Brown Porcelain Insulators

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Brown Porcelain Insulator, available in various listings including vintage telephone insulators, antique glass insulators, and brown porcelain spool insulators. Prices range from $11.25 to $59.99, with some items offering free shipping. Items ship from the United States and typically arrive within 7 days. Some listings include discounts, such as a 25% off sale on a vintage brown porcelain double p…

2. The Gentleman’s Stache – Vintage Brown Ceramic Insulator

Domain: thegentlemansstache.com

Registered: 2017 (8 years)

Introduction: {“name”: “Vintage Brown Ceramic Insulator”, “price”: “$12.99”, “quantity_available”: “Only 1 left!”, “dimensions”: “3 1/2″ x 4” x 2 3/4″”, “condition”: “Found item, sold as is”, “unique”: “Each item is truly unique and one of a kind.”}

3. Non RiverRat Antiques – Vintage 1950s Ceramic High Voltage Insulator

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Vintage 1950s Large Ceramic Electrical High Voltage Insulator with Brown Porcelain Glaze. Era: 1940-50s. Marked: Non RiverRat Antiques. Large industrial high voltage ceramic insulator from the 1950s, typically seen on top of power poles.

4. Collectors Weekly – Brown Porcelain Insulators

Domain: collectorsweekly.com

Registered: 2007 (18 years)

Introduction: Brown porcelain insulators were developed in the 1850s and 1860s, initially as threadless pieces made by local potteries. They saw minimal use for telephone or telegraph lines after threaded glass insulators became available, as glass was cheaper and discouraged insect nesting. With the rise of electric power distribution in the 1880s, porcelain insulators became necessary for higher voltages. Fre…

5. Insulators.info – Porcelain Insulators

Domain: insulators.info

Introduction: Porcelain insulators are available in various colors: True Black (Quite Rare), Dark and mottled brown (Common), Chocolate Brown (Common and typically more modern), Cobalt Blue (less common), Blue (many variations), Light Blue (sky blue to robins egg blue), Green (many variations including Olive, grass green, teal, turquoise), Yellow (mustard yellow, pastel yellow, canary yellow), Butterscotch, Gra…

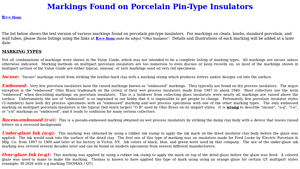

6. R-Infinity – Porcelain Insulator Markings

Domain: r-infinity.com

Registered: 1999 (26 years)

Introduction: Markings on Porcelain Insulators include various types such as Incuse, Embossed, Recess-embossed (r-e), Under-glaze Ink (u-g), Over-glaze Ink (o-g), and Sand-blast (s-b). Notable companies and their markings include: Akron High-Pontential Porcelain Co. (1903-07), American Electric Co. Inc. (U-188 circa 1929-1951), Automatic Electric Co. Inc. (original U-188 circa 1925-1929), Brown, Boveri & Co. (1…

7. Roaring Creek Pallet Crate – 6 Brown Porcelain Insulators

Domain: bonanza.com

Registered: 1997 (28 years)

Introduction: {“item_name”:”6 Brown Porcelain Insulators”,”price”:”$39.99″,”shipping”:”Free via USPS Priority Mail (2 to 3 business days) to United States”,”condition”:”Used”,”material”:”Porcelain”,”country_of_manufacture”:”United States”,”seller”:”roaringcreekpalletcratec0″,”seller_rating”:”5.0 stars average user feedback (39 transactions)”,”return_policy”:”None: All purchases final”,”purchase_protection”:”Bon…

8. Srithai Superware – Vintage Ceramic Insulators

Domain: srithaisuperware.com

Registered: 1998 (27 years)

Introduction: This company, Srithai Superware – Vintage Ceramic Insulators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for brown porcelain insulator

What Are the Key Takeaways for B2B Buyers of Brown Porcelain Insulators?

In conclusion, the strategic sourcing of brown porcelain insulators presents significant opportunities for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. Understanding the various types, styles, and historical significance of these insulators enables buyers to make informed procurement decisions that align with their specific needs. Key considerations include the rarity of certain colors and markings, which can enhance the value of insulators as both functional and collectible items.

How Does Strategic Sourcing Enhance Procurement Efficiency?

Emphasizing strategic sourcing not only improves cost-efficiency but also ensures the procurement of high-quality materials that meet industry standards. Establishing reliable supplier relationships can facilitate access to unique products while fostering innovation in utility applications. Buyers are encouraged to leverage digital platforms and trade networks to connect with reputable manufacturers and distributors.

What’s Next for International B2B Buyers?

As the demand for brown porcelain insulators continues to grow, now is the time for international B2B buyers to explore new partnerships and investment opportunities. By staying informed about market trends and product developments, businesses can position themselves advantageously in a competitive landscape. Take action today—evaluate your sourcing strategies and engage with suppliers to secure the best solutions for your operational needs.