Top 2 Bale Shoes Suppliers (And How to Choose)

Introduction: Navigating the Global Market for bale shoes

Navigating the global market for bale shoes can be a complex endeavor for B2B buyers, particularly when sourcing high-quality footwear that meets specific industry standards. The challenge lies not only in identifying reliable suppliers but also in ensuring that the products fulfill safety and comfort requirements across diverse applications, from construction to hospitality. This guide offers a comprehensive overview of the bale shoe market, exploring various types of footwear, their applications, and essential criteria for supplier vetting.

By diving into key aspects such as material quality, safety certifications, and pricing structures, this guide empowers international buyers, especially those operating in Africa, South America, the Middle East, and Europe, including regions like Nigeria and Saudi Arabia. With actionable insights and expert recommendations, you can make informed purchasing decisions that align with your business needs. From understanding the nuances of different bale shoe styles to evaluating the long-term value of your investment, this guide serves as a crucial resource in your sourcing journey.

As you navigate the complexities of the footwear market, our aim is to equip you with the knowledge necessary to select the right products that enhance your brand’s reputation and meet your customers’ expectations.

Understanding bale shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Safety Boots | Steel toe, composite midsole, heat-resistant, slip-resistant | Construction, mining, utilities | Pros: High protection, durable materials. Cons: Heavier than regular footwear. |

| Casual Bale Shoes | Lightweight, stylish designs, often made from leather | Retail, hospitality, corporate settings | Pros: Versatile, comfortable for everyday wear. Cons: Less protective than safety models. |

| Performance Footwear | Advanced cushioning, moisture-wicking, designed for agility | Sports, outdoor activities, logistics | Pros: Enhanced comfort and support. Cons: May not meet safety standards for all industries. |

| Formal Brogues | Premium leather, Goodyear welted, classic styling | Corporate events, formal occasions | Pros: Elegant appearance, durable construction. Cons: Limited functionality for rugged use. |

| Waterproof Boots | Sealed seams, breathable membranes, non-slip soles | Agriculture, outdoor work, emergency services | Pros: Keeps feet dry, suitable for wet environments. Cons: Can be pricier than standard boots. |

What Are the Key Characteristics of Safety Boots for B2B Buyers?

Safety boots are essential for industries such as construction and mining, where foot protection is paramount. These boots typically feature a steel toe cap and composite midsole for enhanced safety against heavy objects and punctures. Their heat and slip-resistant properties make them suitable for hazardous environments. When purchasing, buyers should consider compliance with safety regulations, comfort for prolonged wear, and the durability of materials used.

How Do Casual Bale Shoes Fit into B2B Applications?

Casual bale shoes are designed for comfort and style, making them a popular choice in retail and hospitality sectors. Often crafted from high-quality leather, these shoes combine functionality with a modern aesthetic. Buyers should focus on the versatility of the designs, ease of maintenance, and overall comfort for staff who may be on their feet for extended periods. While they may lack the protective features of safety boots, they serve well in non-hazardous environments.

What Makes Performance Footwear Ideal for Specific Industries?

Performance footwear is engineered for agility and comfort, making them ideal for sports and logistics sectors. These shoes often incorporate advanced cushioning and moisture-wicking materials, enhancing wearer comfort during physical activities. When considering these products, B2B buyers should assess the specific needs of their workforce, such as the level of activity and duration of wear. However, it’s crucial to note that they may not meet safety standards required in high-risk environments.

Why Should Businesses Consider Formal Brogues for Corporate Events?

Formal brogues are a staple in corporate fashion, characterized by their premium leather construction and classic design. These shoes are well-suited for corporate events and formal occasions, providing an elegant appearance. B2B buyers should evaluate the craftsmanship and comfort of these shoes, as well as their longevity. However, they may not be suitable for rugged or outdoor use, which limits their application in more physically demanding environments.

How Do Waterproof Boots Benefit Industries Working in Challenging Environments?

Waterproof boots are indispensable for industries such as agriculture and emergency services, where wet conditions are common. These boots feature sealed seams and breathable membranes to keep feet dry while providing comfort and support. Buyers should consider the level of waterproofing, slip resistance, and ease of cleaning when making a purchase. While they may carry a higher price tag, their functionality in adverse conditions makes them a worthwhile investment for businesses operating in challenging environments.

Key Industrial Applications of bale shoes

| Industry/Sector | Specific Application of bale shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Fieldwork and farming operations | Enhanced foot protection and comfort in rugged environments | Durability, slip resistance, and water repellency are crucial features. |

| Construction | Heavy-duty construction sites | Safety compliance with steel toe and slip-resistant features | Certifications (e.g., EN ISO 20345) and local regulations must be met. |

| Mining | Underground and surface mining | Robust protection against hazardous conditions | Need for heat resistance and anti-static properties in footwear. |

| Utilities | Maintenance and repair work | Protection from electrical hazards and chemicals | Look for features like anti-static and fuel oil resistance. |

| Rail and Transport | Railway maintenance and logistics | Safety and durability for prolonged use | Importance of comfort for extended wear and compatibility with safety gear. |

How are bale shoes utilized in agriculture, and what benefits do they provide?

In the agricultural sector, bale shoes are essential for fieldwork and farming operations. They provide enhanced foot protection against sharp objects, uneven terrain, and adverse weather conditions. The rugged design and slip-resistant soles ensure that workers can navigate wet and muddy fields safely. For international buyers, especially in regions like Africa and South America, sourcing durable and water-repellent footwear is critical due to the variable climates and working conditions. Additionally, the emphasis on comfort during long hours in the field cannot be overstated.

What role do bale shoes play in construction, and what should buyers consider?

Within the construction industry, bale shoes are invaluable on heavy-duty job sites where safety is paramount. These shoes typically feature steel toe caps and slip-resistant outsoles, ensuring compliance with safety regulations. For B2B buyers, especially in regions like the Middle East and Europe, it’s essential to verify that the shoes meet specific certifications, such as EN ISO 20345. Moreover, considering local regulations and potential climatic conditions can influence the choice of materials and designs, ensuring that the footwear can withstand harsh working environments.

Why are bale shoes critical in mining operations?

In mining, both underground and surface, the use of bale shoes is crucial due to the hazardous working conditions. These shoes are designed to offer robust protection against falling objects, sharp rocks, and extreme temperatures. Buyers in the mining industry must prioritize heat resistance and anti-static properties when sourcing footwear, as these features significantly enhance safety. Additionally, the durability of materials used is vital, given the rugged nature of mining environments, particularly in regions like Africa where mining activities are prevalent.

How do bale shoes benefit utility workers?

Utility workers often face diverse challenges, including exposure to electrical hazards and harsh chemicals. Bale shoes designed for this sector typically include anti-static features and are resistant to fuel oils and other corrosive substances. For B2B buyers, sourcing footwear that meets safety standards while providing comfort for long hours is essential. In regions like Saudi Arabia, where utility work can involve extreme heat, selecting breathable and lightweight materials can further enhance worker safety and comfort.

What are the benefits of bale shoes in rail and transport sectors?

In the rail and transport sectors, bale shoes are used extensively for railway maintenance and logistics operations. These shoes must provide both safety and durability, ensuring that workers can perform their tasks effectively over long periods. B2B buyers should focus on sourcing shoes that offer comfort for extended wear, as well as compatibility with other safety gear. Given the nature of rail work, features such as slip resistance and overall robustness are critical, especially in regions where weather conditions can vary significantly.

3 Common User Pain Points for ‘bale shoes’ & Their Solutions

Scenario 1: Sourcing Durable Bale Shoes for Harsh Environments

The Problem: B2B buyers in sectors like construction, agriculture, or mining often face the challenge of sourcing footwear that can withstand harsh conditions. These environments demand shoes that not only provide safety features such as steel toecaps and slip resistance but also durability to endure wear and tear. Buyers may struggle with finding bale shoes that meet industry standards while also being cost-effective, especially when dealing with fluctuating supply chains or varying local market availability.

The Solution: To overcome this sourcing challenge, it is crucial for buyers to establish relationships with reputable suppliers who specialize in industrial-grade footwear. Prioritize suppliers that can provide detailed product specifications, including compliance with safety standards like EN ISO 20345:2011. Engage in direct communication with manufacturers to understand the material quality and durability features of the bale shoes. Conduct site visits or request samples to assess the footwear’s performance in real-world conditions. Additionally, consider bulk purchasing agreements that can lock in prices and ensure a steady supply, mitigating issues related to fluctuating availability.

Scenario 2: Ensuring Proper Fit and Comfort in Diverse Workforces

The Problem: A significant pain point for B2B buyers is ensuring that the bale shoes they purchase fit a diverse range of employees. With variations in foot size, shape, and the specific needs of different job roles, finding a universal fit can be problematic. Poorly fitting shoes can lead to discomfort, decreased productivity, and even safety risks on the job.

The Solution: To address fit and comfort, buyers should invest in comprehensive size guides and fitting services when selecting bale shoes. Collaborate with suppliers that offer a wide range of sizes and widths, including options for narrow and wide fittings. Consider implementing a fitting day where employees can try on different models and sizes before making a bulk order. Additionally, providing a flexible return policy for sizes that do not fit can reduce the risk of dissatisfaction. Offering comfort features like cushioned insoles or moisture-wicking materials can also enhance employee satisfaction and productivity.

Scenario 3: Navigating Trends and Seasonal Demand Fluctuations

The Problem: B2B buyers often encounter the challenge of adapting to fashion trends and seasonal demand fluctuations in the bale shoe market. As trends evolve, buyers may find themselves with excess inventory of styles that are no longer in demand, leading to financial losses and storage issues. Conversely, they may struggle to meet sudden spikes in demand for trendy designs or seasonal footwear.

The Solution: To effectively navigate these market dynamics, buyers should adopt a proactive inventory management strategy. Utilize data analytics to forecast demand based on historical sales trends and current market insights. Establish partnerships with suppliers that offer flexible ordering options, allowing for smaller, more frequent orders that align with market trends. Additionally, consider diversifying the product range to include both classic and trendy styles, ensuring that there is always a mix available to meet varying customer preferences. Engaging in marketing efforts that highlight the versatility of bale shoes can also help drive sales during off-peak seasons.

Strategic Material Selection Guide for bale shoes

What Are the Key Materials Used in Bale Shoes and Their Properties?

When selecting materials for bale shoes, it’s essential to consider their performance characteristics, durability, and suitability for various applications. Here, we analyze four common materials used in the production of bale shoes, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Leather Perform as a Material for Bale Shoes?

Leather, particularly full-grain leather, is a popular choice for bale shoes due to its durability and comfort. It offers excellent breathability and flexibility, making it suitable for prolonged wear. Leather can withstand moderate temperature variations and provides a degree of water resistance, especially when treated with appropriate coatings.

Pros: Leather is highly durable and can last for years if properly maintained. It also offers a premium aesthetic appeal, which is important for brands targeting high-end markets.

Cons: The cost of high-quality leather can be significant, making it less suitable for budget-conscious buyers. Additionally, leather requires regular maintenance to preserve its properties, which may add to the total cost of ownership.

Impact on Application: Leather is ideal for environments where comfort and style are essential, such as in corporate settings or upscale retail. However, it may not perform well in extreme wet or humid conditions without proper treatment.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial, especially in markets that prioritize safety footwear. Buyers from regions like Africa and the Middle East may also prefer leather for its cultural significance and durability.

What Role Does Rubber Play in the Manufacturing of Bale Shoes?

Rubber is often used for outsoles due to its excellent slip resistance and durability. It can withstand various environmental conditions, including heat and moisture, making it suitable for diverse applications.

Pros: Rubber outsoles provide superior traction and are resistant to oil and chemicals, enhancing safety in industrial settings. They are also relatively low in cost compared to other materials.

Cons: While rubber is durable, it can degrade over time when exposed to UV light, leading to potential performance issues. Additionally, rubber soles may not offer the same level of comfort as leather or synthetic alternatives.

Impact on Application: Rubber is particularly effective in construction, agriculture, and other industries where slip resistance is critical. Its properties make it suitable for outdoor applications, but it may not be the best choice for formal or office environments.

Considerations for International Buyers: Buyers should ensure that the rubber used complies with local safety standards, especially in regions like Europe, where regulations are stringent. Understanding the specific rubber grades and their performance characteristics is vital for ensuring product reliability.

How Do Synthetic Materials Enhance Bale Shoe Performance?

Synthetic materials, such as EVA (ethylene-vinyl acetate) and PU (polyurethane), are increasingly popular in the production of bale shoes. These materials are lightweight, flexible, and often provide enhanced cushioning.

Pros: Synthetics can be engineered for specific performance traits, such as moisture-wicking or enhanced breathability. They are generally less expensive than natural materials and can reduce manufacturing complexity.

Cons: While synthetic materials are often more affordable, they may not offer the same durability as leather or rubber. Additionally, some synthetic options can be less environmentally friendly, which may be a concern for eco-conscious buyers.

Impact on Application: Synthetic materials are ideal for casual or athletic footwear, where comfort and weight are prioritized. However, they may not be suitable for high-end markets that demand premium materials.

Considerations for International Buyers: Buyers should be aware of the environmental impact of synthetic materials and seek products that adhere to sustainability standards. Compliance with international certifications for synthetic materials is also essential.

What Are the Benefits of Composite Materials in Bale Shoes?

Composite materials, which may include combinations of leather, rubber, and synthetics, are increasingly used in bale shoe manufacturing. These materials aim to combine the best properties of each component.

Pros: Composite materials can provide a balance of durability, comfort, and cost-effectiveness. They can also be designed to meet specific performance criteria, such as waterproofing or enhanced breathability.

Cons: The complexity of manufacturing composite materials can lead to higher production costs. Additionally, the performance may vary depending on the specific combination of materials used.

Impact on Application: Composite materials are versatile and can be tailored for various applications, from industrial to casual wear. Their adaptability makes them suitable for a wide range of environments.

Considerations for International Buyers: Understanding the specific properties of composite materials is crucial for ensuring compliance with safety standards. Buyers should also consider regional preferences for materials when selecting products.

Summary of Material Selection for Bale Shoes

| Material | Typical Use Case for bale shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Corporate and upscale retail | High durability and comfort | Requires maintenance | High |

| Rubber | Industrial and outdoor settings | Excellent slip resistance | Degrades under UV exposure | Medium |

| Synthetic | Casual and athletic footwear | Lightweight and cost-effective | Less durable than natural materials | Low |

| Composite | Versatile applications | Balanced performance characteristics | Higher production complexity | Medium |

This strategic material selection guide provides insights into the properties and considerations of various materials used in bale shoes, helping international B2B buyers make informed decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for bale shoes

What Are the Main Stages of Manufacturing Bale Shoes?

The manufacturing process of bale shoes involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages can help B2B buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions when sourcing their footwear products.

Material Preparation: What Materials Are Used in Bale Shoe Manufacturing?

The first stage in the manufacturing process is material preparation. Bale shoes typically utilize high-quality materials such as waxy full-grain leather, which offers durability and water resistance. Other components include nitrile rubber for the outsoles, steel for protective toecaps, and aramid fiber for midsoles. Materials are often sourced from certified suppliers to ensure compliance with international quality standards.

Before production begins, materials undergo rigorous inspections. This includes checking for defects, verifying specifications, and assessing the environmental impact of the materials used. Suppliers should provide material certification, which can be crucial for B2B buyers concerned about sustainability and compliance with local regulations.

Forming: How Are Bale Shoes Shaped?

The forming stage involves creating the shoe’s structure through various techniques, such as cutting, molding, and stitching. Advanced technologies like CAD (Computer-Aided Design) are often employed to ensure precision in shaping and sizing.

Cutting machines are used to slice the leather and other materials into the required shapes, while molds help form the shoe’s upper and sole. Techniques like Goodyear welting are common, providing enhanced durability by stitching the upper to the sole. This method is particularly beneficial for heavy-duty footwear that must endure rigorous use in sectors like construction, agriculture, and mining.

Assembly: What Happens During the Assembly Process?

Once the components are prepared, the assembly stage begins. Skilled workers or automated systems bring together the upper, sole, and other elements. Quality craftsmanship is vital at this stage to ensure that all parts fit together seamlessly.

Assembly processes may also include the incorporation of additional features such as anti-static properties, slip resistance, and heat resistance. These attributes are essential for safety footwear used in hazardous environments. Proper assembly techniques ensure that these features function effectively, providing the necessary protection for end-users.

Finishing: How Is Quality Achieved in the Final Touches?

The finishing stage involves final touches that enhance both aesthetics and functionality. This includes polishing, adding protective coatings, and ensuring that all components are securely attached. Aesthetic elements like branding and labeling are also applied during this stage.

Finishing processes are crucial for ensuring that the shoes meet market expectations in terms of design and quality. B2B buyers should look for suppliers who have a robust finishing process, as this can significantly impact the overall quality of the final product.

What Quality Assurance Practices Should B2B Buyers Expect?

Quality assurance (QA) is essential in the manufacturing of bale shoes to meet both international and industry-specific standards. A comprehensive QA program can help ensure that the products delivered to B2B buyers are consistent and of high quality.

Which International Standards Are Relevant for Bale Shoe Manufacturing?

Bale shoe manufacturers typically adhere to several international standards. ISO 9001 is a widely recognized quality management standard that ensures consistent quality in products and services. For safety footwear, compliance with CE marking standards (European Conformity) is essential, indicating that the shoes meet EU safety, health, and environmental protection requirements.

Additionally, other standards, such as ASTM (American Society for Testing and Materials) and ANSI (American National Standards Institute), may apply, especially for specific industries. Manufacturers that comply with these standards demonstrate their commitment to quality and safety, which can be a selling point for B2B buyers.

What Are the Key Checkpoints in Quality Control?

Quality control (QC) in the manufacturing of bale shoes typically involves several checkpoints, including:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before production begins. Suppliers should provide documentation to confirm that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, random inspections ensure that each stage meets quality standards. This step helps catch defects early, reducing waste and rework.

-

Final Quality Control (FQC): Once production is complete, a thorough inspection of the finished products takes place. This includes checking for defects, verifying compliance with specifications, and ensuring that all safety features function correctly.

B2B buyers should inquire about the QC processes employed by potential suppliers, as robust QC can significantly reduce the risk of receiving subpar products.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control measures is crucial for B2B buyers, especially when sourcing from international markets. Here are several actionable steps that buyers can take:

What Audit Processes Should Be Considered?

Conducting regular audits of suppliers can provide insights into their manufacturing and QC processes. Audits can be carried out internally or by third-party organizations specializing in quality assurance. These audits should assess compliance with international standards, the effectiveness of QC processes, and overall operational efficiency.

What Documentation and Reporting Should Be Requested?

B2B buyers should request documentation related to quality control, including:

-

Quality Assurance Manuals: These documents outline the supplier’s quality management system and procedures.

-

Inspection Reports: Detailed reports from IQC, IPQC, and FQC processes can provide insights into the supplier’s QC practices.

-

Certification Copies: Copies of certifications demonstrating compliance with relevant standards (e.g., ISO, CE) can help verify the supplier’s commitment to quality.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection agencies can further enhance quality assurance. These agencies can perform independent checks on products before shipment, ensuring that they meet specified quality standards. This step is particularly valuable for B2B buyers who may not have the resources to conduct thorough inspections on their own.

What Nuances Should International Buyers Be Aware Of?

For international buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, several nuances can impact the procurement process.

How Do Cultural and Regulatory Differences Affect Sourcing?

Cultural differences can influence communication and business practices. Buyers should be aware of local customs and regulations that may affect product specifications, safety standards, and environmental compliance. Understanding these differences can facilitate smoother negotiations and reduce the risk of misunderstandings.

What Are the Considerations for Shipping and Logistics?

Shipping and logistics can present challenges for international buyers. It’s essential to understand the import/export regulations in both the supplier’s and buyer’s countries, including tariffs, duties, and compliance with local safety standards. Engaging with logistics partners who have experience in footwear can streamline the process and ensure timely delivery.

Conclusion

Understanding the manufacturing processes and quality assurance practices for bale shoes is vital for B2B buyers looking to source high-quality footwear. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control, buyers can ensure that they partner with suppliers who meet their standards. Additionally, being aware of international standards, conducting audits, and verifying QC processes can help mitigate risks associated with sourcing from diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bale shoes’

Introduction

Navigating the procurement of bale shoes can be complex, particularly for international B2B buyers. This guide provides a structured checklist to streamline your sourcing process, ensuring you select high-quality products that meet your business needs. By following these steps, you will enhance your purchasing decisions and foster strong supplier relationships.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is crucial for sourcing the right bale shoes. Consider aspects such as material, size range, safety standards, and specific features (e.g., waterproofing or slip resistance). This step ensures that suppliers can provide products that align with your operational demands and industry regulations.

Step 2: Research Market Trends and Demand

Understanding current market trends can significantly influence your sourcing strategy. Investigate the popularity of various styles, materials, and price points within your target regions (such as Africa and Europe). This insight helps you anticipate customer needs and positions your business competitively in the market.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request company profiles, product samples, and references from previous buyers, especially those in similar industries or regions. Look for suppliers with a proven track record of reliability and quality, as this can mitigate risks in your supply chain.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold necessary certifications relevant to your industry, such as ISO or safety standards. Valid certifications not only demonstrate a commitment to quality but also ensure compliance with local regulations, which is particularly important when sourcing from different continents.

Step 5: Assess Pricing and Terms of Sale

Compare pricing structures among various suppliers while considering terms of sale, such as payment options, minimum order quantities, and shipping costs. Understanding the total cost of ownership will help you make informed decisions that align with your budget and cash flow requirements.

Step 6: Request Samples and Conduct Quality Checks

Before finalizing any orders, request samples to assess the quality firsthand. Inspect materials, craftsmanship, and overall functionality to ensure they meet your specifications. Performing quality checks at this stage can prevent costly mistakes and ensure that you are satisfied with the products before large-scale procurement.

Step 7: Establish Clear Communication Channels

Effective communication is key to successful sourcing. Establish clear lines of communication with your chosen suppliers to facilitate ongoing dialogue regarding orders, delivery schedules, and any potential issues. Strong relationships built on transparency and responsiveness can lead to better pricing, service, and cooperation in the long run.

By adhering to this checklist, B2B buyers can ensure a more efficient and effective sourcing process for bale shoes, ultimately leading to better product offerings and enhanced customer satisfaction.

Comprehensive Cost and Pricing Analysis for bale shoes Sourcing

What Are the Key Cost Components in Bale Shoes Sourcing?

When analyzing the cost structure for sourcing bale shoes, several critical components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The quality of materials directly impacts cost. Bale shoes often utilize premium materials like full-grain leather and specialized rubber for durability. Sustainable materials, such as recycled polyester, are gaining traction, influencing both cost and market appeal.

-

Labor: Labor costs vary significantly based on the region of production. Countries with lower labor costs may offer cheaper options, but this can affect quality. Skilled labor is essential for the craftsmanship of high-end bale shoes, which may raise costs but also enhance product value.

-

Manufacturing Overhead: This includes fixed and variable costs associated with production facilities. Overhead can fluctuate based on local regulations, energy costs, and operational efficiency.

-

Tooling: Custom tooling for unique designs or specifications can add significant upfront costs but may be necessary for specialized orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the shoes meet international safety and quality standards. While this adds to costs, it is crucial for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs are influenced by distance, shipping methods, and Incoterms. Effective logistics planning can reduce costs, especially for international shipments.

-

Margin: The desired profit margin affects pricing strategies. Competitive markets may necessitate lower margins, while niche markets can sustain higher margins.

What Influences the Pricing of Bale Shoes in International Markets?

Several factors can influence the pricing of bale shoes, particularly for international B2B buyers. Understanding these can help buyers make informed purchasing decisions.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can vary by supplier. Larger orders often lead to reduced per-unit costs, making bulk purchases a cost-effective option.

-

Specifications and Customization: Custom specifications can elevate costs due to additional labor and materials. Buyers should assess whether customization aligns with their market needs.

-

Materials Quality and Certifications: Shoes made from high-quality or certified sustainable materials typically command higher prices. Buyers focused on eco-friendly products may need to balance cost with sustainability goals.

-

Supplier Factors: The supplier’s reputation, location, and manufacturing capabilities can significantly affect pricing. Established suppliers may offer higher reliability but at a premium.

-

Incoterms: Understanding Incoterms is crucial for managing shipping costs and responsibilities. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the overall pricing structure.

What Are Essential Buyer Tips for Sourcing Bale Shoes?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost efficiency and negotiation outcomes:

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and bulk discounts. Flexibility can lead to significant savings.

-

Evaluate Total Cost of Ownership: Beyond the initial purchase price, consider factors like durability, maintenance, and potential resale value. A higher-quality shoe may offer better long-term value.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in pricing, particularly for fashion-related products. Timing your orders can lead to better deals.

-

Conduct Supplier Audits: Assessing suppliers for quality assurance, production capabilities, and compliance with international standards can help mitigate risks associated with sourcing.

-

Stay Informed on Market Trends: Trends in fashion and sustainability can influence demand and pricing. Keeping abreast of these trends can inform better purchasing decisions.

Disclaimer on Indicative Prices

Pricing for bale shoes can vary widely based on the aforementioned factors and market conditions. The prices mentioned in various sources are indicative and may not reflect current or future market values. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for accurate pricing.

Alternatives Analysis: Comparing bale shoes With Other Solutions

Understanding Alternatives to Bale Shoes in Industrial Applications

In the realm of industrial footwear, ‘bale shoes’ are known for their durability and safety features. However, there are various alternatives that serve similar purposes across different sectors. Understanding these alternatives can empower B2B buyers to make informed decisions based on performance, cost, and suitability for specific environments.

Comparison Table

| Comparison Aspect | Bale Shoes | Safety Boots | Work Sneakers |

|---|---|---|---|

| Performance | High durability and protection | Excellent for heavy-duty tasks | Moderate protection |

| Cost | Moderate to high | Variable, often lower | Generally lower |

| Ease of Implementation | Ready for immediate use | Requires some break-in period | Often requires minimal break-in |

| Maintenance | Low maintenance, durable | Moderate, with regular cleaning | Low, but may require replacement sooner |

| Best Use Case | Construction, agriculture | Heavy industries, construction | Light to moderate industrial use |

Pros and Cons of Alternatives

Safety Boots

Safety boots are designed for high-risk environments, featuring reinforced toes and slip-resistant soles. They excel in construction and manufacturing settings, providing essential protection against heavy objects and hazardous conditions. However, they can be bulkier and may require a break-in period to achieve comfort. Cost-wise, they vary significantly based on brand and features, but they often present a lower initial investment compared to bale shoes.

Work Sneakers

Work sneakers are increasingly popular in environments that prioritize comfort without sacrificing safety. They are lighter and more flexible than traditional safety footwear, making them ideal for tasks that require prolonged standing or walking. While they offer moderate protection, they may not be suitable for high-risk environments where heavy impacts are a concern. Their lower cost makes them an attractive option for businesses looking to outfit a large workforce with comfortable footwear.

Conclusion: How to Choose the Right Footwear for Your Needs

When selecting footwear for industrial applications, B2B buyers should carefully consider the specific needs of their workforce and the nature of their operations. Bale shoes provide a robust solution for demanding environments, while safety boots cater to those requiring maximum protection. For less hazardous settings, work sneakers offer comfort and cost-effectiveness. Ultimately, the choice should align with the operational demands, safety standards, and budgetary constraints of the business, ensuring that employees are equipped with the most suitable footwear for their tasks.

Essential Technical Properties and Trade Terminology for bale shoes

What Are the Essential Technical Properties of Bale Shoes?

When sourcing bale shoes for industrial applications, understanding their technical specifications is crucial for ensuring quality and suitability for specific environments. Here are some key properties to consider:

1. Material Grade

Bale shoes are typically made from high-grade materials, such as waxy full-grain leather or nitrile rubber. The material grade influences durability, comfort, and protection levels. High-quality leather offers water resistance and breathability, while rubber outsoles provide slip resistance and longevity. For B2B buyers, choosing the right material grade ensures that the footwear can withstand the demands of various industries, such as construction or agriculture.

2. Protective Features

Bale shoes often incorporate protective elements such as steel toecaps and composite midsoles. These features are essential for safeguarding workers’ feet against heavy impacts, punctures, and electrical hazards. Understanding the level of protection (e.g., EN ISO 20345:2011 S3 certification) helps businesses comply with safety regulations and protect their workforce, which can reduce liability and insurance costs.

3. Weight and Comfort

The weight of the shoes, usually measured in grams, can significantly affect comfort during prolonged wear. For example, a typical bale shoe may weigh around 1075 grams. Lighter footwear can enhance mobility and reduce fatigue, making it suitable for tasks requiring extended periods of standing or walking. B2B buyers should consider the balance between weight and protective features to optimize employee comfort and productivity.

4. Slip Resistance Rating

A slip resistance rating, often classified as SRC (the highest level), indicates the shoe’s grip on various surfaces. This is particularly important in environments where spills or wet conditions are common. Ensuring that the footwear meets slip resistance standards helps prevent workplace accidents, enhancing safety and operational efficiency.

5. Size Range and Fit

Bale shoes come in various sizes, often ranging from UK size 6 to 13. Understanding the available size range and fit options (e.g., narrow, regular, wide) is vital for ensuring that all employees can find suitable footwear. Poorly fitting shoes can lead to discomfort and injury, which can negatively impact productivity and increase absenteeism.

What Are Common Trade Terms Associated with Bale Shoes?

Familiarity with industry terminology can streamline the purchasing process and facilitate better communication between buyers and suppliers. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the bale shoe industry, buyers may source shoes from an OEM to leverage their manufacturing capabilities while branding the products as their own. Understanding OEM relationships can help businesses negotiate better prices and maintain quality control.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers to understand their purchasing limits and manage inventory effectively. Setting MOQs can help manufacturers ensure production efficiency, but it may require buyers to purchase more than they initially need.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to request pricing and other details for specific products. It allows businesses to compare offers from multiple suppliers, ensuring they receive the best value for their investment in bale shoes.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. They outline who is responsible for shipping costs, insurance, and risk during transportation. Understanding Incoterms helps B2B buyers navigate global trade logistics and avoid unexpected costs or delays.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Knowing the lead time is crucial for planning inventory and ensuring that adequate stock is available to meet operational demands. B2B buyers should always inquire about lead times when placing orders to avoid disruptions.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, optimize their procurement processes, and ensure compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the bale shoes Sector

What Are the Current Market Dynamics and Key Trends in the Bale Shoes Sector?

The global bale shoes market is witnessing significant growth driven by several factors, including increased consumer awareness about comfort and durability, a rising preference for multifunctional footwear, and the expansion of e-commerce platforms. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek high-quality footwear, brands are adapting to meet these demands. The trend of customization is becoming prominent, with manufacturers offering tailored solutions to fit specific needs, such as size variations and design preferences.

Technological advancements in manufacturing processes, including 3D printing and automated production lines, are also reshaping the industry. These technologies not only streamline operations but also enhance product quality and reduce lead times. Moreover, the integration of artificial intelligence in supply chain management is enabling companies to predict trends and manage inventory more effectively, ensuring that they can respond swiftly to market changes.

Additionally, the growing popularity of online marketplaces is transforming how buyers source products. B2B buyers can now easily compare prices, read reviews, and access detailed product specifications from the comfort of their offices, making informed purchasing decisions simpler than ever. This shift toward digital sourcing necessitates that suppliers maintain a robust online presence and invest in digital marketing strategies to reach potential clients effectively.

How Is Sustainability and Ethical Sourcing Impacting the Bale Shoes Sector?

Sustainability has become a critical consideration in the bale shoes sector, as both consumers and businesses increasingly prioritize environmentally friendly practices. The footwear industry is known for its substantial environmental impact, from resource extraction to manufacturing waste. B2B buyers are now seeking suppliers that demonstrate a commitment to sustainable practices, which can include the use of recycled materials, energy-efficient manufacturing processes, and eco-friendly packaging.

Ethical sourcing is equally important, as buyers are more aware of the social implications of their purchases. Companies that prioritize fair labor practices and transparency in their supply chains are more likely to attract international buyers. Certifications such as Fair Trade, Global Organic Textile Standard (GOTS), and Forest Stewardship Council (FSC) can enhance a brand’s reputation and provide assurance to buyers about the ethical standards of their sourcing practices.

In the bale shoes market, materials such as waxy full-grain leather certified by the Leather Working Group (LWG) and recycled polyester are gaining traction. These materials not only reduce the environmental footprint but also appeal to a growing segment of eco-conscious consumers. As a result, incorporating sustainability into product offerings is no longer just a trend but a necessity for companies aiming to thrive in the competitive B2B landscape.

What Is the Evolution and Historical Context of Bale Shoes?

The evolution of bale shoes is rooted in their practical applications across various industries, including agriculture, construction, and engineering. Traditionally designed for durability and protection, these shoes have adapted over the years to accommodate changing consumer preferences and technological advancements. The introduction of features such as steel toe caps, slip-resistant soles, and waterproof materials has enhanced their functionality, making them a staple in safety footwear.

The historical significance of bale shoes also ties into craftsmanship and quality. Many brands have embraced traditional manufacturing techniques, such as Goodyear welting, which not only prolongs the life of the shoe but also adds to its comfort and style. As the market continues to evolve, the blend of traditional craftsmanship with modern innovation positions bale shoes as a versatile choice for B2B buyers seeking reliability and performance in their footwear.

Frequently Asked Questions (FAQs) for B2B Buyers of bale shoes

-

How do I choose the right bale shoes for my business needs?

When selecting bale shoes for your business, consider the specific requirements of your industry, such as durability, safety ratings, and comfort. Look for features like steel toe caps, slip resistance, and waterproof materials, which are essential for environments like construction or agriculture. Additionally, evaluate the shoe’s weight and breathability, as these factors impact worker comfort during long shifts. It’s also wise to review the supplier’s product specifications and certifications to ensure compliance with safety standards. -

What are the key features of high-quality bale shoes?

High-quality bale shoes should include several critical features. Look for materials such as waxy full-grain leather for durability and comfort. A robust outsole, like Goodyear welted nitrile rubber, provides excellent grip and longevity. Safety features, including steel toe caps and composite midsoles, are essential for protecting workers in hazardous environments. Additionally, consider sustainability aspects, such as recycled materials and environmentally friendly packaging, which can enhance your company’s reputation. -

What should I consider when vetting suppliers of bale shoes?

When vetting suppliers, assess their reputation and experience in the industry. Check for certifications related to quality and safety standards, such as ISO or EN ratings. Request samples to evaluate product quality firsthand and inquire about their production capabilities, lead times, and minimum order quantities (MOQs). Additionally, establish clear communication regarding pricing, payment terms, and after-sales support. It’s beneficial to seek references from other B2B clients to gauge their reliability and service quality. -

How can I customize bale shoes for my brand?

Many suppliers offer customization options for bale shoes, including branding with your logo, color choices, and specific design features. Start by discussing your requirements with potential suppliers and ask for their customization capabilities. Ensure that they can meet your quality standards while accommodating your design preferences. Keep in mind that customization may affect lead times and minimum order quantities, so plan accordingly to align with your marketing strategies. -

What are typical payment terms when sourcing bale shoes internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (usually 30-50%) with the balance due before shipment or upon delivery. It’s essential to clarify terms such as payment methods (e.g., bank transfer, credit card, or letters of credit) and any applicable foreign exchange fees. Consider negotiating terms that align with your cash flow needs and ensure that you have a clear understanding of any penalties for late payments. -

What are the logistics considerations for importing bale shoes?

Logistics play a crucial role in the successful importation of bale shoes. Assess shipping options, including air freight for faster delivery or sea freight for cost savings. Evaluate potential tariffs and customs duties applicable to your region, as these can significantly impact overall costs. Work with a reliable freight forwarder who understands the complexities of international trade to ensure compliance with regulations and smooth delivery processes. -

How do I ensure quality assurance for the bale shoes I purchase?

To ensure quality assurance, establish clear quality standards and specifications with your supplier before production begins. Request regular updates and samples during the manufacturing process to verify compliance with your requirements. Conduct inspections upon receipt of the goods, either in-house or through a third-party inspection service, to identify any defects or discrepancies. Consider implementing a return policy for defective items to safeguard your investment. -

What are the common uses of bale shoes in different industries?

Bale shoes are versatile and commonly used across various industries, including construction, agriculture, and manufacturing. In construction, they provide essential safety features, such as steel toe caps and slip-resistant soles, to protect workers from heavy objects and hazardous conditions. In agriculture, bale shoes offer durability and comfort for long hours in the field. Additionally, industries like mining and utilities benefit from specialized designs that meet specific safety and environmental regulations. Understanding these applications can help you select the right products for your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Bale Shoes Manufacturers & Suppliers List

1. Bale Shoes – Stylish Footwear for All Ages

Domain: baleshoes.com

Registered: 2017 (8 years)

Introduction: Categories: Women, Men, Kids, Bags & Accessories, Shoe Care Products. Women Shoe Categories: Classic Shoes, Stiletto Sneakers, Babet and Linen Sandals, Slipper Boots. Men Shoe Categories: Casual Shoes, Classic Shoes, Sneakers, Slipper, Sandals, Boots. Kids Categories: Baby Boy (19-25), Girl, Male Booties Length (26-30), Girl, Male Filet Size (31-36), Girl, Male. Key Products: MERRELL MORPHAXISK 01…

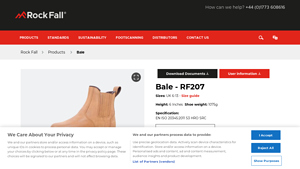

2. Rock Fall – Bale Safety Footwear

Domain: rockfall.com

Registered: 2002 (23 years)

Introduction: {“Product Name”: “Bale”, “Brand”: “Rock Fall Safety Footwear”, “Model”: “RF207”, “Sizes”: “UK 6-13”, “Height”: “6 Inches”, “Weight”: “1075g”, “Safety Standards”: “EN ISO 20345:2011 S3 HRO SRC”, “Upper Material”: “Waxy, full grain LWG certified leather”, “Webbing and Trims”: “Leather pull on loops, Leather covered polyester and EPR elastic”, “Thread”: “Nylon”, “Collar and Heel Binding”: “PU”, “Foot…

Strategic Sourcing Conclusion and Outlook for bale shoes

As the global market for bale shoes continues to evolve, strategic sourcing remains a pivotal aspect for international B2B buyers. The insights drawn from diverse suppliers, such as those from Europe, Africa, and the Middle East, highlight the importance of quality, durability, and compliance with safety standards. Investing in high-quality bale shoes, made from robust materials and featuring advanced safety technologies, can significantly enhance workforce productivity and safety.

Furthermore, understanding regional preferences and market trends can facilitate better alignment between suppliers and buyers, ensuring that the products meet local demands effectively. With competitive pricing and the availability of sustainable options, now is an opportune time for businesses to refine their sourcing strategies.

Looking ahead, B2B buyers are encouraged to leverage these insights to forge strategic partnerships with suppliers that prioritize quality and sustainability. This proactive approach will not only secure a reliable supply chain but also position businesses favorably in the competitive landscape. Engage with trusted suppliers today to explore innovative solutions that meet your operational needs and ensure your workforce is equipped with the best in bale footwear.