Dr Pepper Sizes: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for dr pepper sizes

As businesses expand into the global market, sourcing the right beverage products can be a daunting task, especially when it comes to navigating the various Dr Pepper sizes. Understanding the different packaging options—ranging from 12oz cans to 2-liter bottles—can significantly impact inventory management and customer satisfaction. This comprehensive guide delves into the various types and sizes of Dr Pepper available for international B2B buyers, highlighting their applications across diverse markets, including Africa, South America, the Middle East, and Europe, particularly in countries like Germany and Saudi Arabia.

In this guide, we will explore essential aspects such as supplier vetting processes, cost analysis, and market trends, empowering you to make informed purchasing decisions. By understanding the nuances of Dr Pepper sizes, you can better meet the demands of your clientele, optimize your supply chain, and ultimately enhance your business’s profitability. Each section is designed to equip you with actionable insights, ensuring that you can effectively cater to consumer preferences in your target markets. Whether you’re a distributor, retailer, or food service operator, this guide serves as a vital resource in your quest to deliver the beloved flavor of Dr Pepper to a global audience.

Understanding dr pepper sizes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 12oz Can | Standard serving size, widely recognized, convenient packaging | Retail, vending machines, restaurants | Pros: Popular choice; easy to stack. Cons: Limited volume for high-demand settings. |

| 16oz Bottle | Single-serve, portable, ideal for on-the-go consumption | Convenience stores, gas stations | Pros: Good for impulse purchases; portable. Cons: Higher price per ounce than larger sizes. |

| 2L Bottle | Family-sized, suitable for sharing, economical | Supermarkets, bulk sales | Pros: Cost-effective for families; less waste. Cons: Requires refrigeration; less portable. |

| 5-gallon Bag-in-Box | Large volume, ideal for commercial settings like restaurants | Restaurants, catering services | Pros: Cost-efficient for high-volume use; easy to dispense. Cons: Requires specialized equipment. |

| Fountain Dispenser | Customizable serving sizes, fresh taste, high demand | Fast food chains, cafes, events | Pros: Freshly dispensed; reduces packaging waste. Cons: Requires maintenance and setup costs. |

What Are the Key Characteristics of 12oz Cans for B2B Buyers?

The 12oz can is the quintessential size for soft drink distribution, recognized globally and favored for its convenience. This size is ideal for retail environments, vending machines, and restaurants, where quick and easy service is essential. Buyers should consider the high turnover rate and brand visibility associated with this size, though they may need to manage inventory levels closely due to varying demand.

How Do 16oz Bottles Serve the On-the-Go Market?

The 16oz bottle caters to consumers seeking portability and convenience, making it a popular choice for convenience stores and gas stations. This size is particularly advantageous for impulse purchases, as it is easy to grab while on the move. However, B2B buyers should be aware that the price per ounce is higher compared to larger formats, which could affect profit margins in bulk sales.

Why Choose 2L Bottles for Family and Bulk Sales?

The 2L bottle is designed for family consumption, making it a staple in supermarkets and bulk sales. It offers a cost-effective solution for families looking to purchase larger quantities, reducing the need for multiple smaller purchases. B2B buyers should consider the product’s refrigeration requirements and the potential for waste if not consumed quickly, but its value proposition often outweighs these concerns.

What Are the Benefits of Using 5-Gallon Bag-in-Box Systems?

The 5-gallon bag-in-box option is tailored for commercial applications, particularly in restaurants and catering services. This size allows for high-volume dispensing, making it cost-effective for establishments serving large numbers of customers. Buyers must consider the need for specialized dispensing equipment, but the reduction in packaging waste and lower cost per serving can significantly enhance profitability.

How Do Fountain Dispensers Enhance Customer Experience?

Fountain dispensers offer the flexibility of customizable serving sizes, making them an attractive choice for fast food chains and cafes. This format provides a fresh taste and reduces packaging waste, appealing to environmentally conscious consumers. However, B2B buyers should factor in the initial setup costs and ongoing maintenance needs, as these can impact overall profitability.

Key Industrial Applications of dr pepper sizes

| Industry/Sector | Specific Application of dr pepper sizes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Fast Food Chains using 12oz cans and fountain drinks | Enhanced customer experience with varied drink options | Consistent supply, packaging types, and pricing flexibility |

| Retail | Supermarkets stocking various bottle sizes | Increased sales through diverse product offerings | Supply chain efficiency, promotional strategies, and shelf life |

| Hospitality | Hotels providing mini-bar selections with 16oz bottles | Improved guest satisfaction and convenience | Quality assurance, packaging aesthetics, and distribution logistics |

| Events & Catering | Large events utilizing 5-gallon bag-in-box systems | Cost-effective beverage solutions for large gatherings | Bulk purchasing agreements, storage requirements, and delivery logistics |

| Vending | Vending machines offering various sizes | Maximizing consumer choice and sales opportunities | Machine compatibility, product rotation, and pricing strategies |

How Are Dr Pepper Sizes Utilized in the Food Service Industry?

In the food service sector, particularly within fast food chains, Dr Pepper is commonly offered in both 12oz cans and as a fountain drink. This versatility allows establishments to cater to diverse customer preferences while enhancing their beverage menu. Fast food operators benefit from increased customer satisfaction and repeat business, as patrons enjoy the ability to customize their meal experience. For international buyers, considerations include ensuring consistent supply and maintaining pricing flexibility to adapt to local market conditions.

What Role Does Dr Pepper Sizes Play in Retail Environments?

Supermarkets and convenience stores often stock a variety of Dr Pepper sizes, including 16oz bottles and 12oz cans, to appeal to different consumer segments. This variety not only boosts sales but also enhances the shopping experience by providing options for both single-serve and family-sized purchases. Retailers must prioritize supply chain efficiency and shelf life to optimize inventory management. Additionally, promotional strategies can be vital in driving sales, particularly in competitive markets across Africa and South America.

How Do Hotels Benefit from Offering Dr Pepper Sizes in Mini-Bars?

In the hospitality industry, hotels frequently include 16oz bottles of Dr Pepper in their mini-bar selections. This not only provides guests with a familiar beverage choice but also enhances their overall stay experience. By offering popular brands, hotels can improve guest satisfaction and potentially increase revenue from mini-bar sales. Key considerations for hotels include quality assurance of the product, the aesthetic appeal of packaging, and effective distribution logistics to ensure availability.

Why Are Dr Pepper Sizes Important for Events and Catering Services?

For events and catering services, the 5-gallon bag-in-box systems of Dr Pepper offer an efficient and cost-effective solution for serving large gatherings. This format allows for easy dispensing and minimizes waste, making it ideal for parties, weddings, and corporate events. Buyers in this sector should focus on bulk purchasing agreements and consider storage requirements for the bag-in-box systems. Delivery logistics are also crucial to ensure timely availability at event locations.

How Do Vending Machines Leverage Various Dr Pepper Sizes?

Vending machines that offer a range of Dr Pepper sizes—such as 12oz cans and 16oz bottles—maximize consumer choice and sales opportunities. This flexibility caters to the diverse preferences of consumers on-the-go, increasing the likelihood of impulse purchases. For operators, key factors include ensuring machine compatibility with various packaging types, effective product rotation to minimize spoilage, and competitive pricing strategies to attract customers.

3 Common User Pain Points for ‘dr pepper sizes’ & Their Solutions

Scenario 1: Navigating Diverse Market Preferences for Dr Pepper Sizes

The Problem: In international markets, particularly in regions like Africa and the Middle East, consumer preferences can vary significantly. A B2B buyer may face challenges in selecting the right Dr Pepper sizes to cater to diverse tastes and consumption habits. For instance, larger sizes might be favored in fast-food chains while smaller sizes could be more popular in convenience stores. This inconsistency can lead to overstocking some sizes while understocking others, resulting in lost sales and increased waste.

The Solution: Conduct thorough market research to understand regional preferences and consumption patterns before placing orders. Leverage sales data from existing partners to identify which sizes perform best in specific locations. Additionally, consider offering a mixed-case option that includes various sizes, allowing retailers to test different products without committing to large quantities. This flexible approach helps mitigate the risk of overstocking while maximizing the appeal of Dr Pepper across different customer segments.

Scenario 2: Overcoming Supply Chain Challenges with Dr Pepper Sizes

The Problem: B2B buyers often deal with logistical challenges, especially when importing beverages like Dr Pepper from different regions. Inconsistent supply chain issues can lead to delays in receiving specific sizes, which can disrupt inventory management and sales. Buyers might find themselves with a surplus of one size while being unable to fulfill orders for another, leading to customer dissatisfaction and potential loss of business.

The Solution: Establish strong relationships with reliable suppliers who can provide consistent delivery schedules for all Dr Pepper sizes. Implement a robust inventory management system that tracks sales trends and stock levels in real-time. This system should trigger alerts when specific sizes are running low, allowing for proactive ordering rather than reactive scrambling. Additionally, diversifying your supplier base can help mitigate risks associated with reliance on a single source, ensuring that you have access to the necessary sizes when demand peaks.

Scenario 3: Addressing Pricing and Profitability Concerns for Dr Pepper Sizes

The Problem: B2B buyers often grapple with pricing strategies, especially when sourcing products like Dr Pepper in various sizes. The cost per unit can vary significantly between sizes, and buyers may struggle to determine the optimal pricing to maximize profit margins while remaining competitive. This is especially critical in markets with price-sensitive consumers, where mispricing can lead to lost sales or diminished profit margins.

The Solution: Utilize a comprehensive profit calculator that analyzes costs associated with each Dr Pepper size, factoring in shipping, storage, and local taxes. This tool should help buyers understand the cost breakdown and set competitive prices that still ensure profitability. Additionally, consider promotional strategies that encourage the sale of larger sizes, such as bundled deals or volume discounts, which can enhance profitability while appealing to customers looking for value. Regularly review pricing strategies based on market conditions and consumer feedback to stay agile and responsive to changes.

By addressing these common pain points with tailored solutions, B2B buyers can enhance their operational efficiency and better meet the demands of their diverse customer bases, ultimately driving growth and profitability in their beverage offerings.

Strategic Material Selection Guide for dr pepper sizes

What Are the Key Materials Used for Dr Pepper Packaging?

When selecting materials for Dr Pepper packaging, international B2B buyers must consider several factors, including the performance properties of the materials, their cost-effectiveness, and compliance with regional standards. The following analysis focuses on four common materials used in the packaging of Dr Pepper products: PET (Polyethylene Terephthalate), aluminum, glass, and bag-in-box systems.

How Does PET (Polyethylene Terephthalate) Perform in Dr Pepper Packaging?

PET is widely used in the production of bottles for Dr Pepper due to its excellent clarity, lightweight nature, and strong barrier properties against moisture and gases. It can withstand temperatures up to 60°C (140°F) and is resistant to impact, making it ideal for carbonated beverages.

Pros: PET is cost-effective and lightweight, which reduces shipping costs. It is also recyclable, aligning with sustainability initiatives.

Cons: While PET has good chemical resistance, it can be less effective in high-temperature applications compared to other materials.

Impact on Application: PET’s compatibility with carbonated drinks ensures that it maintains the beverage’s quality and taste over time.

Considerations for International Buyers: Buyers in regions like Europe and South America should ensure compliance with regulations such as EU Plastics Regulation and local recycling guidelines.

What Advantages Does Aluminum Offer for Dr Pepper Cans?

Aluminum is commonly used for Dr Pepper cans due to its lightweight, strength, and excellent barrier properties against light and oxygen. It can handle high-pressure conditions, making it suitable for carbonated beverages.

Pros: Aluminum is highly durable and provides excellent protection for the contents. It is also infinitely recyclable, which is a significant advantage in markets focused on sustainability.

Cons: The manufacturing process for aluminum cans can be more complex and costly compared to PET bottles.

Impact on Application: Aluminum cans are particularly effective in maintaining the carbonation and flavor of Dr Pepper, making them a preferred choice for many consumers.

Considerations for International Buyers: Buyers from the Middle East and Africa should be aware of local recycling initiatives and compliance with standards such as ASTM B209 for aluminum sheet and plate.

Why Is Glass a Viable Option for Dr Pepper Packaging?

Glass is often used for premium packaging of beverages, including Dr Pepper, due to its inert nature and ability to preserve flavor without leaching chemicals.

Pros: Glass provides superior protection against external factors and does not react with the beverage, ensuring a pure taste. It is also recyclable.

Cons: Glass is heavier and more fragile than other materials, which can increase shipping costs and risk of breakage.

Impact on Application: The use of glass is particularly suitable for specialty products or limited editions of Dr Pepper, where brand image and quality perception are critical.

Considerations for International Buyers: Buyers in Europe, particularly Germany, should consider compliance with the EU Packaging Directive, which emphasizes recyclability and sustainability.

How Do Bag-in-Box Systems Work for Dr Pepper?

Bag-in-box systems are increasingly popular for dispensing beverages like Dr Pepper in commercial settings. This system consists of a flexible bag housed in a cardboard box, allowing for easy dispensing.

Pros: Bag-in-box systems are cost-effective for large volumes and minimize waste. They are also lightweight and easy to store.

Cons: They may not be suitable for long-term storage due to potential degradation of the bag material over time.

Impact on Application: This system is ideal for restaurants and events, providing a convenient way to serve Dr Pepper without the need for individual packaging.

Considerations for International Buyers: Buyers should ensure compliance with food safety standards, such as those set by the FDA or local equivalents, and consider the specific requirements for dispensing equipment.

Summary Table of Material Selection for Dr Pepper Sizes

| Material | Typical Use Case for dr pepper sizes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET | Bottles for retail | Lightweight and recyclable | Less effective at high temperatures | Low |

| Aluminum | Cans for retail | Durable and excellent barrier properties | Higher manufacturing complexity | Medium |

| Glass | Specialty packaging | Superior flavor preservation | Heavy and fragile | High |

| Bag-in-Box | Commercial dispensing | Cost-effective for large volumes | Potential degradation over time | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions when sourcing Dr Pepper products tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for dr pepper sizes

What Are the Main Stages of the Manufacturing Process for Dr Pepper Sizes?

The manufacturing process for Dr Pepper, particularly concerning its various packaging sizes, involves several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality ingredients, including carbonated water, high fructose corn syrup, and the proprietary blend of 23 flavors. Suppliers are carefully vetted to ensure consistency and quality. The ingredients undergo rigorous testing for purity and flavor profile before they are approved for use.

-

Forming: In this stage, the prepared ingredients are mixed in precise proportions to create the unique Dr Pepper flavor. This mixing often occurs in large batches using state-of-the-art equipment that ensures uniformity. Advanced blending technologies help maintain consistency across different production runs, which is critical for brand integrity.

-

Assembly: After forming, the beverage is packaged into various sizes, including 12oz cans, 16oz bottles, and 2-liter bottles. Automated bottling and canning lines are utilized to streamline this process. Each packaging line is designed for efficiency and to minimize the risk of contamination, employing methods such as aseptic filling and nitrogen flushing.

-

Finishing: The final stage involves labeling, boxing, and preparing the products for distribution. Quality control checks are conducted at this stage to ensure that all packaging is correctly labeled and sealed. The products are then stored under controlled conditions to preserve their quality until they are shipped to distributors.

How Is Quality Assurance Implemented in Dr Pepper Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for Dr Pepper, ensuring that all products meet stringent quality standards.

-

International Standards Compliance: Dr Pepper adheres to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards helps ensure consistency and reliability in production processes, which is crucial for maintaining customer trust.

-

Industry-Specific Certifications: In addition to ISO 9001, the company may also seek certifications relevant to specific markets, such as CE marking for products sold in Europe or API certifications for certain beverage categories. These certifications can enhance marketability and compliance with local regulations.

What Are the Key Quality Control Checkpoints in Dr Pepper Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that every aspect meets the company’s high standards.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and ingredients upon arrival at the manufacturing facility. Each batch is tested for quality metrics, including taste, purity, and consistency, before it is accepted for use in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing quality checks are performed. This includes monitoring the mixing process, carbonation levels, and packaging integrity. Real-time data collection allows for immediate adjustments to maintain product quality.

-

Final Quality Control (FQC): Once the products are packaged, they undergo final inspections before shipment. This includes checks for proper labeling, packaging integrity, and taste testing. Any products that do not meet quality standards are discarded or reworked.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential.

-

Supplier Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes and quality control measures. This helps buyers assess compliance with international standards and the effectiveness of the supplier’s quality assurance programs.

-

Quality Reports: Requesting regular quality reports from suppliers can help track their performance over time. These reports should include details on any quality issues encountered, corrective actions taken, and results from quality testing.

-

Third-Party Inspections: Engaging independent third-party inspection services can add an additional layer of assurance. These organizations can conduct unbiased assessments of the supplier’s operations and quality control practices, providing objective feedback to buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control in the beverage industry. Understanding these nuances can help in making informed purchasing decisions.

-

Regulatory Compliance: Different regions have varying regulations regarding food and beverage safety. Buyers must ensure that their suppliers comply with local laws, which may include specific labeling requirements, ingredient restrictions, and health standards.

-

Cultural Preferences: Taste preferences can vary significantly across regions. Suppliers must be able to adapt their production processes to meet local tastes while still adhering to quality standards. Buyers should consider this aspect when evaluating potential suppliers.

-

Supply Chain Transparency: Ensuring transparency throughout the supply chain is crucial for maintaining quality. Buyers should look for suppliers that provide clear information about their sourcing practices, production processes, and quality control measures.

By understanding the manufacturing processes and quality assurance practices related to Dr Pepper sizes, B2B buyers can make well-informed decisions that align with their business needs and regulatory requirements. This comprehensive approach not only ensures product quality but also fosters strong relationships with suppliers, ultimately benefiting the end consumer.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dr pepper sizes’

To effectively procure Dr Pepper in various sizes for your business, a structured approach is essential. This guide provides a step-by-step checklist to ensure that you make informed decisions while sourcing Dr Pepper products. Whether you’re catering to local markets in Africa, South America, the Middle East, or Europe, understanding your requirements and suppliers will enhance your purchasing process.

Step 1: Identify Your Market Demand

Before sourcing, analyze the preferences of your target market. Understanding which Dr Pepper sizes are popular in your region—such as 12oz cans, 16oz bottles, or 2-liter bottles—will guide your purchasing decisions. Conduct surveys or review sales data to pinpoint the most in-demand products.

Step 2: Define Your Technical Specifications

Clearly outline the specifications for the Dr Pepper products you wish to procure. Consider factors such as:

– Packaging Types: Choose between cans, bottles, or fountain options based on your distribution method.

– Volume Requirements: Determine how much stock you need for your operations, factoring in seasonal fluctuations.

Step 3: Evaluate Potential Suppliers

Research and evaluate suppliers who can provide Dr Pepper products. This step is vital to ensure reliability and quality. Look for:

– Reputation and Experience: Suppliers with a strong track record in your region are often more reliable.

– Product Availability: Confirm that they can consistently supply the sizes you need, including any special orders.

Step 4: Request Samples for Quality Assurance

Before finalizing your order, request samples of the products you intend to buy. This allows you to assess:

– Taste and Quality: Ensure that the product meets your quality standards.

– Packaging Integrity: Check for any defects in packaging that could affect shelf life or presentation.

Step 5: Verify Compliance with Local Regulations

Different regions may have specific regulations regarding beverage imports. Ensure that your supplier complies with local health and safety standards. Look for:

– Certification and Licensing: Suppliers should have the necessary certifications to operate in your region.

– Labeling Requirements: Verify that the product labels meet local language and nutritional information standards.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Key considerations include:

– Bulk Purchase Discounts: Inquire about pricing tiers based on order volume.

– Lead Times: Understand the expected delivery times to manage your inventory effectively.

Step 7: Establish a Long-term Relationship

Building a strong partnership with your supplier can lead to better service and pricing over time. Consider:

– Regular Communication: Keep open lines of communication to address any issues promptly.

– Feedback Mechanisms: Provide feedback to help the supplier improve their offerings and services.

By following this checklist, B2B buyers can streamline their sourcing process for Dr Pepper sizes, ensuring they meet market demands while maintaining product quality and compliance.

Comprehensive Cost and Pricing Analysis for dr pepper sizes Sourcing

What Are the Key Cost Components in Sourcing Dr Pepper Sizes?

When sourcing Dr Pepper products, particularly in various sizes such as 2L bottles, 16oz bottles, and 12oz cans, understanding the cost structure is critical. The primary cost components include:

-

Materials: This includes the cost of ingredients like carbonated water, high fructose corn syrup, and flavoring agents. The quality of these materials can significantly affect pricing. For international buyers, sourcing high-quality materials that meet local regulatory standards can add to costs.

-

Labor: Labor costs encompass wages for production workers, quality control personnel, and packaging staff. In regions with higher labor costs, such as Europe, this could impact the overall pricing of Dr Pepper products.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help minimize these costs, providing a competitive edge.

-

Tooling: Specific equipment used for bottling and packaging Dr Pepper products can incur initial setup costs. However, once amortized over production runs, these costs become less significant per unit.

-

Quality Control (QC): Ensuring that each batch of Dr Pepper meets quality standards is essential. QC processes can add to the cost but are necessary for maintaining product consistency and safety.

-

Logistics: This encompasses transportation costs for delivering products from manufacturing facilities to distribution centers or directly to retailers. Factors such as distance, shipping methods, and regional regulations can influence these costs.

-

Margin: Suppliers typically add a margin to cover overhead and profit. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Impact Sourcing Decisions for Dr Pepper Sizes?

Several factors can influence the pricing of Dr Pepper products in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced prices per unit due to economies of scale. Buyers should assess their demand patterns to negotiate better terms.

-

Specifications and Customization: Custom packaging or unique product specifications can lead to higher costs. Buyers should clarify their needs upfront to avoid unexpected expenses.

-

Materials: The source and quality of ingredients can affect pricing. Buyers should inquire about sourcing practices and consider suppliers that offer certifications for quality assurance.

-

Quality Certifications: Compliance with international quality standards can influence costs. Buyers should verify that suppliers hold relevant certifications to ensure product safety and quality.

-

Supplier Factors: Supplier reputation, reliability, and geographic location can all impact pricing. Building strong relationships with reputable suppliers can lead to better negotiation outcomes.

-

Incoterms: Understanding shipping terms is essential for cost management. Incoterms define responsibilities for shipping costs, insurance, and risk transfer, influencing the total cost of ownership.

What Are the Best Negotiation Tips for International Buyers Sourcing Dr Pepper Sizes?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can enhance cost-efficiency:

-

Understand Total Cost of Ownership (TCO): Look beyond the unit price to include logistics, tariffs, and potential wastage in your calculations. This holistic approach can reveal more cost-effective sourcing options.

-

Research Market Prices: Familiarize yourself with average pricing for Dr Pepper products in different regions to strengthen your negotiation position. Utilize industry reports and competitor pricing as benchmarks.

-

Leverage Long-Term Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and terms. Demonstrating loyalty may encourage suppliers to offer discounts or improved service.

-

Be Transparent About Needs: Clearly communicate your volume requirements and any specific product needs. Transparency can foster trust and facilitate better terms.

-

Consider Group Purchasing: Joining forces with other businesses to make bulk purchases can enhance negotiating power and lower costs.

Conclusion and Disclaimer

While this analysis provides a comprehensive overview of the cost and pricing dynamics associated with sourcing Dr Pepper sizes, actual prices may vary based on market conditions, supplier negotiations, and regional factors. It is advisable for buyers to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing and quality assurance.

Alternatives Analysis: Comparing dr pepper sizes With Other Solutions

Exploring Alternatives to Dr Pepper Sizes: A Comparative Analysis

In the competitive beverage market, understanding the various options available is crucial for B2B buyers. While Dr Pepper sizes provide a unique offering, several alternatives exist that cater to different consumer preferences and business needs. This analysis will compare Dr Pepper sizes with two viable alternatives: Coca-Cola’s product line and locally-sourced beverage options. By examining key aspects such as performance, cost, ease of implementation, maintenance, and best use cases, businesses can make informed decisions.

| Comparison Aspect | Dr Pepper Sizes | Coca-Cola Product Line | Locally-Sourced Beverages |

|---|---|---|---|

| Performance | Popular for unique flavor | Broad flavor variety | Local tastes and ingredients |

| Cost | Moderate | Competitive pricing | Variable (often lower) |

| Ease of Implementation | Established distribution | Widely available | May require local partnerships |

| Maintenance | Low (minimal upkeep) | Low (standardized) | Variable (depends on supplier) |

| Best Use Case | Fast food, casual dining | Restaurants, events | Local markets, cultural events |

What Are the Advantages and Disadvantages of Coca-Cola’s Product Line Compared to Dr Pepper Sizes?

Coca-Cola’s product line offers a diverse range of beverages, including soft drinks, juices, and waters. The primary advantage lies in its extensive flavor variety and strong brand recognition, which can attract a broader customer base. Additionally, Coca-Cola products are often competitively priced, making them an appealing option for businesses looking to maximize profit margins. However, the downside is that Coca-Cola may lack the unique flavor profile that Dr Pepper fans seek, and some consumers might perceive it as less innovative.

How Do Locally-Sourced Beverages Compare to Dr Pepper Sizes?

Locally-sourced beverages can provide unique flavors that resonate with regional tastes, often at a lower cost than international brands. This option supports local economies and may appeal to consumers interested in sustainability and community engagement. However, the challenges include inconsistent quality and availability, which can complicate supply chain management. Businesses may also need to invest time in building relationships with local suppliers to ensure reliability.

How Can B2B Buyers Choose the Right Beverage Solution for Their Needs?

When evaluating beverage options, B2B buyers should consider their target market, cost structure, and brand positioning. If the focus is on appealing to a diverse consumer base with a range of flavor preferences, Coca-Cola’s offerings may be more suitable. Conversely, if the goal is to provide unique, locally-inspired beverages that foster community engagement, investing in locally-sourced products could be beneficial. Ultimately, the decision should align with the company’s overall strategy, values, and the preferences of their customer base. By weighing these factors, businesses can select the beverage solution that best meets their operational and marketing needs.

Essential Technical Properties and Trade Terminology for dr pepper sizes

What Are the Key Technical Properties of Dr Pepper Sizes?

When sourcing Dr Pepper products, understanding their technical properties is essential for B2B buyers to ensure product quality and compatibility with market needs. Here are several critical specifications:

-

Packaging Size

Dr Pepper is available in various packaging sizes, such as 12 oz cans, 16 oz bottles, and 2-liter bottles. The choice of packaging affects logistics, shelf space, and consumer preferences. For instance, larger packages may reduce per-unit costs but can impact the product’s freshness and shelf life. -

Material Composition

The packaging materials for Dr Pepper typically include aluminum for cans and PET plastic for bottles. Each material has its advantages; aluminum is recyclable and provides better protection against light and oxygen, whereas PET is lightweight and offers cost efficiency in shipping. B2B buyers must consider these factors to align with sustainability goals and cost-effectiveness. -

Shelf Life

The shelf life of Dr Pepper products is generally around 9 months to 1 year, depending on storage conditions. This property is crucial for retailers and distributors to manage inventory effectively, ensuring that products are sold within their optimal consumption period to minimize waste. -

Serving Temperature

Ideal serving temperatures for carbonated beverages like Dr Pepper usually range from 35°F to 50°F (1.6°C to 10°C). Proper temperature management affects customer satisfaction and product experience. Understanding this helps distributors set appropriate storage and display conditions in retail environments. -

Nutritional Information

Each serving of Dr Pepper contains specific caloric and ingredient information, critical for compliance with food regulations and consumer preferences. B2B buyers should ensure that nutritional labels meet local regulations, especially in regions with stringent food labeling laws.

What Trade Terminology Should B2B Buyers Know When Sourcing Dr Pepper?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms relevant to sourcing Dr Pepper:

-

OEM (Original Equipment Manufacturer)

In the context of beverages, an OEM may refer to a company that produces drinks for other brands. Understanding OEM relationships helps buyers identify potential partnerships for exclusive products or co-branded offerings. -

MOQ (Minimum Order Quantity)

This term denotes the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management. Buyers must evaluate whether the MOQ aligns with their sales projections and storage capabilities. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This document helps in comparing offers and negotiating better deals. B2B buyers should prepare detailed RFQs to receive accurate and competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their liabilities and costs involved in international transactions, ensuring smooth import/export operations. -

Lead Time

This term refers to the time it takes from placing an order to receiving it. Understanding lead times is crucial for planning inventory levels and ensuring product availability. B2B buyers must factor in lead times when setting sales strategies and promotional campaigns. -

Distributor Agreement

A distributor agreement outlines the terms between a supplier and a distributor. This document is vital for defining sales territories, pricing structures, and marketing support. Buyers should review these agreements carefully to ensure favorable terms that align with their business objectives.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing Dr Pepper, optimizing their supply chain, and enhancing customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the dr pepper sizes Sector

What Are the Current Market Dynamics for Dr Pepper Sizes?

The market for Dr Pepper sizes is influenced by various global drivers, including changing consumer preferences, health consciousness, and the growth of e-commerce. In recent years, there has been a noticeable shift towards more diverse packaging options, such as smaller cans and bottles, catering to on-the-go lifestyles prevalent in urban settings across Africa, South America, the Middle East, and Europe. This trend is further accelerated by the rise of convenience stores and fast-food chains that offer multiple serving sizes to appeal to different customer segments.

B2B buyers should be aware of emerging technologies that streamline the sourcing process, such as automated inventory management and online ordering systems. These technologies not only improve operational efficiency but also enhance tracking capabilities, allowing businesses to respond swiftly to market demands. Additionally, understanding regional preferences can help international buyers tailor their offerings— for example, in Middle Eastern markets, smaller serving sizes may align better with local consumption habits, while larger sizes might be favored in Europe.

How Is Sustainability Influencing Sourcing for Dr Pepper Sizes?

Sustainability is becoming increasingly vital in the beverage industry, and Dr Pepper sizes are no exception. The environmental impact of packaging is under scrutiny, with a growing demand for eco-friendly options. B2B buyers should prioritize suppliers that utilize sustainable materials, such as recycled plastics or glass, and those that have implemented practices to minimize carbon footprints.

The importance of ethical supply chains cannot be overstated. Buyers should seek partnerships with manufacturers that are committed to fair labor practices and transparency. Certifications such as Fair Trade or EcoCert can serve as indicators of a supplier’s commitment to sustainability. Moreover, many consumers are now willing to pay a premium for products that are environmentally friendly, which can lead to increased sales and brand loyalty for businesses that invest in green initiatives.

What Is the Historical Context of Dr Pepper Sizes in the Market?

Dr Pepper’s journey began in the 1880s, establishing itself as a pioneer in the soft drink market. Over the decades, it has evolved its product offerings to meet changing consumer demands. Initially available in limited sizes, the brand has expanded its portfolio to include a variety of sizes—from smaller 12oz cans to larger 2-liter bottles—catering to both individual consumers and bulk buyers. This evolution reflects broader trends in the beverage industry, where flexibility and variety are key to capturing market share.

For B2B buyers, understanding this historical context is essential as it highlights the brand’s adaptability and commitment to innovation, qualities that can be leveraged when forming partnerships or making purchasing decisions. Recognizing how Dr Pepper has navigated market changes can also provide valuable insights into future trends and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of dr pepper sizes

-

1. How do I choose the right Dr Pepper size for my business needs?

Choosing the appropriate Dr Pepper size depends on your target market and sales strategy. For retail outlets, consider offering a range of sizes—from 12oz cans for impulse purchases to 2L bottles for families. In food service, 5-gallon bag-in-box options are ideal for restaurants and cafes, providing cost-effectiveness for high-volume sales. Analyze your customer preferences and sales data to determine which sizes will drive the most revenue in your specific market. -

2. What is the best packaging option for Dr Pepper in international markets?

The best packaging option varies by region and consumer behavior. In Europe, sleek cans and glass bottles are popular for their premium feel, while in Africa, larger plastic bottles may be favored for affordability and convenience. Ensure that your packaging complies with local regulations and resonates with cultural preferences. Additionally, consider sustainability initiatives, as eco-friendly packaging is increasingly important to consumers globally. -

3. What minimum order quantities (MOQs) should I expect when sourcing Dr Pepper?

Minimum order quantities (MOQs) for Dr Pepper products can vary based on the supplier and the specific size or packaging you require. Typically, MOQs can range from a few pallets for retail sizes to larger quantities for food service options. Always clarify MOQs with your supplier before placing an order, as this can impact your inventory management and cash flow. -

4. How do I vet suppliers for Dr Pepper products?

When vetting suppliers for Dr Pepper, assess their industry reputation, experience, and distribution capabilities. Request references and evaluate their compliance with food safety standards and local regulations. It’s also beneficial to inquire about their logistics infrastructure and delivery timelines. Establishing a strong relationship with a reliable supplier is crucial for ensuring consistent product availability and quality. -

5. What payment terms are common for B2B purchases of Dr Pepper?

Payment terms for B2B transactions can vary widely but typically include options such as net 30, net 60, or even cash on delivery (COD). It’s important to negotiate terms that align with your cash flow needs and the supplier’s policies. Ensure that you have a clear understanding of any additional fees, such as shipping or handling, that may impact your overall costs. -

6. How can I customize Dr Pepper products for my market?

Customization options for Dr Pepper products may include branding, packaging design, or even flavor variations. To explore customization, engage with your supplier to discuss potential options that cater to your local market preferences. Consider conducting market research to identify flavors or packaging styles that resonate with your target demographic, enhancing customer appeal and brand loyalty. -

7. What quality assurance measures should I consider when sourcing Dr Pepper?

Quality assurance is crucial in maintaining product integrity and customer satisfaction. Inquire about the supplier’s quality control processes, including product testing and compliance with international standards. Regular audits and inspections of the production facility can also help ensure that the products meet your expectations. Establish a clear return policy in case of any product discrepancies. -

8. What logistics considerations should I keep in mind for importing Dr Pepper?

When importing Dr Pepper, consider logistics factors such as shipping methods, lead times, and customs regulations. Work with experienced freight forwarders who understand the import process for beverages. Ensure that you factor in potential delays at customs and have all necessary documentation prepared. Additionally, consider warehousing options to manage inventory effectively upon arrival.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Dr Pepper Sizes Manufacturers & Suppliers List

1. Pepper Bottles – Size Variations

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Pepper Bottles – Size Variations, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Dr Pepper – Key Product

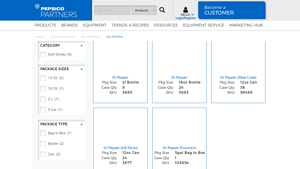

Domain: preprod.pepsicopartners.com

Registered: 2016 (9 years)

Introduction: DR PEPPER®

– Package Sizes:

– 2 L bottle (Case Qty: 8, SKU: 3685)

– 16 oz bottle (Case Qty: 24, SKU: 3683)

– 12 oz can (36pk Cube, Case Qty: 36, SKU: 58488)

– 12 oz can (4/6 Packs, Case Qty: 24, SKU: 3677)

– 5 gal bag in box (Fountain, Case Qty: 1, SKU: 103854)

3. McDonald’s – Dr Pepper® Soda (Small)

Domain: mcdonalds.com

Registered: 1994 (31 years)

Introduction: Dr Pepper® Soda (Small): A classic and refreshing fountain drink with a unique blend of 23 flavors. Contains 190 calories. Available sizes: Extra Small, Small, Medium, Large. Order through the McDonald’s app for pickup or McDelivery® at participating locations. Nutritional information based on standard product formulations and serving sizes. Allergen information available for common allergens. McD…

4. Keurig Dr Pepper – Beverage Portfolio

Domain: keurigdrpepper.com

Registered: 2018 (7 years)

Introduction: Keurig Dr Pepper has a portfolio of over 125 brands, including carbonated soft drinks, premium waters, teas, juices, and non-alcoholic mixers. Key brands include Dr Pepper, 7UP, Crush, Canada Dry, Sunkist, Snapple, and A&W. Ready to Brew products include specialty coffee and beverages in K-Cup® pods, with brands like Green Mountain Coffee Roasters, Swiss Miss, and Krispy Kreme. Ready to Eat produc…

Strategic Sourcing Conclusion and Outlook for dr pepper sizes

What Are the Key Takeaways for B2B Buyers of Dr Pepper Sizes?

In conclusion, strategic sourcing of Dr Pepper products offers international B2B buyers a unique opportunity to cater to diverse consumer preferences across various markets. The variety of packaging sizes—from 12 oz cans to 2-liter bottles—allows businesses to effectively meet the needs of different customer segments, whether they are retail outlets, restaurants, or event organizers. Understanding these options enables buyers to optimize inventory and maximize profitability.

How Can Strategic Sourcing Enhance Your Business?

Effective sourcing not only streamlines procurement but also strengthens supplier relationships, ensuring consistent quality and availability. By leveraging the robust portfolio of Keurig Dr Pepper, buyers can enhance their product offerings and drive customer loyalty. This approach is particularly vital in emerging markets in Africa, South America, and the Middle East, where consumer preferences are rapidly evolving.

What’s Next for International B2B Buyers?

As the beverage market continues to grow, now is the time to act. Explore partnerships that align with your business goals and consumer demands. By strategically sourcing Dr Pepper products, you can position your business for sustained growth and success in competitive landscapes. Engage with suppliers today to capitalize on emerging opportunities and ensure your offerings resonate with consumers in your region.