Pbt Gf30 Plug: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for pbt gf30 plug

In an increasingly interconnected global economy, sourcing the right components, such as the PBT GF30 plug, can present significant challenges for B2B buyers. This versatile connector, known for its durability and electrical reliability, plays a crucial role in various industrial applications, from automotive to telecommunications. However, navigating the complexities of international supply chains, varying standards, and supplier credibility can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia.

This comprehensive guide aims to empower B2B buyers with the insights needed to make informed purchasing decisions. It covers a wide range of topics, including the different types of PBT GF30 plugs available, their specific applications, and essential criteria for supplier vetting. Additionally, we delve into pricing structures and cost-saving strategies, ensuring that you can secure high-quality connectors without compromising your budget.

By providing actionable insights and expert advice, this guide equips international buyers with the knowledge to confidently navigate the global market for PBT GF30 plugs. Whether you are looking to enhance your product offerings or streamline your supply chain, understanding these key elements will enable you to forge successful partnerships and drive your business forward.

Understanding pbt gf30 plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PBT GF30 Connector | 68-way configuration, PA66 housing, high durability | Industrial automation, automotive | Pros: Cost-effective, widely available. Cons: Limited customization options. |

| Custom PBT GF30 Connector | Tailored designs, enhanced glass fiber reinforcement | Specialized machinery, robotics | Pros: Optimized for specific needs. Cons: Longer lead times for production. |

| Inline PBT GF30 Connector | Compact inline design, easy installation | Electrical systems, consumer electronics | Pros: Space-saving, user-friendly. Cons: May require additional adapters. |

| High-Temperature PBT GF30 Connector | Resistant to extreme conditions, specialized materials | Aerospace, oil & gas industries | Pros: Exceptional durability. Cons: Higher price point. |

| Waterproof PBT GF30 Connector | Sealed design to prevent moisture ingress | Outdoor applications, marine | Pros: Reliable performance in wet environments. Cons: Bulkier design. |

What Are the Key Characteristics of the Standard PBT GF30 Connector?

The Standard PBT GF30 Connector features a 68-way configuration housed in durable PA66 material, making it suitable for a variety of industrial applications. Its design is optimized for efficiency, ensuring reliable electrical connections in environments such as automation and automotive sectors. Buyers should consider its cost-effectiveness and availability, although customization options are limited, which may not suit every specific application.

How Do Custom PBT GF30 Connectors Meet Unique Business Needs?

Custom PBT GF30 Connectors are engineered to meet unique specifications, often incorporating enhanced glass fiber reinforcement for improved strength and stability. These connectors are particularly beneficial in specialized machinery and robotics where unique configurations are necessary. While they offer tailored solutions, businesses must account for longer lead times in production, which could impact project timelines.

Why Choose Inline PBT GF30 Connectors for Compact Spaces?

Inline PBT GF30 Connectors are designed for easy installation in compact spaces, making them ideal for electrical systems and consumer electronics. Their user-friendly design allows for quick assembly and maintenance, reducing downtime. However, businesses should be aware that these connectors may require additional adapters, which could complicate installation in certain setups.

What Advantages Do High-Temperature PBT GF30 Connectors Offer?

High-Temperature PBT GF30 Connectors are manufactured using specialized materials that withstand extreme environmental conditions, making them suitable for industries like aerospace and oil & gas. Their exceptional durability ensures reliable performance even in harsh settings. However, buyers should be prepared for a higher price point, which reflects the advanced materials used in their construction.

How Do Waterproof PBT GF30 Connectors Enhance Reliability in Challenging Environments?

Waterproof PBT GF30 Connectors feature a sealed design that effectively prevents moisture ingress, making them ideal for outdoor applications and marine environments. Their reliability in wet conditions ensures consistent performance, which is crucial for businesses operating in unpredictable climates. However, the bulkier design may require careful consideration regarding space constraints in installation areas.

Key Industrial Applications of pbt gf30 plug

| Industry/Sector | Specific Application of pbt gf30 plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electrical connections in vehicle assemblies | Enhanced durability and reliability in harsh conditions | Ensure compliance with automotive standards and certifications |

| Industrial Automation | Control systems in manufacturing equipment | Increased efficiency and reduced downtime | Look for connectors that support high-speed data transmission |

| Telecommunications | Data transmission in network infrastructure | Improved signal integrity and reduced latency | Source connectors that meet international communication standards |

| Consumer Electronics | Power supply connections in electronic devices | Compact design with high performance | Check for compatibility with various device specifications |

| Renewable Energy | Connections in solar panel systems | Long-lasting performance in outdoor environments | Ensure UV resistance and weatherproofing capabilities |

How is the PBT GF30 Plug Used in the Automotive Industry?

In the automotive sector, the PBT GF30 plug is crucial for establishing reliable electrical connections in vehicle assemblies. Its glass fiber reinforcement offers enhanced durability, making it suitable for harsh automotive environments where exposure to heat, moisture, and vibration is common. International buyers, especially in regions like Nigeria and Saudi Arabia, should prioritize sourcing plugs that comply with automotive standards to ensure safety and reliability in their applications.

What Role Does the PBT GF30 Plug Play in Industrial Automation?

In industrial automation, the PBT GF30 plug is utilized in control systems for manufacturing equipment. Its robust design contributes to increased efficiency and reduced downtime, vital for maintaining production schedules. Buyers in South America and the Middle East should focus on sourcing connectors that facilitate high-speed data transmission, as this is essential for modern automation systems that rely on real-time data for optimal performance.

How Does the PBT GF30 Plug Enhance Telecommunications?

Telecommunications infrastructure benefits significantly from the PBT GF30 plug, which is used for data transmission in various network applications. Its ability to maintain signal integrity while reducing latency is crucial for high-performance communication systems. B2B buyers in Europe should ensure that the connectors they source meet international communication standards to guarantee compatibility and performance across different network setups.

In What Ways is the PBT GF30 Plug Applied in Consumer Electronics?

In the consumer electronics sector, the PBT GF30 plug is often employed for power supply connections in devices such as smartphones and laptops. Its compact design, combined with high performance, allows manufacturers to optimize space without compromising on functionality. Buyers should verify compatibility with various device specifications to ensure seamless integration and performance.

How is the PBT GF30 Plug Used in Renewable Energy Applications?

The renewable energy sector, particularly solar energy systems, relies on the PBT GF30 plug for secure connections. These plugs are designed to withstand outdoor conditions, offering long-lasting performance even in extreme weather. When sourcing for applications in Africa or the Middle East, it is crucial to ensure that the plugs possess UV resistance and weatherproofing capabilities, as these features significantly enhance the reliability of solar panel systems.

3 Common User Pain Points for ‘pbt gf30 plug’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality PBT GF30 Plugs

The Problem: B2B buyers often face challenges in sourcing high-quality PBT GF30 plugs, particularly when navigating multiple suppliers across different regions. Disparities in product quality, inconsistent specifications, and lack of reliable suppliers can lead to project delays and increased costs. Furthermore, buyers might struggle to verify the authenticity of the connectors, risking the potential for compatibility issues in their applications.

The Solution: To effectively source quality PBT GF30 plugs, buyers should start by establishing a shortlist of reputable suppliers with strong industry credentials. Engaging suppliers that specialize in connectors and have certifications such as ISO can enhance confidence in product quality. It’s advisable to request product samples to assess the quality firsthand before placing larger orders. Additionally, leveraging platforms that facilitate supplier ratings and reviews can provide insights into reliability. Conducting a thorough technical review of the specifications provided by each supplier against industry standards will also ensure that the chosen connectors meet the required performance metrics. Finally, consider forming long-term partnerships with trusted suppliers to streamline future procurement processes.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem: Another significant challenge for B2B buyers is ensuring that the PBT GF30 plugs they procure are compatible with existing systems and components. Incompatibility can lead to malfunctioning equipment, increased downtime, and costly rework. This issue is especially pronounced in industries where equipment is upgraded incrementally, and new components must seamlessly integrate with older systems.

The Solution: To mitigate compatibility issues, it is essential for buyers to conduct a comprehensive compatibility assessment before purchasing PBT GF30 plugs. This involves reviewing the specifications of current systems and identifying the exact requirements for the connectors. Creating a compatibility checklist that includes pin configurations, voltage ratings, and physical dimensions can be instrumental. Buyers should also engage with technical representatives from the supplier to clarify any doubts regarding compatibility. Utilizing CAD software to model the proposed integration can provide valuable insights into potential fitment issues. Furthermore, documenting all compatibility assessments can serve as a reference for future purchases and upgrades, ensuring that all components work harmoniously together.

Scenario 3: Managing Costs While Maintaining Quality

The Problem: Cost management is a pervasive concern for B2B buyers when procuring PBT GF30 plugs, especially in regions where budget constraints are prevalent. Buyers often find themselves balancing the need for quality with the pressure to reduce costs, which can lead to compromising on product standards. This dilemma can cause long-term issues, as lower-quality connectors may fail sooner, resulting in increased operational costs.

The Solution: To effectively manage costs without sacrificing quality, buyers should implement a multi-faceted procurement strategy. This includes conducting a thorough market analysis to identify competitive pricing for PBT GF30 plugs while also evaluating the total cost of ownership (TCO). Establishing relationships with multiple suppliers can create a competitive bidding environment, allowing buyers to negotiate better terms. Additionally, consider exploring bulk purchasing options, which often come with significant discounts. Buyers should also invest in training for their procurement teams to recognize the value of quality over price, emphasizing that higher initial costs can lead to lower maintenance and replacement costs in the long run. Lastly, conducting regular performance reviews of purchased connectors can help identify any quality issues early, allowing for timely corrective actions that protect the overall budget.

Strategic Material Selection Guide for pbt gf30 plug

When selecting materials for the PBT GF30 plug, understanding the properties and implications of various materials is essential for B2B buyers. Below is an analysis of four common materials used in the construction of PBT GF30 plugs, focusing on their performance, advantages, disadvantages, and considerations for international markets.

What Are the Key Properties of PBT Material in PBT GF30 Plugs?

Polybutylene Terephthalate (PBT) is a thermoplastic engineering polymer known for its excellent electrical insulation properties, thermal stability, and resistance to chemicals. PBT GF30, specifically, is reinforced with 30% glass fiber, enhancing its mechanical strength and dimensional stability. It typically operates effectively in temperatures ranging from -40°C to +120°C and can withstand moderate pressure, making it suitable for various applications.

Pros: PBT GF30 offers high durability and excellent resistance to moisture and chemicals, making it ideal for harsh environments. Its lightweight nature also contributes to lower shipping costs.

Cons: The manufacturing process can be more complex and costly due to the need for specialized equipment to handle glass fiber reinforcement. Additionally, while PBT GF30 is robust, it may not perform well under extreme temperatures beyond its specified limits.

Impact on Application: PBT GF30 is particularly compatible with electronic and automotive applications, where reliable insulation and strength are critical. It is also suitable for environments where exposure to oils, solvents, and other chemicals is expected.

How Does PA66 Compare as a Material for PBT GF30 Plugs?

Polyamide 66 (PA66) is another common material used in connectors. Known for its toughness and high mechanical strength, PA66 can handle higher temperatures (up to 150°C) and has excellent wear resistance.

Pros: PA66 is highly durable and can withstand significant mechanical stress, making it suitable for heavy-duty applications. Its high melting point allows it to perform well in elevated temperature environments.

Cons: The cost of PA66 is generally higher than PBT, and it can absorb moisture, which may affect its electrical properties over time. Additionally, the processing of PA66 may require more energy, increasing manufacturing costs.

Impact on Application: PA66 is ideal for applications requiring high thermal resistance, such as automotive components and industrial machinery. Its moisture absorption characteristics must be considered in humid climates.

What Role Does Polypropylene Play in PBT GF30 Plug Applications?

Polypropylene (PP) is a versatile thermoplastic that is often used in various applications due to its lightweight and chemical resistance properties.

Pros: PP is cost-effective and has good chemical resistance, making it suitable for applications involving exposure to various solvents. Its low density also contributes to reduced shipping costs.

Cons: While PP is resistant to many chemicals, it has lower mechanical strength compared to PBT and PA66. It may also have a lower temperature tolerance, which could limit its application in high-heat environments.

Impact on Application: PP is suitable for applications where weight savings are critical, but its limitations in mechanical strength and temperature resistance should be considered, especially in demanding environments.

What Are the Advantages of Using Custom Materials for PBT GF30 Plugs?

Custom materials allow manufacturers to tailor the properties of connectors to meet specific application requirements. This can include variations in thermal stability, electrical insulation, and mechanical strength.

Pros: Custom materials can enhance performance characteristics, such as improved resistance to specific chemicals or environmental conditions. This flexibility allows for optimization based on end-user needs.

Cons: The development of custom materials can lead to increased costs and longer lead times for production. Additionally, sourcing and compliance with international standards may complicate procurement.

Impact on Application: Custom solutions can provide significant advantages in niche applications or extreme environments, but buyers must ensure that these materials meet relevant standards and regulations.

Summary Table of Material Selection for PBT GF30 Plugs

| Material | Typical Use Case for PBT GF30 Plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PBT | Automotive and electronic connectors | Excellent electrical insulation | Limited high-temperature performance | Medium |

| PA66 | Heavy-duty industrial applications | High thermal and mechanical strength | Higher cost and moisture absorption | High |

| Polypropylene | Lightweight consumer electronics | Cost-effective and lightweight | Lower mechanical strength | Low |

| Custom Materials | Specialized industrial applications | Tailored properties for specific needs | Higher cost and longer lead times | Variable |

This analysis provides a comprehensive overview of the materials commonly used in PBT GF30 plugs, offering valuable insights for B2B buyers in diverse international markets. Understanding these properties and considerations will aid in making informed procurement decisions that align with application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pbt gf30 plug

What Are the Main Stages in the Manufacturing Process of PBT GF30 Plugs?

The manufacturing process of PBT GF30 plugs involves several critical stages to ensure high-quality, durable connectors suitable for various industrial applications. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality raw materials, primarily PBT (Polybutylene Terephthalate) reinforced with 30% glass fiber. This combination enhances mechanical strength, thermal stability, and resistance to chemicals. Suppliers must ensure that the raw materials meet specific industry standards and certifications, which can be verified through material safety data sheets (MSDS) and supplier quality assurance documentation.

-

Forming: In this stage, the prepared materials are processed using injection molding techniques. The PBT GF30 mixture is heated until it reaches a molten state and then injected into molds designed for the plug configuration. Precision in the mold design is critical to achieving the desired dimensions and performance characteristics. Advanced techniques like multi-cavity molds can be employed to optimize production efficiency and minimize waste.

-

Assembly: After the individual components are formed, they undergo assembly. This may involve inserting metal contacts and ensuring proper alignment and fit within the plastic housing. Automated assembly lines are often utilized to enhance precision and speed, reducing the potential for human error.

-

Finishing: The final stage involves surface finishing, which may include cleaning, coating, and packaging. Surface treatments can enhance the electrical properties of the connectors, such as improving conductivity or providing additional insulation. Quality checks are performed at this stage to ensure that the plugs meet all specifications before they are packaged for shipment.

How Is Quality Assurance Implemented in PBT GF30 Plug Manufacturing?

Quality assurance (QA) is a pivotal aspect of the manufacturing process for PBT GF30 plugs, ensuring that each product meets international standards and customer expectations.

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines a framework for quality management systems. Compliance with this standard indicates that the manufacturer consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for oil and gas applications may also be relevant.

-

Quality Control Checkpoints: Various checkpoints throughout the manufacturing process help maintain quality:

-

Incoming Quality Control (IQC): This phase includes the inspection of raw materials and components upon delivery. It ensures that they meet specified quality standards before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This can involve statistical process control (SPC) techniques to analyze production data in real-time.

-

Final Quality Control (FQC): Once manufacturing is complete, the final products are subjected to rigorous testing. This includes dimensional checks, electrical performance tests, and environmental simulations to ensure they can withstand operational conditions.

What Testing Methods Are Commonly Used for PBT GF30 Plugs?

Testing methods for PBT GF30 plugs are crucial to verify their performance and reliability in real-world applications. Common testing methods include:

-

Electrical Testing: This assesses the conductivity and insulation resistance of the plugs. High-voltage tests may also be conducted to ensure that the connectors can handle the required electrical loads without failure.

-

Mechanical Testing: Tests such as tensile strength, impact resistance, and thermal cycling are performed to ensure that the plugs can withstand mechanical stresses and temperature variations.

-

Environmental Testing: Products are subjected to conditions that simulate real-world environments, including humidity, temperature extremes, and exposure to chemicals. This helps verify their durability and longevity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of their suppliers. Here are several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality management systems, and overall operational standards. This is particularly important for international buyers who may not be familiar with local practices.

-

Requesting Quality Reports: Buyers should ask suppliers for documentation related to their quality control processes, including IQC, IPQC, and FQC reports. These documents should detail the methods used and the results of any testing performed.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control measures. These organizations can conduct random inspections and tests to ensure compliance with industry standards.

-

Certifications and Compliance Documents: Request copies of relevant certifications, such as ISO 9001, CE, or API. These documents indicate that the supplier adheres to established quality standards and practices.

What Are the Nuances of Quality Control for International Buyers?

International B2B buyers need to be aware of several nuances regarding quality control when sourcing PBT GF30 plugs:

-

Regulatory Requirements: Different regions may have varying regulatory requirements that affect product specifications. Buyers must ensure that suppliers comply with local standards to avoid issues related to product acceptance.

-

Cultural Differences: Understanding cultural differences in business practices and quality expectations is crucial. Buyers should engage in clear communication with suppliers to establish mutual understanding regarding quality standards.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chain. This includes information about sourcing materials, production processes, and any subcontractors involved. Transparency can significantly impact the perceived quality of the final product.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing PBT GF30 plugs, ensuring that they receive reliable, high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pbt gf30 plug’

The following guide provides a comprehensive checklist for B2B buyers looking to procure the PBT GF30 plug, ensuring a strategic and informed sourcing process.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes the number of contacts, connector gender, and mounting type. Understanding these specifications is crucial as it ensures that the plug will meet your operational needs and integrate seamlessly with existing systems.

Step 2: Research Reliable Suppliers

Invest time in identifying reputable suppliers who specialize in the PBT GF30 plug. Look for manufacturers with a proven track record and positive reviews from other clients. Utilize platforms like industry directories and trade associations to find suppliers with verified credentials.

- Check for Certifications: Ensure that the suppliers have relevant industry certifications, such as ISO 9001, which indicates adherence to quality management standards.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, product catalogs, and case studies to assess their capabilities. It’s also beneficial to seek references from other businesses within your industry or region to gauge reliability and customer service.

- Assess Experience: Look for suppliers who have experience in your specific industry, as they will be more familiar with your unique needs and challenges.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the PBT GF30 plugs. Testing these samples in your operational environment will help verify their performance and compatibility. This step is essential to avoid costly errors after bulk ordering.

- Conduct Compatibility Tests: Ensure that the samples align with your existing systems, checking for proper fit and function.

Step 5: Review Pricing and Payment Terms

Analyze the pricing structures provided by your shortlisted suppliers. Look for transparency in pricing, including any additional costs such as shipping or handling fees. Clarify payment terms to ensure they align with your budgetary constraints.

- Negotiate Bulk Discounts: If you plan to order in large quantities, inquire about volume discounts or flexible payment options.

Step 6: Understand Shipping and Delivery Policies

Before finalizing your order, familiarize yourself with the supplier’s shipping and delivery policies. Ensure they can meet your timeline and provide tracking information. Reliable logistics are vital to prevent delays that could impact your operations.

- Consider Local Pickup Options: If the supplier is nearby, inquire about local pickup to save on shipping costs and time.

Step 7: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process. Confirm that your supplier has a responsive customer service team and clear lines of communication. This will facilitate quick resolution of any issues or queries that may arise.

- Use Multiple Communication Channels: Establish whether the supplier can be contacted through various methods, such as email, phone, or instant messaging, to ensure timely responses.

By following this checklist, B2B buyers can navigate the procurement process for PBT GF30 plugs more effectively, reducing risks and enhancing the likelihood of a successful purchase.

Comprehensive Cost and Pricing Analysis for pbt gf30 plug Sourcing

What Are the Key Cost Components of PBT GF30 Plug Sourcing?

When analyzing the cost structure of PBT GF30 plugs, several critical components come into play. Materials represent a significant portion of the cost, with PBT (Polybutylene Terephthalate) being a high-performance thermoplastic known for its excellent mechanical and electrical properties. The addition of glass fiber (GF30) enhances the strength and thermal stability of the connectors, which can increase material costs.

Labor costs are influenced by the complexity of the manufacturing process and the level of skill required. Manufacturing overhead, including utilities and facility costs, must also be factored in, alongside tooling costs that cover the specialized equipment needed for production. Quality Control (QC) processes add to the expense, ensuring that each plug meets industry standards and specifications.

Lastly, logistics costs—encompassing shipping, handling, and warehousing—are crucial, especially for international buyers. This can vary significantly based on the destination, chosen shipping methods, and the terms of shipment.

How Do Volume and Customization Affect Pricing of PBT GF30 Plugs?

Pricing for PBT GF30 plugs can be heavily influenced by volume and minimum order quantities (MOQs). Suppliers often offer tiered pricing, where larger orders result in lower per-unit costs. For instance, an MOQ might be set at four units, with significant price reductions for orders beyond that threshold.

Customization also plays a pivotal role in determining price. Tailored solutions designed to meet specific application needs can lead to increased costs due to the additional engineering and manufacturing processes involved. Buyers should consider whether they need standard configurations or if custom solutions are essential for their projects.

What Other Factors Influence the Pricing of PBT GF30 Plugs?

Several other factors impact the pricing of PBT GF30 plugs. The quality and certifications of the components can significantly affect the price. Suppliers that meet international standards and provide certifications may charge a premium.

Additionally, supplier factors such as reputation, reliability, and payment terms can influence pricing. Buyers should evaluate suppliers based on their track record and the support they offer, including after-sales service and warranty options.

Incoterms also play a critical role in pricing, as they define the responsibilities of buyers and sellers in shipping and handling. Understanding these terms can help buyers avoid unexpected costs associated with freight and customs duties.

What Negotiation Strategies Can Buyers Use for PBT GF30 Plug Sourcing?

Buyers should approach negotiations with a clear understanding of their needs and market prices. Researching competitors’ pricing can provide leverage during discussions. It’s also advisable to establish a long-term relationship with suppliers, as this can lead to better pricing and favorable terms over time.

Focusing on Total Cost of Ownership (TCO) rather than just the initial purchase price can yield significant savings. This includes considering the lifespan, maintenance, and potential downtime costs associated with the plugs.

What Are the Pricing Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique pricing nuances. Factors such as currency fluctuations, import tariffs, and regional demand can impact overall costs. Buyers should factor in additional charges related to customs clearance and local taxes, which vary by country.

It is crucial to communicate clearly with suppliers about shipping terms and potential hidden costs to avoid surprises. Building a comprehensive understanding of the local market dynamics can help buyers negotiate more effectively and secure favorable pricing.

Disclaimer on Pricing Information

The prices referenced in this analysis are indicative and may vary based on supplier, location, and current market conditions. It is advisable for buyers to obtain quotes from multiple suppliers and consider all cost components before making purchasing decisions.

Alternatives Analysis: Comparing pbt gf30 plug With Other Solutions

Exploring Alternative Solutions to the PBT GF30 Plug

When considering the PBT GF30 plug, it is essential to evaluate alternative solutions that may offer similar functionalities. This comparison helps B2B buyers identify the most suitable option based on their specific requirements, such as performance, cost, and ease of implementation. Below, we compare the PBT GF30 plug with two viable alternatives: the PA66 Connector and Custom PBT Connectors.

| Comparison Aspect | PBT GF30 Plug | PA66 Connector | Custom PBT Connectors |

|---|---|---|---|

| Performance | High durability; excellent thermal and chemical resistance | Good mechanical properties; less durable than PBT GF30 | Tailored performance based on specifications; high durability |

| Cost | Moderate pricing (approx. $22.99) | Generally lower cost (approx. $15) | Higher cost due to customization (varies widely) |

| Ease of Implementation | Standardized design; easy integration | Simple integration; common in various applications | Potentially complex; depends on customization level |

| Maintenance | Low maintenance; reliable under stress | Moderate maintenance; may need frequent checks | Varies based on design; may require specific upkeep |

| Best Use Case | Industrial applications requiring reliability | General-purpose use in electronics | Specialized applications needing custom solutions |

What Are the Advantages and Disadvantages of the PA66 Connector?

The PA66 connector is a popular alternative to the PBT GF30 plug, primarily due to its cost-effectiveness and decent mechanical properties. With a lower price point, it is suitable for general-purpose applications, making it an attractive choice for companies looking to manage budgets. However, while it offers good performance, it does not match the thermal and chemical resistance of the PBT GF30 plug, which may lead to failures in more demanding environments.

How Do Custom PBT Connectors Compare?

Custom PBT connectors provide tailored solutions that can meet specific operational needs, which is a significant advantage for companies with unique requirements. They are designed to offer high durability and reliability, akin to the PBT GF30 plug. However, the cost of custom solutions can be considerably higher, and the complexity involved in their implementation may require specialized knowledge or additional training for the workforce. This can be a drawback for businesses looking for straightforward, plug-and-play options.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the right connector solution involves a careful assessment of the specific needs of your application. B2B buyers should consider factors such as operational environment, budget constraints, and the technical expertise of their teams. If reliability and performance under stress are paramount, the PBT GF30 plug stands out as an excellent choice. However, for those with more flexible requirements or tighter budgets, the PA66 connector may suffice. Custom PBT connectors are ideal for specialized applications but require a more significant investment in both time and resources. Ultimately, understanding these alternatives will empower businesses to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for pbt gf30 plug

What Are the Essential Technical Properties of the PBT GF30 Plug?

Understanding the technical properties of the PBT GF30 plug is crucial for B2B buyers, particularly when selecting components for demanding applications. Here are some key specifications to consider:

-

Material Composition

The PBT GF30 plug is primarily made from Polybutylene Terephthalate (PBT) reinforced with 30% glass fiber. This combination enhances strength, thermal stability, and chemical resistance, making it suitable for various industrial applications. For B2B buyers, the material’s durability means reduced maintenance costs and longer product lifespans. -

Temperature Resistance

Typically, the PBT GF30 can withstand temperatures ranging from -40°C to +120°C. This broad temperature tolerance is essential for applications in extreme environments, such as automotive or industrial machinery. Buyers must ensure that the plugs can operate effectively within their specific temperature ranges to prevent failures. -

Electrical Insulation

The PBT GF30 plug exhibits excellent electrical insulation properties, with a dielectric strength of approximately 20 kV/mm. This characteristic is vital for preventing electrical shorts and ensuring safe operation in electronic applications. Buyers should prioritize connectors that meet or exceed industry standards for insulation to maintain safety and reliability. -

Mechanical Strength

Thanks to the glass fiber reinforcement, the PBT GF30 plug boasts enhanced mechanical strength and resistance to impact. This durability is essential for connectors used in high-stress environments where vibrations or shocks may occur. B2B buyers should consider mechanical specifications when evaluating connectors to ensure they can withstand operational demands. -

Dimensional Stability

The PBT GF30 maintains its shape and dimensions under varying temperature and humidity conditions. This property is crucial for ensuring that connectors fit properly and function reliably over time. Buyers should look for this stability to avoid issues related to connector misalignment or failure. -

Moisture Resistance

The plug’s design offers resistance to moisture absorption, which is essential in preventing corrosion and ensuring electrical integrity. For industries operating in humid environments, this feature can significantly extend the lifespan of electrical components. Buyers should assess moisture resistance when selecting connectors for outdoor or wet applications.

What Are the Common Trade Terms Related to the PBT GF30 Plug?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source components that meet specific standards or specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it affects inventory management and cost calculations. Knowing the MOQ helps businesses plan their purchasing strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. This process is essential for comparing pricing and terms across different suppliers, helping businesses make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. They dictate who is responsible for shipping, insurance, and tariffs, which is crucial for international B2B transactions. Buyers must understand these terms to avoid unexpected costs. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. This concept is vital for businesses that rely on timely deliveries to maintain production schedules. Understanding lead times helps buyers manage their inventory and supply chain effectively. -

Customs Clearance

This term refers to the process of passing goods through customs so they can enter or leave a country. For international buyers, understanding customs clearance is essential to avoid delays and ensure compliance with regulations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing PBT GF30 plugs, leading to better procurement strategies and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the pbt gf30 plug Sector

What Are the Current Market Dynamics and Key Trends in the PBT GF30 Plug Sector?

The global market for PBT GF30 plugs is witnessing significant growth, driven by the increasing demand for high-performance connectors in various industries, including automotive, telecommunications, and consumer electronics. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable and durable electrical components, the PBT GF30 connector’s advantages—such as thermal stability, chemical resistance, and mechanical strength—become paramount.

Emerging trends in sourcing include a shift towards digital procurement processes and the integration of Industry 4.0 technologies. Buyers are increasingly leveraging e-commerce platforms and online catalogs to streamline their purchasing processes, allowing for quicker decision-making and enhanced access to global suppliers. Moreover, the trend toward customization is gaining traction, with manufacturers offering bespoke solutions tailored to specific application requirements, thereby catering to diverse market needs.

Sustainability is another key driver in the market, with businesses prioritizing environmentally friendly materials and practices. This focus is shaping the sourcing strategies of B2B buyers, who are now more inclined to partner with suppliers that demonstrate a commitment to sustainable manufacturing processes and products.

How Is Sustainability Influencing Sourcing Decisions in the PBT GF30 Plug Market?

Sustainability and ethical sourcing are becoming increasingly critical in the PBT GF30 plug sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt practices that minimize carbon footprints and resource consumption. For B2B buyers, this means evaluating potential suppliers based on their environmental certifications and commitments to sustainability.

Key certifications, such as ISO 14001, indicate that a supplier has established effective environmental management systems. Additionally, the use of ‘green’ materials—such as recycled or bio-based plastics—can enhance the appeal of PBT GF30 plugs in the eyes of environmentally conscious buyers. Ethical supply chains are also crucial; buyers are encouraged to scrutinize their suppliers’ labor practices and sourcing methods to ensure compliance with international labor standards. By prioritizing sustainability, companies not only mitigate risks but also enhance their brand reputation and align with the growing consumer demand for responsible business practices.

What Has Been the Evolution of the PBT GF30 Plug in the B2B Landscape?

The PBT GF30 plug has evolved significantly since its introduction, transitioning from basic connector designs to advanced configurations that meet the demands of modern industries. Initially favored for its cost-effectiveness, the PBT GF30 has gained recognition for its superior performance characteristics, including resistance to high temperatures and mechanical stress.

As industries evolved, so did the expectations for connector reliability and efficiency. Manufacturers began integrating advanced glass fiber reinforcements to improve the material’s strength and dimensional stability, making it suitable for applications in harsh environments. The focus on customization has also emerged, with suppliers offering tailored solutions that cater to specific operational needs. This evolution reflects the broader trends in the B2B landscape, where innovation and responsiveness to market demands are crucial for maintaining competitive advantage.

In summary, understanding the market dynamics, sustainability considerations, and historical evolution of the PBT GF30 plug will empower B2B buyers to make informed sourcing decisions that align with their operational goals and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of pbt gf30 plug

-

How do I choose the right PBT GF30 plug for my application?

Selecting the appropriate PBT GF30 plug involves understanding the specific requirements of your application, including electrical specifications, environmental conditions, and mechanical stresses. Consider factors such as the number of contacts needed, the voltage and current ratings, and whether you require features like waterproofing or resistance to chemicals. Collaborate with your supplier to discuss your unique needs and ensure the connector’s specifications align with your project’s demands. -

What are the key benefits of using PBT GF30 connectors?

PBT GF30 connectors offer exceptional durability and performance due to their glass fiber-reinforced construction, which enhances strength and dimensional stability. They are resistant to high temperatures and harsh environmental conditions, making them suitable for various industrial applications. Additionally, their design allows for reliable electrical connections, reducing the risk of failures and downtime in critical operations. This combination of features makes them a preferred choice for manufacturers across different sectors. -

What is the minimum order quantity (MOQ) for PBT GF30 plugs?

Minimum order quantities for PBT GF30 plugs can vary significantly among suppliers. Many manufacturers set an MOQ to ensure cost-effectiveness in production and shipping. Typically, the MOQ may range from as low as 10 units to over 100, depending on the supplier’s policies and the specific product configuration. It’s advisable to inquire directly with your chosen supplier about their MOQ and discuss potential exceptions if you have unique ordering needs. -

How can I vet suppliers when sourcing PBT GF30 plugs?

Vetting suppliers is crucial to ensure product quality and reliability. Start by checking their credentials, including industry certifications and customer reviews. Request samples to evaluate the quality of the connectors and inquire about their production processes. Additionally, consider their experience in your specific market region, as this can affect their understanding of local regulations and logistics. Establish clear communication to assess their responsiveness and customer service capabilities. -

What payment terms are typically offered for international orders of PBT GF30 plugs?

Payment terms can vary widely among suppliers, particularly for international transactions. Common options include advance payment, letter of credit, or payment upon delivery. Many suppliers offer net terms for approved accounts, typically ranging from Net 15 to Net 30 days after shipment. It’s essential to discuss payment options upfront and ensure that both parties agree to the terms to prevent any misunderstandings during the transaction. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of PBT GF30 plugs should have robust quality assurance protocols in place. This typically includes rigorous testing of materials and finished products to meet industry standards. Ask about their quality control processes, including inspections, certifications, and any warranties offered. Suppliers should be willing to provide documentation of compliance with relevant regulations, which is particularly important for international shipments. -

How does shipping work for international orders of PBT GF30 plugs?

Shipping for international orders usually involves various logistics considerations, including customs clearance and potential duties. Most suppliers will offer multiple shipping options, ranging from standard to expedited services. It’s important to clarify shipping costs upfront and confirm who is responsible for import duties and taxes. Ensure that the supplier provides tracking information so you can monitor your shipment’s progress. -

Can I customize PBT GF30 plugs to meet specific requirements?

Many manufacturers offer customization options for PBT GF30 plugs to cater to unique applications. Customizations can include alterations in size, the number of contacts, or specific material properties to enhance performance in particular environments. When seeking customization, provide clear specifications and work closely with the supplier’s engineering team to ensure that your requirements are met. This collaborative approach can lead to optimized solutions tailored to your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Pbt Gf30 Plug Manufacturers & Suppliers List

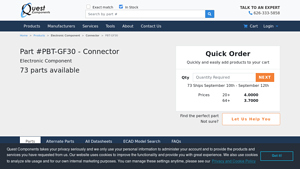

1. AMP – PBT-GF30 Part Number

Domain: questcomp.com

Registered: 2003 (22 years)

Introduction: Part Number: PBT-GF30

Manufacturer: AMP

Availability: 73 parts available

Shipping Dates: September 10th – September 12th

Minimum Order Quantity: 20

Price: $4.0000 each for 20+ units, $3.7000 each for 64+ units

Export Restrictions: Cannot be shipped outside of the US; may not be available for export.

Environmental Compliance: Eu RoHS: Unknown, China RoHS: Unknown, Reach Compliant: Unknown

2. AMP – PBT GF30 Connector

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “AMP PBT GF30 CONNECTOR”, “condition”: “New other (see details)”, “price”: “$25.00 or Best Offer”, “shipping”: “Free shipping”, “estimated_delivery”: “Mon, Sep 15 – Fri, Oct 3”, “quantity_available”: “1”, “outer_material”: “PBT”, “description”: “A new, unused item with absolutely no signs of wear. The item may be missing the original packaging, or in the original packaging but not…

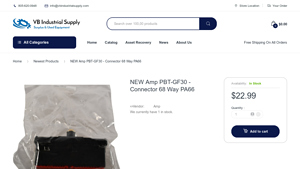

3. Amp – NEW PBT-GF30 Connector 68 Way PA66

Domain: vbindustrialsupply.com

Registered: 2017 (8 years)

Introduction: {“name”:”NEW Amp PBT-GF30 – Connector 68 Way PA66″,”SKU”:””,”vendor”:”Amp”,”availability”:”In Stock”,”price”:”$22.99″,”description”:”NEW Amp PBT-GF30 – Connector 68 Way PA66 NOS, surplus”,”stock_quantity”:1}

4. TE Connectivity – PBT-GF30 Connector

Domain: tedss.com

Registered: 2004 (21 years)

Introduction: {“Part Number”: “PBT-GF30”, “Manufacturer”: “TE Connectivity”, “Item ID”: “2025007360”, “Number of Contacts”: “0”, “Connector Gender”: “-“, “Mounting Type”: “inline”, “Package”: “tube”, “Items per Pack”: “1”, “In Stock”: “Yes”, “Minimum Order Quantity”: “4”, “Unit Price”: “5.00”, “Price for 4”: “20.00”, “Shipping Information”: “Most orders placed before 3:30PM EST Monday to Friday ship same day. O…

5. LHECN – 5268-02A 2 Pin Male Molex Connector

Domain: lhecn.com

Registered: 2007 (18 years)

Introduction: {“Product Name”:”5268-02A 2 Pin Male Molex Pbt Gf30 Connector”,”Product Type”:”Wafer/Header”,”Centerline (Pitch)”:”2.5 mm”,”Connector System”:”Wire-to-Board”,”Material – Resin and Flammability”:”Nylon 66 UL94V-0″,”Material-Metal”:”Brass”,”Plating”:”Tin Plating”,”Color”:”Natural/Beige”,”Number of Positions”:”2″,”Number of Rows”:”1″,”Voltage – Maximum (VAC/DC)”:”250″,”Current – Maximum per Contact (…

6. TE Connectivity – AMP Automotive Connector Caps & Covers

Domain: te.com

Registered: 1992 (33 years)

Introduction: 1456835-1 : AMP Automotive Connector Caps & Covers | TE Connectivity

7. Texas Instruments – PBT-GF30 Connector

Domain: datasheetarchive.com

Registered: 2003 (22 years)

Introduction: Part Number: PBT-GF30 CONNECTOR, Manufacturer: Texas Instruments, Description: Fixed-Point Digital Signal Processor, Package: 176-LQFP, Operating Temperature: -40 to 85

Strategic Sourcing Conclusion and Outlook for pbt gf30 plug

The strategic sourcing of PBT GF30 plugs offers substantial benefits for international B2B buyers, especially in dynamic markets across Africa, South America, the Middle East, and Europe. This high-performance connector, known for its durability and reliability, is essential for various applications, from automotive to industrial sectors. By prioritizing suppliers who offer quality assurance and customized solutions, businesses can enhance operational efficiency and reduce downtime.

Investing in strategic sourcing not only secures superior products but also fosters long-term partnerships that can adapt to evolving market demands. As you consider your next procurement decision, focus on suppliers who emphasize advanced materials and engineering excellence, such as those utilizing glass fiber reinforcement for added strength and stability.

Looking ahead, the demand for PBT GF30 connectors is set to grow as industries increasingly seek reliable, high-quality components. This is an opportune moment for B2B buyers to assess their sourcing strategies and align with manufacturers that can deliver tailored solutions. Engage with trusted suppliers today to ensure you stay competitive in an ever-evolving marketplace.