Is Your 10Ml Bacteriostatic Water Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for 10ml bacteriostatic water

Navigating the global market for 10ml bacteriostatic water presents unique challenges for B2B buyers, particularly when it comes to sourcing reliable suppliers and ensuring product quality. Bacteriostatic water, essential for various medical applications including the dilution of medications and reconstitution of injectable drugs, must be procured with a keen eye on compliance and efficacy. This guide provides a comprehensive overview of the types of bacteriostatic water available, their specific applications, and critical factors to consider when vetting suppliers.

In a landscape where the demand for pharmaceutical-grade solutions is rising, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing 10ml bacteriostatic water becomes imperative. Buyers will gain insights into cost considerations, storage requirements, and best practices for maintaining product integrity. Moreover, the guide offers strategic advice on how to evaluate suppliers based on their quality assurance protocols and regulatory compliance.

By equipping international B2B buyers with actionable insights and detailed knowledge, this guide empowers them to make informed purchasing decisions that enhance operational efficiency and ensure patient safety. In a market marked by diversity and complexity, your ability to navigate these dynamics can significantly impact your business outcomes.

Understanding 10ml bacteriostatic water Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

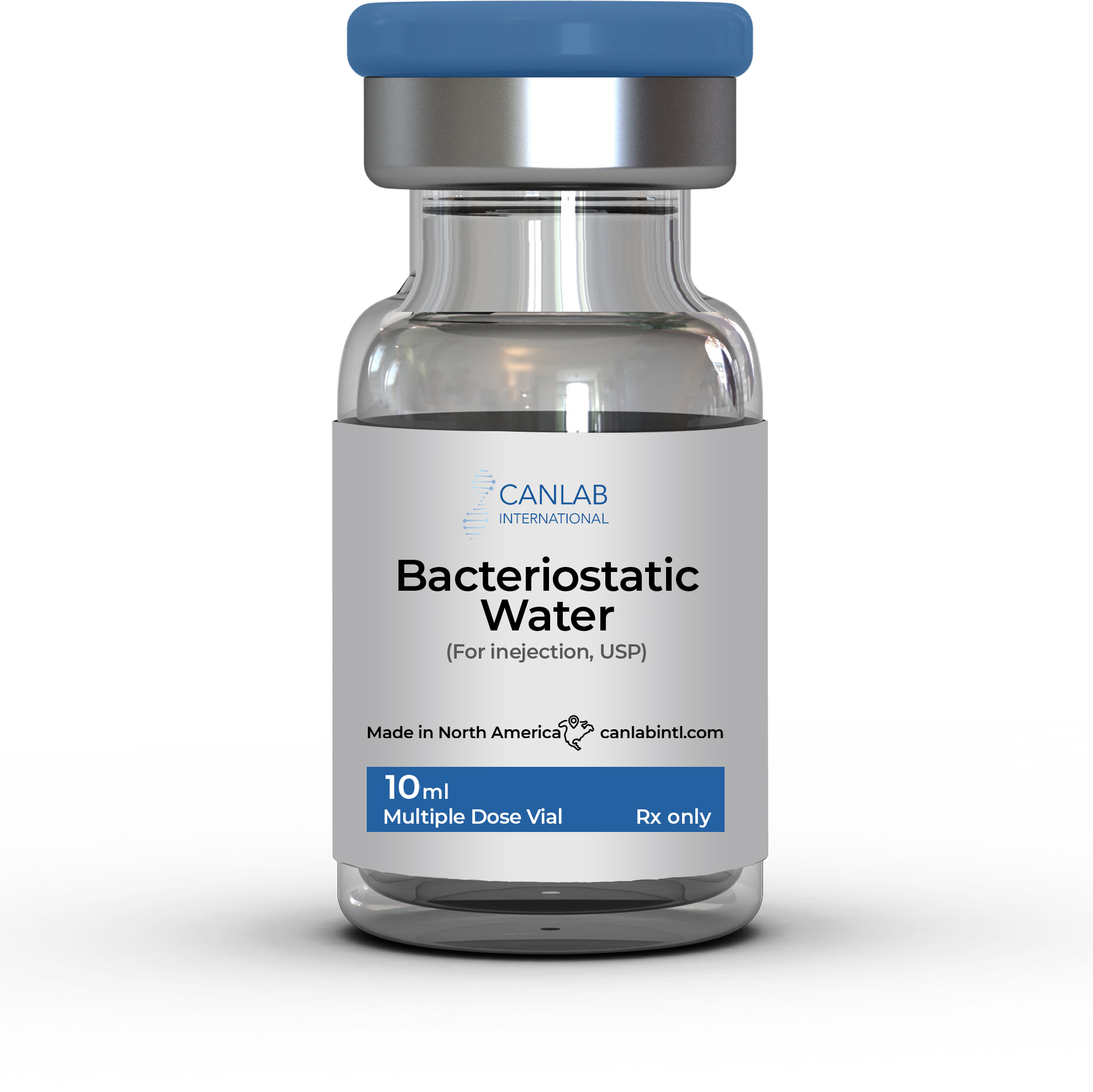

| Multi-Dose Bacteriostatic Water | Contains 0.9% benzyl alcohol for preservation; 30ml vials | Pharmaceutical compounding, medication reconstitution | Pros: Cost-effective for frequent use; Cons: Limited shelf life once opened. |

| Single-Dose Bacteriostatic Water | Typically 10ml or 5ml vials; ideal for single-use applications | Individual patient treatments, emergency care | Pros: Reduces risk of contamination; Cons: Higher per-use cost. |

| Bacteriostatic Water with Additives | May include additional stabilizers or preservatives | Research applications, experimental formulations | Pros: Enhanced stability; Cons: Potential for allergic reactions. |

| Sterile Water vs. Bacteriostatic Water | Bacteriostatic contains additives, unlike sterile water | IV preparations, injection diluents | Pros: Longer shelf life; Cons: Not suitable for all applications. |

| Pre-filled Syringes with Bacteriostatic Water | Convenient, ready-to-use format; often 10ml | Quick emergency injections, outpatient settings | Pros: Time-saving; Cons: May be more expensive than vials. |

What are the Characteristics of Multi-Dose Bacteriostatic Water?

Multi-dose bacteriostatic water is typically packaged in larger vials, such as 30ml, and contains 0.9% benzyl alcohol, which acts as a preservative. This formulation is particularly suited for pharmaceutical compounding and medication reconstitution, allowing healthcare providers to draw multiple doses from a single vial. When considering this option, buyers should evaluate storage conditions and usage frequency, as the shelf life diminishes once opened, impacting overall cost-effectiveness.

Why Choose Single-Dose Bacteriostatic Water?

Single-dose bacteriostatic water vials are designed for immediate use, typically available in sizes like 10ml or 5ml. This type is ideal for individual patient treatments and emergency care, minimizing the risk of contamination that can occur with multi-dose vials. Although the per-use cost is higher, the safety and convenience offered by single-dose vials make them a preferred choice in high-stakes medical environments, where sterility is critical.

What are the Benefits of Bacteriostatic Water with Additives?

Bacteriostatic water with additional stabilizers or preservatives can offer enhanced stability for specific applications, especially in research and experimental formulations. This variation is particularly useful in laboratory settings where longer-term storage of diluted substances is required. Buyers should assess potential allergenic components and regulatory approvals, as the inclusion of additives may limit its applicability in certain clinical settings.

How Does Sterile Water Differ from Bacteriostatic Water?

Sterile water is devoid of any additives, making it suitable for applications that require absolute purity, such as intravenous preparations and injection diluents. In contrast, bacteriostatic water’s preservative properties allow for longer shelf life and multiple uses from a single vial. B2B buyers must carefully consider the intended application, as using bacteriostatic water in scenarios requiring absolute sterility could lead to complications.

What are the Advantages of Pre-filled Syringes with Bacteriostatic Water?

Pre-filled syringes containing bacteriostatic water offer a convenient, ready-to-use solution for quick emergency injections and outpatient settings. This format significantly reduces preparation time and minimizes the risk of contamination, making it ideal for fast-paced medical environments. However, buyers should be aware that pre-filled syringes often come at a premium price compared to traditional vials, necessitating a cost-benefit analysis based on usage frequency.

Key Industrial Applications of 10ml bacteriostatic water

| Industry/Sector | Specific Application of 10ml Bacteriostatic Water | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Reconstitution of powdered medications for injection | Ensures accurate dosing and prolongs shelf life of drugs | Quality assurance, regulatory compliance, and shelf stability |

| Veterinary Medicine | Dilution of medications for animal injections | Enhances medication effectiveness and safety for animals | Sourcing from certified suppliers and adherence to veterinary standards |

| Aesthetic Medicine | Mixing with injectable fillers and anesthetics | Provides safe and sterile solutions for cosmetic procedures | Verification of sterility and proper storage conditions |

| Research Laboratories | Preparation of samples for experimental procedures | Facilitates accurate and reliable experimental results | Sourcing from reputable manufacturers with quality certifications |

| Medical Device Manufacturing | Cleaning and preparing instruments for sterile environments | Reduces the risk of contamination and ensures patient safety | Compliance with health regulations and certifications |

How is 10ml Bacteriostatic Water Used in Pharmaceuticals?

In the pharmaceutical industry, 10ml bacteriostatic water is primarily utilized for the reconstitution of powdered medications intended for injection. The presence of 0.9% benzyl alcohol inhibits bacterial growth, thereby extending the shelf life of the prepared solution. This application is critical for ensuring accurate dosing and maintaining the efficacy of medications, especially when dealing with high-value treatments. International buyers should prioritize suppliers who comply with regulatory standards and provide documentation of quality assurance to avoid issues related to product integrity.

What Role Does 10ml Bacteriostatic Water Play in Veterinary Medicine?

In veterinary practices, 10ml bacteriostatic water is often used to dilute injectable medications, ensuring safe and effective administration to animals. This application is particularly important in treating various conditions in pets and livestock, where the correct dosage can significantly impact treatment outcomes. For B2B buyers in this sector, sourcing from certified suppliers who adhere to veterinary regulations is crucial to guarantee product safety and effectiveness.

How is 10ml Bacteriostatic Water Essential in Aesthetic Medicine?

In the realm of aesthetic medicine, 10ml bacteriostatic water is commonly mixed with injectable fillers and anesthetics. This ensures that the solutions remain sterile and effective during cosmetic procedures. The ability to prolong the usability of these products is a significant advantage for clinics and practitioners. Buyers should ensure that their suppliers can provide evidence of sterility and proper handling protocols to mitigate any risks associated with contamination.

Why is 10ml Bacteriostatic Water Important for Research Laboratories?

Research laboratories utilize 10ml bacteriostatic water for preparing samples in various experimental procedures. The ability to maintain a sterile environment is paramount in scientific research, as it ensures the reliability of results. This application is vital for industries involved in drug development and clinical trials. International buyers should focus on sourcing from reputable manufacturers who can demonstrate compliance with quality certifications to ensure the integrity of their research processes.

How Does 10ml Bacteriostatic Water Contribute to Medical Device Manufacturing?

In medical device manufacturing, 10ml bacteriostatic water is used for cleaning and preparing instruments in sterile environments. This application is critical for reducing contamination risks during medical procedures. For businesses in this sector, compliance with health regulations and obtaining products from certified suppliers are essential to ensure the safety and efficacy of medical devices.

3 Common User Pain Points for ’10ml bacteriostatic water’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance Challenges with Bacteriostatic Water

The Problem:

B2B buyers, especially in the pharmaceutical and healthcare sectors, often grapple with the complex landscape of regulatory compliance when sourcing bacteriostatic water. This is particularly pronounced in regions such as Africa and the Middle East, where regulations can vary significantly by country and even local jurisdictions. Buyers may face difficulties ensuring that their suppliers meet the necessary standards for sterility, quality, and labeling. Failure to comply can result in product recalls, legal penalties, and severe reputational damage.

The Solution:

To mitigate these challenges, buyers should conduct thorough due diligence on potential suppliers. This involves verifying that the suppliers have the required certifications, such as ISO 13485 for medical devices or equivalent standards for pharmaceutical-grade products. Additionally, buyers can request documentation that proves the bacteriostatic water has been manufactured in accordance with Good Manufacturing Practices (GMP). Establishing a relationship with suppliers who are experienced in international shipping and regulations can also streamline compliance. Regular audits and site visits, when possible, can further ensure that the supplier maintains high standards.

Scenario 2: Managing Shelf Life and Storage Concerns

The Problem:

Another common issue faced by B2B buyers of 10ml bacteriostatic water is the management of shelf life and proper storage conditions. Bacteriostatic water typically contains 0.9% benzyl alcohol, which extends its usability, but improper storage can still lead to degradation. In tropical climates, common in parts of Africa and South America, fluctuating temperatures can compromise product integrity, leading to waste and financial loss.

The Solution:

To effectively manage shelf life and storage, buyers should invest in appropriate storage facilities that maintain consistent temperature and humidity levels. It is advisable to use temperature-controlled environments that are monitored with data loggers to ensure compliance with specified storage conditions. Additionally, implementing a first-in, first-out (FIFO) inventory system can help ensure that older stock is used before newer stock, minimizing waste. Suppliers should also provide clear labeling indicating expiration dates and recommended storage conditions. Training staff on proper handling and storage techniques can further enhance product longevity.

Scenario 3: Ensuring Consistency in Quality and Supply Chain Reliability

The Problem:

Quality inconsistency and supply chain disruptions can significantly impact the operations of B2B buyers relying on 10ml bacteriostatic water for critical medical applications. Buyers may encounter variations in product quality, such as differences in sterility or formulation, which can lead to adverse outcomes in patient care. Moreover, geopolitical factors and logistical challenges may result in delays in receiving orders, causing interruptions in production schedules.

The Solution:

To combat these issues, buyers should establish long-term partnerships with reliable suppliers who have a proven track record of consistency and quality. It is beneficial to engage suppliers who have robust quality assurance processes in place, including batch testing and quality control checks. Implementing a contingency plan that includes alternative suppliers can also safeguard against supply chain disruptions. Regular communication with suppliers about inventory levels and anticipated demands can facilitate proactive planning and ensure a steady supply of bacteriostatic water. By fostering collaborative relationships with suppliers, buyers can enhance transparency and trust, further stabilizing their supply chain.

Strategic Material Selection Guide for 10ml bacteriostatic water

What Materials Are Commonly Used for 10ml Bacteriostatic Water?

When selecting materials for 10ml bacteriostatic water, it is crucial to consider the properties of the packaging and the water itself. The most common materials include glass, polypropylene, polyethylene, and aluminum. Each material has unique characteristics that influence its suitability for bacteriostatic water applications.

How Does Glass Perform in Bacteriostatic Water Packaging?

Key Properties: Glass is inert, non-reactive, and can withstand high temperatures, making it an excellent choice for sterilization processes. Its impermeability ensures that the contents remain uncontaminated.

Pros & Cons: Glass vials provide excellent durability and a high level of protection against environmental factors. However, they are more fragile than other materials, which can lead to breakage during transport. The manufacturing process is complex and can result in higher costs compared to plastics.

Impact on Application: Glass is compatible with a wide range of pharmaceutical applications, ensuring that the bacteriostatic properties of the water are maintained.

Considerations for International Buyers: Compliance with international standards such as ASTM and ISO is crucial. Buyers in regions like Europe and the Middle East may prefer glass due to its perceived quality and safety.

What Role Does Polypropylene Play in Bacteriostatic Water Packaging?

Key Properties: Polypropylene (PP) is a lightweight, durable plastic that can withstand moderate temperatures. It is resistant to chemicals and moisture, making it suitable for storing bacteriostatic water.

Pros & Cons: The cost-effectiveness of polypropylene makes it an attractive option for manufacturers. However, it may not offer the same level of barrier protection as glass, potentially compromising the sterility of the contents over time.

Impact on Application: Polypropylene is suitable for applications where weight and cost are significant factors, but it may not be ideal for long-term storage of sensitive compounds.

Considerations for International Buyers: Buyers should ensure that the polypropylene used meets relevant safety standards. In regions like South America and Africa, where cost is a significant factor, this material can be particularly appealing.

How Does Polyethylene Compare for Bacteriostatic Water Applications?

Key Properties: Polyethylene (PE) is another common plastic used for packaging. It offers good chemical resistance and is flexible, which can be beneficial in certain applications.

Pros & Cons: PE is lightweight and relatively inexpensive, making it a popular choice. However, its flexibility may lead to a less secure seal, which can affect the sterility of the bacteriostatic water.

Impact on Application: While suitable for short-term applications, polyethylene may not provide the long-term stability required for bacteriostatic water.

Considerations for International Buyers: Compliance with local regulations is essential, particularly in regions like Africa and the Middle East, where standards may vary significantly.

What Advantages Does Aluminum Offer for Bacteriostatic Water Packaging?

Key Properties: Aluminum is lightweight, corrosion-resistant, and provides an excellent barrier against light and moisture, which can help preserve the integrity of the bacteriostatic water.

Pros & Cons: Aluminum is durable and can be produced at a relatively low cost. However, it may not be as widely accepted in the pharmaceutical industry due to concerns about leaching and chemical interactions.

Impact on Application: Aluminum is suitable for applications where light protection is critical, but its use may be limited in sensitive pharmaceutical applications.

Considerations for International Buyers: Buyers should consider regional preferences for packaging materials. In Europe, for instance, there is a strong emphasis on sustainability, which may influence the choice of aluminum.

Summary Table of Material Selection for 10ml Bacteriostatic Water

| Material | Typical Use Case for 10ml bacteriostatic water | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Pharmaceutical vials for injection | Excellent barrier, inert | Fragile, higher manufacturing costs | High |

| Polypropylene | Cost-effective single-use vials | Lightweight, cost-effective | Less effective barrier, potential sterility issues | Medium |

| Polyethylene | Short-term storage solutions | Inexpensive, lightweight | Flexibility may compromise sealing | Low |

| Aluminum | Light-sensitive applications | Corrosion-resistant, good barrier | Potential leaching concerns | Medium |

This guide provides a comprehensive overview of material options for 10ml bacteriostatic water, enabling international B2B buyers to make informed decisions based on their specific needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 10ml bacteriostatic water

What Are the Main Stages of Manufacturing 10ml Bacteriostatic Water?

The production of 10ml bacteriostatic water involves several critical stages, each designed to ensure the final product meets stringent quality and safety standards.

-

Material Preparation: The process begins with the selection of high-purity water, typically distilled or deionized, which is essential for ensuring the sterility and safety of the product. Additionally, benzyl alcohol (0.9%) is added as a bacteriostatic agent. The materials must be sourced from reliable suppliers who adhere to Good Manufacturing Practices (GMP).

-

Forming: In this stage, the prepared water and additives are combined in a controlled environment. This step often involves automated systems that minimize human intervention to reduce contamination risks. The mixture is then transferred into sterilized vials, ensuring that each vial maintains the necessary sterile conditions.

-

Assembly: After filling, the vials are capped with sterile closures. This process is typically performed in a cleanroom environment to prevent any exposure to contaminants. The assembly line must be equipped with proper sealing mechanisms to ensure that each vial is airtight, thereby maintaining sterility.

-

Finishing: Finally, the vials undergo labeling and packaging. This includes not only the product details but also necessary regulatory information. The packaging must be robust enough to protect the vials during transportation and storage. Quality checks at this stage ensure that all labeling is accurate and that packaging meets international shipping standards.

Which Key Techniques Are Used in the Production of Bacteriostatic Water?

Several advanced techniques are utilized in the manufacturing of bacteriostatic water to ensure quality and compliance:

-

Sterilization Techniques: The water undergoes filtration and sterilization processes, such as autoclaving or using ultraviolet light, to eliminate any microbial contamination. These methods ensure that the final product is safe for injection.

-

Automated Filling Systems: Modern production lines often employ automated filling machines that ensure precise measurements of both water and benzyl alcohol. This automation helps in maintaining consistency and accuracy across batches.

-

Cleanroom Environments: The entire production process is conducted in cleanroom facilities that meet ISO Class 5 or higher standards. This environment minimizes airborne particles and microbial contamination, essential for pharmaceutical-grade products.

What International Standards Govern the Quality of Bacteriostatic Water?

Quality assurance for 10ml bacteriostatic water is governed by several international standards, ensuring that products meet global safety and efficacy criteria:

-

ISO 9001: This is a fundamental quality management standard that outlines criteria for a quality management system (QMS). Compliance with ISO 9001 signifies that the manufacturer has implemented processes to ensure consistent quality and improvement.

-

CE Marking: For products marketed in the European Economic Area (EEA), CE marking indicates conformity with health, safety, and environmental protection standards. It is crucial for manufacturers targeting the European market.

-

United States Pharmacopeia (USP): Products must comply with USP standards, which dictate the quality, purity, strength, and consistency of pharmaceuticals. Bacteriostatic water is classified under USP monographs, ensuring it meets the required specifications.

-

Good Manufacturing Practices (GMP): Compliance with GMP is mandatory for pharmaceutical products. This set of regulations ensures that products are consistently produced and controlled according to quality standards.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integral to the manufacturing of bacteriostatic water. Key checkpoints in the QC process include:

-

Incoming Quality Control (IQC): Before production, raw materials such as water and benzyl alcohol undergo rigorous testing to confirm their purity and suitability for use. This includes checking for contaminants and verifying supplier certificates.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring takes place to ensure that equipment is functioning correctly, and the environmental conditions remain within specified limits. This can include regular sampling and testing of the product at various stages.

-

Final Quality Control (FQC): After production, the final product is subjected to comprehensive testing. This includes sterility testing, pH level checks, and endotoxin testing to ensure it meets all regulatory requirements before packaging and distribution.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers should take proactive measures to verify the quality control processes of their suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, cleanliness of facilities, and adherence to GMP and other relevant standards. This firsthand observation can be invaluable in evaluating supplier reliability.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers provides insights into their QC processes. These reports should include results from routine testing, compliance documentation, and any certifications held.

-

Third-Party Inspections: Engaging third-party organizations to inspect manufacturing facilities can provide an unbiased assessment of the supplier’s compliance with international standards. This can help mitigate risks associated with sourcing from new or unverified suppliers.

What Nuances Should International Buyers Consider in Quality Control?

For international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. For instance, products intended for the European market must comply with CE marking, while those for the U.S. may need to meet FDA requirements. Buyers should ensure that suppliers are familiar with the specific regulations of the target market.

-

Cultural and Language Barriers: Effective communication is crucial for understanding quality assurance practices. Buyers should consider language proficiency and cultural differences when engaging with suppliers, as this can impact the clarity of quality standards and expectations.

-

Supply Chain Reliability: Assessing the entire supply chain is vital. Factors such as transportation, storage conditions, and the ability to respond to quality issues can significantly affect the final product’s quality. Buyers should inquire about the supplier’s logistics capabilities and contingency plans for quality control.

By being diligent in evaluating manufacturing processes and quality assurance practices, B2B buyers can ensure they source high-quality 10ml bacteriostatic water that meets their needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ’10ml bacteriostatic water’

Introduction

This guide aims to provide a comprehensive checklist for B2B buyers looking to procure 10ml bacteriostatic water. Sourcing this essential medical product requires careful consideration of various factors, including quality, supplier reliability, and regulatory compliance. Follow these steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for bacteriostatic water. Understanding the specific needs of your operation will guide your sourcing process. Consider factors such as the volume required, packaging type (e.g., vials), and any particular certifications needed for your region.

Step 2: Research Regulatory Compliance

Ensure that the bacteriostatic water meets local and international regulations. Different regions have varying requirements for medical supplies, and compliance is crucial for legal and safety reasons. Check for certifications such as FDA approval in the U.S. or CE marking in Europe, which indicate that the product meets necessary standards.

Step 3: Evaluate Potential Suppliers

Conduct thorough vetting of potential suppliers. This step is vital to ensure that you partner with reputable companies that can deliver quality products consistently. Request documentation such as company profiles, case studies, and references from other buyers in similar industries or regions to assess their reliability and track record.

- Look for supplier reviews and testimonials.

- Check their history of quality control practices.

Step 4: Assess Quality Assurance Processes

Inquire about the supplier’s quality assurance measures. This is important to guarantee that the bacteriostatic water is produced under strict conditions that prevent contamination and ensure efficacy. Ask about their production processes, testing protocols, and any third-party certifications they may hold.

- Verify if they conduct regular batch testing.

- Ask about their adherence to Good Manufacturing Practices (GMP).

Step 5: Understand Pricing Structures

Review the pricing models and payment terms offered by suppliers. Understanding the cost implications will help you stay within budget while ensuring quality. Be wary of prices that seem too good to be true, as they may indicate inferior quality or hidden costs.

- Compare bulk pricing versus single-unit pricing.

- Inquire about shipping and handling fees.

Step 6: Confirm Availability and Delivery Times

Ensure that the supplier can meet your delivery timelines. Timeliness is critical in the medical field, where delays can impact patient care. Ask about their inventory levels, lead times, and policies for backorders to avoid disruptions.

- Discuss minimum order quantities and restocking schedules.

- Check if they offer expedited shipping options.

Step 7: Establish Communication and Support

Maintain open lines of communication with the supplier. Good communication is essential for addressing any concerns that may arise during the procurement process. Ensure that the supplier has a dedicated customer service team to assist with inquiries and support.

- Ask about their response times to inquiries.

- Inquire about ongoing support for product-related questions.

By following this step-by-step checklist, B2B buyers can effectively navigate the procurement process for 10ml bacteriostatic water, ensuring they select a supplier that meets their needs while adhering to the highest standards of quality and compliance.

Comprehensive Cost and Pricing Analysis for 10ml bacteriostatic water Sourcing

What Are the Key Cost Components in 10ml Bacteriostatic Water Sourcing?

When sourcing 10ml bacteriostatic water, understanding the cost structure is essential for effective budgeting and pricing negotiations. The primary cost components include:

-

Materials: The main ingredient, bacteriostatic water, typically includes 0.9% benzyl alcohol, which enhances its shelf life and safety. The cost of raw materials can fluctuate based on market demand, availability, and supplier pricing.

-

Labor: Labor costs encompass the workforce involved in production, quality control, and packaging. Skilled labor is often required for manufacturing processes to ensure compliance with health and safety regulations.

-

Manufacturing Overhead: This includes indirect costs such as utilities, maintenance, and facility costs. Efficient production processes can help minimize these expenses.

-

Tooling: Specialized equipment for filling and packaging the vials adds to the initial capital investment. The tooling cost is amortized over the production volume, impacting pricing.

-

Quality Control (QC): Given the medical application of bacteriostatic water, rigorous QC processes are necessary to ensure product safety and efficacy. These processes can add significant costs but are vital for regulatory compliance.

-

Logistics: Shipping and handling costs vary depending on the destination, particularly for international buyers. Factors such as packaging, transportation modes, and customs duties can influence the overall logistics costs.

-

Margin: Suppliers typically apply a profit margin to cover their costs and generate profit. This margin can vary based on competition, demand, and supplier reputation.

How Do Price Influencers Impact 10ml Bacteriostatic Water Costs?

Several factors can influence the pricing of 10ml bacteriostatic water:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit prices due to economies of scale. Understanding the minimum order quantity (MOQ) is crucial for optimizing costs.

-

Specifications and Customization: Custom formulations or packaging may incur additional costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., GMP, ISO) can raise costs but are essential for ensuring product safety and compliance, particularly in regulated markets.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can impact pricing. Suppliers with robust quality assurance processes may charge a premium but can offer peace of mind.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) will dictate who bears the cost and risk at various stages of the shipping process. This can affect the total landed cost for international buyers.

What Are the Best Buyer Tips for Sourcing 10ml Bacteriostatic Water?

To optimize your sourcing strategy for 10ml bacteriostatic water, consider the following tips:

-

Negotiate Effectively: Engage suppliers in negotiations to explore pricing flexibility, especially for larger orders. Establishing a long-term partnership may yield better pricing and terms.

-

Focus on Cost-Efficiency: Assess total cost of ownership (TCO) rather than just initial pricing. Include logistics, quality assurance, and potential wastage in your calculations to get a true sense of value.

-

Understand Pricing Nuances for International Sourcing: Be aware of currency fluctuations, import duties, and local regulations that may affect pricing. Researching the market in your region can provide insights into competitive pricing.

-

Build Relationships with Suppliers: A strong relationship can lead to better service, pricing, and reliability. Regular communication and feedback can enhance collaboration.

-

Stay Informed About Market Trends: Keep abreast of changes in material costs, regulatory updates, and industry standards. This knowledge can empower you to make informed purchasing decisions.

Disclaimer

The prices for 10ml bacteriostatic water can vary widely based on the factors outlined above. The figures mentioned in this analysis are indicative and may not reflect current market conditions. Always consult multiple suppliers and conduct thorough market research to obtain accurate pricing information.

Alternatives Analysis: Comparing 10ml bacteriostatic water With Other Solutions

Exploring Alternatives to 10ml Bacteriostatic Water: A Comparative Analysis

In the medical and pharmaceutical sectors, selecting the right solution for medication preparation and injection is critical. While 10ml bacteriostatic water is a widely used option, it’s important for B2B buyers to consider other viable alternatives that may suit their specific needs. This analysis compares 10ml bacteriostatic water with sterile water for injection and saline solution, focusing on key aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | 10ml Bacteriostatic Water | Sterile Water for Injection | Saline Solution |

|---|---|---|---|

| Performance | Inhibits bacterial growth, suitable for multiple uses | Acts as a diluent but does not prevent bacterial growth | Isotonic solution for hydration and electrolyte balance |

| Cost | Moderate ($16.95 per vial) | Low ($8.77 per vial) | Moderate ($10.00 per vial) |

| Ease of Implementation | Requires careful handling and proper storage | Simple to use, no special requirements | Easy to use, widely available |

| Maintenance | Requires strict adherence to storage guidelines | Minimal maintenance needed | No special maintenance |

| Best Use Case | Ideal for reconstituting medications that require multiple doses | Best for single-use applications or immediate dilution | Suitable for hydration and electrolyte replacement |

Understanding the Pros and Cons of Each Alternative

Sterile Water for Injection

Sterile water for injection is a pharmaceutical-grade solution that serves as a solvent or diluent for medications. It is cost-effective, making it appealing for bulk purchases, especially in regions with budget constraints. However, it lacks the bacteriostatic properties of 10ml bacteriostatic water, limiting its use for multiple-dose applications. This makes it suitable primarily for single-use scenarios or immediate dilution, where immediate bacterial growth is not a concern.

Saline Solution

Saline solution, which is essentially a saltwater mixture, is another alternative frequently used in medical settings. It is isotonic, making it ideal for hydration and electrolyte balance in patients. Saline is simple to use and widely available, which can be advantageous for B2B buyers in regions with limited access to specialized medical supplies. Nonetheless, saline does not possess the bacteriostatic properties necessary for reconstituting medications for multiple doses, limiting its application in situations where sterility over time is essential.

How to Choose the Right Solution for Your Needs

When selecting the appropriate solution for your medical or pharmaceutical needs, consider the specific requirements of your applications. If you require a product for multiple-dose reconstitution and need to inhibit bacterial growth, 10ml bacteriostatic water is likely your best choice despite its moderate cost. Conversely, if your focus is on single-use applications or immediate dilution, sterile water for injection may be more suitable due to its lower price point. For situations requiring hydration or electrolyte balance, saline solution is an excellent option, provided that its lack of bacteriostatic properties aligns with your application needs.

In conclusion, understanding the strengths and weaknesses of each alternative allows B2B buyers to make informed decisions, ensuring they procure the most effective solution for their specific medical and pharmaceutical requirements.

Essential Technical Properties and Trade Terminology for 10ml bacteriostatic water

What Are the Key Technical Properties of 10ml Bacteriostatic Water?

When evaluating 10ml bacteriostatic water for purchase, several critical specifications must be considered to ensure quality and efficacy. Here are the essential technical properties:

-

Composition: Bacteriostatic water typically contains 0.9% benzyl alcohol as a preservative, which inhibits bacterial growth. This formulation is crucial for extending the shelf life of the solution, making it suitable for multiple uses. For B2B buyers, understanding the composition helps ensure that the product meets safety and regulatory standards in their respective markets.

-

Sterility Assurance: The product must be certified sterile, meaning it is free from all viable microorganisms. Sterility is paramount in medical applications, particularly for injections, as contamination can lead to severe health risks. Buyers should verify that the manufacturer employs rigorous sterilization processes and provides appropriate certifications.

-

pH Level: The pH of bacteriostatic water should typically range between 5.0 and 7.0. This neutral pH range is important for compatibility with various medications and minimizes the risk of irritation upon injection. Buyers need to confirm that the product’s pH is within this range to ensure optimal compatibility.

-

Packaging: Bacteriostatic water is commonly packaged in 10ml vials, which should be made from high-quality, inert materials that do not leach chemicals into the solution. Proper packaging is critical for maintaining the integrity of the product during storage and transport. Buyers should ensure that the packaging meets international standards to avoid contamination.

-

Shelf Life: The shelf life of bacteriostatic water is typically 28 days after opening and up to three years when unopened. Understanding the shelf life is essential for inventory management and ensuring the product’s efficacy. Buyers should seek products with clear labeling regarding expiration dates and storage conditions.

What Are Common Trade Terms Used in Bacteriostatic Water Transactions?

In B2B transactions, familiarity with industry jargon can facilitate smoother negotiations and better understanding. Here are some common trade terms related to the procurement of 10ml bacteriostatic water:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce products or components that are used in another company’s end product. Buyers should consider OEM relationships to ensure they receive high-quality bacteriostatic water that meets their specific needs.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage their budgets and inventory effectively, especially when dealing with smaller-scale operations.

-

RFQ (Request for Quotation): An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products. Utilizing RFQs can help buyers compare pricing and terms from different manufacturers, facilitating informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international transactions to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for buyers involved in cross-border procurement, ensuring clarity in shipping responsibilities.

-

Lead Time: This term refers to the time it takes from placing an order until the product is delivered. Understanding lead times is essential for buyers to plan their inventory and ensure that they have enough stock on hand to meet demand.

-

Certificate of Analysis (CoA): A CoA is a document provided by manufacturers that certifies the quality and composition of the product. Buyers should always request a CoA to verify that the bacteriostatic water meets the required specifications and regulatory standards.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they procure high-quality bacteriostatic water that meets their specific needs and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the 10ml bacteriostatic water Sector

What Are the Key Market Trends Influencing the 10ml Bacteriostatic Water Sector?

The global market for 10ml bacteriostatic water is experiencing significant growth, driven by an increasing demand for injectable medications and the growing prevalence of chronic diseases. Emerging markets in Africa, South America, the Middle East, and Europe are particularly influential, as healthcare systems in these regions are expanding and modernizing. The rise of telemedicine and digital health solutions is also reshaping procurement strategies, enabling buyers to leverage online platforms for sourcing medical supplies efficiently.

A noteworthy trend is the shift toward multi-dose vials, such as 10ml bacteriostatic water, which enhances cost-effectiveness and reduces waste. This is especially pertinent in markets where healthcare budgets are constrained. Additionally, the integration of advanced technologies like blockchain for supply chain transparency is gaining traction. Buyers are increasingly prioritizing suppliers who can demonstrate compliance with international standards, ensuring product safety and efficacy.

Furthermore, the emphasis on quality assurance and regulatory compliance is becoming paramount. International buyers are seeking suppliers who adhere to stringent pharmaceutical regulations, particularly in regions like Europe and the Middle East, where compliance with Good Manufacturing Practices (GMP) is critical. As a result, sourcing strategies are evolving to prioritize long-term partnerships with reputable manufacturers that can provide consistent quality and reliability.

How Important Is Sustainability and Ethical Sourcing in the Bacteriostatic Water Sector?

Sustainability is increasingly becoming a cornerstone of procurement strategies in the medical supply industry, including bacteriostatic water. Buyers are more aware of the environmental impacts associated with production and distribution. This awareness is driving a demand for ethically sourced materials and processes, particularly in regions like Europe and North America, where regulatory frameworks are stringent.

In the context of 10ml bacteriostatic water, suppliers that can demonstrate sustainable practices—such as minimizing waste and using eco-friendly packaging—are more likely to gain favor with B2B buyers. Certifications such as ISO 14001 (Environmental Management) and the use of recyclable materials can serve as differentiators in a competitive market.

Moreover, ethical sourcing extends beyond environmental considerations; it encompasses fair labor practices and the integrity of supply chains. Buyers are increasingly scrutinizing their suppliers’ sourcing practices, seeking to avoid partnerships with companies involved in unethical labor practices. This trend is particularly relevant in emerging markets, where regulatory oversight may be less stringent, making it essential for buyers to conduct thorough due diligence.

What Is the Historical Context of Bacteriostatic Water in the Pharmaceutical Sector?

The use of bacteriostatic water dates back to the mid-20th century when it was first introduced as a safe diluent for injectable medications. Initially, the focus was predominantly on ensuring sterility and preventing bacterial growth, which was critical in the wake of widespread antibiotic use. Over the years, the formulation has evolved to include 0.9% benzyl alcohol, enhancing its shelf life and usability for multiple doses.

As the pharmaceutical landscape has transformed, so too has the role of bacteriostatic water. Today, it is integral not only in hospitals but also in outpatient settings and home healthcare, reflecting the increasing complexity of patient care. The historical evolution of bacteriostatic water highlights its adaptability and the ongoing need for safe, effective solutions in the ever-changing healthcare environment. This context is crucial for B2B buyers, as understanding the product’s development can inform sourcing decisions and highlight the importance of regulatory compliance and quality assurance in today’s market.

Frequently Asked Questions (FAQs) for B2B Buyers of 10ml bacteriostatic water

-

How do I ensure the quality of 10ml bacteriostatic water before purchasing?

To ensure the quality of 10ml bacteriostatic water, always source from reputable suppliers with proven track records. Request Certificates of Analysis (CoA) that verify the product’s sterility and chemical composition. Additionally, inquire about manufacturing practices, including compliance with Good Manufacturing Practices (GMP). If possible, seek samples for testing before placing a bulk order. Establishing clear communication with the supplier about quality standards will help mitigate risks associated with product efficacy. -

What is the best way to vet suppliers of 10ml bacteriostatic water?

Vetting suppliers involves a multi-step process. Start by researching their reputation within the industry, checking for reviews and testimonials from other B2B buyers. Verify their certifications and compliance with international quality standards. Engage in direct communication to assess their responsiveness and willingness to provide documentation. Additionally, consider visiting their manufacturing facilities if feasible, or request a virtual tour. Finally, establish a trial order to evaluate the product and service quality firsthand before committing to larger purchases. -

What are the minimum order quantities (MOQ) for 10ml bacteriostatic water?

Minimum order quantities for 10ml bacteriostatic water can vary significantly between suppliers. Typically, MOQs may range from 100 to 1,000 vials, depending on the manufacturer and pricing structure. It’s crucial to clarify these details upfront to avoid unexpected costs. Some suppliers may offer flexibility on MOQs for long-term contracts or bulk purchasing agreements. Always negotiate terms that align with your procurement strategy and budget. -

What payment terms should I expect when sourcing 10ml bacteriostatic water internationally?

Payment terms can differ widely based on the supplier and your location. Common options include net 30, net 60, or payment upon shipment. Some suppliers may require a deposit upfront, especially for larger orders. International transactions often involve additional considerations such as currency exchange rates and transaction fees. Always discuss and agree upon payment methods—wire transfer, credit card, or letters of credit—prior to finalizing any orders to ensure a smooth transaction process. -

How can I customize the packaging for my 10ml bacteriostatic water order?

Customization of packaging for 10ml bacteriostatic water is typically available through many suppliers. Discuss your specific requirements, such as branding, labeling, or bulk packaging needs, during the negotiation phase. Ensure that the supplier can meet regulatory requirements for labeling in your target market. Additionally, inquire about the costs associated with customization, as these may impact your overall budget. Establishing clear guidelines and expectations upfront will facilitate a smoother customization process. -

What are the logistics considerations for importing 10ml bacteriostatic water?

When importing 10ml bacteriostatic water, logistics considerations include shipping methods, customs clearance, and temperature control during transit. Choose a reliable freight forwarder familiar with pharmaceutical products to navigate international shipping regulations. Ensure that the supplier provides necessary documentation, including the bill of lading and customs declarations. Additionally, discuss storage conditions upon arrival to maintain product integrity. Understanding these logistical aspects will help prevent delays and ensure compliance with local regulations. -

How do I handle potential customs issues when importing bacteriostatic water?

Customs issues can arise due to regulatory compliance, documentation errors, or product classification. To mitigate these risks, familiarize yourself with your country’s import regulations regarding pharmaceutical products. Ensure that all documentation, such as invoices, CoA, and import permits, is complete and accurate. Collaborating with a customs broker can facilitate smoother clearance processes. If issues arise, maintain open communication with your supplier and broker to quickly resolve any discrepancies. -

What are the shelf life and storage requirements for 10ml bacteriostatic water?

Bacteriostatic water typically has a shelf life of 28 days after opening, while unopened vials can last longer, often up to 24 months. Store the product in a cool, dry place away from direct sunlight. Adhering to proper storage conditions is essential to maintain efficacy and safety. Always check the expiration date before use, and follow manufacturer guidelines for disposal of expired or unused products to ensure compliance with local regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 10Ml Bacteriostatic Water Manufacturers & Suppliers List

1. Bacteriostatic Water – 30ml for Injection (100 Pack)

Domain: bacteriostaticwater.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”30ml Bacteriostatic Water for Injection (100 Pack)”,”price”:”$1,200.00″},{“name”:”30ml Bacteriostatic Water for Injection (25 Pack)”,”price”:”$323.75″},{“name”:”30ml Bacteriostatic Water for Injection (3 pack)”,”price”:”$48.00″,”rating”:5.0,”reviews”:28},{“name”:”30ml Bacteriostatic Water for Injection (5 Pack)”,”price”:”$74.75″,”rating”:5.0,”reviews”:3},{“name”:”30ml Bacteri…

2. Hospira – Bacteriostatic Water for Injection, USP

Domain: mountainside-medical.com

Registered: 2005 (20 years)

Introduction: Bacteriostatic Water for Injection, USP, 30 mL by Hospira, Multiple Dose Vials 25/Pack (Rx) – Original price $299.95, Current price $229.00. Sterile, versatile, and reliable solution for parenteral preparation and medication reconstitution. Contains 0.9% benzyl alcohol for extended shelf life. Ideal for dilution and injection, inhibits bacterial growth. Follow proper dosage guidelines and consult …

3. Atlantic Med Supply – Bacteriostatic Water & Sodium Chloride

Domain: atlanticmedsupply.com

Registered: 2005 (20 years)

Introduction: Bacteriostatic Water for Injection 30ml Vials, Product ID: 03977-03, Unit Price: $0.00; Bacteriostatic Sodium Chloride 0.9% 10ml Vial, Product ID: 0924-10, Unit Price: $0.00; Bacteriostatic Sodium Chloride 0.9% 30ml Vial, Product ID: 0196607, Unit Price: $0.00.

4. Farris Labs – Sterile Water for Injection

Domain: farrislabs.com

Registered: 2003 (22 years)

Introduction: 10ml & 50ml Sterile Water for Injection Vial from Hospira; sterile, nonpyrogenic preparation; contains no bacteriostat, antimicrobial agent, or added buffer; used to dilute or dissolve drugs for injection; sold to licensed medical professionals and available by prescription; stored at room temperature; expiration dates: 10ml exp. 8/30/27, 50ml exp. 12/31/26; available in various pack sizes.

5. Modern Peptides – Bacteriostatic Water (BAC)

Domain: modernpeptides.com

Registered: 2024 (1 years)

Introduction: {“product_name”: “Bacteriostatic Water (BAC)”, “price_range”: “$12 – $28”, “sizes_available”: [“10ml”, “30ml”], “description”: “Our Bacteriostatic (BAC) water is made precisely for reconstitution of research peptides. It is a sterile, multi-dose solution designed for use in diluting or dissolving research peptides, hormones, and other compounds. The inclusion of 0.9% benzyl alcohol acts as a prese…

6. Ameanop Peptides – Bacteriostatic Water 10mL

Domain: ameanopeptides.com

Registered: 2025 (0 years)

Introduction: {“product_name”: “Bacteriostatic Water 10mL”, “price”: “$12.00”, “original_price”: “$15.00”, “volume”: “10mL”, “preservative”: “0.9% benzyl alcohol”, “usage”: “Research use only”, “container_type”: “Multi-use container”, “sterility”: “Sterile handling recommended”, “stock_availability”: “1490 in stock”, “discounts”: [{“quantity_range”: “1 – 4”, “price”: “$12.00”}, {“quantity_range”: “5 – 9”, “pric…

7. Battle Born Research – Reconstitution Solution (BAC Water)

Domain: battlebornresearch.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “Reconstitution Solution (BAC Water)”, “Volume”: “10mL”, “Price”: “$10.00”, “Composition”: “Sterile water with 0.9% benzyl alcohol”, “Container”: “Sealed sterile glass vial”, “Use Window”: “Up to 28 days once opened under sterile conditions”, “Storage”: “Store at 2–8°C after first use”, “Research Applications”: [“Peptide reconstitution for in vitro or in vivo studies”, “Laboratory…

Strategic Sourcing Conclusion and Outlook for 10ml bacteriostatic water

How Can Strategic Sourcing Optimize Your Procurement of 10ml Bacteriostatic Water?

In summary, effective strategic sourcing of 10ml bacteriostatic water is essential for international B2B buyers seeking reliable and high-quality medical supplies. Prioritizing suppliers with proven track records and certifications ensures compliance with safety standards and enhances product efficacy. Additionally, understanding market trends, pricing structures, and regional regulations can significantly inform purchasing decisions, especially in diverse markets across Africa, South America, the Middle East, and Europe.

By leveraging strategic sourcing practices, businesses can not only optimize their supply chains but also foster long-term partnerships that drive value and innovation. The ability to negotiate favorable terms and maintain consistent supply levels can lead to improved operational efficiency and cost savings.

As we look ahead, it is crucial for B2B buyers to remain proactive and adaptable in their sourcing strategies. Engaging with reputable suppliers and exploring emerging markets will be key to navigating the evolving landscape of medical supply procurement. Take the next step in enhancing your sourcing strategy for 10ml bacteriostatic water today—your commitment to quality and reliability can significantly impact your business success.