Top 7 Cq 160U Suppliers (And How to Choose)

Introduction: Navigating the Global Market for cq 160u

In the competitive landscape of sourcing high-performance components like the cq 160u, international B2B buyers face the challenge of navigating a diverse market characterized by varying quality standards, pricing discrepancies, and supplier reliability. This guide serves as a comprehensive resource, addressing critical aspects such as the types and applications of cq 160u products, effective supplier vetting strategies, and cost considerations. By delving into the specifications and benefits of cq 160u components, buyers can make informed decisions that enhance operational efficiency and product performance.

The cq 160u encompasses a range of high-precision components and engines suitable for diverse sectors, including industrial machinery and automotive applications. Understanding the distinct features, such as low power consumption, compact design, and customizable options, allows buyers to align their procurement strategies with their specific operational needs.

This guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—like Nigeria and Brazil—by providing actionable insights into sourcing practices and supplier selection. With a focus on quality assurance and market trends, buyers can confidently navigate the global market for cq 160u, ensuring they secure the best products to meet their business requirements.

Understanding cq 160u Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CQ 160M CW | Operates in CW mode, focuses on low-power communication | Amateur radio contests, emergency communications | Pros: Efficient use of bandwidth; Cons: Requires specific equipment and skills. |

| CQ 160M SSB | Operates in SSB mode, allows voice communication | Commercial radio broadcasting, hobbyist events | Pros: More user-friendly; Cons: Higher power consumption. |

| CQ 160M Digital Modes | Utilizes digital communication protocols (e.g., FT8) | Remote monitoring, automated data transmission | Pros: High efficiency in weak signal conditions; Cons: Complexity in setup. |

| CQ 160M Multi-Operator | Involves multiple operators at one station | Large-scale contests, collaborative projects | Pros: Increased efficiency and score potential; Cons: Coordination challenges. |

| CQ 160M Remote Operation | Allows remote operation of stations within specific limits | Remote communications, disaster recovery | Pros: Flexibility in operation; Cons: Dependence on stable internet connection. |

What Are the Key Characteristics of CQ 160M CW?

CQ 160M CW is distinguished by its use of Continuous Wave (CW) signals, which are ideal for low-power communication. This mode is particularly beneficial in situations where bandwidth is limited or during contests where operators aim to maximize their reach with minimal power. B2B buyers should consider investing in specialized CW transceivers and antennas designed for optimal performance on the 160-meter band. The primary applications include amateur radio contests and emergency communications, making it a valuable tool for organizations focused on disaster preparedness.

How Does CQ 160M SSB Differ in Functionality and Use?

CQ 160M SSB (Single Sideband) enables voice communication, making it more accessible for operators who prefer verbal interaction. This mode is widely used in commercial radio broadcasting and hobbyist events. For B2B buyers, the ease of use and broader appeal of SSB equipment can enhance communication capabilities. However, it typically requires more power than CW and may necessitate additional infrastructure, such as better antennas and amplifiers. Buyers should weigh the pros of user-friendliness against the cons of higher operational costs.

Why Consider CQ 160M Digital Modes for Your Business?

Digital modes, such as FT8, allow for automated communication and can efficiently transmit data even under challenging conditions. This makes them particularly suitable for remote monitoring and automated data transmission applications. B2B buyers should consider the complexity of setting up digital communication systems, which may require specialized software and hardware. However, the ability to operate effectively in weak signal environments is a significant advantage, especially for businesses in remote locations or those requiring reliable data transfer.

What Are the Advantages of Multi-Operator CQ 160M Stations?

Multi-operator CQ 160M stations enable several operators to work from the same location, thereby increasing efficiency and scoring potential in contests. This collaborative approach is beneficial for large-scale events or projects that require diverse skill sets. B2B buyers should consider the logistical challenges of coordinating multiple operators, including equipment sharing and communication among team members. While this setup can lead to higher productivity, it also demands careful planning and management to ensure smooth operations.

How Does Remote Operation Enhance CQ 160M Communication?

Remote operation of CQ 160M stations allows operators to control their equipment from a distance, providing flexibility and convenience. This is particularly advantageous for businesses involved in remote communications or disaster recovery efforts, where on-site presence may not be feasible. B2B buyers should ensure that they have a reliable internet connection and appropriate remote access software. The primary benefit is the flexibility it offers, but buyers must also consider the potential downsides, such as the risk of connectivity issues affecting operations.

Key Industrial Applications of cq 160u

| Industry/Sector | Specific Application of cq 160u | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Machinery | High-precision components for engines | Enhanced performance and reliability | Supplier verification, customization options, MOQ |

| Electronics Manufacturing | Integrated circuits and electronic components | Improved efficiency and reduced power consumption | Quality certifications, fast delivery, compatibility |

| Automotive | Engine parts for motorcycles and vehicles | Increased durability and performance | Material quality, supplier reputation, price negotiations |

| Renewable Energy | Components for solar and wind energy systems | Sustainable solutions and cost savings | Compliance with international standards, scalability |

| Telecommunications | Equipment for radio communication systems | Reliable connectivity and signal quality | Technical support, warranty terms, after-sales service |

How is cq 160u Used in Industrial Machinery Applications?

In the industrial machinery sector, cq 160u components are crucial for manufacturing high-performance engines. These components, characterized by their high precision and durability, ensure optimal engine performance in various applications, including construction and agricultural machinery. Buyers from regions like Africa and South America often seek reliable suppliers that can provide customizable options to meet specific machinery requirements. Key considerations include supplier verification and minimum order quantities (MOQ), which ensure that businesses can scale their operations without compromising quality.

What Role Does cq 160u Play in Electronics Manufacturing?

In the electronics manufacturing industry, cq 160u products, such as integrated circuits and electronic components, are vital for creating efficient and low-power devices. These components are designed to enhance operational efficiency while reducing energy consumption, making them ideal for modern electronic applications. B2B buyers, particularly in Europe and the Middle East, should focus on sourcing suppliers that offer quality certifications and fast delivery times to maintain production schedules. Compatibility with existing systems is also a crucial factor for successful integration.

How is cq 160u Applied in the Automotive Sector?

The automotive industry leverages cq 160u for manufacturing engine parts that enhance the performance and longevity of motorcycles and vehicles. These high-quality components are engineered to withstand harsh conditions and deliver superior power output. B2B buyers, especially in developing markets like Nigeria and Brazil, need to assess material quality and supplier reputation before making purchasing decisions. Price negotiations are also critical, given the competitive nature of the automotive market.

What Benefits Does cq 160u Offer in Renewable Energy Systems?

In renewable energy applications, cq 160u components are used in solar panels and wind turbines, contributing to more sustainable energy solutions. These components help improve efficiency and reduce the overall cost of energy production, making them attractive to businesses focused on sustainability. International buyers must ensure compliance with international standards and consider scalability when sourcing these components, as the demand for renewable energy solutions continues to rise globally.

How Does cq 160u Enhance Telecommunications Equipment?

In telecommunications, cq 160u is integral to the development of equipment used in radio communication systems. These components ensure reliable connectivity and high-quality signal transmission, which are essential for effective communication networks. B2B buyers should prioritize suppliers that offer robust technical support and favorable warranty terms, as well as after-sales service, to minimize downtime and ensure long-term operational efficiency.

3 Common User Pain Points for ‘cq 160u’ & Their Solutions

Scenario 1: Limited Availability and Sourcing Challenges for CQ 160U Components

The Problem: B2B buyers often face difficulties in sourcing CQ 160U components due to limited availability and fluctuating supply chains. This is particularly challenging for companies in regions such as Africa and South America, where access to reliable suppliers can be inconsistent. The fear of production delays looms large, especially when projects hinge on the timely delivery of high-performance components that are crucial for machinery and equipment. Buyers may struggle to find verified suppliers who can meet their specifications without compromising on quality or reliability.

The Solution: To mitigate sourcing challenges, buyers should adopt a proactive approach by establishing relationships with multiple verified suppliers across different regions. Utilizing platforms like Accio, which lists over 6,500 suppliers, can help in identifying reliable sources with good ratings. Additionally, buyers should consider setting up agreements for bulk purchasing to secure better pricing and availability. Implementing a thorough vetting process, including checking supplier reviews and past performance, will ensure that the components meet the required quality standards. By diversifying their supplier base and committing to long-term partnerships, companies can create a more resilient supply chain that can withstand regional disruptions.

Scenario 2: Technical Compatibility Issues with CQ 160U Products

The Problem: Another common pain point is the technical compatibility of CQ 160U products with existing systems or machinery. B2B buyers may find themselves in situations where they purchase components that, while meeting the required specifications, do not integrate seamlessly with their current operations. This can lead to costly delays in production, increased labor for retrofitting systems, and potential losses due to equipment downtime.

The Solution: To address compatibility issues, buyers should prioritize detailed specifications when sourcing CQ 160U components. This includes assessing the voltage, cooling capacity, and other customizable attributes that match existing systems. Before finalizing a purchase, conducting a compatibility analysis or simulation can help identify potential integration challenges. Furthermore, collaborating with suppliers to gain insights into the operational parameters of CQ 160U products can provide valuable information that informs better purchasing decisions. Engaging in pre-purchase discussions to clarify technical requirements will significantly reduce the risk of incompatibility and streamline the integration process.

Scenario 3: Navigating Regulatory Compliance and Standards for CQ 160U

The Problem: B2B buyers often encounter complexities related to regulatory compliance and industry standards when dealing with CQ 160U components. Different regions have varying regulations regarding safety, emissions, and performance standards, which can create confusion and hinder the purchasing process. For international buyers, particularly in regions like the Middle East and Europe, understanding these regulations is crucial to avoid legal penalties and ensure product usability.

The Solution: To navigate regulatory compliance effectively, buyers should conduct comprehensive research on the specific regulations applicable in their region. This includes familiarizing themselves with local and international standards related to CQ 160U products. Collaborating with suppliers who are well-versed in these regulations can provide insights into compliance requirements. Additionally, leveraging industry associations and regulatory bodies for guidance can further aid in ensuring adherence to necessary standards. Implementing a compliance checklist during the procurement process can help buyers systematically verify that all products meet the required legal and safety standards, thereby minimizing risks associated with non-compliance.

Strategic Material Selection Guide for cq 160u

What Are the Key Materials for cq 160u Components?

When selecting materials for cq 160u components, it’s essential to analyze their properties, advantages, and limitations. This analysis helps international B2B buyers make informed decisions tailored to their specific applications and regional standards.

How Do Metals Perform in cq 160u Applications?

Aluminum is a popular choice due to its lightweight and corrosion-resistant properties. It typically has a temperature rating up to 120°C and is suitable for applications requiring good thermal conductivity. The primary advantage of aluminum is its low weight, making it ideal for portable equipment. However, its lower strength compared to steel can be a disadvantage in high-stress applications. For buyers in regions like Africa and South America, compliance with local standards such as ASTM B221 for extruded aluminum products is crucial.

Stainless Steel, particularly grades 304 and 316, offers excellent corrosion resistance and can withstand high temperatures (up to 870°C). Its durability makes it suitable for harsh environments, but it can be more expensive and complex to manufacture compared to aluminum. The high strength of stainless steel is beneficial for structural applications, but its weight can be a drawback for portable systems. Buyers should consider compliance with ASTM A240 for stainless steel sheets and plates, especially in the Middle East and Europe.

What Role Do Polymers Play in cq 160u Components?

Polycarbonate is a high-performance plastic known for its impact resistance and thermal stability, with a temperature rating of up to 120°C. It is lightweight, making it suitable for components that require transparency or electrical insulation. While polycarbonate is generally less expensive than metals, its susceptibility to UV degradation can limit its application in outdoor environments. International buyers should ensure that the polymer meets standards such as ISO 11963 for transparency and impact resistance.

Nylon, another polymer, is valued for its strength and flexibility, with a temperature rating of around 80°C. It is often used in applications requiring wear resistance and low friction. While nylon is cost-effective, it can absorb moisture, which may affect its mechanical properties. Buyers in regions like Brazil should be aware of local standards for engineering plastics, such as ABNT NBR 15575, to ensure compliance with regional regulations.

Summary of Material Selection for cq 160u

The selection of materials for cq 160u components is influenced by their performance characteristics, manufacturing complexities, and compliance with international standards. Understanding these factors helps B2B buyers from diverse regions choose the most suitable materials for their applications.

| Material | Typical Use Case for cq 160u | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight casings and heat sinks | Corrosion resistance and low weight | Lower strength compared to steel | Medium |

| Stainless Steel | Structural components in harsh environments | High strength and corrosion resistance | Higher cost and manufacturing complexity | High |

| Polycarbonate | Transparent covers and electrical insulators | Impact resistance and lightweight | Susceptible to UV degradation | Medium |

| Nylon | Gears and mechanical parts | Strength and flexibility | Moisture absorption affects properties | Low |

This table provides a clear overview of the materials analyzed, aiding B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cq 160u

What Are the Main Stages of Manufacturing for cq 160u Components?

The manufacturing process for cq 160u components involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages helps B2B buyers make informed decisions when sourcing components.

Material Preparation: How Is Raw Material Sourced and Processed?

The manufacturing journey begins with material preparation. High-quality raw materials are sourced, often adhering to specific international standards to ensure reliability. For cq 160u components, this may include metals, plastics, or advanced composites, depending on the application. The materials undergo rigorous testing to assess their properties, such as tensile strength and durability, ensuring they meet specifications before moving to the next stage.

Forming: What Techniques Are Utilized in Shaping Components?

During the forming stage, raw materials are shaped into the desired forms using various techniques. Common methods include precision machining, injection molding, and die casting. Each technique is selected based on the component’s complexity and required tolerances. For instance, precision machining is often used for components requiring tight tolerances, ensuring they function correctly within the broader assembly.

Assembly: How Are Components Integrated into Final Products?

The assembly stage involves integrating various components to create the final product. This may include soldering, welding, or mechanical fastening. Automation plays a significant role here, with robotics increasingly used to enhance precision and efficiency. However, manual assembly remains critical for components that require a high degree of craftsmanship. Quality control measures during this phase include visual inspections and functional testing to ensure all parts fit and operate seamlessly.

Finishing: What Processes Enhance Durability and Aesthetics?

Finishing processes are essential for enhancing both the durability and aesthetics of cq 160u components. Techniques such as surface treatment, coating, and polishing are commonly employed. These not only improve the product’s appearance but also protect it from environmental factors, such as corrosion and wear. Quality assurance in finishing includes verifying coating thickness and adhesion strength, ensuring the product meets both functional and aesthetic criteria.

What Quality Assurance Standards Are Relevant for cq 160u Manufacturing?

Quality assurance is a critical aspect of the manufacturing process for cq 160u components. Adhering to international and industry-specific standards ensures that products are reliable and safe.

How Does ISO 9001 Influence Quality Management in Manufacturing?

ISO 9001 is a globally recognized quality management standard that outlines the criteria for a quality management system (QMS). Manufacturers of cq 160u components often seek ISO 9001 certification to demonstrate their commitment to quality. This certification involves regular audits and assessments, ensuring continuous improvement in processes and customer satisfaction.

What Industry-Specific Certifications Should B2B Buyers Consider?

In addition to ISO 9001, there are industry-specific certifications that may be relevant. For example, CE marking is essential for products marketed in the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Similarly, API (American Petroleum Institute) certifications are critical for components used in the oil and gas industry, ensuring they meet stringent performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Implementing effective quality control checkpoints throughout the manufacturing process is vital for ensuring product integrity.

What Is the Role of Incoming Quality Control (IQC)?

Incoming Quality Control (IQC) is the first checkpoint in the quality assurance process. It involves inspecting raw materials and components upon arrival at the manufacturing facility. This ensures that all inputs meet specified quality standards before they enter the production line. B2B buyers can request IQC reports from suppliers to verify the quality of materials used in manufacturing.

How Does In-Process Quality Control (IPQC) Ensure Ongoing Compliance?

In-Process Quality Control (IPQC) is conducted during the manufacturing process to monitor and control quality at various stages. This includes regular inspections and tests to ensure that the manufacturing process adheres to established standards. IPQC helps identify potential issues early, reducing the risk of defects in the final product.

What Is the Importance of Final Quality Control (FQC)?

Final Quality Control (FQC) is the last checkpoint before products are shipped to customers. This stage involves comprehensive testing and inspections to verify that the finished product meets all specifications. Common testing methods include functional testing, stress testing, and environmental testing. B2B buyers should ensure that FQC protocols are in place and request relevant reports to confirm the quality of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers, especially when sourcing internationally.

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is an effective way to assess a supplier’s quality management practices. Buyers should develop a checklist that includes criteria such as compliance with ISO standards, quality control checkpoints, and manufacturing capabilities. An on-site visit can provide valuable insights into the supplier’s operations, allowing buyers to evaluate their commitment to quality firsthand.

How Can Buyers Leverage Quality Reports and Certifications?

Buyers should request quality reports and certifications from suppliers to verify compliance with international standards. These documents provide evidence of the supplier’s quality management practices and can help buyers make informed decisions. Additionally, third-party inspections can offer an unbiased assessment of a supplier’s quality control processes, further ensuring product reliability.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing cq 160u components, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

How Do Cultural Differences Affect Quality Assurance Practices?

Cultural differences can influence quality assurance practices in various regions. For example, communication styles and business practices may differ significantly. Buyers should engage in open dialogue with suppliers to understand their quality management approaches and any challenges they may face.

What Are the Regulatory Considerations for International Trade?

International buyers must also navigate regulatory considerations that can impact quality assurance. Import regulations, tariffs, and compliance with local standards can affect the sourcing process. Understanding these regulations is crucial for avoiding potential legal issues and ensuring that products meet necessary quality standards upon arrival in the buyer’s country.

Conclusion

In summary, a comprehensive understanding of the manufacturing processes and quality assurance standards for cq 160u components is essential for B2B buyers. By focusing on the main stages of manufacturing, relevant quality standards, quality control checkpoints, and verification practices, buyers can make informed decisions that enhance their procurement strategies. This diligence ensures that the components sourced meet the high standards required for successful business operations across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cq 160u’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring CQ 160u components effectively. The CQ 160u encompasses a range of high-performance components and engines utilized across various industries, making it essential to approach procurement strategically. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their technical requirements and business goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to clearly outline your technical requirements. This includes understanding the specific attributes of CQ 160u products, such as resolution, power consumption, and durability. Having precise specifications will help streamline communication with suppliers and reduce the likelihood of mismatched products.

- Identify performance criteria (e.g., resolution of 160u, response times).

- Consider environmental factors like temperature ranges and integration ease.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers who specialize in CQ 160u components. Look for suppliers with a proven track record in your industry and check their reputation through online reviews and ratings.

- Utilize platforms such as trade directories and industry forums.

- Pay attention to supplier experience and years in business, which often correlate with reliability.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial to ensure compliance with international standards. This step helps mitigate risks associated with quality and safety, particularly for components used in critical applications.

- Look for certifications such as ISO 9001 or other industry-specific quality management systems.

- Confirm that the supplier adheres to relevant safety and environmental regulations.

Step 4: Request Samples and Specifications

Before making a bulk purchase, request samples of the CQ 160u components to evaluate their quality and performance. This allows you to assess whether the products meet your technical specifications.

- Analyze the samples for functionality, durability, and compatibility with your existing systems.

- Ensure that the supplier provides detailed product specifications alongside the samples.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier and evaluated their products, it’s time to discuss pricing, payment terms, and delivery timelines. Effective negotiation can lead to better pricing and favorable terms, enhancing your overall procurement strategy.

- Discuss minimum order quantities (MOQs) and bulk purchase discounts.

- Clarify warranty terms and return policies to protect your investment.

Step 6: Establish a Communication Plan

Effective communication is key to a successful procurement process. Establish a clear communication plan with your supplier to ensure that all parties are aligned throughout the sourcing journey.

- Determine the primary points of contact and preferred communication channels.

- Set regular check-ins to monitor progress and address any potential issues promptly.

Step 7: Monitor Delivery and Quality Assurance

After placing your order, closely monitor the delivery process and conduct quality assurance checks upon receipt. This final step ensures that the components meet your expectations and specifications before they are integrated into your operations.

- Verify that the delivered products match the agreed specifications and quantities.

- Conduct any necessary testing to confirm product performance and reliability.

By following this structured checklist, B2B buyers can navigate the sourcing process for CQ 160u components with confidence, ensuring they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for cq 160u Sourcing

Analyzing the cost structure and pricing for sourcing cq 160u products involves a detailed understanding of various components that contribute to the final price, as well as the factors influencing pricing in the international B2B market.

What Are the Key Cost Components in cq 160u Sourcing?

When sourcing cq 160u products, several cost components must be considered:

-

Materials: The raw materials used significantly impact pricing. For high-performance components like the cq 160u, materials such as high-quality metals, specialized plastics, or advanced semiconductors can drive up costs. Sourcing from regions with lower material costs can be beneficial.

-

Labor: Labor costs vary widely depending on the region of manufacturing. Countries with lower labor costs can offer competitive pricing but may also compromise on quality. It is essential to evaluate the skill level of the workforce, especially for high-precision manufacturing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Custom tooling can add a significant upfront cost, especially for specialized components. Buyers should consider the tooling costs in relation to the expected volume of orders.

-

Quality Control (QC): Rigorous QC processes are essential, particularly for high-performance applications. The cost of implementing and maintaining these processes can influence the final price. Ensure suppliers have certifications that reflect their commitment to quality.

-

Logistics: Shipping and handling costs, including duties and tariffs, can vary significantly based on the shipping method and destination. Incoterms play a crucial role in determining who bears these costs.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding typical margins in the industry can help in negotiations.

How Do Price Influencers Affect cq 160u Pricing?

Several factors can influence the pricing of cq 160u products:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to reduced per-unit costs. Buyers should aim to negotiate favorable MOQs that align with their purchasing strategy.

-

Specifications and Customization: Customized products or those with specific technical specifications may incur higher costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher quality materials and relevant industry certifications can raise costs but also enhance product reliability and performance. Buyers should assess the total cost of ownership, including potential maintenance and replacement costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality and service may charge a premium, but this can be justified by lower risk and higher reliability.

-

Incoterms: Understanding Incoterms is crucial for managing logistics costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can shift responsibility and costs between buyers and suppliers.

What Are Effective Buyer Tips for Negotiating cq 160u Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation and strategic sourcing can lead to significant cost savings:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and pricing. Establishing a good relationship with suppliers can lead to better deals.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and lifecycle costs. This approach helps justify higher upfront costs for better-quality products.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on local economic conditions, currency fluctuations, and geopolitical factors. Keeping abreast of these factors can aid in timing purchases effectively.

-

Conduct Market Research: Research potential suppliers and market prices. This information can strengthen your negotiation position.

-

Consider Local Regulations: Be mindful of import duties, taxes, and local regulations that may affect the overall cost of sourcing cq 160u products.

In conclusion, a comprehensive understanding of the cost components, pricing influencers, and effective negotiation strategies can empower international B2B buyers to make informed sourcing decisions for cq 160u products.

Alternatives Analysis: Comparing cq 160u With Other Solutions

Understanding Alternatives in High-Performance Components

In the competitive landscape of high-performance components, businesses often seek solutions that not only meet their technical requirements but also offer optimal performance and cost-effectiveness. The CQ 160U is a noteworthy option, but it is essential for B2B buyers to consider various alternatives that may better suit their specific applications and operational needs. Below, we compare the CQ 160U with two viable alternatives, helping buyers make informed decisions.

| Comparison Aspect | Cq 160U | Alternative 1: CQ 160X | Alternative 2: BC 160A |

|---|---|---|---|

| Performance | High precision and low latency | Similar precision, slightly slower | Moderate precision, cost-effective |

| Cost | Premium pricing | Competitive pricing | Budget-friendly |

| Ease of Implementation | Requires specific expertise | User-friendly setup | Simple integration |

| Maintenance | Moderate; specialized support needed | Low; general maintenance sufficient | High; frequent replacements needed |

| Best Use Case | Advanced industrial applications | General industrial use | Entry-level projects and small businesses |

What Are the Advantages and Disadvantages of CQ 160X?

The CQ 160X is a robust alternative that offers similar performance to the CQ 160U but at a more competitive price point. It is particularly suitable for general industrial applications where high precision is necessary but not critical. The setup process is user-friendly, making it accessible for companies without specialized expertise. However, it may not deliver the same low-latency performance, which could be a drawback for applications requiring rapid response times.

How Does the BC 160A Fit Into the Landscape?

The BC 160A is an economical choice, perfect for entry-level projects or small businesses with limited budgets. Its cost-effectiveness makes it attractive, and while it provides moderate precision, it is not tailored for high-performance needs. The integration is straightforward, but maintenance can be a concern, as components may require more frequent replacements. This alternative is best suited for companies prioritizing budget over performance.

Choosing the Right Solution: What Should B2B Buyers Consider?

When selecting the right solution, B2B buyers should assess their specific needs against the characteristics of each alternative. Considerations such as the required performance level, budget constraints, and the technical capabilities of the team should influence the decision. The CQ 160U excels in high-performance scenarios, while the CQ 160X offers a balanced approach for general applications, and the BC 160A serves well for cost-sensitive projects. By carefully evaluating these factors, businesses can ensure they choose the most effective solution for their operational requirements.

Essential Technical Properties and Trade Terminology for cq 160u

What Are the Key Technical Properties of cq 160u Components?

Understanding the essential technical properties of cq 160u components is crucial for B2B buyers, particularly those involved in industrial machinery, electronics, or telecommunications. Here are some critical specifications to consider:

-

Resolution (160u): The term ‘160u’ refers to the resolution capability of the component, indicating the precision with which it can operate. High-resolution components are vital in applications requiring accuracy, such as data acquisition systems or precision engineering. For buyers, investing in high-resolution products can lead to improved performance and efficiency in their operations.

-

Durability: The construction quality of cq 160u components is often highlighted as ‘durable.’ Durable components can withstand harsh conditions and extended use, which is essential for businesses looking to minimize downtime and maintenance costs. A longer lifespan translates to better return on investment (ROI) and reliability in critical applications.

-

Power Consumption: Low power consumption is a significant property, especially in today’s energy-conscious market. Components that operate efficiently can lead to reduced operational costs and are often favored in sustainable business practices. Buyers should prioritize suppliers offering energy-efficient solutions to align with global sustainability trends.

-

Temperature Range: The ability to function across a wide temperature range is crucial for components used in diverse environments. This feature ensures that the products can perform reliably in varying climatic conditions, which is particularly relevant for buyers in regions with extreme weather. It can also reduce the need for additional cooling or heating solutions, further lowering costs.

-

Integration Flexibility: The ease of integration with existing systems is a key consideration. Components that are designed for easy integration can save time and resources during installation. Buyers should seek products that offer compatibility with various systems to ensure seamless operations.

What Common Trade Terms Should B2B Buyers Know for cq 160u?

Familiarity with industry jargon can greatly enhance communication and negotiation efficiency in B2B transactions. Here are several essential terms related to cq 160u:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s end products. Understanding OEM relationships is crucial for buyers as it often influences pricing, quality, and support. Buyers should seek OEMs with a strong reputation for reliability to ensure quality components.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory planning. Buyers should evaluate their needs against the supplier’s MOQ to avoid excess inventory costs or insufficient supply.

-

RFQ (Request for Quotation): An RFQ is a standard business process in which a buyer requests pricing and other details from suppliers. This term is significant for buyers looking to compare offers and negotiate better terms. A well-prepared RFQ can streamline the procurement process and ensure that all necessary specifications are communicated clearly.

-

Incoterms (International Commercial Terms): These are predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for B2B buyers, as they affect shipping costs, risk, and insurance. Understanding these terms can help buyers negotiate more favorable shipping arrangements.

-

Lead Time: This refers to the time it takes from placing an order until it is fulfilled. For B2B buyers, knowing the lead time is essential for planning and inventory management. Suppliers with shorter lead times can provide a competitive advantage in fast-paced markets.

-

Quality Assurance (QA): QA refers to the processes and procedures that ensure a product meets specified quality standards. For B2B buyers, understanding a supplier’s QA practices can help mitigate risks associated with product defects and ensure compliance with industry standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, negotiate effectively, and ultimately secure better deals in the market for cq 160u components.

Navigating Market Dynamics and Sourcing Trends in the cq 160u Sector

What Are the Key Market Trends Influencing the cq 160u Sector?

The cq 160u sector is witnessing a dynamic transformation driven by several global factors. Increasing industrial automation and the demand for high-performance components are pivotal in shaping this market. As industries in Africa, South America, the Middle East, and Europe seek to enhance efficiency and reduce operational costs, there is a growing emphasis on sourcing high-precision, durable, and energy-efficient products. The trend toward miniaturization in technology has also led to a surge in demand for compact and customizable solutions, which are integral to various applications, from industrial machinery to consumer electronics.

Additionally, the proliferation of e-commerce platforms has revolutionized the sourcing landscape. International buyers can now easily access a diverse range of suppliers, facilitating competitive pricing and shorter lead times. This digital shift is particularly advantageous for B2B buyers in emerging markets like Nigeria and Brazil, where traditional sourcing methods may have been limited. A key trend to monitor is the increasing focus on integrated solutions that combine multiple functionalities into a single product, enhancing value for buyers.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the cq 160u Sector?

Sustainability is becoming a critical consideration for B2B buyers in the cq 160u sector. As environmental concerns rise globally, companies are under pressure to adopt sustainable practices throughout their supply chains. This includes evaluating the environmental impact of sourcing decisions, particularly concerning product lifecycle and end-of-life disposal. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint and employing environmentally friendly manufacturing processes.

Ethical sourcing is also gaining traction, as businesses recognize the importance of transparency and social responsibility. B2B buyers should look for suppliers who adhere to ethical labor practices and can provide certifications for sustainable materials. These certifications not only enhance brand reputation but also align with the growing consumer demand for responsible sourcing. By prioritizing sustainability and ethical practices, companies can not only mitigate risks associated with regulatory compliance but also appeal to an increasingly conscious customer base.

What is the Historical Context of the cq 160u Sector and Its Evolution?

The cq 160u sector has evolved significantly over the years, reflecting broader technological advancements and shifts in market demands. Initially rooted in basic industrial applications, the sector has expanded to encompass a diverse array of products, including high-performance engines and electronic components. This evolution has been driven by the rapid advancement of technology, which has enabled the development of more sophisticated and reliable products.

As global markets became more interconnected, the cq 160u sector witnessed an influx of international suppliers, particularly from regions like China, which has become a hub for manufacturing high-quality components at competitive prices. This shift has not only increased competition but also enhanced accessibility for international buyers. Moving forward, continued innovation and adaptation to market trends will be crucial for suppliers looking to meet the evolving needs of B2B buyers across different regions.

Frequently Asked Questions (FAQs) for B2B Buyers of cq 160u

-

How can I ensure the quality of cq 160u products before purchasing?

To ensure product quality, request samples from suppliers before placing a bulk order. Additionally, verify supplier certifications and quality control processes. Conduct factory audits, if possible, to assess production standards and compliance with international quality norms. Utilize third-party inspection services for an unbiased evaluation. Establish clear quality assurance criteria in your purchase agreement to protect your interests. -

What are the typical customization options available for cq 160u products?

Customization options for cq 160u products often include specifications such as voltage, cooling capacity, and design style. Many suppliers offer tailored dimensions, materials, and colors to suit your specific needs. When negotiating, clearly outline your requirements and confirm the supplier’s capability to deliver customized solutions. Always review prototypes to ensure they meet your expectations before mass production. -

What is the minimum order quantity (MOQ) for cq 160u products?

The MOQ for cq 160u products can vary significantly based on the supplier and the specific item. Generally, it ranges from 1 to 100 units. It’s advisable to negotiate with suppliers, especially if you are a first-time buyer or looking for a trial order. Some suppliers may be flexible with MOQs for established relationships or larger contracts, so it’s worth exploring options. -

What payment terms should I expect when sourcing cq 160u products internationally?

Payment terms can vary by supplier and region. Common practices include a deposit upfront (usually 30-50%) with the balance paid before shipment. Some suppliers may offer letters of credit or payment upon delivery. It’s essential to discuss and agree on terms that suit both parties, and consider using secure payment methods to mitigate risks in international transactions. -

How do I vet suppliers for cq 160u products in international markets?

Vetting suppliers involves researching their business history, customer reviews, and industry reputation. Utilize platforms like Alibaba or trade directories to find verified suppliers. Request references and conduct background checks. Consider visiting the supplier’s facility or engaging third-party verification services to confirm their legitimacy and production capabilities. Establish communication to gauge their responsiveness and professionalism. -

What logistics considerations should I keep in mind when importing cq 160u products?

When importing cq 160u products, consider shipping methods (air vs. sea), delivery timelines, and customs clearance processes. Ensure you understand the import duties and tariffs applicable in your country. Collaborate with a reliable freight forwarder to streamline logistics and mitigate risks. Additionally, track shipments to address any potential delays promptly. -

Are there specific regulations for importing cq 160u products into Africa and South America?

Import regulations vary by country and product type. It’s crucial to research the import laws specific to cq 160u products in your target market. This may include compliance with safety standards, environmental regulations, and certifications. Consult local trade authorities or customs brokers to ensure adherence to all legal requirements and avoid potential fines or shipment delays. -

What should I include in my purchase agreement for cq 160u products?

Your purchase agreement should encompass key elements like product specifications, pricing, delivery timelines, payment terms, and warranty conditions. Include clauses for quality assurance, inspection rights, and penalties for non-compliance. Clearly outline the process for handling disputes and returns to protect your interests. Having a well-drafted agreement will help ensure a smoother transaction and mitigate risks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cq 160U Manufacturers & Suppliers List

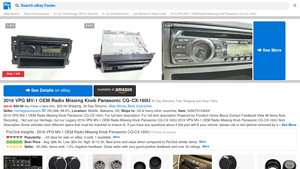

1. Panasonic – CQ-CX160U CD MP3 Player

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “PANASONIC CQ-CX160U CD MP3 PLAYER”, “Condition”: “Used”, “Price”: “US $79.99 or Best Offer”, “Seller”: “allthingsmanly”, “Seller Rating”: “98.7% positive”, “Shipping Cost”: “US $13.00 Economy Shipping”, “Location”: “Chippewa Falls, Wisconsin, United States”, “Delivery Estimate”: “Between Thu, Sep 11 and Tue, Sep 16”, “Returns”: “30 days returns, buyer pays for return shipping”, “…

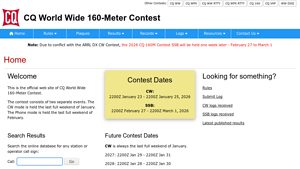

2. CQ World Wide – 160-Meter Contest

Domain: cq160.com

Registered: 2002 (23 years)

Introduction: CQ World Wide 160-Meter Contest consists of two separate events: CW mode held the last full weekend of January and Phone mode held the last full weekend of February. Contest Dates for 2026: CW: 2200Z January 23 – 2200Z January 25, SSB: 2200Z February 27 – 2200Z March 1. Future Contest Dates: CW for 2027: 2200Z Jan 29 – 2200Z Jan 31, 2028: 2200Z Jan 28 – 2200Z Jan 30, 2029: 2200Z Jan 26 – 2200Z Jan…

3. Accio – CQ 160u

Domain: accio.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “cq 160u”, “attributes”: {“resolution”: “High precision 160u”, “response_time”: “Fast response time”, “construction”: “Durable construction”, “power_consumption”: “Low power consumption”, “design”: “Compact design”, “integration”: “Easy integration”, “temperature_range”: “Wide temperature range”, “reliability”: “High reliability”, “lifespan”: “Long lifespan”}, “pricing”: {“min_pri…

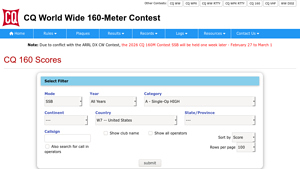

4. WW Digi – CQ 160 Contest Information

Domain: ww-digi.com

Registered: 2019 (6 years)

Introduction: CQ 160 – Scores Other Contests: CQ WW, CQ WPX, CQ WW RTTY, CQ WPX RTTY, CQ 160, CQ VHF WW DIGI, CQ World Wide 160-Meter Contest. Contest Dates: 2026 CQ 160M Contest SSB will be held February 27 to March 1. Categories: A – Single-Op HIGH, B – Single-Op LOW, C – Single-Op QRP, D – Single-Op Assisted HIGH, E – Single-Op Assisted LOW, F – Multi-Op, CK – Checklog, DQ – Disqualified. Logs: Cabrillo Log …

5. CQ – 160 Meter Contest Log 5.0.7

Domain: n3fjp.com

Registered: 2000 (25 years)

Introduction: CQ 160 Meter Contest Log 5.0.7

– System Requirements: Windows 7 through Windows 11 (XP and Vista versions available)

– Features:

– Easy and intuitive to use

– Checks for duplicates (including partials)

– Lists all contacts and multipliers (sections change color when worked)

– Lists countries worked with a country look-up function

– Writes Cabrillo file format for log submission

– Provi…

6. Panasonic – OEM Radio Knob for VPG MV-1

Domain: picclick.com

Registered: 2003 (22 years)

Introduction: {“title”:”2016 VPG MV-1 OEM Radio Missing Knob Panasonic CQ-CX-160U”,”price”:”$50.00″,”shipping_cost”:”$20.00″,”condition”:”Used”,”warranty”:”90 Day Warranty”,”returns”:”30-Day Returns”,”seller”:”heritageautoparts”,”seller_rating”:”98.8%”,”location”:”Mobile, Alabama, US”,”item_number”:”326675743629″,”interchange_part_number”:”638.AM3M16″,”genuine_OEM”:”Yes”,”model”:”MV-1″,”make”:”VEHICLE PRODUCTIO…

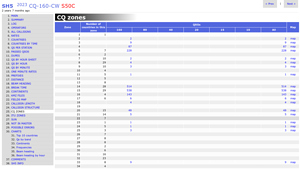

7. S53M – CQ Zones Overview

Domain: s53m.com

Registered: 2004 (21 years)

Introduction: CQ zones – 2023 CQ-160-CW S50C; Version: SH5 v.2.47.21; Created on: 05-02-2023; Registered to: S53ZO; Zone details include the number of countries in each zone and QSOs for various bands (160, 80, 40, 20, 15, 10).

Strategic Sourcing Conclusion and Outlook for cq 160u

In today’s competitive landscape, effective strategic sourcing for cq 160u components offers significant advantages for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By understanding the diverse applications and high-performance attributes of cq 160u products—such as precision, durability, and low power consumption—buyers can make informed decisions that align with their operational needs and financial goals.

Strategic sourcing not only optimizes procurement processes but also fosters long-term partnerships with reliable suppliers, ensuring access to high-quality products at competitive prices. With the growing demand for customizable solutions, businesses can leverage these opportunities to enhance their product offerings and improve their market position.

As we look to the future, it is crucial for B2B buyers to stay ahead of industry trends and technological advancements associated with cq 160u. Embracing innovation and sustainability in sourcing practices will not only drive efficiency but also contribute to a resilient supply chain. We encourage buyers to engage proactively with suppliers, explore new markets, and harness the potential of cq 160u to unlock new avenues for growth and success.