Choosing Your Best Laptop For Fusion 360: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for best laptop for fusion 360

Navigating the intricate landscape of selecting the best laptop for Fusion 360 poses a significant challenge for international B2B buyers. With varying performance requirements and budget constraints, sourcing a laptop that effectively handles complex 3D modeling and design tasks can feel overwhelming. This guide aims to simplify the decision-making process by providing a comprehensive analysis of the essential criteria, including processor capabilities, RAM specifications, and GPU performance, tailored specifically for Fusion 360 applications.

In this resource, we will explore various laptop types, from high-end workstations to budget-friendly options, ensuring that businesses across Africa, South America, the Middle East, and Europe—such as Nigeria and Germany—can find the right fit for their needs. Additionally, we will delve into supplier vetting processes, helping buyers identify reliable manufacturers and distributors that align with their operational demands.

By equipping decision-makers with actionable insights on cost considerations, performance benchmarks, and practical applications, this guide empowers informed purchasing decisions. Whether you are a small enterprise or a large corporation, understanding the nuances of selecting the ideal laptop for Fusion 360 can enhance productivity and streamline workflows, ultimately driving business success in a competitive global market.

Understanding best laptop for fusion 360 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-End Workstations | Powerful CPUs (Intel i7/i9, AMD Ryzen 7/9), professional GPUs | CAD design, complex simulations, rendering | Pros: Exceptional performance, durability. Cons: Higher cost, less portability. |

| Gaming Laptops | High-refresh-rate displays, robust cooling systems, strong GPUs | 3D modeling, game design, multimedia projects | Pros: Great performance for price, versatile. Cons: Bulky, may lack battery efficiency. |

| Mobile Workstations | Optimized for portability, good thermal management, solid build | On-site CAD presentations, field engineering | Pros: Lightweight, reliable. Cons: Generally lower specs than full workstations. |

| Budget-Friendly Laptops | Affordable prices, decent performance (Intel i5, AMD Ryzen 5) | Entry-level CAD, educational purposes | Pros: Cost-effective, suitable for basic tasks. Cons: Limited performance, may struggle with complex projects. |

| MacBook Pro | High-resolution Retina displays, optimized for macOS applications | Design, architecture, creative industries | Pros: Excellent build quality, great for design software. Cons: Higher price point, limited upgrade options. |

What Are the Characteristics of High-End Workstations for Fusion 360?

High-end workstations are specifically designed for intensive computational tasks, making them ideal for professionals using Fusion 360. These laptops typically feature powerful processors like Intel’s i7/i9 or AMD’s Ryzen 7/9, alongside dedicated graphics cards such as NVIDIA’s RTX series. Their solid build quality and extensive RAM (16GB or more) ensure they can handle complex simulations and rendering tasks. B2B buyers should consider the total cost of ownership, including potential upgrades and warranty options, to ensure a reliable investment for demanding applications.

How Do Gaming Laptops Meet the Needs of Fusion 360 Users?

Gaming laptops, while primarily designed for gaming, offer robust performance that can be leveraged for 3D modeling and CAD applications like Fusion 360. Equipped with powerful CPUs and high-refresh-rate displays, these laptops provide excellent graphics capabilities and cooling systems to manage intense workloads. They are often more affordable than dedicated workstations, making them appealing to budget-conscious businesses. However, buyers should assess their portability needs, as gaming laptops can be bulkier and may not have the same battery efficiency.

What Makes Mobile Workstations a Good Choice for On-the-Go Professionals?

Mobile workstations are tailored for professionals who require both performance and portability. They combine powerful hardware with a lightweight design, allowing for easy transport to job sites or client meetings. These laptops often include features like enhanced thermal management and long battery life, which are critical for fieldwork in architecture and engineering. When purchasing, B2B buyers should prioritize models that balance power and weight, ensuring that they can run Fusion 360 effectively without sacrificing mobility.

Why Consider Budget-Friendly Laptops for Entry-Level CAD Work?

Budget-friendly laptops provide a feasible entry point for businesses looking to utilize Fusion 360 without significant financial investment. Typically equipped with mid-range processors (like Intel i5 or AMD Ryzen 5), these laptops can handle basic CAD tasks and educational purposes effectively. While they may not offer the performance needed for complex simulations, they serve well for entry-level users or small firms just starting with CAD software. Buyers should be aware of the limitations in performance and longevity when opting for these models.

How Does the MacBook Pro Stand Out for Creative Industries Using Fusion 360?

The MacBook Pro is renowned for its high-resolution Retina displays and optimized performance for creative applications, making it a strong contender for professionals in design and architecture using Fusion 360. With powerful processors and ample RAM, it excels in rendering and design tasks, providing a seamless user experience. However, its higher price point and limited upgrade options can be a drawback for some businesses. B2B buyers should evaluate the compatibility of Fusion 360 with macOS and consider the total cost against the benefits of superior design and display quality.

Key Industrial Applications of best laptop for fusion 360

| Industry/Sector | Specific Application of best laptop for fusion 360 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Product Design and Prototyping | Accelerates the design process, reducing time-to-market for products. | High-performance CPU and GPU, ample RAM, and storage capacity. |

| Architecture and Engineering | Building Information Modeling (BIM) | Enhances collaboration and visualization of complex structures. | Compatibility with CAD software, high-resolution displays, portability. |

| Automotive | Vehicle Design and Simulation | Improves design accuracy and reduces prototyping costs. | Reliable thermal management, high processing power, and graphics capabilities. |

| Aerospace | Aircraft Component Design | Enables detailed simulations and stress testing of components. | Advanced graphics cards, extensive RAM, and long battery life. |

| Education | Teaching and Learning CAD Skills | Provides students with hands-on experience using industry-standard tools. | Durability, weight, and software compatibility for educational environments. |

How Is the Best Laptop for Fusion 360 Used in Manufacturing?

In the manufacturing sector, laptops optimized for Fusion 360 are crucial for product design and prototyping. They enable engineers and designers to create detailed 3D models, allowing for rapid iterations and modifications. This capability significantly reduces the time-to-market for new products, which is vital in a competitive landscape. International buyers, particularly from regions like Africa and South America, should prioritize laptops with high-performance CPUs and GPUs, as well as sufficient RAM and storage to handle complex designs efficiently.

What Role Does Fusion 360 Play in Architecture and Engineering?

For architecture and engineering professionals, the best laptops for Fusion 360 facilitate Building Information Modeling (BIM). This technology enhances collaboration among teams by allowing multiple users to visualize and interact with a project simultaneously. The ability to manipulate 3D models in real-time leads to better decision-making and fewer costly mistakes. Buyers in Europe and the Middle East must consider laptops that support CAD software, offer high-resolution displays for clear visualizations, and ensure portability for on-site work.

How Is the Best Laptop for Fusion 360 Essential in Automotive Design?

In the automotive industry, laptops equipped for Fusion 360 are essential for vehicle design and simulation. These machines allow engineers to create intricate designs and conduct simulations to test performance and safety features. The detailed analysis provided by these tools can significantly reduce prototyping costs and improve design accuracy. International buyers should look for laptops with reliable thermal management systems and high processing power to handle demanding design tasks.

What Benefits Do Aerospace Professionals Gain from Using Fusion 360?

Aerospace engineers utilize laptops capable of running Fusion 360 for aircraft component design. These laptops enable detailed simulations and stress testing, which are critical for ensuring the safety and reliability of aircraft. The ability to visualize complex designs in 3D helps in identifying potential issues early in the design process. Buyers should prioritize models with advanced graphics capabilities and extensive RAM, alongside long battery life for extended use in various environments.

How Does Fusion 360 Enhance Educational Experiences?

In educational institutions, the best laptops for Fusion 360 provide students with hands-on experience in CAD applications. This exposure is vital for developing the skills needed in the workforce. Laptops must be durable enough to withstand daily use and lightweight for easy transport between classes. Additionally, compatibility with various software tools is essential for a comprehensive learning experience. Institutions in Africa and Europe should focus on sourcing laptops that balance performance with affordability to equip their students effectively.

3 Common User Pain Points for ‘best laptop for fusion 360’ & Their Solutions

Scenario 1: Insufficient Processing Power for Complex Designs

The Problem: B2B buyers often struggle with laptops that cannot handle the processing demands of Fusion 360, especially when working on complex 3D designs or simulations. This leads to slow performance, frequent crashes, and a frustrating user experience that can stall project timelines. For example, an engineering firm in Nigeria may invest in a mid-tier laptop only to find that its single-core performance is inadequate, hindering productivity when using Fusion 360 for detailed modeling.

The Solution: To ensure optimal performance, buyers should prioritize laptops equipped with high-performance CPUs, such as Intel Core i7/i9 or AMD Ryzen 7/9 processors from the latest generations. Additionally, it is crucial to choose devices with dedicated GPUs, like the NVIDIA RTX series or professional-grade options such as the NVIDIA RTX A-series. Before finalizing a purchase, conduct thorough research and consider seeking recommendations from industry forums or consulting experts. Furthermore, ensure that the selected laptop has at least 16GB of RAM, with 32GB being preferable for heavy multitasking. When sourcing laptops, prioritize vendors who offer customization options to tailor specifications to your specific needs, thereby avoiding performance bottlenecks.

Scenario 2: Limited Graphics Capability for Visual Work

The Problem: Many B2B buyers face the challenge of inadequate graphics capability when using Fusion 360, leading to subpar visual experiences and slower rendering times. For instance, a product design company in Germany may find that their chosen laptop’s integrated graphics struggle with rendering detailed 3D models, resulting in an inability to present high-quality visualizations to clients, which could impact business relationships.

The Solution: To address this issue, buyers should look for laptops with powerful dedicated graphics cards. Opting for models equipped with NVIDIA RTX GPUs or AMD Radeon Pro series graphics will significantly enhance rendering performance and provide smoother graphics during complex visual tasks. It is also advisable to verify the graphics card compatibility with Fusion 360, as certain models may offer enhanced performance for specific features within the software. Additionally, consider investing in a laptop with a high-resolution display that supports color accuracy, as this will improve the quality of your visual presentations. Engaging with a trusted IT provider can also aid in selecting models that are specifically tailored for graphic-intensive work.

Scenario 3: Inadequate Cooling Solutions Leading to Overheating

The Problem: Overheating is a prevalent issue for B2B buyers who use laptops for intensive applications like Fusion 360. This scenario often occurs when laptops are not equipped with effective thermal management systems, leading to performance throttling and potential hardware damage. For example, an architectural firm in South America may find that their laptop overheats during lengthy design sessions, causing unexpected shutdowns and delays in project delivery.

The Solution: When selecting a laptop for Fusion 360, it is essential to prioritize models known for their robust cooling systems. Look for laptops with advanced thermal management features, such as multiple fans, vapor chamber cooling, and heat pipes. Additionally, consider purchasing a laptop stand that enhances airflow during extended use. Regular maintenance, such as cleaning the laptop’s vents and fans, will also help prevent overheating. Engage with manufacturers or retailers that provide detailed specifications on cooling capabilities and user reviews to ensure the chosen model can handle sustained workloads without compromising performance. By proactively addressing thermal management, you can safeguard your investment and maintain consistent productivity.

Strategic Material Selection Guide for best laptop for fusion 360

What Materials Should Be Considered for the Best Laptop for Fusion 360?

When selecting a laptop for running Fusion 360, the choice of materials used in the laptop’s construction can significantly impact performance, durability, and user experience. This analysis explores several common materials, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum: The Preferred Choice for Laptop Chassis

Aluminum is widely used in laptop manufacturing due to its excellent strength-to-weight ratio and aesthetic appeal. Key properties include high thermal conductivity, which aids in heat dissipation, and resistance to corrosion.

Pros: Aluminum laptops are typically more durable and lightweight, making them ideal for portability. They also have a premium look and feel, which can enhance brand perception.

Cons: The cost of aluminum is relatively high compared to plastic, and manufacturing complexities can arise due to the need for precise machining. Additionally, while aluminum is durable, it can dent under significant impact.

Impact on Application: Laptops with aluminum chassis can efficiently handle the thermal demands of Fusion 360, ensuring optimal performance during intensive tasks.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local availability and import costs of aluminum laptops. Compliance with international standards, such as ASTM for material specifications, is also crucial.

Plastic: Cost-Effective and Lightweight

Plastic is another common material used in laptop construction, particularly for budget-friendly models. It is lightweight and can be molded into various shapes, allowing for innovative designs.

Pros: The primary advantage of plastic is its low cost, making it accessible for a broader range of buyers. It can also be manufactured quickly and in large quantities.

Cons: Plastic lacks the durability of metals and can be prone to cracking or warping under high temperatures. It also typically offers less thermal management, which can be a drawback for software like Fusion 360 that generates significant heat.

Impact on Application: While plastic laptops can run Fusion 360, they may struggle under heavy workloads, leading to potential performance issues.

Considerations for International Buyers: Buyers should be aware of the varying quality of plastic materials. Compliance with local regulations regarding electronic waste and recycling is also essential.

Magnesium Alloy: The Balance of Strength and Weight

Magnesium alloy is increasingly popular in high-end laptops due to its lightweight and robust properties. It offers a good balance between durability and portability.

Pros: Magnesium alloy is stronger than aluminum and lighter than steel, providing excellent protection for internal components. It also has good thermal properties, helping to manage heat effectively.

Cons: The manufacturing process for magnesium alloys can be more complex and costly than for aluminum or plastic. Additionally, while it is resistant to corrosion, it can be susceptible to damage from certain chemicals.

Impact on Application: Laptops made from magnesium alloy can handle the demands of Fusion 360, making them suitable for professionals who require both performance and durability.

Considerations for International Buyers: Buyers should check for compliance with international safety standards, as magnesium alloys may have specific handling requirements during manufacturing and disposal.

Carbon Fiber: Premium Performance and Durability

Carbon fiber is a high-performance material known for its exceptional strength-to-weight ratio. It is often used in premium laptops aimed at professionals.

Pros: Carbon fiber is incredibly strong and lightweight, providing outstanding durability without adding bulk. It also has excellent thermal properties, making it ideal for high-performance applications.

Cons: The primary drawback is the high cost of carbon fiber, which can significantly increase the price of the laptop. Additionally, the manufacturing process can be complex and time-consuming.

Impact on Application: Laptops with carbon fiber construction can handle the intense computational demands of Fusion 360, making them a top choice for engineers and designers.

Considerations for International Buyers: Buyers should consider the availability of carbon fiber laptops in their regions and the potential for higher import duties due to the material’s premium status.

Summary Table of Material Properties for Best Laptop for Fusion 360

| Material | Typical Use Case for best laptop for fusion 360 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | High-performance laptops | Lightweight and durable | Higher cost and manufacturing complexity | High |

| Plastic | Budget-friendly laptops | Low cost and quick manufacturing | Less durable and poor thermal management | Low |

| Magnesium Alloy | Premium laptops for professionals | Strong, lightweight, good thermal properties | More complex manufacturing process | Medium |

| Carbon Fiber | High-end laptops for engineers | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

This analysis provides a comprehensive overview of the materials used in laptops suitable for Fusion 360, enabling B2B buyers to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for best laptop for fusion 360

What Are the Main Stages of Manufacturing for the Best Laptop for Fusion 360?

When considering the manufacturing processes for laptops tailored for demanding applications like Fusion 360, it’s essential to understand the main stages involved. Each stage plays a critical role in ensuring that the final product meets performance standards and customer expectations.

-

Material Preparation: The manufacturing process begins with the selection of high-quality raw materials. This includes metals for the chassis, high-grade plastics for casing, and advanced semiconductors for the internal components. Suppliers often conduct rigorous inspections on raw materials to ensure they comply with international standards such as ISO 9001. Material properties such as heat resistance, durability, and electrical conductivity are assessed to ensure optimal performance.

-

Forming: In this stage, the raw materials are shaped into components. Techniques such as stamping, molding, and machining are commonly used to create parts like the laptop’s chassis, keyboard, and screen. Advanced techniques, including CNC (Computer Numerical Control) machining, are employed to achieve precise dimensions and tolerances, which are crucial for the assembly process.

-

Assembly: The assembly phase is where components come together to form the final product. This process often involves automated assembly lines that ensure efficiency and accuracy. Workers may also perform manual assembly for intricate parts, such as the motherboard and cooling systems. The assembly process must be meticulously managed to avoid contamination and ensure the correct alignment of components.

-

Finishing: After assembly, laptops undergo finishing processes that include painting, coating, and surface treatments. These processes not only enhance the aesthetic appeal of the laptops but also provide additional protection against wear and tear. Quality control during this stage is vital to ensure that the finish is uniform and meets brand standards.

How Is Quality Assurance Implemented During Laptop Manufacturing?

Quality assurance (QA) is integral to the manufacturing of laptops, especially those used for complex software like Fusion 360. A robust QA process involves several international and industry-specific standards, as well as multiple checkpoints throughout the manufacturing process.

-

What International Standards Are Relevant for Laptop Manufacturing?

Adhering to international standards such as ISO 9001 is essential for manufacturers seeking to ensure consistent quality. ISO 9001 outlines criteria for a quality management system (QMS) and emphasizes continuous improvement, customer satisfaction, and process efficiency. Additionally, certifications like CE (Conformité Européenne) ensure that products meet European safety, health, and environmental protection standards. -

What Are the Common Quality Control Checkpoints?

Quality control checkpoints are established at various stages of the manufacturing process:

– Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified requirements.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to identify defects early. This may involve visual inspections and automated testing of components.

– Final Quality Control (FQC): Once the laptops are fully assembled, they undergo rigorous testing to verify functionality, performance, and compliance with specifications. This includes stress testing and performance benchmarking relevant to software like Fusion 360. -

What Testing Methods Are Commonly Used?

Testing methods may include thermal testing to assess heat dissipation under load, performance testing using CAD software, and longevity testing to simulate prolonged use. Furthermore, manufacturers may conduct electromagnetic compatibility (EMC) testing to ensure that laptops do not interfere with other electronic devices.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are some strategies to ensure that suppliers adhere to high-quality standards:

-

Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should evaluate whether suppliers comply with international standards and whether their processes are aligned with industry best practices.

-

Reviewing Quality Reports: Suppliers should provide comprehensive quality reports detailing their QA processes, inspection results, and compliance with standards. These reports can help buyers assess the reliability of the supplier.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing processes and quality control measures to ensure they meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

When engaging in international procurement, B2B buyers must navigate several nuances related to quality control:

-

Understanding Regional Standards: Different regions may have varying standards and regulations. Buyers should familiarize themselves with local quality standards in their target markets, ensuring that suppliers meet these requirements.

-

Cultural Differences in Quality Expectations: Cultural perceptions of quality can differ significantly across regions. Buyers must communicate their quality expectations clearly and ensure that suppliers understand the importance of adhering to these standards.

-

Logistics and Supply Chain Considerations: Quality control does not end at manufacturing. Buyers should consider the entire supply chain, including transportation and storage, as these factors can impact the quality of the laptops upon arrival.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting laptops for demanding applications like Fusion 360. Ensuring that suppliers adhere to rigorous quality standards will ultimately lead to better performance and reliability in the products purchased.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best laptop for fusion 360’

When sourcing the best laptop for Fusion 360, it’s vital to follow a structured approach to ensure you make an informed decision that aligns with your business needs. This guide provides a practical checklist for B2B buyers, helping you navigate through the complexities of selecting the right laptop for demanding design software.

Step 1: Define Your Technical Specifications

Before starting your search, clearly outline the technical specifications that your team requires. Fusion 360 is resource-intensive, so prioritize components such as:

– Processor: Look for high-performance CPUs like Intel Core i7/i9 or AMD Ryzen 7/9.

– Graphics Card: Opt for dedicated GPUs, preferably from NVIDIA’s RTX series or professional options like AMD Radeon Pro.

– RAM and Storage: Aim for a minimum of 16GB RAM and at least 1TB of SSD storage for optimal performance.

Step 2: Assess Performance Needs Based on Use Cases

Understand how your team will use Fusion 360. If your projects involve complex simulations or rendering, you will need a laptop with superior single-core performance and robust thermal management to prevent overheating.

– Single-Core Performance: Prioritize laptops that excel in single-core tasks, as Fusion 360 primarily utilizes one core for most operations.

– Thermal Management: Investigate cooling solutions to ensure sustained performance during intensive tasks.

Step 3: Evaluate Potential Suppliers

It’s essential to vet suppliers thoroughly before making a purchase. Look for vendors who have experience in providing laptops tailored for CAD software.

– Company Profiles: Request detailed company profiles and product catalogs.

– References: Ask for case studies and references from other businesses in similar industries to understand the supplier’s reliability.

Step 4: Compare Warranty and Support Options

Given the investment involved, review the warranty and support options offered by suppliers. A strong warranty and reliable customer service can save time and costs in case of hardware issues.

– Warranty Duration: Look for at least a one-year warranty with options for extended coverage.

– Technical Support: Ensure that the supplier provides comprehensive technical support, preferably with local representatives in your region.

Step 5: Examine Reviews and User Feedback

Research user reviews and testimonials for the laptops you are considering. This can provide insights into real-world performance and potential issues.

– Online Reviews: Utilize platforms like forums and tech review websites to gather feedback.

– User Communities: Engage with online communities or local user groups that focus on CAD software to gain firsthand experiences.

Step 6: Consider Portability and Battery Life

Depending on your team’s working environment, the portability of the laptop may be crucial. If your team frequently travels or works remotely, look for lightweight options with good battery life.

– Weight and Size: Opt for models that balance performance with portability.

– Battery Performance: Aim for laptops that can sustain a full workday without needing a charge, particularly during critical projects.

Step 7: Finalize the Budget and Payment Terms

Establish a clear budget for your laptop procurement. Consider not only the upfront costs but also the total cost of ownership, including potential upgrades and maintenance.

– Cost Analysis: Include all potential costs such as software licenses and accessories.

– Payment Terms: Negotiate flexible payment options with suppliers to manage cash flow effectively.

By following this checklist, B2B buyers can confidently source the best laptops for Fusion 360, ensuring that their teams are equipped with the right tools for success in their design and engineering projects.

Comprehensive Cost and Pricing Analysis for best laptop for fusion 360 Sourcing

When evaluating the cost structure and pricing for sourcing the best laptops for Fusion 360, it’s crucial to break down the components that contribute to overall expenses. This analysis is particularly relevant for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Laptop Pricing?

-

Materials: The primary materials include high-performance processors, GPUs, RAM, and storage components. The choice of premium materials, especially in graphics and processors, significantly influences costs. For instance, laptops featuring NVIDIA RTX series GPUs or high-end AMD Ryzen processors typically come at a premium due to their advanced capabilities.

-

Labor: Labor costs encompass the workforce involved in assembly, quality assurance, and customer service. Brands that emphasize skilled labor for meticulous assembly or custom configurations may have higher labor costs, which are often reflected in the final pricing.

-

Manufacturing Overhead: This includes costs associated with the facilities, utilities, and equipment necessary for production. High-tech manufacturers often invest heavily in state-of-the-art facilities, impacting their pricing strategy.

-

Tooling: Custom tooling for specific laptop designs or features can add to the initial cost. For buyers looking for unique specifications, such as dual-screen setups or specialized cooling systems, tooling costs may be significant.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure that the laptops meet industry standards. Manufacturers with stringent QC protocols may incur higher costs, which are transferred to the buyer.

-

Logistics: Shipping and handling fees vary based on the destination, mode of transport, and supplier agreements. For international buyers, understanding the logistics involved is essential, as costs can fluctuate based on geopolitical factors and shipping rates.

-

Margin: Each supplier has its own profit margin, which can vary widely. High-end brands often maintain higher margins due to brand loyalty and perceived quality, while budget options may operate on thinner margins to attract price-sensitive customers.

What Influences Pricing for Laptop Buyers?

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically qualify for discounts, allowing buyers to negotiate better pricing. Understanding the MOQ policies of suppliers can help in planning bulk purchases.

-

Specifications and Customization: Buyers requiring specific configurations, such as enhanced RAM or storage options, should be aware that customization often incurs additional costs. It’s advisable to clearly define specifications to avoid unexpected expenses.

-

Materials and Certifications: Laptops with certified components (e.g., Energy Star, EPEAT) might be priced higher due to the assurance of quality and sustainability. Buyers should consider the value of these certifications in their purchasing decisions.

-

Supplier Factors: The reputation and reliability of the supplier can significantly affect pricing. Established brands may offer better after-sales support and warranty services but at a higher cost.

-

Incoterms: Understanding the Incoterms agreed upon in contracts is critical, as they dictate who bears the cost of logistics and insurance. This can impact the total cost significantly, especially for international transactions.

How Can Buyers Optimize Costs?

-

Negotiation Strategies: Effective negotiation can yield better pricing. Buyers should come prepared with market data and competitor pricing to leverage discussions with suppliers.

-

Cost-Efficiency Considerations: Evaluate Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and potential upgrades. A slightly higher upfront cost can lead to lower long-term expenses through better durability and performance.

-

Pricing Nuances for International Buyers: Regional market dynamics can affect pricing. For instance, tariffs or import duties may be higher in certain countries, impacting the final cost. International buyers should factor in these additional expenses when budgeting.

Conclusion

Navigating the complexities of laptop sourcing for Fusion 360 requires a keen understanding of cost components and pricing influencers. By considering these factors and employing strategic negotiation tactics, international B2B buyers can optimize their purchasing decisions, ensuring they acquire high-performance laptops that meet their operational needs while maintaining cost efficiency. Always remember that indicative prices can fluctuate based on market conditions, so continual market analysis is advisable.

Alternatives Analysis: Comparing best laptop for fusion 360 With Other Solutions

Introduction

In the rapidly evolving landscape of design and engineering, selecting the right technology for software like Fusion 360 is crucial for enhancing productivity and efficiency. While a high-performance laptop is often the go-to solution, businesses may also consider alternative methods that can effectively support their design workflows. This analysis presents a comparative overview of the best laptop for Fusion 360 against viable alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Best Laptop For Fusion 360 | Custom PC Build | Cloud-Based CAD Solutions |

|---|---|---|---|

| Performance | High single-core performance; ideal for Fusion 360’s requirements. | Superior performance due to customizable specs; excellent for intensive tasks. | Dependent on internet speed; can vary in performance based on service provider. |

| Cost | Higher upfront cost; investment in quality components. | Potentially lower cost if components are sourced wisely; ongoing costs for upgrades. | Subscription-based; potentially lower initial costs but may accumulate over time. |

| Ease of Implementation | Ready to use out of the box; minimal setup required. | Requires technical knowledge for assembly; may need troubleshooting. | Easy to access; no installation needed, but requires stable internet. |

| Maintenance | Generally low; limited to hardware upgrades or repairs. | Moderate; requires regular updates and potential component replacements. | Minimal; software updates managed by the provider. |

| Best Use Case | Ideal for mobile professionals and small teams requiring portability. | Best for dedicated workstations or teams needing high-end performance. | Suitable for remote teams and businesses looking for flexibility and collaboration. |

Detailed Breakdown

Custom PC Build

Building a custom PC can be an attractive alternative for those who require exceptional performance tailored to their specific needs. The ability to choose high-end components such as powerful CPUs and GPUs allows for superior performance in rendering and simulations. However, this option requires technical expertise for assembly and troubleshooting. Additionally, while the initial costs may be lower, ongoing maintenance and potential upgrades can accumulate over time.

Cloud-Based CAD Solutions

Cloud-based CAD solutions represent a modern approach to design and engineering. They offer flexibility, allowing teams to collaborate remotely without the need for powerful local hardware. Accessibility from various devices enhances productivity, especially for businesses with distributed teams. However, the performance of these solutions heavily relies on internet connectivity, which can lead to inconsistent experiences. Furthermore, while the initial costs might be lower, subscription fees can add up, making it essential for businesses to evaluate long-term financial implications.

Conclusion

Choosing the right solution for running Fusion 360 hinges on specific business needs, including budget constraints, team structure, and the nature of projects. A high-performance laptop remains a strong contender for those needing mobility and immediate access to powerful capabilities. Alternatively, custom PC builds cater to those with more complex requirements, while cloud-based solutions offer unparalleled flexibility for remote collaboration. B2B buyers should assess their unique circumstances and weigh the pros and cons of each option to make an informed decision that aligns with their operational goals and budgetary considerations.

Essential Technical Properties and Trade Terminology for best laptop for fusion 360

What Are the Key Technical Properties to Consider for a Laptop Suitable for Fusion 360?

When selecting a laptop for Fusion 360, several critical specifications should guide your decision. These properties ensure that the device can handle complex CAD tasks efficiently, providing a seamless user experience.

1. Processor (CPU) Performance

The CPU is the heart of any laptop, particularly for software like Fusion 360 that relies heavily on single-core performance for most tasks. For optimal functionality, look for Intel Core i7/i9 or AMD Ryzen 7/9 processors from the latest generations (12th Gen or newer for Intel and 5000/7000 series for AMD). A powerful CPU enables faster calculations and smoother operation, essential for professionals working on intricate designs.

2. Graphics Processing Unit (GPU)

A dedicated GPU is crucial for rendering 3D models and simulations in Fusion 360. NVIDIA’s RTX series (e.g., RTX 4060/4070/4080) or professional-grade GPUs such as the NVIDIA RTX A-series or AMD Radeon Pro series are recommended. The right GPU not only enhances visual performance but also accelerates rendering times, which is vital for meeting project deadlines.

3. Memory (RAM) Capacity

For efficient multitasking and handling large files, a minimum of 16GB of RAM is recommended, with 32GB being ideal for more demanding workflows. RAM plays a significant role in ensuring that the laptop can run multiple applications simultaneously without lag, a common scenario for CAD professionals who often juggle various design software.

4. Storage Type and Capacity

An SSD (Solid State Drive) with at least 1TB of storage is essential for fast data retrieval and ample space for large design files. SSDs significantly outperform traditional HDDs in speed, which translates to quicker boot times and faster loading of applications, thereby improving overall productivity.

5. Display Quality

A high-resolution display (minimum 1920 x 1080) with good color accuracy is vital for design work. Laptops with IPS panels provide better viewing angles and color reproduction, allowing designers to see their work in true detail. This is particularly important for tasks that require precision, such as modeling and rendering.

What Trade Terminology Should B2B Buyers Understand When Purchasing Laptops for Fusion 360?

Understanding industry terminology is crucial for making informed purchasing decisions. Here are some common trade terms relevant to buying laptops for Fusion 360.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of laptops, it indicates the original manufacturer of the hardware components. Understanding OEM can help buyers evaluate product reliability and warranty support.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B transactions, knowing the MOQ can help businesses manage their inventory and budgeting effectively, especially when purchasing multiple laptops for a team.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for a specific quantity of goods. This process is essential for B2B buyers to understand pricing structures and negotiate better deals, ensuring they receive competitive offers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and liability, which is particularly important when importing laptops from different regions.

5. Warranty and Service Level Agreement (SLA)

A warranty provides assurance regarding the quality and durability of a laptop, while an SLA outlines the level of service expected from a supplier. Both are critical for B2B buyers to ensure long-term support and maintenance for their investments.

By understanding these technical specifications and trade terms, B2B buyers can make informed decisions when selecting laptops that meet their Fusion 360 needs, ensuring both performance and value.

Navigating Market Dynamics and Sourcing Trends in the best laptop for fusion 360 Sector

What Are the Current Market Dynamics for Sourcing Laptops for Fusion 360?

The demand for high-performance laptops capable of handling demanding applications like Fusion 360 is on the rise, driven by increasing global digitization and the need for advanced design and engineering solutions. Particularly in regions like Africa, South America, the Middle East, and Europe, businesses are focusing on technology that enhances productivity while accommodating remote work models. Key trends include the shift towards powerful single-core performance, as Fusion 360 predominantly relies on single-threaded processing for most tasks. This trend is prompting manufacturers to optimize their offerings for higher clock speeds and robust cooling systems, ensuring laptops can perform effectively under heavy workloads.

In addition, the emergence of hybrid work environments is influencing sourcing decisions. Companies are prioritizing laptops that offer portability without sacrificing performance, leading to a rise in demand for high-end workstations and gaming laptops equipped with dedicated graphics cards. Notably, NVIDIA’s RTX series and AMD’s Radeon Pro GPUs are frequently recommended due to their superior rendering capabilities. Furthermore, the growing emphasis on sustainability is pushing businesses to evaluate the environmental impact of their technology purchases, fostering a demand for laptops that are not only powerful but also environmentally friendly.

How Is Sustainability Impacting the Sourcing of Laptops for Fusion 360?

Sustainability is becoming a critical consideration in the procurement processes for B2B buyers of laptops for Fusion 360. The environmental impact of electronic waste, energy consumption, and the materials used in manufacturing laptops is prompting companies to seek out environmentally responsible options. This includes prioritizing laptops made from recycled materials and those that are designed for easy disassembly and recycling.

Moreover, ethical supply chains are increasingly important to buyers, as they look for manufacturers that demonstrate commitment to social responsibility. Certifications such as Energy Star, EPEAT, and ISO 14001 are becoming benchmarks for assessing the sustainability of laptops. These certifications indicate adherence to environmental management standards and energy efficiency, which can significantly influence purchasing decisions. As businesses increasingly align their operations with corporate social responsibility goals, sourcing laptops that meet these criteria is not only a strategic choice but also a competitive advantage in the market.

What Is the Evolution of Laptops for Design Software Like Fusion 360?

The evolution of laptops suitable for design software such as Fusion 360 has been marked by significant advancements in technology. Initially, laptops were limited in their processing power and graphics capabilities, making them inadequate for complex design tasks. Over the years, manufacturers have responded to the needs of professionals by introducing high-performance laptops equipped with powerful CPUs and GPUs, increased RAM, and high-resolution displays.

The introduction of mobile workstations marked a turning point, allowing engineers and designers to work on the go without compromising on performance. Recent innovations include the integration of AI capabilities and improved cooling technologies, which have further enhanced the efficiency and reliability of laptops under heavy workloads. As software demands continue to grow, the trend towards customization and modular designs is likely to gain traction, enabling users to upgrade components for longevity and improved performance. This evolution reflects the broader shifts in technology, catering to a market that increasingly values both power and portability.

Frequently Asked Questions (FAQs) for B2B Buyers of best laptop for fusion 360

-

How do I choose the right laptop for Fusion 360?

Selecting the right laptop for Fusion 360 involves focusing on several key specifications. Prioritize a powerful single-core processor, such as an Intel Core i7/i9 or AMD Ryzen 7/9, as Fusion 360 relies heavily on single-core performance. Aim for at least 16GB of RAM, with 32GB being ideal for more demanding tasks. A dedicated graphics card, preferably from the NVIDIA RTX series or AMD Radeon Pro series, is crucial for handling complex designs. Additionally, ensure you have at least 1TB of SSD storage for quick data access and management. -

What is the best laptop for Fusion 360 in 2025?

For 2025, the ASUS ProArt P16 stands out as an excellent choice for Fusion 360. It features a robust AMD Ryzen 9 processor and NVIDIA GeForce RTX 5070 graphics, ensuring high performance for 3D modeling. Its 16-inch OLED display provides vibrant colors and sharp resolution, essential for detailed design work. Other notable options include the Dell XPS 15/17 and Lenovo ThinkPad P1 Gen 7, which also offer powerful specifications and reliability, making them suitable for professionals in design and engineering sectors. -

What are the payment terms typically offered by suppliers for laptops?

Payment terms can vary significantly among suppliers, but common practices include upfront payments, net 30 or net 60 days, and even financing options. For B2B transactions, consider negotiating terms that align with your cash flow needs. Some suppliers may require a deposit before production, especially for custom orders. Always clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit, to ensure a smooth transaction process. -

How can I vet suppliers when sourcing laptops for Fusion 360?

To effectively vet suppliers, start by checking their reputation through online reviews, testimonials, and industry references. Verify their business credentials, such as registration and certifications, to ensure legitimacy. Request product samples to assess quality and performance firsthand. Additionally, engage in direct communication to gauge their responsiveness and willingness to support your specific requirements. Establishing a clear understanding of their warranty policies and after-sales support is also crucial for long-term partnerships. -

What customization options are available for laptops aimed at Fusion 360 users?

Many suppliers offer customization options, allowing you to tailor laptops to your specific needs. Common customizations include selecting different processors, RAM configurations, and storage capacities. Some vendors may also provide options for specialized graphics cards or enhanced cooling systems. When discussing customization, consider the balance between performance and budget, and ensure that the chosen specifications align with the demands of Fusion 360 applications. -

What is the minimum order quantity (MOQ) for laptops from suppliers?

Minimum order quantities (MOQs) can vary widely depending on the supplier and the type of laptop. Some manufacturers may have an MOQ of just one unit, particularly for retail or online orders, while others may require larger quantities for wholesale or bulk purchases. When negotiating, clarify MOQs upfront and explore the potential for flexibility, especially if you are looking to establish a long-term relationship or if you require a mix of models. -

How do logistics and shipping impact the procurement of laptops internationally?

Logistics and shipping are critical factors when sourcing laptops internationally. Consider the shipping methods available, such as air freight for speed or sea freight for cost-effectiveness. Assess the supplier’s experience with international shipping, including customs clearance and compliance with local regulations. Additionally, factor in lead times, which can vary based on the origin and destination. Understanding shipping costs and potential tariffs will help you budget accurately and avoid unexpected expenses. -

What quality assurance practices should I expect from laptop suppliers?

Reputable laptop suppliers should have established quality assurance (QA) practices to ensure product reliability. Look for suppliers who conduct rigorous testing, including performance evaluations and stress tests, before products are shipped. They should also provide warranties that cover defects or malfunctions. Inquire about their quality control certifications, such as ISO standards, which can indicate a commitment to maintaining high manufacturing standards. Regular audits and feedback mechanisms can also demonstrate a supplier’s dedication to continuous improvement.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Best Laptop For Fusion 360 Manufacturers & Suppliers List

1. ASUS – ROG Zephyrus G14 2024

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: ASUS – ROG Zephyrus G14 (2024) 14″ OLED 3K 120Hz Gaming Laptop – AMD Ryzen 9 8945HS – 32GB LPDDR5X – GeForce RTX 4070 – 1TB SSD – Platinum White

2. HP – Victus 15.6 Gaming Laptop

Domain: sourcecad.com

Registered: 2014 (11 years)

Introduction: [{“name”:”HP Victus 15.6″ Gaming Laptop”,”processor”:”AMD Ryzen 7 5800H, 8 cores 16 threads, 4.4 GHz Max Turbo Frequency”,”memory”:”16 GB DDR4-3200 MHz”,”storage”:”512 GB M.2 NVMe PCIe SSD”,”graphics”:”NVIDIA GeForce RTX 3050, 4 GB”,”ports”:”2 USB 3.0 Ports”,”operating_system”:”Windows 11″,”recommended_for”:”Small to medium-size 3D modeling, medium-size assemblies, medium simulations and rendering…

3. Dell – Precision Mobile Workstations for CAD

Domain: dell.com

Registered: 1988 (37 years)

Introduction: Laptops for CAD are designed for engineers and architects, featuring Intel® Core™ Ultra Processors. They are suitable for running processing-intensive CAD software, providing fast, responsive performance. Dell’s Precision mobile workstations are highlighted as the best option for CAD, equipped with high-end components including the fastest CPUs, latest graphics cards, large amounts of RAM, fast SS…

4. Langmuir Systems – Fusion 360 System Requirements

Domain: forum.langmuirsystems.com

Registered: 2017 (8 years)

Introduction: For running Fusion 360, users recommend a desktop or laptop with the following specifications:

– CPU: Intel i7 or i9 (preferably 12900)

– RAM: Minimum of 16GB

– Graphics Card: Nvidia (gaming or workstation style), with examples like RTX 2000 or RTX 3060

– Operating System: Windows 11

– Budget: Around $1500 for a good setup

– Importance of high core speed for CPU and strong graphics managemen…

5. Razer – Blade 15 Advanced

Domain: forum.bambulab.com

Registered: 2019 (6 years)

Introduction: This company, Razer – Blade 15 Advanced, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Facebook – Best Laptops for Fusion 360

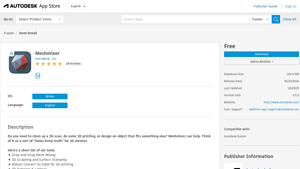

7. Autodesk – Meshmixer

Domain: apps.autodesk.com

Registered: 1989 (36 years)

Introduction: Product Name: Meshmixer

Publisher: Autodesk, Inc.

Reviews: 18 reviews

Price: Free

Operating System: Windows 64-bit

Language: English

Description: Meshmixer is a versatile tool for cleaning up 3D scans, 3D printing, and designing objects. It offers a variety of features including:

– Drag-and-Drop Mesh Mixing

– 3D Sculpting and Surface Stamping

– Convert-to-Solid for 3D printing

– 3D Patterns & Latt…

8. Lenovo – Best Workstation Laptop for 3D Modeling

Domain: lenovo.com

Registered: 2002 (23 years)

Introduction: Best Workstation Laptop for 3D Modeling & Rendering | Lenovo US. Starting at Shop Laptops for 3D modeling. Range of size options. Choose from the latest Intel Core processors. Storage up to 256 GB. Incredible performance on Lenovo P620 with AMD Ryzen™ Threadripper PRO Processors.

Strategic Sourcing Conclusion and Outlook for best laptop for fusion 360

In conclusion, selecting the best laptop for Fusion 360 is crucial for maximizing productivity and efficiency in design and engineering workflows. Key considerations include a powerful single-core processor, dedicated graphics capabilities, ample RAM, and sufficient storage. Brands like Dell, ASUS, and Lenovo offer models that cater to these requirements, ensuring that professionals can seamlessly execute complex tasks.

Strategic sourcing plays a vital role in this decision-making process. By investing time in understanding specific needs and evaluating the options available in different markets, B2B buyers can secure optimal performance while adhering to budget constraints. This approach not only enhances operational efficiency but also fosters long-term partnerships with reliable suppliers.

As international buyers from Africa, South America, the Middle East, and Europe navigate the evolving tech landscape, staying informed about the latest advancements in laptop technology will be essential. Embrace the opportunity to explore tailored solutions that meet your unique business requirements. Engage with trusted vendors and consider conducting thorough market research to ensure your investment aligns with future growth and innovation.