Glass Plates In Bulk: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for glass plates in bulk

Navigating the global market for glass plates in bulk presents a unique set of challenges for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. One key challenge is ensuring that the sourced products not only meet quality and safety standards but also align with local market preferences and pricing strategies. This guide aims to simplify that process by offering a comprehensive overview of the various types of glass plates available, their applications in diverse food service environments, and insights into effective supplier vetting.

Understanding the nuances of bulk purchasing can empower buyers to make informed decisions that enhance their operational efficiency and product presentation. This guide will explore essential factors such as cost considerations, supplier reliability, and product specifications, ensuring that you are well-equipped to navigate the complexities of international procurement. Additionally, we’ll delve into the importance of durability and design, addressing how these elements can impact customer satisfaction and business reputation.

With actionable insights tailored for B2B buyers from diverse markets, this resource serves as a strategic tool for fostering successful partnerships and maximizing value in your glass plate sourcing endeavors. By leveraging the information presented, you can confidently select high-quality products that elevate your service offerings while adhering to regional demands and expectations.

Understanding glass plates in bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tempered Glass Plates | Enhanced durability, heat resistance | Restaurants, catering services | Pros: Highly durable; Cons: Higher cost compared to regular glass. |

| Laminated Glass Plates | Safety features, shatter-resistant | Schools, hospitals, large-scale events | Pros: Safer in high-traffic areas; Cons: Limited aesthetic options. |

| Decorative Glass Plates | Variety of designs and colors | Fine dining, event catering | Pros: Elevates presentation; Cons: May require special care. |

| Opal Glass Plates | Opaque finish, excellent for hot foods | Buffets, cafeterias | Pros: Maintains heat; Cons: Limited visibility for food presentation. |

| Disposable Glass Plates | Lightweight, single-use convenience | Food trucks, outdoor events | Pros: Easy cleanup; Cons: Not environmentally friendly. |

What are Tempered Glass Plates and Their Benefits for B2B Buyers?

Tempered glass plates are designed for high durability and heat resistance, making them an ideal choice for busy restaurants and catering services. They can withstand thermal shock, which is essential for establishments that serve hot dishes. When purchasing tempered glass plates, B2B buyers should consider factors such as size, shape, and weight to ensure they meet their operational needs. Although they tend to be more expensive than regular glass options, their longevity and safety can justify the investment.

How Do Laminated Glass Plates Enhance Safety in Foodservice?

Laminated glass plates offer shatter-resistant properties, making them particularly suitable for environments like schools and hospitals where safety is paramount. These plates are constructed with a layer of plastic sandwiched between two glass layers, which helps prevent breakage. When sourcing laminated glass plates, buyers should assess the thickness and quality of the laminate to ensure it meets safety standards. While they provide excellent safety features, the aesthetic appeal may be less versatile compared to other glass options.

Why Choose Decorative Glass Plates for Fine Dining?

Decorative glass plates come in various designs and colors, allowing businesses to create a memorable dining experience. They are particularly popular in fine dining and event catering, where presentation is key. Buyers should look for plates that not only match their brand aesthetic but also maintain durability under frequent use. While decorative plates can enhance the visual appeal of dishes, they often require more careful handling and cleaning, which can be a consideration for high-volume operations.

What Makes Opal Glass Plates Ideal for Cafeterias and Buffets?

Opal glass plates are characterized by their opaque finish, making them perfect for serving hot foods without compromising on appearance. They are commonly used in buffets and cafeterias, where maintaining food temperature is crucial. When considering opal glass plates, B2B buyers should evaluate their heat retention capabilities and overall design. While they provide excellent insulation, the lack of transparency may limit the visual presentation of the food.

How Do Disposable Glass Plates Benefit Food Trucks and Outdoor Events?

Disposable glass plates offer the convenience of single-use functionality, making them ideal for food trucks and outdoor events. These lightweight plates simplify cleanup and reduce the risk of breakage during transport. Buyers should consider the material quality and design to ensure they align with their brand image. However, the environmental impact of single-use products is a growing concern, which may influence purchasing decisions in sustainability-focused markets.

Key Industrial Applications of glass plates in bulk

| Industry/Sector | Specific Application of glass plates in bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Serving dishes in restaurants and hotels | Enhances food presentation and customer experience | Ensure durability and compliance with food safety standards. |

| Catering | Buffet displays for events and functions | Provides an elegant and hygienic serving solution | Bulk purchasing options and customizable designs preferred. |

| Retail | Displaying food products in grocery stores | Attracts customers with a clear view of offerings | Consider size, shape, and transparency for optimal visibility. |

| Food Processing | Quality control and sampling trays | Facilitates easy handling and assessment of products | Look for heat resistance and ease of cleaning. |

| Education | Cafeteria meal services in schools and universities | Supports efficient meal service and easy cleanup | Focus on non-slip edges and stackability for space-saving. |

How Are Glass Plates in Bulk Used in the Hospitality Industry?

In the hospitality sector, glass plates are essential for serving dishes in restaurants and hotels. Their transparent design elevates the visual appeal of meals, enhancing the dining experience. These plates must be durable to withstand high usage rates while meeting strict food safety regulations. International buyers should prioritize suppliers that guarantee compliance with local health standards and offer a variety of styles to match their brand aesthetics.

What Role Do Glass Plates Play in Catering Services?

Catering companies utilize glass plates for buffet displays at events and functions, providing an elegant and hygienic solution for food service. The clarity of glass enhances the presentation of various dishes, attracting guests and encouraging them to indulge. When sourcing glass plates in bulk for catering, businesses should consider customizable options and bulk pricing to ensure cost-effectiveness while maintaining quality.

How Are Glass Plates Beneficial for Retail Food Displays?

In retail environments, glass plates serve as an effective means to display food products in grocery stores and delicatessens. Their clear surface allows customers to see the quality and freshness of items, thereby driving sales. Retailers should focus on selecting glass plates that are not only visually appealing but also durable enough to handle frequent handling. Sourcing considerations include size and shape to maximize display space while ensuring safety during customer interactions.

Why Are Glass Plates Important in Food Processing Applications?

In food processing, glass plates are often used for quality control and product sampling. Their non-reactive surface ensures that food products maintain their integrity during testing. Buyers in this sector should seek plates that are heat-resistant and easy to clean, allowing for efficient workflow in processing environments. Additionally, sourcing from reputable suppliers who understand the specific needs of the food industry is crucial for maintaining product quality.

How Do Glass Plates Enhance Meal Services in Educational Institutions?

Educational institutions, such as schools and universities, benefit from using glass plates in their cafeteria meal services. These plates support efficient meal service and simplify the cleanup process, which is essential in high-traffic environments. When sourcing glass plates for educational purposes, buyers should prioritize features like non-slip edges and stackability to optimize storage and handling. Ensuring compliance with safety standards is also key to providing a safe dining experience for students.

3 Common User Pain Points for ‘glass plates in bulk’ & Their Solutions

Scenario 1: Quality Assurance for High-Volume Orders

The Problem: A restaurant chain in South America faces a significant challenge when ordering glass plates in bulk. They have previously received shipments with varying quality levels—some plates arrived chipped or flawed, which not only impacts their aesthetic presentation but also raises concerns about food safety and customer satisfaction. The inconsistency in quality has led to increased returns and damaged relationships with their suppliers, creating operational disruptions.

The Solution: To mitigate this issue, buyers should establish strict quality control measures with suppliers before placing bulk orders. It’s essential to request samples of the glass plates to evaluate their durability and overall quality. Additionally, setting clear expectations regarding quality standards and packaging methods can prevent damage during transit. Buyers can also consider sourcing from manufacturers that have certifications such as ISO or NSF, which indicate adherence to industry standards. Regular communication and quality audits can further ensure that the products meet the expected standards consistently.

Scenario 2: Navigating Diverse Local Regulations

The Problem: An African catering company is looking to expand its services and needs to procure glass plates in bulk. However, they are confused by the varying health and safety regulations across different regions they serve. The risk of non-compliance with local laws regarding materials used in food service items could lead to fines or operational shutdowns, which is a major concern for their business.

The Solution: Buyers should conduct thorough research on the specific regulations pertaining to food service items in each target market. Engaging with local regulatory bodies or industry associations can provide valuable insights into compliance requirements. When sourcing glass plates, ensure that they are labeled as food-safe and meet local health standards. It’s also beneficial to work with suppliers who are familiar with these regulations and can provide documentation to prove compliance. Leveraging a local partner or consultant can streamline this process and reduce the risk of costly mistakes.

Scenario 3: Cost Management in Bulk Procurement

The Problem: A restaurant owner in Europe is eager to purchase glass plates in bulk to take advantage of volume pricing. However, they are finding that the initial costs are still higher than expected, and they struggle with managing their budget while ensuring they do not compromise on quality. The challenge is exacerbated by fluctuating shipping costs and duties, which can make it difficult to predict the final expenditure.

The Solution: To effectively manage costs, buyers should consider developing a comprehensive budget that includes all potential expenses associated with bulk purchases, such as shipping, duties, and handling fees. Exploring multiple suppliers for competitive pricing can also help identify the best deal. Additionally, implementing a just-in-time inventory strategy can reduce storage costs and minimize waste. Buyers should negotiate pricing based on long-term partnerships with suppliers, potentially securing better rates for repeat orders. Finally, leveraging technology such as procurement software can help track expenses and optimize inventory management, ensuring that costs remain within budget.

Strategic Material Selection Guide for glass plates in bulk

When selecting glass plates in bulk, understanding the material properties is crucial for B2B buyers, especially those operating in diverse international markets. Here, we analyze four common materials used in the production of glass plates, focusing on their key properties, advantages, disadvantages, and specific considerations for international buyers.

What Are the Key Properties of Tempered Glass Plates?

Tempered glass, also known as toughened glass, is produced through a process of extreme heating and rapid cooling. This method enhances its strength and thermal resistance, making it suitable for high-traffic environments.

- Key Properties: Tempered glass can withstand high temperatures (up to 300°C) and significant pressure, making it ideal for both hot and cold food applications. It is also resistant to thermal shock, which is essential in commercial kitchens.

- Pros & Cons: The primary advantage of tempered glass is its durability, which reduces breakage risks. However, the manufacturing process is more complex and can lead to higher costs compared to standard glass.

- Impact on Application: Its ability to handle extreme conditions makes tempered glass plates suitable for serving hot dishes in restaurants or catering services.

- Considerations for International Buyers: Compliance with safety standards like ASTM C1048 is essential. Buyers from regions like Africa and South America should ensure that suppliers meet local regulations regarding food safety and glass usage.

How Do Laminated Glass Plates Compare in Performance?

Laminated glass consists of two or more layers of glass bonded together with a plastic interlayer. This construction enhances safety and durability.

- Key Properties: Laminated glass offers excellent impact resistance and can withstand moderate temperature variations. It is less likely to shatter, providing added safety in busy environments.

- Pros & Cons: The main advantage is its safety feature; if broken, the glass fragments adhere to the interlayer, minimizing injury risks. However, laminated glass can be heavier and more expensive than standard options.

- Impact on Application: Ideal for buffet settings where the risk of breakage is higher, laminated plates maintain aesthetic appeal while ensuring safety.

- Considerations for International Buyers: Buyers should verify compliance with international standards like DIN EN 12600 for impact resistance, especially in markets with stringent safety regulations.

What Are the Benefits of Borosilicate Glass Plates?

Borosilicate glass is known for its high thermal resistance and chemical durability, making it a popular choice in laboratory and foodservice applications.

- Key Properties: This material can withstand temperature changes of up to 500°C and is resistant to corrosion from various chemicals, making it versatile.

- Pros & Cons: Its high durability and resistance to thermal shock are significant advantages. However, borosilicate glass is generally more expensive and may not be as widely available as other types.

- Impact on Application: Suitable for both hot and cold dishes, borosilicate plates are ideal for upscale dining environments that require high-quality presentation.

- Considerations for International Buyers: Compliance with standards like ASTM E438 is crucial. Buyers in Europe and the Middle East should ensure that their suppliers provide certification for chemical resistance.

Why Choose Standard Glass Plates for Cost-Effective Solutions?

Standard glass plates are the most common type used in various foodservice settings due to their affordability and availability.

- Key Properties: While not as strong as tempered or laminated options, standard glass can handle everyday use and is generally lighter.

- Pros & Cons: The primary advantage is cost-effectiveness, making them suitable for large-scale purchases. However, they are more prone to breakage and thermal shock.

- Impact on Application: Best for casual dining establishments or events where high turnover is expected, standard glass plates serve a wide range of food items.

- Considerations for International Buyers: Buyers should ensure that these plates meet basic food safety standards, particularly in regions with less stringent regulations.

Summary Table of Material Selection for Glass Plates in Bulk

| Material | Typical Use Case for Glass Plates in Bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tempered Glass | High-traffic restaurants and catering services | High durability and thermal resistance | Higher manufacturing cost | Medium |

| Laminated Glass | Buffet settings and high-risk environments | Safety features reduce injury risks | Heavier and more expensive | High |

| Borosilicate Glass | Upscale dining and laboratory settings | Excellent thermal and chemical resistance | More expensive and less available | High |

| Standard Glass | Casual dining and large events | Cost-effective and widely available | Prone to breakage and thermal shock | Low |

This guide provides a comprehensive overview of the materials used in glass plates, enabling B2B buyers to make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for glass plates in bulk

What Are the Main Stages of Manufacturing Glass Plates in Bulk?

The manufacturing process of glass plates typically involves several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages is essential for B2B buyers who are looking to procure high-quality glass plates in bulk.

Material Preparation: What Raw Materials Are Used?

The primary raw material for glass plates is silica sand, which constitutes about 70-75% of the glass composition. Other materials such as soda ash, limestone, and various additives are also included to enhance properties like durability and thermal resistance. In this stage, the raw materials are carefully weighed and mixed to ensure consistency in the final product. This mixture is then melted in a furnace at temperatures exceeding 1,600°C (2,912°F), transforming the raw materials into molten glass.

How Are Glass Plates Formed?

Once the glass is molten, it undergoes the forming stage. This can be accomplished through various techniques, including:

- Press Molding: Suitable for creating thicker plates, this method uses a mold to shape the molten glass into the desired form.

- Blow Molding: Primarily used for hollow glass items, though it can also be adapted for plate production.

- Flat Glass Forming: This involves pouring molten glass onto a flat surface and allowing it to cool, resulting in a flat plate.

The choice of forming technique depends on the design, thickness, and intended use of the glass plates.

What Happens During the Assembly and Finishing Stages?

After forming, the glass plates are subjected to assembly processes where additional features, such as non-slip edges or decorative elements, may be integrated. Following assembly, the plates go through a finishing stage, which often includes annealing—slowly cooling the glass to relieve internal stresses. This is crucial for ensuring durability and preventing breakage during handling and use. The plates may also undergo surface treatments, such as polishing or coating, to enhance their appearance and functionality.

What Quality Assurance Standards Are Relevant for Glass Plates?

For B2B buyers, understanding the quality assurance (QA) processes and standards is crucial. Many manufacturers adhere to international standards like ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with such standards indicates that the manufacturer has established procedures for consistent quality in their production processes.

Which Industry-Specific Certifications Should Buyers Look For?

In addition to ISO standards, buyers should be aware of industry-specific certifications such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards. In regions like Africa and South America, local certifications may also be relevant, and it’s advisable to verify the specific standards applicable to those markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process to ensure that the glass plates meet specified standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the facility. Materials that do not meet specifications are rejected or reprocessed.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular checks are performed to ensure that processes are functioning correctly. This includes monitoring temperatures in the furnace and checking dimensions during the forming process.

-

Final Quality Control (FQC): After the finishing stage, each batch of glass plates undergoes a final inspection. This may involve visual checks for defects, measurement checks for size and shape, and performance testing to assess durability.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers meet quality assurance standards, B2B buyers can take several proactive steps:

-

Conduct Audits: Regular audits of suppliers can help verify their adherence to QA processes and standards. These can be done internally or by hiring third-party auditing firms.

-

Request Quality Reports: Suppliers should be able to provide documentation that details their QC processes, including records of inspections and testing results.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and the quality of the finished products.

What Common Testing Methods Are Used for Quality Assurance?

Several testing methods are commonly employed to assess the quality and safety of glass plates:

-

Visual Inspection: This is the most straightforward method, checking for visible defects like cracks, chips, or uneven surfaces.

-

Dimensional Testing: Using calipers or laser measurement tools, manufacturers can verify that the dimensions of the plates meet specified tolerances.

-

Thermal Shock Testing: This assesses how well the glass can withstand rapid temperature changes, which is critical for plates used in high-heat environments like kitchens.

-

Chemical Resistance Testing: This ensures that the glass can withstand exposure to various chemicals, which is particularly important for food safety.

What Nuances Should International Buyers Consider Regarding Quality Control?

For international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, it is essential to understand regional differences in quality standards. Local regulations may vary significantly, and compliance with international standards does not always guarantee adherence to local requirements.

Additionally, cultural differences in business practices can affect communication regarding quality expectations. It is advisable for buyers to establish clear communication channels with suppliers and ensure that all parties understand the quality standards required for their specific markets.

Conclusion: Ensuring Quality in Bulk Glass Plate Procurement

By understanding the manufacturing processes and quality assurance protocols involved in the production of glass plates, B2B buyers can make informed decisions. Employing rigorous QC checks, verifying supplier certifications, and staying aware of international standards are essential steps for ensuring that the glass plates procured are of the highest quality, suitable for their intended applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘glass plates in bulk’

Introduction

Sourcing glass plates in bulk can be a daunting task for B2B buyers, especially when navigating diverse markets across Africa, South America, the Middle East, and Europe. This step-by-step checklist aims to streamline the procurement process, ensuring you make informed decisions while securing high-quality products that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your requirements for glass plates. Consider factors such as size, shape, material type (e.g., tempered or laminated glass), and design. Defining these specifications will help you communicate effectively with suppliers and ensure that you procure products that align with your business needs.

- Size and Shape: Determine the dimensions and style (round, square, etc.) based on your menu offerings.

- Material Quality: Opt for durable materials that can withstand high-volume use in commercial settings.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is critical in ensuring the quality and reliability of your glass plates. Research potential vendors through online marketplaces, trade shows, and industry referrals.

- Check Reviews and Ratings: Look for feedback from other businesses that have purchased from the suppliers.

- Request Samples: Whenever possible, obtain samples to evaluate the quality firsthand before placing larger orders.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is essential to ensure compliance with international food safety and quality standards. Check for certifications such as NSF, ISO, and other relevant industry standards.

- Food Safety Standards: Ensure that the plates meet food safety regulations applicable in your region.

- Sustainability Practices: Consider suppliers who adhere to environmentally sustainable practices, which can enhance your brand’s reputation.

Step 4: Compare Pricing and Payment Terms

Once you’ve shortlisted potential suppliers, compare their pricing structures and payment terms. Understanding the total cost, including shipping and handling, will help you make a more informed decision.

- Bulk Discounts: Inquire about quantity discounts or flexible payment options for larger orders.

- Hidden Costs: Look out for additional fees that may apply, such as customs duties or shipping charges.

Step 5: Negotiate Delivery Timelines

Discuss and negotiate delivery timelines to ensure that your supply chain remains uninterrupted. Timely delivery is crucial, especially in the foodservice industry, where delays can affect operations.

- Lead Times: Ask suppliers about their typical lead times and any factors that might affect them.

- Contingency Plans: Ensure that suppliers have reliable contingency plans for potential shipping delays.

Step 6: Establish a Quality Control Process

Implementing a quality control process is vital to maintain consistency and quality in your glass plates. Define procedures for inspecting received goods and addressing any discrepancies.

- Inspection Protocols: Develop clear guidelines for assessing the quality of plates upon delivery.

- Return Policy: Familiarize yourself with the supplier’s return policy in case of defects or damage.

Step 7: Build Long-Term Relationships

Cultivating strong relationships with suppliers can lead to better pricing, priority service, and improved collaboration in future orders.

- Open Communication: Maintain regular communication to foster trust and transparency.

- Feedback Loop: Provide constructive feedback to suppliers to help them improve their offerings and service.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing glass plates in bulk, ensuring that they secure high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for glass plates in bulk Sourcing

What Are the Key Cost Components in Bulk Sourcing of Glass Plates?

When sourcing glass plates in bulk, several cost components contribute to the overall price. Understanding these can aid buyers in making informed purchasing decisions.

-

Materials: The primary cost driver is the type of glass used. Tempered or laminated glass, which offers durability and safety, typically comes at a higher price. The quality of raw materials can significantly affect both the cost and performance of the final product.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, quality control, and logistics. Skilled labor is often required for tasks like molding and finishing glass products, which can increase overall expenses.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can help mitigate these costs, making it essential to consider suppliers with optimized production methods.

-

Tooling: Custom molds and tools for specific designs or sizes can add to the initial investment. Buyers should weigh the benefits of custom designs against the potential increase in costs.

-

Quality Control (QC): Ensuring that products meet safety and quality standards incurs additional costs. This includes testing for durability, non-slip features, and compliance with food safety regulations.

-

Logistics: Shipping and handling costs vary based on distance, shipping method, and volume. Bulk orders can reduce per-unit shipping costs, but international shipping may involve additional tariffs and customs fees.

-

Margin: Suppliers typically mark up prices to cover overhead and profit. Understanding the market rate can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of Glass Plates in Bulk?

Several factors influence the pricing of glass plates, particularly for international B2B buyers.

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often come with discounts. Suppliers may offer better pricing tiers based on quantity, encouraging larger purchases.

-

Specifications and Customization: Custom designs or specific sizes can significantly affect pricing. Buyers should clarify their requirements upfront to avoid unexpected costs later in the process.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., NSF for food safety) typically command higher prices. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The supplier’s reputation, production capacity, and geographical location can influence pricing. Established suppliers may offer better reliability but at a premium.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is crucial for international transactions. These terms dictate who bears the shipping costs and risks, impacting the total cost.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Glass Plates?

To maximize value and minimize costs in sourcing glass plates, consider the following tips:

-

Negotiate Pricing: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for large orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Don’t focus solely on the purchase price. Consider factors like durability, maintenance, and replacement costs when evaluating total expenditure over time.

-

Understand Pricing Nuances for International Purchases: For buyers from regions like Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import duties, and regional supply chain challenges that can affect pricing.

-

Establish Strong Supplier Relationships: Building rapport with suppliers can lead to better pricing and terms. Long-term partnerships often result in preferential treatment.

-

Conduct Market Research: Staying informed about market trends and competitor pricing can empower buyers to make strategic decisions and negotiate effectively.

Disclaimer on Indicative Prices

It is essential to note that the prices for glass plates in bulk can vary widely based on the factors outlined above. The information provided serves as a general guideline and may not reflect real-time pricing or specific supplier quotes. Always verify prices directly with suppliers for accurate budgeting.

Alternatives Analysis: Comparing glass plates in bulk With Other Solutions

Exploring Alternatives to Glass Plates in Bulk for Food Service

In the competitive landscape of food service, businesses continuously seek efficient and appealing solutions for serving and displaying food. While glass plates in bulk offer numerous benefits, alternative products can also meet the diverse needs of restaurants, caterers, and other food service providers. This analysis compares glass plates in bulk with two viable alternatives: Plastic Plates and Ceramic Plates.

Comparison Table

| Comparison Aspect | Glass Plates In Bulk | Plastic Plates | Ceramic Plates |

|---|---|---|---|

| Performance | Durable, elegant presentation; easy to clean | Lightweight, often disposable; less elegant | Sturdy, excellent for upscale settings |

| Cost | Moderate to high, depending on style | Low, especially for disposables | Higher due to material and quality |

| Ease of Implementation | Requires careful handling; good for busy kitchens | Easy to stock and use; no cleanup required | Heavy and may require storage space |

| Maintenance | Requires washing and careful handling | Minimal maintenance; disposable options | Needs careful cleaning to avoid chipping |

| Best Use Case | Upscale dining, buffets, and events | Casual dining, outdoor events, and takeout | Fine dining, upscale restaurants, and specialty events |

Detailed Breakdown of Alternatives

Plastic Plates

Plastic plates are a popular alternative in the food service industry due to their affordability and convenience. They are lightweight and often designed for single-use, making them ideal for outdoor events or situations where cleanup speed is critical. However, while they excel in cost-effectiveness, they lack the visual appeal and durability of glass. Additionally, many customers are becoming more environmentally conscious, which can make disposable plastic plates less favorable in settings where sustainability is a priority.

Ceramic Plates

Ceramic plates offer a classic and timeless look, making them suitable for fine dining and upscale events. Their sturdiness ensures longevity and resistance to wear, providing a high-end presentation for dishes. However, the initial investment is typically higher than glass or plastic options, and they can be heavier and more challenging to handle, especially in high-volume environments. Furthermore, ceramic plates require careful washing to prevent chipping, which can add to labor costs.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right serving solution hinges on the specific needs of your business. If your focus is on creating an elegant dining experience with durable, visually appealing options, glass plates in bulk are an excellent choice. However, if cost and convenience are paramount, plastic plates may be more appropriate, particularly for casual settings or takeout services. For upscale dining experiences, ceramic plates can elevate the aesthetic but come with higher costs and maintenance needs. Ultimately, B2B buyers should assess their operational requirements, budget, and customer expectations to determine the best fit for their food service environment.

Essential Technical Properties and Trade Terminology for glass plates in bulk

What Are the Key Technical Properties of Glass Plates in Bulk?

When sourcing glass plates for commercial use, understanding their technical properties is vital to ensure they meet specific operational requirements. Here are several critical specifications to consider:

-

Material Grade

Glass plates are typically made from tempered or laminated glass, which enhances durability and resistance to breakage. Tempered glass undergoes a heating and cooling process that increases its strength, making it ideal for high-traffic environments such as restaurants and catering services. For B2B buyers, selecting the appropriate material grade ensures safety and longevity, reducing replacement costs. -

Thickness

The thickness of glass plates can vary significantly, typically ranging from 5mm to 10mm. Thicker plates provide greater durability and can withstand heavier loads, which is crucial for serving large meals or during busy service periods. Understanding the thickness helps buyers determine if the plates will hold up under the demands of their specific operations. -

Load Capacity

This refers to the maximum weight a glass plate can safely support without risk of breaking. Load capacity is essential for commercial kitchens where plates may be stacked with heavy foods. Buyers need to ensure that the chosen glass plates can handle the expected weight to avoid accidents and enhance service efficiency. -

Finish and Surface Treatment

The finish can affect both the aesthetic appeal and functionality of glass plates. Options include frosted, clear, or colored finishes, which can impact presentation and branding. Additionally, surface treatments may enhance resistance to scratches and stains, making maintenance easier. For B2B buyers, selecting the right finish can elevate the dining experience while ensuring practicality. -

NSF Certification

Many glass plates are certified by the National Sanitation Foundation (NSF), which means they meet strict safety and hygiene standards. This certification is particularly important for buyers in the food service industry, as it assures compliance with health regulations. Ensuring that glass plates are NSF-listed can prevent potential legal issues and enhance customer trust.

What Are Common Trade Terms Related to Glass Plates in Bulk?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of glass plates, an OEM might supply custom designs or specifications tailored to a buyer’s needs. This term is significant for buyers looking for unique or branded products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For glass plates, MOQs can vary widely depending on the manufacturer and type of glass. Understanding MOQs helps buyers plan their inventory and budget effectively, avoiding over-commitment to products they may not need. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of products. Buyers of glass plates often use RFQs to compare offers from multiple suppliers, ensuring they get the best price and terms for their bulk orders. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risks. Familiarity with Incoterms is crucial for international buyers to avoid misunderstandings during the procurement process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. For glass plates, lead times can vary based on customization, order size, and supplier location. Understanding lead times is essential for buyers to manage inventory and ensure timely delivery for their operations.

By grasping these properties and terms, international B2B buyers can make informed decisions, ensuring they select the right glass plates that align with their operational needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the glass plates in bulk Sector

What Are the Current Market Dynamics and Key Trends in the Glass Plates in Bulk Sector?

The global market for glass plates in bulk is witnessing a notable transformation driven by several factors, including changing consumer preferences, advancements in technology, and evolving business models. One of the primary drivers is the growing demand for aesthetically pleasing and versatile dining solutions in the foodservice industry, particularly across regions like Africa, South America, the Middle East, and Europe. In these markets, operators are increasingly seeking high-quality glass plates that not only enhance food presentation but also align with their branding strategies.

Current B2B tech trends such as e-commerce platforms and digital supply chain management are reshaping sourcing practices. International buyers are leveraging these technologies to streamline procurement processes, enabling easier access to a wider range of products at competitive prices. Additionally, the rise of data analytics in inventory management allows businesses to forecast demand more accurately, thereby minimizing excess stock and optimizing supply chains.

Emerging trends include an increased focus on multifunctionality, with glass plates being designed for both service and display purposes. This versatility caters to the fast-paced environment of restaurants and catering services, especially in regions with high turnover rates. Furthermore, the demand for customizable options is on the rise, as buyers look to differentiate their offerings in a crowded marketplace.

How Is Sustainability and Ethical Sourcing Influencing the Glass Plates in Bulk Market?

Sustainability has become a critical consideration for B2B buyers in the glass plates sector. The environmental impact of glass production, particularly in terms of energy consumption and raw material sourcing, is prompting businesses to prioritize suppliers who adhere to sustainable practices. Ethical sourcing involves selecting manufacturers that demonstrate a commitment to reducing carbon footprints and utilizing eco-friendly materials.

The importance of ethical supply chains cannot be overstated, as consumers increasingly prefer brands that align with their values. This shift is leading to a demand for glass plates that are made from recycled or recyclable materials. Certifications such as the Forest Stewardship Council (FSC) and ISO 14001 are becoming essential for manufacturers looking to appeal to environmentally conscious buyers.

Moreover, the trend towards ‘green’ certifications is influencing procurement strategies. Buyers are now more inclined to partner with suppliers who can provide proof of sustainable practices, such as low-emission manufacturing processes or the use of renewable energy. This not only enhances their brand reputation but also helps in complying with regulations aimed at reducing environmental impact.

What Is the Brief Evolution of Glass Plates in Bulk?

The evolution of glass plates dates back to ancient civilizations, where glass was primarily used for decorative purposes. However, the modern era has seen significant advancements in glass manufacturing techniques, leading to the creation of durable, functional products suitable for everyday use in commercial settings. The introduction of tempered glass has further enhanced the safety and durability of glass plates, making them ideal for high-traffic environments such as restaurants and catering services.

In recent years, the design and functionality of glass plates have evolved to meet the demands of contemporary dining experiences. Innovations in production methods and an emphasis on aesthetics have led to a diverse range of products that cater to various culinary presentations. As the market continues to grow, the focus remains on balancing quality with sustainability, ensuring that glass plates not only meet operational needs but also contribute positively to the environment.

Frequently Asked Questions (FAQs) for B2B Buyers of glass plates in bulk

-

How do I ensure the quality of glass plates when sourcing in bulk?

To ensure quality, request samples from potential suppliers before placing a bulk order. Look for certifications such as NSF or ISO that indicate compliance with food safety standards. Assess the glass thickness and durability, especially if the plates will be used in high-traffic environments like restaurants. Additionally, inquire about the supplier’s quality assurance processes, including how they handle defects and returns, to gauge their commitment to quality control. -

What is the best type of glass plate for food presentation in restaurants?

The best type of glass plate for food presentation depends on your menu and aesthetic preferences. Tempered glass plates are highly recommended due to their durability and resistance to breakage, making them ideal for busy kitchens. Clear glass plates allow for beautiful food presentation, while colored or patterned options can enhance the dining experience. Consider also the shape—round plates are traditional, while square or uniquely shaped plates can offer a modern twist. -

How do I vet suppliers for bulk glass plates?

When vetting suppliers, start by researching their reputation through online reviews and ratings. Look for suppliers with experience in international trade and those who specialize in glass products. Request references from other businesses they’ve supplied to, and verify their certifications and compliance with international standards. Additionally, assess their communication responsiveness and willingness to provide detailed product information, which can indicate their reliability as a partner. -

What are common minimum order quantities (MOQs) for glass plates?

Minimum order quantities for glass plates can vary significantly based on the supplier and the specific product. Typically, MOQs range from 100 to 1,000 units for bulk orders. Some suppliers may offer flexibility in MOQs for first-time buyers or larger contracts. Always confirm the MOQ before proceeding to ensure it aligns with your purchasing capacity and budget. -

What payment terms should I expect when purchasing glass plates in bulk?

Payment terms can differ widely among suppliers, but common practices include a deposit (usually 30-50%) upfront, with the balance due upon delivery or before shipping. Some suppliers may offer credit terms for established businesses. It’s essential to clarify payment options, currencies accepted, and any potential transaction fees upfront to avoid surprises later. -

What logistics considerations should I keep in mind for importing glass plates?

When importing glass plates, consider shipping methods (air freight vs. sea freight), as they can significantly affect costs and delivery times. Ensure that your supplier provides proper packaging to prevent breakage during transit. Additionally, familiarize yourself with customs regulations and import duties in your country, as these can impact your overall budget. Engaging a logistics partner can help streamline the process and ensure compliance with local regulations. -

Can I customize the design of glass plates for my brand?

Many suppliers offer customization options for glass plates, including printing your logo or creating specific designs. Customization can enhance brand identity and create a unique dining experience for your customers. Be sure to discuss your requirements with potential suppliers, including design specifications, minimum order requirements for custom products, and lead times for production. -

What are the best practices for maintaining glass plates in a commercial setting?

To maintain glass plates in a commercial setting, implement a regular cleaning schedule using non-abrasive cleaners to avoid scratches. Ensure that staff are trained to handle plates carefully to prevent chipping or breakage. Store plates properly, avoiding stacking them without protective padding. Regular inspections for chips or cracks should be conducted to ensure food safety and presentation quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Glass Plates In Bulk Manufacturers & Suppliers List

1. 10 Strawberry Street – Clear Dinner Plates

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: Glass Plates in Bulk: Clear Dinner Plates & More. Available brands include 10 Strawberry Street, Anchor Hocking, Arcoroc, Duralex, Fortessa Tableware Solutions, Libbey, and Rosseto. Shapes include Oval, Rectangle, Round, Square, and Triangle. Top diameters range from 6 – 8 inches (32 options), 9 – 10 inches (33 options), and 11 – 12 inches (3 options). Features include Dishwasher Safe (78), Fully …

2. Restaurant Supply – Glass Plates

Domain: restaurantsupply.com

Registered: 1998 (27 years)

Introduction: This company, Restaurant Supply – Glass Plates, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Koyal Wholesale – Charger Plates

Domain: koyalwholesale.com

Introduction: This company, Koyal Wholesale – Charger Plates, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Faire – Wholesale Glass Dinner Plates

Domain: k8s.faire.com

Introduction: Wholesale glass dinner plates for your store. Shop wholesale online from over 100,000 brands. Find a variety of products from frames to decorative objects.

5. Komplete Event Rental – Clear Glass Dinner Plate

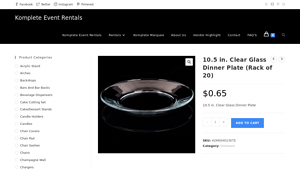

Domain: kompleteeventrental.com

Registered: 2020 (5 years)

Introduction: {“name”: “10.5 in. Clear Glass Dinner Plate”, “quantity”: “Rack of 20”, “price”: “$0.65”, “SKU”: “KOM004023ETE”, “category”: “Dishware”}

6. CV Linens – Wholesale Glass Charger Plates

Domain: cvlinens.com

Registered: 2009 (16 years)

Introduction: Wholesale Glass Charger Plates collection at CV Linens™ offers a variety of designs suitable for weddings, formal dinners, and upscale events. Features include beaded glass plates with gold or silver rims, Monaco glass in silver and white, twigs-trimmed plates, mirror glass options in silver, black, and gold, clear glass reef charger plates, and unique green cabbage and burlap designs. Most plates…

7. eBay – Glass Plates

Domain: ebay.com

Introduction: Glass Plates available in various colors including Clear, Blue, Multicolor, Green, Gold, Red, Silver, Pink, Black, Orange, Purple, and Brown. Types of plates include Dinner Plates, Salad Plates, Plate Sets, Charger Plates, Dessert Plates, Snack Plates, Bread Plates, Side Plates, Starter Plates, and Soup Plates. Popular products include Duralex – Lys Clear Dinner Plate Set of 6 for $48.51, Pioneer …

Strategic Sourcing Conclusion and Outlook for glass plates in bulk

In the ever-evolving landscape of foodservice and hospitality, the strategic sourcing of glass plates in bulk stands out as a critical component for international B2B buyers. The versatility and aesthetic appeal of glass plates not only enhance food presentation but also meet stringent hygiene and durability standards necessary for high-traffic environments. By investing in quality glassware, businesses can ensure long-term cost savings through reduced replacement rates and increased customer satisfaction.

Moreover, leveraging quantity discounts and diverse product offerings allows for tailored procurement strategies that align with specific operational needs. As global markets continue to expand, particularly in regions such as Africa, South America, the Middle East, and Europe, the opportunity for businesses to differentiate themselves through superior service and presentation becomes increasingly vital.

Looking ahead, international buyers should prioritize building strong supplier relationships to navigate potential supply chain challenges effectively. Embracing innovative sourcing strategies will not only streamline operations but also position businesses to adapt to changing market demands. Take the next step today—explore reputable suppliers and make informed decisions that will elevate your brand and ensure lasting success in the competitive foodservice sector.