Choosing Your Used Incubators For Sale: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for used incubators for sale

In the rapidly evolving landscape of laboratory equipment, sourcing used incubators for sale poses a significant challenge for international B2B buyers. The need for reliable, cost-effective solutions is paramount, especially for businesses in regions such as Africa, South America, the Middle East, and Europe, where budget constraints and supply chain complexities often intersect. This guide provides a comprehensive overview of the used incubator market, covering essential topics such as types of incubators, their diverse applications across various industries, and critical supplier vetting processes.

By detailing the range of incubators available—from basic models to advanced, multi-functional systems—this resource empowers buyers to make informed purchasing decisions. Additionally, the guide addresses pricing structures, helping buyers understand the financial implications of acquiring used equipment. With insights into the best practices for sourcing and negotiating, buyers can navigate the global market with confidence, ensuring they select equipment that meets their operational needs while adhering to budgetary constraints. Whether you are a laboratory manager in Germany seeking to enhance your research capabilities or a startup in Nigeria looking to optimize operational costs, this guide serves as your roadmap to successful procurement in the used incubator market.

Understanding used incubators for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Incubators | Controlled CO2 levels, precise temperature and humidity | Cell culture, microbiology, pharmaceuticals | Pros: Ideal for sensitive cultures; Cons: Higher maintenance costs. |

| Refrigerated Incubators | Cooling capabilities, often with multi-zone temperature control | Biological research, environmental testing | Pros: Enhanced sample preservation; Cons: Limited to specific applications. |

| Incubator Shakers | Combines incubation with shaking, adjustable speed | Microbial culture, cell growth | Pros: Efficient mixing; Cons: May require additional space. |

| Forced Air Incubators | Uniform temperature distribution, often with programmable settings | General laboratory use, tissue culture | Pros: Versatile and reliable; Cons: Not suitable for all sensitive samples. |

| Hybrid Incubators | Combines features of CO2 and refrigerated incubators | Advanced research, biotech applications | Pros: Multi-functional; Cons: Higher upfront cost. |

What Are the Key Characteristics of CO2 Incubators?

CO2 incubators are designed to maintain specific atmospheric conditions, particularly the levels of carbon dioxide, which is critical for cell cultures. They typically feature advanced monitoring systems to ensure precise control over temperature, humidity, and CO2 concentration. These incubators are particularly suitable for laboratories focusing on cell biology and microbiology. When purchasing, buyers should consider the model’s calibration capabilities, ease of use, and service availability, as these factors can significantly impact operational efficiency.

How Do Refrigerated Incubators Function in Laboratories?

Refrigerated incubators are equipped with cooling mechanisms that allow for temperature regulation, making them ideal for biological samples that require lower temperatures for preservation. These incubators often feature multi-zone temperature controls, which enable users to maintain different conditions within the same unit. For B2B buyers, it is essential to assess the capacity and energy efficiency of these units, alongside their ability to handle specific sample types, to ensure they meet operational needs without incurring excessive running costs.

What Advantages Do Incubator Shakers Offer for Microbial Cultures?

Incubator shakers are specialized devices that combine incubation with shaking capabilities, providing an optimal environment for microbial cultures and cell growth. The adjustable shaking speed allows for thorough mixing, which is crucial for aerobic organisms. Buyers should evaluate the shaking mechanism’s reliability, the incubator’s capacity, and any additional features such as programmable settings to maximize productivity in research and development settings.

Why Choose Forced Air Incubators for General Laboratory Use?

Forced air incubators utilize a fan-driven system to ensure uniform temperature distribution throughout the chamber. This feature makes them highly versatile for various laboratory applications, including tissue culture and general incubations. When considering a purchase, B2B buyers should focus on the incubator’s temperature accuracy, safety features, and ease of cleaning, as these factors can influence experimental outcomes and compliance with laboratory standards.

What Are the Benefits of Hybrid Incubators in Advanced Research?

Hybrid incubators integrate the functionalities of CO2 and refrigerated incubators, allowing for a broader range of applications in advanced research settings. These units are particularly beneficial for biotechnology applications where precise environmental conditions are critical. Buyers should weigh the initial investment against the potential for improved research outcomes and operational flexibility, as these incubators often come with advanced features that can justify their higher cost.

Key Industrial Applications of used incubators for sale

| Industry/Sector | Specific Application of used incubators for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Biotechnology | Cell culture and tissue engineering | Cost-effective solution for research and development | Ensure compatibility with specific cell lines and protocols |

| Pharmaceuticals | Drug development and stability testing | Accelerates R&D timelines while reducing expenses | Look for incubators with precise temperature and humidity control |

| Agriculture and Agritech | Seed germination and plant tissue culture | Enhances yield and quality of agricultural products | Consider size and capacity for batch processing |

| Microbiology | Cultivation of microbial cultures for research | Supports diverse applications in diagnostics and research | Verify sterilization features and ease of cleaning |

| Education and Research Labs | Student training and experimental studies | Affordable access to essential laboratory equipment | Assess warranty and after-sales support options |

How Are Used Incubators Beneficial in the Biotechnology Sector?

In the biotechnology sector, used incubators are essential for cell culture and tissue engineering applications. They provide controlled environments for growing cells, which is critical for research and development. By opting for used equipment, companies can significantly reduce costs while maintaining high standards in their experiments. Buyers should consider compatibility with specific cell lines and protocols to ensure optimal performance. Additionally, factors such as the incubator’s temperature uniformity and CO2 control are vital for successful cell growth.

What Role Do Used Incubators Play in Pharmaceuticals?

Used incubators are crucial in pharmaceuticals for drug development and stability testing. They allow researchers to maintain optimal conditions for the growth of biological samples, which can influence the efficacy of new drugs. The financial advantage of purchasing used incubators enables companies to allocate resources to other critical areas of research. Buyers should prioritize incubators with precise temperature and humidity controls to ensure reliable experimental results, as variations can affect drug stability and efficacy.

How Are Used Incubators Used in Agriculture and Agritech?

In agriculture and agritech, used incubators are employed for seed germination and plant tissue culture. These incubators create an ideal environment that promotes growth and enhances the yield and quality of crops. Utilizing used equipment allows agricultural businesses to invest in advanced techniques without incurring substantial costs. Buyers should evaluate the size and capacity of the incubators to accommodate different volumes of seeds or cultures, ensuring they meet production needs effectively.

What Are the Applications of Used Incubators in Microbiology?

Microbiology labs utilize used incubators for cultivating microbial cultures essential for various research applications, including diagnostics and environmental studies. These incubators provide a controlled atmosphere necessary for the growth of bacteria, fungi, and other microorganisms. By sourcing used incubators, labs can save on equipment costs while still achieving reliable results. It is crucial for buyers to verify the sterilization features and ease of cleaning to maintain laboratory standards and prevent contamination.

How Are Used Incubators Beneficial for Education and Research Labs?

Educational institutions and research labs often rely on used incubators for training students and conducting experimental studies. These incubators make essential laboratory equipment accessible at a lower cost, allowing institutions to provide hands-on learning experiences. When sourcing used incubators, institutions should assess warranty and after-sales support options to ensure longevity and reliability of the equipment. This consideration is particularly important for international buyers who may face challenges in equipment maintenance and support.

3 Common User Pain Points for ‘used incubators for sale’ & Their Solutions

Scenario 1: Uncertainty Over Equipment Condition and Reliability

The Problem: When purchasing used incubators, B2B buyers often face significant uncertainty regarding the condition and reliability of the equipment. Factors such as previous usage, maintenance history, and the potential need for repairs can lead to anxiety about whether the investment will meet operational needs. This is particularly pressing for buyers in emerging markets, where sourcing high-quality lab equipment can be challenging. Concerns about downtime due to equipment failure can further complicate the decision-making process.

The Solution: To mitigate these concerns, buyers should prioritize sourcing from reputable vendors who provide detailed equipment histories, including maintenance records and previous usage. It’s also advisable to request a pre-purchase inspection or a third-party evaluation, which can provide an unbiased assessment of the incubator’s condition. Additionally, buyers should inquire about any warranties or return policies that the seller offers, as these can safeguard against future issues. Engaging with online marketplaces that specialize in laboratory equipment, such as LabX or EquipNet, can facilitate transparency by allowing buyers to access reviews and ratings of sellers, thus ensuring a more reliable purchasing experience.

Scenario 2: Navigating Technical Specifications and Compatibility

The Problem: Another common pain point for B2B buyers of used incubators is navigating the complex technical specifications and ensuring compatibility with existing laboratory setups. With various models offering different features, such as temperature control, humidity settings, and CO2 levels, the task of selecting the right incubator can be overwhelming. This is especially true for laboratories in regions like Africa and South America, where access to technical support may be limited.

The Solution: Buyers should conduct thorough research to understand the specific requirements of their applications. Creating a checklist of essential features based on intended use—whether for microbiological cultures, cell cultures, or other applications—can streamline the selection process. Additionally, leveraging online resources and forums dedicated to laboratory equipment can provide insights into the best practices and experiences of other users. Consulting with manufacturers or suppliers about compatibility with existing systems can also clarify whether additional adaptations are needed. Before finalizing a purchase, buyers should request comprehensive technical documentation and, if possible, seek demonstrations to ensure the incubator meets their operational needs.

Scenario 3: Price Sensitivity and Budget Constraints

The Problem: Price sensitivity is a significant challenge for many B2B buyers, particularly in developing regions where budgets are often tight. While used incubators present a more affordable option compared to new models, buyers may still encounter a wide price range based on brand, condition, and features. This variability can lead to confusion and difficulty in determining a fair price, causing potential buyers to miss out on quality equipment that fits their budget.

The Solution: To navigate this issue, buyers should start by benchmarking prices across multiple platforms and suppliers to establish a baseline for what constitutes a reasonable price for the specific type of incubator they need. Utilizing online auction sites and marketplaces can also yield competitive prices. Engaging in negotiations with sellers can often lead to discounts, especially if buyers are willing to purchase multiple units or can demonstrate a commitment to ongoing business. Additionally, considering refurbished models can provide access to high-quality equipment at lower prices. Buyers should also factor in potential long-term savings from energy-efficient models, which can offset initial costs over time.

Strategic Material Selection Guide for used incubators for sale

What Are the Key Materials Used in Incubator Construction?

When selecting used incubators for sale, understanding the materials used in their construction is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials: stainless steel, glass, plastic, and aluminum, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Stainless Steel Affect Incubator Performance?

Stainless steel is widely regarded for its strength and resistance to corrosion, making it a popular choice in incubator manufacturing. Key properties include a high-temperature rating and excellent durability against chemical exposure. This material is particularly beneficial for applications requiring rigorous cleaning protocols, such as in microbiology or pharmaceutical labs.

Pros: Stainless steel is highly durable, resistant to rust and corrosion, and easy to clean, which is essential for maintaining sterile conditions. It also has a long lifespan, making it a cost-effective choice in the long run.

Cons: The initial manufacturing costs can be high, and the material may be heavier than alternatives, which could impact shipping and installation logistics.

For international buyers, particularly in regions like Africa and South America, compliance with local standards (such as ASTM or DIN) is vital. Buyers should ensure that the stainless steel used meets these standards to guarantee performance and safety.

What Role Does Glass Play in Incubator Design?

Glass is often utilized in incubators for windows and doors, allowing for visibility into the incubator without compromising the internal environment. Its key properties include excellent thermal insulation and resistance to chemical corrosion.

Pros: Glass provides a clear view of samples, which is beneficial for monitoring without opening the incubator. It also offers good thermal stability, helping maintain consistent temperatures.

Cons: Glass can be fragile and may require careful handling during transport and installation. Additionally, it is less effective in terms of thermal insulation compared to other materials, which may lead to energy inefficiencies.

International buyers should consider the fragility of glass in shipping and the potential need for additional protective packaging, especially in regions with less developed logistics infrastructure.

How Does Plastic Impact Incubator Functionality?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is used in incubator components such as trays and internal structures. Key properties include lightweight construction and good chemical resistance.

Pros: Plastic is generally more affordable than metal or glass and is resistant to many chemicals, making it suitable for various laboratory applications. Its lightweight nature can reduce shipping costs.

Cons: Plastic may not withstand high temperatures as effectively as metals, which can limit its application in high-heat environments. Additionally, it may degrade over time, especially when exposed to UV light.

For international buyers, especially in the Middle East where temperatures can be extreme, it is essential to assess the plastic’s temperature tolerance and durability under local conditions.

What Advantages Does Aluminum Offer in Incubator Manufacturing?

Aluminum is another common material used in incubators, primarily for structural components. It is lightweight, strong, and has good thermal conductivity.

Pros: Aluminum is relatively inexpensive and offers a good strength-to-weight ratio. It can be easily machined and customized, allowing for versatile designs.

Cons: While aluminum is resistant to corrosion, it can be susceptible to certain chemicals and may require protective coatings for specific applications. Additionally, it may not provide the same level of thermal insulation as stainless steel.

International buyers should ensure that any aluminum components comply with relevant standards and consider the specific chemical compatibility for their applications.

Summary Table of Material Selection for Used Incubators

| Material | Typical Use Case for used incubators for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, external casing | High durability and corrosion resistance | Higher initial cost | High |

| Glass | Windows and doors for visibility | Excellent thermal stability | Fragile and less insulating | Medium |

| Plastic | Trays and internal components | Lightweight and cost-effective | Limited temperature resistance | Low |

| Aluminum | Structural and frame components | Good strength-to-weight ratio | Susceptible to certain chemicals | Medium |

Understanding these materials will help international B2B buyers make informed decisions when purchasing used incubators, ensuring they select the right equipment for their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for used incubators for sale

What Are the Key Stages in the Manufacturing Process of Used Incubators?

The manufacturing process for used incubators involves several critical stages that ensure the equipment meets rigorous standards for functionality and safety. Understanding these stages can help B2B buyers make informed decisions when purchasing used incubators.

-

Material Preparation: This initial stage involves selecting high-quality materials that are durable and capable of withstanding various environmental conditions. Common materials include stainless steel for the body, tempered glass for doors, and advanced insulation materials to maintain temperature stability. Suppliers often conduct tests on raw materials to confirm their specifications before they are used in production.

-

Forming: In this phase, materials are shaped into the components required for the incubator. Techniques such as laser cutting, stamping, and molding are commonly employed to achieve precise dimensions. Advanced technologies like CNC (Computer Numerical Control) machining may be used to ensure high accuracy and repeatability in part production.

-

Assembly: Once the components are formed, they are assembled into the final product. This process includes integrating the heating elements, fans, temperature sensors, and control systems. Skilled technicians carefully follow assembly protocols to avoid errors that could affect the incubator’s performance.

-

Finishing: The final stage of manufacturing involves quality finishing touches, such as painting, polishing, or applying protective coatings. This not only enhances the aesthetic appeal of the incubator but also contributes to its longevity and resistance to environmental factors.

How Is Quality Assurance Implemented in the Manufacturing of Used Incubators?

Quality assurance (QA) is paramount in ensuring that used incubators operate effectively and safely. Key international and industry-specific standards guide the QA processes, particularly for B2B transactions.

-

International Standards: Many manufacturers adhere to ISO 9001, which focuses on maintaining a quality management system (QMS). This standard ensures that companies consistently provide products that meet customer and regulatory requirements.

-

Industry-Specific Certifications: Certifications like CE (Conformité Européenne) indicate compliance with European health, safety, and environmental protection standards. For incubators used in pharmaceuticals, adherence to API (Active Pharmaceutical Ingredient) standards is crucial.

What Are the Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process to catch defects early. Here are the main QC checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers are typically required to provide certificates of conformity to confirm that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to ensure that components are being produced according to specifications. This might include measuring dimensions, testing material properties, and checking for defects.

-

Final Quality Control (FQC): After assembly, the entire incubator undergoes rigorous testing to verify its performance. This includes temperature stability tests, humidity control assessments, and safety checks for electrical components. B2B buyers should inquire about the specific tests conducted during FQC.

What Testing Methods Are Commonly Used for Used Incubators?

B2B buyers should be aware of the testing methods that manufacturers employ to ensure the quality of used incubators:

-

Calibration Tests: These tests verify that temperature and humidity sensors are accurately calibrated to maintain optimal growth conditions.

-

Performance Testing: Incubators are subjected to simulations that mimic real-world operating conditions. This helps identify any potential failures before the units are sold.

-

Safety Testing: Electrical safety tests ensure that all components meet safety standards, reducing the risk of electrical hazards during operation.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verification of supplier QC processes is vital for B2B buyers, especially when sourcing used incubators from international markets. Here are several strategies to ensure quality:

-

Supplier Audits: Conducting audits of the manufacturing facility allows buyers to assess the supplier’s adherence to quality standards and practices. This includes evaluating documentation, processes, and the overall quality management system.

-

Requesting Quality Reports: Suppliers should provide detailed reports on their quality control processes, including results from IQC, IPQC, and FQC. These documents can offer insights into the reliability of the equipment being purchased.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the incubators before purchase. These inspectors can conduct thorough tests and verify compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality. Here are some nuances to consider:

-

Regulatory Compliance: Different countries have varying regulations for laboratory equipment. Buyers must ensure that the incubators comply with local regulations, which may require specific certifications not present in the manufacturer’s country.

-

Cultural and Language Barriers: Communication with suppliers can be complicated by language differences and cultural misunderstandings. Clear documentation and open lines of communication can mitigate these issues.

-

Logistics and Shipping Considerations: The condition of used incubators during shipping can affect their performance. Buyers should confirm that suppliers have robust packaging and handling procedures to minimize damage during transit.

By understanding the manufacturing processes, quality assurance measures, and verification strategies, B2B buyers can make informed decisions when purchasing used incubators, ensuring they acquire reliable and effective equipment for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘used incubators for sale’

Introduction

Acquiring used incubators can be a cost-effective strategy for laboratories and businesses looking to optimize their operations without incurring the high costs of new equipment. This guide provides a systematic checklist to help international B2B buyers navigate the sourcing process efficiently, ensuring that they make informed decisions that align with their specific needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the incubator you need. Consider factors such as size, capacity, temperature range, and specific features like CO2 control or humidity regulation. A precise definition of your needs helps streamline the search process and ensures that you only evaluate equipment that meets your operational criteria.

Step 2: Research Reliable Suppliers

Identifying trustworthy suppliers is critical to ensure the quality and reliability of the used incubators. Look for vendors with established reputations and positive customer reviews. Utilize platforms specializing in laboratory equipment, such as LabX or EquipNet, to find verified sellers and avoid potential scams.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their history in selling used incubators and inquire about their warranty and return policies to safeguard your investment.

Step 4: Inspect Equipment Condition

Once you have identified potential incubators, it’s essential to evaluate their condition meticulously. If possible, arrange for an on-site inspection or request detailed images and specifications. Pay attention to:

– Physical Condition: Look for signs of wear, damage, or corrosion.

– Operational Status: Ensure that the incubator has been tested and is in working order, preferably with recent calibration records.

Step 5: Confirm Compliance with Regulatory Standards

Ensure that the used incubators comply with relevant safety and operational standards, particularly in your region. This is especially important if you operate in a regulated industry such as pharmaceuticals or biotechnology. Ask suppliers for documentation that confirms adherence to standards set by organizations such as ISO or local health authorities.

Step 6: Compare Pricing and Financing Options

Evaluate the pricing of the incubators you are considering, comparing them against both new models and other used options. Look for additional costs, such as shipping and installation fees. Discuss potential financing options with suppliers, as many offer flexible payment plans for bulk purchases or long-term leasing agreements.

Step 7: Finalize Your Purchase Agreement

Once you have selected a suitable incubator, ensure that all terms are clearly outlined in a purchase agreement. This should include details on warranty, return policy, and after-sales support. A well-drafted agreement protects both parties and clarifies expectations, ultimately facilitating a smoother transaction.

By following this comprehensive checklist, B2B buyers can confidently navigate the process of sourcing used incubators, ensuring they make informed decisions that align with their laboratory or business needs.

Comprehensive Cost and Pricing Analysis for used incubators for sale Sourcing

What Are the Key Cost Components for Used Incubators?

When sourcing used incubators, understanding the cost structure is crucial. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The quality and type of materials used in the manufacturing of incubators significantly impact costs. For instance, stainless steel models may command a premium due to their durability and corrosion resistance.

-

Labor: The cost of labor varies widely based on the region and the complexity of the assembly. In countries with higher labor costs, like Germany, the final price of used incubators may be elevated compared to those sourced from regions with lower labor expenses.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and indirect labor. A manufacturer with higher overhead may pass these costs onto buyers, affecting the overall price.

-

Tooling: Specialized tools required for the production of incubators can add to the cost. Manufacturers that invest in advanced technology may offer higher-quality products, but these costs will reflect in the price.

-

Quality Control (QC): Rigorous QC processes ensure that used incubators meet industry standards. Higher QC standards can increase costs but provide buyers with assurance regarding product reliability.

-

Logistics: Shipping costs can fluctuate based on the distance between the supplier and buyer, the mode of transportation, and any customs duties applicable. For international buyers, understanding these logistics costs is essential for accurate budgeting.

-

Margin: Suppliers typically apply a profit margin that varies based on market demand, competition, and the perceived value of their products. Understanding the margin can aid buyers in negotiating better deals.

What Influences the Pricing of Used Incubators?

Several factors can influence the pricing of used incubators, including volume or minimum order quantity (MOQ), specifications and customization options, materials used, overall quality and certifications, supplier reputation, and Incoterms.

-

Volume/MOQ: Purchasing in larger volumes often leads to discounts. Buyers should evaluate their needs to determine if a bulk order could provide substantial cost savings.

-

Specifications/Customization: Customized incubators designed for specific applications may incur additional costs. Buyers should weigh the necessity of custom features against budget constraints.

-

Materials: As mentioned, the choice of materials can significantly affect pricing. Buyers should assess whether the durability and performance of higher-cost materials align with their operational needs.

-

Quality/Certifications: Incubators that come with certifications (e.g., ISO) or have undergone stringent testing may carry higher prices. However, these investments can lead to reduced risks and better long-term performance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a history of quality may charge more but offer better support and warranty options.

-

Incoterms: The terms of shipping and delivery can impact the final cost. Understanding Incoterms helps buyers manage risks related to shipping costs, insurance, and duties.

What Are the Best Buyer Tips for Sourcing Used Incubators?

To maximize value when sourcing used incubators, B2B buyers should consider several strategic approaches:

-

Negotiation: Always engage in negotiations. Suppliers may have flexibility in pricing, especially for larger orders or repeat business. Building rapport can also lead to better deals.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the upfront price. Consider maintenance, energy consumption, and longevity when assessing value.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, it’s essential to be aware of currency fluctuations, import taxes, and potential tariffs. These factors can significantly affect the final cost.

-

Research Market Trends: Staying informed about market conditions and competitor pricing can empower buyers to make informed purchasing decisions.

-

Inspect Before Purchase: Whenever possible, inspect used incubators before committing. Assessing the condition can prevent costly surprises down the line.

Disclaimer on Indicative Prices

Prices for used incubators can vary widely based on condition, brand, and specifications. The ranges mentioned in this analysis are indicative and should be verified with suppliers for current market conditions.

Alternatives Analysis: Comparing used incubators for sale With Other Solutions

Introduction: Exploring Alternatives to Used Incubators for Sale

When considering the acquisition of laboratory equipment, particularly incubators, B2B buyers are often faced with a variety of options. While purchasing used incubators offers a cost-effective solution for many laboratories, alternative technologies and methods can also achieve similar objectives. Understanding these alternatives allows buyers to make informed decisions that align with their operational needs and budget constraints.

Comparison Table

| Comparison Aspect | Used Incubators For Sale | Automated Incubator Systems | Environmental Chambers |

|---|---|---|---|

| Performance | Reliable for routine applications; varies by model | High precision with programmable settings; ideal for complex protocols | Excellent for simulating various environmental conditions; suitable for specific experiments |

| Cost | Generally $1,000 – $10,000 | Typically $10,000 – $50,000 | Usually $5,000 – $30,000 |

| Ease of Implementation | Moderate; requires setup and calibration | High; often requires professional installation | Moderate; needs calibration for specific conditions |

| Maintenance | Variable; depends on condition and usage | Low; designed for minimal maintenance | Moderate; requires regular checks and calibration |

| Best Use Case | General microbiological and cell culture applications | Advanced research needing precise control | Studies requiring specific environmental conditions (e.g., humidity, temperature) |

Detailed Breakdown of Alternatives

What Are Automated Incubator Systems and Their Benefits?

Automated incubator systems are designed for high-throughput environments where precision is critical. These systems often come equipped with advanced features such as programmable controls, automated monitoring, and data logging capabilities. The primary advantage of these incubators is their ability to maintain consistent environmental conditions, which is essential for sensitive biological experiments. However, they typically carry a higher initial investment, which may be prohibitive for smaller labs or those on a tight budget. Additionally, their complexity may require specialized training for staff.

How Do Environmental Chambers Compare?

Environmental chambers provide a controlled environment for various applications, including biological experiments, material testing, and product stability studies. These chambers can simulate a range of conditions, such as temperature, humidity, and light cycles, making them versatile for various experimental needs. While they are generally more expensive than used incubators, they offer the benefit of broader application. The downside is that they may not be as efficient for standard microbiological applications, where a simpler incubator would suffice. Maintenance can also be more intensive due to the complexity of the systems involved.

Conclusion: Choosing the Right Laboratory Solution

Selecting the right laboratory equipment involves a careful analysis of specific operational needs, budget, and the intended use case. Used incubators for sale can provide an economical solution for standard applications, while automated incubators and environmental chambers offer advanced capabilities for specialized research. B2B buyers should weigh the performance, cost, and maintenance requirements of each option to determine the best fit for their laboratory environment. By understanding the nuances of each alternative, buyers can make strategic decisions that enhance their research capabilities and operational efficiency.

Essential Technical Properties and Trade Terminology for used incubators for sale

What Are the Key Technical Properties of Used Incubators for Sale?

When considering the purchase of used incubators, understanding the critical specifications is essential for making an informed decision. Here are some key properties to evaluate:

-

Temperature Range

This specification indicates the minimum and maximum temperatures the incubator can maintain. A typical range for biological incubators is between 5°C to 60°C. This is crucial for B2B buyers as it directly impacts the types of samples that can be cultured or tested. Ensuring the incubator meets specific temperature requirements can prevent costly errors in experiments. -

Humidity Control

Many incubators come with built-in humidity control systems that maintain optimal moisture levels for various biological applications. Humidity levels can be critical for the growth of certain cultures; for instance, cell cultures may require a specific range to thrive. Understanding the capabilities of the humidity control system can help buyers select the right incubator for their needs. -

CO2 Levels

For incubators designed for cell cultures, the ability to regulate CO2 concentration is vital. Typical CO2 levels range from 0% to 20%, depending on the application. Buyers must ensure that the incubator can maintain these levels consistently to promote optimal cellular growth conditions. -

Interior Volume

The interior space, measured in cubic feet or liters, determines how many samples can be incubated simultaneously. Understanding this capacity is essential for laboratories with specific throughput needs. Buyers should assess their workflow to ensure the incubator can handle their volume requirements. -

Power Supply Specifications

The power requirements, including voltage and frequency, are important for compatibility with local electrical systems. Buyers from different regions must verify these specifications to avoid operational issues post-purchase. -

Material Grade

The construction materials used in incubators (e.g., stainless steel, aluminum) can affect durability, cleaning ease, and resistance to corrosion. High-grade materials are often more desirable for long-term use and maintenance, which is a significant consideration for B2B buyers looking to maximize investment.

What Are Common Trade Terms in the Used Incubator Market?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several terms commonly encountered in the used incubator market:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that originally manufactured the incubator. Understanding the OEM is crucial for assessing the quality and reliability of the equipment, as well as for sourcing replacement parts or support. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest number of units a buyer can purchase. This term is particularly relevant for businesses looking to acquire multiple incubators or related equipment, as it can affect budgeting and inventory management. -

RFQ (Request for Quote)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific equipment. B2B buyers should use RFQs to ensure they receive competitive pricing and to clarify any specifications or requirements related to the incubators. -

Incoterms

These international commercial terms define the responsibilities of buyers and sellers in global trade. Understanding Incoterms is essential for B2B transactions, particularly when dealing with shipping costs, insurance, and risk transfer during the transportation of incubators. -

Refurbished

Refurbished incubators are pre-owned units that have been restored to a like-new condition. This term is critical for buyers seeking cost-effective options without sacrificing quality, as refurbished units often come with warranties. -

Calibration

Calibration refers to the process of adjusting the incubator’s settings to ensure accurate temperature, humidity, and CO2 levels. Buyers should inquire about the calibration status of used incubators, as proper calibration is essential for experimental accuracy and reproducibility.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing used incubators, ultimately leading to better outcomes for their laboratory needs.

Navigating Market Dynamics and Sourcing Trends in the used incubators for sale Sector

What Are the Current Market Dynamics in the Used Incubators for Sale Sector?

The used incubators market is experiencing notable growth driven by the increasing demand for cost-effective laboratory solutions, particularly in emerging markets across Africa, South America, and the Middle East. As research institutions and clinical laboratories face budget constraints, the appeal of used incubators, which can range from $1,000 to $10,000, is rising. This trend is especially pronounced in regions where new equipment prices can be prohibitive, making refurbished or used options an attractive alternative.

Furthermore, technological advancements in the refurbishment processes have enhanced the reliability and performance of used incubators. Sellers are increasingly offering warranties and guarantees, which can help mitigate buyer concerns about the quality and longevity of used equipment. The proliferation of online marketplaces has also simplified the sourcing process, allowing international buyers to browse a wide array of options and connect directly with sellers. This digital shift is pivotal, as it facilitates easier access to equipment across geographical barriers, thereby broadening the market reach for suppliers.

Emerging trends include a growing emphasis on energy-efficient models and smart technology integration, which align with global sustainability goals. Buyers are increasingly looking for incubators that not only meet their laboratory needs but also contribute to reduced operational costs and environmental impacts.

How Is Sustainability Influencing the Sourcing of Used Incubators?

Sustainability is becoming a crucial factor in the procurement strategies of B2B buyers, particularly within the used incubators sector. The environmental impact of manufacturing new laboratory equipment is significant, leading many organizations to prioritize ethical sourcing practices. By opting for used or refurbished incubators, businesses can significantly reduce their carbon footprint while still acquiring the necessary technology for their operations.

Incorporating sustainability into the supply chain is also tied to the increasing demand for ‘green’ certifications and materials. Buyers are more inclined to partner with suppliers that demonstrate a commitment to environmental stewardship, such as those utilizing energy-efficient technologies or sustainable refurbishing practices. This trend not only aligns with corporate social responsibility goals but also enhances brand reputation and customer loyalty.

Additionally, the market is seeing an increase in suppliers who provide detailed environmental impact reports and certifications for their equipment, enabling buyers to make informed decisions that align with their sustainability objectives. As the global emphasis on reducing waste and promoting circular economies strengthens, the used incubators market is poised to benefit significantly.

What Is the Historical Context of the Used Incubators Market?

The market for used incubators has evolved significantly over the last few decades. Initially, the sector was dominated by a handful of manufacturers and distributors, with limited options for sourcing used equipment. However, the rise of online marketplaces has transformed the landscape, democratizing access to a wider range of products and suppliers.

Historically, the adoption of used incubators was often viewed with skepticism due to concerns about reliability and performance. Over time, as refurbishment technologies improved and regulations tightened, perceptions shifted. Today, many organizations recognize the value of used incubators not only as a cost-effective solution but also as a viable path toward sustainable laboratory practices.

This evolution reflects broader trends within the laboratory equipment market, where buyers are increasingly focused on value, quality, and sustainability. As the industry continues to mature, the availability and acceptance of used incubators are expected to expand, providing significant opportunities for B2B buyers seeking to optimize their laboratory operations.

Frequently Asked Questions (FAQs) for B2B Buyers of used incubators for sale

-

1. How do I ensure the used incubator I purchase is in good working condition?

When buying a used incubator, it’s essential to request a detailed inspection report from the seller, including information on the unit’s age, maintenance history, and any repairs made. Ask for photographs that showcase the incubator’s internal and external condition. If possible, arrange for a third-party technician to evaluate the equipment. Additionally, inquire about the return policy or warranty options to safeguard your investment. -

2. What should I consider when choosing a supplier for used incubators?

Selecting a reliable supplier is crucial for ensuring quality and service. Look for suppliers with a solid reputation, verified customer reviews, and industry certifications. Evaluate their inventory variety, responsiveness to inquiries, and willingness to provide documentation. Establishing a direct line of communication can help gauge their professionalism. Additionally, consider their experience with international shipping and customs regulations, especially when sourcing from different continents. -

3. Are there specific brands known for high-quality used incubators?

Brands such as Thermo Fisher Scientific, Eppendorf, and Memmert are well-regarded for their reliability and advanced technology in incubators. When considering used options, prioritize these brands as they often have robust support networks and spare parts availability. Research the specific model’s performance history and user feedback to ensure it meets your laboratory’s requirements. -

4. What are the typical price ranges for used incubators?

Used incubator prices generally range from $1,000 to $10,000, depending on the model, condition, and features. Factors such as size, capacity, and special functionalities (e.g., CO2 control) can significantly influence pricing. It’s advisable to compare multiple listings and request quotes from different suppliers to secure the best deal while considering the total cost of ownership, including maintenance and operational expenses. -

5. What are the logistics considerations for importing used incubators?

When importing used incubators, consider shipping costs, customs duties, and compliance with local regulations in your country. Collaborate with a freight forwarder experienced in handling laboratory equipment to navigate these complexities. Ensure that the incubator meets your country’s health and safety standards, and obtain necessary import licenses if required. Timely communication with the supplier about shipping details is also critical to avoid delays. -

6. Can I customize a used incubator to meet my specific laboratory needs?

Customization options for used incubators may vary by supplier. While many suppliers offer refurbished units with some level of customization, such as adjusting temperature settings or adding features, extensive modifications may require additional costs or may not be feasible. Discuss your specific needs with the supplier, and inquire if they can accommodate adjustments or recommend suitable models that fit your requirements. -

7. What payment terms should I expect when purchasing used incubators internationally?

Payment terms can vary significantly among suppliers. Common options include upfront payment, deposits with balance upon delivery, or payment via letters of credit for large transactions. Ensure to clarify the payment methods accepted (e.g., bank transfers, credit cards) and any applicable fees. It’s advisable to establish a secure payment process that protects both parties, especially for international transactions. -

8. How can I ensure quality assurance for used incubators purchased from overseas?

To ensure quality assurance, work with suppliers who provide detailed documentation on the incubator’s specifications, maintenance history, and any refurbishments made. Request a certification of compliance with international laboratory standards. Additionally, consider suppliers that offer a warranty or guarantee period, allowing you to test the incubator’s functionality post-purchase. Engaging a third-party inspection service prior to shipment can also help validate the equipment’s condition.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Used Incubators For Sale Manufacturers & Suppliers List

1. eBay – Bird Incubators

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: – 3,800+ results for bird incubators on eBay

– Various brands and models available

– Price range: HK$ 20.00 to HK$ 10,331.72

– Features include automatic egg turning, temperature control, and humidity display

– Capacities range from 12 eggs to 500 eggs

– Shipping options available from the USA and China

– Discounts available on select items (up to 25% off)

– New and fully automatic models highligh…

2. IncuCare – AccuHatch Pro™ Cabinet Incubator & Hatcher

Domain: incubatorwarehouse.com

Registered: 2009 (16 years)

Introduction: Cabinet Incubators for Sale | Large-Capacity Egg Hatching

– Free Shipping on Orders over $25 (Excludes ALL Cabinets & GQF Brooders, Hawaii & Alaska)

– 2 Year IncuCare Warranty on ALL purchases

– AccuHatch Pro™ Cabinet Incubator & Hatcher:

– Price: $749.99 (originally $899.50)

– Features: 2-in-1 design, adjustable egg turners, automatic humidity control, large capacity (up to 600 quail, 280 ch…

3. LabX – Incubators

Domain: labx.com

Registered: 1996 (29 years)

Introduction: Incubators are essential laboratory instruments for cultivating microbiological and cell cultures, providing controlled environments with regulated temperature, humidity, and CO2 levels. They are widely used in research, clinical, and industrial labs, particularly in microbiology, cell biology, and pharmaceuticals. Prices for new incubators range from $2,000 to $20,000, while used models range fro…

4. EquipNet – Used Incubators

Domain: equipnet.com

Registered: 2001 (24 years)

Introduction: EquipNet is the world’s leading provider of used incubators and various other used laboratory equipment. They offer a wide range of used incubators from respected OEMs, including Thermo Scientific, Heraeus, Bellco, Sartorius, Sanyo, and Forma Scientific. Forma Scientific incubators are noted for their innovative technology, efficiency, user-friendliness, and contamination-free solutions. EquipNet …

5. Shurehatch – 2160 Egg Automatic Setter

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Shurehatch – 2160 Egg Automatic Setter, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. GQF – Professional Large Egg Incubator

Domain: machinio.com

Registered: 2013 (12 years)

Introduction: Used Egg Incubators for sale. Key products include: 1. GQF 1700 Professional Large Egg Incubator – 110V, $970 USD, ships in 3-4 weeks ARO. 2. GQF Model 1202E Classic Sportsman Egg Incubator – $840 USD, ships in 4-5 weeks ARO. 3. GQF Model 1510 Digital Professional Egg Incubator – 220V, $876 USD. 4. GQF Model 1500 Digital Professional Egg Incubator – 110V-120V, $884 USD. 5. GQF Model 1550 Digital C…

7. VEVOR – Commercial Egg Incubators

Domain: vevor.com

Introduction: This company, VEVOR – Commercial Egg Incubators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Borotto® – Poultry Egg Incubators

Domain: premier1supplies.com

Registered: 1999 (26 years)

Introduction: Poultry Egg Incubators – Borotto®

– Excellent hatch rates with professional machine performance.

– FREE Ground Delivery on qualified items for orders over $100.

– Made in Italy, known for superior performance and high reliability.

– Key Features:

– Automatically monitors and adjusts temperature.

– Integrated fan for even distribution of warm and humid air.

– Automatic egg turning system.

-…

9. Hatching Time – T Series Incubators

Domain: hatchingtime.com

Registered: 2019 (6 years)

Introduction: Commercial Incubators (Hatch 1000+ Chicken Egg) Cimuka | Hatching Time. T Series large trolley incubators designed for high-capacity hatching of poultry eggs. Features include cabinet-style design, automatic egg turning, precise humidity control, and heavy-duty construction. Suitable for incubating chicken, duck, quail, or turkey eggs. Models include: Cimuka T960 S, T960 H, T1280 S, T1280 H, T1280…

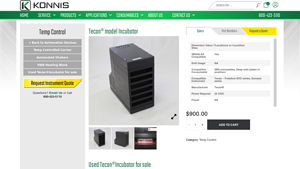

10. Tecan – Used Incubator

Domain: konnis.com

Registered: 2007 (18 years)

Introduction: {“product_name”: “Used Tecan® Incubator”, “price”: “$900.00”, “positions”: “6 positions or 4 position”, “SBS_SLAS_compatible”: “Yes”, “compatible_consumables”: “SBS microplates, Deep-well plates (4 position)”, “compatible_instruments”: “Tecan – Freedom EVO series, Genesis series”, “manufacturer”: “Tecan®”, “power_required”: “24 V/DC”, “konnis_part_number”: “10612679”, “description”: “The incubator…

Strategic Sourcing Conclusion and Outlook for used incubators for sale

In the competitive landscape of laboratory equipment procurement, strategic sourcing for used incubators presents a significant opportunity for B2B buyers. By opting for pre-owned equipment, organizations can access high-quality incubators from reputable brands at a fraction of the cost of new models. This approach not only enhances budget efficiency but also enables laboratories in regions like Africa, South America, the Middle East, and Europe to invest in advanced technologies without compromising on quality.

Understanding the diverse options available—from refurbished units to specific models tailored for unique applications—empowers buyers to make informed purchasing decisions. As the demand for reliable incubators continues to grow, leveraging online marketplaces can streamline the sourcing process, offering a wide range of choices suited to various laboratory needs.

Looking ahead, international buyers should focus on building relationships with trusted vendors and exploring online platforms that facilitate the buying and selling of used incubators. By prioritizing strategic sourcing, laboratories can enhance their operational capabilities while ensuring sustainable financial practices. Embrace the potential of used incubators to elevate your laboratory’s performance and drive innovation in your field.