A Deep Dive into Stainless Steel Sheet Metal 4X8 Solution

Introduction: Navigating the Global Market for stainless steel sheet metal 4×8

In an increasingly competitive global market, sourcing high-quality stainless steel sheet metal 4×8 can be a daunting challenge for international B2B buyers. With diverse applications ranging from food processing and construction to automotive and industrial use, the demand for reliable suppliers has never been greater. This guide aims to demystify the complexities of procuring stainless steel sheet metal, offering insights into various types, key applications, and the nuances of supplier vetting.

From understanding the differences between grades such as T-304 and T-316 to exploring the cost implications and shipping logistics, this comprehensive resource is designed to empower you in making informed purchasing decisions. Tailored specifically for buyers in regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—this guide addresses the unique challenges and opportunities faced in these areas.

By leveraging expert insights and practical advice, you will be better equipped to navigate the global landscape of stainless steel sheet metal procurement. Whether you are seeking to enhance your supply chain efficiency or ensure compliance with local regulations, this guide serves as your roadmap to successful sourcing in a dynamic international marketplace.

Understanding stainless steel sheet metal 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| T-304 | Corrosion-resistant, non-magnetic, versatile | Food processing, commercial kitchens, labs | Pros: Excellent durability and hygiene; Cons: Not suitable for highly corrosive environments. |

| T-316 | Enhanced corrosion resistance, especially against chlorides | Marine applications, chemical processing | Pros: Superior durability in harsh conditions; Cons: Higher cost compared to T-304. |

| T-430 | Magnetic, lower corrosion resistance | Automotive, appliances, decorative projects | Pros: Cost-effective; Cons: Less durable than T-304 and T-316. |

| T-301 | Good strength and ductility, less corrosion-resistant than T-304 | Aerospace, automotive components | Pros: Excellent for forming and welding; Cons: Limited corrosion resistance. |

| T-2B | Smooth, unpolished finish, versatile | Industrial applications, equipment covers | Pros: Cost-effective; Cons: Requires additional finishing for aesthetic applications. |

What are the Characteristics and Applications of T-304 Stainless Steel Sheet Metal?

T-304 stainless steel is the most commonly used grade, known for its excellent corrosion resistance and versatility. It is a non-magnetic alloy, making it ideal for applications in food processing, commercial kitchens, and laboratories where hygiene is paramount. When purchasing T-304, buyers should consider the specific thickness and finish required for their applications, as the #4 brushed finish is popular for aesthetic purposes. Additionally, its ease of fabrication allows for various customizations, making it a go-to choice for many industries.

How Does T-316 Stainless Steel Compare to T-304?

T-316 stainless steel offers enhanced corrosion resistance, particularly against chlorides, making it suitable for marine environments and chemical processing. While it is more expensive than T-304, its durability in harsh conditions justifies the cost for businesses operating in corrosive settings. Buyers should assess their operational environment before choosing T-316, as its superior properties can significantly extend the life of equipment and reduce maintenance costs.

What are the Key Features of T-430 Stainless Steel?

T-430 stainless steel is characterized by its magnetic properties and lower corrosion resistance compared to T-304 and T-316. It is commonly used in automotive applications and decorative projects where cost-effectiveness is crucial. While T-430 is a good choice for certain applications, buyers should be aware of its limitations in terms of durability and resistance to harsh environments. It is essential to evaluate the specific needs of the project to determine if T-430 is the right fit.

What Makes T-301 Stainless Steel Suitable for Aerospace Applications?

T-301 stainless steel is known for its good strength and ductility, making it suitable for aerospace and automotive components that require forming and welding. However, it has a lower corrosion resistance than T-304, which means it may not be ideal for all applications. Buyers should consider the environmental conditions their products will face and whether the enhanced strength of T-301 will meet their performance requirements.

When Should You Choose T-2B Stainless Steel?

T-2B stainless steel features a smooth, unpolished finish and is highly versatile for industrial applications, especially for equipment covers and protective barriers. While it is cost-effective, buyers should be aware that it may require additional finishing for aesthetic applications. Understanding the specific requirements for thickness and size is crucial for businesses looking to optimize their material selection and minimize costs.

Key Industrial Applications of stainless steel sheet metal 4×8

| Industry/Sector | Specific Application of stainless steel sheet metal 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Fabrication of food handling equipment and surfaces | Ensures hygiene, durability, and compliance with food safety standards | Grade 304 stainless steel for corrosion resistance; custom sizes for specific equipment needs |

| Construction and Architecture | Wall cladding and decorative elements | Enhances aesthetic appeal while providing protection against weather and wear | Availability of various finishes; sourcing from local suppliers to minimize shipping costs |

| Automotive Manufacturing | Components for vehicles, including chassis and panels | Lightweight yet strong material that improves fuel efficiency | Consideration of weight specifications; compliance with industry standards for safety |

| Chemical Processing | Storage tanks and piping systems | High resistance to corrosion and chemicals, ensuring safety and longevity | Sourcing corrosion-resistant grades like 316; adherence to specific safety regulations |

| Marine Applications | Boat hulls and marine equipment | Superior resistance to saltwater corrosion, extending equipment lifespan | Local sourcing to meet maritime regulations; custom fabrication options to fit unique designs |

How is Stainless Steel Sheet Metal 4×8 Utilized in Food Processing?

In the food processing industry, stainless steel sheet metal 4×8 is critical for fabricating equipment like tables, sinks, and food storage units. Its non-porous surface prevents bacterial growth, thus ensuring compliance with stringent hygiene standards. International buyers, particularly in regions like Africa and the Middle East, must prioritize sourcing Grade 304 stainless steel, which offers excellent corrosion resistance and durability. Additionally, custom sizing may be required to fit specific machinery, enhancing operational efficiency.

What Role Does Stainless Steel Sheet Metal 4×8 Play in Construction and Architecture?

Stainless steel sheet metal 4×8 is increasingly used in construction for wall cladding and decorative architectural elements. This application not only enhances the aesthetic appeal of buildings but also provides robust protection against environmental factors. For B2B buyers in Europe and South America, sourcing materials with various finishes is essential to meet design requirements. Local suppliers can help mitigate shipping costs while ensuring timely delivery, which is crucial for construction timelines.

How is Stainless Steel Sheet Metal 4×8 Beneficial in Automotive Manufacturing?

In the automotive sector, stainless steel sheet metal 4×8 is commonly used to manufacture lightweight components such as chassis and body panels. The strength-to-weight ratio of stainless steel contributes to improved fuel efficiency and performance. Buyers from regions like Saudi Arabia and Nigeria should consider sourcing materials that meet specific weight and safety standards, ensuring compliance with automotive regulations. Custom fabrication options can also be essential to meet the unique specifications of different vehicle models.

Why is Stainless Steel Sheet Metal 4×8 Important in Chemical Processing?

For chemical processing applications, stainless steel sheet metal 4×8 is vital for constructing storage tanks and piping systems due to its exceptional resistance to corrosion and harsh chemicals. This application is crucial for maintaining safety and longevity in operations. International buyers, particularly from regions with stringent regulatory environments, should prioritize sourcing corrosion-resistant grades like 316 stainless steel. Additionally, understanding local regulations and compliance standards is essential for successful procurement.

How is Stainless Steel Sheet Metal 4×8 Used in Marine Applications?

In marine applications, stainless steel sheet metal 4×8 is utilized for constructing boat hulls and various marine equipment. Its high resistance to saltwater corrosion significantly extends the lifespan of these products, making it a preferred material in the industry. Buyers in coastal regions, especially in Africa and the Middle East, should focus on sourcing locally to meet maritime regulations effectively. Custom fabrication options are also crucial to ensure that components fit specific designs and performance requirements.

3 Common User Pain Points for ‘stainless steel sheet metal 4×8’ & Their Solutions

Scenario 1: Difficulty in Ensuring Quality and Consistency in Sourcing

The Problem: B2B buyers often struggle to find reliable suppliers who can provide high-quality stainless steel sheet metal 4×8 that meets specific industry standards. Inconsistent quality can lead to project delays, increased costs, and even safety risks, especially in industries like food processing and construction, where material integrity is crucial. Buyers may receive materials that are not up to specifications, leading to dissatisfaction and wasted resources.

The Solution: To mitigate quality issues, buyers should establish strong relationships with reputable suppliers who have a proven track record in the industry. It’s essential to request detailed product specifications, including the grade of stainless steel (such as T-304 or T-316), thickness, and finish. Buyers can also ask for certifications, such as ISO 9001 or ASTM standards, to ensure that the materials conform to required quality benchmarks. Regular audits of suppliers and utilizing samples or trial orders can also help gauge quality before committing to larger purchases. Additionally, consider leveraging online platforms that offer user reviews and ratings to identify trustworthy suppliers.

Scenario 2: Challenges in Customization and Size Variability

The Problem: Many projects require customized dimensions or specific finishes that standard suppliers may not readily offer. This can lead to delays in production and increased costs if buyers have to resort to multiple suppliers to fulfill their unique requirements. In regions with limited access to metal fabrication services, this challenge is particularly acute, causing significant setbacks in project timelines.

The Solution: Buyers should prioritize suppliers that offer customization options for stainless steel sheet metal, including various thicknesses, finishes, and cut sizes. When discussing requirements with potential suppliers, be clear about your specific needs, including any custom fabrication or processing such as bending or cutting. Leveraging technology, such as CAD software, can help in communicating precise specifications to suppliers, ensuring that what is delivered meets the exact project requirements. Furthermore, investing in a supplier with in-house fabrication capabilities can streamline the process, allowing for quicker turnaround times and potentially lower costs.

Scenario 3: Navigating Import and Shipping Complexities

The Problem: International buyers often face logistical challenges when importing stainless steel sheet metal 4×8, particularly in regions like Africa and South America. Issues may include long shipping times, high tariffs, and the potential for damage during transit. These factors can complicate project planning and lead to unforeseen costs that impact overall budgets.

The Solution: To effectively navigate these complexities, buyers should conduct thorough research on shipping regulations and tariffs associated with importing stainless steel into their countries. Partnering with suppliers who have experience in international shipping can greatly reduce risks. Buyers should also inquire about packaging practices to ensure that materials are well-protected during transit. Utilizing freight forwarders can help streamline the shipping process and provide insights into the best shipping routes and methods. Additionally, consider purchasing from suppliers who offer local warehousing options to minimize shipping times and costs, enabling a more efficient supply chain.

By addressing these common pain points with actionable strategies, B2B buyers can enhance their procurement processes for stainless steel sheet metal 4×8, ensuring smoother operations and successful project outcomes.

Strategic Material Selection Guide for stainless steel sheet metal 4×8

What are the Key Properties of Common Stainless Steel Materials for Sheet Metal?

When selecting stainless steel sheet metal, particularly in the 4×8 size, several grades are commonly considered. Each grade offers unique properties, advantages, and limitations that can significantly affect the performance of the final product in various applications.

1. T-304 Stainless Steel

Key Properties:

T-304 is renowned for its excellent corrosion resistance, high tensile strength, and good formability. It can withstand temperatures up to 870°C (1,600°F) in continuous service and has a melting point of approximately 1,400-1,600°C (2,500-2,900°F).

Pros & Cons:

The advantages of T-304 include its versatility and aesthetic appeal, making it suitable for both functional and decorative applications. However, it is more expensive than other grades, such as T-430, and may not be the best choice for highly corrosive environments, such as marine applications.

Impact on Application:

T-304 is ideal for food processing equipment, kitchen appliances, and architectural applications due to its hygienic properties and ease of cleaning. It is compatible with a wide range of media, including water, steam, and various chemicals, making it a reliable choice for many industries.

International Considerations:

For buyers in regions like Africa, South America, and the Middle East, compliance with local standards such as ASTM or DIN is crucial. T-304 is widely accepted globally, but buyers should verify that their suppliers adhere to these standards.

2. T-316 Stainless Steel

Key Properties:

T-316 stainless steel offers enhanced corrosion resistance, particularly against chlorides and other aggressive environments. It can handle temperatures similar to T-304 but is more resistant to pitting and crevice corrosion.

Pros & Cons:

While T-316 is more durable and suitable for harsher conditions, it comes at a higher cost compared to T-304. Its increased nickel content makes it more expensive to manufacture, which can impact budget-sensitive projects.

Impact on Application:

This grade is often used in marine environments, chemical processing, and medical applications due to its superior corrosion resistance. It is particularly effective for applications involving saltwater or acidic environments.

International Considerations:

T-316 is recognized internationally, but buyers should ensure that it meets specific local standards. In regions with stringent environmental regulations, T-316 may be preferred for its durability.

3. T-430 Stainless Steel

Key Properties:

T-430 is a ferritic stainless steel known for its moderate corrosion resistance and magnetic properties. It typically withstands temperatures up to 815°C (1,500°F), making it suitable for applications that require heat resistance.

Pros & Cons:

The primary advantage of T-430 is its cost-effectiveness compared to austenitic grades like T-304 and T-316. However, its lower corrosion resistance limits its use in harsh environments, and its magnetic properties may not be suitable for all applications.

Impact on Application:

T-430 is commonly used in kitchen appliances, automotive parts, and decorative applications where aesthetic appeal is essential but exposure to harsh chemicals is limited.

International Considerations:

For international buyers, T-430 may not meet the same standards as T-304 or T-316 in terms of corrosion resistance. Buyers should assess the specific requirements of their applications and ensure compliance with local regulations.

Summary Table of Stainless Steel Sheet Metal Options

| Material | Typical Use Case for stainless steel sheet metal 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| T-304 | Food processing, kitchen appliances, architectural projects | Excellent corrosion resistance and aesthetics | Higher cost compared to other grades | High |

| T-316 | Marine applications, chemical processing, medical equipment | Superior corrosion resistance in harsh environments | More expensive than T-304 | High |

| T-430 | Kitchen appliances, automotive parts, decorative applications | Cost-effective and good for low-corrosion environments | Limited corrosion resistance | Medium |

This guide provides a comprehensive overview of the strategic selection of stainless steel sheet metal for B2B buyers, ensuring informed decisions that align with specific application needs and regional compliance.

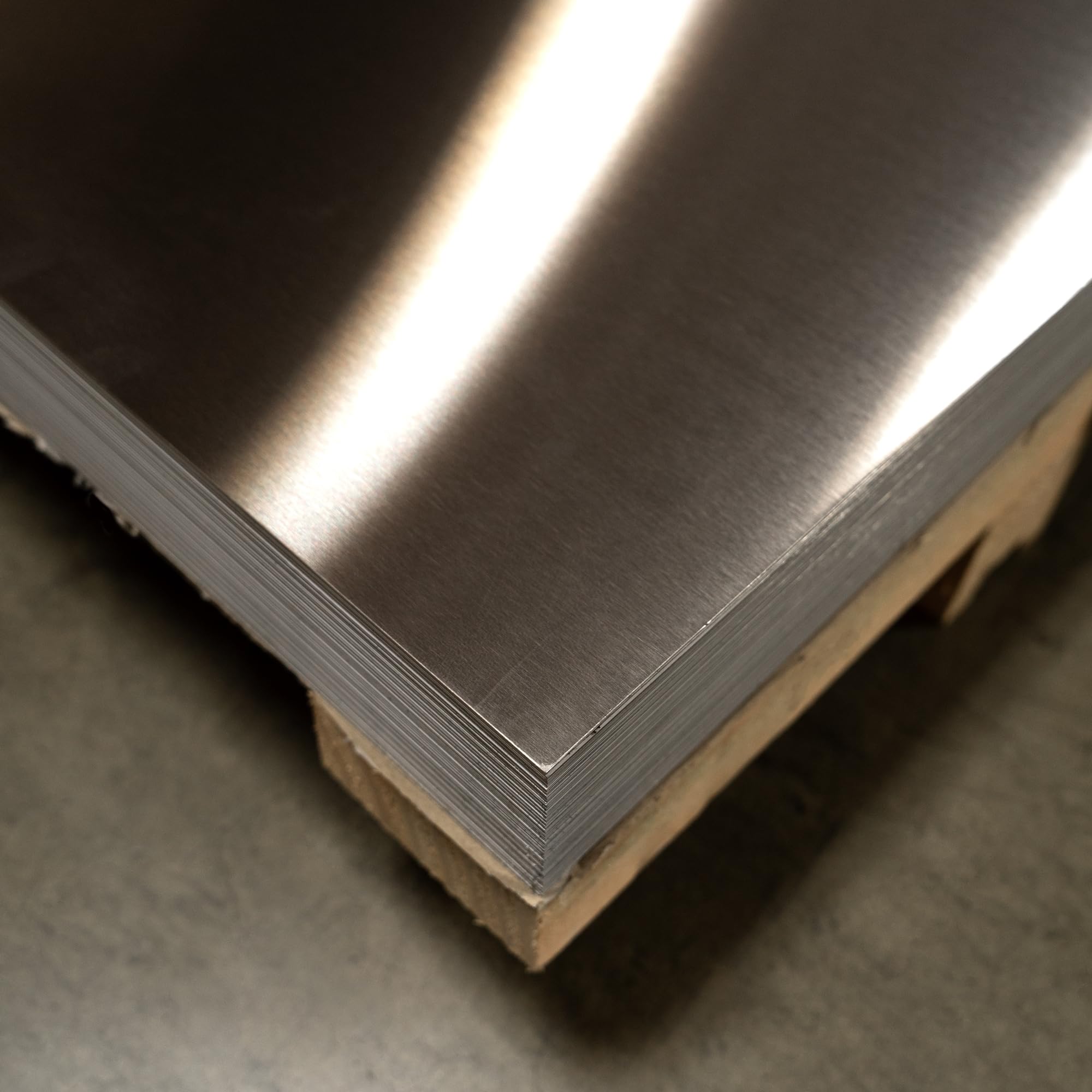

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel sheet metal 4×8

What Are the Main Stages in the Manufacturing Process of Stainless Steel Sheet Metal 4×8?

The manufacturing process of stainless steel sheet metal, particularly in the 4×8 size, involves several critical stages that ensure the product meets the rigorous standards demanded by various industries. Understanding these stages is essential for B2B buyers looking for quality and reliability in their supply chain.

Material Preparation: How Is Stainless Steel Sheet Metal Prepared?

The first step in the manufacturing process is material preparation. Stainless steel sheets are typically made from the 300 series, with T-304 and T-316 being the most common grades used for their excellent corrosion resistance and durability.

- Raw Material Selection: Manufacturers source high-quality stainless steel coils, which are evaluated for chemical composition and mechanical properties.

- Cutting: The coils are then cut into sheets of the desired dimensions, often using shearing techniques or laser cutting for precision.

- Surface Treatment: The sheets may undergo initial surface treatments to remove impurities, which is crucial for achieving the desired finish later in the process.

Forming: What Techniques Are Used in Shaping Stainless Steel Sheets?

Once the sheets are prepared, they proceed to the forming stage, where various techniques are employed to shape the metal according to specifications.

- Bending and Folding: Using press brakes, stainless steel sheets are bent into required angles and shapes. This process is essential for applications requiring specific dimensions.

- Stamping and Punching: For applications that require intricate designs or cutouts, stamping and punching techniques are used, often involving CNC machinery for precision.

- Welding: If assembling multiple sheets or fabricating more complex structures, welding techniques such as TIG or MIG welding are employed to join components securely.

Finishing: How Is the Final Touch Applied to Stainless Steel Sheets?

The finishing stage is vital for enhancing the aesthetic appeal and functional properties of stainless steel sheets.

- Polishing and Texturing: Sheets are polished to achieve various surface finishes, such as #4 brushed or mirror finishes, which not only enhance appearance but also provide corrosion resistance.

- Coating: In some cases, additional coatings may be applied to improve scratch resistance or add specific properties, such as anti-fingerprint coatings.

- Quality Inspection: After finishing, each sheet undergoes a thorough inspection to ensure it meets specified quality standards before packaging and shipping.

What Quality Assurance Standards Should Buyers Look For?

Quality assurance is critical in the manufacturing of stainless steel sheet metal, particularly for international B2B transactions. Understanding the relevant standards and testing methods is essential for ensuring product reliability.

What Are the International Standards for Stainless Steel Sheet Metal Manufacturing?

Manufacturers often adhere to international standards such as ISO 9001, which outlines quality management principles that ensure consistent quality and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) or API (American Petroleum Institute) may be relevant depending on the intended application.

- ISO 9001: This standard emphasizes a process approach to quality management, requiring regular reviews and continuous improvement.

- CE Marking: Necessary for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for manufacturers supplying industries such as oil and gas, API standards ensure that products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that the final product meets established standards.

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specifications. This includes checking for material grade, dimensions, and surface quality.

- In-Process Quality Control (IPQC): During the manufacturing process, periodic inspections are conducted to monitor adherence to specifications and identify any potential issues early.

- Final Quality Control (FQC): Before shipment, a comprehensive inspection of the finished product is performed. This includes dimensional checks, surface finish evaluations, and mechanical property testing.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers to ensure they receive high-quality products.

- Supplier Audits: Conducting audits of suppliers’ manufacturing facilities can provide insights into their quality management systems and adherence to international standards.

- Quality Reports: Requesting detailed quality control reports can help buyers understand the testing methods used, including any certifications obtained for specific products.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality, ensuring that the supplier meets specified standards.

What Testing Methods Are Commonly Used in Quality Control?

Testing methods play a significant role in the quality assurance process, providing measurable data on product performance and compliance.

- Mechanical Testing: Includes tensile tests, hardness tests, and impact tests to assess the material’s strength and durability.

- Corrosion Testing: Salt spray tests or immersion tests are used to evaluate the corrosion resistance of stainless steel sheets, especially for applications in harsh environments.

- Visual Inspection: A thorough visual inspection ensures that the surface finish meets the required aesthetic and functional standards.

What Are the Unique Quality Control Considerations for International B2B Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in international transactions is crucial.

- Cultural Differences: Different regions may have varying expectations regarding quality standards and communication. Establishing clear agreements on quality requirements is essential.

- Logistics and Transportation: Ensure that the supplier has robust packaging and shipping processes to prevent damage during transit, which could compromise quality.

- Local Regulations: Be aware of local regulations and standards that may affect product acceptance in specific markets, ensuring compliance to avoid delays or rejections.

By understanding the manufacturing processes and quality assurance protocols for stainless steel sheet metal, B2B buyers can make informed decisions, ensuring they procure high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel sheet metal 4×8’

Introduction

When sourcing stainless steel sheet metal in a 4×8 size, particularly for B2B applications, a structured approach can streamline the process and ensure that you meet your project’s requirements effectively. This checklist is designed to guide international buyers through essential steps, helping you make informed decisions while navigating the complexities of the procurement landscape.

Step 1: Define Your Technical Specifications

Before initiating your search, it’s crucial to outline your specific requirements. Consider the intended application of the stainless steel sheet metal, including factors such as thickness, finish, and grade. For example, T-304 is suitable for food processing, while T-316 offers enhanced corrosion resistance for marine applications.

- Thickness: Common gauges include 16, 18, and 22; choose based on strength requirements.

- Finish: Options such as #4 brushed or mirror finishes affect aesthetics and functionality.

Step 2: Identify Reliable Suppliers

Sourcing from reputable suppliers is vital for ensuring product quality and reliability. Look for suppliers with established market presence and positive reviews from previous clients.

- Accreditations: Verify that suppliers hold relevant certifications, such as ISO 9001, which indicates a commitment to quality management.

- Experience: Evaluate their experience in serving industries similar to yours.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Product Range: Ensure they offer various grades and finishes of stainless steel sheet metal.

- Customer Support: Assess their responsiveness and willingness to provide technical guidance.

Step 4: Request Samples and Quotes

Obtaining samples allows you to assess the material’s quality and suitability for your specific application. Additionally, requesting quotes from multiple suppliers enables you to compare pricing and terms.

- Samples: Ask for small samples to evaluate quality and finish.

- Pricing: Look for transparent pricing structures and be wary of hidden costs.

Step 5: Confirm Shipping and Delivery Options

Understanding the logistics of your procurement process is essential for timely project execution. Confirm shipping methods, delivery times, and costs with your chosen suppliers.

- Lead Times: Ensure that suppliers can meet your deadlines, especially for large orders.

- Shipping Terms: Clarify who bears shipping costs and the responsibilities of both parties during transit.

Step 6: Understand Payment Terms and Conditions

Establishing clear payment terms can prevent misunderstandings and financial issues later in the transaction. Discuss payment methods, deposits, and any financing options available.

- Flexibility: Some suppliers may offer payment plans or credit terms based on your business relationship.

- Security: Ensure that payment methods are secure to protect against fraud.

Step 7: Review and Finalize the Contract

Once you’ve selected a supplier, it’s time to formalize the agreement. Carefully review the contract to ensure all agreed-upon terms are included, such as pricing, delivery schedules, and quality assurance measures.

- Legal Review: If necessary, have a legal expert review the contract to safeguard your interests.

- Amendments: Ensure that there is a clear process for addressing any potential changes or disputes.

By following this step-by-step checklist, B2B buyers can streamline the procurement process for stainless steel sheet metal 4×8, ensuring quality, reliability, and efficiency in their sourcing decisions.

Comprehensive Cost and Pricing Analysis for stainless steel sheet metal 4×8 Sourcing

What Are the Key Cost Components in Sourcing Stainless Steel Sheet Metal 4×8?

When sourcing stainless steel sheet metal 4×8, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of stainless steel grade significantly impacts pricing. For instance, T-304 stainless steel, known for its corrosion resistance and versatility, typically costs more than lower-grade options like T-430. The market price for raw stainless steel fluctuates based on global demand and supply dynamics.

-

Labor: Labor costs encompass the workforce involved in manufacturing, fabricating, and finishing the sheets. Skilled labor is required for high-quality fabrication, which can increase costs, especially in regions with higher wage standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help mitigate overhead costs, impacting the final price.

-

Tooling: The investment in specific tools and machinery for producing stainless steel sheets adds to the cost. Custom tooling for unique specifications can be particularly expensive.

-

Quality Control (QC): Rigorous quality control measures are necessary to ensure product compliance with international standards. The costs associated with testing and inspection can be significant, especially for grades intended for critical applications.

-

Logistics: Shipping and handling costs are crucial, particularly for international buyers. Factors such as distance, shipping method, and freight rates influence the overall logistics cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on market conditions and supplier competition.

How Do Price Influencers Affect the Cost of Stainless Steel Sheet Metal 4×8?

Several factors can influence the pricing of stainless steel sheet metal:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower unit prices. Suppliers may offer discounts for larger orders, making it beneficial for buyers with high-volume needs.

-

Specifications and Customization: Custom sizes, thicknesses, and finishes can increase costs. Buyers should clearly define their specifications to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials with certifications (like ISO or ASTM) often command premium prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer better quality assurance but at a higher cost.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers in shipping and delivery. Terms like CIF (Cost, Insurance, and Freight) can significantly affect overall costs.

What Tips Can Help Buyers Negotiate Better Prices for Stainless Steel Sheet Metal?

To enhance cost-efficiency when sourcing stainless steel sheet metal 4×8, consider the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for large orders. Suppliers may be willing to adjust prices based on volume or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider factors like durability, maintenance, and the potential for recycling when assessing the TCO. A higher upfront cost may lead to lower long-term expenses.

-

Research Market Prices: Stay informed about market trends and price fluctuations in the stainless steel industry. This knowledge can provide leverage during negotiations.

-

Understand Pricing Nuances for International Transactions: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of additional costs, such as tariffs, taxes, and potential currency fluctuations that can affect the final price.

Disclaimer on Indicative Prices

Prices for stainless steel sheet metal can vary significantly based on market conditions, supplier pricing strategies, and specific buyer requirements. It is advisable to obtain multiple quotes and conduct thorough market research to ensure competitive pricing.

Alternatives Analysis: Comparing stainless steel sheet metal 4×8 With Other Solutions

Exploring Viable Alternatives to Stainless Steel Sheet Metal 4×8

When considering materials for industrial or commercial applications, it’s crucial to evaluate various alternatives to ensure the best fit for specific needs. Stainless steel sheet metal 4×8 is a popular choice due to its durability, corrosion resistance, and aesthetic appeal. However, other materials can also serve similar purposes, each with unique advantages and disadvantages.

| Comparison Aspect | Stainless Steel Sheet Metal 4×8 | Aluminum Sheet Metal 4×8 | Galvanized Steel Sheet 4×8 |

|---|---|---|---|

| Performance | Excellent corrosion resistance; high strength; non-magnetic | Lightweight; good corrosion resistance; not as strong as stainless steel | Strong; good tensile strength; moderate corrosion resistance |

| Cost | Higher initial cost | Lower initial cost | Moderate initial cost |

| Ease of Implementation | Requires specialized tools for cutting and welding | Easier to cut and handle; can be welded | Moderate difficulty; requires proper safety measures during handling |

| Maintenance | Low maintenance; easy to clean | Low maintenance; can dent easily | Moderate maintenance; can rust if not coated |

| Best Use Case | Food processing, medical equipment, architectural applications | Automotive, decorative applications, lightweight structures | Construction, HVAC systems, agricultural applications |

In-Depth Analysis of Alternatives

Aluminum Sheet Metal 4×8

Aluminum sheets are a viable alternative for many applications where weight is a concern. They are significantly lighter than stainless steel, making them easier to handle and transport. Aluminum offers good corrosion resistance, especially when anodized, and is suitable for decorative uses in the automotive and architectural sectors. However, while aluminum is easy to work with, it lacks the strength and durability of stainless steel, making it less ideal for heavy-duty applications.

Galvanized Steel Sheet 4×8

Galvanized steel, coated with a layer of zinc to prevent rust, provides a cost-effective alternative to stainless steel. It is known for its tensile strength, making it suitable for structural applications. Galvanized steel is commonly used in construction and HVAC systems due to its sturdiness and affordability. However, its corrosion resistance is not as high as that of stainless steel, especially in harsh environments, which can lead to rusting over time if the coating is damaged.

Making the Right Choice for Your Business Needs

When selecting the right material for your project, consider the specific requirements of your application. Stainless steel sheet metal 4×8 is ideal for environments that demand high durability and corrosion resistance, such as food processing or medical applications. Conversely, if weight and cost are primary concerns, aluminum may be the better choice, particularly for non-structural applications. Galvanized steel offers a balance of strength and cost-effectiveness for construction projects but may not be suitable for environments with high exposure to moisture or corrosive elements.

Ultimately, the decision should be guided by the specific conditions of your project, including budget, application requirements, and long-term maintenance considerations. By carefully evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for stainless steel sheet metal 4×8

What Are the Key Technical Properties of Stainless Steel Sheet Metal 4×8?

When evaluating stainless steel sheet metal, particularly in the 4×8 size, several technical properties are critical for ensuring that the material meets project requirements. Here are the essential specifications:

1. Material Grade

The most common grades for stainless steel sheets are 304 and 316. Grade 304 is versatile and widely used due to its excellent corrosion resistance and aesthetic appeal. It is suitable for various applications, including kitchen equipment and architectural projects. Grade 316, however, offers superior corrosion resistance, especially in marine or chemical environments. For international buyers, understanding the material grade is essential for compliance with local standards and applications.

2. Thickness (Gauge)

The thickness of stainless steel sheets is measured in gauge (GA). For instance, a 22 GA sheet is approximately 0.030 inches thick, making it suitable for light-duty applications. Thicker sheets (e.g., 16 GA) are more robust and used in heavy-duty environments. The right thickness ensures that the material can withstand the intended load and stress in its application, impacting durability and performance.

3. Finish Type

Stainless steel sheets come in various finishes, such as #4 brushed, mirror, and 2B. The finish affects not only the aesthetic appearance but also the material’s resistance to scratching and staining. A #4 brushed finish, for example, is commonly used in food processing areas due to its hygienic properties and ease of cleaning. Selecting the appropriate finish can enhance both functionality and visual appeal in commercial settings.

4. Tolerance

Tolerance refers to the allowable deviation from specified dimensions. In the context of stainless steel sheets, a tighter tolerance ensures better fit and functionality in applications such as fabrication and assembly. This is particularly crucial for projects requiring precision, such as custom installations or sensitive equipment. Understanding tolerances helps buyers avoid costly reworks and delays.

5. Corrosion Resistance

Stainless steel is known for its resistance to rust and corrosion, but this property can vary based on the alloy composition. Grade 304 provides good resistance to a wide range of corrosive environments, while Grade 316 is better suited for harsher conditions, such as those involving saltwater. For buyers in regions with high humidity or exposure to corrosive substances, selecting the right grade is vital for longevity and performance.

6. Formability

The ability to fabricate and shape stainless steel sheets is crucial for many applications. Stainless steel is known for its excellent formability, allowing it to be cut, bent, and welded with relative ease. This property is significant for manufacturers and fabricators who need to create custom parts or structures.

What Are Common Trade Terms in the Stainless Steel Sheet Metal Industry?

Understanding industry terminology is crucial for navigating the procurement process effectively. Here are some common trade terms relevant to stainless steel sheet metal:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of stainless steel sheets, OEMs often require high-quality materials for their products. Understanding OEM relationships can help buyers identify reliable suppliers that meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is important for buyers as it can impact inventory management and cost efficiency. International buyers should be aware of MOQs to ensure they can meet production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific quantities and types of goods. For stainless steel sheets, an RFQ can help buyers compare pricing, lead times, and terms of service across multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping and freight transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs and risks associated with international procurement.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the stainless steel industry, lead times can vary based on product availability and supplier location. Understanding lead times is essential for project planning and inventory management, especially for international buyers facing logistical challenges.

6. Certification

Certification refers to the documentation that verifies that materials meet specific standards, such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). Buyers should seek certified materials to ensure compliance with industry standards and enhance product reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing stainless steel sheet metal, ensuring that their projects are successful and compliant with industry standards.

Navigating Market Dynamics and Sourcing Trends in the stainless steel sheet metal 4×8 Sector

What Are the Current Market Dynamics and Key Trends in the Stainless Steel Sheet Metal 4×8 Sector?

The stainless steel sheet metal 4×8 market is witnessing significant growth driven by various global factors. The rising demand for durable and corrosion-resistant materials across industries such as construction, automotive, and food processing is a primary driver. Emerging economies in Africa and South America are particularly ramping up infrastructure projects, increasing the need for high-quality stainless steel products. Moreover, the Middle East’s construction boom and Europe’s push for sustainable building practices are creating new avenues for international suppliers.

Technological advancements in B2B sourcing are also reshaping the landscape. Digital platforms and marketplaces are facilitating easier access to suppliers and buyers, enabling quicker comparisons and transactions. The introduction of data analytics tools allows for better inventory management and demand forecasting, helping companies optimize their supply chains. Furthermore, the trend toward customization is gaining momentum, with buyers increasingly seeking specific grades, finishes, and dimensions to suit unique project requirements.

In terms of market dynamics, fluctuations in raw material prices, particularly nickel and chromium, are influencing the pricing strategies of suppliers. This volatility necessitates that buyers remain vigilant and informed about market trends to negotiate better deals. Additionally, geopolitical factors, such as trade tariffs and regulations, can impact sourcing decisions, making it crucial for international buyers to stay updated on global trade policies.

How Does Sustainability and Ethical Sourcing Impact the Stainless Steel Sheet Metal 4×8 Industry?

Sustainability has become a crucial consideration in the stainless steel sheet metal 4×8 sector. The environmental impact of stainless steel production, which involves significant energy consumption and carbon emissions, has prompted many companies to adopt more sustainable practices. Buyers are increasingly demanding transparency in the sourcing of materials, emphasizing the importance of ethical supply chains.

Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential for suppliers looking to attract international B2B buyers. These certifications not only demonstrate a commitment to reducing environmental impact but also provide assurance that the materials are sourced responsibly.

Moreover, the use of recycled stainless steel is gaining traction, as it reduces the need for virgin materials and minimizes waste. Buyers interested in sustainable options should inquire about suppliers’ practices concerning recycling and waste management. By prioritizing suppliers who focus on sustainability, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Brief Evolution of the Stainless Steel Sheet Metal Sector?

The stainless steel sheet metal sector has evolved significantly since the introduction of stainless steel in the early 20th century. Initially developed for its corrosion resistance, stainless steel has expanded its applications across multiple industries, including food processing, construction, and automotive. The introduction of various grades, such as 304 and 316, has allowed for tailored solutions to meet specific performance requirements.

In recent decades, advancements in manufacturing processes, including laser cutting and precision fabrication, have improved the quality and versatility of stainless steel sheets. The rise of global trade has also facilitated the international exchange of materials, enabling B2B buyers to source high-quality stainless steel from various regions. Today, the emphasis on sustainability and ethical sourcing is shaping the future of the industry, driving innovation and redefining supplier relationships.

By understanding these dynamics, international B2B buyers can navigate the complexities of the stainless steel sheet metal 4×8 market, ensuring informed sourcing decisions that align with their business goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel sheet metal 4×8

-

How do I choose the right grade of stainless steel sheet metal for my project?

Selecting the appropriate grade of stainless steel sheet metal depends on the specific requirements of your application. For general use, T-304 is the most common choice due to its excellent corrosion resistance and versatility. However, if your project involves exposure to harsh chemicals or saline environments, consider T-316, which offers superior corrosion resistance. Assess your project’s environmental conditions, aesthetic preferences, and mechanical requirements to determine the most suitable grade. -

What are the key factors to consider when sourcing stainless steel sheet metal internationally?

When sourcing stainless steel sheet metal internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. Review the supplier’s certifications and customer reviews to gauge their reputation. Additionally, inquire about their manufacturing processes, quality assurance protocols, and the availability of material traceability. Understanding shipping logistics, customs duties, and lead times is also essential to ensure timely delivery and cost-effectiveness. -

What are the typical minimum order quantities (MOQs) for stainless steel sheet metal?

Minimum order quantities (MOQs) for stainless steel sheet metal can vary significantly among suppliers and may depend on factors such as the type of grade, thickness, and customization options. Generally, MOQs range from 100 to 500 square feet for standard sizes. For custom sizes or specific grades, some suppliers may require higher MOQs. It’s advisable to discuss your project needs with potential suppliers to negotiate favorable terms that align with your purchasing strategy. -

How can I ensure the quality of stainless steel sheet metal before purchase?

To ensure quality, request detailed product specifications, including material certifications and compliance with industry standards (e.g., ASTM, ISO). Consider asking for samples to evaluate the material’s finish, thickness, and overall quality. Additionally, inquire about the supplier’s quality assurance processes, such as inspections and testing methods. Establishing a clear communication channel with the supplier can also help address any concerns regarding quality before finalizing your order. -

What payment terms should I expect when purchasing stainless steel sheet metal?

Payment terms for stainless steel sheet metal can vary based on the supplier and the transaction size. Common terms include a percentage deposit upfront, with the balance due upon shipment or delivery. Some suppliers may offer credit terms for established businesses, while others may require full payment in advance for international orders. It’s crucial to clarify payment methods accepted (e.g., bank transfers, letters of credit) and to negotiate terms that align with your cash flow requirements. -

What are the common applications for 4×8 stainless steel sheet metal?

Stainless steel sheet metal in 4×8 sizes is widely used across various industries due to its durability and corrosion resistance. Common applications include kitchen equipment in the food processing industry, wall cladding in commercial buildings, and decorative elements in architecture. Additionally, it is utilized in automotive and aerospace components, as well as in industrial machinery. Understanding the specific application will help you select the right grade and finish for your project. -

How do I vet a potential supplier for stainless steel sheet metal?

Vetting a supplier involves researching their industry reputation, financial stability, and production capabilities. Start by checking their certifications and compliance with international standards. Seek references from previous clients to assess their reliability and quality of service. Additionally, visit their manufacturing facility if possible, or request virtual tours. Evaluate their responsiveness and willingness to provide detailed information about their products and processes, which can be indicative of their professionalism. -

What shipping options are available for international orders of stainless steel sheet metal?

Shipping options for international orders typically include air freight, sea freight, and courier services, depending on the urgency and volume of the order. Sea freight is generally more cost-effective for larger shipments, while air freight offers faster delivery for smaller quantities. Ensure to discuss shipping terms, costs, and delivery times with your supplier. Additionally, inquire about insurance options to protect your investment during transit, as well as customs clearance assistance to avoid delays upon arrival.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Stainless Steel Sheet Metal 4X8 Manufacturers & Suppliers List

1. Metals Depot – T304 Stainless Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “T304 Stainless Steel Sheet”, “Material”: “304 Stainless Steel”, “Corrosion Resistance”: “Good corrosion resistance to many chemical corrodents, industrial atmospheres, and marine environments”, “Magnetism”: “May become slightly magnetic when worked”, “Heat Treatment”: “Not heat treatable”, “Grain Direction”: “Random and not guaranteed unless specified or custom quoted”, “Specific…

2. JTC Metals – Stainless Steel Sheet Metal

Domain: jtcmetals.com

Registered: 2019 (6 years)

Introduction: Product: Stainless Steel Sheet Metal

Materials Available: 304, 316 Stainless Steel

Finishes Available: 2B, #4, #8

Thickness Options: 14 ga. (.078″), 16 ga. (.063″), 18 ga. (.050″), 20 ga. (.038″), 22 ga. (.031″), 24 ga. (.025″)

Standard Sizes: Up to 48″ x 120″

Custom Sizes: Up to 48″ x 120″

Shipping: Live, Competitive Rates; Well Packaged for Safe Arrival

Recommended Uses: 304 Stainless Steel for …

3. Aoxing – 4×8 Stainless Steel Sheet

Domain: aoxingmetal.com

Registered: 2022 (3 years)

Introduction: 4×8 Stainless Steel Sheet, High-quality, Durable, Corrosion-resistant, Manufactured by Aoxing Cold Rolled Stainless Steel Mill, Trusted China-based manufacturer, Suitable for commercial, industrial, and residential applications, Smooth surface finish, Excellent corrosion resistance, Ideal for harsh environments (marine, chemical, food processing), Consistent thickness, size, and tolerance, Quality…

4. 430 Stainless Steel Sheet – 24GA Brushed Finish

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”430 Stainless Steel Sheet”,”Thickness”:”24GA (.025 inches)”,”Dimensions”:”48 inches x 96 inches (4ft x 8ft)”,”Finish”:”#4 Brushed”,”Condition”:”New”,”Quantity Available”:”58″,”Price”:”$160.00″,”Shipping Cost”:”$99.00 (UPS Ground)”,”Pickup Location”:”Ontario, California, United States”,”Returns”:”Seller does not accept returns”,”Brand”:”SIZEMETAL”,”Item Type”:”Stainless Steel Sheet…

5. Speedy Metals – 18ga 304 Stainless Steel Sheet #4 Finish

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “18ga (.048″) 304 Stainless Steel Sheet #4 Finish”, “Material”: “Stainless Steel”, “Grade”: “304”, “Shape”: “Sheet”, “Finish”: “#4 Finish”, “Dimensions”: [{“Size”: “12\”x12\””, “Weight”: “2.0016 lbs”, “Price”: “$25.27”}, {“Size”: “12\”x18\””, “Weight”: “3.0024 lbs”, “Price”: “$37.91”}, {“Size”: “12\”x24\””, “Weight”: “4.0032 lbs”, “Price”: “$50.54”}], “Cutting Tolerance”: “+/- 1/4…

6. Online Metals – Stainless Steel Sheet/Plate

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: Stainless Steel Sheet/Plate, Cut to Size, available for sale at Online Metals. Deep discounts on expedited shipping options. Materials delivered fast. Stainless steel sheet is known for its corrosion-resistance, strength, and hygienic properties, used in construction, food industry, and small appliances. Available alloys include 15-5, 17-4, 17-7, 301, 302, 303, 304, 310, 316, 321, 347, 410, 416, 4…

7. SAS Manufacturing – Stainless Steel Sheets

Domain: sasmfg.com

Registered: 2014 (11 years)

Introduction: Stainless Steel Sheets, Price: $107.64, Dimensions: Inside dimensions, Options: Gauge, Material, Finish, Size, Special Instructions required.

Strategic Sourcing Conclusion and Outlook for stainless steel sheet metal 4×8

In conclusion, the strategic sourcing of 4×8 stainless steel sheet metal presents a multitude of advantages for international B2B buyers, particularly in dynamic markets across Africa, South America, the Middle East, and Europe. The versatility of T-304 stainless steel, known for its corrosion resistance and aesthetic appeal, makes it suitable for various applications, from commercial kitchens to industrial environments. Understanding the unique specifications, such as thickness and finish, is essential for making informed procurement decisions that align with project requirements.

Establishing robust relationships with reliable suppliers is critical to ensuring consistent quality and competitive pricing. By leveraging local and international sources, businesses can enhance their supply chain resilience and adapt to market fluctuations more effectively.

As we look to the future, the demand for high-quality stainless steel sheet metal is poised to grow, driven by expanding industries and infrastructure projects. Now is the time for B2B buyers to explore partnerships that can provide not only material supply but also value-added services like customization and logistics support. Engage with trusted suppliers today to secure the materials that will drive your projects forward and foster long-term success in your market.