A B2B Buyer’s Guide to Protective Bubble Suit For Adults: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for protective bubble suit for adults

In today’s rapidly evolving marketplace, sourcing protective bubble suits for adults presents unique challenges for international B2B buyers. As concerns over safety and well-being escalate, businesses across sectors are increasingly seeking reliable protective gear that balances functionality with comfort. This comprehensive guide delves into the diverse types of protective bubble suits, their applications, and critical considerations for supplier vetting, pricing structures, and compliance with safety standards.

Buyers from Africa, South America, the Middle East, and Europe—such as those in Nigeria and Germany—will find invaluable insights tailored to their specific regional needs and market conditions. By exploring the intricacies of material options, design features, and regulatory requirements, this guide empowers organizations to make informed purchasing decisions that enhance workplace safety and employee satisfaction.

With a keen focus on understanding the global market dynamics, readers will gain actionable strategies to identify trustworthy suppliers and negotiate effectively, ensuring they secure high-quality protective bubble suits that meet their operational demands. Whether you are a procurement officer in a manufacturing facility or a safety manager in a healthcare setting, this guide serves as your go-to resource for navigating the complexities of protective apparel in today’s global economy.

Understanding protective bubble suit for adults Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air Supplied Bubble Suit | Made from durable materials with air supply system; flame-resistant | Hazardous environments, industrial applications | Pros: High protection level; customizable sizes. Cons: Higher cost; requires maintenance. |

| PVC Air Supplied Suit | Lightweight, fire-retardant PVC; pullover design with attached boots | Chemical handling, emergency response | Pros: Cost-effective; good chemical resistance. Cons: Limited durability; less comfort. |

| Two-Piece Protective Suit | Versatile design; includes hood and boots; various material options | General industrial use, maintenance work | Pros: Flexible usage; easy to wear. Cons: May not offer full encapsulation; size limitations. |

| Bubble Soccer Suit | Inflatable design with cushioning; promotes safety during impact | Recreational sports, team-building events | Pros: Fun and engaging; protects during activities. Cons: Not suitable for hazardous environments; limited professional use. |

| Air Supplied Bubble Hood | Designed for respiratory protection; compatible with other suits | Contaminated environments, industrial safety | Pros: Excellent respiratory safety; enhances overall protection. Cons: Requires air supply; can be cumbersome. |

What Are the Characteristics of Air Supplied Bubble Suits?

Air Supplied Bubble Suits are engineered for high-risk environments where protection against airborne contaminants is essential. Constructed from robust materials, these suits feature an integrated air supply system, ensuring a continuous flow of clean air. They are primarily utilized in hazardous industrial applications, such as chemical handling and emergency response scenarios. When considering a purchase, businesses should evaluate the suit’s certification for safety standards, maintenance requirements, and the availability of replacement parts.

How Do PVC Air Supplied Suits Differ in Application?

PVC Air Supplied Suits are notable for their lightweight design and fire-retardant properties. Typically made from clear PVC, these suits are ideal for environments involving chemical exposure. They are commonly used in industries such as pharmaceuticals and hazardous waste management. Buyers should assess the suit’s resistance to specific chemicals, ease of use, and overall cost-effectiveness, ensuring they meet their operational safety needs without compromising on quality.

Why Choose a Two-Piece Protective Suit for Versatile Use?

Two-Piece Protective Suits offer flexibility and comfort, making them suitable for a wide range of industrial applications. Featuring a hood and boots, these suits can be made from various materials like polyethylene and PVC, providing options for different levels of protection. Ideal for maintenance work and general industrial use, they are easy to don and doff. When purchasing, companies should consider the specific material properties, sizing options, and the suit’s suitability for the intended work environment.

What Makes Bubble Soccer Suits Unique for Recreational Use?

Bubble Soccer Suits are designed primarily for recreational activities, providing cushioning to protect users during gameplay. Their inflatable nature allows for safe collisions, making them popular for team-building events and recreational sports. While they are not suitable for hazardous environments, their engaging design promotes safety and fun. Businesses considering these suits should evaluate their durability, ease of inflation, and maintenance needs to ensure they can withstand frequent use.

How Does the Air Supplied Bubble Hood Enhance Safety?

The Air Supplied Bubble Hood is an essential component for workers in contaminated environments, providing respiratory protection while being compatible with other protective gear. This hood is designed to integrate with air supply systems, ensuring a safe breathing environment. It is particularly relevant in industries facing chemical exposure or airborne hazards. Buyers should focus on the hood’s compatibility with existing safety equipment, ease of use, and the reliability of the air supply system to ensure optimal protection for their workforce.

Key Industrial Applications of protective bubble suit for adults

| Industry/Sector | Specific Application of Protective Bubble Suit for Adults | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Infection Control in Hospitals | Provides a barrier against contaminants, ensuring staff and patient safety. | Compliance with health regulations and certifications. |

| Manufacturing | Protection in Hazardous Material Handling | Reduces risk of exposure to harmful substances during the transport and handling of materials. | Suit durability and material specifications for chemical resistance. |

| Event Management | Entertainment and Team-Building Activities | Engages participants in safe, fun activities, enhancing team cohesion. | Suit design and comfort for prolonged use during events. |

| Agriculture | Safety in Pesticide Application | Protects workers from harmful chemicals during crop treatment, ensuring health and compliance. | Suit breathability and chemical resistance features. |

| Construction | Safety in Demolition and Renovation Projects | Offers protection against debris and hazardous materials on-site, minimizing injury risks. | Suit weight and flexibility for ease of movement. |

How Are Protective Bubble Suits Used in Healthcare Settings?

In healthcare settings, protective bubble suits are essential for infection control, especially in environments dealing with infectious diseases. These suits provide a physical barrier against contaminants, ensuring that healthcare workers remain safe while attending to patients. For international buyers, particularly in regions with varying health regulations, it’s crucial to ensure that the suits meet local compliance standards and certifications, which may differ significantly from one country to another.

What Role Do Protective Bubble Suits Play in Manufacturing?

In manufacturing, especially in sectors handling hazardous materials, protective bubble suits serve as vital personal protective equipment (PPE). They minimize the risk of exposure to dangerous substances during the transport and handling of chemicals and materials. Buyers must consider the suit’s material specifications, particularly its durability and chemical resistance, to align with the specific safety requirements of their operations.

How Are Protective Bubble Suits Used in Event Management?

In the event management industry, protective bubble suits are often utilized for entertainment purposes, such as bubble soccer or team-building activities. These suits allow participants to engage in fun and safe physical interactions, fostering team spirit and cooperation. Buyers should focus on the design and comfort of the suits, ensuring they can withstand prolonged use during events while providing adequate protection and mobility.

Why Are Protective Bubble Suits Important in Agriculture?

Agricultural workers frequently use protective bubble suits when applying pesticides or handling chemicals. These suits protect against harmful substances that can pose serious health risks. For buyers in agricultural sectors, particularly in developing regions, the breathability and chemical resistance of the suits are critical factors to consider, as they directly impact worker safety and regulatory compliance.

How Do Protective Bubble Suits Enhance Safety in Construction?

In the construction industry, protective bubble suits are crucial for ensuring worker safety during demolition and renovation projects. They protect against flying debris and hazardous materials, significantly reducing the risk of injury on-site. Buyers should prioritize the weight and flexibility of the suits, as these features enhance ease of movement, enabling workers to perform tasks efficiently while remaining protected.

3 Common User Pain Points for ‘protective bubble suit for adults’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Protective Bubble Suits

The Problem: B2B buyers often face challenges in sourcing protective bubble suits that meet specific safety and performance standards. In regions like Africa and the Middle East, where safety regulations can vary significantly, it can be difficult to find suppliers who offer suits that are compliant with local standards. Additionally, the quality of materials used in these suits can impact their effectiveness. Buyers may worry that subpar materials won’t provide adequate protection against hazards, leading to safety incidents and potential liabilities.

The Solution: To address these concerns, buyers should conduct thorough research on potential suppliers, focusing on their certifications and quality control processes. It is advisable to request samples and review technical specifications to ensure that the suits are made from durable, high-quality materials that meet relevant safety standards. Establishing relationships with manufacturers who have a proven track record in protective clothing can also provide insights into the latest innovations in material technology, ensuring that the suits offer the necessary protection while maintaining comfort and mobility for the users.

Scenario 2: Ensuring Proper Fit and Comfort for Diverse Body Types

The Problem: Another significant pain point for B2B buyers is ensuring that protective bubble suits fit a diverse workforce. In many industries, employees come in various shapes and sizes, and a poorly fitting suit can hinder mobility and reduce overall safety. For instance, in sectors like construction or chemical handling, a suit that is too tight or too loose can lead to accidents or exposure to hazardous materials, ultimately affecting worker safety and productivity.

The Solution: Buyers should prioritize suppliers that offer a wide range of sizes and custom fitting options. When sourcing protective bubble suits, consider working with manufacturers who provide detailed sizing charts and the option for custom orders based on specific body measurements. Additionally, conducting fit tests with employees before making bulk purchases can help identify any potential issues with sizing and comfort. This proactive approach not only ensures that the suits are effective but also enhances employee satisfaction and safety compliance in the workplace.

Scenario 3: Balancing Protection with Mobility in High-Intensity Environments

The Problem: In high-intensity work environments, such as emergency response or industrial applications, the need for protective clothing is often at odds with the requirement for mobility and agility. B2B buyers may struggle to find protective bubble suits that offer sufficient protection without compromising the wearer’s ability to move freely. This balance is crucial, as a suit that is too restrictive can lead to fatigue and hinder performance during critical tasks.

The Solution: Buyers can overcome this challenge by selecting suits designed with advanced mobility features, such as articulated joints, stretchable materials, and breathable fabrics. Engaging in discussions with suppliers about the specific demands of the work environment can help identify suits that are tailored for high-performance use. Additionally, conducting real-world trials of the suits in the intended operational settings will provide valuable feedback on their performance under pressure. This ensures that the selected protective bubble suits not only safeguard employees but also empower them to perform their duties effectively and efficiently.

Strategic Material Selection Guide for protective bubble suit for adults

What Are the Key Materials for Protective Bubble Suits for Adults?

When selecting materials for protective bubble suits designed for adults, it is essential to consider various factors, including durability, safety, and compliance with international standards. Below, we analyze four common materials used in the production of these suits, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Polyvinyl Chloride (PVC) Perform in Protective Bubble Suits?

Polyvinyl Chloride (PVC) is a widely used material in protective clothing due to its excellent chemical resistance and durability. It can withstand exposure to a variety of chemicals, making it suitable for environments where spills or splashes may occur. PVC is also relatively cost-effective, which is a significant advantage for mass production.

Pros:

– High resistance to chemicals and moisture.

– Cost-effective and widely available.

– Good flexibility and ease of manufacturing.

Cons:

– Limited breathability, which can lead to discomfort in hot climates.

– Potential environmental concerns regarding disposal and recycling.

Impact on Application: PVC suits are ideal for applications in chemical handling and industrial settings, particularly where liquid protection is necessary.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations regarding PVC use. Standards such as ASTM D6413 for flame resistance may also apply.

What Are the Benefits of Polyurethane in Protective Bubble Suits?

Polyurethane is known for its exceptional abrasion resistance and flexibility, making it a popular choice for protective suits. This material can handle a wide range of temperatures and provides a comfortable fit, which is crucial for extended wear.

Pros:

– Excellent durability and resistance to wear and tear.

– Good temperature tolerance, suitable for various climates.

– Breathable options available, enhancing comfort.

Cons:

– Generally more expensive than PVC.

– Can be less resistant to certain chemicals compared to PVC.

Impact on Application: Polyurethane suits are well-suited for environments requiring high mobility and comfort, such as in construction or emergency response.

International Considerations: Compliance with standards like DIN EN 343 for protective clothing against rain is essential for buyers in Europe, particularly in Germany, where stringent regulations may apply.

How Does Tyvek® Compare as a Material for Protective Bubble Suits?

Tyvek® is a brand of flash-spun high-density polyethylene fibers that are known for their lightweight and breathable properties. This material is often used in applications requiring a balance between protection and comfort, such as in healthcare and cleanroom environments.

Pros:

– Lightweight and breathable, reducing heat stress.

– Good barrier against particles and some liquids.

– Easy to don and doff, enhancing user convenience.

Cons:

– Limited chemical resistance compared to PVC and polyurethane.

– Less durable in high-abrasion environments.

Impact on Application: Tyvek® is ideal for use in healthcare settings or clean environments where particulate protection is necessary without compromising comfort.

International Considerations: Buyers must check for compliance with ASTM F1670 for liquid barrier protection, especially in healthcare applications across Europe and the Middle East.

What Role Does Saranex Play in Protective Bubble Suits?

Saranex is a multi-layered material that offers excellent chemical and abrasion resistance. It is often used in suits designed for hazardous environments, such as those involving toxic substances.

Pros:

– Superior chemical resistance and durability.

– Multi-layer construction enhances protection.

– Suitable for high-risk environments.

Cons:

– Higher manufacturing complexity may lead to increased costs.

– Heavier than other materials, which may affect mobility.

Impact on Application: Saranex suits are specifically designed for use in environments with high exposure to hazardous chemicals, making them suitable for industries such as pharmaceuticals and petrochemicals.

International Considerations: Compliance with standards like NFPA 1991 for vapor-protective suits is crucial for buyers in the Middle East and Africa, where safety regulations are increasingly stringent.

Summary Table of Material Selection for Protective Bubble Suits

| Material | Typical Use Case for Protective Bubble Suit for Adults | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Chemical handling and industrial settings | High chemical resistance | Limited breathability | Low |

| Polyurethane | Construction and emergency response | Excellent durability and flexibility | More expensive than PVC | Medium |

| Tyvek® | Healthcare and cleanroom environments | Lightweight and breathable | Limited chemical resistance | Medium |

| Saranex | Hazardous chemical environments | Superior chemical resistance | Higher manufacturing complexity | High |

This analysis provides a comprehensive overview of the materials used in protective bubble suits, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for protective bubble suit for adults

What Are the Key Manufacturing Processes for Protective Bubble Suits for Adults?

The manufacturing of protective bubble suits for adults involves a series of meticulously planned processes that ensure the final product meets safety and comfort standards. The primary stages of production include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Protective Bubble Suits?

The manufacturing process begins with the careful selection of materials. Commonly used materials include high-density polyethylene (HDPE), polyvinyl chloride (PVC), and various breathable fabrics that provide both comfort and protection. The materials must be sourced from reputable suppliers who comply with international quality standards.

Once selected, the materials undergo a rigorous preparation phase that includes cutting them into appropriate sizes and shapes. This phase may also involve treating the materials to enhance their protective properties, such as adding flame retardant or anti-static treatments. Ensuring that materials are free from defects is crucial, as any flaws can compromise the suit’s integrity and safety.

What Techniques Are Used in Forming Protective Bubble Suits?

Forming involves shaping the prepared materials into the desired suit design. This can include processes such as heat sealing, stitching, or ultrasonic welding, depending on the suit’s intended use and required specifications.

For example, ultrasonic welding is often employed for seams that need to be both waterproof and durable, while traditional stitching may be used for areas that require flexibility. The forming process must be carried out under controlled conditions to ensure that the materials retain their protective qualities, such as resistance to chemicals or punctures.

How Are Protective Bubble Suits Assembled?

Assembly is where the individual components of the suit come together. This phase involves attaching various parts, such as hoods, cuffs, and zippers, ensuring that all elements fit seamlessly. Quality control is critical at this stage to confirm that all components are securely attached and that the suit is functional.

Manufacturers often use advanced machinery to automate parts of this process, improving efficiency and consistency. However, skilled labor remains essential for final inspections and adjustments, particularly for custom orders or specialized suits designed for specific industries, such as healthcare or hazardous materials handling.

What Finishing Techniques Enhance the Quality of Protective Bubble Suits?

Finishing processes add the final touches that enhance both the appearance and functionality of protective bubble suits. This may include adding reflective strips for visibility, applying water-resistant coatings, or conducting a final quality check to ensure that all zippers, seams, and closures operate smoothly.

Additionally, suits may undergo a sterilization process if they are intended for medical use. This ensures that they are free from contaminants and safe for immediate use in sensitive environments.

What Quality Assurance Standards Are Relevant for Protective Bubble Suits?

Quality assurance is paramount in the production of protective bubble suits, as these garments must meet rigorous safety standards. International standards such as ISO 9001 provide a framework for maintaining quality management systems, ensuring consistent production quality.

Which Industry-Specific Certifications Should B2B Buyers Look For?

In addition to general quality management standards, specific certifications may be required depending on the suit’s intended application. For example, suits used in the medical field may need to comply with CE marking standards in Europe, indicating conformity with health, safety, and environmental protection standards.

For suits designed for chemical protection, adherence to the American Petroleum Institute (API) standards may be necessary. B2B buyers should verify that their suppliers hold the relevant certifications for their target markets and industries.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Effective quality control (QC) involves several checkpoints throughout the manufacturing process. These can be categorized into three main phases: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

What Are the Key Checkpoints for Quality Control?

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers should provide certificates of compliance to ensure that materials meet specified standards.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the manufacturing process. This includes checking that machinery is functioning correctly and that workers are adhering to safety protocols. Any deviations from the standard must be documented and addressed immediately.

-

Final Quality Control (FQC): Once the suits are completed, a comprehensive review is performed to ensure that each suit meets all design specifications and safety standards. This may involve physical inspections, testing for durability, and checking for any defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Conducting audits is one effective method. These can be scheduled visits to the manufacturing facility to assess the production process and review quality control records.

Additionally, buyers can request QC reports that detail the results of inspections and tests conducted during the manufacturing process. Engaging third-party inspectors to evaluate the manufacturing facility and processes can provide an unbiased assessment of the supplier’s quality assurance practices.

What QC and Certification Nuances Should International Buyers Consider?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. Different regions may have varying requirements for protective clothing, influenced by local regulations and market demands.

Buyers should familiarize themselves with both local and international standards applicable to their industries. This ensures compliance and helps mitigate risks associated with importing products that may not meet local regulations. Engaging with legal experts or industry consultants can provide valuable insights into the specific requirements for each market.

In conclusion, the manufacturing processes and quality assurance practices for protective bubble suits for adults are complex but crucial for ensuring safety and compliance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to better quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘protective bubble suit for adults’

This practical sourcing guide is designed to assist B2B buyers in procuring protective bubble suits for adults. The protective bubble suit serves various purposes, from recreational uses in bubble soccer to protective applications in hazardous environments. Following this checklist will help ensure you make informed decisions throughout the sourcing process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline what you need from the protective bubble suit. Consider factors such as material durability, size range, and intended use—whether for recreational activities or safety in hazardous environments. This will help you communicate your requirements effectively and streamline the selection process.

Step 2: Research Potential Suppliers

Identify suppliers that specialize in protective clothing and bubble suits. Look for companies with a strong reputation in the industry, particularly those that have experience serving markets similar to yours, such as Africa, South America, the Middle East, and Europe. Online reviews, trade show participation, and industry publications can provide insights into a supplier’s reliability and quality.

Step 3: Evaluate Product Quality and Compliance

Inspect product specifications and compliance with relevant safety standards. Depending on the intended use, you may need suits that meet specific regulations, such as flame resistance or chemical protection. Request certifications and test reports to ensure that the suits can withstand the conditions they will be exposed to.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of their protective bubble suits. Testing samples will allow you to assess the quality, fit, and comfort of the suits firsthand. This step is crucial, especially if the suits are intended for prolonged use in demanding environments.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers hold necessary certifications and licenses to operate in your target market. This includes compliance with local regulations and international standards. Certifications not only indicate quality but also give you confidence in the supplier’s commitment to safety and reliability.

Step 6: Negotiate Pricing and Terms

When you’ve selected a supplier, negotiate pricing and payment terms. Be clear about your budget and any bulk order discounts or long-term partnership agreements you may require. Discuss lead times and shipping options to ensure they align with your operational needs.

Step 7: Establish a Clear Communication Plan

Effective communication is vital throughout the sourcing process. Establish a point of contact within the supplier’s organization and define how often you will communicate regarding order status, product updates, and any potential issues. This will help build a strong relationship and facilitate smooth transactions.

By following this checklist, B2B buyers can systematically approach the procurement of protective bubble suits for adults, ensuring they select the best products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for protective bubble suit for adults Sourcing

What Are the Key Cost Components in Sourcing Protective Bubble Suits for Adults?

When sourcing protective bubble suits for adults, understanding the cost structure is vital for B2B buyers. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type and quality of materials used significantly influence the overall cost. High-quality, durable fabrics that meet safety standards can be expensive but are crucial for ensuring protection. For example, suits made from flame-resistant or chemical-resistant materials will typically cost more due to their specialized properties.

-

Labor: Labor costs can vary based on the region of production. Countries with higher wage standards will generally incur greater labor costs, impacting the final pricing of the suits. Skilled labor is necessary for ensuring the quality of the suits, especially for those requiring precise manufacturing techniques.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs associated with production. A manufacturer with advanced technology may have higher overhead costs but can produce higher quality products more efficiently.

-

Tooling: The initial investment in molds and machinery for suit production can be significant. For custom designs or specialized sizes, these costs will be higher, reflecting the need for tailored tooling.

-

Quality Control (QC): Implementing robust QC measures is essential for safety and compliance. This process can add to production costs, but it ensures that the suits meet necessary regulatory standards, which can be a critical factor for international buyers.

-

Logistics: Shipping and handling costs should not be overlooked, especially for international transactions. Import duties, taxes, and freight charges can all add to the total cost, impacting pricing strategies.

-

Margin: Finally, manufacturers will apply a profit margin to cover their operational costs and ensure sustainability. This margin can vary widely based on market conditions and competitive pressures.

How Do Price Influencers Affect the Cost of Protective Bubble Suits?

Several factors influence the pricing of protective bubble suits, which B2B buyers should consider:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Bulk orders usually result in lower per-unit costs. Buyers should assess their needs to determine the optimal order size that balances cost with inventory requirements.

-

Specifications and Customization: Custom suits tailored to specific industry needs or regulations will typically cost more due to additional design and manufacturing processes. Buyers should weigh the benefits of customization against budget constraints.

-

Quality and Certifications: Suits that meet specific safety certifications will command higher prices. It’s essential for buyers to ensure that the products they source comply with local regulations, especially in industries like healthcare or hazardous materials handling.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge premium prices, but they often offer better quality assurance and customer support.

-

Incoterms: Understanding international commercial terms (Incoterms) is crucial for pricing, as they dictate shipping responsibilities and costs. Buyers should clarify these terms to avoid unexpected expenses.

What Are Effective Buyer Tips for Sourcing Protective Bubble Suits?

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your purchasing power to negotiate better terms, including discounts or favorable payment terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the purchase price. This includes maintenance, compliance costs, and potential downtime due to suit failures.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and regional market conditions, as these can significantly affect final costs.

-

Disclaimer for Indicative Prices: It’s important to note that prices can vary widely based on the factors discussed. Always request quotes from multiple suppliers to compare costs accurately and ensure you are making an informed decision.

By understanding these cost components and pricing influencers, B2B buyers can effectively navigate the sourcing process for protective bubble suits, ensuring they receive the best value for their investment.

Alternatives Analysis: Comparing protective bubble suit for adults With Other Solutions

Understanding the Alternatives to Protective Bubble Suits for Adults

In the realm of personal protective equipment (PPE), the protective bubble suit for adults offers a unique approach to safety and mobility. However, there are various alternative solutions that cater to similar protective needs, each with its own set of advantages and limitations. This analysis will explore these alternatives, providing B2B buyers with a comprehensive understanding to make informed decisions.

Comparison Table

| Comparison Aspect | Protective Bubble Suit For Adults | Air Supplied Suits | Inflatable Bubble Soccer Suits |

|---|---|---|---|

| Performance | Limited protection, mainly for fun | High protection against hazardous materials | Fun activity with limited safety features |

| Cost | Moderate ($26.99 – $35.99) | High (starting around $200) | Moderate to High ($100 – $300) |

| Ease of Implementation | Simple, one-size fits most | Requires training and setup | Easy to set up, but requires space |

| Maintenance | Low, disposable after damage | Moderate, regular inspections needed | Low, mainly surface cleaning |

| Best Use Case | Entertainment, light protection | Hazardous environments, chemical handling | Recreational activities and events |

Detailed Breakdown of Alternatives

Air Supplied Suits

Air supplied suits are designed for high-risk environments, providing robust protection against hazardous materials, including chemicals and airborne contaminants. Constructed from durable materials like flame-resistant scrim and polyvinyl chloride, these suits often require a supply of clean air, making them suitable for industrial and emergency response applications. The major downside is their higher cost and the need for proper training to ensure effective use. Additionally, they can be cumbersome, requiring more effort to put on and maintain.

Inflatable Bubble Soccer Suits

Inflatable bubble soccer suits offer a fun and engaging way to participate in recreational activities while providing some level of physical protection. These suits are primarily designed for sports and entertainment, allowing players to bump into one another without injury. While they are easy to set up and use, their protective capabilities are limited, making them unsuitable for hazardous environments. Their cost is moderate, but they require space for activities and can be damaged easily during rough play.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a protective solution, B2B buyers should consider the specific requirements of their operations or activities. For environments where safety from hazardous materials is paramount, air supplied suits are the clear choice despite their higher cost and complexity. Conversely, for light-hearted entertainment purposes, the protective bubble suit for adults or inflatable bubble soccer suits can offer a playful alternative without significant investment. Ultimately, understanding the unique features and limitations of each option will empower buyers to align their choice with their operational goals and safety standards.

Essential Technical Properties and Trade Terminology for protective bubble suit for adults

What Are the Key Technical Properties of a Protective Bubble Suit for Adults?

When considering the procurement of protective bubble suits for adults, it’s essential to understand the critical technical specifications that define their functionality and suitability for various applications. Here are some key properties to consider:

-

Material Composition

– Definition: The materials used in manufacturing protective suits, typically including PVC, polyurethane, and polyethylene.

– B2B Importance: The choice of material directly impacts the suit’s durability, flexibility, and resistance to environmental hazards. For example, PVC offers good chemical resistance, making it suitable for industrial applications, while polyurethane provides enhanced flexibility and comfort for prolonged wear. -

Thickness

– Definition: The gauge or thickness of the material, often measured in mils (thousandths of an inch).

– B2B Importance: Thickness affects the protective capabilities of the suit. A thicker suit may offer better resistance to punctures and tears, which is crucial in hazardous environments. Buyers should assess the required thickness based on the specific risks present in their operational environments. -

Size Range

– Definition: The available sizes of the suit, typically ranging from small to XXL or larger.

– B2B Importance: A comprehensive size range ensures that all personnel can find a suitable fit, which is vital for comfort and mobility. Ill-fitting suits can reduce effectiveness and increase the risk of exposure to hazards. -

Closure Type

– Definition: The method by which the suit is secured, such as zippers, Velcro, or hook-and-loop fasteners.

– B2B Importance: The closure type influences ease of use and the suit’s ability to provide a secure fit. A reliable closure mechanism is essential for maintaining protection against contaminants and ensuring that the suit can be donned and doffed quickly, particularly in emergency situations. -

Breathability

– Definition: The ability of the suit to allow moisture and heat to escape while preventing contaminants from entering.

– B2B Importance: Breathable materials enhance comfort, especially during extended use. This property is particularly significant in environments where workers may engage in physically demanding tasks, as it reduces the risk of heat stress.

What Are Common Trade Terms Relevant to Protective Bubble Suits?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to protective bubble suits:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: When sourcing protective bubble suits, knowing whether the supplier is an OEM can indicate product quality and reliability, as OEMs typically adhere to strict manufacturing standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Understanding MOQ is crucial for budget planning and inventory management. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specified products.

– Importance: An RFQ is a vital tool for buyers to compare prices and terms among different suppliers, ensuring they secure the best deal for protective bubble suits. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC).

– Importance: Understanding Incoterms is essential for determining the responsibilities of buyers and sellers in international trade, including shipping costs, insurance, and risk management. -

Lead Time

– Definition: The time taken from placing an order to the delivery of goods.

– Importance: Knowing the lead time helps buyers plan effectively for inventory replenishment and project timelines, ensuring that they have the necessary protective gear available when needed.

By familiarizing yourself with these technical properties and trade terms, you can make informed purchasing decisions regarding protective bubble suits for adults, ensuring that they meet your specific operational requirements while aligning with best practices in procurement.

Navigating Market Dynamics and Sourcing Trends in the protective bubble suit for adults Sector

What Are the Current Market Dynamics and Key Trends in the Protective Bubble Suit for Adults Sector?

The protective bubble suit for adults sector is experiencing a notable transformation driven by global health concerns, environmental sustainability, and technological advancements. With the increasing prevalence of health emergencies, such as pandemics, businesses are seeking innovative protective gear to ensure employee safety. This trend is particularly prominent in regions like Africa, South America, the Middle East, and Europe, where health regulations are becoming stricter and demand for personal protective equipment (PPE) is on the rise.

Emerging technologies are revolutionizing the manufacturing process of protective bubble suits. Companies are leveraging materials that enhance comfort while maintaining safety standards, such as breathable fabrics and lightweight designs. Additionally, digital platforms for sourcing and procurement are gaining traction, allowing international B2B buyers to connect with manufacturers more efficiently. This trend is critical for buyers in diverse markets, including Nigeria and Germany, as it enables them to access a wider range of products that meet specific regulatory requirements.

Moreover, as the protective gear market expands, the focus on customization is increasing. Buyers are looking for suits that can be tailored to specific industries, such as healthcare, construction, and event management. This shift underscores the necessity for manufacturers to be agile and responsive to the unique needs of various sectors.

How Is Sustainability and Ethical Sourcing Impacting the Protective Bubble Suit for Adults Market?

Sustainability has become a cornerstone of B2B sourcing strategies in the protective bubble suit sector. As environmental concerns escalate, businesses are increasingly scrutinizing the ecological footprint of their supply chains. The production of protective suits often involves materials that can be harmful to the environment; therefore, manufacturers are exploring alternatives such as recycled materials and biodegradable options.

Ethical sourcing is equally crucial. B2B buyers are prioritizing suppliers who adhere to fair labor practices and possess certifications that demonstrate their commitment to social responsibility. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX can serve as valuable indicators of a supplier’s dedication to sustainability and ethical practices. This focus not only enhances brand reputation but also aligns with the growing consumer demand for environmentally friendly products.

Furthermore, the integration of sustainable practices in the production of protective bubble suits can lead to cost savings in the long run. By investing in sustainable materials and processes, manufacturers can reduce waste and lower energy consumption, translating to more competitive pricing for B2B buyers. As a result, international buyers from diverse regions are encouraged to seek partnerships with suppliers who prioritize sustainability.

How Has the Protective Bubble Suit for Adults Evolved Over Time?

The evolution of the protective bubble suit for adults reflects broader trends in safety, fashion, and technology. Initially, protective suits were primarily functional, designed for industrial or hazardous environments. However, as awareness of personal safety and health risks has increased, the market has shifted towards more versatile and stylish designs that appeal to a wider audience.

The introduction of lightweight materials and innovative designs has made these suits more accessible for various applications beyond traditional use, including entertainment and recreational activities. Companies are now producing bubble suits that serve both protective and aesthetic purposes, catering to events such as bubble soccer and themed parties. This evolution underscores the importance of versatility in product offerings and highlights the potential for manufacturers to tap into niche markets.

As the market continues to grow, understanding these dynamics will be essential for B2B buyers looking to make informed sourcing decisions in the protective bubble suit sector.

Frequently Asked Questions (FAQs) for B2B Buyers of protective bubble suit for adults

-

How can I ensure the protective bubble suit meets my industry standards?

To ensure compliance with industry standards, request certifications and test reports from suppliers. Look for suits that adhere to relevant safety regulations, such as ISO or ASTM standards, depending on your region. It’s essential to verify that the materials used are suitable for your specific application, whether it involves chemical exposure, biological hazards, or physical protection. Additionally, consider conducting on-site evaluations or third-party testing for peace of mind before placing a bulk order. -

What materials are commonly used in protective bubble suits for adults?

Protective bubble suits are typically constructed from materials like polyethylene, PVC, and polyurethane, which provide varying levels of protection against chemicals, liquids, and particulates. Some suits may also include additional layers for enhanced durability and resistance to punctures or tears. When sourcing, inquire about the specific material properties, such as thickness and breathability, to ensure they align with your intended use and environmental conditions. -

How do I assess the reliability of a supplier for protective bubble suits?

When vetting suppliers, look for established companies with a proven track record in protective clothing. Request references and case studies from previous clients, particularly those in your industry. Evaluate their production capabilities, quality control processes, and certifications. It’s also beneficial to visit their manufacturing facility if possible or request virtual tours to gain insights into their operational standards and workforce training. -

What is the minimum order quantity (MOQ) for protective bubble suits?

MOQs for protective bubble suits can vary significantly by supplier and product type. Typically, MOQs may range from a few dozen to several hundred units. Always clarify the MOQ during your initial discussions with potential suppliers. If your needs are lower than the MOQ, some suppliers may offer flexibility or suggest combining orders with other clients to meet minimum requirements. -

Can I customize the protective bubble suits for my business needs?

Many suppliers offer customization options, including size variations, color choices, and additional features such as reinforced seams or specialized closures. Customization may also extend to branding, allowing you to add logos or specific markings for identification. Discuss your requirements upfront with suppliers to understand the scope of customization available and any associated costs or lead times. -

What payment terms should I expect when ordering protective bubble suits?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (usually 30-50%) with the balance due upon delivery or before shipment. Some suppliers may offer credit terms for established customers. Always negotiate payment terms that are favorable for your cash flow and ensure they are documented in your purchase agreement to avoid misunderstandings. -

How do I handle logistics and shipping for international orders of protective bubble suits?

When dealing with international orders, consider factors such as shipping methods, lead times, and customs regulations. Work with suppliers who have experience in exporting and can provide assistance with documentation and compliance. It’s advisable to use reliable freight forwarders who can navigate the complexities of customs clearance and ensure timely delivery. Always factor in additional costs such as tariffs and insurance when budgeting for your order. -

What quality assurance measures should I expect from suppliers of protective bubble suits?

Reputable suppliers should have robust quality assurance protocols in place, including material inspections, in-process quality checks, and final product testing. Request details about their quality management system, such as ISO certifications, and inquire about their return or defect policies. Some suppliers may also offer warranties or guarantees on their products, which can provide additional assurance of their commitment to quality and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Protective Bubble Suit For Adults Manufacturers & Suppliers List

1. vat19 – Air Bubble Suit

Domain: vat19.com

Registered: 2002 (23 years)

Introduction: Air Bubble Suit: Costume made from real bubble wrap. Price: $35.99. In Stock. Item #3507. Features: Hooded jacket with velcro closure, pants with elastic waistband, one size fits most adults (S to L). Not protective gear, designed for fun. Free shipping. Popular for ASMR, entertaining gifts, and unique costumes. Used costumes are not returnable.

2. Rich Industries – Air-Supplied Suits & Coveralls

Domain: richindustriesinc.com

Registered: 2004 (21 years)

Introduction: This company, Rich Industries – Air-Supplied Suits & Coveralls, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

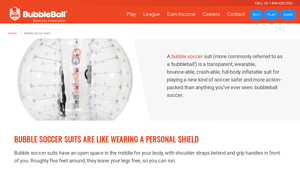

3. BubbleBall – Inflatable Soccer Suits

Domain: bubbleball.us

Registered: 2014 (11 years)

Introduction: Bubble Soccer Suits, also known as bubbleballs, are transparent, inflatable, full-body suits designed for a safer and more action-packed soccer experience. They feature an open space for the body, shoulder straps, and grip handles, allowing players to run freely while being protected. The suits are made of durable, flexible plastic and provide a personal shield for players to engage in physical pl…

4. Designlibero – Bubble Shield

Domain: designboom.com

Registered: 1999 (26 years)

Introduction: Product Name: Bubble Shield

Designers: Libero Rutilo and Ekaterina Shchetina (Designlibero)

Type: Inflatable personal environment

Power Source: Solar-powered and electric

Materials: Thermic-welded ETFE (Ethylene Tetrafluoroethylene)

Function: Provides a physical barrier to protect users from viruses and air pollution in public spaces

Features:

– Inflatable ball structure

– Battery pack located in…

5. Tenor – Bubble Suit GIFs

Domain: tenor.com

Registered: 1995 (30 years)

Introduction: Bubble Suit GIFs featuring various themes and tags such as #bubble, #Bubble-Boy, #hazmat, #protection, #dancing, #playtime, and references to COVID-19. The content includes GIFs related to bubble suits, bubble wrap, and playful activities, showcasing emotions like excitement and happiness.

6. AliExpress – Adult Bubble Suits

7. Get Digital – Bubble Wrap Suit

Domain: getdigital.co.uk

Registered: 2006 (19 years)

Introduction: Bubble Wrap Suit – Price: 19,95 lei RON (including VAT, excluding shipping costs). Description: Two-piece suit made of bubble wrap, one size fits all. The suit consists of pants with an elastic waistband and a top with a hood. It is transparent, so wearing something underneath is recommended. Age Recommendation: 14+. Note: The delivery situation for this product is unclear, possibly due to the man…

Strategic Sourcing Conclusion and Outlook for protective bubble suit for adults

What Are the Key Insights for Sourcing Protective Bubble Suits?

In conclusion, the strategic sourcing of protective bubble suits for adults reveals critical considerations for international B2B buyers. Understanding the diverse applications of these suits—ranging from entertainment to specialized protective gear—allows businesses to tailor their purchasing decisions effectively. The emphasis on quality materials, such as flame-resistant and durable fabrics, ensures that the products meet safety standards while providing comfort and functionality.

Moreover, engaging with reputable suppliers who offer customizable options can enhance operational efficiency and workforce safety. Buyers should also consider the logistics of sourcing from regions with established manufacturing capabilities, which can mitigate costs and lead times.

How Should B2B Buyers Approach Future Procurement Strategies?

As we look ahead, it is essential for buyers in Africa, South America, the Middle East, and Europe to adopt a proactive approach to sourcing. Establishing long-term relationships with suppliers can foster collaboration and innovation in product development. By prioritizing quality and compliance, businesses can ensure their investments in protective gear yield significant returns in safety and employee satisfaction.

We encourage you to explore new sourcing opportunities and leverage strategic partnerships to enhance your procurement processes. The market for protective bubble suits is evolving, and aligning with the right partners will position your business for future success.