Everything You Need to Know About Popsicle Bags Sourcing in 2025

Introduction: Navigating the Global Market for popsicle bags

In today’s dynamic global market, sourcing high-quality popsicle bags poses a significant challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. With a growing demand for innovative, eco-friendly packaging solutions, businesses must navigate a plethora of options that cater to various applications—from disposable freezer tubes to reusable DIY pouches. This comprehensive guide delves into the multifaceted world of popsicle bags, offering insights into different types, their applications, and essential considerations for supplier vetting and cost analysis.

Understanding the specific requirements of your target market is crucial. For instance, the preferences for popsicle packaging may vary significantly between regions, influenced by local consumption habits and sustainability trends. This guide empowers international B2B buyers by providing actionable insights and expert recommendations, enabling informed purchasing decisions that align with market demands.

By exploring factors such as material selection, design innovation, and supplier reliability, businesses can enhance their product offerings and stand out in a competitive landscape. Whether you are looking to introduce new flavors in vibrant packaging or seeking cost-effective solutions for bulk production, this guide serves as your essential resource in navigating the complexities of the popsicle bag market.

Understanding popsicle bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Disposable Popsicle Bags | Made from BPA-free plastic, often pre-formed for easy filling. | Food service, event catering, retail. | Pros: Cost-effective, convenient for single-use. Cons: Environmental concerns due to disposability. |

| Reusable Popsicle Bags | Durable, washable, and designed for multiple uses; often feature zip seals. | Home use, schools, health-conscious businesses. | Pros: Eco-friendly, cost-saving over time. Cons: Requires cleaning and maintenance. |

| Custom Printed Popsicle Bags | Personalized designs for branding; available in various sizes and materials. | Food brands, marketing promotions, events. | Pros: Enhances brand visibility, tailored to specific needs. Cons: Higher upfront costs, longer lead times. |

| Ice Pop Mold Bags | Typically come with a funnel for easy filling; designed for thicker mixtures. | Home kitchens, DIY food businesses. | Pros: Ideal for creative recipes, easy to use. Cons: Limited to specific types of frozen treats. |

| Heat-Seal Popsicle Bags | Sealed at the top to prevent leaks; often made from multi-layer materials for insulation. | Commercial ice cream producers, gourmet food shops. | Pros: Superior sealing for freshness, professional appearance. Cons: More complex machinery required for sealing. |

What Are the Key Characteristics of Disposable Popsicle Bags?

Disposable popsicle bags are typically made from BPA-free plastic and are designed for single-use applications. Their pre-formed shape allows for quick filling, making them ideal for food service operations, event catering, and retail environments. Buyers should consider the cost-effectiveness and convenience of these bags, but they must also weigh the environmental impact of single-use products.

How Do Reusable Popsicle Bags Benefit Businesses?

Reusable popsicle bags are crafted from durable materials that can withstand multiple uses, making them an eco-friendly option for consumers. They often feature zip seals to prevent leaks, which is advantageous for home use, schools, and health-conscious businesses looking to promote sustainable practices. While they can save costs over time, buyers need to factor in the requirement for cleaning and maintenance.

Why Choose Custom Printed Popsicle Bags?

Custom printed popsicle bags offer businesses the opportunity to enhance brand visibility through personalized designs. Available in various sizes and materials, these bags are particularly useful for food brands and marketing promotions. However, buyers should consider the higher upfront costs and longer lead times associated with custom orders, which may impact their production schedules.

What Makes Ice Pop Mold Bags Unique?

Ice pop mold bags are designed for thicker mixtures, often including a funnel for easy filling. They are perfect for home kitchens and DIY food businesses looking to create unique frozen treats. While these bags are user-friendly and ideal for creative recipes, their application is somewhat limited compared to other types of popsicle bags.

How Do Heat-Seal Popsicle Bags Ensure Freshness?

Heat-seal popsicle bags are manufactured to provide a superior seal that prevents leaks and maintains product freshness. They are commonly used by commercial ice cream producers and gourmet food shops, as their professional appearance can enhance product presentation. However, businesses must consider the additional investment in sealing machinery, which can complicate production processes.

Key Industrial Applications of popsicle bags

| Industry/Sector | Specific Application of popsicle bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Custom-branded popsicle production | Enhances brand visibility and customer loyalty | Quality of materials, customization options, compliance with food safety standards |

| Retail | Bulk packaging for frozen treats | Cost-effective storage and improved shelf appeal | Durability, resealability, and ease of use for consumers |

| Event Catering | Personalized popsicle bags for events | Unique offerings that enhance customer experience | Customization capabilities, delivery timelines, and order flexibility |

| Health & Wellness | Packaging for nutritious frozen snacks | Appeals to health-conscious consumers | Material safety certifications, eco-friendliness, and design options |

| Educational Institutions | DIY popsicle kits for educational purposes | Engages students in fun and healthy activities | Safety standards, ease of use, and educational value |

How Are Popsicle Bags Used in the Food & Beverage Industry?

In the food and beverage sector, popsicle bags are increasingly being utilized for custom-branded popsicles. Businesses can create unique flavors and packaging that reflect their brand identity. This application solves the challenge of standing out in a competitive market while also allowing for creative marketing strategies. Buyers in this sector should prioritize sourcing materials that are food-safe and customizable to meet specific branding requirements.

What is the Role of Popsicle Bags in Retail?

Retailers use popsicle bags for bulk packaging of frozen treats, which not only streamlines storage but also enhances the visual appeal of products on shelves. This application addresses the need for cost-effective solutions while ensuring that products remain fresh and accessible. When sourcing, retailers should consider the durability and resealability of the bags to improve customer experience and reduce waste.

How Can Event Catering Benefit from Personalized Popsicle Bags?

Event catering businesses can leverage personalized popsicle bags to offer unique treats at gatherings. This application not only adds a creative touch to events but also allows caterers to differentiate their services. The key for buyers in this sector is to focus on customization capabilities, ensuring that the bags align with the event’s theme and guest preferences, along with timely delivery options.

Why are Popsicle Bags Important for Health & Wellness Brands?

In the health and wellness industry, popsicle bags are perfect for packaging nutritious frozen snacks, appealing to a growing market of health-conscious consumers. This application addresses the demand for convenient, healthy options while enhancing brand credibility. Buyers should prioritize sourcing eco-friendly materials and ensuring that packaging meets safety certifications to attract their target audience.

How Do Educational Institutions Use Popsicle Bags for DIY Kits?

Educational institutions often utilize popsicle bags in DIY kits for engaging students in fun and healthy activities. This application promotes creativity while teaching students about nutrition and food preparation. When sourcing these bags, institutions should consider safety standards and ease of use, ensuring that they are suitable for children and enhance the educational experience.

3 Common User Pain Points for ‘popsicle bags’ & Their Solutions

Scenario 1: Ensuring Product Integrity During Distribution

The Problem: One of the primary challenges B2B buyers face with popsicle bags is maintaining the integrity of frozen products throughout the supply chain. In regions with varying climates, such as Africa or the Middle East, the risk of temperature fluctuations can lead to product spoilage or leakage. This not only results in financial losses but also impacts brand reputation, especially when products arrive damaged or of inferior quality.

The Solution: To address this issue, B2B buyers should prioritize sourcing popsicle bags that are specifically designed for temperature stability. Look for bags made from high-quality, food-grade materials that offer insulation properties to help maintain the desired temperature. Additionally, consider investing in vacuum-sealed options to reduce air exposure, which can cause degradation of the product. Collaborating with suppliers who provide temperature-controlled logistics can further enhance product integrity during transportation. Establishing a reliable distribution network that maintains cold chain logistics will ensure that popsicle bags reach their destination without compromising quality.

Scenario 2: Navigating Regulatory Compliance in Different Markets

The Problem: B2B buyers often encounter difficulties with regulatory compliance when sourcing popsicle bags, particularly in diverse markets like Europe and South America. Different countries have varying regulations regarding food safety and packaging materials, which can lead to confusion and potential penalties if the wrong materials are used.

The Solution: To effectively navigate these regulations, buyers should conduct thorough research on the specific compliance standards in their target markets. Engaging with local regulatory bodies or consulting firms can provide insights into the necessary certifications for popsicle bags. Sourcing from manufacturers who are ISO-certified and can provide documentation for food safety standards is crucial. Additionally, consider leveraging suppliers who offer customizable packaging solutions that can be tailored to meet local regulations, ensuring that the product not only meets compliance but also resonates with consumer preferences in each region.

Scenario 3: Addressing Environmental Concerns with Sustainable Packaging

The Problem: As global awareness of environmental issues grows, B2B buyers are increasingly challenged to find popsicle bags that align with sustainable practices. Consumers are demanding eco-friendly packaging, and companies that fail to meet these expectations risk losing market share and customer loyalty. Buyers are often unsure how to transition from traditional plastic options to more sustainable alternatives without compromising functionality.

The Solution: Buyers should explore partnerships with manufacturers who specialize in biodegradable or recyclable popsicle bags. Investigating materials such as plant-based plastics or recycled polyethylene can significantly reduce environmental impact while still providing the necessary durability for frozen products. Additionally, implementing a clear sustainability strategy that communicates the eco-friendly initiatives of the packaging can enhance brand image. It’s also beneficial to engage in consumer education campaigns about the benefits of sustainable packaging, which can further build brand loyalty and differentiate products in the marketplace. By aligning packaging choices with sustainability goals, businesses can not only comply with emerging regulations but also attract environmentally conscious consumers.

Strategic Material Selection Guide for popsicle bags

What Are the Key Materials for Popsicle Bags?

When selecting materials for popsicle bags, it is essential to consider factors such as temperature resistance, durability, and compliance with international standards. Here, we analyze four common materials used in the production of popsicle bags: polyethylene (PE), polypropylene (PP), biodegradable materials, and aluminum foil. Each material has unique properties that can impact product performance and suitability for various markets.

How Does Polyethylene (PE) Perform in Popsicle Bag Applications?

Polyethylene is one of the most widely used materials for popsicle bags due to its excellent flexibility and moisture barrier properties. It can withstand low temperatures, making it suitable for freezing applications. PE is also resistant to chemicals, which ensures that the flavors of the popsicles are preserved without contamination.

Pros: PE is cost-effective and easy to manufacture, allowing for high-volume production. It is also lightweight, which reduces shipping costs.

Cons: While PE is durable, it may not be as puncture-resistant as other materials. Additionally, it is not biodegradable, which can be a concern for environmentally conscious consumers.

International Considerations: Buyers in regions like Europe may need to ensure compliance with EU regulations regarding food safety and environmental impact. In contrast, markets in Africa and South America may prioritize cost over sustainability.

What Advantages Does Polypropylene (PP) Offer for Popsicle Bags?

Polypropylene is another popular choice for popsicle bags, known for its high melting point and excellent clarity. This material is ideal for applications requiring transparency, allowing consumers to see the product inside.

Pros: PP is more rigid than PE, providing better structural integrity during transport. It also has a higher resistance to heat, making it suitable for products that may be exposed to varying temperatures.

Cons: The manufacturing process for PP can be more complex and costly than for PE. Additionally, while it is recyclable, it is not biodegradable, which may deter eco-conscious buyers.

International Considerations: Buyers should be aware of the recycling capabilities in their region. For example, countries in Europe have more established recycling systems for PP, while other regions may lack such infrastructure.

Why Consider Biodegradable Materials for Popsicle Bags?

Biodegradable materials, such as PLA (polylactic acid), are gaining traction in the market due to growing environmental concerns. These materials can decompose under specific conditions, making them an attractive option for eco-friendly products.

Pros: The primary advantage of biodegradable materials is their reduced environmental impact, appealing to consumers who prioritize sustainability. They can also be designed to mimic the properties of traditional plastics.

Cons: Biodegradable materials often come with higher production costs and may have limited shelf life compared to conventional materials. They also require specific conditions to decompose effectively.

International Considerations: Compliance with environmental regulations is crucial, especially in Europe, where there are stringent standards for biodegradable products. Buyers in Africa and South America may find these materials appealing due to increasing awareness of sustainability.

How Does Aluminum Foil Enhance Popsicle Bag Performance?

Aluminum foil is a premium option for popsicle bags, offering superior barrier properties against moisture and light. This material is ideal for preserving the quality and flavor of frozen treats.

Pros: Aluminum foil provides excellent insulation, keeping popsicles frozen longer during transport. It is also recyclable, aligning with sustainability goals.

Cons: The cost of aluminum foil is significantly higher than other materials, which may not be feasible for all manufacturers. Additionally, it is less flexible, which can complicate packaging processes.

International Considerations: Buyers should consider the recycling infrastructure in their region. In Europe, aluminum recycling is well-established, while other regions may have varying capabilities.

Summary Table of Material Selection for Popsicle Bags

| Material | Typical Use Case for popsicle bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Standard popsicle bags | Cost-effective and flexible | Less puncture-resistant, non-biodegradable | Low |

| Polypropylene (PP) | Clear popsicle bags | High melting point, good clarity | More complex manufacturing, non-biodegradable | Medium |

| Biodegradable Materials | Eco-friendly popsicle bags | Reduced environmental impact | Higher production costs, limited shelf life | High |

| Aluminum Foil | Premium popsicle packaging | Excellent barrier properties | High cost, less flexibility | High |

This analysis provides a comprehensive overview of the materials available for popsicle bags, offering B2B buyers essential insights for making informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for popsicle bags

What Are the Main Stages in the Manufacturing Process of Popsicle Bags?

The manufacturing process of popsicle bags involves several key stages, each crucial for ensuring the final product meets quality standards and consumer expectations. The main stages include:

-

Material Preparation: The first step involves selecting appropriate raw materials, typically food-grade plastics such as polyethylene (PE) or polypropylene (PP). These materials must comply with international safety standards to ensure they are non-toxic and suitable for food contact. Material testing is conducted to verify the physical properties, including flexibility, durability, and resistance to temperature variations.

-

Forming: This stage involves transforming the raw materials into the desired bag shape. Techniques such as extrusion or blow molding are commonly used. In extrusion, molten plastic is forced through a die to create a continuous tube, which is then cut to the desired length. Blow molding is often employed for creating more complex shapes. During this phase, manufacturers focus on maintaining consistent thickness and integrity to prevent leaks.

-

Assembly: Once the bags are formed, they are assembled with features like zip seals or spouts for ease of use. Automated machinery often performs this task to ensure precision and efficiency. Quality checks during assembly are critical to identify any defects, such as improper seals or misalignments that could affect usability.

-

Finishing: The final stage includes printing and adding any necessary labels or branding elements. Advanced printing technologies, such as flexographic or digital printing, allow for high-quality graphics that can enhance the product’s market appeal. After printing, bags may undergo additional treatments, such as UV coating or lamination, to improve durability and aesthetic quality.

What Quality Assurance Standards Are Relevant for Popsicle Bags?

Quality assurance is a vital aspect of the popsicle bag manufacturing process. International standards such as ISO 9001 play a significant role in maintaining quality throughout production. This standard emphasizes a quality management system that ensures consistent product quality, customer satisfaction, and continuous improvement.

In addition to ISO 9001, industry-specific certifications like CE marking or FDA approval may be required, depending on the target market. CE marking indicates compliance with European health, safety, and environmental protection standards, while FDA approval is crucial for products entering the U.S. market.

What Are the Key Quality Control Checkpoints in Popsicle Bag Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that the final product meets the required standards:

-

Incoming Quality Control (IQC): This is the initial stage where raw materials are inspected for compliance with specifications. Suppliers should provide certificates of analysis (CoA) to validate the quality of the materials.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is essential. This involves checking for dimensional accuracy, seal integrity, and material consistency. Statistical process control (SPC) techniques may be employed to detect variations in the manufacturing process in real-time.

-

Final Quality Control (FQC): Once the bags are completed, a final inspection is conducted. This includes visual checks for defects, testing for seal strength, and ensuring that printing meets design specifications. Random sampling is often used to assess the overall quality of the batch.

What Common Testing Methods Are Used for Popsicle Bags?

Several testing methods are commonly employed to ensure the quality and safety of popsicle bags:

-

Seal Strength Testing: This method assesses the strength of the seals to ensure they can withstand freezing and handling without breaking.

-

Leak Testing: Bags are subjected to pressure tests to identify any leaks that may compromise product integrity.

-

Thermal Resistance Testing: This evaluates how well the bags perform under extreme temperature conditions, simulating real-world usage scenarios.

-

Migration Testing: This is particularly crucial for food-contact packaging, as it assesses whether harmful substances migrate from the bag into the food.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product safety and compliance. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing process firsthand. This includes reviewing documentation, observing production practices, and evaluating QC measures.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes. These reports should outline the results of IQC, IPQC, and FQC checks, along with any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s manufacturing practices. These agencies can perform audits, product testing, and compliance checks.

What Are the Quality Control Nuances for International Buyers?

When sourcing popsicle bags from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must navigate specific nuances:

-

Regulatory Compliance: Different regions have distinct regulations regarding food packaging. Understanding these regulations is vital to ensure compliance and avoid potential legal issues.

-

Cultural Considerations: Quality expectations may vary across cultures. Buyers should communicate their quality requirements clearly to avoid misunderstandings.

-

Supply Chain Logistics: International shipping can introduce additional risks. Buyers should ensure that suppliers have robust logistics and handling practices to maintain product quality during transit.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing popsicle bags, ensuring they receive high-quality products that meet their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘popsicle bags’

Introduction

Sourcing popsicle bags effectively is essential for businesses looking to deliver quality frozen treats to their customers. This practical checklist will guide you through the key steps to ensure you select the right bags that meet your needs while adhering to industry standards. By following this guide, B2B buyers can streamline their procurement process and ensure a successful partnership with suppliers.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the popsicle bags you require. Consider factors such as size, material (e.g., BPA-free, food-grade plastics), and design features (e.g., zipper seals, built-in labels). Defining these specifications ensures that you communicate your needs effectively to potential suppliers, reducing the risk of receiving unsuitable products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in popsicle bags. Utilize online directories, trade shows, and industry publications to create a list of potential vendors. Focus on suppliers with experience in your target market regions, such as Africa, South America, the Middle East, and Europe, as they will be familiar with local preferences and regulations.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial for ensuring product safety and compliance with international standards. Look for certifications such as ISO, FDA, or SGS that demonstrate adherence to quality and safety regulations. Additionally, confirm that the materials used are food-safe and compliant with local regulations in your target market.

Step 4: Request Samples for Quality Assessment

Before making a bulk order, request samples from shortlisted suppliers. Assess the quality of the bags, focusing on their durability, seal integrity, and usability features. This step allows you to gauge whether the product meets your specifications and helps avoid costly mistakes later in the procurement process.

Step 5: Compare Pricing and Terms of Service

Gather pricing information and compare it across different suppliers. Consider not only the cost per unit but also other factors such as minimum order quantities, shipping costs, and payment terms. A comprehensive comparison helps you find a supplier that offers the best overall value, balancing quality and cost-effectiveness.

Step 6: Negotiate Contracts and Terms

Once you have identified a preferred supplier, engage in negotiations to finalize contracts. Ensure that all terms are clearly outlined, including delivery timelines, payment schedules, and return policies. A well-defined contract protects both parties and sets clear expectations for the business relationship.

Step 7: Establish a Communication Plan

Effective communication is key to a successful sourcing process. Establish a plan for regular updates with your supplier, including check-ins during production and shipping. Clear communication helps address any potential issues promptly and fosters a strong partnership moving forward.

By following this checklist, B2B buyers can navigate the complexities of sourcing popsicle bags with confidence, ensuring they find the right products to meet their business needs.

Comprehensive Cost and Pricing Analysis for popsicle bags Sourcing

What Are the Key Cost Components in Sourcing Popsicle Bags?

When considering the sourcing of popsicle bags, understanding the cost structure is critical for B2B buyers. The cost components typically include:

-

Materials: The choice of materials significantly impacts cost. Common materials for popsicle bags include food-grade plastic, which can vary in quality and price based on thickness, durability, and environmental certifications (e.g., BPA-free, recyclable). Higher quality materials may incur a higher initial cost but can lead to greater customer satisfaction and lower returns.

-

Labor: Labor costs are influenced by the location of the manufacturing facility. In regions like Southeast Asia, labor costs may be lower, whereas in Europe or North America, they can be significantly higher. It’s essential to consider the implications of labor costs on overall pricing.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these overhead costs, impacting the final price of the bags.

-

Tooling: Custom designs or unique specifications may require specialized tooling, which can be a significant upfront investment. Buyers should evaluate whether the tooling costs are justified by the expected volume of orders.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the products meet safety and quality standards. This can add to the cost but is crucial for maintaining brand reputation, especially when exporting to regions with stringent regulations.

-

Logistics: Shipping costs can vary widely based on the distance from the manufacturer to the buyer, the shipping method, and current fuel prices. For international buyers, understanding Incoterms and their implications on shipping costs is vital.

-

Margin: Suppliers will typically add a profit margin to the total cost, which can vary based on market conditions, competition, and their financial strategies.

How Do Price Influencers Affect Popsicle Bag Costs?

Several factors influence the pricing of popsicle bags, including:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often attract discounts, while smaller orders may result in higher per-unit costs. Buyers should assess their needs to optimize order sizes.

-

Specifications and Customization: Unique designs or custom sizes can increase production costs. Buyers should balance the desire for customization with the associated costs and potential volume reductions.

-

Material Quality and Certifications: Higher quality materials and certifications (like FDA approval) can lead to higher prices. However, they may also justify a premium price when marketing to health-conscious consumers.

-

Supplier Factors: The reputation and reliability of suppliers can influence prices. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipment can help buyers anticipate additional costs. For instance, FOB (Free On Board) indicates that the seller is responsible for the goods until they are loaded onto the shipping vessel, while CIF (Cost, Insurance, and Freight) includes shipping costs to the destination port.

What Are Effective Buyer Tips for Sourcing Popsicle Bags?

To ensure cost-efficiency in sourcing popsicle bags, consider these tips:

-

Negotiate: Don’t hesitate to negotiate terms with suppliers. Building a long-term relationship can result in better pricing and terms as volumes increase.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also the long-term costs associated with quality, durability, and logistics. A higher upfront cost may lead to lower overall expenses if the product lasts longer or reduces shipping frequency.

-

Be Aware of Pricing Nuances: International buyers must navigate currency fluctuations, import duties, and taxes that can significantly affect the final cost. Understanding local market conditions in regions like Africa, South America, or Europe is essential for accurate budgeting.

-

Research Supplier Backgrounds: Investigate potential suppliers’ backgrounds, certifications, and reviews to ensure quality and reliability. This can help prevent costly mistakes later in the procurement process.

Disclaimer on Indicative Prices

Pricing for popsicle bags can vary widely based on specifications, order volumes, and market conditions. The prices mentioned in various retail settings serve as indicators but may not reflect wholesale costs. Always seek quotes from multiple suppliers to establish a competitive price point.

Alternatives Analysis: Comparing popsicle bags With Other Solutions

Exploring Alternatives to Popsicle Bags for Frozen Treat Packaging

In the competitive landscape of frozen treat packaging, popsicle bags are a popular choice for many businesses. However, there are alternative solutions that may offer different advantages depending on specific needs and contexts. This section compares popsicle bags with two viable alternatives: traditional popsicle molds and ready-made plastic cups.

Comparison Table

| Comparison Aspect | Popsicle Bags | Traditional Popsicle Molds | Ready-Made Plastic Cups |

|---|---|---|---|

| Performance | Flexible, allows for creative flavors; easy to store | Limited by shape; can freeze unevenly | Ready-to-use; consistent shape and portion |

| Cost | Generally low cost per unit | Moderate initial investment; reusable | Higher per-unit cost, but no additional tools needed |

| Ease of Implementation | Simple to use; minimal equipment required | Requires specific molds and freezing time | No preparation needed; immediate use |

| Maintenance | Single-use or reusable; easy to clean | Requires cleaning; can be cumbersome | Disposable; no cleaning required |

| Best Use Case | Ideal for customized flavors and family use | Great for homemade popsicles; eco-friendly | Convenient for events and retail settings |

Detailed Breakdown of Alternatives

Traditional Popsicle Molds

Traditional molds are typically made of silicone or plastic and allow users to create frozen treats in various shapes. They offer the advantage of being reusable, making them an eco-friendly option. However, they can be cumbersome to clean and may not freeze mixtures evenly, leading to inconsistent results. Furthermore, they require a more significant initial investment compared to popsicle bags, which might deter smaller businesses or startups.

Ready-Made Plastic Cups

These cups provide a convenient solution for businesses that need quick turnaround times without the hassle of preparation. They come pre-filled and sealed, ensuring consistent product quality. While the upfront cost per unit is higher, they eliminate the need for additional tools or labor for filling and sealing, making them ideal for large events or retail settings. However, their disposable nature raises sustainability concerns, which may not align with eco-conscious brands.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the best packaging solution for frozen treats, B2B buyers should consider their specific operational needs, budget constraints, and target market preferences. Popsicle bags offer flexibility and creativity, making them suitable for businesses that want to experiment with flavors and presentations. On the other hand, traditional molds may appeal to environmentally conscious brands, while ready-made cups are perfect for those prioritizing convenience and speed. By thoroughly evaluating these alternatives against their business goals, buyers can make informed decisions that enhance their product offerings and meet consumer expectations.

Essential Technical Properties and Trade Terminology for popsicle bags

What Are the Key Technical Properties of Popsicle Bags?

When sourcing popsicle bags, understanding their technical properties is crucial for ensuring product quality and compliance with industry standards. Below are essential specifications that B2B buyers should consider:

1. Material Grade

Popsicle bags are typically made from food-grade plastics such as polyethylene (PE) or polypropylene (PP). The material grade affects durability, flexibility, and safety. Food-grade materials comply with safety regulations, ensuring that they do not leach harmful substances into the popsicles. For international buyers, verifying the material grade against local regulations is vital.

2. Barrier Properties

The barrier properties of a popsicle bag refer to its ability to resist moisture, oxygen, and light. High barrier materials help prevent freezer burn and preserve the quality of the frozen product. This property is especially important for suppliers looking to export popsicle bags to regions with varying climates, as it ensures product integrity during transit and storage.

3. Seal Strength

Seal strength is a critical specification that determines how well the bags can hold liquids without leaking. A strong seal prevents spills during filling and storage, enhancing customer satisfaction. For manufacturers, conducting seal strength tests ensures that the bags meet the required tolerances and can withstand the rigors of freezing and thawing.

4. Dimensions and Tolerance

The dimensions of popsicle bags, including length, width, and thickness, should be consistent to ensure efficient packing and filling. Tolerance refers to the acceptable variation in these dimensions. Precise dimensions are crucial for automated filling machines and can impact production efficiency. B2B buyers should specify their dimensional requirements clearly to avoid discrepancies.

5. Zipper or Closure Type

Many popsicle bags feature closures like zippers or heat seals that enhance usability and prevent leaks. The choice of closure impacts convenience for end-users and can influence purchasing decisions. Buyers should consider the target market’s preferences when selecting the type of closure for their popsicle bags.

What Are Common Trade Terms in the Popsicle Bag Industry?

Familiarity with industry jargon can streamline communication between buyers and suppliers. Below are key terms that are frequently used in the popsicle bag market:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of popsicle bags, buyers may work with OEMs to create custom packaging solutions that fit their specific branding needs.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding the MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs based on their sales forecasts to avoid excess inventory or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. For B2B buyers, issuing an RFQ for popsicle bags can help compare prices and terms from different manufacturers, aiding in the decision-making process.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs and liability during transit, which is crucial for international B2B transactions.

5. FDA Compliance

In the context of popsicle bags, FDA compliance indicates that the packaging meets the Food and Drug Administration’s standards for food safety in the United States. International buyers should be aware of similar regulations in their countries to ensure that the products they import are safe for consumer use.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing popsicle bags, ensuring that they meet their operational needs and comply with industry standards.

Navigating Market Dynamics and Sourcing Trends in the popsicle bags Sector

What Are the Key Trends Influencing the Popsicle Bags Market?

The popsicle bags market is experiencing notable growth driven by various global factors. Increasing consumer demand for convenient, portable snacks, particularly in regions like Africa, South America, the Middle East, and Europe, is reshaping product offerings. The trend towards healthier eating has led to a rise in the popularity of DIY popsicles, prompting manufacturers to introduce versatile packaging solutions that cater to home preparation. Furthermore, technological advancements in production methods are enabling suppliers to offer customizable options, enhancing their competitive edge in the B2B landscape.

Emerging B2B technology trends, such as automation in manufacturing and the use of smart logistics, are transforming how popsicle bags are sourced. Companies are leveraging data analytics to forecast demand more accurately, optimizing inventory levels and reducing wastage. As international trade continues to expand, suppliers are increasingly focused on building robust online platforms to facilitate seamless transactions and enhance buyer-supplier relationships. This digital evolution is crucial for international buyers, particularly those from regions with diverse market needs and regulatory environments.

How Is Sustainability Reshaping the Popsicle Bags Sector?

Sustainability is becoming a critical factor for B2B buyers in the popsicle bags sector. The environmental impact of packaging waste is a growing concern, and businesses are actively seeking suppliers who prioritize eco-friendly materials. The rise of biodegradable and recyclable options is reshaping sourcing strategies, as companies aim to minimize their carbon footprint while meeting consumer expectations for responsible packaging.

Ethical sourcing practices are also gaining traction. Buyers are increasingly scrutinizing their supply chains, looking for partners who demonstrate transparency and social responsibility. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 for environmental management are becoming essential for suppliers aiming to distinguish themselves in a crowded market. By prioritizing sustainable materials and ethical practices, B2B buyers not only enhance their brand image but also align with the values of environmentally conscious consumers.

What Is the Evolution of Popsicle Bags in the Market?

The evolution of popsicle bags reflects broader trends in consumer behavior and packaging innovation. Initially, popsicle bags were simple plastic pouches primarily used for freezing flavored liquids. Over the years, advancements in materials science have led to the development of more durable, leak-proof options that cater to both disposable and reusable markets.

As consumer preferences shifted towards healthier and customizable snacks, the popsicle bag market adapted by incorporating features such as zip seals for easy access and built-in labels for flavor identification. This evolution not only improved the user experience but also opened up new avenues for branding and marketing. Today, popsicle bags are not just functional; they are a canvas for creative designs and sustainable practices, reflecting the changing landscape of food packaging and consumer expectations.

Conclusion

Navigating the popsicle bags sector requires an understanding of market dynamics, sustainability trends, and the historical evolution of packaging solutions. For international B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe, leveraging these insights can lead to more informed sourcing decisions. As the market continues to evolve, staying attuned to these trends will be crucial for maintaining competitiveness and meeting the demands of today’s environmentally conscious consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of popsicle bags

-

How do I choose the right popsicle bags for my business needs?

Selecting the appropriate popsicle bags involves considering several factors such as material, size, and functionality. Look for food-grade materials that are BPA-free to ensure safety for consumers. If your business focuses on health-conscious products, opt for reusable or biodegradable options. Additionally, consider the size of the bags to accommodate your product volume, and features like zip seals for leak prevention. Evaluate the branding capabilities as well, such as custom printing, to enhance your product’s market appeal. -

What types of popsicle bags are available for wholesale purchasing?

Wholesale popsicle bags come in various types, including disposable, reusable, and custom-printed options. Disposable bags are generally made from single-use plastic, suitable for quick consumption. Reusable bags often feature durable materials and zip seals, ideal for environmentally conscious consumers. Custom-printed bags allow you to incorporate branding elements, enhancing your marketing efforts. When sourcing, ensure your supplier can provide samples to assess quality before committing to bulk orders. -

What is the minimum order quantity (MOQ) for popsicle bags?

Minimum order quantities for popsicle bags can vary significantly depending on the manufacturer and type of bag. Typically, MOQs range from 1,000 to 10,000 units for custom designs, while standard products may have lower MOQs. It’s advisable to discuss your specific needs with potential suppliers to negotiate terms that suit your business scale. Keep in mind that larger orders often yield better pricing, which can be beneficial for budget management. -

How do I ensure the quality of popsicle bags from international suppliers?

To ensure quality, start by vetting suppliers through industry certifications like ISO and FDA compliance. Request product samples to evaluate the material, durability, and safety features. Additionally, consider conducting factory visits or third-party audits to assess manufacturing processes. Establish clear quality assurance protocols, including specifications for materials and performance tests, to maintain product standards throughout the supply chain. -

What payment terms should I expect when sourcing popsicle bags internationally?

Payment terms for international orders typically vary by supplier but often include options such as wire transfers, letters of credit, or escrow services. Common arrangements include a 30% deposit upfront with the balance due before shipping. It’s crucial to clarify these terms during negotiations to avoid misunderstandings. Consider utilizing payment methods that offer buyer protection, especially when dealing with new suppliers, to mitigate risks associated with international transactions. -

What logistics considerations should I keep in mind when importing popsicle bags?

When importing popsicle bags, consider shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but may take longer. Ensure you understand the import duties and taxes applicable in your country to avoid unexpected costs. Partner with a reliable freight forwarder who can assist with customs documentation and ensure timely delivery of your goods. -

How can I customize popsicle bags for my brand?

Customization options for popsicle bags include size, material, and design elements such as colors and logos. Many suppliers offer digital printing services that allow for high-quality graphics and branding. Discuss your design requirements with potential manufacturers and request mock-ups to visualize the final product. Consider the impact of customization on your overall budget, as more intricate designs may involve higher costs. -

What are the environmental considerations for sourcing popsicle bags?

Sustainability is increasingly important for consumers and businesses alike. When sourcing popsicle bags, look for suppliers that offer eco-friendly options, such as biodegradable or recyclable materials. Assess the supplier’s manufacturing practices to ensure they align with your environmental goals. Additionally, consider the lifecycle of the product, including packaging and disposal methods, to minimize your business’s carbon footprint and appeal to environmentally conscious consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Popsicle Bags Manufacturers & Suppliers List

1. Reuse-a-Pop – Reusable DIY Popsicle Bags

Domain: russbe.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Reusable DIY Popsicle bags”, “set_size”: 12, “brand”: “Reuse-a-Pop”, “price”: “$6.99”, “description”: “These reusable and versatile bags are perfect for creating your own frozen juice pops, fruit and yogurt smoothies and other fun-filled treats. Ideal for after-school snacks or parties, our durable, freezer-safe REUSE-A-POP bags allow you and your family to experiment with creati…

2. Yocupco – Popsicle Bags OPP Plastic

Domain: shop.yocupco.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “Popsicle Bags OPP Plastic Ice Pop Bags Food Grade Transparent Ice Popsicle Mold”, “Size”: “#2”, “Dimensions”: {“Front Length”: “135mm (5.3\”)”, “Width”: “78mm (3\”)”, “Back Length”: “150mm (5.9\”)”}, “Quantity”: “5000/cs”, “Price”: “$37.89”, “SKU”: “41702”, “Shipping Weight”: “15.000000 lb”}

3. Wellfa Pack – Custom Printed Popsicle Packaging

Domain: wellfapack.com

Registered: 2023 (2 years)

Introduction: Popsicle Packaging – Specially crafted to keep frozen delights intact, designed for hassle-free enjoyment. Products include: 1. Heat Seal Custom Colorful Printed Plastic Packing For Ice Candy – Rated 5.00 out of 5 2. Heat Seal Factory Colorful Printed Ice Cream Bag Packing Popsicle – Rated 5.00 out of 5 3. Colorful Custom Printed Factory Food Grade Frozen Ice Cream Popsicle Packaging Wrappers – Ra…

4. PackFresh – Clear Freezer Pop Bags

Domain: packfreshusa.com

Registered: 2015 (10 years)

Introduction: Product Name: Clear Freezer Pop Bags (100 Pack)

Price: $19.99

SKU: FPB

UPC: Not specified

Size: 2.5″ x 10″

Material: Food grade non-toxic BPA-free plastic

Features:

– Clear front and back

– Free from harmful chemicals and toxins

– Suitable for making smoothies, fruit juice, yogurt, chopped fruits, and beverages

– Ideal for camping, hiking, picnics, and road trips

– Includes recipe guide for kids …

5. KDW – Popsicle Bags

Domain: kdwpack.com

Registered: 2023 (2 years)

Introduction: Popsicle Bags are specialized bags designed to hold and store popsicles or ice pops, made from durable materials that withstand freezing temperatures without leaking. KDW’s innovative popsicle bags feature a dual-function design: consumers can suck the popsicles up through a spout when in liquid form, and once frozen, they can tear open the bag to transform the spout into a stick, allowing for tra…

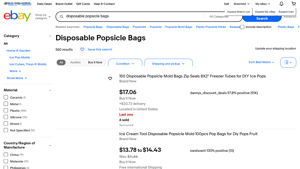

6. Disposable Popsicle Bags – Key Product Details

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for Disposable Popsicle Bags on eBay include:

– Various pack sizes available: 50, 100, 150, 200, 240, 300, and 400 pieces.

– Prices range from approximately $5.00 to $20.00, with options for ‘Best Offer’ and discounts on bulk purchases.

– Materials: Most bags are made from BPA-free plastic and are designed for freezing.

– Features: Many products include self-sealing pockets and…

Strategic Sourcing Conclusion and Outlook for popsicle bags

As the global demand for popsicle bags continues to rise, strategic sourcing emerges as a vital component for international B2B buyers. Key insights from recent trends highlight the importance of selecting suppliers who prioritize quality, sustainability, and innovation in their product offerings. By collaborating with manufacturers that offer customizable solutions—such as reusable and disposable options—businesses can meet diverse consumer preferences while enhancing their brand appeal.

Investing in high-quality popsicle packaging not only ensures product integrity but also aligns with the growing consumer focus on eco-friendly practices. This is particularly relevant in markets across Africa, South America, the Middle East, and Europe, where sustainability is becoming a key differentiator in purchasing decisions.

Looking ahead, B2B buyers are encouraged to leverage strategic sourcing to create competitive advantages. Engaging with manufacturers who can provide tailored solutions will facilitate the introduction of unique product offerings in the market. As the industry evolves, staying ahead of packaging innovations will be crucial for driving growth and satisfying the changing needs of consumers. Take action now to secure partnerships that will elevate your product line and position your business for future success.