Choosing Your Hpht Diamond Machine: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for hpht diamond machine

In the rapidly evolving landscape of the global diamond industry, sourcing high-quality HPHT diamond machines presents a unique challenge for B2B buyers. As demand for lab-grown diamonds surges, fueled by their ethical appeal and cost-effectiveness, understanding the intricacies of these advanced manufacturing systems becomes imperative. This comprehensive guide delves into the various types of HPHT machines available in the market, their diverse applications, and the factors to consider when evaluating suppliers.

From exploring the latest technologies and models, such as the popular UDS650 and UDS850, to understanding the importance of precise temperature and pressure controls, this resource equips international buyers—particularly those from Africa, South America, the Middle East, and Europe—with the knowledge they need to make informed purchasing decisions. Furthermore, the guide emphasizes supplier vetting processes, including assessing warranties, technical support, and customization options, ensuring that buyers can confidently navigate their sourcing journey.

By providing actionable insights and a detailed understanding of costs associated with HPHT diamond machines, this guide empowers businesses to enhance their production capabilities and stay competitive in a growing market. Whether you are looking to invest in your first machine or expand your existing operations, the information contained herein will serve as a valuable tool in your strategic planning.

Understanding hpht diamond machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| HPHT Cubic Press | Utilizes cubic press technology for high-pressure diamond synthesis | Synthetic diamond production, jewelry making | Pros: High efficiency, customizable options. Cons: Requires skilled operators, initial investment cost. |

| Forging HPHT Machine | Compact design with robust structure and easy maintenance | Diamond tools manufacturing, industrial uses | Pros: Long service life, flexible operation. Cons: Limited to specific diamond types. |

| HPHT Diamond Color Enhancement | Advanced control systems for optimizing diamond color | Gem quality enhancement, jewelry design | Pros: Enhances value of diamonds, precise adjustments. Cons: Complexity may require additional training. |

| Continuous HPHT Machine | Enables uninterrupted operation for long production runs | Large-scale diamond production | Pros: High throughput, reduced labor costs. Cons: Higher upfront capital investment. |

| Portable HPHT Units | Smaller, mobile machines for on-site diamond synthesis | Small-scale operations, research applications | Pros: Flexibility and mobility, lower cost. Cons: Limited production capacity, less robust. |

What Are the Key Characteristics of HPHT Cubic Press Machines?

HPHT Cubic Press machines are primarily designed for producing synthetic diamonds through high-pressure and high-temperature processes. They are known for their efficiency and ability to create diamonds with exceptional clarity and color. These machines are ideal for businesses focused on jewelry manufacturing and synthetic diamond production, as they can be customized according to specific production needs. Buyers should consider the technical expertise required for operation and the significant initial investment when purchasing.

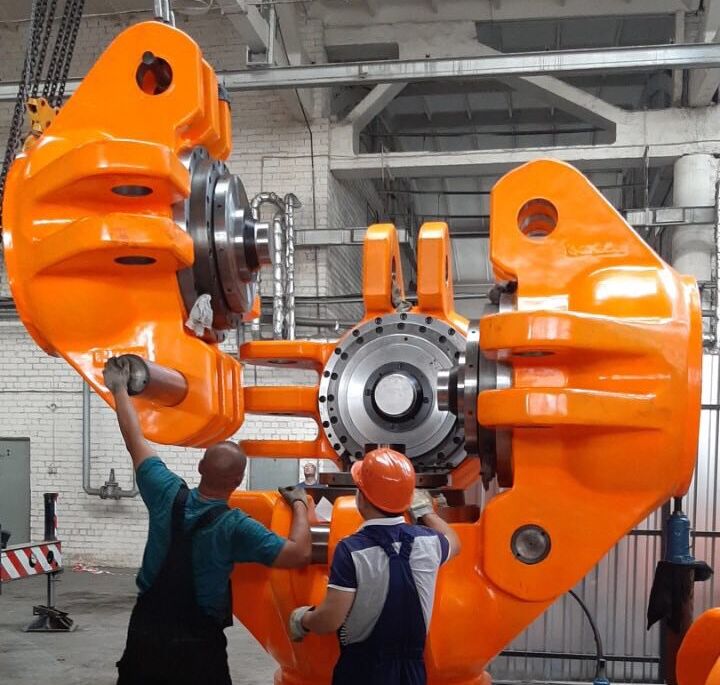

How Do Forging HPHT Machines Differ from Other Types?

Forging HPHT machines stand out due to their compact design and robust construction, which allows for easy maintenance and operation. They are particularly suitable for producing diamond tools and other industrial applications. The long service life and ability to operate flexibly make them appealing to businesses looking to optimize production processes. However, potential buyers should be aware that these machines may be limited to specific types of diamond production.

What Advantages Do HPHT Diamond Color Enhancement Machines Offer?

HPHT Diamond Color Enhancement machines incorporate advanced control systems that allow for precise adjustments in temperature and pressure, optimizing the color of diamonds. This makes them invaluable for businesses in the jewelry industry that aim to enhance the value of their products. While they offer significant advantages in terms of quality enhancement, buyers need to consider the complexity of operation and the necessity for skilled personnel.

Why Consider Continuous HPHT Machines for Large-Scale Production?

Continuous HPHT machines are designed for high-volume production, allowing businesses to operate without interruptions for extended periods. This feature significantly reduces labor costs and enhances overall productivity, making them suitable for large-scale diamond manufacturing operations. However, the higher capital investment required for these machines might be a barrier for smaller businesses.

What Are the Benefits of Portable HPHT Units?

Portable HPHT units are smaller and designed for mobility, making them ideal for on-site diamond synthesis in small-scale operations or research environments. They offer flexibility and a lower initial cost compared to larger machines. However, businesses should consider their limited production capacity and robustness when evaluating these units for their operations.

Key Industrial Applications of hpht diamond machine

| Industry/Sector | Specific Application of hpht diamond machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Jewelry Manufacturing | Production of lab-grown diamonds for retail jewelry | Cost-effective, ethical sourcing of high-quality diamonds | Supplier reliability, customization options, and warranty support |

| Industrial Tools | Creation of diamond cutting and grinding tools | Enhanced durability and performance of tools | Machine precision, maintenance support, and operational training |

| Electronics | Manufacturing of diamond-based heat sinks | Improved thermal conductivity for electronic components | Compliance with international standards and quality certifications |

| Medical Equipment | Development of diamond-coated surgical instruments | Increased precision and longevity of surgical tools | Technology integration, after-sales service, and training programs |

| Optical Devices | Production of diamond optics for high-precision applications | Superior clarity and resilience in optical components | Customization capabilities, technical support, and scalability |

How is the hpht diamond machine utilized in jewelry manufacturing?

In the jewelry sector, hpht diamond machines are employed to create lab-grown diamonds that cater to a growing market for ethical and sustainable products. By producing high-quality diamonds that mirror the physical and chemical properties of natural stones, businesses can offer consumers an appealing alternative. Buyers in this sector should consider supplier reliability, the ability to customize diamond specifications, and warranty support to ensure a consistent supply of superior products.

What role does the hpht diamond machine play in industrial tool production?

The industrial tools sector uses hpht diamond machines to manufacture diamond cutting and grinding tools, which are essential for various manufacturing processes. These tools benefit from the exceptional hardness and durability of lab-grown diamonds, resulting in longer-lasting products that enhance productivity. When sourcing, businesses should prioritize machine precision, availability of maintenance support, and comprehensive operational training to maximize tool performance.

How does the hpht diamond machine contribute to electronics manufacturing?

In electronics, hpht diamond machines are utilized to create diamond-based heat sinks that significantly improve thermal management in devices. The superior thermal conductivity of diamond helps prevent overheating, enhancing the reliability and lifespan of electronic components. International buyers should focus on suppliers who comply with international standards and provide quality certifications to ensure the effectiveness of their heat management solutions.

What advantages does the hpht diamond machine offer in the medical equipment industry?

The medical equipment industry leverages hpht diamond machines to produce diamond-coated surgical instruments that offer increased precision and longevity. The hardness of diamonds allows for sharper edges and improved cutting efficiency, which is critical in surgical procedures. Buyers in this sector must evaluate technology integration capabilities, after-sales service, and training programs to ensure their staff can effectively use and maintain the equipment.

How are optical devices enhanced by hpht diamond machines?

In the optical devices sector, hpht diamond machines are crucial for manufacturing diamond optics that provide unparalleled clarity and resilience. These optics are used in high-precision applications such as lasers and microscopes, where performance is paramount. Businesses should consider customization capabilities, technical support, and scalability when sourcing machines to meet the specific needs of their optical applications.

3 Common User Pain Points for ‘hpht diamond machine’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality HPHT Machines

The Problem:

B2B buyers often struggle with sourcing high-quality HPHT diamond machines that meet their production needs. The market is flooded with various suppliers, but not all machines are created equal. Buyers can face issues such as poor build quality, lack of necessary features, or insufficient warranties. This can lead to costly downtimes and reduced operational efficiency, ultimately impacting profitability. International buyers, particularly from regions like Africa or South America, may also face challenges related to shipping costs, customs, and equipment compatibility with local power standards.

The Solution:

To navigate this challenge, buyers should begin by conducting thorough research on reputable manufacturers. Look for companies with a proven track record and positive reviews from other buyers in similar markets. Engaging with manufacturers that offer customizable solutions can also be beneficial, as they can tailor machines to specific needs. Request detailed specifications and certifications to ensure quality standards are met. Additionally, consider suppliers that provide comprehensive after-sales support, including installation services and operator training. This not only helps in smooth operation but also ensures that the machine is used to its fullest potential, maximizing production efficiency.

Scenario 2: Managing Operational Complexity and Training

The Problem:

Operating an HPHT diamond machine involves a complex interplay of high pressure, high temperature, and precise material handling. Many buyers face the daunting task of training their workforce on how to operate these machines effectively. Without adequate training, operators may struggle with the intricacies of the machinery, leading to inefficient production processes, increased waste, and potential safety hazards. This is particularly challenging for businesses in developing regions, where access to experienced technicians may be limited.

The Solution:

Investing in comprehensive training programs is essential for overcoming this operational complexity. Buyers should collaborate with manufacturers that offer training as part of their purchase agreement. This training should cover not only the technical aspects of operating the machine but also maintenance protocols and safety measures. Additionally, consider establishing a mentorship program where experienced operators can guide new staff. Utilizing online resources and video tutorials can also supplement training efforts. By prioritizing workforce development, companies can ensure that their staff is well-equipped to operate HPHT machines efficiently, leading to improved productivity and reduced operational risks.

Scenario 3: High Maintenance Costs and Downtime

The Problem:

Maintenance of HPHT diamond machines can be a significant concern for many B2B buyers. Over time, these machines can experience wear and tear, leading to unexpected breakdowns and costly repairs. For businesses operating in competitive markets, even a short period of downtime can result in lost revenue and customer trust. Buyers often find it challenging to predict maintenance costs and may not have access to local service providers, especially in less industrialized regions.

The Solution:

To mitigate high maintenance costs, buyers should consider machines that come with extended warranties and comprehensive service packages. When selecting a machine, inquire about the availability of spare parts and the reputation of the manufacturer for reliability and support. Establishing a proactive maintenance schedule can also help identify potential issues before they lead to breakdowns. Regular training for maintenance staff on proper handling and care can reduce wear and extend the machine’s lifespan. Furthermore, forming partnerships with local technicians or service providers can ensure timely assistance when needed, minimizing downtime and maintaining production flow.

Strategic Material Selection Guide for hpht diamond machine

When selecting materials for HPHT diamond machines, it is crucial to consider the specific properties and performance characteristics that impact efficiency, durability, and the quality of the end product. Here, we analyze four common materials used in the construction of these machines, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel in HPHT Diamond Machines?

Steel is a primary material used in the construction of HPHT diamond machines due to its excellent strength and durability. High-carbon steel, in particular, can withstand the extreme pressures (up to 1,000 MPa) and temperatures (over 1,500°C) involved in the diamond synthesis process. Its corrosion resistance can be enhanced through various treatments, making it suitable for the harsh environments encountered during operation.

Pros: Steel is relatively cost-effective, widely available, and can be easily fabricated into complex shapes. It also offers good wear resistance, which is essential for the longevity of machine components.

Cons: While steel is strong, it can be susceptible to corrosion if not properly treated, especially in humid environments. Additionally, the weight of steel can impact the overall machine design and transport costs.

Impact on Application: Steel’s compatibility with high-pressure and high-temperature applications makes it ideal for HPHT processes. However, buyers in regions with high humidity, such as parts of Africa and South America, should prioritize corrosion-resistant coatings or alloys.

How Does Tungsten Carbide Enhance Performance in HPHT Machines?

Tungsten carbide is another material frequently used in HPHT diamond machines, particularly for components that require exceptional hardness and wear resistance. This material can withstand high temperatures and pressures, making it suitable for critical parts such as dies and anvil blocks.

Pros: Tungsten carbide offers superior hardness, which significantly reduces wear and extends the lifespan of machine components. It is also resistant to deformation under extreme conditions.

Cons: The primary drawback of tungsten carbide is its high cost compared to steel and its brittleness, which can lead to failure under shock loading.

Impact on Application: Tungsten carbide’s high-temperature stability and wear resistance make it ideal for producing high-quality diamonds. Buyers should consider the cost-benefit ratio, especially in regions with budget constraints.

What Role Does Ceramic Play in HPHT Diamond Machines?

Ceramics are increasingly used in HPHT machines due to their excellent thermal stability and resistance to chemical corrosion. Advanced ceramics can withstand the extreme conditions of the HPHT process, making them suitable for insulating components and high-temperature applications.

Pros: Ceramics are lightweight and offer excellent thermal insulation properties. They are also chemically inert, making them suitable for various environments.

Cons: The main limitation of ceramics is their brittleness, which can lead to cracking under mechanical stress. Additionally, their manufacturing processes can be more complex and costly.

Impact on Application: For international buyers, especially in regions with varying climatic conditions, ceramics can provide a reliable solution for thermal management. However, careful consideration of mechanical stresses is necessary to avoid premature failure.

How is Graphite Utilized in HPHT Diamond Machines?

Graphite is often used in HPHT machines for its unique properties, including high thermal conductivity and the ability to withstand high temperatures. It serves as a lubricant and is also used in the form of electrodes in some HPHT systems.

Pros: Graphite’s ability to conduct heat efficiently helps maintain stable temperatures during the diamond synthesis process. It also provides excellent lubrication, reducing wear on moving parts.

Cons: Graphite can be sensitive to oxidation at high temperatures, which may limit its use in certain applications. Additionally, it can be more expensive than traditional lubricants.

Impact on Application: For buyers, particularly in regions with high operational temperatures, understanding the thermal management capabilities of graphite is essential. Compliance with international standards for material safety and performance is also crucial.

Summary Table

| Material | Typical Use Case for hpht diamond machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | Cost-effective and durable | Susceptible to corrosion | Low |

| Tungsten Carbide | Dies and anvil blocks | Superior hardness and wear resistance | High cost and brittleness | High |

| Ceramic | Insulating components | Lightweight and thermally stable | Brittleness and complex fabrication | Medium |

| Graphite | Lubricants and electrodes | Excellent thermal conductivity | Sensitive to oxidation | Medium |

This analysis provides a comprehensive overview of the materials commonly used in HPHT diamond machines, enabling international B2B buyers to make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for hpht diamond machine

What Are the Key Stages in the Manufacturing Process of HPHT Diamond Machines?

The manufacturing process of HPHT diamond machines is intricate and requires a high level of precision to produce machines capable of synthesizing high-quality diamonds. This process can be broken down into several main stages:

-

Material Preparation: The initial stage involves selecting high-grade raw materials that will form the components of the HPHT machine. Common materials include high-strength steel for the frame and specialized alloys that can withstand extreme pressure and temperature conditions. Quality sourcing of these materials is critical, as their properties directly affect the machine’s performance and longevity.

-

Forming: This stage involves the shaping of components, typically through processes like forging and machining. Forging ensures that the materials have enhanced structural integrity, while precision machining allows for the creation of components with exact specifications. Techniques such as CNC (Computer Numerical Control) machining are commonly employed to achieve the necessary tolerances.

-

Assembly: Once the individual components are formed, they are assembled into the complete machine. This stage requires skilled technicians who can ensure that all parts fit together correctly and function as intended. Proper alignment of the pressure and temperature controls is vital, as these systems must operate seamlessly to create the optimal environment for diamond synthesis.

-

Finishing: After assembly, the machines undergo finishing processes, which may include surface treatment to enhance durability and performance. This could involve coatings that resist wear and corrosion, as well as polishing to ensure smooth operation of moving parts. The finishing stage is crucial for the overall aesthetics and functionality of the machine.

What International Standards Should B2B Buyers Look for in HPHT Diamond Machines?

Quality assurance in the manufacturing of HPHT diamond machines is paramount, particularly for B2B buyers operating in international markets. Several international standards and certifications are relevant:

-

ISO 9001: This standard pertains to quality management systems and is crucial for any manufacturing process. Compliance indicates that the manufacturer has established a robust framework for maintaining quality throughout production.

-

CE Marking: This certification is mandatory for products sold within the European Economic Area. It signifies that the machine meets health, safety, and environmental protection standards.

-

API Standards: For manufacturers targeting the oil and gas sectors, adherence to American Petroleum Institute (API) standards can enhance credibility and ensure that machinery can operate under high-stress conditions.

What Quality Control Checkpoints Are Essential in HPHT Diamond Machine Manufacturing?

Quality control (QC) is integral to the manufacturing process of HPHT diamond machines. The following checkpoints are typically included in a comprehensive QC plan:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival. Verification of material specifications ensures that only the highest quality inputs are used in production.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to ensure that processes are carried out according to specified standards. This includes monitoring temperature and pressure during the forming stage, which are critical for the machine’s functionality.

-

Final Quality Control (FQC): Once the machine is fully assembled, a final inspection is conducted to verify that all components function as intended. This may include testing pressure and temperature controls, as well as assessing the machine’s overall performance.

What Common Testing Methods Are Used to Ensure HPHT Diamond Machine Quality?

Testing methods for HPHT diamond machines are varied and thorough to ensure compliance with quality standards. Common techniques include:

-

Hydraulic Testing: This method assesses the machine’s ability to withstand high pressures without failure. It is critical for ensuring safety and operational reliability.

-

Temperature Calibration: Given the extreme temperatures involved in the HPHT process, machines must be tested for accurate temperature regulation. Calibration ensures that the machine can maintain the necessary conditions for diamond synthesis.

-

Functional Testing: This involves running the machine under simulated operational conditions to verify that all systems function correctly. This may include monitoring pressure and temperature fluctuations during extended operation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure that the machines meet expected standards. Here are several strategies:

-

Supplier Audits: Conducting audits of the manufacturing facility allows buyers to assess the quality management systems in place. This includes reviewing documentation related to ISO certifications and other relevant standards.

-

Requesting Quality Reports: Suppliers should be able to provide comprehensive quality reports detailing the results of IQC, IPQC, and FQC. These documents offer transparency regarding the machine’s production quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes. These inspections can help ensure compliance with international standards and provide additional assurance of product quality.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in HPHT diamond machine manufacturing is critical. Here are some considerations:

-

Regional Standards: Different regions may have varying standards for machinery. Buyers should familiarize themselves with local regulations and ensure that the supplier adheres to these requirements.

-

Cultural Differences: Communication styles and business practices can differ significantly across regions. Establishing clear expectations and open lines of communication with suppliers can help mitigate misunderstandings related to quality assurance.

-

Logistics and Supply Chain: The transportation of heavy machinery like HPHT diamond machines requires careful planning to avoid damage during transit. Buyers should consider suppliers who have experience with international shipping and can provide assurances regarding the condition of the machinery upon arrival.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing HPHT diamond machines, ensuring they invest in reliable and high-quality equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hpht diamond machine’

To assist B2B buyers in procuring HPHT diamond machines, this checklist outlines essential steps to ensure a successful sourcing process. By following this guide, you can make informed decisions that align with your business needs and market demands.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your operation is crucial. Determine the type of diamonds you plan to produce (e.g., single-crystal, lab-grown) and the desired output capacity. This will help in selecting a machine that meets your production goals and integrates seamlessly into your existing workflow.

Step 2: Research the Market and Pricing

Conduct thorough market research to understand the pricing landscape for HPHT machines. Look for reputable manufacturers and compare their offerings. Pay attention to factors such as machine specifications, warranty terms, and after-sales support, as these can significantly impact your total cost of ownership.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to vet your suppliers. Request comprehensive company profiles, including their manufacturing capabilities and customer testimonials. Engage with other businesses in your industry to gain insights into their experiences with specific suppliers, ensuring they have a solid reputation for quality and service.

Step 4: Check Certifications and Compliance

Ensure that the machines and suppliers comply with international standards and certifications. This includes checking for ISO certifications or other relevant quality assurances. Compliance not only guarantees the reliability of the equipment but also minimizes risks associated with operational failures.

Step 5: Request Customization Options

Many manufacturers offer customization to meet specific production needs. Inquire about the possibility of modifying machine features such as size, pressure capacity, and control systems. Tailored solutions can enhance operational efficiency and align with your unique production processes.

Step 6: Assess Technical Support and Training

Technical support is vital for the successful implementation and operation of HPHT machines. Confirm that the supplier offers training for your staff on machine operation and maintenance. Additionally, inquire about ongoing support services, including troubleshooting and spare parts availability, to ensure long-term operational success.

Step 7: Review Payment Terms and Shipping Options

Understanding the payment structure and shipping logistics is crucial before finalizing your purchase. Look for flexible payment options that suit your budget, such as trade assurances or installment plans. Additionally, clarify shipping costs, timelines, and responsibilities to avoid unexpected delays in machine delivery.

By following this checklist, B2B buyers can navigate the complexities of sourcing HPHT diamond machines effectively, ensuring they select the right equipment and partner for their business needs.

Comprehensive Cost and Pricing Analysis for hpht diamond machine Sourcing

Analyzing the cost structure and pricing of HPHT diamond machines is crucial for international B2B buyers aiming to make informed purchasing decisions. This section breaks down the essential cost components, identifies key price influencers, and offers actionable tips for buyers, particularly those from Africa, South America, the Middle East, and Europe.

What Are the Primary Cost Components for HPHT Diamond Machines?

-

Materials: The cost of raw materials is significant in the overall pricing of HPHT machines. Key components include high-quality steel, specialized alloys, and high-pressure seals. The purity and source of these materials can affect both performance and cost, with higher-grade materials yielding better durability and efficiency.

-

Labor: Labor costs are influenced by the location of manufacturing. Countries with lower labor costs may provide a more competitive pricing structure, but this could also impact quality. Skilled labor is required for the assembly and maintenance of these complex machines, which can increase the overall cost.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory management. Efficient production processes can help reduce these overhead costs, allowing manufacturers to offer more competitive pricing.

-

Tooling: Investment in tooling and machinery for the production of HPHT diamond machines is substantial. Custom tooling for specific machine configurations can lead to higher initial costs, but it may be necessary for specialized applications.

-

Quality Control (QC): Ensuring the machines meet industry standards involves rigorous testing and certification processes. The costs associated with quality assurance practices can vary significantly based on the manufacturer’s commitment to quality and certification levels.

-

Logistics: Transportation costs, including shipping and customs, can significantly influence the total cost of ownership. Buyers should consider the implications of shipping methods and delivery timelines, especially for international orders.

-

Margin: Suppliers typically add a margin to cover their risks and operational costs. This margin can vary based on market demand, competition, and the supplier’s reputation.

What Influences the Pricing of HPHT Diamond Machines?

-

Volume and Minimum Order Quantity (MOQ): Pricing often becomes more favorable with larger orders. Manufacturers may offer discounts for bulk purchases, making it advantageous for buyers planning to invest in multiple machines.

-

Specifications and Customization: Custom machines designed to meet specific requirements can lead to increased costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Machines built with higher-quality materials and those that have been certified by recognized industry standards can command higher prices. Buyers should assess whether these certifications are essential for their operations.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established manufacturers with a proven track record may charge more, but they often provide better support and warranty terms.

-

Incoterms: Understanding the terms of shipping, insurance, and delivery responsibilities can affect the final cost. Negotiating favorable Incoterms can lead to cost savings and risk mitigation.

What Tips Should Buyers Consider for Cost-Efficiency?

-

Negotiation: Engage in negotiations to explore price reductions, especially for bulk purchases. Leverage quotes from multiple suppliers to create competitive pressure.

-

Total Cost of Ownership: Consider not just the purchase price but also maintenance costs, energy consumption, and potential downtime. A more expensive machine may offer better long-term value.

-

Pricing Nuances for International Buyers: Factor in currency fluctuations, import taxes, and tariffs when calculating the overall cost. Understanding local regulations can prevent unexpected expenses.

-

Research and Due Diligence: Evaluate suppliers based on reviews, case studies, and their service offerings. A supplier with a strong customer support system can save costs related to training and machine maintenance.

Disclaimer on Pricing

Prices for HPHT diamond machines can fluctuate based on market conditions, material costs, and supplier pricing strategies. The figures mentioned in this analysis are indicative and should be verified with the respective suppliers for accurate and current pricing.

Alternatives Analysis: Comparing hpht diamond machine With Other Solutions

Understanding Alternatives to HPHT Diamond Machines

When evaluating the production of lab-grown diamonds, particularly in the context of B2B purchasing, it’s essential to consider the various technologies available. While HPHT (High Pressure High Temperature) machines are popular for their efficiency in creating high-quality synthetic diamonds, other methods also exist that may better align with specific business needs, budgets, and operational capabilities. This analysis will provide a comparative overview of HPHT diamond machines against two viable alternatives: CVD (Chemical Vapor Deposition) machines and traditional natural diamond mining.

| Comparison Aspect | HPHT Diamond Machine | CVD Diamond Machine | Traditional Natural Diamond Mining |

|---|---|---|---|

| Performance | High-quality single-crystal diamonds; fast production cycles. | Produces high-quality diamonds; slower growth rate. | Variable quality; dependent on geological factors. |

| Cost | Generally high initial investment (e.g., $200,000+). | Moderate to high; depends on scale and technology. | High operational costs; variable based on location and mining conditions. |

| Ease of Implementation | Requires specialized knowledge for setup and operation. | More straightforward with modern automation; training still needed. | Complex logistics and environmental regulations; not feasible for all businesses. |

| Maintenance | Requires regular servicing; skilled technicians needed. | Generally low maintenance due to automated systems. | High maintenance; equipment wear and environmental challenges. |

| Best Use Case | Ideal for businesses focusing on high clarity and color diamonds. | Best for producing larger volumes of diamonds with varying characteristics. | Suitable for companies in established mining regions with sustainable practices. |

Pros and Cons of Each Alternative

CVD Diamond Machines

CVD technology offers a method of producing synthetic diamonds that is gaining traction due to its relatively lower operational costs and ability to create diamonds in various sizes and qualities. One of the main advantages of CVD is its capacity for automated operation, which can significantly reduce labor costs and human error. However, the process tends to be slower than HPHT, resulting in longer production cycles, which may not suit businesses needing rapid output.

Traditional Natural Diamond Mining

For companies focused on the natural diamond market, traditional mining remains a viable option. While this method can yield high-quality diamonds, it is fraught with challenges, including fluctuating costs, environmental concerns, and regulatory hurdles. Mining operations often require significant capital investment, and the quality of diamonds can be inconsistent due to geological variations. Moreover, the impact on local communities and ecosystems is a critical consideration for ethical sourcing.

Choosing the Right Solution for Your Business

Selecting the appropriate diamond production method is crucial for B2B buyers, as each option presents distinct advantages and challenges. Businesses should evaluate their specific needs, such as production volume, desired diamond quality, initial investment capacity, and long-term sustainability goals. For instance, if producing high-quality, single-crystal diamonds is paramount, an HPHT machine may be the best choice. Conversely, if operational efficiency and lower costs are priorities, CVD technology may present a more suitable alternative. Ultimately, understanding these differences will empower buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for hpht diamond machine

What Are the Key Technical Properties of HPHT Diamond Machines?

When considering the purchase of HPHT diamond machines, understanding their technical specifications is crucial for making informed decisions. Here are some essential properties to evaluate:

-

Pressure Capacity (MPa)

The pressure capacity, often measured in megapascals (MPa), indicates the maximum pressure the machine can generate. For instance, many models have a design capacity ranging from 102 to 105 MPa. High pressure is vital for the synthesis of diamonds, as it replicates the natural conditions under which diamonds form. A higher pressure capacity can lead to improved quality and larger diamond yields, making it a critical factor for production efficiency. -

Temperature Control (°C)

Maintaining precise temperature control is essential for diamond growth. HPHT machines typically operate at temperatures exceeding 1500°C. The ability to regulate temperature accurately impacts the diamond’s clarity and color. For B2B buyers, selecting a machine with advanced temperature control systems can ensure consistent quality and reduce the risk of defects. -

Cycle Time (Hours)

The cycle time refers to the duration required for one production cycle, from the initiation of diamond growth to completion. Machines with shorter cycle times (often several hours to a few days) can significantly enhance productivity. For manufacturers, minimizing cycle time is crucial for maximizing output and meeting market demand. -

Automation Features

Many modern HPHT machines come equipped with automation capabilities, allowing for easier operation and monitoring. Features such as software control for pressure and temperature adjustments enable users to optimize the production process. Automation not only reduces the likelihood of human error but also allows for more efficient training of personnel, which is particularly important for companies scaling up operations. -

Warranty and Support

A robust warranty (often up to five years) and post-purchase support are critical for ensuring machine longevity and operational reliability. Buyers should evaluate the manufacturer’s commitment to service and support, as this can impact maintenance costs and downtime. -

Material Grade and Build Quality

The material grade of the machine components, including the type of steel used and any coatings, affects the durability and performance of the HPHT press. High-quality materials can withstand extreme conditions, leading to longer machine life and reduced operational costs.

What Are Common Trade Terms in the HPHT Diamond Machine Industry?

Understanding industry-specific terminology is essential for effective communication and negotiation in the B2B market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, partnering with an OEM can ensure access to high-quality machines tailored to specific production needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for buyers, as it can affect inventory management and cash flow. Negotiating favorable MOQs can lead to cost savings, especially for startups or smaller operations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. This process allows buyers to compare options and ensure they are getting competitive pricing and terms. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms is essential for understanding shipping logistics, costs, and liability during the transportation of machines. -

Lead Time

Lead time refers to the time between placing an order and receiving the product. In the context of HPHT machines, shorter lead times are preferable, as they allow businesses to respond quickly to market demands. -

End-of-Line Testing

This refers to the quality assurance process conducted on machines before they are shipped to buyers. Ensuring that the machine has passed end-of-line testing can provide peace of mind regarding its performance and reliability.

By grasping these technical properties and trade terms, B2B buyers can make more informed purchasing decisions, ultimately leading to better operational efficiency and product quality in their diamond production processes.

Navigating Market Dynamics and Sourcing Trends in the hpht diamond machine Sector

What Are the Current Market Dynamics and Key Trends in the HPHT Diamond Machine Sector?

The HPHT diamond machine sector is witnessing significant growth, driven by increasing demand for lab-grown diamonds across various industries, particularly in jewelry and industrial applications. As sustainability becomes a focal point for consumers, B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking towards ethical sourcing options. This shift is compounded by advancements in technology that enhance the efficiency and quality of HPHT diamond production.

Emerging trends include the adoption of automation and intuitive control systems in HPHT machines, which simplify operations and reduce labor costs. Additionally, customization has become a key factor for international buyers, as manufacturers offer tailored solutions that align with specific production requirements. The market is also seeing a rise in competitive pricing, particularly from manufacturers in Asia, which is appealing to cost-sensitive markets in regions like Nigeria and Vietnam.

Furthermore, the global supply chain for HPHT machines is evolving, with manufacturers expanding their presence through e-commerce platforms, making it easier for international buyers to source equipment. This accessibility is reshaping traditional procurement methods and encouraging small to medium enterprises to enter the diamond production space, thereby diversifying the market landscape.

How Is Sustainability Influencing the Sourcing of HPHT Diamond Machines?

Sustainability is a crucial consideration for B2B buyers in the HPHT diamond machine sector. The environmental impact of traditional diamond mining has led to a growing preference for lab-grown diamonds, which are produced in a controlled environment with significantly lower carbon footprints. As a result, buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices.

Ethical supply chains are becoming essential, with buyers seeking manufacturers that adhere to green certifications and use environmentally friendly materials in their production processes. This trend is particularly prevalent among European and Middle Eastern buyers, who are more inclined to invest in technology that supports sustainable practices.

Moreover, transparency in sourcing is critical. Buyers are encouraged to engage with suppliers who provide clear information about their production processes, including the sourcing of raw materials and energy consumption. By aligning with manufacturers that prioritize sustainability, international buyers can not only meet regulatory standards but also appeal to a growing consumer base that values ethical consumption.

What Is the Historical Context of HPHT Diamond Machine Development for B2B Buyers?

The development of HPHT diamond machines has evolved significantly since the mid-20th century, paralleling advancements in diamond synthesis technology. Initially, HPHT methods were limited and primarily used for industrial applications. However, the commercialization of lab-grown diamonds in the 2000s catalyzed a transformation in the sector.

The technology has advanced to enable the production of gem-quality diamonds that are chemically and structurally identical to their mined counterparts. This evolution has opened new markets and opportunities for B2B buyers, who can now access high-quality diamond production at a lower cost and with reduced environmental impact.

As the market continues to mature, understanding the historical context of HPHT technology helps buyers appreciate the innovations that have shaped the industry. This knowledge can inform purchasing decisions, ensuring that B2B buyers are equipped with the insights necessary to navigate the complexities of sourcing HPHT diamond machines in today’s dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of hpht diamond machine

-

How do I solve issues related to HPHT diamond machine maintenance?

To effectively address maintenance issues with HPHT diamond machines, establish a routine inspection and maintenance schedule based on the manufacturer’s guidelines. Regularly check critical components such as the hydraulic system, temperature controls, and pressure gauges for optimal performance. Additionally, invest in training for your operational staff to ensure they are familiar with troubleshooting common problems. If complex issues arise, maintain a direct line of communication with the manufacturer or supplier for technical support and replacement parts. -

What is the best HPHT diamond machine for small-scale production?

For small-scale production, models like the UDS650 or UDS750 are typically recommended due to their compact size and efficient operation. These machines offer a balance between performance and footprint, making them ideal for businesses with limited space. Evaluate your specific production needs, including the desired output quality and type of diamonds, to select the best machine. Additionally, consider the level of automation and ease of operation, which can enhance productivity and reduce the learning curve for your team. -

What customization options are available when purchasing an HPHT diamond machine?

Many manufacturers offer customizable HPHT diamond machines tailored to specific production requirements. Customizations may include modifications in size, capacity, heating systems, and control interfaces. When discussing customization with suppliers, clearly communicate your production goals and any special features you require. This ensures that the machine aligns with your operational needs and enhances overall efficiency. Additionally, inquire about potential lead times and costs associated with customization. -

What are the typical minimum order quantities (MOQ) for HPHT diamond machines?

Minimum order quantities (MOQ) for HPHT diamond machines can vary significantly between manufacturers. Generally, MOQs can range from one unit to several machines, depending on the supplier’s production capacity and business model. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Some manufacturers may offer flexible MOQs for first-time buyers or bulk orders, which can be beneficial if you’re looking to expand your operations gradually. -

What payment terms should I expect when sourcing HPHT diamond machines internationally?

Payment terms for international purchases of HPHT diamond machines typically include options such as T/T (telegraphic transfer), letter of credit, or trade assurance. Many suppliers may require a deposit upfront, with the balance due prior to shipment or upon delivery. It’s essential to clarify payment schedules and any associated fees during negotiations. Additionally, consider using escrow services for larger transactions to ensure security for both parties involved. -

How can I ensure quality assurance (QA) when sourcing HPHT diamond machines?

To ensure quality assurance when sourcing HPHT diamond machines, conduct thorough research on potential suppliers, including checking their certifications, customer reviews, and case studies. Request detailed specifications and performance data for the machines you are considering. Additionally, inquire about the manufacturer’s quality control processes, warranty terms, and after-sales support. If possible, arrange for a factory visit or seek third-party inspections to verify the quality of the machines before finalizing your purchase. -

What logistics considerations should I keep in mind when importing HPHT diamond machines?

When importing HPHT diamond machines, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling heavy machinery to ensure safe transport. Be aware of any import duties or taxes applicable in your country, as these can significantly impact your overall costs. Additionally, establish clear communication with your supplier regarding packaging requirements to prevent damage during transit. -

How can I vet suppliers of HPHT diamond machines effectively?

Vetting suppliers of HPHT diamond machines involves assessing their reputation, experience, and reliability. Start by checking online reviews, testimonials, and industry certifications. Request references from previous clients to gauge their satisfaction with the supplier’s products and services. Additionally, evaluate the supplier’s production capabilities, customer service responsiveness, and willingness to provide technical support. Attending industry trade shows can also provide valuable insights into potential suppliers and allow you to establish personal connections.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Hpht Diamond Machine Manufacturers & Suppliers List

1. Labrilliante – HPHT Cubic Press Machine

Domain: labrilliante.com

Registered: 2017 (8 years)

Introduction: HPHT Cubic Press Machine Manufacturer: Labrilliante. Product Type: Diamond Making Machine. Contact: +1 551 321 8771.

2. Huanghe Whirlwind – Forging Cubic Synthetic Diamond Making Machine

Domain: huanghewhirlwind.com

Registered: 2004 (21 years)

Introduction: {‘product_name’: ‘Forging Cubic Synthetic Diamond Making Machine’, ‘manufacturer’: ‘Henan Huanghe Whirlwind Co., Ltd’, ‘popular_models’: [‘UDS650’, ‘UDS850’], ‘features’: [{‘description’: ‘Full-forged cylinder beam with long life and five-year warranty’}, {‘description’: ‘Compact overall size with large internal space for easy installation and operation’}, {‘description’: ‘Ultra-high pressure prel…

3. HPHT Machines – Essential Equipment for Lab-Grown Diamonds

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: HPHT machines for lab-grown diamonds cost around $200-450k. Hydrogen generator costs $22k, coring machine costs $120k. Monthly electricity cost is $1100 for two runs. Seeds cost $150-190 each, and cutting costs are $65 per carat. It takes about 3 weeks to grow 1 carat.

4. Henan Huanghe Whirlwind – HPHT Diamond Machine

Domain: idexonline.com

Registered: 1999 (26 years)

Introduction: A lab grown diamond machine priced at $200,000, manufactured by Henan Huanghe Whirlwind International. The machine weighs 44 tons and utilizes HPHT (high pressure high temperature) technology. It requires diamond seed crystals, high-quality graphite, iron or cobalt catalysts, and precise temperature and pressure control systems. A discount price of $190,000 is available for purchases of 10 or more…

5. Ars Technica – Diamond-Making Machines

Domain: arstechnica.com

Registered: 1998 (27 years)

Introduction: You can buy a diamond-making machine for $200,000 on Alibaba. There are two primary methods for creating lab-grown diamonds: the HPHT (High-Pressure, High-Temperature) process and Chemical Vapor Deposition (CVD). A CVD machine is priced around $450,000. The HPHT Cubic Press Synthetic Diamond Making Machine is made by Henan Huanghe Whirlwind Co., Ltd. Operating these machines requires expertise, hi…

6. Qiming – HPHT Cubic Press

Domain: qmdiamond.com

Registered: 2011 (14 years)

Introduction: Product Name: HPHT Cubic Press

Manufacturer: Luoyang Qiming Superhard Co., Ltd.

Cylinder Diameter Range: 420mm to 1000mm

Maximum Thrust: 94.2 MN

Pressure Accuracy: 0.01 MPa

Diamond Size: 0.2-20 Carat

Diamond Color Levels: D, E, F

Structure: Simple Structure

Additional Features: Customizable factory layout plans, equipment operation training, installation and maintenance services, 24-hour customer …

7. With Clarity – HPHT Diamonds

Domain: withclarity.com

Registered: 2006 (19 years)

Introduction: HPHT diamonds are real diamonds created using the High Pressure High Temperature process, which allows for the rapid formation of diamonds in a controlled environment. This process can also enhance the color of existing diamonds, making them whiter. HPHT diamonds share the same chemical and physical properties as naturally grown diamonds, ensuring durability and beauty. The process begins with a s…

8. SPI – HPHT Diamond Manufacturing Machine

Domain: indiamart.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Hpht Diamond Manufacturing Machine”, “Technique”: “HPHT Treated High Pressure High Temperature”, “Size”: “5 Crt”, “Weight”: “42 ton”, “Brand”: “SPI”, “Usage/Application”: “Jewellery”, “Availability”: “In Stock”, “Location”: “Ahmedabad”, “Supplier Name”: “Shree Path Impex”, “GST Number”: “24AFMPG7562G1ZC”, “Legal Status”: “Proprietorship”, “Nature of Business”: “Wholesaler/Distrib…

Strategic Sourcing Conclusion and Outlook for hpht diamond machine

In conclusion, the strategic sourcing of HPHT diamond machines offers significant advantages for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By investing in advanced technologies like HPHT, businesses can produce high-quality lab-grown diamonds that meet the increasing global demand for ethical and sustainable alternatives to natural diamonds. The competitive pricing and customizable options available from manufacturers worldwide ensure that companies can find solutions tailored to their specific needs.

As the market for lab-grown diamonds is projected to grow exponentially in the coming years, now is the opportune time for buyers to explore strategic partnerships with reputable suppliers. Engaging with manufacturers who provide comprehensive support, from installation to training, can enhance operational efficiency and product quality.

For businesses poised to capitalize on this trend, leveraging strategic sourcing not only secures a reliable supply chain but also positions them as leaders in the evolving diamond industry. We encourage prospective buyers to actively seek out partnerships with experienced manufacturers and take the next step toward enhancing their production capabilities. The future of diamonds is bright—embrace the opportunity today.