Unlocking Value: A Strategic Analysis of the Electric Stun Gloves Market

Introduction: Navigating the Global Market for electric stun gloves

In an increasingly complex global landscape, sourcing effective and reliable electric stun gloves poses significant challenges for security and law enforcement agencies. These innovative devices, designed to provide non-lethal immobilization, are essential for professionals in high-stakes environments, yet navigating the myriad options available can be overwhelming. This comprehensive guide addresses key aspects of electric stun gloves, including their various types, applications across different sectors, and vital supplier vetting processes, ensuring that international B2B buyers can make informed decisions tailored to their specific needs.

Understanding the unique requirements of diverse markets—particularly in regions like Africa, South America, the Middle East, and Europe—is crucial for successful procurement. For instance, buyers from countries such as Nigeria and Brazil must consider local regulations, operational climates, and the specific challenges faced by their security forces. This guide empowers stakeholders by providing insights into cost structures, performance specifications, and the latest technological advancements in electric stun gloves. By equipping buyers with the knowledge to evaluate suppliers and products critically, we facilitate the selection of tools that enhance safety and effectiveness in law enforcement and security operations.

Understanding electric stun gloves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conductive Distraction Glove | Utilizes low-voltage pulses for quick immobilization; often integrates with existing law enforcement tools. | Law enforcement, corrections, military | Pros: Non-lethal, enhances existing protocols. Cons: Requires training for effective use. |

| Electric Taser Glove | Features neuro-muscular disruption technology; delivers rapid pulses for immobilization. | Riot control, event security | Pros: Immediate incapacitation, versatile. Cons: Limited effectiveness on resistant individuals. |

| High-Performance Defense Glove | Incorporates unique activation features for issuing warnings; designed for professional use only. | Security personnel, personal defense | Pros: Innovative safety features, robust design. Cons: Restricted access for non-professionals. |

| Carbon Fiber Reinforced Glove | Blends electric shock capability with physical protection; protects against blunt force attacks. | VIP protection, mental health interventions | Pros: Dual functionality, durable materials. Cons: Heavier, may require acclimatization for users. |

| Smart Touch Electric Glove | Equipped with smart features such as event recording and standby mode for enhanced user control. | Security training, civilian defense | Pros: Advanced technology, user-friendly. Cons: Higher cost due to added features. |

What Are the Key Characteristics of Conductive Distraction Gloves?

Conductive distraction gloves are designed primarily for law enforcement and military applications. They deliver low-voltage electric pulses to incapacitate a target without causing permanent harm. These gloves integrate seamlessly with existing equipment, enhancing the effectiveness of standard operating procedures. B2B buyers should consider the ease of training and compatibility with current tactics when purchasing.

How Do Electric Taser Gloves Function in Real-World Scenarios?

Electric taser gloves employ neuro-muscular disruption technology to deliver rapid electric pulses, effectively immobilizing assailants within seconds. They are ideal for riot control and event security, providing a non-lethal means of subduing aggressive individuals. Buyers should evaluate the gloves’ effectiveness against various threat levels and ensure that personnel are adequately trained for optimal use.

What Sets High-Performance Defense Gloves Apart?

High-performance defense gloves are specifically tailored for security professionals and incorporate unique activation features that allow for issuing warnings during interventions. This added functionality makes them a valuable asset for security personnel. B2B buyers should ensure that their staff possesses the necessary credentials to utilize these gloves, as they are often restricted to certified professionals.

Why Are Carbon Fiber Reinforced Gloves Preferred for Protection?

These gloves combine electric shock capabilities with physical protection, featuring carbon fiber reinforcements that guard against blunt force attacks. They are particularly useful in VIP protection and mental health interventions where both defense and incapacitation are required. Buyers should weigh the durability and weight of the gloves, as the added protection may increase bulk.

What Advantages Do Smart Touch Electric Gloves Offer?

Smart touch electric gloves incorporate advanced features such as event recording and standby modes, making them user-friendly and efficient in high-stress situations. They are suitable for security training and civilian defense applications. Buyers should consider the investment in technology, as these gloves typically come at a higher price point but offer enhanced operational capabilities.

Key Industrial Applications of electric stun gloves

| Industry/Sector | Specific Application of electric stun gloves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Suspect apprehension and riot control | Provides law enforcement with a non-lethal means to subdue suspects quickly and safely, reducing the risk of permanent injury. | Compliance with local regulations and standards, durability, and effectiveness in real-world scenarios. |

| Security Services | VIP protection and event security | Enhances personal safety for security personnel, allowing them to manage aggressive individuals without lethal force. | Training requirements, ease of use, and integration with existing security protocols. |

| Corrections Facilities | Inmate management and de-escalation in prisons | Reduces violent confrontations and enhances safety for staff and inmates, improving overall facility management. | Robust design for frequent use, battery life, and maintenance support. |

| Animal Control | Safe handling of aggressive animals | Allows animal control officers to subdue dangerous animals without causing lasting harm, ensuring safety for both the officer and the animal. | Effectiveness on various animal species, weight, and ease of transport. |

| Civilian Self-Defense | Personal protection for civilians in high-risk environments | Provides individuals with a means of self-defense that is effective yet non-lethal, promoting personal safety. | Availability in different sizes, ease of operation, and battery reliability. |

How Are Electric Stun Gloves Utilized in Law Enforcement?

In law enforcement, electric stun gloves serve as a critical tool for suspect apprehension and riot control. These gloves allow officers to immobilize suspects quickly and effectively, minimizing the risk of injury to both the officer and the suspect. In high-stress situations, the ability to deploy a non-lethal option enhances officer safety and reduces liability. International buyers must consider compliance with local laws regarding the use of such devices, as well as the gloves’ durability and effectiveness in various environmental conditions.

What Role Do Electric Stun Gloves Play in Security Services?

Security services utilize electric stun gloves for VIP protection and event security, providing personnel with a non-lethal means to manage aggressive individuals. These gloves enhance the safety of security staff, allowing for quick responses to threats without resorting to lethal force. Buyers in this sector should focus on the gloves’ ergonomic design, ease of use, and the necessity of training personnel to ensure effective deployment during high-stakes events.

How Do Electric Stun Gloves Improve Corrections Facility Operations?

In corrections facilities, electric stun gloves are employed for inmate management and de-escalation. They help reduce violent confrontations, enhancing safety for both staff and inmates. This non-lethal option allows corrections officers to maintain order without escalating situations into potentially harmful encounters. For international buyers, sourcing considerations include the gloves’ robustness for frequent use, battery life, and the availability of maintenance support to ensure continuous operation.

Why Are Electric Stun Gloves Important for Animal Control?

Electric stun gloves are essential for animal control officers tasked with handling aggressive animals safely. These gloves allow officers to subdue dangerous animals without causing lasting harm, ensuring the safety of both the officer and the animal involved. Buyers in this field must assess the gloves’ effectiveness on various animal species, their weight for ease of transport, and any special features that enhance usability in the field.

How Can Civilians Benefit from Electric Stun Gloves for Self-Defense?

For civilians, electric stun gloves offer a practical solution for personal protection in high-risk environments. These gloves empower individuals to defend themselves effectively while minimizing the risk of causing permanent harm to an assailant. When sourcing these products, buyers should look for options available in different sizes, ease of operation, and reliable battery performance to ensure they are prepared for any potential threats.

3 Common User Pain Points for ‘electric stun gloves’ & Their Solutions

Scenario 1: Ensuring Effective Training for Law Enforcement Personnel

The Problem: A significant concern for B2B buyers in the security and law enforcement sectors is the effective training of personnel on using electric stun gloves. Many organizations find that their officers are not adequately trained in the operational protocols of these devices, leading to improper usage in high-stress situations. This not only jeopardizes the safety of both officers and civilians but also poses legal risks and potential liability for the organization.

The Solution: To address this training gap, organizations should invest in comprehensive training programs that include simulations and hands-on experience with electric stun gloves. Collaborating with manufacturers to develop customized training sessions can ensure that personnel are familiar with the specific models they will be using. Additionally, organizations should implement a structured refresher course schedule to keep skills sharp and knowledge current. Emphasizing real-life scenario training will prepare officers to respond effectively, minimizing risks and enhancing operational readiness.

Scenario 2: Balancing Safety and Compliance with Local Regulations

The Problem: B2B buyers often struggle with navigating the complex landscape of regulations surrounding the use of electric stun gloves. Different regions may have varying laws regarding the use of non-lethal weapons, which can lead to confusion and potential legal challenges for organizations operating in multiple jurisdictions. This is particularly critical in regions like Africa and the Middle East, where local laws can be stringent and enforcement varies widely.

The Solution: To ensure compliance, buyers should conduct thorough research into local laws governing the use of electric stun gloves in each operational area. Partnering with legal experts who specialize in security and compliance can provide clarity and guidance. Additionally, buyers should prioritize sourcing stun gloves from manufacturers that offer clear documentation on compliance with international standards and local regulations. Regularly updating training and operational protocols in accordance with evolving legal landscapes will further safeguard organizations against potential liabilities.

Scenario 3: Addressing Maintenance and Reliability Concerns

The Problem: Another common pain point for B2B buyers is the maintenance and reliability of electric stun gloves. Many organizations report issues with battery life, device performance, and the durability of materials, which can undermine confidence in the product’s effectiveness during critical situations. This can lead to costly downtimes and the need for frequent replacements, impacting budget and operational efficiency.

The Solution: To mitigate these concerns, organizations should establish a comprehensive maintenance schedule that includes regular inspections and testing of electric stun gloves. Collaborating with manufacturers for ongoing support and maintenance services can help ensure devices remain in optimal condition. Buyers should also seek out models with proven durability, robust battery life, and user-friendly maintenance features. Investing in gloves with long-lasting batteries and easy-to-clean materials will enhance reliability and reduce the total cost of ownership, ensuring that personnel always have access to effective tools when needed.

Strategic Material Selection Guide for electric stun gloves

What Are the Most Common Materials Used in Electric Stun Gloves?

Electric stun gloves are designed for non-lethal defense, and the choice of materials significantly impacts their performance, durability, and user safety. Below are analyses of four common materials used in electric stun gloves, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Goat Skin Leather

Key Properties: Goat skin leather is known for its excellent flexibility and comfort. It can withstand temperatures ranging from -20°C to 50°C, making it suitable for various climatic conditions.

Pros & Cons: The primary advantage of goat skin is its durability and resistance to wear and tear, which is crucial for gloves used in high-stress situations. However, it can be more expensive than synthetic alternatives and requires careful maintenance to prevent deterioration over time.

Impact on Application: Goat skin leather provides a good grip and tactile feedback, essential for handling equipment during critical interventions. Its natural properties also offer some level of water resistance.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the leather complies with local regulations regarding animal products. Standards such as ASTM for leather quality may also be relevant.

2. Carbon Fiber Reinforced Materials

Key Properties: Carbon fiber composites are lightweight yet incredibly strong, offering high tensile strength and impact resistance. They can operate effectively within a temperature range of -10°C to 50°C.

Pros & Cons: The main advantage of carbon fiber is its exceptional strength-to-weight ratio, which enhances the glove’s protective features without adding bulk. However, the manufacturing process is complex and can lead to higher costs.

Impact on Application: Carbon fiber enhances the glove’s ability to protect against blunt force while maintaining flexibility, making it suitable for law enforcement and security applications.

Considerations for International Buyers: Buyers should verify that carbon fiber materials meet international safety standards, such as those set by ISO or ASTM, especially in regions with stringent compliance requirements.

3. Synthetic Fabrics (e.g., Polyester Blends)

Key Properties: Synthetic fabrics like polyester are resistant to moisture and abrasion, with operating temperatures typically ranging from -20°C to 50°C. They are also lightweight and flexible.

Pros & Cons: The advantages of synthetic materials include lower cost and ease of production, allowing for mass manufacturing. However, they may not provide the same level of tactile sensitivity or durability as natural materials.

Impact on Application: Synthetic fabrics are particularly useful in gloves designed for lighter applications or where cost-effectiveness is a priority. They can also be treated for enhanced water resistance.

Considerations for International Buyers: Buyers from Europe and the Middle East should ensure that synthetic materials comply with environmental regulations, such as REACH in the EU, which governs chemical safety.

4. Kevlar

Key Properties: Kevlar is renowned for its high strength and cut resistance, with a temperature tolerance of up to 200°C. It provides excellent protection against sharp objects.

Pros & Cons: The key advantage of Kevlar is its ability to offer high levels of protection without compromising flexibility. However, it tends to be more expensive and may require specialized manufacturing techniques.

Impact on Application: Kevlar is particularly beneficial in gloves intended for high-risk environments where sharp objects may be present, such as in law enforcement or security operations.

Considerations for International Buyers: Buyers should be aware of the specific regulations regarding the use of Kevlar in protective equipment, as some countries have stringent import and safety standards.

Summary Table of Material Selection for Electric Stun Gloves

| Material | Typical Use Case for Electric Stun Gloves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Goat Skin Leather | General law enforcement and security | Durable and comfortable | Higher maintenance and cost | High |

| Carbon Fiber Reinforced | Riot control and high-impact scenarios | Lightweight with excellent strength | Complex manufacturing process | High |

| Synthetic Fabrics | Cost-effective, general use | Lower cost and easy to produce | Less tactile sensitivity | Low |

| Kevlar | High-risk environments | High cut resistance | More expensive, specialized manufacturing | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions when sourcing electric stun gloves, considering both performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric stun gloves

What Are the Key Stages in the Manufacturing Process of Electric Stun Gloves?

The manufacturing process of electric stun gloves involves several critical stages that ensure the final product meets both safety and performance standards. Understanding these stages can help B2B buyers evaluate the production capabilities of potential suppliers.

Material Preparation: What Materials Are Used?

The first stage of manufacturing electric stun gloves is material preparation. High-quality gloves typically use a combination of conductive materials, such as conductive textiles and metals, along with durable outer materials like leather or synthetic fibers. For instance, carbon fiber reinforcement is often integrated to provide protection against blunt force, while lithium-ion batteries are selected for their lightweight and efficient power delivery.

This stage also includes sourcing materials from certified suppliers, ensuring that they meet international safety standards. Buyers should inquire about the origin and certifications of these materials to ensure compliance with regulations in their respective markets.

How Are Electric Stun Gloves Formed?

Once materials are prepared, the forming process begins. This involves cutting, shaping, and molding the materials to create the glove’s structure. Advanced techniques like laser cutting are often employed to achieve precise dimensions, ensuring that each glove fits well and allows for full mobility.

Additionally, the conductive surfaces are integrated during this stage. These surfaces are crucial for the glove’s functionality, as they must effectively deliver electric pulses upon contact. Buyers should assess whether suppliers use advanced forming techniques that enhance product quality and performance.

What Does the Assembly Process Entail?

The assembly phase is where the glove components come together. This includes stitching the outer material, attaching the conductive elements, and incorporating electronic components such as switches and batteries. Quality assembly is vital, as improper connections can lead to malfunctions or safety hazards.

During this stage, manufacturers often implement automation technology to enhance precision and efficiency. Buyers should ask potential suppliers about their assembly techniques and whether they use automated systems to minimize human error.

What Are the Finishing Techniques Used in Production?

Finishing processes enhance the aesthetic and functional qualities of the electric stun gloves. This may include applying protective coatings, conducting final inspections, and packaging the gloves for distribution. Finishing techniques are essential for ensuring durability and user comfort, which can significantly impact buyer satisfaction.

Quality control during the finishing phase is crucial. Manufacturers may perform tests to ensure the gloves can withstand various environmental conditions, such as extreme temperatures and humidity. B2B buyers should ensure that suppliers conduct thorough finishing inspections.

What Quality Assurance Measures Are in Place for Electric Stun Gloves?

Quality assurance (QA) is a critical component of the manufacturing process for electric stun gloves, ensuring that products meet safety and performance standards. B2B buyers should be aware of the QA measures implemented by suppliers.

Which International Standards Should B2B Buyers Consider?

Most reputable manufacturers adhere to international quality management standards such as ISO 9001. This certification demonstrates a commitment to maintaining high-quality production processes. Additionally, compliance with industry-specific standards like CE marking (for European markets) or API (American Petroleum Institute) standards can be crucial, especially when selling to sectors like law enforcement and security.

B2B buyers should verify that suppliers hold these certifications and understand the implications of non-compliance in their respective markets.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control occurs at several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial inspection stage evaluates raw materials upon arrival. Suppliers should conduct tests to confirm that materials meet predefined specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, ongoing inspections ensure that any deviations from quality standards are identified and corrected promptly.

-

Final Quality Control (FQC): Before shipping, a comprehensive inspection of the finished product is performed. This includes functional tests to verify that the electric stun gloves operate as intended.

B2B buyers should inquire about the specific QC checkpoints used by suppliers and the methodologies employed for testing.

What Common Testing Methods Are Employed?

Testing methods for electric stun gloves are essential for validating performance and safety. Common methods include:

-

Electrical Testing: Verifying that the gloves deliver the correct voltage and current levels as specified, ensuring user safety.

-

Durability Testing: Subjecting gloves to various environmental conditions to assess their resistance to wear and tear.

-

User Safety Testing: Conducting simulations to ensure that the gloves do not cause permanent harm when used according to guidelines.

B2B buyers should request documentation of testing results and methodologies from suppliers to verify compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control processes of potential suppliers is critical for B2B buyers. Here are several approaches:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards directly.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including test results and compliance certifications. This documentation can help validate the supplier’s claims regarding product quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. This is particularly useful for international buyers who may face challenges in conducting on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential. Each region may have specific regulatory requirements and standards that must be met.

Buyers should be aware of local laws regarding the importation of non-lethal weapons, which can vary significantly. Engaging with local experts or legal advisors can provide clarity on compliance requirements.

Additionally, buyers should consider the logistics of sourcing products from international suppliers, including shipping, customs clearance, and potential delays. Establishing clear communication with suppliers regarding these factors can help mitigate risks and ensure a smooth procurement process.

Conclusion

In summary, the manufacturing processes and quality assurance measures for electric stun gloves are multifaceted and critical for ensuring product efficacy and safety. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, leading to successful partnerships and enhanced operational effectiveness in their respective markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric stun gloves’

In the competitive landscape of law enforcement and security, the procurement of electric stun gloves requires a strategic approach. This guide serves as a comprehensive checklist for B2B buyers looking to source these innovative devices effectively. By following these steps, organizations can ensure they select the right products to enhance safety and operational efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the electric stun gloves meet your operational needs. Consider factors such as voltage levels, pulse duration, and battery life. For example, gloves that deliver a non-lethal, immobilizing shock with a quick activation time (e.g., within 2-3 seconds) are ideal for law enforcement applications.

Step 2: Research Supplier Reputation

Investigate the market to identify reputable suppliers known for quality and reliability. Look for suppliers with a strong track record in the law enforcement sector and positive reviews from other B2B buyers. Utilize platforms like LinkedIn or industry-specific forums to gather insights and feedback.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request detailed company profiles, case studies, and references from buyers in a similar industry or region. Assess their certifications and compliance with international safety standards, as this will impact the gloves’ effectiveness and legality.

Step 4: Assess Product Features and Benefits

Examine the unique features of the electric stun gloves offered by different suppliers. Key aspects to evaluate include:

– Ergonomic Design: Ensure the gloves allow for full mobility while providing adequate protection.

– Safety Mechanisms: Look for features like quick-release mechanisms and smart touch technology that enhance user safety.

Step 5: Inquire About Training and Support

Effective use of electric stun gloves often requires training for personnel. Inquire whether the supplier offers training programs or resources to ensure proper usage. Additionally, confirm if ongoing technical support is available for troubleshooting and maintenance.

Step 6: Review Pricing and Terms of Purchase

Request quotes from multiple suppliers to compare pricing structures and payment terms. Ensure that the costs align with your budget while also considering the total cost of ownership, which includes maintenance and potential replacement parts. Look for bulk purchase discounts or long-term partnership benefits.

Step 7: Understand Import Regulations and Compliance

Before finalizing your purchase, familiarize yourself with the import regulations in your region regarding electric stun gloves. Compliance with local laws is essential to avoid legal issues. Ensure that the supplier provides all necessary documentation to facilitate smooth importation.

By following this structured checklist, B2B buyers can make informed decisions when sourcing electric stun gloves, ensuring that they acquire high-quality products that meet their specific operational requirements. This strategic approach not only enhances safety but also optimizes overall procurement efficiency.

Comprehensive Cost and Pricing Analysis for electric stun gloves Sourcing

What Are the Key Cost Components for Electric Stun Gloves?

When sourcing electric stun gloves, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: High-quality materials such as conductive fabrics, carbon fiber reinforcements, and durable leather are crucial for performance and safety. The choice of materials directly impacts the unit cost, with advanced composites typically commanding higher prices.

-

Labor: Manufacturing electric stun gloves involves skilled labor for assembly and quality control. The labor cost can vary significantly based on the region, with countries offering lower labor costs potentially providing more competitive pricing.

-

Manufacturing Overhead: This encompasses the costs associated with running the manufacturing facility, including utilities, equipment maintenance, and administrative expenses. Efficient production practices can help lower these overhead costs.

-

Tooling: Initial tooling costs for specialized equipment or molds can be substantial but are amortized over larger production runs. Buyers should inquire about tooling costs if they seek custom designs.

-

Quality Control (QC): Ensuring that the gloves meet safety and performance standards requires rigorous testing and quality assurance processes, which can add to the overall cost.

-

Logistics: Shipping, customs duties, and handling fees contribute significantly to the total cost, especially for international buyers. These costs can vary based on shipping methods and distances.

-

Margin: Suppliers typically build a profit margin into their pricing, which varies by manufacturer and market positioning.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of electric stun gloves:

-

Volume/MOQ: Bulk purchasing often leads to reduced unit prices. Buyers should negotiate minimum order quantities (MOQ) to secure better pricing.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO standards) can drive up costs but may enhance safety and reliability. Buyers should weigh the benefits of these features against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The choice of Incoterms can impact logistics costs. Understanding the responsibilities of both parties in the shipping process is crucial for calculating total costs.

How Can Buyers Optimize Costs and Negotiate Effectively?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Engage in open discussions with suppliers about pricing, particularly for larger orders. Leverage competitive quotes from multiple suppliers to strengthen your negotiating position.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, operation, and potential replacements. A lower initial cost may not always equate to better value over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes that can affect the final price. Establishing a good relationship with suppliers who understand these nuances can lead to better pricing arrangements.

What Should Buyers Keep in Mind Regarding Pricing Estimates?

It is essential to approach pricing estimates with caution. While suppliers may provide indicative prices, these can fluctuate based on market conditions, raw material costs, and production capacity. Buyers should request detailed quotes that outline all components of the cost structure to avoid surprises.

By understanding the complexities of cost and pricing in sourcing electric stun gloves, buyers can make well-informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing electric stun gloves With Other Solutions

Understanding Alternatives to Electric Stun Gloves

When evaluating the effectiveness of electric stun gloves for security and law enforcement applications, it’s essential to consider alternative solutions that offer similar benefits. This analysis will compare electric stun gloves with two viable alternatives: traditional stun guns and pepper spray. Each option serves the purpose of immobilizing a threat without causing permanent harm but varies significantly in performance, cost, and implementation.

Comparison Table

| Comparison Aspect | Electric Stun Gloves | Traditional Stun Guns | Pepper Spray |

|---|---|---|---|

| Performance | Instant immobilization; 3-5 seconds | Immediate incapacitation; 5-10 seconds | Temporary blindness; 20-30 minutes effect |

| Cost | Moderate to high ($100-$300) | Moderate ($50-$150) | Low ($10-$30) |

| Ease of Implementation | Requires training; user-friendly | Requires training; straightforward | Minimal training; easy to use |

| Maintenance | Regular battery checks; cleaning required | Battery checks; periodic maintenance | Minimal; check expiration date |

| Best Use Case | Close-quarters situations; crowd control | Confrontations with individuals | Crowd control; personal defense |

Detailed Breakdown of Alternatives

Traditional Stun Guns

Traditional stun guns are handheld devices that deliver an electric shock to incapacitate an assailant. They are typically effective within a range of a few feet and can immobilize a target almost instantly. While they are generally more affordable than electric stun gloves, they require the user to be in close proximity to the threat, which can be risky in volatile situations. The ease of use and lower cost make them an appealing choice for many security personnel; however, they lack the versatility and hand protection that electric stun gloves provide.

Pepper Spray

Pepper spray is a popular non-lethal defense tool that causes temporary blindness and respiratory distress to deter assailants. Its low cost and ease of use make it widely accessible for both professional and civilian applications. However, its effectiveness can be influenced by environmental factors such as wind, and it may not work effectively against individuals under the influence of drugs or alcohol. Additionally, pepper spray does not provide physical protection to the user, making it less suitable for close-quarters scenarios compared to electric stun gloves.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate self-defense tool, B2B buyers must consider the specific contexts in which their personnel will operate. Electric stun gloves offer a unique blend of immobilization and hand protection, making them ideal for close-quarters encounters and crowd control situations. Traditional stun guns and pepper spray, while effective in their own right, come with limitations that may not meet the needs of all scenarios. By evaluating the performance, cost, ease of implementation, and maintenance of each option, buyers can make informed decisions that enhance the safety and effectiveness of their security operations.

Essential Technical Properties and Trade Terminology for electric stun gloves

What Are the Key Technical Properties of Electric Stun Gloves?

When sourcing electric stun gloves for law enforcement, security, or personal protection, it’s crucial to understand specific technical properties that can impact performance and suitability for various applications. Here are some essential specifications:

-

Voltage and Current Ratings

Electric stun gloves typically operate within a voltage range of 210V to 380V, with current ratings usually between 0.7A to 1.5A. Understanding these ratings is vital for ensuring the gloves deliver effective immobilization without causing permanent harm. Buyers must verify that the voltage levels comply with local regulations and safety standards. -

Pulse Duration and Frequency

The pulse duration, often measured in microseconds (μs), is the length of time the electrical current is delivered. For example, a pulse duration of 105-116 μs is common. The frequency, expressed in pulses per second (pps), can range from 29 to 300 pps. These properties affect how quickly and effectively the gloves can incapacitate an assailant, making them essential metrics for decision-makers. -

Material Composition

The materials used in electric stun gloves significantly impact their durability and safety. Common materials include reinforced carbon fiber for impact resistance and high-grade leather for flexibility and comfort. A thorough understanding of material composition helps buyers assess the gloves’ long-term performance and suitability for harsh environments. -

Battery Life and Charge Time

Battery specifications are critical for operational readiness. Many electric stun gloves utilize lithium-ion batteries with a charge time of 2 to 6 hours and an operational duration of 1.5 to 2 hours. Buyers should consider these factors to ensure that the gloves will meet their usage demands without frequent recharging. -

Weight and Ergonomics

The weight of electric stun gloves typically ranges from 260g to 650g per pair. Ergonomic designs enhance usability, allowing for better dexterity and comfort during use. Understanding weight and ergonomic features is essential for ensuring that personnel can use the gloves effectively without fatigue. -

Temperature Range

Operating temperature ranges from -10°C to 50°C are common for electric stun gloves. This specification is crucial for buyers in diverse climates, ensuring that the gloves maintain functionality in extreme conditions.

What Are Common Trade Terms in the Electric Stun Gloves Industry?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some key terms that international B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another company’s brand. Understanding OEM relationships is crucial for buyers looking to source private-label products or collaborate on custom designs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers budget their purchases effectively and avoid overstocking or understocking issues. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is essential for procurement, allowing buyers to compare pricing and terms from different suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for understanding shipping responsibilities, risk transfer, and cost allocation. -

Warranty and Service Agreement

These agreements outline the terms under which a supplier will repair or replace defective products. Understanding warranty terms is crucial for buyers to assess the long-term value and reliability of their investment. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Knowing the lead time helps buyers plan their inventory and operational needs effectively, minimizing disruptions in their supply chain.

By grasping these essential properties and terms, B2B buyers can make informed decisions when sourcing electric stun gloves that align with their operational needs and compliance standards.

Navigating Market Dynamics and Sourcing Trends in the electric stun gloves Sector

What Are the Current Global Drivers Influencing the Electric Stun Gloves Market?

The electric stun gloves market is witnessing significant growth, driven by increasing global concerns over public safety and the rising demand for non-lethal self-defense tools. Law enforcement agencies, security personnel, and private individuals are increasingly turning to electric stun gloves as effective alternatives to traditional weapons. This shift is largely influenced by the need for tools that can incapacitate threats without causing permanent harm, aligning with the growing emphasis on humane policing practices. Emerging markets in Africa, South America, the Middle East, and Europe are particularly receptive to this trend, as they seek innovative solutions to manage civil unrest and personal safety challenges.

Another key trend is the incorporation of advanced technologies such as neuro-muscular disruption and smart features in electric stun gloves. These innovations enhance the effectiveness of the gloves while ensuring user safety, making them appealing to a broader audience. Additionally, the rise of e-commerce has facilitated easier access to these products, allowing international buyers to source electric stun gloves from various manufacturers worldwide. As buyers navigate this evolving market, they should consider the compliance of products with regional regulations, especially in jurisdictions with strict weapon laws.

How Is Sustainability and Ethical Sourcing Shaping the Electric Stun Gloves Sector?

Sustainability and ethical sourcing are becoming increasingly vital in the electric stun gloves sector. Manufacturers are now prioritizing environmentally friendly practices, from sourcing raw materials to the production processes involved. The environmental impact of manufacturing and disposing of these gloves is under scrutiny, leading to a demand for green certifications and sustainable materials. International B2B buyers are encouraged to seek suppliers who utilize recyclable materials and implement eco-friendly production methods, as this not only meets regulatory requirements but also aligns with corporate social responsibility goals.

Furthermore, ethical supply chains are gaining traction among consumers and organizations alike. Buyers are urged to vet suppliers for their labor practices, ensuring that workers involved in the production of electric stun gloves are treated fairly and work under safe conditions. Certifications such as Fair Trade or adherence to international labor standards can serve as indicators of a supplier’s commitment to ethical practices. By prioritizing sustainability and ethical sourcing, B2B buyers can enhance their brand reputation and foster long-term relationships with conscientious suppliers.

What Is the Brief Evolution and History of Electric Stun Gloves?

The evolution of electric stun gloves can be traced back to the broader development of non-lethal defense technologies. Initially, stun devices were primarily handheld units, but the need for more versatile and portable options led to the innovation of wearable technologies. The introduction of electric stun gloves marked a significant advancement, allowing security personnel to maintain dexterity while effectively incapacitating threats. Over the years, these gloves have undergone substantial technological improvements, incorporating features such as rechargeable batteries, enhanced voltage control, and ergonomic designs for better user experience.

Today, electric stun gloves are recognized not only for their effectiveness but also for their role in promoting safer intervention practices across various sectors, including law enforcement, private security, and personal defense. As the market continues to grow, ongoing advancements in technology and materials will likely drive further innovations, making electric stun gloves an essential tool in modern security protocols.

Frequently Asked Questions (FAQs) for B2B Buyers of electric stun gloves

-

How do I determine the appropriate specifications for electric stun gloves for my needs?

To select the right electric stun gloves, assess your operational requirements, such as the intended use—whether for law enforcement, security, or personal defense. Evaluate the voltage, pulse duration, and maximum current specifications to ensure they align with your safety standards. Consider features like battery life, weight, and material for comfort and effectiveness. Consulting with manufacturers about their product capabilities and seeking samples can also help you make an informed decision. -

What is the best electric stun glove for law enforcement applications?

The ideal electric stun glove for law enforcement should combine effective immobilization with user safety. Look for models that deliver a non-lethal voltage (ideally under 380V) and provide a rapid incapacitation time (2-3 seconds). Gloves with carbon fiber reinforcement and ergonomic designs ensure protection against blunt force while allowing full hand mobility. Additionally, features like smart touch technology and event recording can enhance operational effectiveness during interventions. -

How do I verify the credibility of a supplier for electric stun gloves?

To vet a supplier, start by researching their business history, customer reviews, and industry certifications. Request references from previous clients, especially those in similar sectors. Evaluate their compliance with international safety standards and regulations. It’s also beneficial to visit the supplier’s manufacturing facility if possible or request third-party audits to ensure product quality. Engaging in direct communication can help clarify any concerns regarding their operational practices. -

What are the typical minimum order quantities (MOQs) for electric stun gloves?

Minimum order quantities for electric stun gloves vary by supplier and product type, typically ranging from 100 to 500 units. Factors influencing MOQs include customization requirements, production capacity, and material availability. If you are a smaller buyer, consider negotiating with the supplier or looking for manufacturers that cater to smaller orders. Bulk purchases often result in better pricing, but ensure that the supplier can meet your specific needs without compromising quality. -

What payment terms are commonly offered by suppliers of electric stun gloves?

Payment terms for electric stun gloves can vary, but common arrangements include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer net 30 or net 60 terms based on the buyer’s creditworthiness and relationship with the supplier. Always clarify payment methods accepted, such as wire transfer, credit card, or PayPal, and ensure that you have a secure transaction process in place. -

What quality assurance practices should I expect from suppliers?

Reputable suppliers of electric stun gloves should adhere to stringent quality assurance practices, including raw material inspection, in-process quality checks, and final product testing. They should also provide certifications that demonstrate compliance with safety standards, such as ISO or CE markings. Request documentation of their quality control procedures and inquire about their warranty policies to ensure you receive a reliable product. -

How can I ensure timely delivery and logistics for my order of electric stun gloves?

To guarantee timely delivery, discuss logistics and shipping methods with your supplier upfront. Understand the estimated production lead time and confirm shipping timelines, including customs clearance procedures if importing. Working with suppliers who have experience in international logistics can simplify the process. Additionally, consider using freight forwarders to help manage shipping and ensure that all necessary documentation is in order for smooth transit. -

What customization options are available for electric stun gloves?

Many manufacturers offer customization options for electric stun gloves, including branding, color choices, and specific features tailored to operational needs. You can inquire about modifications such as enhanced grip materials, additional safety features, or integrated technology. Discuss your requirements with the supplier during the initial conversations, as customization may affect MOQs and lead times. Always request prototypes to evaluate the effectiveness of any modifications before finalizing your order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Electric Stun Gloves Manufacturers & Suppliers List

1. Hinaray – Electric Taser Glove

Domain: hinaray.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Electric Taser Glove”, “introduction”: “Electric pulse gloves represent a revolutionary advancement in non-lethal defense technology. These innovative devices integrate the immobilizing power of stun guns into wearable glove form, providing law enforcement and security personnel with an effective tool for subduing assailants without causing permanent harm.”, “key_features”: {“ins…

2. Akis® – Police Stun Glove II

Domain: helyss-sports.com

Registered: 2023 (2 years)

Introduction: {“Product Name”: “Police Stun Glove II”, “Manufacturer”: “Akis®”, “Type”: “Electric Defense Glove”, “Target Audience”: “Security and law enforcement professionals”, “Key Features”: {“Non-Lethal Defense Technology”: “High-voltage impulse system delivering 15,000 volts, penetrates up to 5 mm of fabric”, “User Safety”: “Fully insulated to prevent accidental self-electrocution, even in wet conditions”…

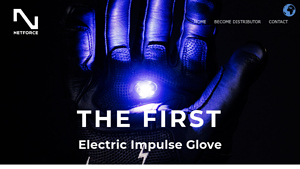

3. Nexstun – E-Stunglove

Domain: nexstun.com

Registered: 2018 (7 years)

Introduction: Nexstun’s E-Stunglove is the first electric impulse glove designed for law enforcement and personal protection. It features an electric impulse mechanism that delivers a maximum discharge of 25 mA for 2 seconds, classified in the AC-3 zone, allowing for temporary immobilization without irreversible damage. The glove is designed to minimize risks in high-risk scenarios, ensuring safety for both the…

4. Unicun – Stun Gun Gloves

Domain: unicun.com

Registered: 2018 (7 years)

Introduction: Product Name: Stun Gun Gloves

Rating: 4.40 out of 5 (based on 5 customer reviews)

Description: Stun Gun Gloves allow you to incapacitate an opponent with a small electric current through a handshake or touch. They are designed to be ergonomic and lightweight, resembling your own skin for comfort.

Features:

– Low-voltage pulse current to incapacitate opponents

– Compact and ergonomic design

– Idea…

Strategic Sourcing Conclusion and Outlook for electric stun gloves

In today’s rapidly evolving landscape of non-lethal defense technology, electric stun gloves stand out as essential tools for law enforcement and security personnel across the globe. These innovative devices not only provide immediate immobilization capabilities but also enhance user safety and operational efficiency. Key features such as low-voltage pulses, ergonomic design, and dual functionality cater to diverse applications, making them indispensable in various sectors including police work, event security, and personal defense.

Strategic sourcing of electric stun gloves is paramount for international buyers, especially in regions like Africa, South America, the Middle East, and Europe. By partnering with reputable manufacturers, organizations can ensure access to high-quality products that comply with safety regulations while meeting their unique operational needs. Investing in these advanced tools not only enhances security measures but also contributes to effective conflict de-escalation strategies.

As you consider your sourcing options, evaluate the latest technologies and features that align with your operational requirements. Embrace the future of security equipment—equip your teams with electric stun gloves that empower them to act decisively and safely. Your proactive approach today will pave the way for enhanced safety and effectiveness in your operations tomorrow.