Everything You Need to Know About Grossiste Mousse Acoustique Sourcing in 2025

Introduction: Navigating the Global Market for grossiste mousse acoustique

In today’s global marketplace, sourcing high-quality grossiste mousse acoustique can be a daunting task for B2B buyers, particularly when navigating the diverse needs of various industries such as construction, entertainment, and manufacturing. As businesses increasingly prioritize sound insulation to enhance productivity and comfort, the demand for effective acoustic solutions continues to rise. This comprehensive guide addresses the critical challenges faced by international buyers from regions like Africa, South America, the Middle East, and Europe, including Germany and Vietnam.

The guide delves into various types of acoustic foam, examining their unique applications—from soundproofing studios and offices to insulating industrial machinery. Additionally, it provides insights into supplier vetting processes, ensuring that buyers can confidently select reliable manufacturers who meet their specific needs. Cost considerations are also discussed, enabling businesses to make informed financial decisions without compromising on quality.

By leveraging this guide, B2B buyers will be empowered to make strategic purchasing decisions that align with their operational goals and budgetary constraints. With an authoritative tone and a focus on actionable insights, this resource serves as a vital tool for companies looking to optimize their acoustic solutions and enhance their overall operational efficiency.

Understanding grossiste mousse acoustique Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mousse Acoustique Alvéolaire | Increased surface area for sound absorption (30-40%) | Studios, theaters, industrial spaces | Pros: High absorption efficiency; Cons: May require specific installation methods. |

| Mousse Acoustique Composite | High density (160-200 Kg/m3), durable, moisture-resistant | Manufacturing facilities, commercial buildings | Pros: Versatile, long-lasting; Cons: Heavier and may be costlier. |

| Mousse Acoustique Mélamine | Lightweight, non-flammable, excellent sound absorption | Public venues, schools, offices | Pros: Safe for public use; Cons: Less effective in very high-frequency noise environments. |

| Panneaux Acoustiques Suspendus | Decorative panels that reduce reverberation | Restaurants, conference rooms, open offices | Pros: Aesthetic appeal; Cons: Installation may require professional assistance. |

| Sous-couche Acoustique | Designed to isolate impact noise from floors | Residential buildings, multi-story offices | Pros: Effective for floor noise reduction; Cons: Installation can be complex. |

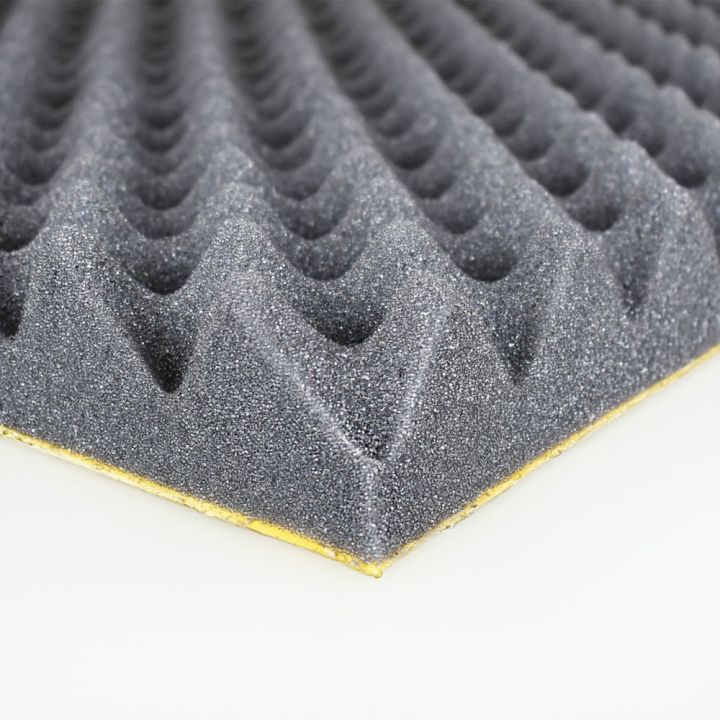

What Are the Key Characteristics of Mousse Acoustique Alvéolaire?

Mousse acoustique alvéolaire, often referred to as “egg crate” foam, is distinguished by its unique surface structure, which significantly enhances sound absorption capabilities. With an absorption efficiency of 30-40%, it is ideal for environments where sound quality is paramount, such as recording studios and theaters. B2B buyers should consider the specific installation requirements and the need for proper mounting to maximize effectiveness.

How Does Mousse Acoustique Composite Stand Out in the Market?

Mousse acoustique composite is known for its high density and durability, making it suitable for demanding environments like manufacturing facilities and commercial buildings. Its moisture resistance adds to its versatility, allowing it to perform well in various conditions. Buyers should weigh the benefits of its longevity against potential higher costs and installation challenges due to its weight.

What Makes Mousse Acoustique Mélamine a Preferred Choice?

Mousse acoustique mélamine is lightweight and boasts excellent sound absorption properties, making it an excellent choice for public venues like schools and offices. Its non-flammable classification enhances its safety profile in environments with strict fire regulations. However, buyers should be aware that while it effectively absorbs sound, it may not perform as well against very high-frequency noise.

Why Are Panneaux Acoustiques Suspendus Popular in Commercial Spaces?

Panneaux acoustiques suspendus are not only functional but also add an aesthetic element to spaces such as restaurants and conference rooms. These panels help reduce reverberation, improving overall sound quality. B2B buyers should consider the installation complexity and potential need for professional services, which can add to project timelines and budgets.

How Do Sous-couches Acoustiques Benefit Multi-Story Buildings?

Sous-couches acoustiques are specifically designed to mitigate impact noise, making them essential in residential and multi-story office buildings. Their ability to isolate sound between floors enhances occupant comfort. Buyers should evaluate the installation requirements, as these products can be complex to fit, but the long-term noise reduction benefits often justify the investment.

Key Industrial Applications of grossiste mousse acoustique

| Industry/Sector | Specific Application of grossiste mousse acoustique | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Acoustic insulation for walls and ceilings | Enhanced soundproofing, improved tenant satisfaction | Compliance with local building codes and standards |

| Entertainment | Soundproofing for recording studios and theaters | Superior sound quality, reduced noise pollution | Material certifications for fire safety and durability |

| Manufacturing | Machinery noise reduction solutions | Lower operational noise levels, increased worker comfort | Customizable solutions for specific machinery types |

| Education | Noise control in classrooms and libraries | Improved learning environments, increased focus | Eco-friendly materials suitable for schools |

| Hospitality | Acoustic treatment in restaurants and hotels | Enhanced guest experience, reduced noise levels | Aesthetic options that complement interior design |

How is ‘grossiste mousse acoustique’ Utilized in the Construction Industry?

In the construction sector, ‘grossiste mousse acoustique’ is primarily used for acoustic insulation in walls and ceilings. This application helps mitigate sound transmission between rooms and from external sources, addressing issues of noise pollution. For international buyers, particularly in regions like Africa and the Middle East, compliance with local building codes and standards regarding sound insulation is crucial. Selecting high-quality, durable materials ensures longevity and effectiveness, thus enhancing tenant satisfaction and property value.

What Role Does ‘grossiste mousse acoustique’ Play in the Entertainment Sector?

In entertainment venues such as recording studios and theaters, ‘grossiste mousse acoustique’ is essential for soundproofing. The use of acoustic foam helps control sound reflections and echoes, resulting in superior audio quality. B2B buyers in Europe, especially in countries like Germany, must consider materials with certifications for fire safety and durability, as these venues often host large audiences. Investing in effective soundproofing not only improves performance quality but also minimizes noise complaints from nearby residents.

How Does ‘grossiste mousse acoustique’ Benefit the Manufacturing Sector?

Manufacturing facilities often face challenges with machinery noise, which can affect worker comfort and productivity. ‘Grossiste mousse acoustique’ provides effective noise reduction solutions that can be tailored to specific machinery types. International buyers, particularly from South America, should prioritize customizable acoustic solutions that meet their operational needs. By reducing noise levels, companies can enhance workplace comfort, potentially leading to higher employee satisfaction and lower turnover rates.

In What Ways is ‘grossiste mousse acoustique’ Important for Educational Institutions?

In educational settings, such as classrooms and libraries, ‘grossiste mousse acoustique’ is utilized to control noise levels, fostering better learning environments. Acoustic foam helps reduce distractions, allowing students to focus more effectively. For buyers in Africa and the Middle East, sourcing eco-friendly materials is increasingly important, aligning with sustainability goals. Ensuring that these materials are suitable for schools will also enhance the overall educational experience.

How is ‘grossiste mousse acoustique’ Applied in the Hospitality Industry?

In the hospitality sector, ‘grossiste mousse acoustique’ is critical for acoustic treatment in restaurants and hotels. By effectively managing sound levels, businesses can enhance the guest experience and create a more inviting atmosphere. B2B buyers from Europe should consider aesthetic options that complement interior design while ensuring sound absorption. This dual focus on functionality and design can significantly improve customer satisfaction, leading to repeat business and positive reviews.

3 Common User Pain Points for ‘grossiste mousse acoustique’ & Their Solutions

Scenario 1: Navigating Product Quality and Compliance Challenges

The Problem: B2B buyers often face difficulties in ensuring that the acoustic foam they source meets both quality standards and regulatory compliance. This challenge is particularly acute for companies in regions with stringent building codes, such as parts of Europe, where materials must adhere to fire safety and environmental regulations. Buyers may struggle to identify trustworthy suppliers that offer products certified for fire resistance, low emissions, and durability. The risk of procuring subpar materials not only leads to project delays but also potential legal liabilities.

The Solution: To mitigate these risks, buyers should prioritize sourcing from established grossistes mousse acoustique that provide detailed product specifications and compliance certificates. Engaging with suppliers who openly share test results for their products, such as fire ratings and acoustic performance metrics, is crucial. Additionally, buyers can request samples to conduct their own assessments or even perform third-party testing. It is also beneficial to develop a clear checklist of required certifications and compliance standards specific to their region or industry to streamline the evaluation process. Building strong relationships with suppliers who demonstrate transparency and reliability can lead to better product choices and reduced procurement headaches.

Scenario 2: Overcoming Installation and Application Complexities

The Problem: Many B2B buyers encounter significant challenges when it comes to the installation and effective application of acoustic foam products. Whether in industrial settings, concert venues, or office spaces, improper installation can lead to ineffective sound absorption, resulting in ongoing noise issues. Buyers often lack access to professional installers or the necessary technical expertise, leading to frustration and wasted resources.

The Solution: Buyers should seek suppliers that not only provide high-quality acoustic foam but also offer comprehensive installation guides and technical support. This can include detailed documentation, instructional videos, or even on-site assistance from technical representatives. Additionally, investing in training for staff on best practices for foam installation can greatly enhance project outcomes. Consideration of pre-assembled kits, which include all necessary components for installation, can simplify the process. Collaborating with acoustical engineers during the planning phase can also ensure that the chosen products are correctly applied based on the specific acoustical needs of the space.

Scenario 3: Addressing Budget Constraints While Maintaining Quality

The Problem: Budget limitations are a common pain point for B2B buyers, particularly in developing markets where cost pressures are high. Buyers may find themselves torn between sourcing affordable acoustic foam and ensuring that they do not compromise on quality. This dilemma can lead to suboptimal purchasing decisions, where low-cost products fail to deliver the desired acoustic performance, ultimately resulting in higher costs over time due to replacements or ineffective solutions.

The Solution: To navigate budget constraints effectively, buyers should conduct a thorough cost-benefit analysis of different acoustic foam products. This involves not just evaluating the initial purchase price but also considering long-term performance, durability, and potential maintenance costs. Buyers should look for grossistes mousse acoustique that offer a range of products at different price points, allowing them to compare features and benefits. Additionally, exploring bulk purchasing discounts or long-term contracts can provide financial flexibility. Engaging in discussions with suppliers about their value propositions and any potential financing options can also open up avenues for acquiring quality materials without exceeding budget limits.

Strategic Material Selection Guide for grossiste mousse acoustique

When selecting materials for acoustic foam, it is essential to understand the characteristics and applications of various types. This guide analyzes four common materials used in the production of acoustic foam, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Polyurethane Foam in Acoustic Applications?

Polyurethane foam is one of the most widely used materials for acoustic applications. It features a high degree of flexibility and is available in various densities, typically ranging from 25 to 50 kg/m³. Its temperature resistance is generally good, withstanding temperatures from -30°C to 70°C. Polyurethane foam also exhibits excellent sound absorption properties, particularly in the mid to high-frequency ranges.

Pros & Cons: The primary advantage of polyurethane foam is its affordability and versatility. It can be easily molded into different shapes, making it suitable for various applications, including studios, offices, and industrial environments. However, it can degrade over time, especially when exposed to UV light or high humidity, which may limit its durability in certain applications.

Impact on Application: Polyurethane foam is compatible with a wide range of environments, but it may not perform well in high-moisture areas unless treated. Buyers should consider its application in specific environments, such as recording studios or open offices, where sound clarity is paramount.

How Does Melamine Foam Compare as an Acoustic Material?

Melamine foam, known for its lightweight and open-cell structure, provides excellent sound absorption, particularly in high-frequency ranges. It is rated as non-flammable (M1 classification), making it suitable for public spaces and compliance with safety standards. This foam typically has a density of around 30 kg/m³ and can withstand temperatures up to 120°C.

Pros & Cons: One of the key advantages of melamine foam is its fire resistance and superior acoustic properties, making it ideal for applications in theaters, concert halls, and educational institutions. However, its higher cost compared to polyurethane foam can be a disadvantage for budget-conscious projects.

Impact on Application: Melamine foam is particularly effective in environments where fire safety is a concern. International buyers should ensure compliance with local fire safety regulations, which may vary significantly between regions.

What Are the Benefits of Composite Acoustic Foam?

Composite acoustic foam combines different materials, such as polyurethane and soundproofing barriers, to enhance sound absorption and insulation. This material can have a density ranging from 160 to 200 kg/m³, providing robust durability and resistance to moisture and impact.

Pros & Cons: The primary advantage of composite foam is its enhanced performance in soundproofing applications, making it suitable for industrial settings or environments with high noise levels. However, the manufacturing complexity can lead to higher costs and longer lead times.

Impact on Application: Composite foams are particularly effective in environments where both sound absorption and insulation are required, such as manufacturing facilities or large auditoriums. Buyers should consider the specific acoustic requirements of their projects, as well as the material’s compatibility with local regulations.

What Should Buyers Know About Rubber Acoustic Foam?

Rubber acoustic foam is often used in environments where moisture resistance is critical. Typically dense (around 130 kg/m³), it provides excellent sound absorption and is 100% waterproof, making it suitable for outdoor applications or humid environments.

Pros & Cons: The main advantage of rubber foam is its durability and resistance to environmental factors, which makes it ideal for outdoor use. However, it tends to be more expensive than other foam types and may require specialized installation techniques.

Impact on Application: Rubber acoustic foam is particularly effective in settings such as swimming pools, gyms, or outdoor venues. International buyers should be aware of the specific installation requirements and ensure compliance with local building codes.

Summary of Material Selection for Acoustic Foam

| Material | Typical Use Case for grossiste mousse acoustique | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam | Studios, offices, industrial environments | Affordable and versatile | Degrades over time in UV/high humidity | Low |

| Melamine Foam | Theaters, concert halls, educational institutions | Fire-resistant and superior acoustics | Higher cost compared to polyurethane foam | High |

| Composite Acoustic Foam | Industrial settings, auditoriums | Enhanced soundproofing | Higher costs and longer lead times | Medium |

| Rubber Acoustic Foam | Outdoor applications, humid environments | Durable and moisture-resistant | More expensive and requires specialized installation | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, ensuring informed decisions that align with both performance requirements and budget constraints.

In-depth Look: Manufacturing Processes and Quality Assurance for grossiste mousse acoustique

What Are the Key Stages in the Manufacturing Process of Acoustic Foam?

The manufacturing process of acoustic foam typically involves several critical stages that ensure the final product meets the required specifications for sound absorption and insulation. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial step involves sourcing high-quality raw materials, primarily polyurethane or melamine foams. Depending on the desired characteristics, additives may be included to enhance properties such as fire resistance or moisture resistance. The selection of raw materials is crucial, as it directly impacts the acoustic performance and durability of the foam.

-

Forming: In this stage, the prepared materials are processed using techniques such as pouring, molding, or extrusion. For instance, the foam is often poured into molds that shape it into specific designs, such as egg-crate patterns or flat sheets. This process may also involve cutting the foam into various dimensions, which is essential for meeting diverse application needs.

-

Assembly: While acoustic foam typically does not require extensive assembly, some products, like composite panels or specialized kits, may involve layering different types of foam or combining foam with other materials (e.g., plywood or metal). This stage ensures that the final product achieves the desired performance characteristics.

-

Finishing: The finishing stage involves applying surface treatments, such as coatings for enhanced fire resistance or sound absorption. Additionally, products may undergo cutting to specified sizes, packaging, and labeling to ensure they are ready for shipping. Quality control checks are typically integrated into this stage to verify that the products meet defined standards.

Which Quality Control Standards Are Relevant for Acoustic Foam Manufacturers?

Quality control (QC) is paramount in the production of acoustic foam to ensure that products not only meet customer expectations but also comply with international and industry-specific standards. Key standards include:

-

ISO 9001: This international standard outlines criteria for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements. It includes processes for continual improvement and stakeholder satisfaction.

-

CE Marking: For products sold in the European market, compliance with CE marking regulations is essential. This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

-

API Standards: In specific applications, such as industrial noise control, compliance with American Petroleum Institute (API) standards may be required. These standards ensure that products meet rigorous performance criteria essential for high-stakes environments.

What Are the Key Quality Control Checkpoints in Acoustic Foam Production?

To ensure that acoustic foam products meet the required specifications, manufacturers typically implement several quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. Quality control teams verify that the materials meet specified standards, checking for consistency in density, porosity, and any other critical parameters.

-

In-Process Quality Control (IPQC): During the manufacturing process, in-process checks are conducted to monitor critical factors such as temperature, humidity, and curing time. These factors can significantly affect the performance characteristics of the foam.

-

Final Quality Control (FQC): After production, a final inspection is performed to assess the finished products. This includes dimensional checks, visual inspections for defects, and performance testing, such as sound absorption and fire resistance tests.

How Do Acoustic Foam Manufacturers Test Product Quality?

Manufacturers employ various testing methods to ensure that acoustic foam products perform as intended:

-

Sound Absorption Testing: This involves measuring the Noise Reduction Coefficient (NRC) or the Sound Absorption Average (SAA) in a controlled environment to assess how effectively the foam absorbs sound.

-

Flame Resistance Testing: Products are subjected to tests such as the ASTM E84 (Standard Test Method for Surface Burning Characteristics of Building Materials) to evaluate their flame spread and smoke development.

-

Durability Testing: Stress tests may be conducted to evaluate how the foam withstands physical impact, compression, and environmental factors over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of their suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, QC checkpoints, and adherence to standards. This firsthand evaluation can provide insights into the supplier’s commitment to quality.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline testing results, compliance with standards, and any certifications held by the manufacturer. These documents should include data from both internal testing and third-party inspections.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased assessment of product quality. These agencies can verify compliance with international standards and the effectiveness of the manufacturer’s quality control processes.

What Are the Specific Quality Control Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific QC nuances:

-

Regulatory Compliance: Different countries have varying regulations regarding product safety, environmental impact, and labeling. Buyers should ensure that their suppliers are compliant with both local and international regulations to avoid legal issues.

-

Cultural and Market Differences: Understanding market expectations and cultural preferences can influence quality perceptions. Buyers should communicate their specific needs and expectations clearly to suppliers to ensure alignment.

-

Logistical Considerations: Quality control in international shipments involves checking for damage during transit and ensuring that products meet specifications upon arrival. Buyers should establish clear protocols for inspections upon receipt.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing acoustic foam products, ensuring they receive high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘grossiste mousse acoustique’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure acoustic foam (mousse acoustique) from wholesalers. Acoustic foam is essential for noise reduction and soundproofing in various applications, including industrial settings, studios, and public venues. By following these steps, buyers can ensure they select the right suppliers and products that meet their specific needs.

Step 1: Define Your Technical Specifications

Before initiating your search for suppliers, clearly outline your technical requirements. Consider factors such as the type of foam (e.g., polyurethane, melamine), density, fire resistance ratings, and specific applications (e.g., studios, industrial use). This helps in narrowing down suppliers that can meet your exact needs.

- Example Specifications:

- Thickness and density of foam

- Required fire safety standards (e.g., M1 classification)

- Environmental certifications (e.g., recyclable materials)

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential wholesalers of acoustic foam. Look for companies with a strong reputation in the industry and experience in your specific market. Utilize online directories, trade shows, and industry publications to compile a list of candidates.

- Key Considerations:

- Years of operation and customer reviews

- Product range and specialization in acoustic solutions

- Geographic distribution capabilities, especially for international shipping

Step 3: Evaluate Supplier Certifications

Before finalizing your choices, verify that potential suppliers possess the necessary certifications. This includes ISO standards for quality management and relevant safety certifications for their products. Compliance with international standards not only ensures product quality but also mitigates risks associated with non-compliance.

- What to Look For:

- ISO 9001 for quality management

- Fire safety certifications (e.g., EN 13501)

- Environmental impact certifications (e.g., LEED)

Step 4: Request Samples for Testing

Request samples of the acoustic foam products from shortlisted suppliers. Testing samples in your specific environment is crucial to assess their performance in sound absorption and durability. This hands-on evaluation helps in making informed decisions before placing a bulk order.

- Testing Considerations:

- Conduct sound absorption tests in controlled environments

- Evaluate durability and resistance to wear and moisture

- Assess ease of installation and compatibility with existing structures

Step 5: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that the terms are favorable for your budget and timeline, while also considering the total cost of ownership, including shipping and installation.

- Negotiation Tips:

- Discuss volume discounts for larger orders

- Clarify terms for returns or exchanges if products do not meet specifications

- Ensure transparency in pricing to avoid hidden costs

Step 6: Establish a Communication Plan

Effective communication is vital throughout the procurement process. Establish a clear line of communication with your chosen supplier to address any questions or issues that may arise. Regular updates on order status and delivery timelines can prevent misunderstandings.

- Communication Strategies:

- Designate a point of contact for both parties

- Schedule regular check-ins during production and shipping phases

- Utilize project management tools for transparent tracking

Step 7: Assess Post-Purchase Support

After the purchase, evaluate the level of post-purchase support offered by the supplier. This includes installation assistance, warranty options, and customer service responsiveness. Strong support can enhance your overall experience and help resolve any issues that may occur.

- Support Aspects to Consider:

- Availability of technical support for installation

- Warranty terms and conditions

- Feedback mechanisms for ongoing supplier relationship management

By following this checklist, B2B buyers can navigate the complexities of sourcing acoustic foam effectively and ensure a successful procurement process.

Comprehensive Cost and Pricing Analysis for grossiste mousse acoustique Sourcing

Analyzing the cost structure and pricing for sourcing ‘grossiste mousse acoustique’ reveals several critical components and influencing factors that international B2B buyers should consider. Understanding these elements can lead to better negotiation outcomes and cost efficiency.

What Are the Key Cost Components in Mousse Acoustique Sourcing?

The cost structure for acoustic foam products typically includes several key components:

-

Materials: The choice of materials significantly impacts pricing. Common options include polyurethane, melamine, and composite foams, each varying in cost based on density and acoustic properties. Higher density materials often yield better performance but at a higher cost.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with lower labor costs may offer more competitive pricing, but this can sometimes lead to variability in product quality.

-

Manufacturing Overhead: This encompasses fixed costs related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, potentially lowering prices for buyers.

-

Tooling: The initial setup costs for molds and tools can be substantial, particularly for custom designs. Buyers should be aware that custom tooling can result in higher upfront costs but may lead to better long-term pricing for large orders.

-

Quality Control (QC): Ensuring product quality involves additional costs. Manufacturers that adhere to stringent QC processes may charge more, but this investment often results in lower returns on defective products.

-

Logistics: Shipping costs, including freight and insurance, can significantly affect total pricing. Buyers should consider the logistics involved in importing products, especially when sourcing from overseas suppliers.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the standard margins in the industry can aid buyers in evaluating whether a quoted price is reasonable.

What Influences Pricing for Mousse Acoustique Products?

Several factors can influence the pricing of acoustic foam products:

-

Volume/MOQ: Minimum Order Quantities (MOQ) often dictate pricing tiers. Larger orders typically qualify for volume discounts, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom specifications, such as unique dimensions or special materials, can increase costs. Buyers should weigh the necessity of customization against potential price increases.

-

Material Quality and Certifications: Products that meet specific industry standards or certifications (e.g., fire ratings, environmental impact) may command higher prices. It’s essential for buyers to evaluate the benefits of these certifications against their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may offer more consistent quality but could be priced higher than newer entrants.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They determine responsibilities for shipping costs, insurance, and risk transfer, which can significantly impact the total landed cost.

How Can Buyers Negotiate Better Prices for Mousse Acoustique?

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with installation, maintenance, and potential replacements. A lower upfront price may not always equate to a better deal.

-

Leverage Volume Discounts: Consolidating orders or partnering with other businesses can help achieve bulk pricing, reducing overall costs.

-

Request Samples: Before committing to large orders, request samples to assess quality and suitability for your specific needs. This can prevent costly mistakes down the line.

-

Be Aware of Pricing Nuances in Different Regions: Pricing can vary significantly based on geographic location. For example, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to varying costs of compliance and production.

-

Negotiate Payment Terms: Flexible payment terms can enhance cash flow and reduce immediate financial pressure. Consider negotiating for extended payment terms, which can help manage budget constraints.

Conclusion

In the competitive landscape of sourcing ‘grossiste mousse acoustique’, understanding the cost structure and pricing influences is essential for international B2B buyers. By focusing on total cost considerations and employing strategic negotiation tactics, businesses can secure favorable terms while ensuring they meet their acoustic insulation needs effectively.

Alternatives Analysis: Comparing grossiste mousse acoustique With Other Solutions

Introduction to Alternatives in Acoustic Solutions

In the quest for effective soundproofing and acoustic treatment, businesses often seek various solutions tailored to their specific environments. While ‘grossiste mousse acoustique’ provides a robust option for sound absorption, exploring alternative methods and technologies can lead to optimal results. This analysis compares ‘grossiste mousse acoustique’ with two viable alternatives: acoustic panels and soundproofing curtains. Each option has distinct characteristics, advantages, and limitations, making it essential for B2B buyers to understand their differences to make informed decisions.

Comparison Table

| Comparison Aspect | Grossiste Mousse Acoustique | Acoustic Panels | Soundproofing Curtains |

|---|---|---|---|

| Performance | High absorption, reduces echo | Effective for mid to high frequencies | Moderate absorption, reduces noise levels |

| Cost | Moderate to high | Varies widely, generally higher | Generally lower, affordable options available |

| Ease of Implementation | Requires adhesive or mounting | Typically easy to install, some require professional help | Simple to hang, no installation tools needed |

| Maintenance | Low maintenance | Low, may require occasional cleaning | Low, machine washable options available |

| Best Use Case | Studios, industrial settings | Offices, schools, auditoriums | Residential, temporary spaces |

Detailed Breakdown of Alternatives

Acoustic Panels

Acoustic panels are specialized sound-absorbing products designed to control reverberation and improve sound quality in various environments. These panels often come in various shapes, sizes, and colors, making them aesthetically pleasing for commercial spaces. Their effectiveness is particularly notable in mid to high-frequency sound absorption, making them ideal for offices and auditoriums. However, the installation may require professional assistance, especially for larger projects, which can increase overall costs. Additionally, while they perform well in sound absorption, they may not be as effective in dampening low-frequency sounds as ‘grossiste mousse acoustique’.

Soundproofing Curtains

Soundproofing curtains are a flexible and often more affordable option for businesses looking to reduce noise. These curtains are typically made from dense, heavy materials that help block sound from entering or leaving a space. Their primary advantage lies in their ease of installation—simply hang them like regular curtains. They are particularly useful in residential settings, temporary spaces, or where aesthetics are a priority. However, their sound absorption capabilities are generally moderate compared to acoustic panels and ‘grossiste mousse acoustique’, making them less effective in environments requiring high sound control.

Conclusion: Choosing the Right Acoustic Solution

When selecting the appropriate acoustic solution, B2B buyers must consider their specific needs, budget, and the environment in which the product will be used. ‘Grossiste mousse acoustique’ stands out for its high performance in sound absorption, particularly in industrial and studio settings. However, for offices or educational environments, acoustic panels may provide a more tailored solution due to their aesthetic appeal and effective sound management. Conversely, soundproofing curtains offer a versatile and cost-effective alternative for residential or temporary spaces. By evaluating the performance, cost, ease of implementation, and maintenance of each option, businesses can make informed decisions that align with their acoustic requirements and budget constraints.

Essential Technical Properties and Trade Terminology for grossiste mousse acoustique

What Are the Key Technical Properties of Mousse Acoustique for B2B Buyers?

Understanding the essential technical properties of mousse acoustique (acoustic foam) is vital for B2B buyers, especially when selecting materials that meet specific acoustic performance requirements. Here are several critical specifications:

-

Material Composition

Acoustic foam can be made from various materials, including polyurethane, melamine, and rubber. Each material has distinct acoustic absorption qualities and durability. For instance, polyurethane foam is often favored for its lightweight and cost-effectiveness, while melamine foam is known for superior sound absorption and fire resistance. Buyers should assess material composition based on the intended application and environmental conditions. -

Density

The density of acoustic foam, typically measured in kilograms per cubic meter (kg/m³), is crucial for sound absorption performance. Higher density foams (e.g., 160-200 kg/m³) generally provide better sound insulation and durability. For B2B buyers, selecting the appropriate density can significantly impact the effectiveness of noise reduction in various settings, such as industrial environments or public spaces. -

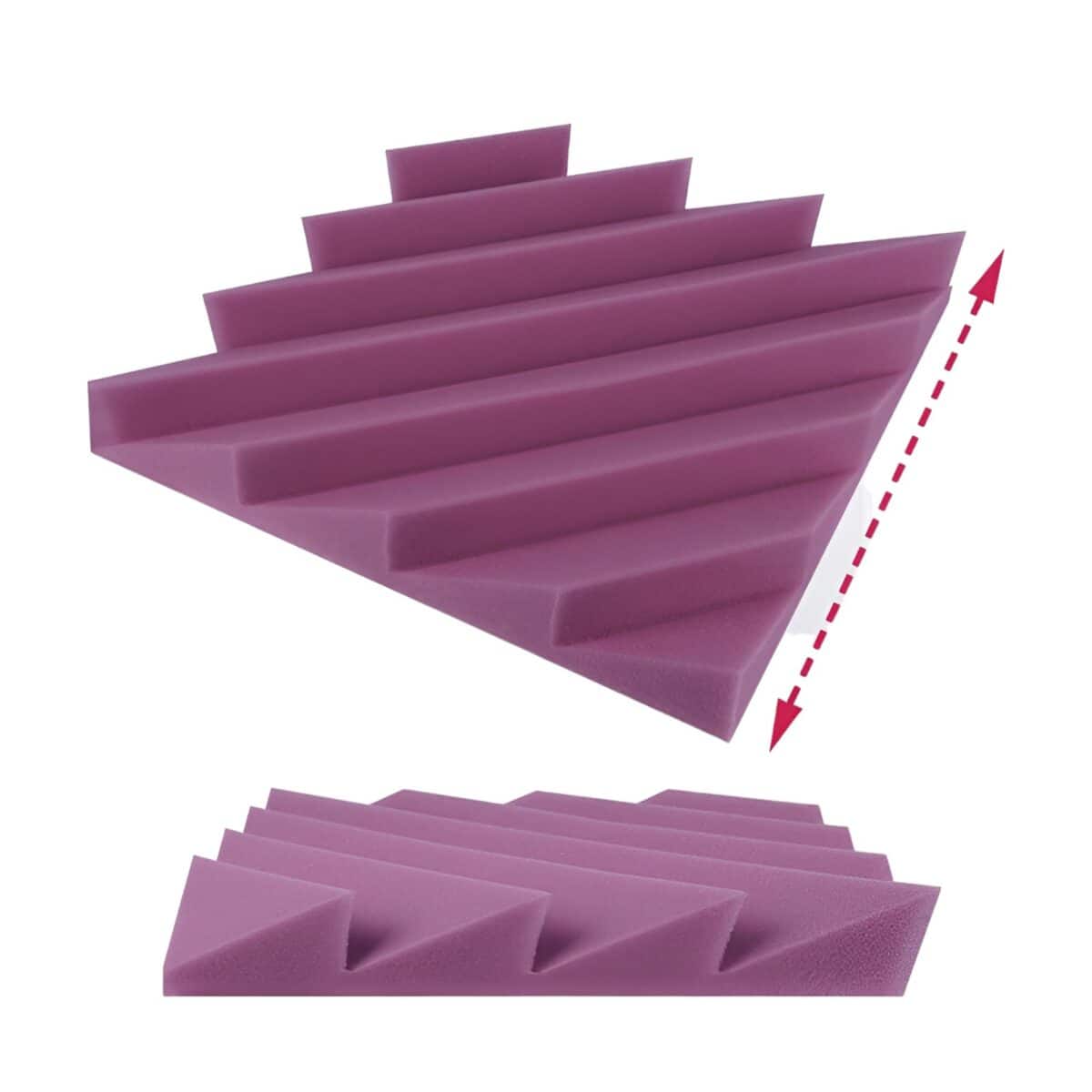

Thickness and Surface Profile

The thickness of the foam plays a significant role in its acoustic performance. Thicker panels can absorb lower frequencies more effectively. Additionally, surface profiles—such as pyramidal or egg-crate designs—enhance sound absorption by increasing the surface area available for sound wave interaction. Buyers should consider the specific acoustic challenges of their environments when choosing thickness and profile. -

Fire Rating

Fire safety is a critical consideration, especially in public spaces and commercial buildings. Acoustic foams are often rated according to their fire resistance, with classifications such as M1 or B1 indicating non-flammability. For B2B buyers, ensuring compliance with local fire safety regulations is essential to avoid potential liabilities and ensure the safety of occupants. -

Moisture Resistance

Acoustic materials intended for humid environments or outdoor applications should exhibit moisture resistance. Materials like closed-cell foam or treated melamine can resist mold and degradation. Buyers operating in such environments should prioritize moisture-resistant properties to prolong the lifespan of their acoustic solutions. -

Acoustic Performance Metrics

Acoustic performance is often quantified using metrics such as Noise Reduction Coefficient (NRC) and Sound Absorption Average (SAA). These ratings help buyers evaluate how effectively a foam can absorb sound across various frequencies. Selecting products with high NRC or SAA ratings is crucial for achieving desired acoustic outcomes.

Which Trade Terms Should B2B Buyers of Mousse Acoustique Be Familiar With?

Navigating the trade terminology associated with mousse acoustique can enhance communication and decision-making. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers looking to integrate acoustic solutions into larger projects or products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it can affect pricing and inventory management. Buyers should negotiate MOQs to align with their project needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. It typically includes details about the required quantities, specifications, and delivery timelines. Utilizing RFQs can streamline the purchasing process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) helps buyers clarify shipping responsibilities and costs, ensuring a smooth transaction. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. For B2B buyers, understanding lead times is essential for project planning and inventory management. Suppliers with shorter lead times can help businesses respond quickly to market demands. -

Technical Data Sheet (TDS)

A TDS provides detailed information about a product’s specifications, applications, and performance characteristics. Reviewing a TDS is vital for buyers to ensure that the selected mousse acoustique meets their specific needs and industry standards.

By familiarizing themselves with these properties and terms, B2B buyers can make informed decisions when sourcing acoustic foam, ultimately leading to more effective sound management solutions in their projects.

Navigating Market Dynamics and Sourcing Trends in the grossiste mousse acoustique Sector

Global drivers and trends in the grossiste mousse acoustique sector are influenced by several factors, including urbanization, regulatory changes, and technological advancements. The demand for effective sound insulation solutions is surging as urban areas expand, leading to increased noise pollution. This trend is particularly evident in developing regions in Africa and South America, where rapid urban growth necessitates improved acoustic management in residential and commercial properties.

Emerging technologies in manufacturing processes, such as advanced foam formulations and eco-friendly materials, are reshaping sourcing strategies. International B2B buyers are increasingly seeking suppliers who can offer innovative products like polyurethane and melamine-based foams that provide superior sound absorption properties. Additionally, the rise of e-commerce platforms is facilitating easier access to a wider range of products, enabling buyers from diverse regions to compare prices and specifications seamlessly.

Market dynamics are also shifting towards customization. Buyers are looking for solutions tailored to specific applications, such as studios, industrial environments, and public spaces. This demand for customized solutions is pushing suppliers to enhance their product offerings, ensuring they meet the diverse needs of different sectors. As a result, B2B relationships are becoming more collaborative, with suppliers working closely with clients to deliver bespoke acoustic solutions.

How is Sustainability Shaping the Sourcing of Mousse Acoustique?

Sustainability is becoming a critical focus within the grossiste mousse acoustique sector. The environmental impact of production processes and materials used is under scrutiny, prompting buyers to consider the lifecycle of products. Ethical supply chains are gaining importance, as businesses aim to reduce their carbon footprint and promote eco-friendly practices.

B2B buyers are increasingly prioritizing suppliers that offer ‘green’ certifications and materials. Products made from recycled or sustainably sourced materials, such as PET panels, are becoming more desirable. These sustainable options not only align with corporate social responsibility goals but also appeal to end-users who are increasingly environmentally conscious.

Furthermore, the incorporation of sustainability in sourcing strategies is leading to improved brand reputation and customer loyalty. Buyers who emphasize ethical sourcing are more likely to attract clients who value transparency and responsibility in their purchasing decisions. As a result, suppliers that commit to sustainable practices are likely to see a competitive edge in the marketplace.

What is the Historical Context of the Mousse Acoustique Market?

The evolution of the grossiste mousse acoustique market can be traced back to the early developments in sound insulation technologies. Initially, acoustic foams were primarily utilized in industrial settings. However, as awareness of noise pollution grew, the demand for acoustic solutions expanded into residential and commercial applications.

Over the decades, advancements in material science have led to the development of high-performance acoustic foams, such as melamine and polyurethane-based products, which offer enhanced sound absorption capabilities. The introduction of regulations regarding noise control in public spaces has further accelerated the adoption of acoustic solutions.

Today, the market is characterized by a diverse range of products tailored for various applications, from recording studios to open office environments. This historical progression highlights the industry’s adaptability and responsiveness to changing market demands, paving the way for continued innovation and growth in the grossiste mousse acoustique sector.

Frequently Asked Questions (FAQs) for B2B Buyers of grossiste mousse acoustique

-

1. How do I solve noise issues in my industrial space?

To effectively address noise problems in an industrial setting, consider using high-density acoustic foam products such as polyurethane or melamine-based solutions. These materials excel in sound absorption and can significantly reduce reverberation and noise levels. Consulting with acoustic specialists can help you determine the right products based on the specific layout and activities within your facility. Additionally, implementing a combination of wall panels, ceiling tiles, and flooring solutions can yield comprehensive noise control. -

2. What is the best type of acoustic foam for reducing reverberation in a studio?

For recording studios, the best acoustic foam typically includes products with a high sound absorption coefficient, such as melamine foam or pyramidal-shaped polyurethane foam. These types provide excellent control over sound reflections and echoes, enhancing overall audio quality. It’s essential to consider the room’s dimensions and intended use, as strategic placement of these panels can optimize acoustics effectively. -

3. How can I assess the quality of a grossiste mousse acoustique?

To evaluate the quality of a supplier, review their product certifications, such as fire ratings and environmental compliance. Request samples to test their acoustic performance in your specific application. Additionally, check for customer testimonials and case studies to gauge their reliability and service quality. A reputable supplier should also provide technical support and detailed product information to help you make informed decisions. -

4. What are the typical minimum order quantities (MOQs) for acoustic foam products?

Minimum order quantities for acoustic foam can vary significantly between suppliers. Generally, MOQs range from 50 to 500 square meters, depending on the product type and customization requirements. It’s advisable to discuss your specific needs with potential suppliers to see if they can accommodate smaller orders, especially for initial trials or smaller projects. Some suppliers may offer flexibility for long-term partnerships or larger orders. -

5. What payment terms should I expect when sourcing acoustic foam internationally?

Payment terms can differ widely among suppliers, but common practices include 30% upfront deposit with the balance due before shipment, or payment via letters of credit for larger orders. It’s crucial to clarify terms during negotiations, ensuring they align with your cash flow preferences. Additionally, consider using escrow services for added security, particularly when dealing with new suppliers. -

6. How do I ensure timely delivery of my acoustic foam products?

To ensure timely delivery, communicate your project timelines clearly with the supplier. Confirm their production capacity and lead times before placing an order. It’s also beneficial to choose suppliers with established logistics networks and track records of on-time delivery. Regular follow-ups during the production and shipping phases can help mitigate delays and keep your project on schedule. -

7. Can I customize acoustic foam products to fit my specific needs?

Yes, many suppliers offer customization options for acoustic foam products, including dimensions, colors, and densities. Discuss your requirements with the supplier to explore available options. Custom products may involve additional costs and longer lead times, so it’s advisable to plan ahead and confirm all specifications before production begins. -

8. What should I consider regarding quality assurance (QA) when sourcing acoustic foam?

When sourcing acoustic foam, ensure the supplier has a robust quality assurance process in place. This includes testing for acoustic performance, durability, and compliance with safety standards. Request detailed QA documentation and inquire about their production processes. Regular audits and third-party testing can also enhance confidence in the supplier’s commitment to quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Grossiste Mousse Acoustique Manufacturers & Suppliers List

1. Solutions Elastomères – Mousse Acoustique Made in France

Domain: solutions-elastomeres.com

Registered: 2006 (19 years)

Introduction: Mousse acoustique et phonique “Made in France” en vente. Gamme de produits : mousse de polyuréthane, mousse de mélamine, sous-couches, plaques résiliantes, isolants pour murs et tuyaux. Types de mousses : 1. Mousse Acoustique Alvéolaire : surface d’absorption accrue de 30 à 40%. 2. Mousse Acoustique Composite : haute densité (160-200 Kg/m3), excellente isolation acoustique, résiste à l’humidité et…

2. Panasorb – Isolants Acoustiques et Mousses Acoustiques

Domain: panasorb.eu

Introduction: Isolant acoustique et mousse acoustique fabriqués en France et Allemagne. Plus de 500 000 clients. Expédition rapide en 24h. 20 000 m² d’espace de production et de stockage. Qualité depuis 2001. Produits disponibles : Mousse en Basotect®, mousse alvéolaire, mousses à relief pyramidal, mousses planes, mousses acoustiques de différentes couleurs, absorbeur de basses, isolation phonique, caoutchouc m…

3. TI Fitness Center – Acoustique 12 Pièces Noir

Domain: tifitnesscenter.com

Registered: 2017 (8 years)

Introduction: Acoustique 12 Pièces Noir 12x12x2 Inch

4. Skum Acoustics – Vågor (10 pcs.)

Domain: skumacoustics.com

Registered: 2010 (15 years)

Introduction: {“name”: “Vågor (10 pcs.)”, “type”: “Mousse alvéolée”, “reference”: “SKLC002”, “dimensions”: “1000mm x 1000mm x 30mm”, “quantity_per_package”: “10 pcs.”, “coverage_area”: “10 m2”, “price”: “164,00 € TTC”, “color”: “Gris anthracite”, “material”: “Mousse acoustique FR28”, “fire_rating”: “Auto-extinguible (UNE 53127)”, “density”: “28 Kg/m3”, “porosity”: “25 L/min”, “resilience”: “30 %”, “acoustic_abs…

5. Groupe Cellutec – Mousse Insonorisante et Solutions d’Isolation

Domain: groupe-cellutec.fr

Registered: 2020 (5 years)

Introduction: Mousse insonorisante pour l’isolation phonique, solutions sur-mesure pour insonorisation et isolation thermique, mousse de polyéthylène réticulée (PER) et polyuréthane (PU) utilisées, mousses recyclables disponibles, applications dans l’emballage de luxe, protection industrielle, calage sur-mesure, pièces techniques, isolation thermique et acoustique, confort et ameublement. Importance de l’isolat…

6. Triangle – Mousse AVL

Domain: triangle-insonorisation.com

Registered: 2005 (20 years)

Introduction: Nom du produit : Mousse AVL

Type : Mousse polyuréthane (PU) à cellules ouvertes

Densité : 24 à 30 kg/m3

Applications : Isolation acoustique dans l’automobile, capotage machine, électroménager, bâtiment, climatisation, engin TP, plasturgie

Caractéristiques :

– Absorbant phonique

– Absorbe le bruit aérien

– Élimine le phénomène de résonance de cavité

– Diminue la réverbération

Mise en œuvre :

– Appl…

7. Produits Acoustiques – Feuilles de Mousse

Domain: produitsacoustiques.fr

Registered: 2022 (3 years)

Introduction: This company, Produits Acoustiques – Feuilles de Mousse, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for grossiste mousse acoustique

How Can Strategic Sourcing Enhance Your Supply Chain for Acoustic Foam?

In summary, the strategic sourcing of acoustic foam offers significant advantages for international B2B buyers. By partnering with specialized suppliers, businesses can access high-quality products that cater to diverse acoustic needs, from industrial applications to residential solutions. Key considerations include evaluating material types, understanding fire safety classifications, and recognizing the importance of eco-friendly options, which are increasingly demanded in markets across Africa, South America, the Middle East, and Europe.

Establishing strong supplier relationships not only ensures a reliable supply chain but also fosters innovation and cost efficiency. As global demand for effective acoustic solutions continues to rise, leveraging strategic sourcing can position your business competitively within the market.

Looking ahead, it is essential for buyers to remain proactive in their sourcing strategies. Explore partnerships with reputable manufacturers who can provide tailored solutions that meet your specific requirements. By doing so, you can enhance your project outcomes and contribute positively to the acoustic environment in your target markets. Engage with suppliers today to unlock the full potential of acoustic foam solutions in your business.