Top 6 Types Of Battery Connectors Suppliers (And How to Choose)

Introduction: Navigating the Global Market for types of battery connectors

In the rapidly evolving global market, sourcing the right types of battery connectors presents a significant challenge for international B2B buyers. The diverse applications of battery connectors—from automotive and marine to renewable energy systems—require a nuanced understanding of the various connector types available. Selecting the appropriate connectors is critical not only for ensuring compatibility and efficiency but also for enhancing safety and durability in demanding environments. This comprehensive guide delves into the myriad options of battery connectors, covering their types, applications, supplier vetting processes, cost considerations, and more.

By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Vietnam and Saudi Arabia—with actionable insights, this guide empowers informed purchasing decisions. Whether you are looking to optimize energy transfer in electric vehicles or ensure reliable connections in consumer electronics, understanding the intricacies of battery connectors is crucial. The information presented here will help you navigate supplier options, assess product quality, and ultimately choose connectors that meet your specific operational needs. As you explore the content, you will gain the knowledge necessary to mitigate risks, enhance performance, and achieve greater efficiency in your applications.

Understanding types of battery connectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alligator Clips | Simple, versatile, and easy to connect; often color-coded. | Automotive testing, prototyping. | Pros: Inexpensive, easy to use. Cons: Less secure, may slip off. |

| Anderson Connectors | High current capacity, quick-connect design, robust construction. | Electric vehicles, renewable energy. | Pros: Durable, reliable, and easy to connect. Cons: Higher cost. |

| XT60 Connectors | Lightweight, secure locking mechanism, rated for high currents. | RC vehicles, drones, and hobby applications. | Pros: Excellent conductivity, compact design. Cons: Requires soldering for installation. |

| Molex Connectors | Modular design with various pin configurations; secure fit. | Consumer electronics, automotive. | Pros: Versatile, widely used. Cons: Can be complex to install. |

| Battery Terminals | Standardized designs (top post, side post); durable materials. | Automotive, marine, industrial. | Pros: Strong connection, easy to replace. Cons: Limited to specific battery types. |

What Are Alligator Clips and Their Applications?

Alligator clips are simple battery connectors characterized by their spring-loaded jaws, allowing for quick and easy connections. They are commonly used in automotive testing and prototyping due to their versatility and low cost. However, while they are convenient, their less secure connection may lead to slippage, particularly in dynamic environments. B2B buyers should consider the application environment and whether a more secure connector might be necessary.

How Do Anderson Connectors Stand Out in the Market?

Anderson connectors are designed for high current applications, making them ideal for electric vehicles and renewable energy systems. They feature a robust construction and a quick-connect mechanism that facilitates easy connections and disconnections. While they are generally more expensive than other options, their durability and reliability make them a valuable investment for businesses looking for long-term solutions. Buyers should evaluate their current and future power needs when considering Anderson connectors.

Why Choose XT60 Connectors for High-Performance Applications?

XT60 connectors are favored in the hobbyist market, particularly for RC vehicles and drones, due to their lightweight and secure locking mechanism. They can handle high current loads, ensuring efficient power transfer. However, they require soldering for installation, which may necessitate additional skills or tools. B2B buyers should assess their technical capabilities and the specific requirements of their applications before selecting XT60 connectors.

What Are the Advantages of Using Molex Connectors?

Molex connectors are known for their modular design and secure fit, making them versatile for various applications, including consumer electronics and automotive industries. They come in multiple pin configurations, allowing for customization according to specific needs. However, their installation can be complex, which may deter some buyers. Businesses should weigh the benefits of customization against the potential installation challenges when considering Molex connectors.

How Do Battery Terminals Fit into Different Applications?

Battery terminals, available in standardized designs like top post and side post, are essential for establishing secure connections in automotive, marine, and industrial applications. They are made from durable materials, ensuring a strong and reliable connection. While they are easy to replace, their use is typically limited to specific battery types. B2B buyers should ensure compatibility with their existing battery systems when selecting battery terminals.

Key Industrial Applications of types of battery connectors

| Industry/Sector | Specific Application of types of battery connectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Vehicle (EV) Battery Management Systems | Enhances safety and efficiency of energy transfer | Ensure compatibility with EV systems and high current ratings |

| Renewable Energy | Solar Power Storage Systems | Improves energy efficiency and longevity of storage systems | Look for connectors with moisture and corrosion resistance |

| Telecommunications | Backup Power Systems for Communication Towers | Ensures reliable power supply during outages | Prioritize connectors that offer quick-connect features |

| Industrial Machinery | Heavy Machinery Power Supply | Reduces energy loss and increases operational uptime | Consider connectors rated for high voltage and current |

| Marine | Battery Systems for Electric Boats | Enhances performance and safety in marine environments | Source connectors that are resistant to saltwater corrosion |

How Are Battery Connectors Used in the Automotive Sector?

In the automotive industry, particularly in electric vehicles (EVs), battery connectors are crucial for the battery management systems (BMS). These connectors ensure a secure electrical connection between the battery packs and the vehicle’s electronic control units. They solve problems related to energy efficiency and safety, as improper connections can lead to overheating or system failures. International buyers should focus on sourcing connectors that meet high current ratings and are compatible with various EV architectures to ensure optimal performance.

What Role Do Battery Connectors Play in Renewable Energy Applications?

In renewable energy sectors, especially solar power storage systems, battery connectors facilitate the efficient transfer of energy from solar panels to storage batteries. They help maintain consistent electrical contact, which is vital for maximizing energy output and prolonging battery life. Buyers in regions with high humidity or corrosive environments, such as parts of Africa and South America, should prioritize connectors with anti-corrosion coatings and moisture resistance to ensure durability and reliability in harsh conditions.

How Are Battery Connectors Critical for Telecommunications?

Telecommunications rely heavily on backup power systems to ensure uninterrupted service during outages. Battery connectors in these systems ensure that power flows seamlessly from backup batteries to critical communication equipment. They address the challenge of maintaining reliable power supply, crucial for business continuity. When sourcing connectors for this application, businesses should consider quick-connect features that allow for easy installation and replacement, enhancing operational efficiency.

Why Are Battery Connectors Important in Industrial Machinery?

In industrial machinery, battery connectors are essential for connecting power supplies to heavy equipment. They play a significant role in reducing energy loss and increasing the uptime of machinery. This is particularly important in sectors where operational efficiency directly impacts profitability. Buyers should look for connectors that are rated for high voltage and current to meet the demands of heavy machinery, ensuring that they can withstand rigorous operational conditions.

How Do Battery Connectors Enhance Marine Applications?

In the marine industry, battery connectors are vital for electric boats, facilitating the connection between batteries and propulsion systems. They enhance performance by ensuring efficient energy transfer and minimizing the risk of electrical failures in challenging marine environments. Buyers should focus on sourcing connectors specifically designed to resist saltwater corrosion, ensuring longevity and reliability in maritime applications, which is crucial for maintaining safety and performance on the water.

3 Common User Pain Points for ‘types of battery connectors’ & Their Solutions

Scenario 1: Compatibility Confusion in Multi-Application Environments

The Problem: B2B buyers often operate in diverse sectors where different equipment requires various battery connectors. For instance, a company supplying renewable energy solutions may need connectors for both solar batteries and electric vehicles, which can lead to confusion over compatibility. Mismatched connectors can result in operational failures, downtime, and potential damage to expensive equipment, causing significant losses.

The Solution: To mitigate compatibility issues, it is crucial to conduct a thorough assessment of all devices that will utilize the battery connectors. Buyers should create a comprehensive inventory of all equipment and their respective connector requirements. Engaging with suppliers who offer a wide range of connectors and can provide compatibility guidelines is essential. Additionally, investing in universal connectors or adaptable systems that can interface with multiple types of devices will enhance flexibility and reduce the risk of mismatches.

Scenario 2: Overheating and Safety Risks from Inadequate Current Handling

The Problem: Another common challenge is selecting connectors that cannot handle the required current load, which can lead to overheating. For example, in industrial applications, where heavy machinery draws significant power, using inadequate connectors may not only cause performance issues but also pose safety hazards such as fire risks. Buyers may not always be aware of the current ratings needed for their specific applications.

The Solution: It is imperative to understand the current requirements of all connected devices before purchasing battery connectors. Buyers should consult the technical specifications of their equipment to determine the maximum current draw and choose connectors that can comfortably handle this load, ideally with a safety margin. Suppliers should be asked for detailed specifications and testing results to ensure the connectors meet industry standards for safety and performance. Regular inspections and temperature monitoring during operation can also help identify potential overheating issues early.

Scenario 3: Installation Challenges Leading to Operational Delays

The Problem: Many B2B buyers experience difficulties during the installation of battery connectors, particularly when soldering is involved. This can be especially challenging for companies that lack in-house technical expertise. Installation errors can lead to unreliable connections, resulting in operational delays and increased costs due to downtime or the need for professional services.

The Solution: To streamline the installation process, buyers should opt for pre-assembled battery connectors whenever possible, which eliminate the need for soldering and reduce installation time. Training sessions for staff on proper installation techniques can also prove beneficial. Furthermore, collaborating with suppliers who provide installation support or consulting services can ensure that the connectors are installed correctly the first time. Investing in tools designed for ease of use can also empower non-technical staff to perform installations confidently, thereby enhancing overall operational efficiency.

Strategic Material Selection Guide for types of battery connectors

What Are the Key Properties of Common Materials Used in Battery Connectors?

When selecting battery connectors, the choice of material significantly influences performance, durability, and application suitability. Below is an analysis of four common materials used in battery connectors, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Copper Perform as a Material for Battery Connectors?

Copper is one of the most widely used materials for battery connectors due to its excellent electrical conductivity, which is crucial for efficient energy transfer. It typically has a temperature rating of up to 200°C and can withstand high-pressure applications.

Pros: Copper connectors are highly durable and provide low resistance, which minimizes energy loss. They are relatively easy to manufacture and can be plated with nickel or tin for enhanced corrosion resistance.

Cons: The primary drawback of copper is its susceptibility to corrosion, especially in humid environments. Additionally, copper connectors can be more expensive than alternatives like aluminum, which may deter cost-sensitive buyers.

Impact on Application: Copper connectors are ideal for high-performance applications, including electric vehicles and renewable energy systems, where efficient power transfer is critical.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local electrical standards, such as IEC or NEMA, which may dictate the use of specific materials.

What Role Does Aluminum Play in Battery Connector Applications?

Aluminum is another popular choice for battery connectors, particularly in automotive and marine applications. It has a lower density than copper, making it lightweight, and can handle temperatures up to 150°C.

Pros: Aluminum is cost-effective and offers good conductivity, especially when alloyed with other metals. It is also more resistant to corrosion than copper, making it suitable for outdoor applications.

Cons: While aluminum is lightweight, its conductivity is lower than copper, which may lead to higher energy loss in some applications. Additionally, aluminum connectors can be more challenging to manufacture due to their tendency to oxidize.

Impact on Application: Aluminum connectors are often used in applications where weight is a concern, such as in automotive wiring systems, but they may not be suitable for high-current applications without careful design.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM or DIN, which may affect the selection of aluminum grades for connectors in specific applications.

How Do Brass Connectors Compare in Terms of Performance?

Brass, an alloy of copper and zinc, is frequently used for battery connectors due to its favorable balance of conductivity and corrosion resistance. Brass connectors can typically handle temperatures up to 180°C.

Pros: Brass offers excellent mechanical strength and is less prone to corrosion compared to pure copper. Its manufacturing process is also straightforward, making it a popular choice for mass production.

Cons: The primary disadvantage of brass is its higher cost compared to aluminum. Additionally, while it is more resistant to corrosion than copper, it can still corrode under certain conditions, particularly in saline environments.

Impact on Application: Brass connectors are well-suited for applications in marine environments or where mechanical strength is paramount, such as in heavy machinery.

Considerations for International Buyers: Buyers should consider the specific corrosion resistance requirements dictated by their operational environments and ensure that the brass used complies with relevant international standards.

What Advantages Do Plastic Connectors Offer?

Plastic connectors, often used in conjunction with metal components, provide insulation and protection against environmental factors. They can typically handle temperatures up to 100°C.

Pros: Plastic connectors are lightweight, cost-effective, and resistant to corrosion and moisture. They also provide excellent electrical insulation, enhancing safety.

Cons: The main limitation is their lower mechanical strength compared to metal connectors, which may not be suitable for high-stress applications. Additionally, they may not handle high temperatures as effectively as metal connectors.

Impact on Application: Plastic connectors are ideal for low-power applications and environments where weight savings are essential.

Considerations for International Buyers: Buyers must ensure that plastic materials used in connectors meet the necessary fire safety and environmental regulations, such as RoHS compliance in Europe.

Summary Table of Material Properties for Battery Connectors

| Material | Typical Use Case for types of battery connectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance applications (e.g., EVs) | Excellent electrical conductivity | Susceptible to corrosion | High |

| Aluminum | Automotive and marine applications | Lightweight and cost-effective | Lower conductivity than copper | Medium |

| Brass | Marine and heavy machinery applications | Good mechanical strength and corrosion resistance | Higher cost than aluminum | Medium |

| Plastic | Low-power applications | Lightweight and excellent insulation | Lower mechanical strength | Low |

This material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on the specific requirements of their applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of battery connectors

What Are the Main Stages of Manufacturing Battery Connectors?

The manufacturing of battery connectors involves several critical stages that ensure the final product meets the required performance and safety standards. Understanding these stages helps B2B buyers identify quality suppliers and make informed purchasing decisions.

Material Preparation: What Materials Are Used in Battery Connector Manufacturing?

The first step in the manufacturing process is material preparation. Battery connectors are typically made from conductive metals such as brass, copper, or nickel-plated alloys. These materials are chosen for their excellent conductivity, durability, and resistance to corrosion.

Before manufacturing begins, raw materials undergo rigorous quality checks to ensure they meet specified standards. These checks may include assessing the purity of metals and their mechanical properties. Suppliers should provide material certifications to confirm compliance with international standards.

How Are Battery Connectors Formed?

Once the materials are prepared, the next stage is forming. This process involves shaping the raw materials into the desired connector designs through techniques such as stamping, forging, or extrusion.

Key Techniques:

– Stamping: This involves cutting and shaping metal sheets into connector components using high-pressure machines. It’s efficient for producing large volumes with consistent quality.

– Forging: This method uses mechanical force to shape metal at elevated temperatures, enhancing its strength.

– Injection Molding: For plastic components, injection molding is often used, allowing for complex shapes and designs.

Each technique has specific advantages, and the choice depends on the intended application of the connectors.

What Does the Assembly Process Entail?

After the components are formed, they move to the assembly stage. This is where different parts, such as terminals, housings, and insulation, are combined to create the final connector.

Assembly Techniques:

– Soldering: This involves melting a filler metal to join electrical components, ensuring a strong and conductive connection.

– Ultrasonic Welding: This technique uses high-frequency vibrations to join plastic parts without additional materials, which is beneficial for lightweight connectors.

Automated assembly lines are commonly used to improve efficiency and consistency, especially for high-volume production.

What Finishing Processes Are Applied to Battery Connectors?

The finishing stage is crucial for enhancing the durability and performance of battery connectors. This may include:

– Plating: Applying a thin layer of metal (like nickel or gold) to improve conductivity and corrosion resistance.

– Coating: Utilizing anti-corrosion coatings to protect connectors from environmental factors, which is especially important for connectors used in harsh conditions.

Finishing processes can significantly affect the lifespan and reliability of battery connectors, making this a vital stage for B2B buyers to consider.

What Quality Assurance Measures Are in Place for Battery Connectors?

Quality assurance (QA) is essential in ensuring that battery connectors meet industry standards and function reliably. Different international and industry-specific standards guide the QA process.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Other relevant certifications may include:

– CE Marking: Indicates compliance with European safety standards.

– API Standards: Relevant for connectors used in the oil and gas industry.

These certifications help B2B buyers assess the credibility and quality of potential suppliers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure product integrity. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during manufacturing to monitor processes and detect issues early.

- Final Quality Control (FQC): A thorough inspection of the finished product to ensure it meets all specifications and standards before shipping.

These checkpoints help identify and rectify defects, ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s QC processes is essential to ensure they are receiving reliable products. Here are several ways to do so:

What Methods Can Buyers Use to Verify Supplier Quality?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, processes, and QC practices firsthand.

-

Requesting Quality Reports: Suppliers should provide documentation that details their quality control procedures, including results from recent inspections and tests.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing and QC practices.

-

Certifications and Compliance: Buyers should request copies of relevant certifications to verify that suppliers meet industry standards.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing battery connectors from international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should consider several nuances:

- Regulatory Compliance: Different countries have varying regulations regarding electrical components. Understanding these can prevent potential legal issues.

- Supply Chain Transparency: Establishing clear communication regarding the source of materials and the manufacturing processes can enhance trust and reliability.

- Cultural Considerations: Understanding the business practices and expectations in different regions can help in negotiating terms and ensuring quality.

By being aware of these factors, B2B buyers can make more informed decisions and establish successful partnerships with suppliers of battery connectors.

In conclusion, the manufacturing processes and quality assurance measures for battery connectors are complex and multi-faceted. Buyers should prioritize understanding these aspects to ensure they are sourcing high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of battery connectors’

In today’s competitive B2B landscape, sourcing the right battery connectors is crucial for ensuring the efficient performance of your electrical systems. This guide provides a structured checklist to help international buyers navigate the complexities of procuring battery connectors tailored to their specific needs.

Step 1: Define Your Technical Specifications

Before beginning your search for battery connectors, it’s essential to clearly outline your technical requirements. Consider the voltage, current capacity, and environmental conditions the connectors will face. This step is vital as it determines the type of connectors you will need, ensuring compatibility with your existing systems and avoiding costly mistakes.

Step 2: Research Different Connector Types

Battery connectors come in various forms, including top post, side post, and quick-connect types. Understanding the specific applications of each type is important; for example, quick-connect connectors are ideal for applications requiring frequent disconnection and reconnection. Take the time to explore the advantages and disadvantages of each type to make an informed decision.

Step 3: Evaluate Supplier Certifications

When selecting a supplier, verify their certifications and compliance with international standards, such as ISO or IEC. Certifications ensure that the connectors meet safety, quality, and performance benchmarks. This step is crucial for maintaining the integrity of your projects and safeguarding against potential failures in high-stakes environments.

Step 4: Assess Material Quality

The materials used in battery connectors significantly affect their performance and longevity. Common materials include brass and nickel-plated alloys, known for their conductivity and resistance to corrosion. Ensure that the connectors you consider are made from high-quality materials to minimize energy loss and enhance overall efficiency.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples from potential suppliers. Testing these samples in your specific application will provide insights into their performance and compatibility. This step can help identify any potential issues early on, ensuring that the connectors will meet your operational requirements.

Step 6: Review Supplier Reputation and Experience

Investigate the reputation and experience of your potential suppliers within the industry. Look for customer reviews, case studies, and references to gauge their reliability and service quality. A supplier with a solid track record is more likely to provide high-quality products and support, which is crucial for long-term partnerships.

Step 7: Negotiate Terms and After-Sales Support

Once you have identified a suitable supplier, negotiate terms that include pricing, delivery schedules, and after-sales support. Establishing clear communication regarding warranties and support services is essential for addressing any future issues. This final step ensures you have a comprehensive understanding of the supplier’s commitments, which can significantly impact your operational success.

By following this checklist, you can navigate the sourcing process effectively, ensuring you procure the right battery connectors that meet your specifications and enhance your system’s performance.

Comprehensive Cost and Pricing Analysis for types of battery connectors Sourcing

What Are the Key Cost Components in Battery Connector Sourcing?

When sourcing battery connectors, understanding the cost structure is essential for effective budgeting and price negotiation. The primary cost components include:

-

Materials: The choice of materials greatly influences the cost. Common materials such as copper, brass, and nickel-plated alloys are often used due to their excellent conductivity and durability. Specialty materials for high-performance applications can increase costs significantly.

-

Labor: Labor costs vary by region and the complexity of the connector design. Skilled labor is required for manufacturing, especially when custom connectors are involved, which can lead to higher labor costs.

-

Manufacturing Overhead: This encompasses all indirect costs related to the production process, including utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom connector designs. These costs are typically amortized over large production runs, making them less significant per unit in high-volume orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and safety, particularly important for applications in automotive and renewable energy sectors. While QC adds to the cost, it prevents costly recalls and warranty claims.

-

Logistics: Transportation and warehousing costs can vary significantly based on the shipping method, distance, and import/export tariffs. Efficient logistics management is crucial for minimizing these costs.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This can vary based on market conditions, supplier relationships, and the competitive landscape.

What Factors Influence Battery Connector Pricing?

Several factors impact the pricing of battery connectors, and understanding them can lead to more effective purchasing decisions:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower unit costs due to economies of scale. Be aware of the supplier’s MOQ, as smaller orders may incur higher per-unit prices.

-

Specifications and Customization: Custom designs or specific specifications can significantly increase costs. Standardized connectors are generally more cost-effective, while custom solutions require additional design and manufacturing resources.

-

Material Quality and Certifications: Connectors that meet specific industry standards or certifications (like UL or CE) often command a premium. Investing in certified products can enhance safety and compliance but may increase upfront costs.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. Established suppliers with a track record of quality and service may charge higher prices, but they often provide better reliability and support.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate shipping responsibilities and costs. Understanding these terms is crucial for calculating the total cost of ownership (TCO).

What Buyer Tips Can Enhance Cost Efficiency in Battery Connector Sourcing?

To optimize sourcing strategies, consider these actionable tips:

-

Negotiate with Suppliers: Leverage competitive quotes to negotiate better terms. Suppliers may be willing to offer discounts for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as installation costs, maintenance, and potential downtime when assessing the true cost of connectors.

-

Understand Pricing Nuances for International Markets: When sourcing from different regions (e.g., Africa, South America, the Middle East, and Europe), be mindful of currency fluctuations, local tariffs, and trade regulations. These factors can significantly impact overall costs.

-

Assess Quality vs. Price: While it may be tempting to choose the lowest-cost option, ensure that the connectors meet necessary performance and safety standards. Poor-quality connectors can lead to failures and increased costs in the long run.

-

Stay Informed on Market Trends: Keeping abreast of market trends and technological advancements can help identify new suppliers or innovations that may offer cost savings or improved performance.

Disclaimer

Prices for battery connectors can vary widely based on the aforementioned factors. This analysis provides indicative costs and insights; actual prices may differ based on specific sourcing conditions and market dynamics. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing types of battery connectors With Other Solutions

Exploring Alternatives to Battery Connectors: What Are Your Options?

When evaluating battery connectors, it’s essential to consider viable alternatives that can meet similar needs for energy transfer and connectivity. This comparison highlights how different solutions stack up against traditional battery connectors, providing B2B buyers with actionable insights to make informed decisions.

| Comparison Aspect | Types Of Battery Connectors | Alternative 1: Wireless Power Transfer | Alternative 2: Hardwired Connections |

|---|---|---|---|

| Performance | High efficiency for current transfer; reliable under load | Limited by distance; efficiency decreases with distance | Very high efficiency; minimal energy loss |

| Cost | Moderate initial investment; varies by type | Higher upfront costs due to technology | Typically lower costs; labor and installation can add to total |

| Ease of Implementation | Generally straightforward; requires basic tools | More complex; installation of transmitters/receivers needed | Simple for fixed installations; complex for mobile applications |

| Maintenance | Low; occasional checks for wear and corrosion | Moderate; requires monitoring of devices | Low; infrequent maintenance required |

| Best Use Case | Automotive, marine, and energy storage systems | Consumer electronics, medical devices, and charging stations | Permanent installations in industrial applications |

Understanding Wireless Power Transfer: Pros and Cons

Wireless power transfer (WPT) utilizes electromagnetic fields to transfer energy between two objects. This technology offers the advantage of eliminating physical connectors, reducing wear and tear associated with mechanical connections. However, WPT is limited by distance; efficiency drops significantly as the gap between the transmitter and receiver increases. Furthermore, the initial costs for implementing WPT systems can be high, making it less appealing for cost-sensitive applications.

Evaluating Hardwired Connections: Advantages and Disadvantages

Hardwired connections involve direct electrical connections using cables and terminals. They boast very high efficiency with minimal energy loss, making them ideal for applications requiring significant power transfer. Additionally, hardwired systems are typically less expensive than advanced technologies like WPT. However, the installation can be complex, especially in mobile applications where flexibility is needed. Maintenance is generally low, but ensuring the integrity of connections in harsh environments may require occasional checks.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When deciding between battery connectors and alternative solutions like wireless power transfer or hardwired connections, B2B buyers should consider their specific application requirements, budget constraints, and maintenance capabilities. Battery connectors provide a reliable, cost-effective solution for most applications, especially in automotive and industrial settings. However, for specialized needs such as medical devices or consumer electronics, wireless options may offer unique advantages despite higher costs. Ultimately, understanding the operational context and long-term goals will guide buyers in selecting the most suitable energy transfer method for their projects.

Essential Technical Properties and Trade Terminology for types of battery connectors

What Are the Key Technical Properties of Battery Connectors?

When selecting battery connectors, it is essential to understand several critical specifications that can affect performance, reliability, and safety. Here are some key properties to consider:

1. Material Grade: What Materials Are Best for Battery Connectors?

Battery connectors are typically made from materials like brass, nickel-plated alloys, or lead, each offering unique benefits. Brass provides excellent conductivity and corrosion resistance, while nickel plating enhances durability and reduces wear. The choice of material can directly impact the connector’s lifespan and efficiency, making it crucial for buyers to select connectors that align with their specific application requirements.

2. Current Rating: How Much Current Can the Connector Handle?

The current rating, measured in amps, indicates the maximum electrical load a connector can safely carry. Choosing a connector with a rating that meets or exceeds the current demands of the connected devices is vital for preventing overheating and potential failure. This specification is particularly important in high-performance applications, such as electric vehicles or renewable energy systems, where efficiency and safety are paramount.

3. Voltage Rating: What Is the Maximum Voltage Tolerance?

Voltage rating refers to the maximum voltage the connector can handle without risk of breakdown or failure. It is essential to ensure that the connectors chosen can withstand the operational voltage of the battery system. A mismatch in voltage ratings can lead to catastrophic failures, making it a critical factor in connector selection.

4. Temperature Tolerance: How Does Temperature Affect Connector Performance?

Temperature tolerance indicates the range of temperatures within which the connector can operate effectively. Connectors that can withstand extreme temperatures are essential for applications in harsh environments, such as automotive or industrial settings. High-temperature tolerance helps maintain performance and safety, preventing failures in critical applications.

5. Contact Resistance: What Is the Importance of Low Contact Resistance?

Contact resistance is the resistance to current flow at the connection point between the battery and the connector. Lower contact resistance leads to higher efficiency and less energy loss during power transfer. High contact resistance can lead to overheating and reduced performance, making it essential for buyers to consider this specification when selecting connectors.

6. Waterproof Rating: How Important Is It to Have a Waterproof Connector?

The waterproof rating indicates the connector’s ability to resist moisture ingress, which is crucial for applications exposed to water or humidity. Connectors with a high waterproof rating are essential for marine applications or outdoor equipment, ensuring reliable performance and longevity in challenging conditions.

What Are Common Trade Terminology and Jargon Used in Battery Connector Procurement?

Understanding the industry-specific terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms you should be familiar with:

1. OEM (Original Equipment Manufacturer): What Does OEM Mean?

OEM refers to companies that produce components that are used in another company’s end product. In the context of battery connectors, an OEM may manufacture connectors specifically designed for a particular brand of battery or device. Understanding OEM relationships can help buyers identify quality standards and compatibility.

2. MOQ (Minimum Order Quantity): Why Is MOQ Important?

MOQ is the minimum number of units a supplier is willing to sell in a single order. Knowing the MOQ is crucial for budgeting and inventory planning, particularly for international buyers who may face larger shipping costs.

3. RFQ (Request for Quotation): What Is an RFQ Process?

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. In the battery connector market, submitting an RFQ can help buyers gather competitive pricing and assess supplier capabilities.

4. Incoterms: How Do Incoterms Affect Shipping and Delivery?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms can help buyers understand shipping costs, insurance, and liability during transport, which is vital for international procurement.

5. Lead Time: What Is Lead Time and Why Does It Matter?

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times helps buyers plan their inventory and production schedules effectively, ensuring that they have the necessary components when needed.

By familiarizing yourself with these technical properties and trade terminologies, you can make informed decisions in the procurement of battery connectors, ensuring optimal performance and reliability for your applications.

Navigating Market Dynamics and Sourcing Trends in the types of battery connectors Sector

What Are the Global Drivers Shaping the Battery Connectors Market?

The battery connectors market is experiencing significant growth driven by the increasing demand for energy storage solutions, particularly in sectors such as electric vehicles (EVs), renewable energy systems, and consumer electronics. As global governments push for greener energy initiatives, the need for efficient energy transfer solutions has never been more critical. This trend is particularly pronounced in emerging markets across Africa, South America, the Middle East, and Europe, where infrastructure development and modernization efforts are underway.

Moreover, technological advancements are leading to the development of innovative battery connectors that enhance efficiency and safety. Features such as quick-release mechanisms, corrosion resistance, and lightweight materials are becoming standard. The rise of smart connectors that integrate safety features and compatibility with various battery types is also a key trend. For international B2B buyers, understanding these market dynamics is essential to sourcing connectors that not only meet current demands but also anticipate future needs.

How Are Sustainability and Ethical Sourcing Influencing Battery Connector Choices?

Sustainability is increasingly influencing the sourcing decisions of international B2B buyers in the battery connectors sector. The environmental impact of manufacturing processes and materials used in battery connectors is under scrutiny, driving the demand for eco-friendly options. Buyers are looking for connectors made from sustainable materials, such as recycled metals and plastics, which reduce the carbon footprint of their operations.

Ethical sourcing is also a critical consideration. Companies are prioritizing suppliers that adhere to strict environmental and labor standards, ensuring that their supply chains are not only efficient but also socially responsible. Certifications like ISO 14001 (Environmental Management) and materials that are free from conflict minerals are becoming essential in supplier evaluations. By prioritizing sustainability and ethical sourcing, businesses can enhance their brand reputation and meet the growing consumer demand for responsible manufacturing practices.

What Is the Brief Evolution of Battery Connectors and Their Significance?

The evolution of battery connectors has been closely linked to advancements in technology and energy storage solutions. Initially, connectors were simple and designed primarily for basic electrical applications. However, as the demand for more efficient and reliable energy transfer grew, manufacturers began to innovate. Modern battery connectors now incorporate advanced features like anti-corrosion coatings and smart technology that enhances performance and safety.

Today, battery connectors are integral to high-performance applications, including electric vehicles and renewable energy systems. Their ability to ensure a secure and efficient connection directly impacts the performance and longevity of battery systems. Understanding the historical context of these developments helps B2B buyers appreciate the importance of selecting high-quality connectors that align with their technological and operational needs.

In summary, navigating the battery connectors market requires a keen understanding of global drivers, sustainability considerations, and the historical evolution of the technology. By focusing on these areas, international B2B buyers can make informed decisions that enhance their operational efficiency and sustainability efforts.

Frequently Asked Questions (FAQs) for B2B Buyers of types of battery connectors

-

How do I choose the right battery connector for my application?

Selecting the appropriate battery connector involves assessing several critical factors. Begin by determining the current capacity requirements of your application; connectors must handle the maximum load without overheating. Compatibility with the battery and devices is crucial, so ensure the connectors match in type and size. Additionally, consider environmental factors like temperature and moisture levels, which may necessitate connectors with specific protective features. Consult technical specifications and manufacturer recommendations to make an informed decision. -

What is the best battery connector type for high-performance applications?

For high-performance applications such as electric vehicles or renewable energy systems, connectors designed for high current loads and durability are essential. Look for connectors that offer features like anti-corrosion coatings, temperature tolerance, and moisture resistance. Options like Anderson Powerpole or XT60 connectors are popular due to their robust design and efficiency. Ultimately, the best choice will depend on the specific requirements of your system, including voltage, current capacity, and environmental conditions. -

What are the key factors to consider when vetting battery connector suppliers?

When vetting battery connector suppliers, prioritize their industry experience and reputation. Review their product range to ensure they offer connectors that meet your specifications. Check for compliance with international safety and quality standards, such as ISO or CE certifications. It’s beneficial to request samples for testing and assess the supplier’s responsiveness and customer service. Additionally, consider their production capabilities, lead times, and after-sales support to ensure a reliable partnership. -

How can I customize battery connectors for my specific needs?

Customization options for battery connectors often include variations in size, material, and configuration to suit specific applications. Many manufacturers offer bespoke solutions where you can specify features like wire gauge, connector type, and additional functionalities such as locking mechanisms or color coding. Discuss your requirements with potential suppliers to explore available customization options, and ensure that they can accommodate your needs within your project timeline. -

What is the minimum order quantity (MOQ) for battery connectors?

Minimum order quantities (MOQs) for battery connectors can vary significantly among suppliers based on their production capabilities and the type of connectors. Generally, MOQs may range from a few hundred to several thousand units. It is essential to clarify the MOQ with your supplier during negotiations, as lower MOQs may be possible for customized orders or trial runs. Understanding MOQs helps you plan your inventory and budget more effectively. -

What payment terms should I expect when sourcing battery connectors internationally?

Payment terms for international sourcing of battery connectors can vary widely depending on the supplier and your relationship with them. Common terms include a deposit upfront (usually 30-50%) with the balance due prior to shipment. Some suppliers may offer net 30 or net 60 terms for established customers. Be sure to discuss payment methods, such as wire transfers or letters of credit, and clarify any additional fees, such as currency conversion or transaction costs, to avoid unexpected expenses. -

What quality assurance measures should be in place for battery connectors?

Quality assurance (QA) measures for battery connectors should include rigorous testing for electrical performance, durability, and safety. Ensure that suppliers conduct tests such as current load capacity, temperature cycling, and corrosion resistance. Request documentation of compliance with relevant industry standards and ask for third-party testing certifications if available. Establishing a QA process helps to mitigate risks associated with faulty connectors and enhances the reliability of your products. -

How can I ensure timely logistics and delivery for battery connector shipments?

To ensure timely logistics and delivery of battery connector shipments, collaborate closely with your supplier to establish clear timelines and shipping methods. Choose reliable logistics partners with experience in international shipping, and consider factors such as customs clearance and potential delays. It’s beneficial to use tracking systems to monitor shipment progress and communicate proactively with your supplier regarding any changes in demand or scheduling. Planning for lead times and potential disruptions can enhance your supply chain efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Types Of Battery Connectors Manufacturers & Suppliers List

1. BatteryStuff – Battery Connectors & Cables

Domain: batterystuff.com

Registered: 1999 (26 years)

Introduction: This company, BatteryStuff – Battery Connectors & Cables, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Horizon Hobby – RC Battery Connectors

Domain: horizonhobby.com

Registered: 1996 (29 years)

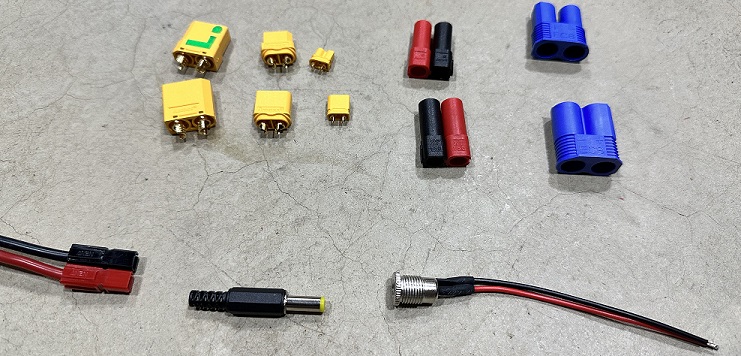

Introduction: RC battery connectors are female plugs attached to the wire leads of RC battery packs, designed to connect to male plugs on devices like radio receivers or electronic speed controls. They can be purchased with leads already attached or as separate plugs for DIY soldering. Key characteristics include bright colors for visibility, durability for repeated connections, and the ability to withstand hig…

3. Eurorc – RC Connectors Guide

Domain: eurorc.com

Registered: 2010 (15 years)

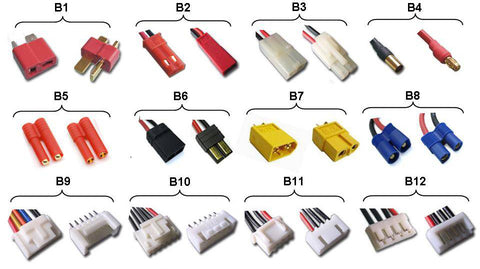

Introduction: RC Connectors Explained: 1. **Types of Connectors**: – Battery Connectors – General Connectors 2. **Battery Connectors**: – Designed for high currents and voltages – Durable and colorful for easy identification – Common types: Bullet/Banana, Deans, XT-30, XT-60, XT-90 3. **Bullet/Banana Connectors**: – Sizes: 2mm-8mm – Current Ratings: 2mm (25A), 3.5mm (50A), 4mm (90A), 5mm (120A), 5.5mm (130A), 6…

4. TE – Battery Connector Types

Domain: te.com

Registered: 1992 (33 years)

Introduction: This company, TE – Battery Connector Types, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Remy Battery – Battery Terminal Connectors

Domain: remybattery.com

Registered: 1998 (27 years)

Introduction: This company, Remy Battery – Battery Terminal Connectors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Lipo Connectors – XT30 vs XT60

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Lipo battery connectors such as XT30 and XT60 are commonly used in RC planes. XT30 is smaller and lighter, suitable for smaller scale FPV applications, while XT60 is more standard for larger batteries. Users express frustration over the variety of connectors, as it often requires adapters or soldering to standardize equipment. The discussion highlights the need for different connectors based on ba…

Strategic Sourcing Conclusion and Outlook for types of battery connectors

The selection of battery connectors plays a pivotal role in enhancing operational efficiency and safety across various applications. B2B buyers must prioritize strategic sourcing to ensure compatibility, durability, and optimal performance of battery connectors tailored to their specific needs. By understanding the diverse types available—from quick-connect to heavy-duty connectors—organizations can mitigate risks such as overheating and energy loss, thereby extending the lifespan of their battery systems.

Investing in high-quality connectors not only safeguards operational integrity but also aligns with sustainability goals by reducing energy waste. Buyers in emerging markets like Africa, South America, and the Middle East should consider local suppliers that offer reliable, compliant products suited to their environmental conditions.

Looking ahead, the demand for advanced battery connectors is set to rise, driven by the growth of electric vehicles and renewable energy systems. Now is the time for international B2B buyers to engage with reputable suppliers, evaluate their sourcing strategies, and adopt innovative solutions that will empower their operations and support their long-term growth objectives. Make informed decisions today to stay ahead in a rapidly evolving market.