Gbl For Sale: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for gbl for sale

In the dynamic landscape of international trade, sourcing gamma-butyrolactone (GBL) can pose significant challenges for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. The complexities of finding reliable suppliers, navigating regulatory environments, and ensuring product quality can hinder the procurement process. This guide is designed to empower businesses by offering a comprehensive overview of the global GBL market, addressing crucial aspects such as product types, applications, supplier vetting, and cost considerations.

Through in-depth insights, buyers will learn how to effectively evaluate suppliers, identify the most suitable product formulations for their specific needs, and understand the regulatory frameworks that govern GBL usage in different markets. Additionally, this guide provides actionable strategies for negotiating prices and establishing long-term partnerships with suppliers.

By equipping international B2B buyers, particularly from Brazil and Nigeria, with the knowledge and tools necessary for informed purchasing decisions, this resource aims to streamline the sourcing process and minimize risks. With a focus on transparency and reliability, businesses can confidently navigate the complexities of the GBL market, ensuring they secure high-quality products that meet their operational requirements.

Understanding gbl for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard GBL Solution | Typically available in concentrations like 1 mg/mL | Chemical manufacturing, pharmaceuticals | Pros: Reliable quality, consistent results. Cons: Limited customization options. |

| GBL Reference Standards | High purity, often used for calibration | Laboratory analysis, research | Pros: Ensures accuracy in testing. Cons: Higher cost due to purity standards. |

| Industrial GBL | Bulk quantities, often less pure, cost-effective | Cleaning agents, solvents, manufacturing | Pros: Cost-efficient for large-scale use. Cons: May not meet stringent quality requirements. |

| Custom GBL Solutions | Tailored formulations to meet specific needs | Specialized industries, custom applications | Pros: Meets unique specifications. Cons: Longer lead times for production. |

| GBL for Cleaning Applications | Formulated for specific cleaning tasks | Automotive, industrial cleaning | Pros: Effective for targeted cleaning. Cons: May require additional safety precautions. |

What are the characteristics of Standard GBL Solutions for B2B Buyers?

Standard GBL solutions are commonly available in concentrations such as 1 mg/mL and are primarily used in chemical manufacturing and pharmaceuticals. These products are characterized by their reliability and consistent quality, making them suitable for various applications. B2B buyers should consider the supplier’s reputation and the product’s compliance with industry standards to ensure they are obtaining a dependable solution.

How do GBL Reference Standards differ from other types?

GBL reference standards are designed for high purity and are often utilized in laboratory settings for calibration and testing. These products ensure accuracy in analytical processes, which is crucial for research and development. While they are generally more expensive due to their stringent purity requirements, they are indispensable for buyers who prioritize precision and quality in their operations.

Why choose Industrial GBL for specific applications?

Industrial GBL is typically offered in bulk quantities and is less pure than other types, making it a cost-effective option for businesses engaged in manufacturing or cleaning applications. This type of GBL is ideal for companies looking to maximize their budget while still obtaining a functional product. However, it’s essential for buyers to evaluate whether the lower purity meets their operational needs, especially in sensitive environments.

What benefits do Custom GBL Solutions offer to businesses?

Custom GBL solutions are tailored to meet the specific requirements of various industries, providing a unique advantage for B2B buyers. These formulations can address particular challenges or applications, enhancing operational efficiency. However, businesses should be prepared for potentially longer lead times, which may impact project timelines.

How effective is GBL for Cleaning Applications in various industries?

GBL formulated for cleaning applications is specifically designed to tackle tough residues and contaminants, making it popular in sectors like automotive and industrial cleaning. While these products are effective and can improve cleaning efficiency, buyers must also consider safety precautions due to the chemical nature of GBL. Understanding the specific cleaning requirements and safety guidelines is crucial for successful application.

Key Industrial Applications of gbl for sale

| Industry/Sector | Specific Application of gbl for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Solvent in drug formulation | Enhances solubility and bioavailability of active ingredients | Ensure compliance with local regulations and purity standards |

| Chemical Manufacturing | Intermediate in chemical synthesis | Facilitates production of various chemicals and polymers | Verify supplier reliability and quality certifications |

| Cleaning Products | Component in industrial cleaners | Effective in removing tough stains and residues | Look for bulk purchasing options and shipping capabilities |

| Agriculture | Soil conditioner and growth enhancer | Improves soil quality and enhances crop yields | Assess environmental impact and regulatory compliance |

| Cosmetics and Personal Care | Solvent in cosmetic formulations | Increases product stability and enhances texture | Demand safety data sheets and stability testing results |

How is GBL Used in the Pharmaceutical Industry?

In the pharmaceutical sector, gamma-butyrolactone (GBL) serves as an essential solvent in drug formulation. It enhances the solubility and bioavailability of active pharmaceutical ingredients, making medications more effective. International buyers, particularly from regions like Africa and South America, must ensure that the GBL they source complies with stringent local regulations regarding purity and safety. Understanding the specific formulation requirements is crucial to avoid costly production delays.

What Role Does GBL Play in Chemical Manufacturing?

GBL is widely utilized as an intermediate in chemical synthesis within the chemical manufacturing industry. It plays a critical role in producing various chemicals and polymers, which are foundational to many products across multiple sectors. Buyers should prioritize suppliers with a proven track record of reliability and quality certifications to ensure consistent supply and adherence to industry standards. Moreover, understanding the specific chemical processes involved can aid in optimizing procurement strategies.

How is GBL Beneficial in Cleaning Products?

In the cleaning products sector, GBL is a key component in formulating industrial cleaners. Its effectiveness in removing tough stains and residues makes it invaluable for businesses that rely on high-performance cleaning solutions. For B2B buyers, seeking bulk purchasing options is essential to manage costs effectively. Additionally, ensuring that suppliers can meet shipping requirements for hazardous materials can streamline the procurement process.

How is GBL Applied in Agriculture?

GBL finds applications in agriculture as a soil conditioner and growth enhancer. It improves soil quality and enhances crop yields, making it a valuable asset for agricultural businesses looking to increase productivity. Buyers from various regions must assess the environmental impact of GBL and ensure compliance with local agricultural regulations. Establishing relationships with suppliers who understand regional agricultural practices can also provide a competitive advantage.

Why is GBL Important in Cosmetics and Personal Care?

In the cosmetics and personal care industry, GBL acts as a solvent in various formulations. It helps increase product stability and enhance texture, which is critical for consumer acceptance. B2B buyers should demand safety data sheets and stability testing results to ensure that the products meet safety standards and perform as expected. Establishing a reliable supply chain for GBL can significantly impact product quality and brand reputation.

3 Common User Pain Points for ‘gbl for sale’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for GBL Purchases

The Problem: B2B buyers often encounter significant hurdles when it comes to understanding and complying with the various regulations surrounding the purchase and use of Gamma-Butyrolactone (GBL). Different countries have unique legal frameworks regarding chemical substances, and failing to navigate these can result in severe penalties or shipment delays. For instance, buyers from regions like the Middle East or South America may find it challenging to ascertain whether GBL is classified as a controlled substance in their jurisdictions, leading to confusion and potential disruptions in their supply chains.

The Solution: To effectively navigate regulatory compliance, buyers should first conduct thorough research on the legal status of GBL in their respective countries. This involves consulting with local regulatory bodies or seeking legal counsel to understand the nuances of chemical regulations. Additionally, buyers should partner with suppliers that provide clear documentation, including Certificates of Analysis (CoA) and Safety Data Sheets (SDS), which detail the composition and safety of GBL. Choosing suppliers who are transparent about their compliance processes can also help mitigate risks. Establishing a checklist that includes regulatory requirements specific to GBL can streamline the purchasing process, ensuring that buyers remain compliant while minimizing potential legal repercussions.

Scenario 2: Ensuring Product Quality and Consistency in GBL Supply

The Problem: Quality inconsistency is a prevalent issue in the procurement of GBL, especially when sourcing from multiple suppliers. Variations in purity levels and the presence of impurities can severely impact downstream applications, leading to operational inefficiencies and potential product recalls. B2B buyers from industries such as pharmaceuticals or chemical manufacturing may find themselves in a precarious position if the GBL they receive does not meet their stringent quality standards, resulting in lost revenue and reputational damage.

The Solution: To ensure product quality and consistency, buyers should prioritize sourcing GBL from reputable suppliers with a proven track record in the industry. It is crucial to request detailed specifications regarding the GBL’s purity and any potential contaminants. Establishing a robust quality assurance process that includes regular testing of received products against established benchmarks can help maintain high standards. Buyers should also consider entering into long-term contracts with a single supplier to foster a more reliable supply chain, allowing for better quality control measures and consistent product offerings. Additionally, leveraging technology for inventory management can help track batch numbers and quality metrics, ensuring any quality issues can be swiftly addressed.

Scenario 3: Streamlining Logistics and Shipping for GBL Orders

The Problem: Logistics can be a daunting aspect of purchasing GBL, particularly for international B2B transactions. Complications can arise from shipping restrictions, customs regulations, and unexpected delays that can disrupt production schedules. For buyers in regions like Africa or South America, the lack of reliable shipping options can lead to increased costs and longer lead times, adversely affecting their operational efficiency and customer satisfaction.

The Solution: To streamline logistics and shipping, buyers should engage suppliers who have established, reliable shipping channels and experience handling international shipments of chemical products. It’s beneficial to discuss shipping options upfront, including the possibility of expedited shipping if necessary. Buyers should also familiarize themselves with the customs clearance process in their country and work closely with suppliers to ensure all necessary documentation is prepared in advance. Building relationships with freight forwarders who specialize in chemical shipments can also enhance shipping efficiency. Implementing a logistics management system can provide visibility into shipment status, helping buyers anticipate potential delays and adjust their operations accordingly.

Strategic Material Selection Guide for gbl for sale

What Are the Key Materials for GBL in B2B Applications?

When considering the strategic selection of materials for Gamma-Butyrolactone (GBL) applications, it is essential to evaluate the properties, advantages, and limitations of various materials. This analysis focuses on four common materials used in the formulation and packaging of GBL, providing insights specifically for international B2B buyers.

1. Acetonitrile

Key Properties: Acetonitrile is a polar aprotic solvent with a high boiling point of 82 °C and excellent solubility for a variety of organic compounds. It is stable under a wide range of temperatures and pressures.

Pros & Cons: Acetonitrile is cost-effective and readily available, making it a popular choice for GBL formulations. However, it is moderately toxic and requires careful handling, which can complicate manufacturing processes.

Impact on Application: Acetonitrile’s compatibility with GBL enhances the solubility of various compounds, making it suitable for applications in pharmaceuticals and chemical synthesis.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding the use of toxic solvents, including proper labeling and safety data sheets (SDS).

2. Glass Containers

Key Properties: Glass is non-reactive, resistant to corrosion, and can withstand a wide range of temperatures, making it ideal for storing GBL.

Pros & Cons: Glass containers are durable and provide excellent barrier properties against moisture and gases. However, they can be heavy and fragile, increasing shipping costs and the risk of breakage during transport.

Impact on Application: The inert nature of glass ensures that GBL remains uncontaminated, which is critical for applications requiring high purity.

Considerations for International Buyers: Buyers should consider the shipping regulations for glass containers, especially in regions with stringent import regulations. Ensuring proper packaging to prevent breakage is also essential.

3. Polyethylene (PE)

Key Properties: Polyethylene is a lightweight, flexible plastic with good chemical resistance and a melting point of around 120 °C.

Pros & Cons: PE is cost-effective and easy to manufacture, making it a common choice for packaging. However, it has lower temperature resistance compared to glass and may not be suitable for all GBL applications.

Impact on Application: PE’s chemical resistance allows it to be used for GBL storage, but its lower durability may limit its use in high-pressure applications.

Considerations for International Buyers: Buyers should verify compliance with local plastic regulations, especially in regions like Europe, where there are strict guidelines on plastic use and recycling.

4. Stainless Steel

Key Properties: Stainless steel is known for its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressures.

Pros & Cons: While stainless steel offers exceptional durability and longevity, it is more expensive than other materials and can complicate manufacturing due to its hardness.

Impact on Application: Stainless steel is ideal for high-pressure applications and environments where contamination must be minimized, making it suitable for industrial GBL processing.

Considerations for International Buyers: Buyers should ensure that the stainless steel used meets international standards such as ASTM or DIN, particularly in regions with strict quality control measures.

Summary Table of Material Selection for GBL

| Material | Typical Use Case for gbl for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acetonitrile | Solvent in GBL formulations | Cost-effective and widely available | Moderately toxic | Low |

| Glass Containers | Storage and transport of GBL | Excellent barrier properties | Heavy and fragile | Medium |

| Polyethylene (PE) | Packaging for GBL products | Lightweight and flexible | Lower temperature resistance | Low |

| Stainless Steel | Industrial processing of GBL | High strength and corrosion resistant | Higher cost and manufacturing complexity | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for GBL applications, facilitating informed decision-making in their procurement processes.

In-depth Look: Manufacturing Processes and Quality Assurance for gbl for sale

What Are the Key Stages in the Manufacturing Process of GBL?

The manufacturing process of Gamma-Butyrolactone (GBL) involves several critical stages that ensure the production of a high-quality product. Understanding these stages is essential for B2B buyers looking to source GBL effectively.

Material Preparation: What Is Involved?

The first step in the GBL manufacturing process is material preparation. The primary raw materials for GBL production typically include butyric acid and a dehydrating agent, often an anhydride. These materials must be of high purity to minimize impurities in the final product. Suppliers often conduct rigorous screening to ensure that the raw materials meet specific quality standards, which can include both chemical composition and physical properties.

How Is GBL Formed?

Once the materials are prepared, the next step is the formation process. This typically involves a chemical reaction known as cyclization, where butyric acid undergoes a dehydration reaction. The reaction conditions, such as temperature and pressure, are meticulously controlled to optimize yield and minimize by-products. Advanced techniques, such as continuous flow reactors, may be employed to enhance efficiency and scalability.

What Is the Assembly Phase?

The assembly phase for GBL production is relatively straightforward compared to more complex manufacturing processes. In this context, assembly refers to the integration of various components in the production line, including distillation units and filtration systems. This phase ensures that the GBL is separated from other by-products and impurities, resulting in a purer product ready for the finishing stage.

What Finishing Techniques Are Used?

The finishing stage involves several key processes, including distillation, drying, and packaging. Distillation is critical for achieving the desired purity levels of GBL, which is often specified at 99% or higher for industrial applications. After distillation, the product is typically dried to remove any residual solvents. Finally, GBL is packaged in suitable containers that ensure stability during transport, often involving nitrogen flushing to minimize oxidation.

What Are the International Quality Assurance Standards for GBL?

Quality assurance is a vital aspect of GBL manufacturing, particularly for international B2B buyers. Adherence to recognized quality standards not only enhances product reliability but also builds trust between suppliers and buyers.

Which International Standards Are Relevant?

ISO 9001 is one of the most recognized quality management systems globally, applicable to all organizations, regardless of size or industry. For GBL manufacturers, compliance with ISO 9001 ensures that processes are standardized, leading to consistent product quality. Additionally, specific certifications such as CE marking for products sold in Europe and API (Active Pharmaceutical Ingredient) standards for pharmaceutical applications may also be relevant, depending on the intended use of GBL.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This phase assesses the quality of raw materials before they enter the production process. Suppliers often require certificates of analysis (CoAs) to confirm material specifications.

-

In-Process Quality Control (IPQC): During production, various parameters such as temperature, pressure, and reaction time are monitored to ensure they remain within specified limits. Regular sampling may occur to assess product quality at different stages.

-

Final Quality Control (FQC): After the manufacturing process, the finished GBL product undergoes thorough testing to verify its purity and compliance with relevant specifications. This may involve chromatographic analysis, spectroscopic methods, and other analytical techniques.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to ensure they are sourcing a reliable product. Here are effective strategies to achieve this.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is a proactive approach to assess the manufacturing and QC practices of potential suppliers. During an audit, buyers can evaluate the facilities, review documentation, and interview staff about their processes. Audits can be done internally or through third-party inspection agencies, which can lend additional credibility to the findings.

How Important Are Quality Control Reports?

Requesting detailed quality control reports from suppliers is another effective way to verify their commitment to quality. These reports should include results from IQC, IPQC, and FQC, along with CoAs for raw materials and finished products. A transparent supplier will readily provide these documents, enabling buyers to assess compliance with international standards.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add another layer of assurance for buyers. These independent entities can conduct inspections and testing of GBL products before shipment, ensuring that they meet the required specifications. This is particularly important for B2B buyers from regions like Africa and South America, where local regulations may differ significantly from those in Europe or the Middle East.

How Do QC and Certification Nuances Affect International Buyers?

International B2B buyers must navigate various certification nuances that can impact their procurement processes. For instance, regulations regarding chemical imports may vary by country, affecting how GBL is sourced and sold.

What Are the Regional Considerations for Compliance?

In regions such as Africa and South America, where regulatory frameworks may be less stringent than in Europe or North America, buyers should be cautious. It is advisable to work with suppliers who comply with international standards and can demonstrate their commitment to quality through relevant certifications.

How Can Buyers Stay Informed About Changes in Regulations?

Staying updated on changes in international regulations and standards is vital for B2B buyers. Subscribing to industry newsletters, participating in trade associations, and attending relevant conferences can provide insights into the latest compliance requirements. This proactive approach can help buyers mitigate risks associated with sourcing GBL and ensure that they remain compliant with their local laws.

In conclusion, understanding the manufacturing processes and quality assurance measures for GBL is essential for international B2B buyers. By focusing on these aspects, buyers can make informed decisions and establish successful partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gbl for sale’

To assist B2B buyers in procuring gamma-butyrolactone (GBL), this practical sourcing guide offers a systematic checklist. Each step is designed to ensure that you engage with reputable suppliers and secure high-quality products that meet your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the GBL you need, including purity levels, concentration, and packaging requirements. This step is critical as it helps you communicate your needs effectively to suppliers and ensures you receive products that meet your intended application. Consider factors such as whether you require GBL in solution form, like in acetonitrile, or as a standalone product.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in GBL. Look for companies with a proven track record in the chemical industry and positive customer reviews. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers that meet your criteria.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold the necessary certifications and comply with international standards. This includes checking for ISO certifications, safety data sheets (SDS), and any relevant regulatory compliance documents. Such certifications are crucial in ensuring product quality and safety, especially in regions with stringent regulations.

Step 4: Request Samples for Quality Assessment

Always request samples of the GBL before placing a bulk order. This allows you to conduct your own quality testing and confirm that the product meets your specifications. Pay attention to the sample’s purity, appearance, and any accompanying documentation, such as a Certificate of Analysis (CoA).

Step 5: Inquire About Shipping and Handling Procedures

Understand the supplier’s shipping and handling processes, including packaging standards and delivery timelines. Ensure they can accommodate your location’s specific import/export regulations. Reliable shipping practices are essential to maintain product integrity and ensure timely delivery, especially when dealing with sensitive chemicals like GBL.

Step 6: Negotiate Pricing and Payment Terms

Engage in discussions regarding pricing, payment options, and terms of sale. Consider not only the unit price but also factors like minimum order quantities and bulk discounts. Establishing favorable terms can enhance your procurement strategy and ensure a sustainable relationship with the supplier.

Step 7: Establish Clear Communication Channels

Set up clear communication channels with your chosen supplier. This includes agreeing on regular updates regarding order status, potential delays, or changes in product availability. Effective communication is vital for maintaining a smooth procurement process and addressing any issues promptly.

By following this checklist, B2B buyers can make informed decisions when sourcing GBL, ensuring that they partner with reliable suppliers who can deliver high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for gbl for sale Sourcing

What Are the Key Cost Components in GBL Sourcing?

When sourcing gamma-butyrolactone (GBL), understanding the cost structure is crucial for effective budget planning and negotiation. The primary cost components include:

-

Materials: The price of raw materials, specifically GBL and any solvents or additives, constitutes a significant portion of the total cost. Variability in global chemical prices can affect sourcing costs, so monitoring market trends is essential.

-

Labor: Labor costs encompass the workforce involved in manufacturing, quality control, and logistics. Depending on the supplier’s location, these costs can vary significantly, impacting the overall pricing structure.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient production processes can help minimize these costs, making it important for buyers to assess suppliers’ operational efficiencies.

-

Tooling: If customization is required, tooling costs may arise. This is particularly relevant for suppliers who need to adapt production lines to meet specific buyer specifications.

-

Quality Control (QC): Ensuring product quality often involves additional testing and compliance certifications, which can add to the overall cost. Buyers should prioritize suppliers who adhere to recognized quality standards.

-

Logistics: Transportation costs vary based on the shipping method, distance, and weight of the shipment. Incoterms (International Commercial Terms) will also affect who bears these costs, so understanding these terms is vital for budgeting.

-

Margin: Suppliers will factor in their profit margins, which can differ based on competition and market demand. Negotiating on this aspect can lead to more favorable pricing.

How Do Price Influencers Impact GBL Pricing?

Several factors can influence the pricing of GBL, and understanding these can empower buyers to make informed decisions:

-

Volume/MOQ: Suppliers often provide discounts for larger orders or Minimum Order Quantities (MOQ). Buyers should evaluate their needs and consider consolidating orders to leverage better pricing.

-

Specifications and Customization: Custom formulations or specific purity levels can lead to increased costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The source and quality of materials can significantly impact pricing. Suppliers that provide higher-grade GBL or possess relevant certifications may charge a premium, but this often translates to better performance and reliability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers with a proven track record may command higher prices but often provide greater reliability and support.

-

Incoterms: Understanding the implications of Incoterms is critical. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate responsibility for costs and risks, impacting the total cost of ownership.

What Buyer Tips Can Lead to Cost-Efficiency in GBL Procurement?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, implementing strategic procurement practices can enhance cost-efficiency:

-

Negotiation: Engage in open discussions with suppliers to negotiate pricing, especially if you represent a large order volume. Building a good relationship can also lead to more favorable terms.

-

Total Cost of Ownership: Evaluate the total cost of ownership, not just the purchase price. This includes logistics, storage, and potential waste or spoilage costs, particularly for sensitive chemical products like GBL.

-

Pricing Nuances: Be aware of regional pricing differences. Factors such as local regulations, import duties, and currency fluctuations can affect overall costs. Conduct thorough research to understand these nuances.

-

Supplier Diversification: Consider sourcing from multiple suppliers to mitigate risks and enhance competitive pricing. This strategy can also help ensure continuity of supply in case of disruptions.

-

Stay Informed: Regularly monitor the chemical market and stay updated on price trends, regulatory changes, and technological advancements that could affect GBL sourcing.

Disclaimer on Pricing

The prices for GBL can vary significantly based on supplier, location, and market conditions. The figures provided in this analysis are indicative and may not reflect current market prices. Buyers are encouraged to conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing gbl for sale With Other Solutions

Understanding the Importance of Exploring Alternatives

In the competitive landscape of B2B procurement, especially for chemical products like gamma-butyrolactone (GBL), it is essential for buyers to explore various alternatives. This enables businesses to make informed decisions based on performance, cost, and suitability for their specific applications. By comparing GBL for sale with other viable solutions, businesses can identify the most effective option that aligns with their operational needs and budget constraints.

Comparison Table of GBL for Sale Against Alternatives

| Comparison Aspect | GBL For Sale | Alternative 1: 1,4-Butanediol (BDO) | Alternative 2: Ethyl Lactate |

|---|---|---|---|

| Performance | High solubility, effective solvent | Similar performance in solvent applications | Biodegradable, less toxic |

| Cost | Moderate cost ($40.50/mL) | Generally lower cost | Higher cost per volume |

| Ease of Implementation | Requires specific handling | Easier handling and storage | Simple integration in many processes |

| Maintenance | Requires careful storage | Low maintenance | Low maintenance |

| Best Use Case | Laboratory use, industrial solvents | Industrial applications, polymer production | Cleaning agents, food applications |

In-Depth Analysis of Alternatives

1. 1,4-Butanediol (BDO)

1,4-Butanediol (BDO) is an alternative to GBL that offers similar performance in solvent applications. It is often used in the production of plastics, elastic fibers, and other industrial products. One of the significant advantages of BDO is its lower cost, making it an attractive option for businesses looking to minimize expenses. However, BDO requires careful handling due to its toxicity, which may necessitate additional safety measures. Its versatility makes it suitable for a variety of applications, but companies must consider regulatory compliance and safe storage requirements.

2. Ethyl Lactate

Ethyl lactate is a biodegradable solvent derived from renewable resources, making it an environmentally friendly alternative to GBL. It is widely used in cleaning agents and food applications due to its lower toxicity profile. While ethyl lactate may have a higher cost per volume compared to GBL, its safety and environmental benefits can justify the investment for companies focused on sustainability. The ease of integration into existing processes is another advantage, although businesses must assess its performance in specific applications compared to GBL.

Making the Right Choice: Factors for B2B Buyers to Consider

When selecting the right chemical solution for their needs, B2B buyers should consider several factors. Assessing the performance requirements for their specific applications is crucial, as is understanding the cost implications of each alternative. Additionally, the ease of implementation and long-term maintenance needs should be evaluated, especially in industries with strict regulatory standards. Ultimately, the choice between GBL and its alternatives will depend on the buyer’s unique operational context, budget, and sustainability goals. By conducting thorough research and considering the insights provided, businesses can make strategic decisions that enhance their operational efficiency and align with their values.

Essential Technical Properties and Trade Terminology for gbl for sale

What Are the Key Technical Properties of GBL for Sale?

When sourcing gamma-butyrolactone (GBL), understanding its technical specifications is crucial for ensuring quality and compliance in various applications. Here are some essential properties to consider:

-

Molecular Formula and Weight

GBL is chemically represented as C4H6O2, with a molecular weight of 86.09 g/mol. This specification is vital for buyers to ascertain the compound’s reactivity and compatibility with other substances in chemical processes. -

Purity Grade

The purity of GBL is often quantified in percentage, with high-grade products typically exceeding 99%. High purity is essential for applications in pharmaceuticals and chemical synthesis, where impurities can lead to adverse reactions or ineffective results. -

Concentration

GBL is commonly available in various concentrations, such as 1 mg/mL in acetonitrile. This specification is crucial for B2B buyers to ensure that the product meets the requirements of specific applications, such as laboratory testing or industrial use. -

Storage and Shipping Conditions

GBL should be stored at a controlled temperature (ideally around +5°C) to maintain its stability. Understanding shipping conditions, including temperature limits during transit, is essential for buyers to prevent product degradation. -

CAS Number

The Chemical Abstracts Service (CAS) number for GBL is 96-48-0. This unique identifier allows buyers to verify product specifications and ensures they are acquiring the correct chemical substance. -

Matrix Composition

GBL is often supplied in a solvent, such as acetonitrile. Knowing the matrix composition is important for buyers to evaluate the solvent’s compatibility with their processes and ensure it does not interfere with the intended applications.

What Are Common Trade Terms Used in GBL Transactions?

Navigating the procurement of GBL involves familiarity with several industry-specific terms that facilitate smooth transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help B2B buyers identify reliable sources of GBL integrated into their products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to plan their purchases effectively, ensuring they meet supplier requirements while managing inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other terms for a specific quantity of goods. This is a critical step in procurement that allows buyers to compare options and negotiate better deals. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, as they clarify costs and risks associated with shipping GBL across borders. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until delivery. Understanding lead times helps buyers plan their production schedules and manage supply chain efficiency effectively. -

Certificate of Analysis (CoA)

A CoA is a document issued by a quality assurance organization that confirms that a product meets its specifications. For GBL buyers, obtaining a CoA is critical for ensuring the quality and compliance of the product with industry standards.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing GBL, ensuring they obtain high-quality materials that meet their specific requirements.

Navigating Market Dynamics and Sourcing Trends in the gbl for sale Sector

What Are the Current Market Dynamics and Key Trends in the GBL for Sale Sector?

The global market for gamma-butyrolactone (GBL) is experiencing significant growth, driven by various factors including its application in industrial solvents, pharmaceuticals, and as a precursor in the production of other chemicals. Emerging markets in Africa, South America, the Middle East, and Europe are increasingly becoming pivotal in the sourcing landscape, primarily due to the rising demand for high-quality chemical products.

One of the notable trends is the integration of technology in the sourcing process. Digital platforms are facilitating B2B transactions, enabling buyers to compare prices, check product specifications, and review supplier ratings with ease. Additionally, the rise of e-commerce in regions like Brazil and Nigeria is reshaping how GBL is sourced, allowing for more transparency and efficiency in procurement.

Moreover, sustainability is becoming a critical consideration for international buyers. Companies are increasingly looking for suppliers who can demonstrate responsible sourcing practices, which include minimizing environmental impact and ensuring compliance with regulatory standards. These trends point to a market that is not only expanding but also evolving, making it essential for buyers to stay informed about the latest developments and adapt their sourcing strategies accordingly.

How Is Sustainability and Ethical Sourcing Shaping the GBL for Sale Sector?

Sustainability and ethical sourcing are emerging as pivotal factors in the GBL market, with significant implications for B2B transactions. The environmental impact of chemical production is under scrutiny, prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes reducing carbon footprints, managing waste responsibly, and using renewable energy sources.

Moreover, ethical supply chains are gaining importance among B2B buyers. Companies are increasingly demanding transparency from their suppliers regarding sourcing practices and labor conditions. This shift is not only about compliance; it reflects a growing consumer preference for ethically sourced products, which can influence purchasing decisions in the B2B space.

Certifications such as ISO 14001 for environmental management and initiatives for green chemistry are becoming essential for suppliers looking to attract international buyers. By investing in sustainable practices and obtaining relevant certifications, suppliers can differentiate themselves in a competitive market, ultimately appealing to businesses that prioritize sustainability in their procurement processes.

What Is the Brief Evolution and History of GBL in the B2B Context?

Gamma-butyrolactone (GBL) was first synthesized in the 19th century and has since evolved from a niche chemical compound to a widely used solvent and intermediate in various industries. Initially, GBL found applications in the production of plastics and pharmaceuticals. Over the decades, its versatility has led to expanded uses, including in the formulation of cleaning agents, adhesives, and as a solvent in chemical synthesis.

The B2B landscape for GBL has also transformed, particularly with the advent of globalization and digital commerce. Suppliers now have the opportunity to reach a broader audience, while buyers benefit from a more competitive marketplace. Today, GBL is not only recognized for its industrial applications but is also increasingly associated with sustainability and ethical sourcing practices, reflecting the changing dynamics of global trade and procurement.

Frequently Asked Questions (FAQs) for B2B Buyers of gbl for sale

-

How do I ensure the quality of GBL before purchasing?

To ensure the quality of gamma-butyrolactone (GBL), request a Certificate of Analysis (CoA) from your supplier. This document should detail the product’s purity, composition, and any contaminants. Additionally, verify the supplier’s reputation through reviews and testimonials from other B2B buyers. Conducting independent testing of sample batches can also help confirm quality. Establishing a clear communication channel with your supplier can facilitate discussions about quality assurance processes and standards they adhere to. -

What is the typical minimum order quantity (MOQ) for GBL?

The MOQ for GBL can vary significantly among suppliers, generally ranging from 1 liter to 100 liters or more, depending on the supplier’s production capabilities and the buyer’s needs. It’s advisable to inquire directly with potential suppliers to understand their specific MOQs. Some suppliers may offer flexibility for first-time orders or smaller businesses. Consider negotiating terms that allow for trial orders, enabling you to assess product quality without committing to large quantities upfront. -

What are the best payment terms when buying GBL internationally?

When purchasing GBL internationally, consider payment terms such as letters of credit, bank transfers, or PayPal for security. Letters of credit are a safe option as they provide financial assurance to both parties. Ensure to clarify payment timelines and any upfront deposits required. Additionally, assess whether the supplier offers flexible payment terms based on order volume or repeat business, which can improve cash flow for your operations. -

How can I vet suppliers for GBL to ensure reliability?

To vet suppliers for GBL, start by checking their certifications and compliance with international regulations. Look for suppliers with ISO certifications or those registered with local regulatory bodies. Reading reviews and testimonials from other B2B clients can provide insights into their reliability. Furthermore, consider requesting references and conducting background checks on their operational history. A site visit or virtual audit can also enhance your understanding of their production capabilities and quality control measures. -

What are the shipping considerations when sourcing GBL internationally?

Shipping GBL internationally requires careful attention to regulations and logistics. Ensure that your supplier complies with all shipping regulations in both the exporting and importing countries. Shipping options may include air freight or sea freight, each with different cost and time implications. Factor in customs clearance processes, potential tariffs, and the need for specific shipping documentation, such as safety data sheets (SDS). Establishing a good relationship with a logistics partner can streamline this process. -

Can I customize GBL products to meet my specific needs?

Many suppliers offer customization options for GBL, allowing you to specify concentrations, packaging sizes, or formulations tailored to your requirements. Discuss your needs directly with the supplier to see if they can accommodate custom orders. Be prepared to meet any minimum order requirements that may apply to customized products. Additionally, confirm whether there are additional costs or lead times associated with customization. -

What quality assurance processes should I expect from GBL suppliers?

Reputable GBL suppliers typically have stringent quality assurance processes in place. This may include regular quality checks during production, batch testing by independent laboratories, and adherence to international quality standards. Ask potential suppliers about their QA protocols, including how they handle deviations in product quality. Understanding their commitment to quality can help mitigate risks associated with sourcing GBL. -

What regulations should I be aware of when importing GBL?

Importing GBL involves navigating various regulations that differ by country. It’s crucial to familiarize yourself with the import regulations specific to your country, including any permits or licenses required. Some countries classify GBL under controlled substances, necessitating special handling and documentation. Consulting with a customs broker can provide clarity on the specific requirements and help ensure compliance, thus avoiding potential legal issues during the import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Gbl For Sale Manufacturers & Suppliers List

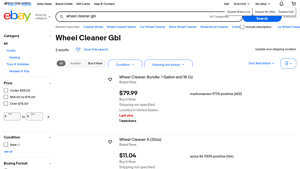

1. Wheel Cleaner Gbl – Various Sizes Available

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Wheel Cleaner Gbl available in various sizes and formats including 32oz and 1 Gallon options. Prices range from approximately $11.04 to $79.99 depending on the bundle and seller. Most listings are brand new with free delivery options. Sellers have high positive ratings, indicating reliability. Products include non-acid and acid-based cleaners suitable for different wheel types. Shipping typically …

2. Restek – Gamma-Butyrolactone (GBL) 1000 µg/mL

Domain: restek.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Gamma-Butyrolactone (GBL)”, “Concentration”: “1000 µg/mL”, “Solvent”: “Acetonitrile”, “Volume”: “1 mL/ampul”, “Catalog No.”: “34077”, “Price”: “$40.50”, “Shipping Note”: “Ground freight is the default shipping method; expedited methods available upon request.”, “Stability Note”: “Remains stable after being continuously exposed to an elevated temperature of 40 °C for 7 days.”, “CA…

3. WebMD – Gamma Butyrolactone (GBL)

Domain: webmd.com

Registered: 1998 (27 years)

Introduction: Gamma Butyrolactone (GBL) is a chemical found in cleaning solutions and nail polish. In the body, it converts to gamma-hydroxybutyrate (GHB), which is associated with serious safety concerns, including its use as a date-rape drug. GBL is classified as a Schedule I controlled substance in the US, making it illegal. It is considered unsafe when taken by mouth, with potential side effects including s…

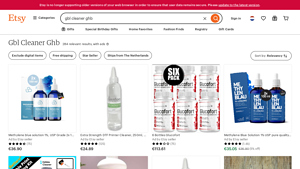

4. Etsy – GBL Cleaner GHB

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – GBL Cleaner GHB, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for gbl for sale

As the global demand for gamma-butyrolactone (GBL) continues to rise, strategic sourcing becomes essential for B2B buyers looking to secure reliable supply chains. Key considerations include understanding the product specifications, such as concentration and purity levels, and ensuring compliance with international regulations. Buyers should prioritize suppliers with proven stability in shipping and handling practices, particularly those who can provide certifications of analysis (CoA) to guarantee product quality.

Furthermore, exploring partnerships with suppliers from diverse regions can enhance procurement flexibility and mitigate risks associated with market fluctuations. Buyers from Africa, South America, the Middle East, and Europe should leverage the growing availability of GBL products to negotiate favorable terms and optimize their sourcing strategies.

Looking ahead, embracing a proactive approach to sourcing GBL will be crucial in adapting to market trends and demands. Engaging with reputable suppliers and staying informed about industry developments will empower businesses to make informed purchasing decisions. We encourage international B2B buyers to explore the opportunities within the GBL market and establish strategic partnerships that will drive growth and innovation in their respective sectors.