Top 8 20000 Watt Power Inverter Suppliers (And How to Choose)

Introduction: Navigating the Global Market for 20000 watt power inverter

In an increasingly electrified world, sourcing a reliable 20,000 watt power inverter is essential for businesses aiming to ensure uninterrupted power supply, particularly in regions with inconsistent electricity access. This comprehensive guide addresses a critical challenge faced by international B2B buyers: navigating the complexities of inverter technology and supplier options. From exploring various types of inverters—such as pure sine wave and modified sine wave—to understanding their applications in commercial, industrial, and off-grid settings, this resource is designed to equip decision-makers with the knowledge needed to make informed purchasing choices.

Moreover, our guide delves into supplier vetting processes, cost considerations, and performance specifications that are crucial for selecting the right inverter for your business needs. With a focus on diverse markets in Africa, South America, the Middle East, and Europe—including key countries like Germany and Saudi Arabia—this guide empowers buyers to identify trustworthy suppliers, understand local regulations, and evaluate product quality against international standards.

By the end of this guide, you will have the tools necessary to navigate the global market for 20,000 watt power inverters confidently. Whether you are looking to enhance your renewable energy capabilities or ensure backup power for critical operations, this resource will support your strategic purchasing decisions, ultimately driving efficiency and sustainability in your operations.

Understanding 20000 watt power inverter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pure Sine Wave Inverter | High-quality output; suitable for sensitive electronics | Commercial buildings, data centers | Pros: Clean power, efficient; Cons: Higher cost compared to modified sine wave inverters. |

| Modified Sine Wave Inverter | Cost-effective; simpler design | Small businesses, basic appliances | Pros: Affordable; Cons: Not suitable for all devices, can cause overheating. |

| Hybrid Inverter | Combines solar and grid power; battery charging capability | Off-grid systems, renewable energy projects | Pros: Versatile, energy-efficient; Cons: More complex installation and maintenance. |

| Inverter Charger | Integrated battery charging; often includes advanced features | Emergency backup systems, remote locations | Pros: Dual functionality, reliable power source; Cons: Higher upfront investment. |

| DC to AC Inverter | Converts various DC voltages (12V, 24V, 48V) to AC | Automotive applications, portable devices | Pros: Wide range of input voltages; Cons: Limited output capacity for high-demand applications. |

What are the Characteristics of Pure Sine Wave Inverters?

Pure sine wave inverters provide a high-quality output that closely mimics the electricity supplied by utility companies. This makes them ideal for powering sensitive electronics and equipment, such as medical devices, computers, and laboratory instruments. Businesses in sectors like IT, healthcare, and telecommunications often prefer pure sine wave inverters to ensure the reliability and longevity of their equipment. When purchasing, buyers should consider the inverter’s efficiency, waveform quality, and compatibility with their existing systems.

How do Modified Sine Wave Inverters Differ in Performance?

Modified sine wave inverters are simpler and more cost-effective than their pure sine counterparts. They generate a square-like waveform that is adequate for powering basic appliances and tools but may not be suitable for sensitive electronics. Small businesses and startups often utilize modified sine wave inverters for applications like lighting and basic power tools. When considering this type, buyers should weigh the lower initial costs against the potential risks of equipment damage and inefficiency in certain applications.

What Advantages do Hybrid Inverters Offer for Renewable Energy Projects?

Hybrid inverters are designed to work seamlessly with both solar energy systems and the grid, allowing for battery charging and energy management. They are particularly valuable in off-grid applications and renewable energy projects, where energy independence is crucial. Businesses looking to invest in sustainable energy solutions will find hybrid inverters advantageous due to their flexibility and ability to optimize energy use. Key purchasing considerations include the inverter’s compatibility with battery systems and solar panels, as well as its efficiency ratings.

Why Choose an Inverter Charger for Backup Power Solutions?

Inverter chargers combine the functions of an inverter and a battery charger, making them an excellent choice for emergency backup systems. They automatically switch between grid power and battery power, ensuring a continuous power supply during outages. This is particularly important for businesses in remote locations or those requiring uninterrupted power for critical systems. When selecting an inverter charger, buyers should assess the charging speed, surge capacity, and any additional features like remote monitoring capabilities.

How Do DC to AC Inverters Cater to Diverse Applications?

DC to AC inverters convert a variety of DC voltages into AC power, making them versatile for different applications, including automotive and portable devices. They are often used in vehicles, RVs, and for backup power in smaller setups. Buyers should consider the inverter’s input voltage range and output capacity to ensure it meets their specific needs. While they offer flexibility, these inverters may not support high-demand applications as effectively as larger inverter types.

Key Industrial Applications of 20000 watt power inverter

| Industry/Sector | Specific Application of 20000 watt power inverter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Off-grid solar power systems | Provides reliable power for remote installations | Compatibility with local solar setups and grid regulations |

| Construction | Temporary power supply for construction sites | Ensures uninterrupted operations and tools usage | Durability and weather resistance for outdoor environments |

| Agriculture | Powering irrigation systems and farm equipment | Enhances productivity and crop yield | Voltage compatibility with various agricultural machinery |

| Telecommunications | Backup power for communication towers | Maintains service continuity during power outages | Compliance with telecommunications standards and certifications |

| Events and Entertainment | Power supply for outdoor events and festivals | Facilitates reliable audio/visual setups | Portability and ease of setup for quick deployment |

How is the 20000 Watt Power Inverter Utilized in Renewable Energy Applications?

In the renewable energy sector, a 20000 watt power inverter is crucial for off-grid solar power systems. These inverters convert DC electricity generated by solar panels into AC power, making it usable for homes and businesses. They solve the issue of energy access in remote areas, particularly in regions like Africa and South America where grid connectivity is limited. Buyers should consider compatibility with existing solar setups and local regulations to ensure optimal performance and compliance.

What Role Does the 20000 Watt Power Inverter Play in Construction?

For the construction industry, a 20000 watt power inverter serves as a temporary power supply to support tools and equipment at job sites. This inverter enables contractors to operate heavy machinery without relying on grid power, which can be unreliable or unavailable in remote locations. The benefit lies in maintaining productivity and reducing downtime. When sourcing, businesses should prioritize durability and weather resistance, as construction sites often expose equipment to harsh conditions.

How Does the 20000 Watt Power Inverter Enhance Agricultural Operations?

In agriculture, a 20000 watt power inverter can power irrigation systems and various farm equipment, ensuring that operations run smoothly and efficiently. By providing a reliable power source, it helps farmers enhance productivity and ultimately improve crop yields. Buyers in this sector need to ensure that the inverter is compatible with the specific voltage and power requirements of their machinery, facilitating seamless integration into existing systems.

Why is the 20000 Watt Power Inverter Essential for Telecommunications?

Telecommunications companies utilize 20000 watt power inverters as backup power for communication towers. These inverters ensure that essential services remain operational during power outages, thereby maintaining connectivity for users. The key benefit is the assurance of service continuity, which is critical in today’s digital landscape. Buyers should ensure that the inverters comply with telecommunications standards and certifications to guarantee reliability.

How Can the 20000 Watt Power Inverter Support Events and Entertainment?

In the events and entertainment industry, a 20000 watt power inverter provides a reliable power supply for outdoor events and festivals. This inverter supports audio and visual equipment, ensuring that events proceed without technical hitches. The primary value lies in its ability to deliver consistent power in temporary setups. When sourcing, businesses should look for inverters that offer portability and ease of setup, allowing for quick deployment and disassembly.

3 Common User Pain Points for ‘20000 watt power inverter’ & Their Solutions

Scenario 1: Overcoming Incompatibility Issues with Existing Systems

The Problem: B2B buyers often face challenges when integrating a 20,000-watt power inverter with their existing electrical systems. This is especially true in regions where voltage standards vary, such as in Africa and South America. A buyer may purchase an inverter only to discover it is incompatible with their local grid or existing equipment, leading to costly delays and potential system failures. This incompatibility can stem from differences in voltage, frequency, or the inverter’s design (e.g., pure sine wave vs. modified sine wave), which can significantly impact performance and reliability.

The Solution: To mitigate these issues, buyers should conduct a comprehensive compatibility assessment before purchasing a power inverter. This includes understanding the voltage and frequency specifications of their local grid, as well as the power requirements of connected devices. Additionally, sourcing inverters that offer adjustable output settings can provide greater flexibility. Collaborating with a knowledgeable supplier who understands local regulations and standards can also streamline the selection process. Utilizing inverter models that feature built-in configuration options or remote monitoring capabilities can further ensure that the inverter operates harmoniously with existing systems.

Scenario 2: Managing High Initial Costs and Budget Constraints

The Problem: Many organizations, particularly in emerging markets, struggle with the high upfront costs associated with acquiring a 20,000-watt power inverter. This initial investment can be a significant barrier, especially for small to medium-sized enterprises (SMEs) that may lack the capital or financing options. As a result, these businesses may delay critical energy upgrades, risking operational efficiency and productivity.

The Solution: To address budget constraints, B2B buyers should explore financing options such as leasing or installment payment plans that allow for gradual investment without sacrificing cash flow. Additionally, buyers can take advantage of government incentives, tax credits, or rebates available for renewable energy solutions, which can significantly reduce the net cost. Engaging with suppliers who offer bundled solutions, including solar panels and inverters, can also lead to cost savings through package deals. Finally, conducting a cost-benefit analysis to project long-term savings from reduced energy bills can help justify the initial investment to stakeholders.

Scenario 3: Ensuring Reliable Performance During Peak Demand

The Problem: B2B buyers often encounter reliability issues with power inverters during peak demand periods. Businesses that depend on high power loads—such as manufacturing plants or data centers—risk downtime if their inverter cannot handle sudden spikes in demand. This risk is heightened in regions with unstable power supplies, where a reliable backup power solution is critical for maintaining operations and service delivery.

The Solution: To ensure reliable performance, buyers should select a 20,000-watt inverter with a robust surge capacity that can handle sudden increases in power demand. Inverters with features like a high surge rating (e.g., 60,000 watts for 20 seconds) are ideal for environments where equipment may draw significantly more power at startup. It is also advisable to conduct a thorough load analysis to understand peak usage patterns and select an inverter that not only meets current needs but also allows for future expansion. Regular maintenance and monitoring can further enhance performance reliability, ensuring that potential issues are addressed before they escalate into operational disruptions.

Strategic Material Selection Guide for 20000 watt power inverter

What Are the Common Materials Used in 20000 Watt Power Inverters?

When selecting materials for 20000 watt power inverters, several key factors must be considered to ensure optimal performance and durability. The following analysis covers four common materials used in the construction of these inverters: aluminum, copper, steel, and plastic. Each material has unique properties that can significantly impact the inverter’s performance and suitability for various applications.

How Does Aluminum Contribute to Power Inverter Performance?

Aluminum is widely used in power inverter construction due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and offers good corrosion resistance, making it suitable for various environmental conditions.

Pros: Aluminum’s lightweight characteristic allows for easier installation and transportation. Its thermal properties help dissipate heat effectively, enhancing the inverter’s efficiency.

Cons: While aluminum is durable, it is less robust than steel, which can lead to structural concerns in high-impact environments. Additionally, the cost of aluminum can be higher than that of other materials, depending on market fluctuations.

Impact on Application: Aluminum is compatible with various media, including air and liquids, making it versatile for different inverter configurations.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM B221 for aluminum extrusions and DIN 1725 for corrosion resistance.

What Role Does Copper Play in Electrical Conductivity?

Copper is essential for electrical components within power inverters due to its superior conductivity. It can handle high current loads, making it ideal for inverters that require efficient power transfer.

Pros: Copper’s excellent conductivity reduces energy loss, enhancing overall inverter efficiency. It is also highly ductile, allowing for intricate wiring designs.

Cons: The primary drawback of copper is its cost, which is generally higher than aluminum. Additionally, copper is susceptible to corrosion if not adequately protected, which can affect long-term reliability.

Impact on Application: Copper’s compatibility with high-voltage applications makes it suitable for inverters operating under demanding conditions.

Considerations for International Buyers: Compliance with standards such as ASTM B3 for copper conductors is crucial, especially in regions with stringent electrical safety regulations.

How Does Steel Impact Structural Integrity?

Steel is often used in the frames and casings of power inverters due to its strength and durability. It can withstand high pressure and temperature ratings, typically up to 250°C.

Pros: Steel provides excellent structural integrity and impact resistance, making it ideal for rugged applications. Its longevity reduces the need for frequent replacements.

Cons: The weight of steel can complicate installation and transportation. It is also prone to rusting if not properly coated, which can lead to maintenance challenges.

Impact on Application: Steel is suitable for environments where the inverter may be exposed to physical stress or harsh conditions.

Considerations for International Buyers: Buyers should consider compliance with standards like ASTM A36 for structural steel, especially in regions with specific construction codes.

What Advantages Does Plastic Offer in Power Inverters?

Plastic materials are commonly used for housing and insulation in power inverters due to their lightweight and insulating properties. They typically have a temperature rating of up to 85°C.

Pros: Plastic is cost-effective and offers excellent insulation properties, reducing the risk of electrical shorts. Its lightweight nature facilitates easier handling.

Cons: Plastic can be less durable than metals, making it unsuitable for high-stress applications. It may also degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Plastic is ideal for non-structural components where insulation is critical.

Considerations for International Buyers: Compliance with standards such as UL 94 for flammability and IEC 60695 for thermal properties is important, especially in regions with strict safety regulations.

Summary of Material Selection for 20000 Watt Power Inverters

| Material | Typical Use Case for 20000 watt power inverter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and heat sinks | Lightweight and good thermal conductivity | Less durable than steel | Medium |

| Copper | Electrical wiring and components | Excellent conductivity | High cost and corrosion susceptibility | High |

| Steel | Structural frames and casings | High strength and durability | Heavy and prone to rust | Medium |

| Plastic | Insulation and non-structural components | Cost-effective and lightweight | Less durable and UV sensitive | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in 20000 watt power inverters, helping them make informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 20000 watt power inverter

What Are the Key Stages in the Manufacturing Process of a 20000 Watt Power Inverter?

The manufacturing of a 20000 watt power inverter involves several critical stages, each designed to ensure that the final product meets stringent performance and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing high-quality raw materials such as copper for windings, aluminum for casings, and various electronic components. Suppliers often provide materials that meet specific industry standards, ensuring reliability and performance. Conducting a material quality assessment is vital, where incoming materials are checked for compliance with specifications.

-

Forming: During this phase, raw materials are shaped into the necessary components of the inverter. Techniques such as stamping, molding, and machining are commonly used to create parts like heat sinks, circuit boards, and enclosures. Advanced technologies, such as CNC machining, are employed to achieve precision and consistency, which are crucial for high-performance applications.

-

Assembly: This stage involves the integration of all components into a finished unit. Automated assembly lines may be utilized, but skilled technicians often perform critical tasks such as soldering and wiring. Here, adherence to strict assembly protocols is essential to minimize defects. Each inverter is assembled following specific designs that dictate the layout and connections of components to optimize efficiency and safety.

-

Finishing: The final stage includes testing, painting, and packaging the inverters. Surface treatments may be applied to enhance durability and corrosion resistance. Functionality tests, including electrical performance checks and thermal management assessments, are critical to ensuring that the inverter operates effectively under various conditions.

How Is Quality Assurance Implemented in the Production of 20000 Watt Power Inverters?

Quality assurance (QA) is integral to the manufacturing process, ensuring that each inverter meets international standards and customer expectations. Here’s a closer look at the QA protocols typically followed:

-

International and Industry-Specific Standards: Compliance with international quality standards such as ISO 9001 is essential for manufacturers targeting global markets. This standard emphasizes a process-oriented approach to quality management, requiring continuous improvement and customer satisfaction. Industry-specific certifications, such as CE (Conformité Européenne) and UL (Underwriters Laboratories), indicate compliance with safety and performance regulations, particularly important for markets in Europe and North America.

-

Quality Control Checkpoints: Throughout the manufacturing process, various quality control (QC) checkpoints are established. These include:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): QC measures during production focus on monitoring processes to catch defects early. This may involve real-time testing of electrical parameters during assembly.

– Final Quality Control (FQC): The finished product undergoes comprehensive testing, including load tests and efficiency evaluations, to verify performance against specifications. -

Common Testing Methods: Manufacturers employ a range of testing methods to ensure product reliability. These include:

– Electrical Testing: Verifying output voltage, frequency, and load capabilities.

– Thermal Imaging: Assessing heat distribution and identifying potential overheating issues.

– Environmental Testing: Ensuring the inverter can withstand various conditions, such as humidity, dust, and temperature fluctuations.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is critical to ensure product reliability and performance. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. During these audits, buyers can assess compliance with international standards, the effectiveness of QC measures, and the overall production environment.

-

Quality Reports and Certifications: Requesting documentation such as quality management system certifications and test reports can help verify a supplier’s commitment to quality. Look for certifications from recognized bodies, such as ISO and UL, which indicate adherence to stringent quality standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and product quality. These services can conduct inspections at various stages of production, ensuring that the products meet the required specifications before shipment.

-

Understanding Regional Quality Nuances: Different regions may have specific quality requirements and standards. For instance, European buyers might prioritize CE certification, while buyers in the Middle East may focus on compliance with local regulations. Understanding these nuances can help buyers make informed decisions when selecting suppliers.

Conclusion

The manufacturing processes and quality assurance protocols for 20000 watt power inverters are designed to deliver high-performance, reliable products that meet international standards. By understanding these processes and actively verifying supplier quality control measures, B2B buyers can ensure they are sourcing top-quality inverters that will meet their operational needs and expectations. Implementing thorough due diligence in supplier selection not only mitigates risks but also builds a foundation for long-term partnerships in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘20000 watt power inverter’

This guide serves as a comprehensive checklist for B2B buyers looking to procure a 20000 watt power inverter. Given the diverse applications and specifications of power inverters, following a systematic approach will ensure that your investment meets your operational needs while maximizing efficiency and reliability.

Step 1: Define Your Technical Specifications

Understanding your specific power requirements is critical. Identify the voltage (12V, 24V, 48V, etc.) and the type of output waveform (pure sine wave vs. modified sine wave) that suits your application. This clarity will guide your selection process and help you avoid purchasing an inverter that does not meet your operational demands.

Step 2: Assess Application Requirements

Determine the intended use of the inverter. Will it be for residential, commercial, or industrial applications? Each context may have unique demands regarding power surge capacity, continuous output, and efficiency. For instance, industrial applications may require inverters with higher surge ratings to accommodate heavy machinery.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to their experience with international shipping and logistics, especially if you are sourcing from different continents like Africa or South America.

- Verify Certifications: Ensure that suppliers have relevant certifications (e.g., CE, UL) that meet your region’s standards.

- Check Warranty Policies: Look for suppliers that offer comprehensive warranty options to safeguard your investment.

Step 4: Analyze Product Features

Scrutinize the technical specifications of the inverters under consideration. Key features to evaluate include:

- Surge Capacity: Look for inverters with a surge capacity that exceeds your maximum load requirements. For instance, a 20000 watt inverter with a 60000 watt surge capability can handle sudden spikes in power demand.

- Efficiency Ratings: Higher efficiency translates to lower energy losses. Aim for inverters with efficiency ratings above 90% to maximize performance.

Step 5: Compare Pricing and Total Cost of Ownership

Request quotes from multiple suppliers and compare pricing structures. Take into account not just the initial purchase price but also factors like shipping costs, installation fees, and maintenance requirements. A lower upfront cost may lead to higher long-term expenses if the unit requires frequent repairs or replacements.

Step 6: Understand After-Sales Support and Service

Investigate the level of customer service and support offered by the supplier. Reliable after-sales service can significantly impact the operational longevity of your inverter. Ask about:

- Technical Support: Availability of technical assistance for installation and troubleshooting.

- Replacement Parts: Ensure that the supplier provides easy access to spare parts and components.

Step 7: Finalize Your Purchase and Plan Installation

Once you have selected a supplier and product, finalize the purchase details. Coordinate with the supplier regarding shipping timelines and installation requirements. Prepare your site for installation, considering factors such as ventilation, accessibility, and safety measures.

By following this checklist, B2B buyers can make informed decisions when sourcing a 20000 watt power inverter, ensuring that their procurement aligns with both current and future power needs.

Comprehensive Cost and Pricing Analysis for 20000 watt power inverter Sourcing

What are the Key Cost Components in Sourcing a 20000 Watt Power Inverter?

When sourcing a 20000 watt power inverter, it is essential to understand the various cost components involved. The primary cost components include:

-

Materials: The quality and type of materials used in manufacturing power inverters significantly impact costs. High-quality components such as copper windings, durable casings, and advanced circuitry can drive up material costs.

-

Labor: Labor costs depend on the complexity of the manufacturing process and the skill level required. Automated production lines may reduce labor costs, whereas custom or intricate designs may require more skilled labor, increasing expenses.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient production facilities can help minimize these overheads.

-

Tooling: Initial setup costs for molds and specialized tools can be substantial, particularly for custom designs. These costs can be amortized over large production runs, making them less significant on a per-unit basis for high-volume orders.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, especially for power inverters that must meet specific safety and performance standards. Higher QC standards may increase production costs but reduce returns and warranty claims.

-

Logistics: Transportation costs can vary widely based on the shipping method, distance, and volume of goods being transported. Incoterms will also dictate responsibility for shipping costs and risks.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market demand, competition, and the supplier’s strategic goals.

How Do Price Influencers Affect the Cost of 20000 Watt Power Inverters?

Several factors influence the pricing of 20000 watt power inverters in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts, significantly reducing the per-unit cost. Establishing a long-term relationship with suppliers can also provide leverage for better pricing.

-

Specifications and Customization: Customized inverters that meet specific requirements (such as unique input/output voltages or additional features) typically come at a premium. Standardized products generally offer more competitive pricing.

-

Material Quality and Certifications: Inverters that meet international certifications (like CE or UL) may incur higher manufacturing costs, reflecting enhanced safety and reliability. Buyers should weigh the benefits of certified products against potential cost savings from non-certified alternatives.

-

Supplier Factors: The reputation, location, and operational efficiency of suppliers can affect pricing. Suppliers with established quality records may charge more, but the assurance of quality and reliability can justify the higher cost.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define responsibilities between buyers and sellers, influencing logistics costs and risk management.

What Tips Can Help International Buyers Optimize Costs When Sourcing Power Inverters?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, can take several steps to optimize their sourcing process:

-

Negotiate Terms: Engage in negotiations with suppliers to secure favorable pricing, payment terms, and delivery schedules. Building a rapport can lead to better deals.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, and operational costs over the inverter’s lifespan. A lower upfront cost may result in higher long-term expenses if the inverter is less efficient or reliable.

-

Research Local Market Conditions: Understanding the regional market dynamics can help buyers identify trends, pricing fluctuations, and potential supply chain challenges.

-

Leverage Group Buying: Collaborating with other businesses for bulk purchases can increase negotiating power and reduce costs.

-

Stay Informed on Regulations: Familiarize yourself with import regulations and tariffs in your country to avoid unexpected expenses that could affect the overall cost.

Conclusion

Sourcing a 20000 watt power inverter involves a complex interplay of cost components and pricing influencers. By understanding these elements, international B2B buyers can make informed decisions that optimize their procurement process and enhance their competitive edge in the market. Always approach sourcing with a strategic mindset, focusing on the long-term value rather than just the immediate costs.

Alternatives Analysis: Comparing 20000 watt power inverter With Other Solutions

Exploring Alternatives to the 20000 Watt Power Inverter

When considering power solutions for high-demand applications, the 20000 watt power inverter is a popular choice due to its versatility and efficiency. However, various alternatives can serve similar purposes, particularly in different geographical and operational contexts. This section compares the 20000 watt power inverter with two viable alternatives: solar energy systems and diesel generators. Each solution has unique characteristics that can cater to specific business needs.

Comparison Table

| Comparison Aspect | 20000 Watt Power Inverter | Solar Energy Systems | Diesel Generators |

|---|---|---|---|

| Performance | Converts DC to AC; supports up to 20000W | Provides renewable energy; variable output | Reliable power source; high output capabilities |

| Cost | Initial investment: $3,999 – $4,399 | High upfront cost; potential tax incentives | Moderate to high initial cost; ongoing fuel costs |

| Ease of Implementation | Requires setup and battery integration | Requires installation of panels and inverter | Quick setup; requires fuel management |

| Maintenance | Low; mainly battery care | Moderate; panel cleaning and inverter checks | High; regular fuel and oil changes needed |

| Best Use Case | Off-grid applications, backup power | Sustainable energy for long-term savings | Emergency power, high energy demand situations |

Detailed Breakdown of Alternatives

Solar Energy Systems

Solar energy systems consist of solar panels, inverters, and battery storage to convert sunlight into usable electricity. They provide a renewable energy source that can significantly reduce long-term energy costs. The initial investment can be high, but many regions offer tax incentives and rebates that can offset these costs. However, solar systems have variable output depending on weather conditions and time of day, which may not suit all businesses, especially those with continuous high energy demands.

Diesel Generators

Diesel generators are known for their reliability and ability to deliver high power outputs quickly. They are particularly effective in emergency situations or areas with unstable grid power. While the initial investment is moderate, ongoing fuel costs can add up, making them less economical in the long run compared to solar systems. Maintenance is also a significant consideration, as diesel generators require regular fuel and oil changes to ensure optimal performance. They are best suited for industries where uninterrupted power is critical, but the environmental impact and fuel dependency can be drawbacks.

Conclusion: How to Choose the Right Power Solution

Selecting the right power solution involves assessing your specific operational needs, budget constraints, and long-term energy goals. The 20000 watt power inverter is ideal for businesses requiring reliable power in off-grid or backup scenarios. In contrast, solar energy systems can provide sustainable, cost-effective solutions for those looking to reduce dependence on fossil fuels. Diesel generators serve as a dependable option for high-demand scenarios, particularly in regions with unreliable electricity supply. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational requirements and sustainability objectives.

Essential Technical Properties and Trade Terminology for 20000 watt power inverter

What Are the Essential Technical Properties of a 20000 Watt Power Inverter?

When considering a 20000 watt power inverter for industrial or commercial use, several technical properties are crucial for ensuring efficiency and reliability. Below are key specifications that B2B buyers should evaluate:

-

Continuous Output Power

This is the maximum power the inverter can provide continuously without overheating or shutting down. For a 20000 watt inverter, this means it can consistently supply 20,000 watts of AC power. Understanding this rating is vital for businesses to ensure their equipment operates smoothly without interruptions. -

Surge Rating

The surge rating indicates the maximum power the inverter can handle for short periods, typically during equipment startup. For example, a surge rating of 60,000 watts means the inverter can support devices that require a high inrush current. This feature is especially important in applications where heavy machinery is involved, as it prevents potential damage to both the inverter and the equipment. -

Input Voltage

The input voltage (e.g., 48V or 24V) determines the type of battery system needed to operate the inverter. A compatible battery system is essential for optimal performance. Buyers must ensure that the inverter’s input voltage matches their existing power supply systems to avoid costly upgrades or incompatibility issues. -

Output Waveform

Inverters can produce different types of waveforms, such as pure sine wave or modified sine wave. Pure sine wave inverters are preferred for sensitive electronics as they provide cleaner power, reducing the risk of damage. Understanding the output waveform is crucial for businesses that rely on delicate machinery or electronic devices. -

Efficiency Rating

The efficiency rating reflects how much input power is converted into usable output power. An inverter with an efficiency rating above 90% minimizes energy loss, leading to reduced operational costs. This is particularly beneficial for businesses looking to optimize their energy consumption. -

Transfer Time

This specification indicates how quickly the inverter can switch from battery to AC power and vice versa. A transfer time of less than 10 milliseconds is ideal for applications requiring uninterrupted power, such as data centers or medical facilities. Understanding this metric helps businesses assess the inverter’s suitability for critical applications.

What Trade Terminology Should B2B Buyers Know When Sourcing Power Inverters?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms relevant to the procurement of 20000 watt power inverters:

-

OEM (Original Equipment Manufacturer)

Refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify trusted suppliers and ensure product quality. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for buyers to determine their purchasing strategy, especially when budgeting for large-scale projects. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and availability information from suppliers. Utilizing RFQs can help businesses compare different offers and make informed purchasing decisions. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international buyers to understand their liabilities and ensure smooth logistics. -

Warranty Period

This term refers to the duration for which the manufacturer guarantees the product’s performance. A longer warranty period often indicates higher confidence in the product’s reliability and can be a deciding factor in a purchase. -

Lead Time

Lead time is the time taken from placing an order to the delivery of the product. Understanding lead times is crucial for project planning and ensuring that equipment is available when needed.

By grasping these technical specifications and trade terminologies, B2B buyers can make more informed decisions, ensuring they select the right 20000 watt power inverter for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the 20000 watt power inverter Sector

What Are the Key Trends Shaping the 20000 Watt Power Inverter Market?

The global market for 20,000-watt power inverters is experiencing significant growth, driven by the increasing demand for renewable energy sources, particularly in developing regions such as Africa and South America. As countries pursue energy independence and sustainability, the adoption of solar energy systems is on the rise, leading to a surge in inverter demand. Furthermore, the growing trend toward off-grid energy solutions in remote areas highlights the importance of high-capacity inverters that can support various applications, from residential use to commercial and industrial power needs.

Technological advancements are also transforming the landscape of power inverters. The emergence of smart inverters, which integrate advanced monitoring and control capabilities, is reshaping buyer expectations. These devices can optimize energy consumption, enhance grid resilience, and facilitate seamless integration with energy storage systems. In regions like the Middle East and Europe, regulatory frameworks are increasingly favoring energy-efficient technologies, prompting buyers to seek products that comply with stringent energy standards.

Moreover, the competitive nature of the 20,000-watt inverter market is prompting manufacturers to innovate continuously. This includes developing inverters with higher efficiency ratings, lower total harmonic distortion (THD), and enhanced durability for various environmental conditions. For international B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with both market trends and regional energy policies.

How Does Sustainability Influence Sourcing Decisions for 20000 Watt Power Inverters?

Sustainability has become a core consideration for B2B buyers in the 20,000-watt power inverter sector. The environmental impact of manufacturing processes, materials used, and end-of-life disposal of products is under increasing scrutiny. Companies are now prioritizing suppliers who demonstrate a commitment to sustainability, including those using recyclable materials and energy-efficient production methods.

Ethical sourcing is equally important, as buyers seek to partner with manufacturers who adhere to fair labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and RoHS for hazardous substances can serve as indicators of a supplier’s commitment to sustainable practices. Buyers should also consider the lifecycle assessment of products, evaluating how inverters are designed for longevity and recyclability.

Furthermore, the rise of green certifications is influencing purchasing decisions. Products that are certified as energy-efficient or environmentally friendly not only appeal to eco-conscious businesses but may also qualify for government incentives and rebates. As international buyers navigate this evolving landscape, aligning with suppliers who prioritize sustainability can enhance brand reputation and meet regulatory compliance, ultimately leading to a competitive advantage in their respective markets.

What Historical Developments Have Influenced the Current State of the 20000 Watt Power Inverter Market?

The history of power inverters dates back several decades, with significant advancements occurring in the late 20th century as the demand for renewable energy sources began to rise. Initially, inverters were primarily used in small-scale applications, but the introduction of solar energy systems in the 1990s expanded their use in residential and commercial sectors. The development of high-capacity inverters, such as the 20,000-watt models, emerged in response to the growing need for more robust energy solutions.

The early 2000s saw further innovation, driven by improvements in semiconductor technology and power electronics, which enhanced inverter efficiency and performance. As global interest in renewable energy intensified, particularly during the 2010s, manufacturers began to focus on creating inverters that could withstand harsh environmental conditions while providing reliable power conversion.

Today, the 20,000-watt power inverter market is characterized by a blend of tradition and innovation, with a strong emphasis on sustainability and smart technology integration. This evolution has set the stage for a dynamic market that continues to adapt to the needs of international B2B buyers across various regions.

Frequently Asked Questions (FAQs) for B2B Buyers of 20000 watt power inverter

-

How do I select the right 20000 watt power inverter for my business needs?

Choosing the right 20000 watt power inverter depends on several factors including your specific power requirements, type of appliances, and whether you need a pure sine wave or modified sine wave inverter. Assess the total wattage of devices you plan to power, consider efficiency ratings, and check compatibility with your existing systems. Additionally, look for features like surge capacity, remote monitoring, and warranty terms to ensure reliability in your operations. -

What is the best power inverter type for renewable energy applications?

For renewable energy applications, a pure sine wave inverter is typically the best choice as it provides clean and stable power, making it suitable for sensitive electronics and appliances. If you’re integrating with solar panels, ensure the inverter can handle the input voltage and is compatible with your solar energy system. This type of inverter maximizes the efficiency of your energy system, especially in off-grid or hybrid configurations. -

What are the typical payment terms for purchasing a 20000 watt power inverter?

Payment terms can vary significantly between suppliers. Common arrangements include a 30% deposit upon order confirmation, with the remaining balance due prior to shipping. Some suppliers may offer extended payment plans or financing options, particularly for large orders. It’s crucial to clarify these terms before placing an order to avoid any potential cash flow issues. -

What minimum order quantities (MOQs) should I expect when sourcing power inverters?

Minimum order quantities for 20000 watt power inverters can vary by manufacturer and supplier. Typically, MOQs may range from 5 to 20 units depending on the supplier’s production capabilities and your location. If your business requires fewer units, consider negotiating with suppliers or looking for distributors that cater to smaller businesses. -

How can I ensure the quality of the 20000 watt power inverter I am purchasing?

To ensure quality, research suppliers thoroughly by checking their certifications, customer reviews, and warranty policies. Request product specifications and performance data, and consider asking for samples or visiting the manufacturing facility if feasible. Look for inverters that comply with international quality standards such as ISO, CE, or UL certifications to guarantee reliability and safety. -

What logistics considerations should I keep in mind when importing power inverters?

When importing 20000 watt power inverters, consider shipping costs, customs duties, and import regulations specific to your country. Ensure that the supplier can provide necessary documentation for customs clearance. Additionally, choose a reliable logistics partner who can manage shipping timelines and handle any potential delays, especially in regions with complex import processes. -

How do I vet suppliers for purchasing 20000 watt power inverters internationally?

Vetting suppliers is essential for mitigating risks in international trade. Start by verifying their business credentials, such as registration and licensing. Check for industry experience, read customer testimonials, and request references from other B2B buyers. Utilizing platforms like Alibaba or Global Sources can also help identify reputable suppliers through their ratings and reviews. -

Can I customize my 20000 watt power inverter order?

Yes, many manufacturers offer customization options for 20000 watt power inverters. Customizations can include modifications to output voltage, enclosure design, or specific features like integrated chargers or monitoring systems. Discuss your requirements with the supplier during the initial inquiry to understand the feasibility, associated costs, and lead times for custom orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 20000 Watt Power Inverter Manufacturers & Suppliers List

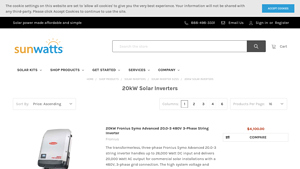

1. Fronius – Symo Advanced 20.0-3 480V Inverter

Domain: sunwatts.com

Registered: 2018 (7 years)

Introduction: 20000 Watt DC Solar Inverter: Fronius Symo Advanced 20.0-3 480V 3-Phase String Inverter. MSRP: $4,100.00. Sale Price: Order by June 1. Features: Transformerless, three-phase inverter, handles up to 26,000 Watt DC input, delivers 20,000 Watt AC output for commercial solar installations with a 480V, 3-phase grid connection.

2. AIMS Power – 10000-Watt Modified Sine Power Inverter

Domain: aimscorp.net

Registered: 2002 (23 years)

Introduction: 10000-Watt Modified Sine Power Inverter, Input: 12VDC, Output: 120VAC, Free Shipping (some products excluded), 15% OFF with code AIMSPOWER15 (online purchases only, minimal purchase amount $2500).

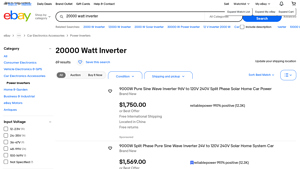

3. AIMS Power – 20000W Inverter

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 20000W Inverter available on eBay. Input Voltage: 12-23V, 24-35V, 36-47V, 48-99V, 100-149V. Brands include AIMS Power, Solar, Unbranded, WAGAN. Features: DC/AC, Overheating Protection, High Voltage Input Protection, Low Voltage Input Protection, On/Off Switch, Short Circuit Protection, Reverse Polarity Protection, Over Battery Voltage Protection. Output Voltage: 100-149V, 200-249V. Types: Pure Sin…

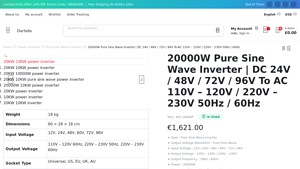

4. Dartello – 20000W Pure Sine Wave Power Inverter

Domain: dartello.com

Introduction: {“Product Name”: “20000W Pure Sine Wave Power Inverter”, “Input Voltage”: [“12V”, “24V”, “48V”, “60V”, “72V”, “96V”], “Output Voltage”: [“110V – 120V”, “220V – 230V”], “Output Frequency”: [“50Hz”, “60Hz”], “Peak Power”: “20000W”, “Rated Power”: “10000W”, “Inversion Efficiency”: “>95%”, “Weight”: “18 kg”, “Dimensions”: “60 × 28 × 16 cm”, “Socket Type”: [“Universal”, “US”, “EU”, “UK”, “AU”], “Warran…

5. Sigineer – 20000 Watt Pure Sine Wave Inverter Charger

Domain: sigineer.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “20000 Watt 48V Pure Sine Wave Inverter Charger 120V / 240Vac Split Phase”, “Model Number”: “HP20048D”, “Price”: “$3,999.00”, “Original Price”: “$4,399.00”, “Power Output”: “20000 Watts”, “Surge Rating”: “60000 Watts (20 Seconds)”, “Output Waveform”: “Pure Sine Wave”, “Output Voltage”: “120/240Vac”, “Nominal Efficiency”: “85% (Peak)”, “Line Mode Efficiency”: “>95%”, “Output Freque…

6. OneInverter – LSI-203 Hybrid Off Grid Solar Inverter

Domain: oneinverter.com

Registered: 2018 (7 years)

Introduction: {“Model No.”: “LSI-203”, “Power Output”: “20000 Watt”, “Type”: “Pure Sine Wave AC Inverter”, “Voltage”: “96V”, “Application”: “Hybrid off Grid Solar Inverter”, “Features”: [“Pure sine wave output”, “Strong load capacity”, “High conversion efficiency”, “Quick start”, “Low no-load current”], “Working Principle”: “PV gives power to the load first. When PV power is less than load power, energy storage…

7. Wagan – ProLine 10,000W Inverter

Domain: donrowe.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “Wagan 3748 ProLine 10,000W, 12V Modified Sine Inverter”, “List Price”: “$1,729.95”, “Sale Price”: “$1,099.90”, “Product Code”: “WAG10000P”, “Input Voltage”: “12 VDC”, “Output Voltage”: “115 VAC, 60 Hz”, “Continuous Power Output”: “10,000 W (87.0 A)”, “Surge Power”: “20,000 W (173.9 A)”, “Output Waveform”: “Modified sine wave”, “Dimensions”: “21.5 x 7.3 x 6.3 in (546 x 185 x 160 m…

8. Wagan Tech – ProLine 10,000 Watt Power Inverter

Domain: wagan.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “ProLine 10,000 Watt Power Inverter”, “Brand”: “Wagan Tech”, “Model”: “ProLine 10,000 Watt (MSW)”, “Price”: {“12V”: “$1,729.95”, “24V”: “$1,749.95”, “48V”: “$1,729.95”}, “SKU”: “EL3748”, “Power”: “10,000W”, “Surge Power”: “20,000W”, “AC Outlets”: “4 @ 1500W max each”, “AC Output”: “115-125V”, “Frequency”: “60Hz”, “Socket Type”: “U.S. standard 3-prong (4x)”, “Maximum Efficiency”: “…

Strategic Sourcing Conclusion and Outlook for 20000 watt power inverter

In conclusion, the strategic sourcing of 20,000-watt power inverters presents a unique opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. By leveraging competitive pricing and advanced technology, companies can ensure reliable power solutions that meet their specific operational needs. The adoption of high-efficiency models, such as pure sine wave inverters, not only guarantees quality performance but also enhances energy savings, making them an ideal choice for both off-grid and grid-tied applications.

As international markets evolve, the importance of strategic sourcing becomes increasingly apparent. Buyers should focus on establishing partnerships with reputable manufacturers that offer robust warranties and support services. This approach minimizes risk and maximizes value, ensuring that your investment in power infrastructure is secure and sustainable.

Looking ahead, the demand for high-capacity inverters is set to grow, driven by the increasing reliance on renewable energy sources and the need for dependable backup power solutions. Now is the time to act—explore your options, compare suppliers, and invest in the future of energy management for your business. Engage with trusted distributors and manufacturers to secure the best deals and position your company for success in this dynamic market.