A Deep Dive into Emu Incubator For Sale Solution

Introduction: Navigating the Global Market for emu incubator for sale

In today’s competitive agricultural landscape, sourcing an efficient emu incubator for sale poses significant challenges for international B2B buyers. With varying climate conditions, diverse agricultural practices, and differing regulatory environments across regions like Africa, South America, the Middle East, and Europe, selecting the right incubator can be a daunting task. This guide aims to simplify that process by providing a comprehensive overview of the emu incubator market, including types, applications, supplier vetting, and pricing considerations.

By delving into the nuances of various incubator models—such as cabinet incubators designed for high-capacity hatching and specialized equipment for emu eggs—this guide empowers buyers to make informed decisions that enhance their operational efficiency and productivity. Additionally, it offers insights into evaluating suppliers, ensuring product quality, and understanding the total cost of ownership, which is crucial for establishing long-term partnerships.

As the global demand for emu farming grows, particularly in emerging markets like Brazil and Nigeria, this resource serves as an essential tool for navigating the complexities of sourcing and procuring emu incubators. By equipping buyers with actionable insights and expert recommendations, this guide not only facilitates successful procurement strategies but also helps foster sustainable agricultural practices in their respective regions.

Understanding emu incubator for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cabinet Incubators | High capacity, automatic controls, dual functionality | Large-scale hatcheries, commercial farms | Pros: Efficient, user-friendly, high output. Cons: Higher initial cost, requires space. |

| Sportsman Incubators | Designed specifically for emu eggs, adjustable racks | Specialty emu farms, breeding operations | Pros: Tailored for emu, reliable performance. Cons: Limited to specific egg types. |

| Hatchrite Incubators | Insulated, refurbished, adjustable for various eggs | Budget-conscious farms, small operations | Pros: Cost-effective, versatile. Cons: May have wear and tear, limited warranty. |

| Mini Incubators | Compact size, lower capacity, basic features | Small farms, hobbyists | Pros: Affordable, easy to manage. Cons: Limited capacity, less automation. |

| Digital Egg Incubators | Advanced temperature and humidity control, user-friendly | Research institutions, advanced breeding | Pros: Precision control, great for varied species. Cons: Higher price point, complex setup. |

What Are the Key Characteristics of Cabinet Incubators?

Cabinet incubators are ideal for businesses looking to hatch large quantities of emu eggs simultaneously. With features like automatic humidity control and adjustable egg turners, they provide a stable environment for various egg types. These incubators are particularly suited for commercial hatcheries and large-scale farming operations due to their high capacity and dual functionality as both incubators and hatchers. Buyers should consider the upfront investment and space requirements, as these units can be substantial.

How Do Sportsman Incubators Stand Out?

Sportsman incubators are specifically designed for emu eggs, featuring adjustable trays that cater to their unique size. This specialization makes them a preferred choice for emu farms and breeding operations focused on producing high-quality offspring. While they offer reliable performance and are tailored for specific needs, potential buyers should be aware that their use is limited to certain egg types, which could restrict versatility in operations.

Why Choose Hatchrite Incubators for Budget-Conscious Buyers?

Hatchrite incubators provide a cost-effective solution for small farms or those just starting with emu breeding. These refurbished units are insulated and can be adjusted to accommodate various egg sizes, making them versatile for different poultry. However, buyers should evaluate the condition of refurbished models and consider that they may come with limited warranties, which could impact long-term reliability.

What Benefits Do Mini Incubators Offer for Small Operations?

Mini incubators are compact and designed for lower-capacity needs, making them suitable for small farms or hobbyists interested in emu breeding. Their affordability and ease of use are significant advantages, especially for those new to incubation. However, the limited capacity and basic features may not meet the demands of larger operations, so buyers should assess their specific needs before purchasing.

How Do Digital Egg Incubators Enhance Precision in Hatching?

Digital egg incubators are equipped with advanced controls for temperature and humidity, making them suitable for research institutions and advanced breeding facilities. Their user-friendly interfaces and precise monitoring capabilities provide a significant edge in ensuring optimal hatching conditions. However, these incubators often come with a higher price point and may require a more complex setup, which could be a consideration for budget-conscious buyers.

Key Industrial Applications of emu incubator for sale

| Industry/Sector | Specific Application of emu incubator for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture & Farming | Emu Farming and Breeding | Increases hatch rates and optimizes breeding efficiency | Consider capacity, temperature control, and humidity management features |

| Poultry Production | Diversification into Exotic Poultry | Expands product offerings and market reach | Evaluate adaptability for different egg sizes and types |

| Eco-Tourism & Wildlife Conservation | Breeding Programs for Endangered Species | Supports biodiversity and conservation efforts | Ensure compliance with local regulations and ethical sourcing |

| Food Industry | Emu Meat Production | Provides a unique protein source with health benefits | Assess incubator’s efficiency and reliability for consistent production |

| Research & Education | Academic Studies on Avian Biology | Facilitates research on emu biology and hatching processes | Prioritize precision controls and data monitoring capabilities |

How is the Emu Incubator Used in Agriculture and Farming?

In the agriculture sector, emu incubators are essential for emu farming and breeding operations. They enable farmers to manage large batches of eggs efficiently, leading to higher hatch rates and reduced labor costs. By maintaining optimal temperature and humidity levels, these incubators solve common challenges related to egg viability. Buyers in this sector should focus on features such as capacity, temperature control accuracy, and humidity management to ensure maximum productivity.

What Role Does the Emu Incubator Play in Poultry Production?

For businesses looking to diversify their poultry offerings, emu incubators provide a pathway to enter the exotic poultry market. The unique meat and oil products derived from emus can significantly enhance a farm’s product line. Specific requirements include the ability to handle various egg sizes and types, as well as reliable performance to ensure consistent hatching outcomes. Buyers should evaluate the adaptability of the incubator to accommodate different poultry species.

How Can Eco-Tourism and Wildlife Conservation Benefit from Emu Incubators?

Emu incubators also play a critical role in eco-tourism and wildlife conservation efforts. They are used in breeding programs aimed at protecting endangered species, helping to maintain biodiversity. These incubators must comply with local regulations regarding wildlife breeding and ensure ethical sourcing practices. Businesses should consider the incubator’s reliability and its ability to create ideal conditions for hatching to support successful conservation initiatives.

What Advantages Does the Emu Incubator Offer to the Food Industry?

In the food industry, emu incubators facilitate the production of emu meat, which is known for its health benefits and unique flavor profile. This can help businesses tap into niche markets and meet growing consumer demand for alternative protein sources. Key considerations for sourcing include the incubator’s efficiency and reliability to ensure consistent production cycles. Buyers must also assess the overall cost-effectiveness of the incubator to maximize profit margins.

How Is the Emu Incubator Useful for Research and Education?

Academic institutions and research organizations utilize emu incubators for studies focused on avian biology and hatching processes. These incubators provide a controlled environment that is crucial for experimental consistency and data accuracy. Buyers in this sector should prioritize incubators with advanced precision controls and data monitoring capabilities, ensuring that they can gather reliable data for their research projects.

3 Common User Pain Points for ’emu incubator for sale’ & Their Solutions

Scenario 1: Ensuring Optimal Hatching Conditions

The Problem: B2B buyers often face the challenge of maintaining optimal hatching conditions for emu eggs, which are sensitive to temperature and humidity fluctuations. For instance, a hatchery manager in Nigeria might find that the local climate can lead to inconsistent conditions inside the incubator, resulting in poor hatch rates. This can lead to financial losses and affect the overall viability of the emu farming business, especially in regions with limited access to reliable incubation technology.

The Solution: To address this issue, buyers should prioritize incubators that feature advanced temperature and humidity control systems. For example, selecting an emu incubator with automatic humidity regulation and precise temperature settings can significantly enhance hatching success. Additionally, consider models with real-time monitoring capabilities that alert users to any deviations from set parameters. Regularly calibrating these settings and investing in backup generators or solar-powered options can ensure consistent operation, especially in areas prone to power outages. Engaging with suppliers who provide comprehensive user manuals and customer support can also facilitate better understanding and management of the incubator’s functions.

Scenario 2: Navigating Import Regulations and Shipping Challenges

The Problem: International B2B buyers often encounter logistical hurdles when importing emu incubators, particularly regarding compliance with local regulations and shipping costs. For example, a buyer in Brazil may struggle to find a supplier that understands the specific import duties or certification requirements for agricultural equipment, leading to unexpected delays and increased expenses.

The Solution: To mitigate these challenges, buyers should conduct thorough research on their country’s import regulations before purchasing. Establishing a clear line of communication with potential suppliers can help clarify any necessary documentation or compliance certifications needed for the incubators. Additionally, working with suppliers who offer transparent shipping options and can assist with customs clearance will streamline the process. Buyers may also benefit from consulting with local agricultural associations or trade experts to navigate these complexities effectively, ensuring a smoother procurement process.

Scenario 3: Understanding the Variability in Incubator Quality

The Problem: With numerous options available in the market, B2B buyers often struggle to discern the quality and reliability of different emu incubators. A buyer from South Africa, for instance, might be overwhelmed by varying specifications and pricing, leading to concerns about investing in a product that may not perform as expected or last long enough to justify the cost.

The Solution: To make informed purchasing decisions, buyers should seek out reputable suppliers with a proven track record in the industry. This involves looking for customer reviews, testimonials, and case studies that demonstrate the incubator’s effectiveness in real-world applications. Additionally, buyers should inquire about warranty policies and after-sales support, as these factors can indicate the manufacturer’s confidence in their product’s durability. Engaging in discussions with other emu farmers or joining online forums dedicated to emu incubation can provide insights and recommendations on reliable brands. Finally, consider investing in a trial period or a refurbished model from a trusted source to evaluate its performance before committing to a larger purchase.

Strategic Material Selection Guide for emu incubator for sale

What Materials Are Commonly Used in Emu Incubators?

When selecting an emu incubator for sale, the choice of materials significantly impacts the performance, durability, and overall effectiveness of the incubator. Understanding the properties, pros and cons, and international compliance considerations of these materials is essential for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

How Does Polypropylene Benefit Emu Incubators?

Polypropylene is a thermoplastic polymer known for its excellent chemical resistance and durability. Its temperature rating typically ranges from -20°C to 100°C, making it suitable for the temperature fluctuations experienced in incubation processes.

Pros: Polypropylene is lightweight and cost-effective, which translates to lower shipping costs and affordability for buyers. Its resistance to moisture and chemicals ensures longevity and minimal maintenance.

Cons: While durable, polypropylene can be less impact-resistant compared to other materials. Additionally, it may not provide the same level of insulation as other options, which could affect temperature stability.

Impact on Application: Its compatibility with various incubation media makes it a versatile choice for different egg types, including emu eggs.

Considerations for International Buyers: Buyers should ensure that the polypropylene used complies with international standards like ASTM D638 for tensile properties and ISO 527 for mechanical testing, which may vary by region.

What Role Does Stainless Steel Play in Incubator Design?

Stainless steel is often favored for its strength and corrosion resistance, especially in environments with high humidity. It can withstand temperatures up to 600°C, making it ideal for the heating elements in incubators.

Pros: The durability of stainless steel ensures a long lifespan and low maintenance, while its non-reactive nature makes it safe for hatching eggs.

Cons: The primary drawback is the higher cost of stainless steel compared to other materials, which can increase the overall price of the incubator. Additionally, it is heavier, potentially increasing shipping costs.

Impact on Application: Stainless steel’s compatibility with various cleaning agents allows for easy sanitation, crucial for maintaining biosecurity in hatcheries.

Considerations for International Buyers: Buyers should check compliance with standards such as ASTM A240 for stainless steel sheets and plates, ensuring the material meets the necessary quality requirements in their respective markets.

How Does Expanded Polystyrene Contribute to Insulation?

Expanded polystyrene (EPS) is widely used for insulation in incubators due to its excellent thermal properties. It can maintain a temperature range of -50°C to 70°C, which is vital for consistent incubation conditions.

Pros: EPS is lightweight and offers superior insulation, reducing energy costs associated with maintaining optimal temperatures. Its affordability also makes it an attractive option for budget-conscious buyers.

Cons: While EPS is effective as an insulator, it is less durable than other materials and can be susceptible to damage from impacts or moisture.

Impact on Application: Its insulation properties are crucial for energy efficiency, particularly in regions with extreme temperatures.

Considerations for International Buyers: Buyers should ensure compliance with international insulation standards such as ASTM C578, which governs the physical properties of EPS, ensuring it meets local regulations.

What Advantages Does High-Density Polyethylene Offer?

High-density polyethylene (HDPE) is known for its high strength-to-density ratio and excellent resistance to impact and chemicals. It can withstand temperatures from -40°C to 60°C.

Pros: HDPE is highly durable and resistant to environmental stress, making it suitable for long-term use in various climates. Its lightweight nature also reduces shipping costs.

Cons: The primary limitation of HDPE is its higher manufacturing complexity, which can lead to increased production costs. Additionally, it may not provide the same level of insulation as EPS.

Impact on Application: HDPE’s chemical resistance makes it suitable for various cleaning agents used in hatchery environments.

Considerations for International Buyers: Compliance with ASTM D638 for tensile properties and ISO 1183 for density is crucial for ensuring that the material meets quality standards in different markets.

Summary of Material Properties for Emu Incubators

| Material | Typical Use Case for emu incubator for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Egg trays and body panels | Lightweight and cost-effective | Less impact-resistant than other materials | Low |

| Stainless Steel | Heating elements and structural components | Durable and corrosion-resistant | Higher cost and weight | High |

| Expanded Polystyrene | Insulation panels | Superior thermal insulation | Less durable and moisture susceptible | Low |

| High-Density Polyethylene | Structural components and trays | Durable and resistant to chemicals | Higher manufacturing complexity | Medium |

This guide provides a comprehensive overview of material selection for emu incubators, enabling international B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for emu incubator for sale

What Are the Key Stages in the Manufacturing Process of Emu Incubators?

The manufacturing process of emu incubators encompasses several critical stages that ensure the final product meets the necessary quality and operational standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials, such as durable plastics and metals, which are essential for the incubator’s structure and functionality. Manufacturers often prioritize materials that provide excellent insulation and durability, which are crucial for maintaining the optimal environment for egg incubation.

-

Forming: This stage involves shaping the materials into the required parts of the incubator. Techniques such as injection molding for plastic components and stamping or machining for metal parts are commonly used. Precision in forming is vital to ensure that parts fit together seamlessly and function effectively.

-

Assembly: Once the components are ready, they are assembled into the final product. This stage typically involves integrating various systems, such as heating elements, humidity control mechanisms, and digital monitoring systems. Manufacturers often employ automated assembly lines to enhance efficiency while ensuring that skilled technicians oversee critical assembly tasks.

-

Finishing: The final stage includes painting, branding, and applying protective coatings to enhance durability and aesthetic appeal. It also involves final inspections to ensure that all components are correctly installed and functioning as intended.

How Is Quality Assurance Implemented in Emu Incubator Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of emu incubators to ensure product reliability and compliance with international standards. Manufacturers typically follow a structured QA process that includes several checkpoints and testing methods.

-

International Standards Compliance: Many manufacturers adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the specific features and markets served by the incubators.

-

Quality Control Checkpoints: The QA process often involves multiple quality control (QC) checkpoints:

– Incoming Quality Control (IQC): This stage verifies the quality of raw materials and components upon arrival at the manufacturing facility. Suppliers are evaluated based on their quality performance to ensure only the best materials are used.

– In-Process Quality Control (IPQC): During manufacturing, inspections are conducted to monitor production processes and identify any deviations from quality standards. This proactive approach helps in minimizing defects early in the production cycle.

– Final Quality Control (FQC): Before shipping, finished incubators undergo comprehensive testing to confirm that they meet all performance and safety standards. This may include temperature and humidity tests, as well as functionality checks of digital monitoring systems. -

Common Testing Methods: Various testing methods are employed, including:

– Performance Testing: Simulated incubation conditions are created to evaluate the incubator’s ability to maintain the required temperature and humidity levels.

– Durability Testing: Stress tests may be performed to assess the durability of materials under different environmental conditions.

– Safety Testing: Compliance with electrical safety standards is verified through rigorous testing procedures.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure the reliability of the emu incubators being purchased.

-

Supplier Audits: Conducting on-site audits of the manufacturing facility can provide firsthand insight into the supplier’s quality control processes. Buyers should look for evidence of compliance with international standards and effective QA practices.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures in place. These reports should include information on testing results, defect rates, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an objective assessment of the manufacturer’s quality control. These services can conduct inspections at various stages of production and provide comprehensive reports on compliance with quality standards.

-

Certifications and Documentation: Buyers should verify that suppliers possess relevant certifications (e.g., ISO, CE) and maintain proper documentation of quality control processes. This documentation serves as proof of the supplier’s commitment to maintaining high-quality standards.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must navigate specific nuances in quality control that may vary by region. Understanding these factors can enhance the procurement process and ensure product quality.

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and quality. Buyers must ensure that the incubators comply with local regulations in their respective countries, which may require additional testing or certifications.

-

Cultural and Communication Differences: Effective communication with suppliers from different cultural backgrounds is vital. Buyers should be clear about their quality expectations and ensure that suppliers understand and can meet these requirements.

-

Supply Chain Transparency: Given the complexities of international trade, maintaining transparency throughout the supply chain is crucial. Buyers should seek suppliers who can provide traceability for materials and components, ensuring that all aspects of production adhere to agreed-upon quality standards.

-

Risk Mitigation: Assessing the potential risks associated with sourcing from different regions can help buyers make informed decisions. This includes evaluating the stability of the supply chain, potential tariffs, and the reliability of shipping methods.

By understanding the manufacturing processes and quality assurance measures in place for emu incubators, B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ’emu incubator for sale’

Introduction

This guide is designed to assist B2B buyers in sourcing emu incubators effectively. Whether you are a new entrant in the emu farming industry or looking to upgrade your existing equipment, following this checklist will help ensure that you make informed purchasing decisions. Each step is tailored to address key considerations unique to emu incubation, ensuring you find a product that meets your operational needs.

Step 1: Define Your Technical Specifications

Before you begin your search for an emu incubator, it’s essential to outline your technical requirements. This includes determining the capacity needed based on your production goals, as well as the specific features that will enhance your hatching success, such as temperature control and humidity regulation.

- Capacity: Consider how many emu eggs you plan to incubate at a time.

- Functionality: Look for features like automatic turning and humidity control, which can simplify the incubation process.

Step 2: Research Reliable Suppliers

Identifying trustworthy suppliers is crucial for securing quality equipment. Investigate potential vendors by checking their reputation in the market, reviewing customer testimonials, and assessing their experience in providing emu incubators specifically.

- Certifications: Ensure the suppliers adhere to industry standards and have relevant certifications.

- Track Record: Look for suppliers with a history of successful deliveries in your region or similar markets.

Step 3: Evaluate Product Quality and Specifications

Once you have a shortlist of suppliers, focus on the quality and specifications of the incubators they offer. High-quality materials and construction will directly affect the longevity and performance of the incubator.

- Materials: Check if the incubator is made from durable, insulated materials to maintain consistent temperatures.

- User Reviews: Read reviews or case studies that highlight the performance of the incubator in real-world scenarios.

Step 4: Assess After-Sales Support and Warranty

A solid warranty and after-sales support can save you time and money down the line. Verify what kind of support is offered, including installation assistance, maintenance services, and warranty terms.

- Warranty Length: A longer warranty period indicates the manufacturer’s confidence in their product.

- Customer Service: Ensure the supplier provides accessible customer support for troubleshooting and guidance.

Step 5: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to assess pricing structures. This step is vital in ensuring you receive competitive pricing while also considering the value of the features offered.

- Cost Breakdown: Look for detailed quotes that break down the costs for shipping, installation, and any additional features.

- Bulk Discounts: Inquire about discounts for bulk purchases, which can significantly reduce your overall costs.

Step 6: Confirm Shipping and Delivery Terms

Understanding the shipping and delivery terms is essential, especially for international transactions. Confirm the lead times and shipping costs, as these factors can impact your operational timeline.

- Shipping Policies: Ensure the supplier has clear policies regarding international shipping, including any customs duties or fees.

- Delivery Timelines: Get a firm estimate of delivery dates to align with your incubation schedule.

Step 7: Finalize Your Purchase and Document Everything

Once you’ve selected a supplier and agreed on terms, finalize your purchase. Ensure that all agreements, including warranties and specifications, are documented clearly to prevent misunderstandings in the future.

- Contracts: Review contracts thoroughly before signing to ensure all terms are favorable.

- Documentation: Keep copies of all correspondence and agreements for your records.

By following this checklist, you can streamline the process of sourcing an emu incubator and make well-informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for emu incubator for sale Sourcing

What Are the Key Cost Components for Emu Incubators?

When sourcing emu incubators, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality insulation materials, durable plastics, and advanced electronic components contribute to a higher initial investment but can enhance performance and longevity.

-

Labor: Labor costs vary by region and manufacturer. Countries with lower labor costs might offer cheaper products, but quality control could be a concern. Conversely, higher labor costs may reflect better craftsmanship and reliability.

-

Manufacturing Overhead: This includes utilities, rent, and other indirect costs associated with production. Efficient manufacturing processes can minimize overhead and positively affect pricing.

-

Tooling: Initial tooling costs can be significant, especially for customized incubators. The more specialized the design, the higher the tooling costs, which are often amortized over the production run.

-

Quality Control (QC): Investing in rigorous quality control measures ensures that the incubators meet necessary safety and performance standards. This can add to costs but is essential for maintaining a solid reputation in the market.

-

Logistics: Shipping costs are influenced by the weight and size of the incubators, as well as the shipping method and distance. International shipping can also incur additional customs duties and tariffs.

-

Margin: Manufacturers and suppliers typically add a margin to cover their operational costs and profit. This margin can vary widely based on market competition and demand.

How Do Price Influencers Affect Emu Incubator Costs?

Several factors influence the pricing of emu incubators:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts, as manufacturers can achieve economies of scale. Understanding the supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom features such as automatic humidity control, digital displays, and specific egg capacities can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Incubators made from premium materials or those certified for specific quality standards (e.g., ISO certification) typically command higher prices. However, these certifications can be essential for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more due to their brand value and service offerings, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) used in the transaction is vital. They define the responsibilities of buyers and sellers in shipping and delivery, which can significantly impact total costs.

What Buyer Tips Can Help Optimize Costs When Sourcing Emu Incubators?

International B2B buyers should consider several strategies to optimize their sourcing costs:

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices, especially for bulk orders. Understanding the cost structure can provide leverage in discussions with suppliers.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also operational costs, maintenance, and energy efficiency over the incubator’s lifespan. A higher upfront cost might be justified by lower operational costs.

-

Understand Pricing Nuances for International Buyers: Factors such as currency fluctuations, import taxes, and shipping costs can alter the final price. Buyers from regions like Africa, South America, the Middle East, and Europe should factor these elements into their budgeting.

-

Conduct Market Research: Familiarize yourself with various suppliers and their offerings. This knowledge can help in making informed decisions and identifying the best value for your specific needs.

-

Request Samples or Prototypes: Before making large investments, request samples or prototypes to assess quality and functionality. This step can prevent costly mistakes in bulk orders.

By taking these insights into account, B2B buyers can navigate the complexities of sourcing emu incubators more effectively, ensuring they achieve a balance between cost, quality, and reliability.

Alternatives Analysis: Comparing emu incubator for sale With Other Solutions

Understanding Alternatives for Emu Incubators

When considering the purchase of an emu incubator, it’s important for B2B buyers to evaluate alternative solutions that can meet their incubation needs. This analysis will compare the emu incubator with other viable options, providing insights into performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Emu Incubator For Sale | Cabinet Incubator | Natural Incubation |

|---|---|---|---|

| Performance | Specifically designed for emu eggs | High capacity, versatile | Dependent on hen’s ability |

| Cost | Varies widely, generally higher | Moderate to high (e.g., $749+) | Minimal (cost of hens) |

| Ease of Implementation | Plug-and-play setup | Requires calibration and setup | Requires no setup |

| Maintenance | Regular cleaning and monitoring | Moderate, needs regular checks | Minimal, relies on natural care |

| Best Use Case | Professional emu farming | Large-scale egg hatching | Small-scale or hobbyist farming |

Detailed Breakdown of Alternatives

Cabinet Incubator

Cabinet incubators are a popular alternative for those looking to hatch various types of eggs, including emu. These incubators, such as the AccuHatch Pro™, offer high capacity and advanced features like automatic humidity control and adjustable egg turners. While they can handle a variety of egg types, their initial investment can be significant, often starting at around $749. They require some setup and calibration, which may pose challenges for less experienced users. However, their versatility makes them a solid choice for large-scale operations looking to diversify their egg-hatching capabilities.

Natural Incubation

Natural incubation involves using hens to hatch eggs, which is a traditional method that requires minimal investment beyond the cost of maintaining the hens themselves. This method is highly dependent on the hen’s ability to provide the necessary warmth and humidity, which can vary significantly. While natural incubation requires no specialized equipment, it may not be suitable for larger operations or those seeking consistent results. This approach is best for small-scale or hobbyist farmers who prefer a low-cost, low-maintenance method of egg hatching.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right incubation solution, B2B buyers must consider their specific operational requirements and objectives. The emu incubator for sale is ideal for dedicated emu farming, providing specialized features for optimal hatching success. In contrast, cabinet incubators offer versatility for those looking to hatch a wider variety of eggs and may suit larger-scale operations. Meanwhile, natural incubation presents a cost-effective option for small-scale farmers willing to rely on traditional methods. By evaluating these alternatives based on performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for emu incubator for sale

What Are the Key Technical Properties of an Emu Incubator for Sale?

When evaluating emu incubators, several technical specifications are critical for ensuring optimal performance and reliability. Understanding these properties can help businesses make informed purchasing decisions.

-

Capacity

The capacity of an emu incubator indicates how many eggs it can hold at one time. For instance, some incubators can accommodate up to 36 emu eggs or even more, depending on the model. A larger capacity is essential for commercial operations, allowing for increased production and efficiency. Businesses should assess their hatching goals to determine the suitable capacity that meets their operational needs. -

Temperature Control Range

The temperature control range is vital for successful incubation, as different species of eggs require specific temperature settings. Typically, emu eggs incubate best at temperatures between 95°F and 104°F (35°C to 40°C). Precise temperature control minimizes the risk of egg mortality and maximizes hatching rates. Businesses must ensure that the incubator provides accurate and stable temperature management to support their breeding programs. -

Humidity Regulation

Maintaining optimal humidity levels is crucial for the development of embryos within the eggs. Many modern incubators feature automatic humidity control systems, which can adjust humidity levels from 30% to 70%. This capability helps avoid dehydration of the eggs and supports healthy chick development. Businesses should prioritize incubators with reliable humidity regulation features to enhance hatching success. -

Material Construction

The materials used in constructing the incubator significantly affect its insulation and durability. High-strength plastic or double-walled construction often provides better insulation, leading to more consistent internal conditions and energy efficiency. Selecting an incubator made from durable materials ensures longevity and reduces maintenance costs, making it a sound investment for businesses. -

User-Friendly Design

Features such as digital displays, adjustable egg turners, and easy access doors are essential for user-friendly operation. These elements facilitate monitoring and managing the incubation process, reducing labor efforts. A well-designed incubator can lead to better operational efficiency, which is crucial for businesses aiming to scale their operations.

What Are Common Trade Terms Used in Emu Incubator Transactions?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For emu incubators, an OEM may create specific components that are integrated into the final product. This is important for buyers looking for customized solutions or parts replacements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is a critical factor for businesses, as it can affect inventory management and initial investment costs. Understanding the MOQ helps buyers gauge their purchasing power and align it with their operational scale. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For emu incubators, issuing an RFQ allows businesses to compare prices, specifications, and terms from multiple suppliers, ensuring they make competitive and informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Terms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify who pays for shipping, insurance, and other logistical costs. Familiarity with Incoterms is crucial for businesses engaging in cross-border trade, as they help mitigate risks and set clear expectations. -

Hatching Rate

This term refers to the percentage of eggs that successfully hatch from a given batch. It is a key performance indicator for incubators and is crucial for evaluating their effectiveness. Businesses should inquire about the hatching rates associated with specific incubator models to ensure they meet their production goals.

By understanding these technical properties and trade terms, B2B buyers can make better decisions when purchasing emu incubators, ultimately enhancing their operational efficiency and productivity.

Navigating Market Dynamics and Sourcing Trends in the emu incubator for sale Sector

What Are the Current Market Dynamics and Key Trends Influencing the Emu Incubator Sector?

The emu incubator market is experiencing robust growth driven by increasing demand for emu farming across various regions, particularly in Africa, South America, the Middle East, and Europe. As the global demand for emu products—such as meat, oil, and leather—continues to rise, so does the necessity for efficient and reliable incubation solutions. Key trends shaping this sector include the integration of advanced technologies such as digital monitoring systems and automated temperature controls, which enhance hatching success rates and operational efficiency.

International B2B buyers are increasingly looking for suppliers that offer not only high-quality products but also comprehensive support services, including installation and maintenance. The emergence of e-commerce platforms is also revolutionizing the way buyers source incubators, providing them with a wider array of options and facilitating easier comparison shopping. Additionally, the trend toward sustainability is influencing purchasing decisions, with buyers favoring suppliers that demonstrate a commitment to environmentally friendly practices.

Emerging markets, particularly in Brazil and Nigeria, are showing heightened interest in emu farming, stimulated by government incentives and a growing awareness of the profitability associated with emu products. Suppliers that can navigate these complex market dynamics and align their offerings with local needs and regulations will find lucrative opportunities in this evolving landscape.

How Are Sustainability and Ethical Sourcing Affecting the Emu Incubator Market?

Sustainability is becoming a pivotal concern for B2B buyers in the emu incubator sector. The environmental impact of production processes is under scrutiny, prompting buyers to seek suppliers who prioritize sustainable practices. This includes the use of eco-friendly materials in incubator construction and energy-efficient technologies that reduce carbon footprints.

Ethical sourcing is equally important, as buyers demand transparency in the supply chain. Suppliers that can provide certifications indicating responsible sourcing of materials will gain a competitive edge. Green certifications, such as ISO 14001 for environmental management, can reassure buyers of a supplier’s commitment to sustainability.

Moreover, as consumers become more environmentally conscious, B2B buyers are increasingly aligning their sourcing strategies with these values. This shift not only enhances brand reputation but also meets the growing consumer demand for ethical and sustainable products. Suppliers who proactively adopt these practices can differentiate themselves in a crowded market, appealing to a more discerning customer base.

What Is the Historical Context of the Emu Incubator Market?

The emu incubator market has evolved significantly over the past few decades. Initially, incubators were simple, manually operated devices with limited capacity and control features. However, as the emu farming industry gained traction, particularly in countries like Australia and the United States, the demand for more sophisticated incubation solutions surged.

Advancements in technology have transformed incubators into sophisticated machines capable of precise temperature and humidity control, automatic egg turning, and real-time monitoring. This evolution has been driven by the need for higher hatching success rates and operational efficiency, which are crucial for commercial emu farming. Today, modern incubators not only cater to emu eggs but are also versatile enough to handle various poultry species, reflecting the growing diversification within the poultry sector.

As the market continues to evolve, suppliers who embrace technological innovations and sustainable practices will be well-positioned to lead in this dynamic industry.

Frequently Asked Questions (FAQs) for B2B Buyers of emu incubator for sale

-

How do I solve issues with low hatch rates in emu incubators?

Low hatch rates can often be attributed to improper temperature and humidity levels during incubation. To address this, ensure that your incubator is calibrated correctly and equipped with reliable automatic humidity control. Regularly monitor the temperature, keeping it within the recommended range of 95°F to 104°F (35°C to 40°C) for emu eggs. Additionally, ensure that the eggs are turned regularly and that the incubator has adequate ventilation. Consider consulting with the manufacturer for troubleshooting tips or potential upgrades to improve performance. -

What is the best emu incubator for large-scale operations?

For large-scale operations, the GQF 1502 Digital Sportsman Cabinet Incubator is an excellent choice. It has a high capacity, accommodating up to 36 emu eggs with features like precise digital temperature and humidity control. Its multiple turning racks allow for efficient egg rotation, which is crucial for successful hatching. This incubator is designed for both hobbyists and professionals, making it versatile for various breeding needs. Always verify the specifications against your operational requirements before purchasing. -

What should I consider when vetting suppliers of emu incubators?

When vetting suppliers, prioritize their reputation, product quality, and after-sales support. Look for manufacturers with positive customer reviews and a history of reliability in the market. Verify if they comply with international safety and quality standards. Additionally, inquire about their warranty policies and customer service responsiveness. It’s also beneficial to request references from other buyers in your region to gauge their experiences with the supplier. -

Are there customization options available for emu incubators?

Many manufacturers offer customization options for emu incubators to meet specific operational needs. This can include adjustments to capacity, temperature control systems, and additional features like automated egg turning mechanisms. When inquiring about customization, clearly outline your requirements and ask for any additional costs associated with these modifications. It’s advisable to work closely with the supplier to ensure that the final product aligns with your operational goals. -

What are the minimum order quantities (MOQ) for emu incubators?

Minimum order quantities for emu incubators can vary significantly between suppliers. Some manufacturers may have an MOQ of one unit, while others might require bulk orders to qualify for wholesale pricing. It’s essential to communicate your needs directly with potential suppliers to determine their specific policies. If you are a smaller operation, consider consolidating orders with other buyers to meet MOQ requirements while still benefiting from bulk pricing. -

What payment terms should I expect when purchasing emu incubators internationally?

Payment terms for international purchases typically include options such as wire transfers, letters of credit, or payment through online platforms. Suppliers may require a deposit upfront, with the balance due upon shipment or delivery. Always clarify the payment terms before finalizing the order and ensure they align with your cash flow capabilities. Additionally, inquire about any potential currency exchange fees or tariffs that may apply to your transaction. -

How can I ensure the quality of emu incubators before purchase?

To ensure quality, request detailed product specifications and certifications from the supplier. It’s beneficial to ask for samples or visit the manufacturing facility if possible. Additionally, consider conducting independent research on the supplier’s reputation and previous customer experiences. Quality assurance processes such as third-party inspections before shipment can also provide peace of mind. Finally, ensure that the incubator comes with a comprehensive warranty to cover any defects. -

What logistics considerations should I keep in mind when importing emu incubators?

When importing emu incubators, consider shipping methods, customs regulations, and delivery times. Choose a reliable freight forwarder familiar with international shipping to handle logistics. Research the import regulations specific to your country, including any tariffs or duties that may apply. Additionally, factor in the potential for delays in customs clearance, and ensure you have proper documentation for a smooth import process. Always plan for contingencies in your logistics strategy to accommodate unforeseen delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Emu Incubator For Sale Manufacturers & Suppliers List

1. IncuCare – AccuHatch Pro™ Cabinet Incubator & Hatcher

Domain: incubatorwarehouse.com

Registered: 2009 (16 years)

Introduction: Cabinet Incubators for Sale | Large-Capacity Egg Hatching

– Free Shipping on Orders over $25 (Excludes ALL Cabinets & GQF Brooders, Hawaii & Alaska)

– 2 Year IncuCare Warranty on ALL purchases

**AccuHatch Pro™ Cabinet Incubator & Hatcher**

– Price: $749.99 (originally $899.50)

– 2-in-1 Design: Incubates and hatches eggs in one unit.

– Adjustable Egg Turners: Fits quail, chicken, and goose eggs.

…

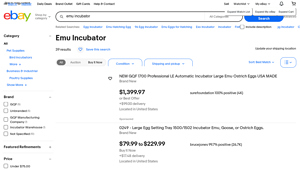

2. GQF – Emu Incubator

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Emu Incubator listings on eBay include various brands and models, with prices ranging from $20.00 to $2,899.97. Key brands include GQF, Rite Farm Products, and unbranded options. Features include automatic egg turning, temperature control, and different egg capacities (e.g., 4, 6, 32, 48, 1700, and 1750 egg capacities). Most items are new, with some used options available. Shipping options include…

3. Gum Creek Emus – Incubation Supplies

Domain: gumcreekemus.com

Registered: 2020 (5 years)

Introduction: Incubation supplies include: 1. Sportsman incubator – Designed for emu eggs. 2. Emu starter kits – Includes a Sportsman incubator, hatcher, and 4 emu eggs. 3. Hatchrite incubators – Refurbished, insulated incubators for ratite eggs, adjustable for most poultry eggs (except quail). 4. Hatching eggs – Available only from February to April. 5. Emu chicks – Sold in lots of 6, subject to availability. …

4. WONEGG – Emu Egg Incubator

Domain: incubatoregg.com

Registered: 2022 (3 years)

Introduction: Emu Egg Incubator from WONEGG, available in various capacities including 4, 7, 8, 9, 10, 12, 16, 20, 24, 30, 32, 35, 36, 42, 48, 52, 56, 88, 96, 112, 120, 360, 480, 600, 720, 840, 960, 1080, 1000, 2000, 4000, 6000, 8000, and 10000 eggs. Features include auto humidity control, LED lighting options, and various series such as E Series and H Series. The incubators are designed for hatching chicken, e…

5. Cimuka – CT60 SH Egg Incubator

Domain: hatchingtime.com

Registered: 2019 (6 years)

Introduction: Automatic Egg Incubator and Hatchers – Cimuka | Hatching Time

Key Products:

1. Cimuka CT60 SH – Egg Incubator – Setter & Hatcher

– Price: $789.99

– Rating: ★★★★★ (84)

– Availability: In stock

2. Cimuka CT120 SH – Egg Incubator – Setter & Hatcher

– Price: $949.99

– Rating: ★★★★★ (86)

– Availability: In stock

3. Cimuka CT180 SH – Egg Incubator – Setter & Hatcher

– Price: $1,0…

6. Accio – Emu Incubator

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Emu Incubator for Sale: High Hatch Rate Models & Best Prices. Key considerations include: Unit Price: $1.95 – $3340, Quantity: Minimum order quantity < 5. Product attributes: Automatic egg turning, Digital temperature control, Humidity control, LED display, High hatch rate, Adjustable ventilation, Multi-stage incubation, Overheat protection, Egg capacity 100+, Energy efficient. Various models avai…

7. Gypsy Shoals Farm – Essential Hatching Supplies

Domain: gypsyshoalsfarm.com

Registered: 2017 (8 years)

Introduction: 1. Incubator: A reliable egg incubator with temperature and humidity controls is necessary for hatching emu eggs. 2. Fertile emu eggs: Fresh, fertile emu eggs should be obtained from a reputable source. 3. Thermometer and hygrometer: These tools are essential for monitoring temperature and humidity levels inside the incubator. 4. Egg turner (optional): An egg turner automates the process of rotati…

8. Pinnon Hatch – 1700 GQF Large Egg Incubator

Domain: pinnonhatch.com

Registered: 2006 (19 years)

Introduction: 1700 GQF Large Egg Emu Ostrich Incubator

Price: $1,139.99

Shipping: FREE SHIPPING (No shipping outside of the Continental USA)

Current handling time: 15 business days

Approximate Capacity: 16 Ostrich Eggs and up to 32 Emu Eggs

Type: Large egg setting incubator (does not include a hatching tray)

Humidity Setting: Maintains one humidity setting

Thermostat: Accurate digital thermostat with LCD displa…

9. ONELYE – Automatic Egg Setter Incubator Hatcher

Domain: sinopfe.com

Registered: 2010 (15 years)

Introduction: Product Name: Automatic Egg Setter Incubator Hatcher 120 144 Emu Eggs Cabinet Hatcher

Model Number: EZ-E144

Capacity: 144 Emu eggs (setting), 36 Emu eggs (hatching)

Place of Origin: ONELYE

Brand Name: ONELYE

Certification: ONELYE

Minimum Order Quantity: 1 set

Price: negotiable

Packaging Details: wooden case

Delivery Time: 14 work days

Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram

Sup…

Strategic Sourcing Conclusion and Outlook for emu incubator for sale

In navigating the landscape of emu incubators for sale, B2B buyers must prioritize strategic sourcing to maximize their investment and operational efficiency. Key takeaways include the importance of selecting incubators that not only meet the specific needs of emu egg incubation but also offer features such as automatic humidity control, large capacity, and durability. The ability to source high-quality equipment from reliable suppliers, whether local or international, can significantly impact the success of hatchery operations.

Furthermore, understanding the varying requirements across different regions, including Africa, South America, the Middle East, and Europe, enables buyers to tailor their sourcing strategies effectively. This could involve evaluating shipping logistics, understanding regional regulations, and identifying local supplier partnerships that can enhance service delivery and support.

As you look to the future, consider the evolving trends in incubator technology and the growing demand for sustainable and efficient farming practices. Embrace this opportunity to invest in advanced emu incubators that will not only improve hatch rates but also streamline your operations. Take the next step today—engage with trusted suppliers to explore the best options available for your business needs.