Defond Switch: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for defond switch

In an increasingly interconnected world, sourcing the right components, such as the Defond switch, presents a unique challenge for international B2B buyers. With diverse applications ranging from automotive to consumer electronics, understanding the specifications, reliability, and compatibility of these switches is critical to ensuring operational efficiency and product quality. This guide serves as a comprehensive resource, meticulously outlining the various types of Defond switches, their applications, and essential criteria for supplier vetting.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil—will find actionable insights that empower them to make informed purchasing decisions. The complexities of global supply chains can often lead to uncertainties in quality and cost. By equipping buyers with knowledge about Defond’s extensive product offerings, including features such as anti-welding contacts and intelligent control modules, this guide not only facilitates better sourcing strategies but also fosters long-term supplier relationships.

Ultimately, whether you are seeking high-load rocker switches for power tools or intelligent control modules for smart home devices, this guide aims to streamline your procurement process, enhance product innovation, and drive business growth in your respective markets.

Understanding defond switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rocker Switch (High Load Compact) | Compact design, high load capacity, multiple circuits | Power tools, household appliances | Pros: Space-efficient, versatile. Cons: May require specific installation space. |

| AC/DC On-Off Switch | Anti-welding contacts, signal outputs | Industrial equipment, automotive | Pros: Reliable operation, low maintenance. Cons: Limited to on-off functionality. |

| Intelligent Control Module | Smart features, programmable settings | Smart home devices, appliances | Pros: Enhanced functionality, energy-efficient. Cons: Higher initial cost. |

| Seat Adjustment Switch | 18-way adjustment capability | Automotive seats, office furniture | Pros: Customizable comfort, ergonomic design. Cons: Complexity in installation. |

| Rocker Switch (SPDT) | Single pole double throw, multiple positions | Electronics, consumer products | Pros: Flexible switching options. Cons: May require additional wiring. |

What are the Key Characteristics of Rocker Switches (High Load Compact)?

High load compact rocker switches are designed for applications requiring substantial power without occupying excessive space. They come with options for multiple circuits and various terminal types, making them ideal for power tools and household appliances. When purchasing, buyers should consider the switch’s load capacity and installation requirements, as these can impact both performance and compatibility with existing systems.

How Do AC/DC On-Off Switches Stand Out in Industrial Applications?

AC/DC on-off switches are equipped with anti-welding contacts and signal outputs, ensuring reliable performance in demanding environments. These switches are commonly used in industrial equipment and automotive applications, where durability and low maintenance are critical. Buyers should evaluate the specific load requirements and ensure that the switch’s ratings align with their operational needs to avoid performance issues.

What Makes Intelligent Control Modules Ideal for Smart Devices?

Intelligent control modules offer programmable settings that enhance the functionality of smart home devices and appliances. These modules are particularly suited for applications that prioritize energy efficiency and user customization. B2B buyers should weigh the benefits of advanced features against the higher initial costs, as the long-term savings from energy efficiency can justify the investment.

Why Choose a Seat Adjustment Switch for Automotive and Furniture Applications?

Seat adjustment switches provide up to 18-way adjustment capabilities, making them essential for automotive seats and ergonomic office furniture. They enhance user comfort and personalization, which can be a significant selling point for manufacturers. Buyers should consider the complexity of installation and compatibility with existing designs when selecting these switches for their products.

What Are the Advantages of SPDT Rocker Switches in Electronics?

SPDT (Single Pole Double Throw) rocker switches offer versatile switching options, allowing for multiple positions in a compact format. These switches are widely used in consumer electronics and other applications where space is at a premium. Buyers should consider the wiring requirements and ensure that the switch meets their specific operational needs to maximize efficiency and effectiveness.

Key Industrial Applications of defond switch

| Industry/Sector | Specific Application of defond switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Control Modules for Vehicle Features | Enhances user experience and safety in vehicles | Compliance with automotive standards and certifications |

| Home Appliances | Smart Home Device Controls | Increases energy efficiency and user convenience | Compatibility with various home automation systems |

| Power Tools | Switches for Cordless Tools | Improves tool reliability and performance | Durability in harsh environments and high load capacity |

| HVAC Systems | On/Off Controls for HVAC Units | Optimizes energy consumption and system performance | Resistance to environmental factors (humidity, temperature) |

| Industrial Equipment | Control Switches for Heavy Machinery | Ensures operational efficiency and safety | Ability to handle high loads and robust construction |

How is the defond switch utilized in the automotive industry?

In the automotive sector, defond switches are integral in control modules for various vehicle features, including lighting, heating, and infotainment systems. These switches enhance user experience by providing reliable and intuitive controls, which are essential for safety and convenience. B2B buyers in this industry must consider compliance with strict automotive standards and certifications, ensuring that the switches meet the necessary durability and performance requirements.

What role do defond switches play in home appliances?

Defond switches are increasingly used in smart home devices, allowing for precise control over appliances like air purifiers, coffee machines, and air fryers. By integrating these switches, manufacturers can enhance energy efficiency and user convenience, appealing to the growing market for smart technology. Buyers from regions such as Africa and South America should ensure that the switches are compatible with various home automation systems and can withstand different electrical standards.

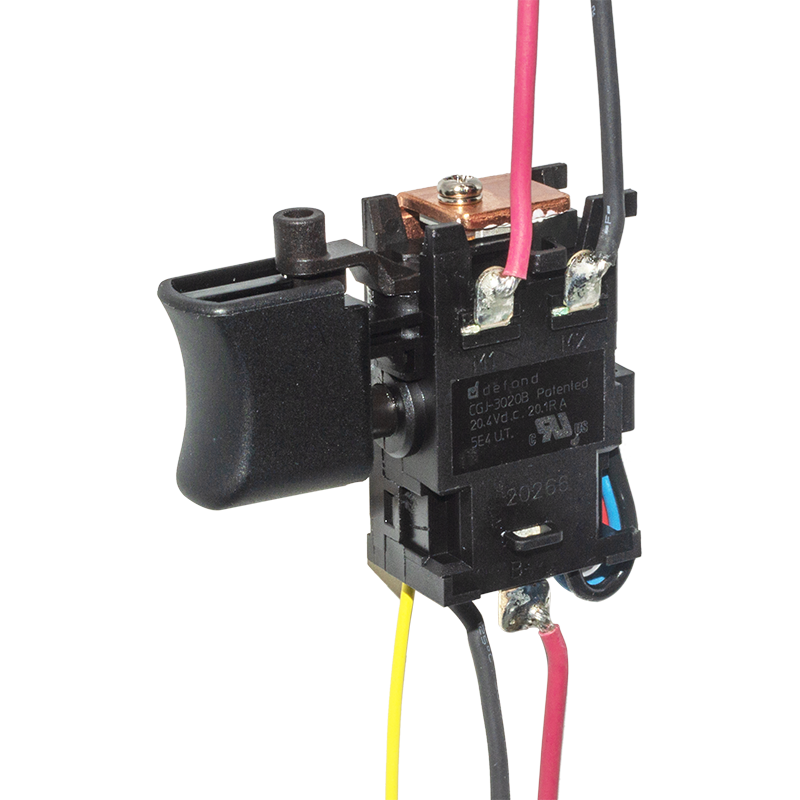

How do defond switches improve power tool functionality?

In the power tools industry, defond switches are crucial for the operation of cordless tools, offering robust performance and reliability. These switches are designed to withstand the rigors of heavy use while providing a seamless user experience. For international buyers, especially in Europe and the Middle East, sourcing switches that demonstrate high durability in harsh working conditions is essential, as is ensuring compliance with safety regulations.

What benefits do defond switches provide in HVAC systems?

Defond switches are utilized in HVAC systems for on/off control, playing a vital role in energy optimization and system performance. By allowing precise control over heating and cooling units, these switches help businesses reduce energy costs and enhance operational efficiency. Buyers in regions with extreme climates, such as the Middle East, should focus on sourcing switches that can withstand high humidity and temperature variations.

How do defond switches contribute to industrial equipment safety?

In industrial applications, defond switches are employed in heavy machinery for control and safety functions. These switches ensure operational efficiency by allowing operators to manage equipment effectively, thus preventing potential hazards. When sourcing for industrial applications, businesses must prioritize switches that can handle high loads and are built with robust materials to withstand demanding environments, ensuring longevity and reliability.

3 Common User Pain Points for ‘defond switch’ & Their Solutions

Scenario 1: Ensuring Compatibility with Diverse Applications

The Problem: B2B buyers often face challenges when trying to integrate Defond switches into their existing systems or products. Compatibility issues arise due to variations in voltage ratings, current specifications, and circuit configurations. For example, a manufacturer in Nigeria may require a specific switch for an air conditioning unit that operates on a unique voltage standard, but they might find that the options available do not match their technical requirements. This can lead to delays in production, increased costs, and frustration as they seek alternatives.

The Solution: To ensure compatibility, buyers should conduct thorough research on Defond’s extensive product range before making a purchase. Understanding the specifications of your application is crucial—ensure you know the voltage, current rating, and type of circuit needed. Utilize Defond’s technical resources or consult with their customer support team to clarify specifications. Additionally, consider custom solutions through Defond’s OEM and ODM services, which allow for tailored switches that perfectly fit your needs. This proactive approach not only saves time but also minimizes the risk of costly mismatches.

Scenario 2: Navigating Supply Chain Challenges

The Problem: Supply chain disruptions can significantly impact the availability of Defond switches, especially in regions like South America and Africa, where logistics may be less reliable. Buyers may encounter delays in receiving essential components, leading to halted production lines and unmet customer demands. The uncertainty surrounding lead times and stock levels can create significant stress for procurement teams trying to maintain operational continuity.

The Solution: To mitigate supply chain risks, B2B buyers should establish a robust relationship with Defond’s sales and logistics teams. Regular communication can provide insight into stock levels and anticipated lead times, allowing for better planning and inventory management. Additionally, consider adopting a Just-In-Time (JIT) inventory strategy to reduce excess stock while ensuring that critical components are readily available. Buyers might also explore alternative sourcing options or local distributors to diversify their supply chain. Engaging in strategic partnerships with Defond can facilitate smoother operations and enhance reliability.

Scenario 3: Managing Product Quality and Performance Expectations

The Problem: Quality control is a significant concern for buyers when incorporating Defond switches into their products. Users often report issues such as premature failure or inconsistency in performance, which can lead to product recalls or loss of customer trust. For example, a power tools manufacturer in Europe might find that switches used in their devices do not withstand high humidity or temperature conditions, resulting in operational failures and customer dissatisfaction.

The Solution: To address quality concerns, buyers should prioritize sourcing switches that meet rigorous industry standards and certifications. When selecting Defond switches, review the product specifications, including lifecycle ratings and environmental resistances, such as IP ratings for dust and moisture. Conduct thorough testing in actual operating conditions before full-scale implementation. Additionally, establish a feedback loop with your manufacturing and quality assurance teams to monitor performance and report any issues directly to Defond. This collaborative approach not only ensures product reliability but also fosters continuous improvement in quality standards.

Strategic Material Selection Guide for defond switch

What Are the Key Materials Used in Defond Switches?

When selecting materials for Defond switches, it is essential to consider their properties, advantages, disadvantages, and how they impact specific applications. This analysis focuses on four common materials: thermoplastics, metals, ceramics, and composites.

How Do Thermoplastics Enhance the Performance of Defond Switches?

Thermoplastics, such as polycarbonate and nylon, are widely used in the housing and components of Defond switches. These materials offer excellent electrical insulation properties and are resistant to impact and moisture.

Key Properties: Thermoplastics can withstand temperatures ranging from -40°C to 120°C, making them suitable for various environments. They also exhibit good chemical resistance to oils and solvents.

Pros & Cons: The primary advantage of thermoplastics is their lightweight nature and ease of manufacturing, which allows for complex shapes and designs. However, they may not be as durable as metals under extreme mechanical stress, and their cost can be moderate depending on the type used.

Impact on Application: Thermoplastics are ideal for applications requiring insulation and protection from moisture, such as in automotive and consumer electronics.

Considerations for International Buyers: Compliance with international standards such as ASTM and UL is crucial. Buyers from regions like Africa and South America should ensure that the selected thermoplastics meet local regulations regarding safety and environmental impact.

Why Are Metals Preferred for Certain Components of Defond Switches?

Metals, particularly copper and aluminum, are often utilized in the conductive parts of Defond switches due to their excellent electrical conductivity and strength.

Key Properties: Metals can handle high temperatures and pressures, with copper rated for continuous use at up to 200°C. They also provide good corrosion resistance when treated properly.

Pros & Cons: Metals offer durability and reliability, making them suitable for heavy-duty applications. However, they can be heavier and more expensive than thermoplastics, and their manufacturing process can be more complex.

Impact on Application: Metals are essential in applications that require high current carrying capacity, such as in industrial machinery and power tools.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades and coatings that comply with local standards, particularly in regions with stringent regulations on electrical components.

How Do Ceramics Contribute to the Functionality of Defond Switches?

Ceramics are increasingly used in specialized applications, particularly for their insulating properties and resistance to high temperatures.

Key Properties: Ceramics can withstand temperatures exceeding 1500°C and are highly resistant to chemical corrosion and wear.

Pros & Cons: The primary advantage of ceramics is their exceptional thermal stability and electrical insulation. However, they can be brittle and prone to cracking under mechanical stress, which limits their use in some applications.

Impact on Application: Ceramics are suitable for high-temperature environments, such as those found in industrial ovens or high-performance electrical applications.

Considerations for International Buyers: It is essential to verify that ceramic materials meet specific international standards, as their use may be limited in certain markets due to safety concerns.

What Role Do Composites Play in the Manufacturing of Defond Switches?

Composite materials, which combine two or more different materials, are used to enhance the properties of Defond switches.

Key Properties: Composites can be engineered to provide specific benefits, such as increased strength-to-weight ratios and improved thermal stability.

Pros & Cons: The major advantage of composites is their versatility and the ability to tailor properties for specific applications. However, they can be more expensive and complex to manufacture compared to traditional materials.

Impact on Application: Composites are particularly beneficial in applications requiring lightweight and strong components, such as in aerospace and automotive sectors.

Considerations for International Buyers: Understanding the specific composite materials used is crucial, as different regions may have varying standards for composite safety and performance.

Summary Table of Material Selection for Defond Switches

| Material | Typical Use Case for defond switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastics | Housing and insulation components | Lightweight and easy to manufacture | Less durable under extreme stress | Medium |

| Metals | Conductive parts | High strength and electrical conductivity | Heavier and more expensive | High |

| Ceramics | High-temperature applications | Exceptional thermal stability | Brittle and prone to cracking | Medium to High |

| Composites | Lightweight structural components | Tailored properties for specific needs | More expensive and complex to manufacture | High |

This guide provides essential insights into the strategic selection of materials for Defond switches, allowing international B2B buyers to make informed decisions based on performance, application, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for defond switch

What Are the Key Stages in the Manufacturing Process of Defond Switches?

The manufacturing process of Defond switches involves several critical stages to ensure the production of high-quality components. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves sourcing high-grade materials that comply with international standards. Common materials used in the production of Defond switches include plastics, metals, and electronic components. Suppliers are often required to provide Material Safety Data Sheets (MSDS) to confirm compliance with safety and environmental regulations. Proper storage and handling of these materials are essential to prevent contamination and ensure that all components meet quality specifications.

Forming Techniques Used in Defond Switch Manufacturing

Once the materials are prepared, they undergo various forming techniques. These techniques can include injection molding for plastic components, stamping for metal parts, and circuit board fabrication for electronic elements. The choice of technique is determined by the specific requirements of the switch design. For example, injection molding allows for complex geometries and high-volume production, while stamping is ideal for creating robust metal contacts.

How Is the Assembly of Defond Switches Conducted?

The assembly stage involves bringing together all the formed components. This process is typically automated but may also include manual assembly for intricate parts. Key assembly techniques include soldering, which is used for electronic connections, and mechanical fastening for structural integrity. Quality checks are integrated into this stage to ensure that each switch meets design specifications and is free from defects.

What Finishing Processes Are Employed for Defond Switches?

Finishing processes enhance the durability and aesthetic appeal of the switches. This may involve surface treatments such as plating, painting, or coating to improve corrosion resistance and provide insulation. Additionally, the finishing stage may include testing for electrical performance, ensuring that the switches operate effectively under various conditions.

What Quality Assurance Practices Are in Place for Defond Switches?

Quality assurance is a cornerstone of the manufacturing process for Defond switches. The company adheres to international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards ensures that the manufacturing process is consistently monitored and improved.

How Does Defond Ensure Compliance with International Standards?

Defond switches also meet industry-specific certifications, including CE marking, which signifies compliance with European health, safety, and environmental protection standards. Other relevant certifications may include API for products used in the oil and gas sector or UL certification for electrical safety.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These checkpoints include:

-

Incoming Quality Control (IQC): This stage verifies the quality of incoming materials and components before they enter the production line. Suppliers must provide certification for their materials, and random sampling is conducted to ensure compliance.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct periodic checks to ensure that components are being produced to specifications. This may involve visual inspections, dimensional checks, and functional tests.

-

Final Quality Control (FQC): Once the switches are fully assembled, they undergo a comprehensive final inspection. This includes electrical testing, durability tests, and functional performance evaluations to ensure that they meet all specifications.

What Testing Methods Are Commonly Used in the Quality Assurance of Defond Switches?

Various testing methods are employed to validate the performance and reliability of Defond switches. These methods include:

-

Electrical Testing: This ensures that switches operate correctly under specified voltage and current ratings. Tests may involve checking for short circuits, open circuits, and contact resistance.

-

Environmental Testing: Switches may be subjected to conditions simulating extreme temperatures, humidity, and dust to assess their operational reliability. This is particularly relevant for switches designed for use in harsh environments.

-

Mechanical Testing: This includes cycle testing to determine the durability of the switch under repeated use. Manufacturers often simulate thousands of on/off cycles to ensure longevity.

How Can B2B Buyers Verify Supplier Quality Assurance Processes?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is crucial. Here are several actionable steps buyers can take:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their quality management systems and manufacturing practices. Buyers should request documentation of previous audits and any corrective actions taken.

-

Request Quality Reports: Suppliers should provide quality reports detailing the results of IQC, IPQC, and FQC. These reports should include data on defect rates, testing outcomes, and any non-conformance issues.

-

Engage Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality processes. These inspections can occur at various stages of production and provide additional assurance of compliance.

What Are the Quality Control Nuances for International Buyers?

International buyers need to be aware of specific nuances regarding quality control that may affect their procurement decisions. Different regions may have varying standards and certifications. For example, while CE marking is essential for the European market, other certifications may be required for compliance in Africa or South America. Buyers should familiarize themselves with the local regulations and ensure that their suppliers can meet these requirements.

In conclusion, understanding the manufacturing processes and quality assurance practices behind Defond switches is vital for B2B buyers looking for reliable components. By focusing on the details of manufacturing, quality checkpoints, and testing methods, buyers can make informed decisions and ensure they partner with suppliers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘defond switch’

In today’s competitive landscape, sourcing high-quality components such as Defond switches requires a strategic approach. This guide serves as a practical checklist for international B2B buyers looking to procure Defond switches effectively, ensuring that they meet their technical and operational needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for the Defond switch. Consider factors such as current and voltage ratings, switch type (e.g., rocker, push-button), and specific applications (e.g., power tools, home appliances). Having these specifications defined will streamline your sourcing process and help you communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Identify and compile a list of reputable suppliers who specialize in Defond switches. Look for manufacturers with a proven track record in your industry. Utilize online marketplaces, industry directories, and trade shows to gather information on suppliers and their offerings. Focus on those who have experience supplying businesses in your region, as they may better understand local regulations and market needs.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers hold necessary certifications relevant to your market and industry standards, such as ISO 9001 for quality management. Certifications guarantee that the manufacturer adheres to international quality standards and can produce reliable products. Check for additional certifications like UL or CE, especially if you are sourcing for safety-critical applications.

Step 4: Request Samples for Testing

Once you have narrowed down your list of suppliers, request samples of the Defond switches you are considering. Testing samples is essential to verify their performance and compatibility with your application. Pay attention to the quality of materials used, operational reliability under specified conditions, and ease of installation.

Step 5: Assess Pricing and Payment Terms

Compare pricing across different suppliers while taking into account the total cost of ownership, including shipping, tariffs, and potential bulk discounts. Evaluate payment terms that align with your cash flow needs. Negotiate terms that provide you with flexibility while ensuring that the supplier remains viable and can meet your delivery timelines.

Step 6: Check References and Reviews

Before making a final decision, check references and read reviews from other businesses that have sourced from the suppliers you are considering. This step can provide insights into the supplier’s reliability, customer service, and product quality. Consider reaching out directly to a few references to gather qualitative feedback.

Step 7: Finalize Your Order and Establish Communication

Once you have selected a supplier, finalize your order by confirming all specifications, quantities, and delivery timelines. Establish clear communication channels for ongoing support and updates. This ensures that any potential issues can be addressed swiftly, maintaining a smooth supply chain process.

By following this checklist, international B2B buyers can navigate the complexities of sourcing Defond switches, ensuring they select the right products and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for defond switch Sourcing

Understanding the cost structure and pricing dynamics of Defond switches is crucial for B2B buyers aiming to optimize their sourcing strategies. Below is a detailed analysis focusing on cost components, price influencers, and actionable buyer tips tailored for international markets, particularly in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components Involved in Sourcing Defond Switches?

Sourcing Defond switches involves several cost components that contribute to the final pricing.

-

Materials: The primary materials used in manufacturing Defond switches include high-quality plastics and metals, which impact durability and performance. The choice of materials directly influences the switch’s functionality, especially for applications requiring high load and moisture resistance.

-

Labor: Labor costs encompass wages for skilled technicians and assembly line workers involved in the production process. The level of craftsmanship and expertise required for manufacturing specialized switches can vary significantly between regions.

-

Manufacturing Overhead: This includes utilities, factory maintenance, and equipment depreciation. Efficient production processes and advanced manufacturing technologies can help minimize overhead costs, reflecting in competitive pricing.

-

Tooling: The initial investment in tooling, particularly for custom switch designs, can be substantial. This cost is often amortized over the production run, affecting the unit price based on the volume ordered.

-

Quality Control (QC): Rigorous testing and quality assurance protocols ensure that products meet international standards. These processes incur additional costs but are essential for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping, warehousing, and customs duties contribute to logistics costs. The geographical location of the buyer can significantly affect these expenses, especially for international transactions.

-

Margin: Suppliers typically build a profit margin into their pricing, influenced by market conditions, competition, and their operational efficiency.

What Influences the Pricing of Defond Switches in the B2B Market?

Several factors can influence the pricing of Defond switches, making it essential for buyers to understand these dynamics:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes usually result in lower per-unit prices due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications and Customization: Custom designs or specific technical specifications can lead to increased costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (e.g., UL, ENEC) can significantly impact pricing. High-quality materials may lead to higher initial costs but can offer long-term savings through durability and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a track record of quality may charge more but can reduce the risk of defects and delays.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they dictate the responsibilities of buyers and sellers in shipping. This knowledge can help manage logistics costs effectively.

What Are Some Effective Tips for Negotiating Prices on Defond Switches?

-

Leverage Total Cost of Ownership (TCO): When negotiating, consider the TCO rather than just the unit price. Analyze potential maintenance, replacement, and operational costs associated with the switches over their lifespan.

-

Research and Benchmark: Conduct market research to understand prevailing prices and benchmark against competitors. This information can empower buyers during negotiations.

-

Build Strong Relationships: Cultivating relationships with suppliers can lead to better pricing, exclusive offers, and improved service.

-

Explore Alternate Suppliers: While Defond is a reputable brand, exploring alternative suppliers for similar specifications may provide leverage in negotiations.

-

Be Aware of Pricing Nuances for International Transactions: Currency fluctuations and local market conditions can impact pricing. Buyers from regions like Nigeria and Brazil should consider these factors when planning their purchases.

Conclusion

Sourcing Defond switches involves a multifaceted understanding of costs and pricing dynamics. By grasping the key components and influencers, and employing strategic negotiation techniques, international B2B buyers can achieve favorable terms and optimize their procurement processes. Always keep in mind that prices can vary based on specific circumstances, so maintaining flexibility and open communication with suppliers is essential for successful sourcing.

Alternatives Analysis: Comparing defond switch With Other Solutions

In the competitive landscape of electronic components, businesses must evaluate various switch solutions to meet their operational needs. The Defond switch is known for its reliability and performance; however, buyers should consider alternative products that may offer different advantages. This section compares the Defond switch with two viable alternatives, helping B2B buyers make informed decisions.

| Comparison Aspect | Defond Switch | Alternative 1: TE Connectivity Switch | Alternative 2: Omron Switch |

|---|---|---|---|

| Performance | High load capacity, robust design | Versatile options, reliable in harsh conditions | Compact design, excellent durability |

| Cost | Moderate pricing | Slightly higher cost | Competitive pricing |

| Ease of Implementation | Simple integration with existing systems | Requires specific configurations | User-friendly installation |

| Maintenance | Low maintenance needs | Moderate maintenance requirements | Low maintenance, easy to service |

| Best Use Case | Power tools, automotive applications | Industrial equipment, smart devices | Consumer electronics, appliances |

What Are the Key Benefits and Drawbacks of TE Connectivity Switches?

TE Connectivity switches are recognized for their versatility and reliability, particularly in demanding environments. They can handle a broad range of applications, making them suitable for industrial equipment and smart devices. However, their slightly higher cost may be a consideration for budget-conscious buyers. Additionally, these switches may require specific configurations during installation, which could lead to longer implementation times.

How Do Omron Switches Compare in Terms of Performance and Cost?

Omron switches are celebrated for their compact design and excellent durability. They are ideal for consumer electronics and appliances, where space is a premium, and reliability is paramount. Their competitive pricing makes them an attractive option for many businesses. However, while they offer low maintenance requirements, users should ensure they are compatible with their specific applications to avoid any operational issues.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between the Defond switch and its alternatives, B2B buyers should consider their specific application requirements, budget constraints, and long-term maintenance capabilities. The Defond switch excels in heavy-duty applications, while TE Connectivity offers versatility, and Omron provides compact solutions ideal for consumer electronics. Ultimately, the right choice will align with the operational demands and strategic goals of the business, ensuring optimal performance and value.

Essential Technical Properties and Trade Terminology for defond switch

What Are the Essential Technical Properties of a Defond Switch?

When sourcing Defond switches, understanding their technical properties is crucial for making informed purchasing decisions. Below are key specifications that define the performance and suitability of these switches for various applications.

-

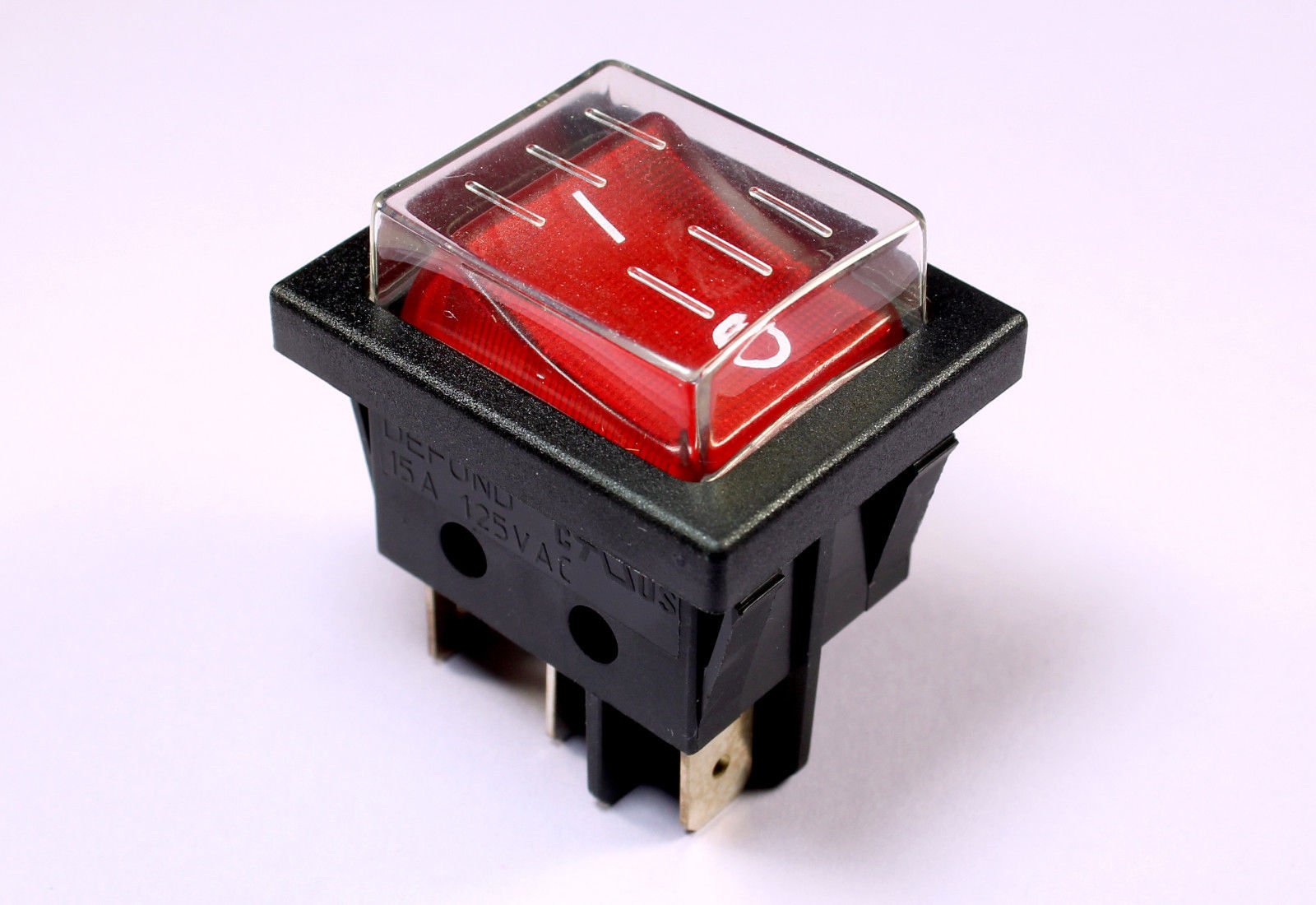

Current Rating: This indicates the maximum current the switch can handle safely, typically expressed in amperes (A). For example, a Defond switch may have ratings like 15A at 125VAC and 7.5A at 250VAC. The current rating is vital for ensuring the switch can support the electrical load of the application without overheating or failing.

-

Voltage Rating: This specification denotes the maximum voltage the switch can operate at, measured in volts (V). Common ratings include 125VAC and 250VAC. Understanding voltage ratings helps buyers ensure compatibility with their electrical systems and avoids potential electrical hazards.

-

Cycle Life: The number of operations a switch can perform before failure is termed its cycle life, typically indicated as a number of cycles (e.g., 10,000 cycles). A longer cycle life translates to reduced maintenance and replacement costs, making it essential for applications requiring reliability and durability.

-

Insulation Resistance: Measured in megohms (MΩ), this property indicates the effectiveness of the switch’s insulation in preventing electrical leakage. A high insulation resistance (e.g., ≥ 50MΩ) is crucial for safety and performance, particularly in high-voltage applications.

-

Contact Resistance: This specification refers to the resistance encountered by the electrical current passing through the switch contacts, expressed in milliohms (mΩ). A low contact resistance (e.g., ≤ 50mΩ) is important to minimize energy loss and prevent overheating during operation.

-

Environmental Ratings: Many Defond switches are rated for specific environmental conditions, such as humidity and temperature. For instance, switches designed for high humidity or dusty environments will have different materials and construction than standard switches. Understanding these ratings ensures that the switch will perform reliably in its intended environment.

What Are Common Trade Terms Related to Defond Switches?

Navigating the procurement process involves familiarity with key industry terminology. Below are essential trade terms that B2B buyers should know.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Defond switches, OEMs often supply components that are integrated into larger systems, such as appliances or automotive products.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is crucial for budgeting and inventory management, as it can impact the overall cost and feasibility of sourcing switches.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. B2B buyers should use RFQs to gather competitive quotes for Defond switches, ensuring they receive the best value.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and insurance responsibilities, which can affect the total landed cost of the switches.

-

Lead Time: This refers to the time it takes from placing an order until the goods are delivered. Understanding lead times is essential for project planning and inventory control, especially when sourcing switches for time-sensitive applications.

-

Certification Standards: These are industry-recognized benchmarks that products must meet to ensure safety and performance. Common certifications for switches include UL (Underwriters Laboratories) and ENEC (European Norms Electrical Certification). Knowing the relevant certifications helps buyers ensure compliance with local regulations and quality standards.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Defond switches, optimizing their procurement strategies for efficiency and reliability.

Navigating Market Dynamics and Sourcing Trends in the defond switch Sector

What Are the Current Trends and Market Dynamics in the Defond Switch Sector?

The global market for Defond switches is witnessing significant transformation driven by technological advancements, increasing automation, and the growing demand for energy-efficient solutions. With industries such as automotive, consumer electronics, and smart home applications expanding rapidly, the need for reliable and high-performance switches has escalated. B2B buyers from Africa, South America, the Middle East, and Europe, particularly Nigeria and Brazil, are increasingly looking for suppliers that can offer innovative designs and robust performance, ensuring their products remain competitive in the global landscape.

Emerging trends include the integration of IoT capabilities into switch designs, enabling smarter, more efficient systems. Buyers are prioritizing suppliers who can provide custom solutions, emphasizing the importance of flexibility and innovation in product offerings. Additionally, the push towards digital transformation is leading to increased demand for intelligent control modules that can enhance functionality and user experience. This evolution is not only reshaping product specifications but also influencing supply chain strategies, as international buyers seek partners who can adapt quickly to changing market needs.

How Does Sustainability and Ethical Sourcing Impact the Defond Switch Sector?

Sustainability has become a cornerstone of sourcing strategies in the B2B sector, with buyers increasingly focused on the environmental impact of their supply chains. In the context of Defond switches, this means selecting suppliers who adhere to strict environmental standards and prioritize sustainable practices. The use of eco-friendly materials and processes is gaining traction, as companies aim to reduce their carbon footprint and meet regulatory requirements.

The importance of ethical sourcing cannot be overstated. B2B buyers are now looking for partners who demonstrate transparency in their supply chains and commitment to fair labor practices. Certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) are becoming essential criteria for evaluating potential suppliers. Buyers in emerging markets are particularly concerned about ensuring that their suppliers comply with these standards, not only to enhance their brand reputation but also to cater to an increasingly environmentally conscious consumer base.

What Is the Evolution of the Defond Switch Sector?

The Defond switch sector has evolved significantly since its inception, driven by technological innovations and changing consumer demands. Initially focused on basic switch functionalities, the market has expanded to include sophisticated designs capable of supporting advanced applications in various industries. Over the past few decades, the introduction of smart technologies and automation has transformed traditional switches into intelligent control modules that can communicate and interact with other devices.

This evolution is marked by a growing emphasis on quality and reliability, with manufacturers investing in advanced production techniques and quality management systems. As B2B buyers increasingly seek customized and innovative solutions, the Defond switch sector continues to adapt, ensuring it meets the needs of diverse markets across the globe. Understanding this historical context helps international buyers appreciate the current landscape and the direction in which the industry is heading, allowing them to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of defond switch

-

How do I resolve compatibility issues with Defond switches in my product design?

To address compatibility concerns with Defond switches, first, review the technical specifications for the switch models you are considering, such as voltage ratings and current capacities. Collaborate closely with Defond’s engineering team to assess your product’s requirements and ensure that the switch can handle the necessary load. Additionally, prototype testing is essential; conduct rigorous testing to validate performance within your specific application, especially under varying environmental conditions typical in regions like Africa or South America. -

What is the best Defond switch for high-load applications?

For high-load applications, the High Load Compact Rocker Switch (CRT series) is ideal due to its robust design and ability to handle up to 15A at 125VAC. It features multiple circuit options, various terminal configurations, and is built to endure demanding environments. Always ensure that the specific model meets your application’s voltage and current requirements. Engaging with a Defond representative can provide tailored recommendations based on your unique needs. -

What are the minimum order quantities (MOQs) for Defond switches?

Defond typically has minimum order quantities that vary by product line and regional distribution policies. For many products, MOQs may range from a few dozen to hundreds of units. It’s advisable to check with your local distributor or directly with Defond to understand specific MOQs for the switches you intend to purchase, especially if you are considering bulk orders to optimize costs. -

What payment terms are available for purchasing Defond switches?

Payment terms can vary based on your location and the volume of your order. Commonly, international buyers may negotiate terms such as advance payment, letters of credit, or net 30/60 days, depending on the relationship established with the supplier. Ensure you clarify these terms upfront to avoid any potential delays in processing your order. -

How can I ensure quality assurance when sourcing Defond switches?

To ensure quality assurance, request detailed certifications for the switches, such as UL, ENEC, and CQC. Establish a quality control process that includes pre-shipment inspections and testing of samples. Collaborate with Defond’s production team to understand their quality management practices. Additionally, consider visiting the manufacturing facility if possible, to gain firsthand insight into their production standards. -

What logistics options are available for importing Defond switches?

Logistics options for importing Defond switches include air freight for quicker delivery or sea freight for cost-effective shipping over larger volumes. It’s essential to work with a freight forwarder experienced in international trade to navigate customs regulations and ensure timely delivery. Determine the most suitable option based on your timeline and budget, and factor in potential tariffs and duties applicable in your region. -

Can Defond switches be customized for specific applications?

Yes, Defond offers customization options for their switches, including modifications to circuit design, size, and functionality to meet your specific application needs. Engage with their engineering team early in your project to discuss your requirements, and consider the implications on lead times and costs. Custom solutions can significantly enhance product performance in targeted applications across diverse markets. -

What support does Defond provide for international buyers?

Defond provides comprehensive support for international buyers, including technical assistance, product training, and dedicated account management. Their team can assist with product selection, provide documentation for compliance, and offer insights into best practices for integration. Utilizing their support resources can facilitate a smoother purchasing experience and ensure that you maximize the performance of their switches in your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Defond Switch Manufacturers & Suppliers List

1. Defond – 2 Pole Rocker Switch

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Defond 2 Pole Rocker Switch”, “Specifications”: {“Current Rating”: “16A-125VAC, 8A-250VAC”}, “Quantity”: “Lot of 5”, “Condition”: “New – Open box”, “Price”: “$20.00”, “Shipping”: “$10.40”, “Estimated Delivery”: “Mon, Sep 29 – Fri, Oct 10”, “Brand”: “Defond”, “Category”: “Business & Industrial > Electrical Equipment & Supplies > Switches > Rocker Switches”, “Item Number”: “2541891…

2. Defond – Switch Replacement Inquiry

Domain: forum.digikey.com

Registered: 1995 (30 years)

Introduction: This company, Defond – Switch Replacement Inquiry, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Defond – DMP-1101 Switches

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Defond DMP-1101 switches, rated for 50 million clicks. Available in three variants: white (65gf), transparent (55gf), and black (75gf). The white switch is noted to feel similar to Japanese Omron D2F-F-3-7. The transparent and black switches are newer with limited user feedback.

4. DEFOND – FSRSPDT-16A-ON-OFF-ON-PN

Domain: tedss.com

Registered: 2004 (21 years)

Introduction: {“Part Number”:”FSRSPDT-16A-ON-OFF-ON-PN”,”Manufacturer”:”DEFOND”,”Item ID”:”2027005321″,”Current Rating 1″:”16.00 A”,”Voltage Rating 1″:”125 VAC”,”Current Rating 2″:”8.00 A”,”Voltage Rating 2″:”250 VAC”,”Power Rating”:”-“,”Mounting Type”:”Quick Connect”,”Switch Function”:”SPDT”,”Switch Circuit”:”ON – OFF – ON”,”Number of Positions”:”3″,”Package”:”Bulk”,”Item per Pack”:”1″,”Dimensions”:{“Width”:”0…

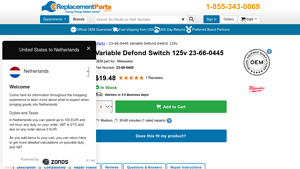

5. Milwaukee – Variable Defond Switch 125v

Domain: ereplacementparts.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “Variable Defond Switch 125v”, “Part Number”: “23-66-0445”, “OEM Brand”: “Milwaukee”, “Classification”: “Part”, “Weight”: “0.04 lbs.”, “Price”: “$19.48”, “Availability”: “In Stock”, “Shipping”: “Ships Worldwide”, “Delivery Time”: “Delivers in 3-5 Business Days”, “Compatibility”: “Fits Milwaukee 0240-20 (C32A) 3/8″ (10Mm) Electric Drill”, “Repair Difficulty”: “Medium”, “Estimated R…

6. Canva – Video Background Remover

Domain: canva.com

Registered: 2001 (24 years)

Introduction: Video Background Remover on Canva Pro allows users to instantly erase video backgrounds and set a new scene. It requires no design experience or green screen, as it uses AI to automatically analyze and remove backgrounds with one click. Users can upload their videos, edit them using various tools, and download the final product as a high-quality MP4 file. The tool is part of Canva’s suite of video…

Strategic Sourcing Conclusion and Outlook for defond switch

Defond switches represent a vital component in numerous industries, from automotive to consumer electronics. Their diverse product range—including high-load rocker switches and intelligent control modules—caters to the specific needs of various applications, ensuring reliability and performance. For international B2B buyers, especially in emerging markets such as Nigeria and Brazil, strategic sourcing of these components can significantly enhance product quality and operational efficiency.

Understanding the intricacies of Defond’s supply chain management and their commitment to sustainability can provide a competitive edge. By leveraging Defond’s expertise and innovative solutions, businesses can streamline their procurement processes, reduce lead times, and ultimately drive profitability.

Looking ahead, the demand for reliable and efficient switching solutions is set to rise, particularly as industries continue to embrace automation and smart technologies. This presents an excellent opportunity for B2B buyers to engage with Defond as a trusted partner. By prioritizing strategic sourcing now, you can position your business for success in a rapidly evolving market landscape. Don’t hesitate to reach out to Defond today to explore how their products can elevate your offerings and meet the growing demands of your customers.