2 Inch/1.5Inch Reducer Cpvc L: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for 2 inch/1.5inch reducer cpvc l

In today’s global marketplace, sourcing the right 2 inch/1.5 inch reducer CPVC fittings can be a daunting challenge for B2B buyers. With a diverse range of suppliers and product specifications, navigating this landscape requires careful consideration. This comprehensive guide addresses key aspects of the CPVC reducer market, including the various types available, their applications, and the essential criteria for supplier vetting. Additionally, we will explore cost implications, ensuring that you are equipped with the knowledge to make informed purchasing decisions.

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe—such as Nigeria and Germany—understanding the nuances of CPVC fittings is crucial. The guide empowers you to identify reliable suppliers, compare product features, and evaluate pricing structures in a way that minimizes risk and maximizes value.

By delving into industry standards, material specifications, and market trends, this resource aims to enhance your procurement strategy, ensuring that you select the most suitable reducer fittings for your specific needs. Whether you are involved in construction, plumbing, or industrial applications, this guide serves as your go-to reference for making strategic purchasing decisions that align with your business objectives.

Understanding 2 inch/1.5inch reducer cpvc l Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Schedule 80 Reducer Bushing | Higher pressure rating, spigot x socket connection | Industrial plumbing, chemical processing | Pros: High durability, suitable for high pressure. Cons: Heavier and more expensive than Schedule 40. |

| Slip x Slip Reducing Elbow | 90-degree turn capability, slip connection | Residential and commercial plumbing | Pros: Easy installation, versatile for direction changes. Cons: Limited pressure rating compared to Schedule 80. |

| Reducer Coupling | Joins two pipes of different diameters, slip x slip | Water distribution systems | Pros: Simple connection, ideal for transitions. Cons: May require additional fittings for secure joints. |

| Schedule 40 Reducer Bushing | Lower pressure rating, lightweight | Irrigation systems, HVAC applications | Pros: Cost-effective, lighter weight. Cons: Not suitable for high-pressure applications. |

| CPVC Reducing Tee | Three-way connection, accommodates multiple lines | Plumbing and drainage systems | Pros: Efficient for branching, easy installation. Cons: More complex connections can increase risk of leaks. |

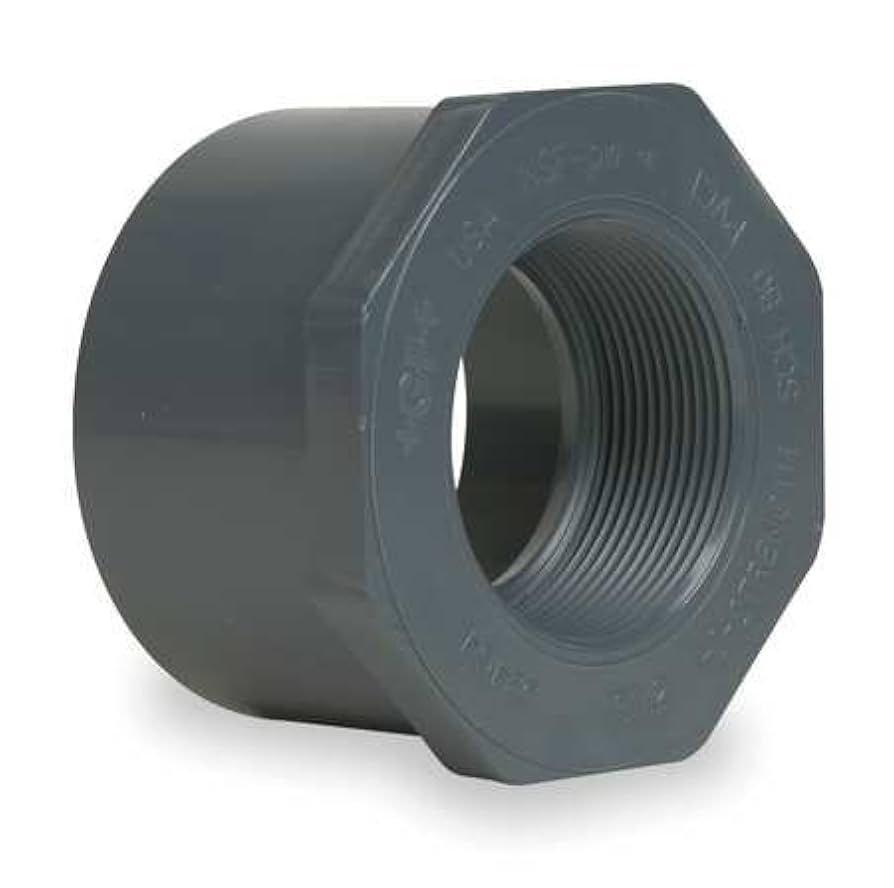

What Are the Key Characteristics of Schedule 80 Reducer Bushings?

Schedule 80 reducer bushings are designed to handle higher pressures and temperatures, making them suitable for industrial applications. They typically feature a spigot x socket connection, allowing for secure fittings in high-stress environments such as chemical processing. When purchasing, buyers should consider the specific pressure ratings and compatibility with existing systems, as these bushings can be heavier and pricier than their Schedule 40 counterparts.

How Do Slip x Slip Reducing Elbows Function in Plumbing?

Slip x slip reducing elbows are ideal for making 90-degree turns in plumbing systems. They are characterized by their slip connections, which allow for easy installation without the need for additional fittings. This type of fitting is commonly used in residential and commercial plumbing applications. Buyers should evaluate the pressure ratings and ensure compatibility with existing pipe sizes to avoid installation issues.

What Are the Advantages of Using Reducer Couplings?

Reducer couplings are essential for connecting pipes of varying diameters. They are typically slip x slip fittings that provide a straightforward way to transition between different pipe sizes. Commonly used in water distribution systems, these couplings are valued for their simplicity and ease of use. Buyers should consider the specific dimensions and materials to ensure compatibility with their piping systems.

Why Choose Schedule 40 Reducer Bushings for Your Projects?

Schedule 40 reducer bushings are lighter and more cost-effective than Schedule 80 options, making them suitable for applications where pressure ratings are less critical. They are commonly used in irrigation and HVAC systems. However, buyers should be aware that these bushings are not designed for high-pressure environments, so it’s crucial to assess the specific requirements of the project before purchasing.

How Do CPVC Reducing Tees Enhance Plumbing Systems?

CPVC reducing tees allow for efficient branching of pipes, accommodating multiple lines within a single fitting. This design is particularly useful in plumbing and drainage systems where space is limited. While they are easy to install, buyers should be cautious as the complexity of connections can lead to potential leak points. Evaluating the installation environment and ensuring proper fitting techniques are essential for optimal performance.

Key Industrial Applications of 2 inch/1.5inch reducer cpvc l

| Industry/Sector | Specific Application of 2 inch/1.5inch reducer cpvc l | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Used in piping systems for transporting treated water. | Ensures efficient flow and minimizes leakage. | Compliance with local water quality standards and certifications. |

| Chemical Processing | Serves as connectors in chemical transfer systems. | Resistant to corrosion, enhancing system longevity. | Material compatibility with specific chemicals being transported. |

| Construction | Integrates into plumbing systems for residential/commercial buildings. | Facilitates reliable water distribution and pressure management. | Consideration of local building codes and installation standards. |

| Irrigation | Connects various pipe sizes in agricultural irrigation systems. | Optimizes water usage and distribution efficiency. | Durability against environmental factors and pressure requirements. |

| HVAC Systems | Utilized in cooling and heating systems for fluid transfer. | Enhances energy efficiency and system performance. | Must meet temperature and pressure ratings for specific applications. |

How is the 2 inch/1.5inch reducer cpvc l utilized in water treatment?

In the water treatment industry, the 2 inch/1.5inch reducer cpvc l is essential for creating a reliable piping system that transports treated water. This fitting helps in transitioning between different pipe sizes, ensuring smooth flow and reducing the risk of leaks. For international buyers, especially in regions like Africa and the Middle East, sourcing CPVC that meets local water quality standards is crucial, as it directly impacts public health and safety.

What role does the 2 inch/1.5inch reducer cpvc l play in chemical processing?

In chemical processing, the 2 inch/1.5inch reducer cpvc l is used to connect pipes of varying diameters, facilitating the transfer of corrosive chemicals. Its resistance to corrosion and chemicals is a significant advantage, prolonging the lifespan of the piping system. Buyers in South America and Europe should ensure that the materials used are compatible with specific chemicals, adhering to industry regulations to avoid costly failures.

How does the 2 inch/1.5inch reducer cpvc l support construction projects?

In construction, particularly for plumbing systems in residential and commercial buildings, the 2 inch/1.5inch reducer cpvc l is critical for managing water distribution. This fitting allows for effective pressure management and reduces the risk of leaks, which is vital for maintaining building integrity. For international buyers, understanding local building codes and installation standards is essential to ensure compliance and avoid project delays.

Why is the 2 inch/1.5inch reducer cpvc l important for irrigation systems?

In agricultural irrigation, the 2 inch/1.5inch reducer cpvc l is utilized to connect various pipe sizes, optimizing water distribution across large areas. This fitting enhances the efficiency of water usage, which is particularly important in regions facing water scarcity. Buyers need to consider the durability of the material against environmental factors and the pressure requirements of the irrigation system to ensure long-term performance.

How does the 2 inch/1.5inch reducer cpvc l enhance HVAC systems?

In HVAC systems, the 2 inch/1.5inch reducer cpvc l is used for fluid transfer in cooling and heating applications. Its ability to withstand high temperatures and pressures while maintaining flow efficiency makes it a valuable component in these systems. For buyers in Europe and other regions, ensuring that the fittings meet specific temperature and pressure ratings is critical for optimal system performance and energy efficiency.

3 Common User Pain Points for ‘2 inch/1.5inch reducer cpvc l’ & Their Solutions

Scenario 1: Sourcing Quality Reducers in Diverse Markets

The Problem: B2B buyers often struggle to find reliable suppliers for 2 inch/1.5 inch reducer CPVC fittings, particularly in diverse markets across Africa, South America, and the Middle East. The challenge is compounded by varying quality standards and compliance regulations that differ by region. Buyers frequently encounter subpar products that do not meet necessary certifications, leading to operational delays, increased costs, and potential safety hazards in their plumbing projects.

The Solution: To overcome this sourcing challenge, buyers should prioritize suppliers who can provide certified products that comply with international standards such as ASTM and NSF approvals. Establishing partnerships with reputable manufacturers and distributors who specialize in CPVC fittings can ensure access to high-quality reducers. Furthermore, leveraging online platforms to conduct thorough supplier evaluations, including checking reviews and requesting product samples, can mitigate risks. Consider bulk purchasing to negotiate better terms and pricing while ensuring a steady supply of compliant products for ongoing projects.

Scenario 2: Installation Difficulties and Compatibility Issues

The Problem: Another common pain point for B2B buyers is the difficulty encountered during the installation of 2 inch/1.5 inch reducer CPVC fittings. Compatibility issues arise when attempting to connect these reducers to existing systems, especially when transitioning between different types of piping materials or sizes. This can lead to leaks, system inefficiencies, and increased labor costs due to rework.

The Solution: To ensure smooth installation, buyers should conduct a comprehensive assessment of their existing plumbing systems before procuring reducers. Using pipe compatibility charts can help identify the right fittings for specific applications. Additionally, investing in training for installation teams or utilizing detailed installation guides can significantly reduce the likelihood of errors. For complex systems, engaging a plumbing consultant to evaluate the overall design and ensure correct fitting usage can save time and costs in the long run.

Scenario 3: Understanding Technical Specifications and Performance Limits

The Problem: B2B buyers often face confusion regarding the technical specifications and performance limits of 2 inch/1.5 inch reducer CPVC fittings. Many are uncertain about maximum pressure ratings, temperature tolerances, and chemical compatibility, which can lead to inappropriate application and ultimately system failures.

The Solution: To navigate this complexity, it is essential for buyers to familiarize themselves with the technical datasheets provided by manufacturers. This includes understanding the significance of different schedules (e.g., Schedule 40 vs. Schedule 80) and their implications for pressure and temperature ratings. Buyers should also consult with engineers or technical experts when selecting fittings for specific applications, especially in environments with extreme conditions or chemical exposure. Regular training sessions or workshops on the latest industry standards and material properties can empower procurement teams to make informed decisions, thereby enhancing the overall reliability of plumbing systems.

By addressing these common pain points with actionable strategies, B2B buyers can optimize their procurement processes, enhance installation efficiency, and ensure long-term performance of their plumbing systems.

Strategic Material Selection Guide for 2 inch/1.5inch reducer cpvc l

What Are the Key Materials for 2 Inch/1.5 Inch Reducer CPVC L?

When selecting materials for a 2 inch/1.5 inch reducer CPVC L, it’s crucial to consider the properties, advantages, and limitations of various materials. This analysis focuses on four common materials: CPVC, PVC, Polypropylene, and Stainless Steel. Each material has distinct characteristics that can significantly influence performance, durability, and suitability for specific applications.

How Does CPVC Perform as a Material for Reducers?

Chlorinated Polyvinyl Chloride (CPVC) is widely used for plumbing and industrial applications due to its excellent temperature and pressure ratings. CPVC can withstand temperatures up to 200°F (93°C) and has a pressure rating that varies based on the schedule (e.g., Schedule 80). Its corrosion resistance makes it suitable for transporting potable water and various chemicals.

Pros: CPVC is lightweight, easy to install, and resistant to scaling and corrosion. It is also compliant with standards like ASTM D1784 and NSF, making it a reliable choice for international buyers.

Cons: While CPVC is durable, it can become brittle over time, especially when exposed to UV light. Its cost can be higher compared to standard PVC, which may be a consideration for budget-conscious buyers.

Impact on Application: CPVC is ideal for applications involving hot water and corrosive chemicals, making it suitable for various industries, including construction and manufacturing.

What About PVC as a Material Choice?

Polyvinyl Chloride (PVC) is another common material for reducers, particularly in low-pressure applications. PVC fittings are generally rated for temperatures up to 140°F (60°C) and are widely used in irrigation, drainage, and waste systems.

Pros: PVC is cost-effective, lightweight, and easy to work with. It is also resistant to corrosion and chemical leaching, making it suitable for many applications.

Cons: PVC has lower temperature resistance compared to CPVC and may not be suitable for hot water applications. It can also become brittle in colder temperatures.

Impact on Application: PVC is often used in non-potable water systems and is not recommended for transporting hot water or aggressive chemicals.

How Does Polypropylene Compare?

Polypropylene is a thermoplastic polymer known for its high chemical resistance and durability. It can handle temperatures up to 180°F (82°C) and is often used in industrial applications.

Pros: Polypropylene is resistant to a wide range of chemicals, making it suitable for transporting aggressive media. It is also lightweight and has a good strength-to-weight ratio.

Cons: It can be more expensive than PVC and may not be as readily available in all regions. Its lower temperature resistance compared to CPVC can limit its applications.

Impact on Application: Polypropylene is ideal for chemical processing industries and applications requiring high levels of chemical resistance.

Is Stainless Steel a Viable Option?

Stainless steel is often used in high-pressure applications and environments where corrosion is a significant concern. It can withstand high temperatures and is suitable for a variety of fluids.

Pros: Stainless steel offers exceptional durability and resistance to corrosion and high temperatures. It is also recyclable, making it an environmentally friendly option.

Cons: The initial cost of stainless steel fittings is significantly higher than plastic options. Additionally, installation can be more complex due to the need for specialized tools and skills.

Impact on Application: Stainless steel is ideal for applications in the oil and gas industry, food processing, and other sectors requiring high durability and corrosion resistance.

Summary Table of Material Selection for 2 Inch/1.5 Inch Reducer CPVC L

| Material | Typical Use Case for 2 inch/1.5inch reducer cpvc l | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| CPVC | Potable water, hot water systems | High temperature and pressure ratings | Brittle over time, higher cost | Medium |

| PVC | Irrigation, drainage, waste systems | Cost-effective, lightweight | Lower temperature resistance | Low |

| Polypropylene | Chemical processing, industrial applications | High chemical resistance | Higher cost, limited availability | Medium |

| Stainless Steel | Oil and gas, food processing | Exceptional durability and corrosion resistance | High initial cost, complex installation | High |

This guide provides essential insights into material selection for 2 inch/1.5 inch reducer CPVC L, enabling international buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 2 inch/1.5inch reducer cpvc l

What Are the Main Manufacturing Stages for 2 Inch/1.5 Inch Reducer CPVC?

The manufacturing of 2 inch/1.5 inch reducer fittings made from CPVC (Chlorinated Polyvinyl Chloride) involves several critical stages, each designed to ensure the final product meets stringent quality standards and performance criteria. Understanding these stages is vital for B2B buyers who are sourcing these fittings for various applications, including plumbing, chemical handling, and water distribution.

How Is Material Prepared for CPVC Fittings?

The first step in the manufacturing process is material preparation. CPVC resin is sourced from reputable suppliers, ensuring it meets international quality standards. The resin undergoes a drying process to eliminate moisture, which is crucial for achieving optimal flow properties during molding. Additionally, additives such as stabilizers and lubricants may be blended into the resin to enhance performance characteristics like heat resistance and ease of processing.

What Techniques Are Used in Forming CPVC Reducers?

Forming the fittings typically utilizes either injection molding or extrusion methods. In injection molding, heated CPVC resin is injected into a mold where it cools and solidifies into the desired shape. This method is ideal for producing complex geometries with high precision. On the other hand, extrusion is often employed for creating longer components or profiles, where the material is continuously pushed through a die to form a consistent shape.

How Is Assembly and Finishing Done for CPVC Reducers?

Once formed, the components may require assembly, particularly if they include multiple parts or connections. For instance, a reducer may consist of a spigot and a socket connection. After assembly, finishing processes such as trimming, polishing, and surface treatment are performed to ensure that the fittings are free from defects and ready for installation.

What Quality Assurance Standards Are Relevant for CPVC Reducers?

Quality assurance (QA) is paramount in the manufacturing of CPVC fittings to ensure they meet safety and performance specifications. For international B2B buyers, understanding relevant standards is critical.

Which International Standards Should B2B Buyers Be Aware Of?

Common international standards include ISO 9001, which focuses on quality management systems, and ASTM standards specific to CPVC materials and fittings, such as ASTM D1784 and ASTM F439. Additionally, certifications like CE mark for Europe and NSF for potable water applications are crucial indicators of compliance with safety and quality benchmarks.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Implementing robust quality control (QC) measures throughout the manufacturing process is essential. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage verifies the quality of raw materials and components before they enter production. Suppliers must provide certificates of compliance and material safety data sheets (MSDS) for the CPVC resin used.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor parameters such as temperature, pressure, and cycle time. This ensures that the fittings are being produced within specified tolerances.

-

Final Quality Control (FQC): After production, the finished products undergo rigorous testing for dimensional accuracy, pressure resistance, and visual inspections for surface defects.

What Common Testing Methods Are Employed for CPVC Reducers?

To ensure reliability, several testing methods are commonly used:

-

Hydrostatic Pressure Testing: This involves subjecting the fittings to high pressure to evaluate their integrity and leak resistance.

-

Thermal Stability Testing: Assessing how well the CPVC fittings can withstand high temperatures, which is essential for applications involving hot water.

-

Chemical Resistance Testing: Evaluating the fittings’ resistance to various chemicals, ensuring they can perform in diverse environments without degrading.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

-

Conduct Supplier Audits: Regularly visiting manufacturing facilities can provide insights into production practices, workforce training, and adherence to quality standards.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results, certifications, and compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing independent quality inspection services can provide an unbiased evaluation of the manufacturing process and final product quality. This is particularly important for buyers in regions like Africa and South America, where local regulations may differ from international standards.

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of specific nuances related to quality control and certification. For instance, regulations in Europe may require CE marking for certain applications, while buyers in the Middle East may need to comply with local standards that differ significantly from those in Europe or North America. Understanding these requirements ensures that the sourced products are compliant and reduces the risk of costly delays or rejections.

By comprehensively understanding the manufacturing processes and quality assurance protocols for 2 inch/1.5 inch reducer CPVC fittings, B2B buyers can make informed decisions, ensuring they procure reliable and high-quality products suited for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2 inch/1.5inch reducer cpvc l’

Introduction

This sourcing guide provides a structured approach for B2B buyers looking to procure 2 inch/1.5 inch CPVC reducers. With the increasing demand for reliable and durable plumbing components in various industries, it’s essential to follow a clear checklist that ensures you select the right products and suppliers. This guide will help you navigate the procurement process effectively, ensuring that you meet your project specifications and budget requirements.

1. Define Your Technical Specifications

Before initiating the sourcing process, clarify the technical specifications of the reducer you need. This includes the size, material (CPVC), pressure rating (e.g., Schedule 80), and temperature tolerance (up to 200°F). Clearly defined specifications help you avoid costly mistakes and ensure compatibility with existing systems.

- Consider application requirements: Determine if the reducer will be used for potable water systems or other applications to ensure compliance with relevant standards.

2. Research Market Trends

Understanding current market trends for CPVC fittings is crucial for making informed purchasing decisions. Investigate pricing fluctuations, availability, and new product innovations in the market.

- Utilize industry reports: Leverage market research reports and trade publications to gain insights into the latest developments and competitor offerings.

3. Identify Reliable Suppliers

Compile a list of potential suppliers who specialize in CPVC products. Research their reputation and reliability by checking online reviews and industry ratings.

- Focus on experience: Prioritize suppliers with a proven track record in your industry, as they are more likely to understand your specific needs and provide quality products.

4. Verify Supplier Certifications

Ensure that your shortlisted suppliers possess the necessary certifications and compliance with international standards, such as ASTM and NSF. This guarantees that the products meet safety and quality benchmarks.

- Request documentation: Ask for copies of certifications and compliance reports to verify their legitimacy and adherence to industry standards.

5. Evaluate Product Quality

Request samples or detailed product specifications from potential suppliers. Assess the quality of the 2 inch/1.5 inch CPVC reducers based on their material properties and manufacturing processes.

- Inspect for durability: Check for features such as corrosion resistance and heat tolerance to ensure long-term performance in your specific application.

6. Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements can prevent misunderstandings and ensure a smooth procurement process.

- Discuss warranty and support: Ensure that warranty terms are favorable and that the supplier offers technical support for installation and maintenance.

7. Plan for Logistics and Distribution

Consider the logistics involved in the delivery of the CPVC reducers. Evaluate shipping options, lead times, and costs to ensure timely receipt of products.

- Factor in international considerations: If sourcing from overseas suppliers, be aware of customs regulations and import duties that may affect your overall budget.

By following this comprehensive checklist, B2B buyers can streamline the procurement process for 2 inch/1.5 inch CPVC reducers, ensuring that they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for 2 inch/1.5inch reducer cpvc l Sourcing

What Are the Key Cost Components for 2 Inch/1.5 Inch Reducer CPVC Sourcing?

When evaluating the cost structure for sourcing 2 inch/1.5 inch reducer CPVC fittings, several components must be considered. These include:

-

Materials: CPVC (Chlorinated Polyvinyl Chloride) is a key material for these fittings. The quality and grade of CPVC can significantly affect pricing. Higher-grade CPVC that meets ASTM D1784 and ASTM F439 standards generally incurs higher costs but ensures better performance, especially in high-temperature applications.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembling, and packaging the fittings. Labor rates can vary widely based on geographical location, skill levels, and local labor laws. In regions with lower labor costs, such as parts of Africa and South America, manufacturers may offer more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can lower overhead costs, thus impacting the final price.

-

Tooling: Custom tooling for specific fitting designs can add to initial costs. However, once established, these costs can be amortized over larger production runs, making them less significant per unit.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but can also increase costs. Buyers should weigh the benefits of investing in higher QC standards against the potential for reduced returns or warranty claims.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. These costs can fluctuate based on shipping methods, distance, and the volume of the order. Understanding Incoterms is essential for determining who bears these costs during transit.

-

Margin: Suppliers will typically apply a markup to cover their costs and achieve profit margins. The margin can vary based on market conditions and competition.

How Do Price Influencers Impact the Cost of 2 Inch/1.5 Inch Reducers?

Several factors influence the pricing of 2 inch/1.5 inch reducer fittings:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Custom fittings tailored to specific applications can incur higher costs due to additional design and manufacturing requirements. Standardized products typically offer more competitive pricing.

-

Material Quality and Certifications: Certifications such as NSF approval can enhance product credibility but may also increase costs. Buyers should consider the trade-off between price and the assurance of quality.

-

Supplier Factors: Established suppliers with a strong track record may charge premium prices due to their reputation. However, they may also offer better support and reliability.

-

Incoterms: The chosen Incoterms affect the overall cost structure. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for budgeting.

What Are Some Effective Buyer Tips for Negotiating Prices?

International B2B buyers should consider several strategies to enhance cost-efficiency:

-

Leverage Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Highlighting long-term partnership potential can also create leverage for better terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the costs associated with installation, maintenance, and potential downtime. A lower upfront cost may lead to higher TCO if the product is of inferior quality.

-

Be Aware of Pricing Nuances: Understand regional pricing variations. For instance, suppliers in Europe may have different pricing structures than those in Africa or South America due to local market dynamics and regulations.

-

Request Samples: Before committing to larger orders, request samples to evaluate quality. This can prevent costly mistakes and ensure that the fittings meet your specifications.

Disclaimer on Indicative Prices

It is important to note that the prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always confirm current pricing directly with suppliers to ensure accuracy and transparency in your sourcing efforts.

Alternatives Analysis: Comparing 2 inch/1.5inch reducer cpvc l With Other Solutions

Understanding the Alternatives to 2 Inch/1.5 Inch Reducer CPVC L

When considering plumbing solutions, particularly in international markets, it’s essential to evaluate various options. The 2 inch/1.5 inch reducer CPVC L fitting is popular for its efficiency in connecting different pipe sizes. However, other alternatives exist that might better suit specific needs based on performance, cost, and application.

Comparison Table

| Comparison Aspect | 2 Inch/1.5 Inch Reducer CPVC L | Alternative 1: 2 Inch x 1.5 Inch Reducing Elbow | Alternative 2: 2 Inch x 1.5 Inch Reducer Coupling |

|---|---|---|---|

| Performance | Excellent for high-temperature applications (up to 200°F) | Good for standard applications; less pressure capacity | Suitable for connecting two pipes of different sizes |

| Cost | Moderate ($11.99) | Lower ($9.99) | Lower ($5.99) |

| Ease of Implementation | Requires specific jointing techniques | Simple slip connection; quick installation | Easy to install; minimal tools required |

| Maintenance | Low maintenance; durable | Low maintenance; standard PVC durability | Low maintenance; similar durability as CPVC |

| Best Use Case | Potable water systems, high-temperature applications | General plumbing, irrigation systems | Residential plumbing, non-potable applications |

Detailed Breakdown of Alternatives

Alternative 1: 2 Inch x 1.5 Inch Reducing Elbow

The reducing elbow fitting serves as a versatile option for changing the direction of flow in pipelines. This fitting is made from standard PVC, which is cost-effective and readily available. However, its performance may not match that of CPVC in high-temperature scenarios. While installation is quick due to its slip connection design, buyers should consider the potential limitations in pressure capacity when selecting this fitting for specific applications.

Alternative 2: 2 Inch x 1.5 Inch Reducer Coupling

The reducer coupling provides a straightforward method for connecting two pipes of different diameters. With a lower price point, it offers an economical solution for residential and non-potable plumbing applications. The installation process is simple, requiring minimal tools, which can be a significant advantage for contractors working on tight schedules. However, it may not withstand the same high temperatures as CPVC fittings, making it less suitable for applications involving hot water.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate fitting for your plumbing projects involves understanding the specific requirements of your application. While the 2 inch/1.5 inch reducer CPVC L is ideal for high-temperature and potable water systems, alternatives like the reducing elbow and coupling may offer cost savings and easier installation for less demanding scenarios. B2B buyers should consider factors such as performance, cost, and the nature of the application to make informed decisions that align with their operational needs and budget constraints. By weighing these aspects, businesses can ensure they choose the best solution for their plumbing systems.

Essential Technical Properties and Trade Terminology for 2 inch/1.5inch reducer cpvc l

What Are the Key Technical Properties of 2 Inch/1.5 Inch Reducer CPVC L?

Understanding the technical specifications of the 2 inch/1.5 inch reducer CPVC L is essential for B2B buyers aiming for durability and performance in their plumbing systems. Here are critical specifications to consider:

1. Material Grade: What Is CPVC and Its Significance?

Chlorinated Polyvinyl Chloride (CPVC) is a thermoplastic material known for its superior chemical resistance and temperature tolerance. CPVC is suitable for hot and cold water applications, making it ideal for both residential and commercial plumbing systems. Understanding the material grade is crucial, as it influences the product’s longevity and performance under varying environmental conditions.

2. Schedule Rating: How Does Schedule 80 Differ from Schedule 40?

The schedule rating indicates the wall thickness of the pipe and fitting. Schedule 80 CPVC fittings, for example, have thicker walls compared to Schedule 40, allowing them to withstand higher pressures and temperatures. For B2B buyers, selecting the appropriate schedule is vital to ensure the fitting can handle the specific demands of their applications, particularly in industrial settings.

3. Connection Type: Why Are Spigot x Socket Connections Important?

The connection type specifies how the reducer connects to other pipes or fittings. A spigot x socket connection means one end of the fitting is designed to fit into another fitting (socket), while the other end fits over a pipe (spigot). This type of connection is significant for ensuring leak-free joints, reducing the risk of system failures and costly repairs.

4. Maximum Temperature: What Temperature Ratings Should You Consider?

The maximum temperature rating indicates the highest temperature the fitting can safely handle. For CPVC fittings, this is typically around 200°F (93°C). Understanding this specification is crucial for buyers in regions where high temperatures are common, as exceeding this limit can lead to deformation or failure of the fitting.

5. Certifications and Standards: Why Do They Matter?

Most CPVC fittings are certified to standards such as ASTM D1784 and NSF, which ensure they meet safety and performance criteria. For international buyers, verifying these certifications is essential to ensure compliance with local regulations and to guarantee product quality.

What Common Trade Terms Should B2B Buyers Know When Sourcing Reducer CPVC L?

Familiarity with industry jargon can significantly enhance communication and negotiation in the B2B landscape. Here are key terms to understand:

1. OEM (Original Equipment Manufacturer): What Is Its Role in Sourcing?

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, sourcing from an OEM can assure quality and compatibility with existing systems, which is particularly important for large-scale projects.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs to align with their purchasing capabilities and project requirements.

3. RFQ (Request for Quotation): How to Use This Tool Effectively?

An RFQ is a document issued by a buyer to solicit price offers from suppliers. It typically includes details about the products needed, including specifications like size and material. This tool is crucial for obtaining competitive pricing and ensuring suppliers understand the buyer’s requirements.

4. Incoterms: What Are They and How Do They Affect Shipping?

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms can help B2B buyers understand shipping costs, risk management, and delivery responsibilities, ultimately aiding in smoother transactions.

5. Pallet Quantity: Why Does It Matter for Logistics?

Pallet quantity indicates how many units of a product can be shipped on a single pallet. Understanding pallet quantities helps buyers optimize shipping costs and manage storage efficiently, especially when dealing with large orders.

By grasping these essential properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring their projects are both cost-effective and reliable.

Navigating Market Dynamics and Sourcing Trends in the 2 inch/1.5inch reducer cpvc l Sector

What Are the Current Market Dynamics for 2 Inch/1.5 Inch Reducer CPVC L?

The global market for 2 inch/1.5 inch reducer CPVC fittings is experiencing significant transformation, driven by various factors including infrastructure development, regulatory changes, and technological advancements. The growing need for efficient and durable plumbing solutions, particularly in emerging markets such as Africa and South America, is a notable driver. For instance, nations like Nigeria are investing heavily in water supply and sanitation projects, increasing the demand for reliable CPVC fittings.

A key trend influencing sourcing strategies is the shift towards digital platforms for procurement. B2B buyers are increasingly leveraging e-commerce solutions and online marketplaces to streamline their sourcing processes, enhancing efficiency and reducing lead times. Additionally, the integration of advanced technologies like artificial intelligence and big data analytics is enabling companies to make informed purchasing decisions based on market trends and consumer behavior.

Moreover, sustainability is becoming a critical factor in purchasing decisions. Buyers are now prioritizing products that align with environmental regulations and certifications. The rise of eco-friendly construction practices and green building certifications is prompting manufacturers to innovate and offer sustainable options within the CPVC sector.

How Does Sustainability Influence Sourcing Trends in the CPVC Sector?

Sustainability and ethical sourcing are paramount in the current B2B landscape, particularly in the plumbing and fittings market. The environmental impact of manufacturing processes has led buyers to critically assess their supply chains. Companies are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as utilizing recycled materials and reducing carbon footprints in production.

The importance of ethical supply chains cannot be overstated. B2B buyers are inclined to partner with manufacturers that adhere to internationally recognized environmental standards. Certifications like NSF (National Sanitation Foundation) and ASTM (American Society for Testing and Materials) are becoming essential criteria for procurement decisions, assuring buyers that products meet stringent quality and safety requirements.

Furthermore, the shift towards green materials is evident, with CPVC fittings now being produced with enhanced sustainability features. Manufacturers are exploring alternative materials that minimize environmental impact while maintaining performance standards. This trend is particularly relevant for regions focused on sustainable development and climate resilience, such as those in Europe.

What Is the Historical Context of CPVC Reducers in the Market?

The evolution of CPVC fittings, particularly reducers, reflects broader advancements in plumbing technology and materials science. Initially introduced in the 1960s, CPVC was recognized for its superior resistance to heat and corrosion compared to traditional materials like metal and PVC. Over the decades, the adoption of CPVC has expanded significantly, driven by its versatility and durability in various applications, including potable water systems.

The introduction of regulations surrounding water quality and safety has further propelled the use of CPVC fittings. As global standards became more stringent, manufacturers innovated to ensure compliance, leading to the development of high-performance CPVC reducers that cater to specific market needs.

Today, the 2 inch/1.5 inch reducer CPVC fittings are integral to modern plumbing systems, meeting the demands of both residential and commercial sectors. This historical context underscores the importance of innovation and regulatory compliance in shaping the current landscape for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of 2 inch/1.5inch reducer cpvc l

-

How do I ensure the quality of 2 inch/1.5 inch reducer CPVC fittings?

To ensure quality, source your fittings from reputable suppliers who comply with industry standards such as ASTM D1784 and NSF certification. Request product samples and test their durability, heat resistance, and pressure ratings. Additionally, ask for documentation regarding the manufacturing process and quality assurance measures. Establish a clear quality control protocol that includes regular inspections and audits of your suppliers’ facilities to maintain consistent quality in your orders. -

What are the advantages of using CPVC for plumbing applications?

CPVC offers several advantages for plumbing applications, including excellent resistance to corrosion, chemicals, and high temperatures (up to 200°F or 93°C). Its lightweight nature makes installation easier, and it has a lower thermal conductivity compared to metal pipes, which helps reduce energy costs. CPVC is also flame-retardant and does not leach harmful substances, making it suitable for potable water applications, especially in diverse climates found across Africa and South America. -

What is the typical lead time for ordering 2 inch/1.5 inch reducer CPVC fittings?

Lead times can vary significantly based on the supplier’s location, inventory levels, and your order quantity. Generally, expect a lead time of 2 to 6 weeks for standard orders. For bulk orders, lead times may extend due to production schedules. Always communicate your project timelines with suppliers and inquire about expedited shipping options to meet urgent requirements. -

What minimum order quantities (MOQs) should I expect when sourcing these fittings?

MOQs for 2 inch/1.5 inch reducer CPVC fittings can vary by supplier and region. Typically, you may encounter MOQs ranging from 100 to 1,000 units. Some suppliers may offer flexibility for smaller orders, especially for new clients or trial purchases. Clarify MOQs upfront, and consider negotiating terms that align with your purchasing strategy and project needs. -

What payment terms are common for international B2B transactions?

Common payment terms in international B2B transactions include letters of credit, wire transfers, and payment upon delivery. Many suppliers may request a deposit (often 30-50%) upfront, with the balance due before shipment. It’s crucial to negotiate terms that provide mutual security and align with your cash flow needs. Always confirm the currency used for transactions and factor in any potential fees related to international payments. -

How can I vet suppliers for 2 inch/1.5 inch reducer CPVC fittings?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with international standards. Check for certifications and client testimonials, and consider requesting references from previous clients. Visit their manufacturing facilities if possible, or conduct virtual audits. Additionally, assess their customer service responsiveness and willingness to provide documentation related to quality assurance and product specifications. -

What are the logistics considerations when importing CPVC fittings?

Logistics considerations include shipping methods, customs clearance, and compliance with local regulations in your country. Choose a reliable freight forwarder familiar with handling CPVC products to ensure timely delivery. Factor in duties, taxes, and potential tariffs when calculating total costs. Staying informed about changes in trade agreements and import regulations can help mitigate delays and unexpected expenses. -

Can I customize the size or specifications of 2 inch/1.5 inch reducer CPVC fittings?

Many manufacturers offer customization options for size, shape, and specifications to meet specific project requirements. When inquiring about custom fittings, provide detailed specifications, including dimensions, pressure ratings, and any unique environmental conditions. Be aware that customization may affect lead times and costs, so discuss these factors with suppliers to ensure they align with your project timeline and budget.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 2 Inch/1.5Inch Reducer Cpvc L Manufacturers & Suppliers List

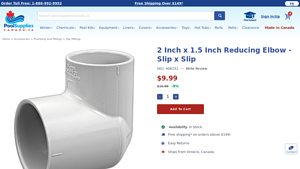

1. Pool Supplies Canada – 2 Inch x 1.5 Inch Reducing Elbow

Domain: poolsuppliescanada.ca

Registered: 2010 (15 years)

Introduction: {“Product Code”:”406251″,”Product Name”:”2 Inch x 1.5 Inch Reducing Elbow – Slip x Slip”,”Color”:”White”,”Connects to”:”PVC Pipe”,”Material”:”Schedule 40 PVC”,”Price”:”$9.99″,”Original Price”:”$10.99″,”Discount”:”9%”,”Availability”:”In Stock”,”Shipping”:”Free shipping on orders above $149″,”Warranty”:”30 Days Limited Manufacturers Warranty”}

2. Spears Manufacturing – 1/4 PVC TEE SOC SCH80

Domain: parts.spearsmfg.com

Registered: 1996 (29 years)

Introduction: {“Part Number”: “801-002”, “Size”: “1/4”, “Box Qty”: 50, “Weight (lbs)”: 0.04, “Weight (gm)”: 17.00, “Weight (kg)”: 0.02, “Material”: “PVC”, “MSRP”: “$20.48”, “Prod Code”: “080”, “Color”: “GRAY”, “Bsh/Fab/Mld”: “Molded”, “Description”: “1/4 PVC TEE SOC SCH80”, “Available Sizes”: [{“Size”: “1/4”, “Part No”: “801-002”, “MSRP”: “$20.48”, “Description”: “1/4 PVC TEE SOC SCH80”}, {“Size”: “3/8”, “Part …

3. Sioux Chief – PEX x PVC Adapter

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Sioux Chief PEX x PVC adapter, Megaloc pipe dope, Teflon tape (3 or 4 wraps recommended), Blue Monster pipe dope.

4. Spa Depot – Reducer Bushing 2SP x 1½SS

Domain: spadepot.com

Registered: 1997 (28 years)

Introduction: Reducer Bushing 2″SP x 1½”SS, Regular price: $3.95, In stock, ready to ship, Ships next business day, Chemically-resistant PVC, Adapts 2″ spa plumbing (including 2″ heater tailpieces and filter canister connections) to 1½” plumbing, California Proposition 65 warning: WARNING: Cancer and Reproductive Harm.

5. Reducer Bushing – PVC 2 x 1.5S

Domain: spapumpsandmore.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “Reducer Bushing PVC 2″ x 1.5″S – 421-4070”, “Description”: “Reduces 2″ PVC socket to 1-1/2″ socket. Outside diameter measures same as 2″ pipe (2.375″) and inside diameter the same as 1-1/2″ pipe (1.9″). Use in pump or heater union fittings to convert a 2″ union to 1-1/2″.”, “Price”: “$3.00”, “Availability”: “In Stock”, “Product Code”: “4214070”}

6. PVC Fittings Online – Schedule 80 CPVC Reducer Bushings

Domain: pvcfittingsonline.com

Registered: 2011 (14 years)

Introduction: Schedule 80 CPVC Reducer Bushings are designed to connect pipes of differing diameters in PVC pipe systems. They meet ASTM D1784 Standards and are NSF-14 Certified. There are 75 products available in various sizes including: 3/8 inch, 1/2 inch, 3/4 inch, 1 inch, 1 1/2 inch, 2 inch, 2 1/2 inch, 3 inch, 4 inch, 6 inch, 8 inch, 10 inch, and 12 inch. Prices range from $3.05 to $31.49.

Strategic Sourcing Conclusion and Outlook for 2 inch/1.5inch reducer cpvc l

In the competitive landscape of B2B sourcing for 2-inch/1.5-inch CPVC reducers, understanding the unique demands of various regions is paramount. As international buyers from Africa, South America, the Middle East, and Europe navigate sourcing decisions, prioritizing quality and compliance with industry standards (such as ASTM and NSF certifications) can significantly impact operational efficiency. The strategic sourcing of CPVC fittings not only enhances supply chain reliability but also ensures that projects meet both local and international regulations.

Furthermore, leveraging relationships with trusted manufacturers and suppliers can lead to cost savings and improved access to innovative products, thus fostering long-term partnerships. It’s essential for buyers to consider factors like material durability, temperature resistance, and overall product specifications, which directly influence project success.

Looking ahead, the demand for CPVC fittings, including reducers, is expected to grow as industries increasingly prioritize sustainability and efficiency. We encourage B2B buyers to act proactively—engage with suppliers, explore diverse product offerings, and invest in quality solutions that align with evolving market needs. By doing so, businesses can position themselves advantageously in an ever-changing global marketplace.