Peanut Oil 5 Gallon: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for peanut oil 5 gallon

In today’s competitive landscape, sourcing high-quality peanut oil in 5-gallon quantities presents a unique challenge for international B2B buyers. As the demand for versatile cooking oils continues to rise across various culinary markets—particularly in regions such as Africa, South America, the Middle East, and Europe—understanding the nuances of this product becomes essential. This comprehensive guide aims to equip buyers with the knowledge necessary to navigate the global peanut oil market effectively.

We will delve into the different types of peanut oil available, their various applications in cooking and food preparation, and the critical factors to consider when vetting suppliers. Additionally, we will explore cost considerations and pricing strategies that can help optimize purchasing decisions. By providing actionable insights and detailed information, this guide empowers B2B buyers to make informed choices, ensuring they select the right products that meet both quality standards and budget constraints.

As you read through this guide, you will gain a deeper understanding of the peanut oil landscape, enabling you to confidently source the best options for your business needs. Whether you are in Nigeria looking to enhance local cuisine or in Brazil seeking reliable supply chains, this resource is tailored to help you succeed in your procurement endeavors.

Understanding peanut oil 5 gallon Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Refined Peanut Oil | High smoke point (450°F), neutral flavor | Commercial kitchens, food processing | Pros: Versatile, long shelf life. Cons: Less flavor than unrefined. |

| Unrefined Peanut Oil | Stronger nutty flavor, lower smoke point | Specialty restaurants, gourmet cooking | Pros: Rich flavor profile. Cons: Shorter shelf life, higher cost. |

| Peanut Oil Blend | Mix of peanut oil and other oils, cost-effective | Fast food chains, large-scale frying | Pros: Economical, consistent quality. Cons: May lack pure peanut oil flavor. |

| Organic Peanut Oil | Non-GMO, produced without synthetic additives | Health-conscious establishments, organic markets | Pros: Appeals to health-focused consumers. Cons: Higher price point. |

| Blended Frying Oil | Combines peanut oil with oils like canola for enhanced performance | High-volume frying operations | Pros: Improved stability and flavor. Cons: May dilute peanut oil benefits. |

What Are the Characteristics of Refined Peanut Oil for B2B Buyers?

Refined peanut oil is characterized by its high smoke point of 450°F, making it ideal for deep frying and high-heat cooking. This type is stripped of most impurities, resulting in a neutral flavor that does not overpower the food. B2B buyers often prefer this oil for its versatility in various culinary applications, particularly in commercial kitchens and food processing operations. When purchasing, consider the oil’s shelf life and storage requirements, as refined oils typically last longer than their unrefined counterparts.

How Does Unrefined Peanut Oil Differ in Flavor and Usage?

Unrefined peanut oil retains its natural nutty flavor and aroma, making it a favorite in gourmet and specialty cooking. However, it has a lower smoke point than refined oil, which may limit its applications in high-heat frying. This oil is suitable for restaurants aiming to provide a rich flavor in dishes, particularly in Asian cuisines. Buyers should weigh the benefits of enhanced flavor against the shorter shelf life and higher price, as unrefined oils can spoil more quickly.

What Advantages Does Peanut Oil Blend Offer for Bulk Buyers?

Peanut oil blends combine peanut oil with other oils, often to create a cost-effective solution for businesses that require large quantities of frying oil. These blends maintain a reasonable smoke point and consistent quality, making them ideal for fast food chains and high-volume frying operations. Buyers should consider the balance between cost and flavor, as blends may not deliver the same distinctive taste as pure peanut oil. However, the economic benefits often make this a popular choice for large-scale operations.

Why Should B2B Buyers Consider Organic Peanut Oil?

Organic peanut oil is produced without synthetic additives or genetically modified organisms (GMOs), appealing to health-conscious consumers and establishments. This oil is often sought after by organic markets and health-focused restaurants. While it generally comes at a higher price point, the demand for organic products can justify the investment for businesses aiming to attract a specific clientele. Buyers should evaluate the potential return on investment based on market trends and consumer preferences in their region.

What Are the Benefits of Blended Frying Oil for High-Volume Operations?

Blended frying oils typically combine peanut oil with canola or other oils to enhance performance and stability during frying. These blends are particularly useful for high-volume operations, as they can provide a consistent frying experience. Buyers should consider the trade-off between flavor and practicality; while blended oils may not deliver the full flavor of pure peanut oil, they often offer improved heat stability and cost-effectiveness. This makes them a viable option for businesses focused on efficiency and operational cost savings.

Key Industrial Applications of peanut oil 5 gallon

| Industry/Sector | Specific Application of peanut oil 5 gallon | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Deep frying for restaurants and catering services | High smoke point and flavor enhancement for fried foods | Quality assurance, certifications (e.g., Kosher, non-GMO), price stability |

| Snack Manufacturing | Production of snack foods like chips and nuts | Enhances taste and texture, suitable for high-heat cooking | Bulk purchasing options, supply chain reliability, shelf life |

| Food Processing | Ingredient in sauces and dressings | Adds flavor and improves product stability | Consistency in quality, sourcing from reputable suppliers, import regulations |

| Cosmetics and Personal Care | Base ingredient in skincare and haircare products | Natural emollient properties, enhances product appeal | Compliance with cosmetic regulations, sourcing organic options, ethical sourcing |

| Biofuels | Feedstock for biodiesel production | Renewable energy source, reduces carbon footprint | Availability of sustainable sourcing, production capacity, pricing volatility |

In the food service industry, peanut oil is a popular choice for deep frying due to its high smoke point of around 450°F. Restaurants and catering services benefit from its ability to produce crispy, flavorful fried foods, making it an essential item in their kitchens. International buyers, especially from regions like Africa and the Middle East, should prioritize sourcing quality oils that meet local food safety standards and are competitively priced to ensure profitability.

In snack manufacturing, peanut oil is integral for frying products such as chips and nuts. It not only enhances the flavor profile but also contributes to the desired crunch and texture. For B2B buyers in South America, considerations include bulk purchasing agreements and understanding the shelf life of the oil to minimize waste, alongside ensuring compliance with local food regulations.

The food processing sector utilizes peanut oil as a key ingredient in various sauces and dressings. Its nutty flavor complements many recipes and helps stabilize emulsions. Buyers from Europe and Africa should focus on quality consistency and the supplier’s ability to deliver on time, as fluctuations in oil quality can affect end products significantly.

In the cosmetics and personal care industry, peanut oil is valued for its emollient properties, making it an excellent choice for moisturizers and hair care products. B2B buyers should be aware of regulatory compliance regarding cosmetic ingredients, as well as the growing demand for organic and ethically sourced oils in the market.

Lastly, the biofuels sector is increasingly turning to peanut oil as a sustainable feedstock for biodiesel production. This application not only supports renewable energy initiatives but also helps businesses reduce their carbon footprint. Buyers should evaluate suppliers based on their sustainability practices and capacity to deliver consistent quality at competitive prices.

3 Common User Pain Points for ‘peanut oil 5 gallon’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Bulk Purchases

The Problem: When sourcing peanut oil in bulk, particularly in 5-gallon containers, B2B buyers often face significant challenges related to quality assurance. The risk of receiving subpar or contaminated oil can have dire consequences for businesses, especially in the food service industry where quality directly impacts customer satisfaction and safety. Additionally, inconsistencies in product specifications, such as smoke point and flavor profile, can lead to operational disruptions and affect the reputation of the business.

The Solution: To mitigate these risks, buyers should prioritize sourcing peanut oil from reputable suppliers with transparent quality control processes. Requesting certificates of analysis (COA) for each shipment can help ensure the oil meets specified standards for purity and performance. Furthermore, conducting sample testing before committing to larger orders can help identify any potential quality issues early on. Establishing a strong relationship with suppliers who are willing to provide detailed product information and support can further enhance quality assurance measures, ensuring consistent supply and performance.

Scenario 2: Managing Storage and Shelf Life Concerns

The Problem: Another common pain point for B2B buyers of peanut oil in 5-gallon containers is the effective management of storage conditions and shelf life. Peanut oil, like many cooking oils, has a limited shelf life, which can be further compromised by exposure to heat, light, and air. In regions with fluctuating temperatures or inadequate storage facilities, buyers may experience accelerated spoilage, leading to financial losses and waste.

The Solution: To address storage and shelf life concerns, businesses should invest in proper storage solutions that maintain optimal conditions for peanut oil. This includes using cool, dark storage areas and airtight containers to minimize exposure to light and air. Implementing a first-in, first-out (FIFO) inventory system can help ensure older stock is used before it expires. Additionally, buyers should educate staff on recognizing signs of oil spoilage, such as off odors or changes in color, to prevent the use of compromised oil. Regular inventory audits can help manage stock levels effectively and reduce waste.

Scenario 3: Cost Management and Price Volatility

The Problem: B2B buyers often struggle with price volatility in the peanut oil market, which can be influenced by factors such as crop yield, import tariffs, and global supply chain disruptions. Fluctuating prices can complicate budgeting and financial forecasting, making it difficult for businesses to maintain consistent profit margins. This unpredictability can lead to difficulties in pricing strategies and can affect overall operational stability.

The Solution: To manage cost effectively, buyers should consider entering into long-term contracts with suppliers to lock in prices and mitigate the impact of market volatility. Additionally, exploring multiple sourcing options across different regions can provide leverage in negotiations and reduce dependency on a single supplier. Regularly monitoring market trends and being proactive in adjusting procurement strategies can also help businesses stay ahead of price fluctuations. Finally, conducting a thorough cost-benefit analysis for different peanut oil suppliers can aid in identifying the best value without compromising on quality, ensuring both economic and operational stability.

Strategic Material Selection Guide for peanut oil 5 gallon

What are the Key Materials Used in Packaging Peanut Oil for B2B Buyers?

When selecting materials for packaging peanut oil, especially in 5-gallon containers, several options are commonly considered. Each material has its unique properties, advantages, and drawbacks that can significantly impact the product’s performance and suitability for various markets. Here, we analyze four prevalent materials: high-density polyethylene (HDPE), glass, aluminum, and composite materials.

How Does High-Density Polyethylene (HDPE) Perform for Peanut Oil Packaging?

High-density polyethylene (HDPE) is a popular choice for packaging peanut oil due to its excellent chemical resistance and durability. It can withstand temperatures up to 120°C (248°F) without deforming, making it suitable for hot-filling processes. HDPE containers are lightweight and cost-effective, which is beneficial for large-scale shipping.

Pros: HDPE is resistant to impact and moisture, ensuring the oil remains uncontaminated. It’s also recyclable, aligning with sustainability goals.

Cons: While HDPE is durable, it can be susceptible to UV light degradation, which may affect the oil’s quality if exposed for extended periods.

Impact on Application: HDPE containers are compatible with peanut oil, maintaining the oil’s integrity during storage and transport.

Considerations for International Buyers: Compliance with international standards such as ASTM D3350 for polyethylene is crucial. Buyers from regions like Africa and South America should ensure that suppliers can provide certification for food-grade materials.

What Role Does Glass Play in Peanut Oil Packaging?

Glass is another option for packaging peanut oil, known for its inert properties and ability to preserve flavor and aroma. Glass containers can handle high temperatures and provide an excellent barrier against oxygen and moisture.

Pros: Glass is non-reactive, ensuring that the peanut oil retains its quality over time. It is also fully recyclable and can be produced in various shapes and sizes.

Cons: The primary drawback of glass is its weight, which can increase shipping costs and make handling more cumbersome. Additionally, glass is more prone to breakage compared to other materials.

Impact on Application: Glass containers are ideal for premium products where quality preservation is paramount.

Considerations for International Buyers: Buyers should be aware of the fragility of glass and ensure that packaging meets international shipping standards to prevent breakage during transit.

How Does Aluminum Compare for Peanut Oil Packaging?

Aluminum is increasingly used for packaging peanut oil, especially in the food service industry. It offers excellent barrier properties and is lightweight, which aids in reducing transportation costs.

Pros: Aluminum containers are resistant to corrosion and can be hermetically sealed, extending the shelf life of the oil. They are also recyclable and can be produced in various sizes.

Cons: However, aluminum can react with certain substances if not properly coated, potentially affecting the oil’s flavor.

Impact on Application: Aluminum is suitable for bulk applications and can be used for both retail and food service packaging.

Considerations for International Buyers: Compliance with food safety regulations is essential, particularly in markets like the Middle East and Europe, where stringent standards apply.

What Are the Benefits of Composite Materials for Peanut Oil Packaging?

Composite materials, often a combination of plastic and paperboard, are gaining traction for packaging peanut oil. They offer a balance of durability and lightweight characteristics.

Pros: These materials can provide excellent insulation and protection against light and moisture, which is crucial for maintaining oil quality.

Cons: The manufacturing process can be more complex and costly compared to single-material options, which may affect pricing.

Impact on Application: Composite materials are suitable for both retail and industrial applications, providing versatility in design.

Considerations for International Buyers: Buyers should ensure that composite materials meet local regulations, particularly in terms of recyclability and food safety.

Summary Table of Material Selection for Peanut Oil Packaging

| Material | Typical Use Case for peanut oil 5 gallon | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Density Polyethylene (HDPE) | Bulk storage and transport | Lightweight and cost-effective | UV degradation potential | Low |

| Glass | Premium product packaging | Excellent flavor preservation | Heavy and breakable | High |

| Aluminum | Food service and retail packaging | Corrosion-resistant and lightweight | Potential reactivity without coating | Medium |

| Composite Materials | Retail and industrial applications | Good insulation and moisture protection | More complex manufacturing process | Medium |

This guide provides actionable insights for B2B buyers looking to select the most suitable material for peanut oil packaging, ensuring compliance with international standards and meeting market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for peanut oil 5 gallon

What are the Main Stages in the Manufacturing Process of Peanut Oil?

The manufacturing process for peanut oil, particularly in bulk packaging such as the 5-gallon format, involves several critical stages. Understanding these stages is vital for B2B buyers to ensure they source high-quality products that meet their operational needs.

-

Material Preparation: This initial stage focuses on sourcing high-quality peanuts. Peanuts must be cleaned to remove foreign materials and contaminants. This often involves washing, drying, and sorting the peanuts based on size and quality. The selection of peanuts significantly impacts the oil’s flavor, aroma, and overall quality.

-

Oil Extraction: After preparation, the peanuts undergo oil extraction. The most common methods are mechanical pressing and solvent extraction. Mechanical pressing involves using hydraulic or screw presses to extract oil, preserving its flavor and nutritional qualities. Solvent extraction, using hexane, is more efficient for large-scale production but may require additional refining steps to remove solvent residues.

-

Refining Process: Once extracted, crude peanut oil typically undergoes refining to enhance its purity and stability. This process includes degumming, neutralization, bleaching, and deodorization. Each step removes impurities, free fatty acids, and undesirable flavors, resulting in a clean, high-quality oil suitable for various culinary applications.

-

Filling and Packaging: After refining, the oil is filtered and stored in tanks before being filled into 5-gallon containers. This stage requires precise filling equipment to ensure consistency in volume and minimize contamination. Packaging materials should be food-safe and designed to protect the oil from light and air, which can degrade quality over time.

-

Labeling and Palletizing: The final stage involves labeling containers with essential information such as batch number, expiry date, and nutritional information. After labeling, the containers are palletized for storage or shipment. Proper handling during this stage is crucial to prevent damage and ensure that the product remains intact until it reaches the buyer.

Which Key Techniques are Used in Peanut Oil Manufacturing?

The manufacturing process employs various techniques to ensure efficiency and product quality.

- Cold Pressing: This technique is increasingly popular for producing high-quality oil without the use of heat, preserving the oil’s natural properties.

- Deodorization: Essential in the refining process, this technique removes volatile compounds that can impart undesirable odors and flavors to the oil.

- Filtration: Post-extraction, filtration is used to remove any remaining solids, ensuring a clear product that meets consumer expectations.

What Quality Control Measures are Important for Peanut Oil Production?

Quality assurance is critical in the peanut oil industry to comply with international standards and meet consumer expectations. Here are key aspects of quality control:

-

International Standards Compliance: Manufacturers should adhere to ISO 9001 standards, which focus on quality management systems. This certification ensures that processes are in place for continual improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the market.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This stage examines raw materials upon arrival, ensuring that only high-quality peanuts are processed.

– In-Process Quality Control (IPQC): During manufacturing, regular checks ensure that the processes are adhered to and that the product remains within specified quality parameters.

– Final Quality Control (FQC): This critical stage involves testing the finished product for quality attributes, including flavor, aroma, and composition. -

Testing Methods: Common testing methods include:

– Gas Chromatography: Used to analyze fatty acid profiles and ensure the absence of contaminants.

– Sensory Evaluation: Trained panels assess flavor and odor, ensuring the product meets market expectations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those sourcing from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are actionable steps:

-

Supplier Audits: Conducting regular audits of suppliers can help assess their compliance with quality standards. These audits should cover production processes, quality control measures, and storage conditions.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC. These documents should outline testing methods and results, giving buyers insights into product quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These organizations can verify compliance with international standards and offer certifications that enhance credibility.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

International buyers should consider several nuances when evaluating quality control measures in peanut oil production:

-

Regulatory Differences: Different countries may have varying regulations regarding food safety and quality. Buyers should familiarize themselves with local regulations in their market and ensure that suppliers comply.

-

Cultural Preferences: Taste and quality perceptions can differ across regions. Suppliers should be aware of these preferences and adjust their processes accordingly to meet market demands.

-

Logistics and Storage Conditions: The quality of peanut oil can degrade due to improper storage and transportation. Buyers should verify that suppliers have adequate logistics in place to maintain product integrity.

By understanding the manufacturing processes and quality assurance practices involved in peanut oil production, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘peanut oil 5 gallon’

Introduction

Sourcing peanut oil in bulk, particularly in 5-gallon containers, requires careful consideration and strategic planning. This guide provides a step-by-step checklist to assist international B2B buyers in effectively procuring high-quality peanut oil that meets their operational needs. From defining specifications to evaluating suppliers, each step is designed to help you make informed purchasing decisions.

1. Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of a successful sourcing process. Consider factors such as oil quality, intended use (e.g., frying, cooking), and any dietary restrictions (e.g., non-GMO, kosher). Defining these specifications helps narrow down potential suppliers and ensures the product meets your operational standards.

2. Research Market Trends and Pricing

Understanding current market trends and pricing dynamics is essential for making cost-effective decisions. Monitor fluctuations in peanut oil prices and investigate regional demand, especially in target markets like Africa, South America, and Europe. Utilize industry reports and market analysis to forecast potential price changes and secure favorable terms.

3. Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your criteria. Request company profiles, certifications, and references from other buyers in similar industries. Look for suppliers with a proven track record of reliability and quality, as this can significantly impact your supply chain.

- Check for certifications: Ensure the supplier has relevant certifications (e.g., ISO, HACCP) to guarantee product safety and quality.

- Assess production capabilities: Confirm that the supplier can meet your volume requirements consistently.

4. Request Samples for Quality Assessment

Obtaining product samples is a critical step in evaluating the quality of peanut oil. Request samples from shortlisted suppliers to test for taste, aroma, and cooking performance. This hands-on assessment helps avoid future discrepancies and ensures the oil meets your specific culinary needs.

5. Negotiate Terms and Conditions

Once you have identified a suitable supplier, it’s time to negotiate terms and conditions. Discuss pricing, payment methods, delivery schedules, and return policies. Ensure that the terms align with your financial and operational capabilities, and don’t hesitate to negotiate for better rates based on order volume.

6. Verify Compliance with Import Regulations

Before finalizing your order, ensure that the supplier complies with your country’s import regulations for food products. This includes understanding any tariffs, import duties, and documentation required for smooth customs clearance. Non-compliance can lead to delays and additional costs.

7. Establish a Long-term Partnership

Building a long-term relationship with a reliable supplier can lead to better pricing, priority service, and enhanced collaboration. Communicate regularly with your supplier to discuss future needs and any concerns that arise. A strong partnership can provide stability in your supply chain and foster mutual growth.

By following this checklist, B2B buyers can confidently navigate the sourcing process for peanut oil in 5-gallon containers, ensuring they make informed decisions that support their business objectives.

Comprehensive Cost and Pricing Analysis for peanut oil 5 gallon Sourcing

What Are the Key Cost Components for Sourcing 5-Gallon Peanut Oil?

When sourcing 5-gallon peanut oil, several cost components must be considered to form a comprehensive understanding of the overall pricing structure. The primary cost components include:

-

Materials: The quality of peanuts used directly influences the cost of the oil. Premium peanuts yield higher-quality oil, which may come at a premium price. Additionally, the extraction process (cold-pressed vs. refined) can affect material costs.

-

Labor: Labor costs encompass not only the workforce involved in the extraction and processing of the oil but also those in packaging and distribution. Regions with higher labor costs will naturally see increased prices.

-

Manufacturing Overhead: This includes utilities, rent, equipment maintenance, and other indirect costs associated with the production process. Efficient manufacturing processes can help reduce these overheads, thereby lowering costs.

-

Tooling: Investment in quality machinery can lead to higher initial costs, but it often results in better efficiency and quality, leading to a more favorable long-term cost structure.

-

Quality Control (QC): Rigorous QC processes are essential to ensure product consistency and safety, especially for international markets. The costs associated with testing and compliance can vary based on local regulations.

-

Logistics: Shipping and distribution costs can significantly impact the final price. Factors include distance from the production facility to the buyer, mode of transport, and potential tariffs or import duties.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. The margin can vary widely based on market conditions and supplier strategies.

How Do Price Influencers Affect the Cost of 5-Gallon Peanut Oil?

Several factors can influence the price of peanut oil:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases generally lead to lower per-unit costs. Buyers should consider their storage capabilities and demand forecasts when negotiating MOQs.

-

Specifications and Customization: Customized products, such as organic or non-GMO peanut oil, often come at a premium. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Oils with specific certifications (e.g., Kosher, organic) will typically command higher prices. Buyers should assess the value of such certifications against their target market’s demands.

-

Supplier Factors: The supplier’s reputation, reliability, and history of quality can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) can significantly affect costs. Understanding these terms is crucial for managing shipping costs and responsibilities.

What Are the Best Buyer Tips for Cost-Efficiency in Peanut Oil Sourcing?

B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should consider several strategies for negotiating and optimizing costs:

-

Effective Negotiation: Buyers should be prepared to negotiate prices based on volume commitments and long-term contracts. Building relationships with suppliers can lead to better pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but all associated costs, including shipping, storage, and handling. TCO provides a clearer picture of what the oil will actually cost over its lifecycle.

-

Understand Pricing Nuances for International Markets: Currency fluctuations, local regulations, and import duties can impact pricing. Buyers should stay informed about these factors to make more accurate cost predictions.

-

Explore Multiple Suppliers: Diversifying the supplier base can create competitive pricing and reduce risks associated with relying on a single source.

-

Plan for Quality Assurance: Investing in quality assurance can prevent costly recalls or product issues in the future. Ensure that suppliers meet quality standards before finalizing contracts.

Disclaimer on Indicative Prices

It is essential to note that the prices for peanut oil can vary based on market conditions, regional availability, and fluctuations in raw material costs. Buyers should conduct thorough research and obtain quotes from multiple suppliers to ensure they receive the best value for their sourcing needs.

Alternatives Analysis: Comparing peanut oil 5 gallon With Other Solutions

When evaluating cooking oils for industrial or commercial use, it’s crucial to consider various alternatives to peanut oil, particularly in regions with diverse culinary traditions and specific dietary needs. This analysis will compare peanut oil in a 5-gallon format with two viable alternatives: canola oil and sunflower oil. Each option presents unique benefits and challenges that can influence purchasing decisions for B2B buyers.

| Comparison Aspect | Peanut Oil 5 Gallon | Canola Oil | Sunflower Oil |

|---|---|---|---|

| Performance | High smoke point (450°F); ideal for frying and sautéing. | Moderate smoke point (400°F); suitable for frying and baking. | High smoke point (440°F); versatile for frying and baking. |

| Cost | Approximately $55-$60 per 35 lbs. | Generally lower, around $45-$50 for similar quantities. | Similar pricing to canola, $45-$55 for comparable sizes. |

| Ease of Implementation | Readily available in bulk; easy to store and use. | Widely available; commonly used in food service. | Easily accessible and familiar to many chefs. |

| Maintenance | Requires careful storage to prevent rancidity; can be reused a few times. | Longer shelf life; less prone to rancidity. | Similar to canola, with a decent shelf life. |

| Best Use Case | Best for frying due to flavor and stability at high temperatures. | Versatile; good for frying, baking, and dressings. | Excellent for frying and as a base for dressings; neutral flavor. |

What Are the Advantages and Disadvantages of Canola Oil Compared to Peanut Oil?

Canola oil is a popular alternative due to its lower cost and versatility. It has a moderate smoke point, making it suitable for various cooking methods, including frying and baking. One significant advantage is its health profile; canola oil contains less saturated fat and is often marketed as heart-healthy. However, its flavor is neutral, which may not enhance dishes as much as peanut oil. Additionally, canola oil is often derived from genetically modified crops, which could be a concern for some buyers, especially in regions with a preference for non-GMO products.

How Does Sunflower Oil Stack Up Against Peanut Oil?

Sunflower oil is another viable alternative, appreciated for its high smoke point and light flavor. It is often used in frying and can also serve as a base for salad dressings. Its neutral taste allows it to blend well in various cuisines without overpowering other flavors. Sunflower oil is typically priced similarly to canola oil, making it a cost-effective choice. However, like canola, sunflower oil may lack the distinctive nutty flavor that peanut oil imparts to fried foods, which could be a downside for culinary applications where flavor is paramount.

How Can B2B Buyers Choose the Right Cooking Oil for Their Needs?

When selecting the right cooking oil, B2B buyers should consider their specific culinary requirements, budget constraints, and the health preferences of their target market. Peanut oil is ideal for those prioritizing flavor and high-heat cooking, especially in frying applications. In contrast, canola and sunflower oils offer more neutral flavors and potentially lower costs, making them suitable for a broader range of uses. Ultimately, the decision should align with the business’s operational goals, customer preferences, and culinary practices to ensure maximum satisfaction and efficiency.

Essential Technical Properties and Trade Terminology for peanut oil 5 gallon

What Are the Key Technical Properties of Peanut Oil in 5-Gallon Containers?

When sourcing peanut oil in 5-gallon containers, international B2B buyers should consider several essential technical properties. These properties not only influence the product’s usability but also its compliance with food safety standards and cooking performance.

-

Smoke Point

The smoke point of peanut oil is typically around 450°F (232°C). This high smoke point makes it ideal for frying and sautéing, as it can withstand high temperatures without breaking down. For B2B buyers in the food service industry, selecting oils with a high smoke point is crucial for ensuring the quality and flavor of fried foods. -

Fat Composition

Peanut oil is composed of approximately 14 grams of total fat per serving, which includes monounsaturated and polyunsaturated fats. These fats are considered healthier options compared to saturated fats. Understanding the fat composition is essential for businesses focused on health-conscious consumers, as they can market their offerings as healthier cooking options. -

Purity and Additives

Buyers should verify the purity of the peanut oil, ensuring it is non-GMO and free from harmful additives. For instance, some brands may include dimethylpolysiloxane as an anti-foaming agent. Knowledge about additives is vital for compliance with local regulations and consumer expectations regarding product safety. -

Packaging and Shelf Life

The packaging of peanut oil in 5-gallon containers should be designed to minimize exposure to light and air, which can degrade oil quality. Typically, peanut oil has a shelf life of about 12 months when stored properly. Businesses should consider this aspect for inventory management and to prevent product spoilage. -

Kosher Certification

Many peanut oil products are Kosher certified, making them suitable for a broader range of dietary preferences. This certification can be a selling point in markets with significant Jewish populations or for restaurants that want to appeal to specific customer bases.

What Are the Common Trade Terms Used in the Peanut Oil Industry?

Understanding industry jargon is key for B2B buyers when negotiating purchases or contracts related to peanut oil. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of peanut oil, OEMs may produce specialized oil dispensers or fryers that are optimized for specific types of oil. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell. For peanut oil, this could be set at 5 gallons or more. Understanding MOQ helps businesses manage their inventory levels and cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to invite suppliers to submit price quotes for specific products or services. In the peanut oil market, an RFQ would detail requirements such as volume, packaging, and delivery terms, enabling suppliers to provide tailored quotes. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international transactions, as they clarify who bears the risk and costs at various stages of the supply chain. -

FOB (Free on Board)

FOB is a term indicating that the seller is responsible for delivering the goods to a designated port, at which point the buyer assumes responsibility. In the peanut oil trade, this term can significantly impact shipping costs and logistics planning. -

Certification Standards

Various certification standards, such as ISO or HACCP, ensure that the product meets specific safety and quality requirements. Buyers should be aware of these certifications to ensure compliance with local regulations and to reassure their customers of the product’s quality.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing peanut oil in 5-gallon containers, ensuring they meet both operational needs and market expectations.

Navigating Market Dynamics and Sourcing Trends in the peanut oil 5 gallon Sector

What are the Current Market Dynamics and Key Trends in the Peanut Oil 5 Gallon Sector?

The global peanut oil market is experiencing notable growth, driven by increasing consumer demand for healthier cooking oils and the rising popularity of fried foods. As an international B2B buyer, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The health-conscious trend is pushing manufacturers to promote peanut oil’s high smoke point and favorable fat profile, making it a preferred choice for both home cooks and commercial kitchens.

Emerging technologies in sourcing are also transforming the peanut oil sector. Digital platforms are facilitating more efficient supply chain management, allowing buyers to connect directly with producers. E-commerce and B2B marketplaces enable bulk purchasing, enhancing price competitiveness. Moreover, data analytics is increasingly used to forecast demand and optimize inventory levels, which is particularly beneficial for large-scale operations in diverse markets.

Another key trend is the rise of private-label products. Retailers and distributors are increasingly investing in their own brands of peanut oil, creating competitive pricing strategies that appeal to budget-conscious consumers. In regions such as Nigeria and Brazil, where local production may vary, sourcing trends are also influenced by geopolitical factors and trade agreements, necessitating a flexible approach to procurement.

How is Sustainability and Ethical Sourcing Affecting the Peanut Oil 5 Gallon Market?

Sustainability is becoming a pivotal consideration in the peanut oil sector. As global awareness of environmental issues rises, B2B buyers are prioritizing suppliers who practice ethical sourcing and offer certifications such as Non-GMO, organic, and fair trade. These certifications not only enhance brand reputation but also align with consumer preferences for environmentally friendly products.

The environmental impact of peanut oil production, particularly concerning land use and water consumption, cannot be overlooked. Buyers are increasingly seeking suppliers who employ sustainable farming practices, thereby minimizing their ecological footprint. This shift towards sustainability is not just a trend but a necessity for companies aiming to meet regulatory standards and consumer expectations.

Furthermore, integrating sustainability into the supply chain can lead to cost savings in the long term. Efficient resource management, waste reduction, and the use of renewable energy sources contribute to operational efficiencies, making businesses more resilient in a volatile market. As ethical sourcing continues to gain traction, international buyers must ensure that their suppliers are committed to these principles to maintain competitiveness.

What is the Evolution of the Peanut Oil Market in a B2B Context?

Historically, peanut oil has been a staple in culinary traditions, especially in Asian and Southern cuisines. Its popularity surged in the late 20th century as global interest in fried foods grew. The evolution of the peanut oil market reflects broader trends in health and wellness, with a shift from traditional fats to oils perceived as healthier alternatives.

In recent years, the peanut oil sector has witnessed significant advancements in production and processing technologies, leading to improved quality and shelf-life. Innovations such as cold-press extraction methods have emerged, providing a more natural product that appeals to health-conscious consumers.

As international trade barriers have relaxed, the global peanut oil market has expanded, allowing B2B buyers from diverse regions to access high-quality products. This evolution highlights the importance of adaptability in sourcing strategies, as market demands continue to shift towards healthier and more sustainable options. Understanding this historical context can provide valuable insights for current and future sourcing decisions in the peanut oil sector.

Frequently Asked Questions (FAQs) for B2B Buyers of peanut oil 5 gallon

-

How do I ensure the quality of peanut oil when sourcing?

To ensure the quality of peanut oil, request samples from potential suppliers to conduct your own quality tests, including checks for purity, taste, and smoke point. Verify that suppliers adhere to international food safety standards, such as ISO or HACCP certifications. Additionally, review lab test results for contaminants and fatty acid profiles. Establish clear quality assurance protocols in your purchase agreements and consider conducting regular audits of your suppliers to maintain consistent quality. -

What is the best storage method for peanut oil?

Peanut oil should be stored in a cool, dark place to prevent oxidation and preserve its quality. Use airtight containers made of food-grade materials to minimize exposure to air and light. For bulk storage, consider stainless steel or food-grade plastic drums. Additionally, monitor storage conditions regularly, including temperature and humidity, to ensure they remain within optimal ranges, as improper storage can lead to rancidity and spoilage. -

What are the common uses of 5-gallon peanut oil in the food industry?

5-gallon peanut oil is widely used for frying, sautéing, and baking due to its high smoke point and nutty flavor. It is particularly popular for deep-frying turkey and making fried snacks such as French fries and chicken wings. Additionally, it can be used in salad dressings and marinades, enhancing the flavor profile of various dishes. Its versatility makes it a staple in both commercial kitchens and food processing facilities. -

What should I consider regarding payment terms when sourcing peanut oil?

When negotiating payment terms, consider factors such as order size, supplier reputation, and your own cash flow. Common terms include a deposit upfront with the balance paid upon delivery or net 30/60 days after invoice. Ensure that payment methods are secure and that you have clear agreements on penalties for late payments. It’s also advisable to understand any currency exchange implications if dealing with international suppliers. -

What is the minimum order quantity (MOQ) for peanut oil?

Minimum order quantities (MOQ) for peanut oil can vary by supplier, but they typically range from 5 to 20 gallons for bulk purchases. It’s essential to discuss MOQs upfront during negotiations to ensure they align with your purchasing needs. If you require flexibility, seek suppliers willing to accommodate smaller orders or consider forming cooperative buying groups with other businesses to meet MOQ requirements. -

How do I vet suppliers for peanut oil in international markets?

To vet suppliers effectively, conduct thorough research on their reputation, including checking for customer reviews and industry certifications. Request references from other buyers and verify their production capabilities and adherence to quality standards. Utilizing platforms like Alibaba or Global Sources can also provide insights into supplier reliability. Additionally, consider conducting site visits or audits when feasible to assess their operations firsthand. -

What are the logistics considerations for importing peanut oil?

Logistics for importing peanut oil include understanding shipping options, customs regulations, and import duties specific to your country. Evaluate whether to use sea or air freight based on cost and time sensitivity. Collaborate with a freight forwarder familiar with food products to streamline the process and ensure compliance with health regulations. Be prepared for potential delays and factor in lead times for both production and shipping when planning your inventory. -

Can I customize my peanut oil order for specific needs?

Many suppliers offer customization options for peanut oil, including variations in packaging, blends, or specific formulations tailored to your needs. Discuss your requirements with potential suppliers to explore available options. Custom orders may involve additional costs and longer lead times, so it’s important to communicate your specifications clearly and confirm all details in writing before finalizing the order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Peanut Oil 5 Gallon Manufacturers & Suppliers List

1. Kirkland Signature – Peanut Oil 35 lbs

Domain: costcobusinessdelivery.com

Registered: 1998 (27 years)

Introduction: Kirkland Signature Peanut Oil, 35 lbs

2. Facebook – Oil Storage Tips

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Oil Storage Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

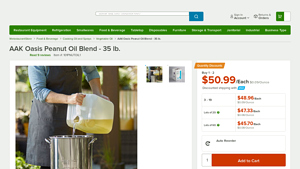

3. AAK – Oasis Peanut Oil Blend

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “AAK Oasis Peanut Oil Blend”, “Weight”: “35 lbs”, “Volume”: “Approx 4.5 Gallons”, “Rating”: “4.9 out of 5 stars”, “Reviews”: “9 reviews”, “Usage”: “Deep Frying, Light Frying, and Sautéing”, “Smoke Point”: “450 degrees Fahrenheit”, “Features”: [“Great for deep frying turkey, French fries, and more”, “Does not transfer flavor to food”, “Economical substitute for pure peanut oil”, “V…

Strategic Sourcing Conclusion and Outlook for peanut oil 5 gallon

In navigating the global market for peanut oil, particularly in the 5-gallon segment, businesses must prioritize strategic sourcing to optimize their supply chains and ensure quality. The versatility of peanut oil, characterized by its high smoke point and nutty flavor, makes it an ideal choice for various cooking applications, from deep frying to sautéing. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing—including price variations, quality standards, and supplier reliability—is critical for maintaining competitive advantage.

Leveraging strategic sourcing practices not only enhances product quality but also facilitates better pricing structures and availability, enabling businesses to meet consumer demands efficiently. As market dynamics evolve, staying informed about emerging suppliers and market trends will empower international buyers to make data-driven decisions that align with their operational goals.

Looking ahead, it is essential for businesses to foster partnerships with trusted suppliers and explore bulk purchasing options to maximize value. By proactively engaging in strategic sourcing, companies can position themselves to capitalize on growth opportunities in the peanut oil market. Now is the time to take action—evaluate your sourcing strategies and consider expanding your supplier network to ensure a robust supply of peanut oil that meets your business needs.