Unlocking Value: A Strategic Analysis of the 8A 125V Fuse Market

Introduction: Navigating the Global Market for 8a 125v fuse

In the ever-evolving landscape of global commerce, sourcing the right components can be a daunting task for B2B buyers, particularly when it comes to critical electrical components like the 8A 125V fuse. As industries increasingly rely on reliable electrical systems, understanding the nuances of these fuses—ranging from types and applications to regulatory standards—becomes essential for informed purchasing decisions. This guide offers a comprehensive overview of the 8A 125V fuse market, addressing key considerations such as the various types available, their specific applications across different sectors, effective supplier vetting processes, and cost considerations.

International buyers from regions like Africa, South America, the Middle East, and Europe, including countries like Vietnam and Brazil, will find valuable insights tailored to their unique market challenges. By delving into the technical specifications, quality certifications, and sourcing strategies, this guide empowers businesses to make educated decisions that align with their operational needs and budget constraints. Whether you are looking to enhance your supply chain efficiency or ensure compliance with local regulations, understanding the global market dynamics surrounding the 8A 125V fuse will be pivotal in navigating your sourcing journey successfully.

Understanding 8a 125v fuse Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| GMA-8A Glass Fuse | Fast acting, glass tube, low breaking capacity | Consumer electronics, lighting applications | Pros: Widely available, cost-effective. Cons: Limited to lower voltage applications. |

| 312008125V Littelfuse | Cartridge style, high interrupting rating | Industrial machinery, automotive applications | Pros: High reliability, robust design. Cons: Typically higher cost than glass fuses. |

| Mersen-Ferraz SMG8 | Glass body, nickel-plated brass endcaps | HVAC systems, power distribution | Pros: Durable construction, good thermal performance. Cons: May have longer lead times. |

| Hillman 8A Fuse Pack | Packaged for bulk purchasing, fast acting | Seasonal lighting, holiday decorations | Pros: Convenient bulk options, affordable. Cons: May not be suitable for high-demand applications. |

| GMA-8-R Fuse | UL listed, compact size (5mm x 20mm) | General circuit protection | Pros: Compact design, easy to replace. Cons: Limited current rating for high-power applications. |

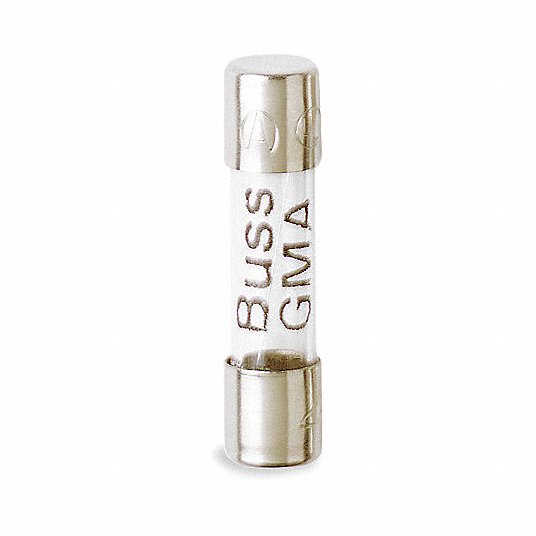

What are the Characteristics and Suitability of GMA-8A Glass Fuses?

The GMA-8A glass fuse is a popular choice for various consumer electronics and lighting applications. Its fast-acting nature allows it to respond quickly to overcurrent situations, ensuring safety and protection for sensitive components. This fuse type is typically characterized by a low breaking capacity, making it ideal for lower voltage applications. B2B buyers should consider the availability and cost-effectiveness of the GMA-8A, as it is widely stocked and used across many industries.

How Does the 312008125V Littelfuse Stand Out in Industrial Applications?

The Littelfuse 312008125V is designed for heavy-duty applications, featuring a cartridge style that allows for easy installation in industrial machinery and automotive systems. Its high interrupting rating provides superior protection against short circuits, making it a reliable choice for demanding environments. When purchasing, B2B buyers should focus on the fuse’s robustness and reliability, especially in critical applications where downtime can be costly.

What Makes Mersen-Ferraz SMG8 Fuses Ideal for HVAC Systems?

Mersen-Ferraz SMG8 fuses are specifically designed with durability in mind, featuring a glass body and nickel-plated brass endcaps that enhance thermal performance. This type of fuse is commonly used in HVAC systems and power distribution setups, where consistent performance is crucial. B2B buyers should evaluate the thermal characteristics and lead times associated with this fuse, as its reliability in high-temperature environments can justify a potentially higher price point.

Why Choose Hillman 8A Fuse Packs for Seasonal Lighting?

The Hillman 8A fuse pack is tailored for bulk purchasing, making it an economical choice for seasonal lighting and holiday decorations. These fast-acting fuses are convenient for businesses that require multiple replacements throughout the year. While they offer affordability and convenience, B2B buyers should be aware that these fuses may not be suitable for high-demand applications, which could lead to performance issues under stress.

What are the Advantages of GMA-8-R Fuses for General Circuit Protection?

The GMA-8-R fuse is a compact solution for general circuit protection, measuring 5mm x 20mm, which makes it easy to replace in various applications. It is UL listed, ensuring compliance with safety standards, and is suitable for general electronic circuits. B2B buyers should consider its compact design and ease of replacement, although its limited current rating may restrict its use in high-power situations.

Key Industrial Applications of 8a 125v fuse

| Industry/Sector | Specific Application of 8a 125v Fuse | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Protection of circuit boards and components | Prevents damage to sensitive electronics, ensuring reliability and longevity. | Ensure compliance with international standards (UL, CSA) and availability of bulk purchasing options. |

| Automotive | Fuses in automotive lighting and electronic systems | Enhances safety and prevents electrical failures in vehicles. | Look for high interrupting ratings and fast-acting characteristics suitable for automotive applications. |

| Renewable Energy | Integration in solar power systems | Safeguards inverters and batteries from overloads, improving system efficiency. | Consider sourcing from manufacturers with certifications for renewable energy applications. |

| Home Appliances | Use in kitchen and household appliances | Protects against overloads, enhancing safety and durability of appliances. | Assess compatibility with various appliance types and ensure local availability for replacements. |

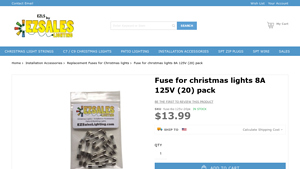

| Christmas Lighting | Protection in decorative lighting setups | Ensures safe operation of seasonal lighting, preventing electrical hazards. | Source in bulk for cost efficiency, and verify compatibility with specific lighting types (C7, C9). |

How is the 8a 125v Fuse Used in Electronics Manufacturing?

In electronics manufacturing, the 8a 125v fuse is crucial for protecting circuit boards and components from overcurrent conditions. This application is particularly vital as it prevents damage to sensitive electronic parts, ensuring the reliability and longevity of products. Buyers in this sector must prioritize sourcing fuses that comply with international standards, such as UL and CSA, and consider suppliers offering bulk purchasing options to optimize costs and availability.

What Role Does the 8a 125v Fuse Play in the Automotive Industry?

In the automotive industry, the 8a 125v fuse is typically used in lighting and electronic systems, safeguarding against electrical failures. This is essential for enhancing vehicle safety and ensuring that lighting systems operate reliably. Buyers should focus on fuses with high interrupting ratings and fast-acting characteristics, as these features are necessary to meet the demanding requirements of automotive applications, particularly in regions with varying electrical standards.

How is the 8a 125v Fuse Applied in Renewable Energy Systems?

The 8a 125v fuse finds significant application in renewable energy systems, particularly in solar power installations. It protects inverters and batteries from overloads, thereby improving the overall efficiency and safety of the energy system. For international buyers, particularly from Africa and South America, it is essential to source fuses from manufacturers that have specific certifications for renewable energy applications, ensuring compliance with local regulations and standards.

Why is the 8a 125v Fuse Important for Home Appliances?

In the realm of home appliances, the 8a 125v fuse is used to protect devices such as refrigerators, microwaves, and other kitchen equipment from electrical overloads. This protection enhances the safety and durability of the appliances, reducing the risk of fire hazards. Buyers should ensure that the fuses are compatible with various appliance types and consider local availability for easy replacements, particularly in regions with diverse electrical systems.

How Does the 8a 125v Fuse Benefit Christmas Lighting Applications?

The 8a 125v fuse is commonly employed in decorative lighting setups, especially for Christmas lights. It ensures safe operation by preventing electrical hazards that can arise from overloads. For B2B buyers, sourcing these fuses in bulk can lead to cost efficiency, and it is crucial to verify compatibility with specific lighting types, such as C7 and C9, to ensure optimal performance during the festive season.

3 Common User Pain Points for ‘8a 125v fuse’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Suppliers for 8A 125V Fuses

The Problem: Many B2B buyers, particularly those operating in regions like Africa and South America, face challenges in finding reliable suppliers for 8A 125V fuses. This issue is compounded by inconsistent product quality and varying compliance standards. Buyers often report frustration with suppliers who fail to deliver on time, offer subpar products, or lack transparency regarding product specifications and certifications. This not only affects their production timelines but also compromises the safety and performance of their electrical systems.

The Solution: To effectively source high-quality 8A 125V fuses, buyers should prioritize suppliers with established reputations and verifiable certifications such as UL, CSA, and CE. Conducting thorough due diligence is crucial—this includes checking supplier reviews, requesting samples, and verifying compliance with industry standards. Additionally, leveraging online platforms that specialize in electrical components can help streamline the sourcing process. Tools like supplier rating systems and trade references can provide insights into the reliability and product quality of potential suppliers. Establishing long-term relationships with a select few trusted suppliers can also mitigate risks associated with sourcing inconsistencies.

Scenario 2: Misunderstanding Fuse Specifications Leading to System Failures

The Problem: A common issue faced by B2B buyers is the misunderstanding of fuse specifications, which can lead to incorrect installations and system failures. For instance, buyers may mistakenly select fuses with inappropriate voltage ratings or breaking capacities, resulting in equipment damage or even safety hazards. This problem is particularly prevalent among companies new to electrical components, where the complexities of fuse specifications can be overwhelming.

The Solution: To avoid costly mistakes, buyers should invest time in understanding the technical specifications of the 8A 125V fuses they intend to purchase. This includes familiarizing themselves with terms such as interrupting rating, breaking capacity, and response time. Engaging with knowledgeable suppliers who can provide technical support and guidance is also essential. Furthermore, creating a standardized checklist that outlines the required specifications for fuses used in different applications can help streamline the decision-making process. Training sessions or workshops on electrical components can enhance the team’s understanding, ensuring they make informed purchasing decisions.

Scenario 3: Managing Inventory for 8A 125V Fuses Efficiently

The Problem: Many B2B buyers struggle with inventory management for electrical components like 8A 125V fuses. Over-ordering can lead to increased holding costs and capital lock-up, while under-ordering can result in production delays and missed deadlines. This balancing act is particularly challenging for companies that operate in fluctuating markets, where demand can vary significantly.

The Solution: Implementing an efficient inventory management system is critical for optimizing the procurement of 8A 125V fuses. Buyers should adopt a just-in-time (JIT) inventory approach, which minimizes holding costs while ensuring that the necessary stock is available when needed. Utilizing inventory management software can provide real-time insights into stock levels, enabling buyers to make informed decisions about reordering. Additionally, establishing minimum order quantities based on historical consumption data can help manage stock levels effectively. Collaborating with suppliers to set up automatic reorder points based on usage patterns can further streamline inventory management, ensuring that buyers maintain the right balance without overcommitting resources.

Strategic Material Selection Guide for 8a 125v fuse

What are the Key Materials Used in 8A 125V Fuses?

When selecting materials for 8A 125V fuses, it’s vital to consider the properties that influence performance, durability, and compliance with international standards. The most common materials used in these fuses include glass, ceramic, copper, and nickel-plated brass. Each material has distinct characteristics that can impact the fuse’s effectiveness in various applications.

How Does Glass Perform in 8A 125V Fuses?

Glass is widely used in the construction of 8A 125V fuses due to its excellent electrical insulation properties and transparency, which allows for visual inspection of the fuse element. Glass fuses typically have a low breaking capacity and are designed to operate effectively at temperatures up to 125°C.

Pros: Glass fuses are cost-effective and easy to manufacture, making them suitable for high-volume production. Their transparency allows users to quickly assess whether a fuse has blown.

Cons: However, glass is more fragile than other materials, making it susceptible to breakage under mechanical stress. It also has limited resistance to thermal shock.

Impact on Application: Glass fuses are ideal for applications in consumer electronics and lighting, where visual inspection is beneficial. However, they may not be suitable for environments with high vibration or shock.

What Role Does Ceramic Play in 8A 125V Fuses?

Ceramic is another common material used in fuses, particularly for applications requiring higher durability and thermal resistance. Ceramic fuses can withstand higher temperatures and pressures compared to glass, making them suitable for industrial applications.

Pros: Ceramic offers superior mechanical strength and thermal stability. It is also less prone to breaking under stress, enhancing the fuse’s longevity.

Cons: The main drawback is the higher manufacturing cost associated with ceramic materials. Additionally, ceramic fuses can be heavier, which may not be ideal for all applications.

Impact on Application: Ceramic fuses are often used in heavy-duty applications, such as industrial machinery and automotive systems, where durability is critical. Compliance with international standards such as IEC and UL is essential for these applications.

How Do Copper and Nickel-Plated Brass Contribute to Fuse Performance?

Copper and nickel-plated brass are commonly used for the end caps and terminals of fuses. These materials are selected for their excellent electrical conductivity and resistance to corrosion.

Pros: Both materials ensure efficient current flow and are resistant to oxidation, which can degrade performance over time. Nickel plating, in particular, enhances corrosion resistance, making these materials suitable for various environments.

Cons: The primary downside is the cost associated with high-quality copper and nickel plating, which can increase the overall price of the fuse. Additionally, they may require more complex manufacturing processes.

Impact on Application: Copper and nickel-plated brass are essential for ensuring reliable connections in high-performance applications, including automotive and industrial sectors. International buyers should ensure compliance with standards such as ASTM for material quality.

What Should International B2B Buyers Consider When Selecting Fuse Materials?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, it is crucial to consider local compliance standards, such as ASTM, DIN, or JIS. Understanding regional preferences for materials and the specific applications they cater to can significantly influence purchasing decisions. Additionally, factors such as supply chain reliability, manufacturing capabilities, and cost-effectiveness should be evaluated.

| Material | Typical Use Case for 8A 125V Fuse | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Glass | Consumer electronics, lighting | Cost-effective, easy to inspect | Fragile, limited thermal resistance | Low |

| Ceramic | Industrial machinery, automotive systems | High durability, thermal stability | Higher manufacturing cost | Medium |

| Copper | Electrical connections, terminals | Excellent conductivity | Costly, complex manufacturing | High |

| Nickel-Plated Brass | High-performance applications | Corrosion-resistant, durable | Higher cost, requires plating process | High |

This strategic material selection guide provides insights into the various materials used in 8A 125V fuses, enabling B2B buyers to make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 8a 125v fuse

What Are the Main Stages in the Manufacturing Process of an 8A 125V Fuse?

The manufacturing process of an 8A 125V fuse involves several critical stages, each designed to ensure the final product meets both safety and performance standards.

-

Material Preparation: The first step includes selecting high-quality raw materials such as glass for the fuse body, nickel-plated brass for the end caps, and metal alloys for the filament. Suppliers often need to ensure that the materials comply with international standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals).

-

Forming: In this stage, the raw materials are shaped into the desired components. The glass is molded into the tubular shape of the fuse, while the metal components are stamped or extruded. Precision is crucial here, as the dimensions must be exact to ensure compatibility with various fuse holders.

-

Assembly: The assembly process involves fitting the filament into the glass body and sealing it with the end caps. This step often employs automated machinery to enhance speed and accuracy. The assembly must ensure that the fuse can withstand the intended electrical load without failure.

-

Finishing: The final stage includes testing the assembled fuses, applying markings, and packaging. Fuses may undergo a coating process to enhance durability and resistance to environmental factors. This stage often involves quality checks to ensure that the fuses are free from defects.

How Is Quality Assurance Integrated into the Manufacturing of 8A 125V Fuses?

Quality assurance (QA) is paramount in the manufacturing of fuses, given their critical role in electrical safety. The following international and industry-specific standards are typically adhered to:

-

International Standards: Compliance with ISO 9001 is common, as it ensures that manufacturers implement a quality management system that meets customer and regulatory requirements. This certification is essential for B2B buyers, especially those in regions like Africa, South America, and the Middle East, where regulatory scrutiny is increasing.

-

Industry-Specific Standards: Fuses must also comply with standards such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association), which specify safety and performance criteria. CE marking is crucial for products sold in Europe, as it indicates conformity with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Fuse Manufacturing?

Quality control (QC) checkpoints are integral to maintaining the integrity and reliability of fuses. The following are common QC stages:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers must provide certification of compliance with relevant standards to avoid issues downstream.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted. This may include checking dimensions during forming and monitoring assembly processes to ensure all components are correctly fitted.

-

Final Quality Control (FQC): After assembly, fuses undergo rigorous testing to ensure they meet specified electrical characteristics and safety standards. Common testing methods include current overload tests, voltage ratings, and interrupting capacity tests.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers, particularly in international markets, must ensure that their suppliers maintain rigorous quality control measures. Here are some actionable steps:

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. This includes reviewing their adherence to ISO standards and industry-specific certifications.

-

Quality Reports: Requesting access to quality assurance reports can offer a glimpse into a supplier’s past performance, including defect rates and corrective actions taken for any issues.

-

Third-Party Inspections: Engaging third-party inspection services before shipment can ensure that the products meet specified standards and reduce the risk of receiving subpar goods.

What Testing Methods Are Commonly Used in Quality Control for Fuses?

Testing methods are critical in ensuring that the 8A 125V fuses perform reliably under specified conditions. Common methods include:

-

Current Overload Testing: Fuses are subjected to higher-than-rated currents to verify their ability to blow under overload conditions. This test is essential for ensuring that the fuse will protect electrical circuits effectively.

-

Voltage Rating Tests: Fuses are tested at their maximum voltage rating to ensure that they can handle the electrical stress without failure.

-

Interrupting Capacity Tests: This test measures the fuse’s ability to interrupt fault currents, ensuring that it can safely disconnect the circuit in the event of a fault.

What Quality Control Nuances Should International Buyers Consider?

International B2B buyers must navigate several nuances when sourcing 8A 125V fuses:

-

Regulatory Compliance: Different regions have varying regulations governing electrical components. Buyers must ensure that the products comply with local regulations, which may require additional certifications not needed in the supplier’s country.

-

Cultural Differences in Quality Standards: Buyers should be aware that quality expectations may vary between regions. Understanding local market expectations can help in selecting suppliers that align with specific needs.

-

Supply Chain Transparency: Ensuring transparency in the supply chain can mitigate risks associated with quality control. Buyers should seek suppliers who are open about their manufacturing processes and quality assurance practices.

In conclusion, the manufacturing processes and quality assurance measures for 8A 125V fuses are designed to ensure safety, reliability, and compliance with international standards. By understanding these processes, B2B buyers can make informed decisions, ultimately leading to better procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘8a 125v fuse’

To assist international B2B buyers in successfully procuring 8A 125V fuses, this practical sourcing guide outlines essential steps to streamline your purchasing process. By following this checklist, you can ensure that you select the right products and suppliers, thus minimizing risks and maximizing efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the specific requirements for the 8A 125V fuse, including dimensions, type (e.g., fast-acting or slow-blow), and voltage ratings. This clarity will help in identifying suitable products and ensuring compatibility with your applications.

Step 2: Research and Identify Reputable Suppliers

Take the time to research potential suppliers in the market. Look for established companies with a proven track record in electrical components, particularly fuses. Utilize online resources, industry forums, and trade shows to gather information and narrow down your options.

- Key Factors to Consider:

- Supplier reputation and experience in the industry.

- Customer reviews and testimonials.

- Product certifications (e.g., UL, CSA).

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify that they hold necessary certifications and comply with industry standards. Certifications such as UL and CSA ensure that the products meet safety and performance requirements, which is critical for electrical components.

- Important Aspects to Check:

- Validity of certifications and compliance documents.

- Any recent audits or inspections performed by regulatory bodies.

Step 4: Request Samples and Technical Data Sheets

Once you have shortlisted potential suppliers, request samples of the 8A 125V fuses along with technical data sheets. This step allows you to evaluate the quality and performance of the fuses firsthand, ensuring they meet your specifications.

- What to Look For:

- Physical dimensions and material quality.

- Performance characteristics as outlined in the technical data sheets.

Step 5: Compare Pricing and Payment Terms

After evaluating product samples, compare pricing among different suppliers. Take note of the total cost, including shipping and any applicable duties or taxes. Additionally, consider the payment terms offered by each supplier, as favorable terms can significantly impact your cash flow.

- Pricing Considerations:

- Bulk purchase discounts.

- Payment flexibility (e.g., net 30, net 60).

Step 6: Establish Communication and Support Channels

Effective communication is essential in maintaining a strong supplier relationship. Ensure that the supplier offers reliable customer support and is responsive to inquiries. Establish clear lines of communication for order tracking and addressing any concerns that may arise.

Step 7: Finalize Purchase Agreement and Place Order

Once you have completed your evaluations and are satisfied with your chosen supplier, finalize the purchase agreement. Ensure that all terms, including delivery timelines and warranties, are clearly stated. Then, proceed to place your order, keeping records of all transactions for future reference.

By following this checklist, B2B buyers can confidently navigate the procurement of 8A 125V fuses, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for 8a 125v fuse Sourcing

What Are the Key Cost Components for Sourcing 8A 125V Fuses?

When sourcing 8A 125V fuses, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The raw materials used in the production of fuses, such as glass, metal end caps, and internal elements, significantly influence the price. Variations in material quality can lead to price differences.

-

Labor: Labor costs encompass wages for factory workers involved in the manufacturing process. Regions with lower labor costs may offer more competitive pricing, but this can sometimes impact quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: The initial setup for manufacturing fuses requires investment in molds and machinery. This upfront cost is typically amortized over the production volume.

-

Quality Control (QC): Ensuring that fuses meet safety and performance standards incurs additional costs. Certifications such as UL and CSA add to the overall expense but are essential for market acceptance.

-

Logistics: Transportation and storage costs are significant, especially for international shipments. Incoterms will dictate who bears these costs and can greatly affect the total price.

-

Margin: Suppliers add a markup to cover their overhead and profit, which varies based on market conditions and competition.

How Do Price Influencers Affect 8A 125V Fuse Costs?

Several factors influence the pricing of 8A 125V fuses, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. However, buyers must balance inventory holding costs against the benefits of bulk purchasing.

-

Specifications and Customization: Custom specifications can lead to higher costs. Fuses designed for specific applications or environments may require unique materials or manufacturing processes.

-

Materials and Quality Certifications: Higher-quality materials or additional certifications can increase costs. Buyers should assess whether the benefits of these enhancements justify the price increase.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) will influence who pays for shipping and insurance, affecting the total landed cost of products.

What Are the Best Buyer Tips for Cost-Efficiency in Fuse Sourcing?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, here are several strategies to enhance cost efficiency:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may be willing to offer discounts or better terms for large orders or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Look beyond the purchase price to evaluate the total cost of ownership, which includes installation, maintenance, and disposal costs. Investing in higher-quality fuses may reduce long-term costs.

-

Understand Pricing Nuances: Be aware of regional pricing variations. Prices for 8A 125V fuses may fluctuate based on local demand, currency exchange rates, and import duties.

-

Research Supplier Backgrounds: Investigate potential suppliers for reliability and quality. Consider requesting samples to assess performance before committing to larger orders.

-

Leverage Technology: Utilize online platforms and databases to compare prices and specifications across different suppliers. This can help in identifying the best deals and negotiating from an informed position.

Conclusion

Navigating the complexities of sourcing 8A 125V fuses involves understanding cost structures, price influencers, and strategic purchasing tips. By leveraging these insights, B2B buyers can make informed decisions that not only enhance their supply chain efficiency but also ensure they achieve the best value for their investment.

Disclaimer: Prices mentioned are indicative and may vary based on market conditions, supplier agreements, and regional factors. Always confirm current pricing directly with suppliers before proceeding with purchases.

Alternatives Analysis: Comparing 8a 125v fuse With Other Solutions

When considering electrical circuit protection, the 8A 125V fuse is a common choice for safeguarding devices against overloads and short circuits. However, there are several alternative solutions available that can provide similar protection while offering unique benefits. Understanding these alternatives is crucial for B2B buyers looking to optimize their purchasing decisions based on performance, cost, and application.

| Comparison Aspect | 8A 125V Fuse | Circuit Breaker | Polyfuse (Resettable Fuse) |

|---|---|---|---|

| Performance | Fast acting, low breaking capacity | Reliable, adjustable trip settings | Self-resetting, can handle overloads |

| Cost | $2.00 – $3.00 per unit | $10.00 – $30.00 per unit | $1.00 – $5.00 per unit |

| Ease of Implementation | Simple to replace; requires minimal tools | Requires installation; more complex | Simple installation; no replacement needed |

| Maintenance | Regular checks recommended | Low maintenance; periodic testing advised | Minimal; resets automatically after fault |

| Best Use Case | Small appliances, electronics | Industrial applications, heavy machinery | Consumer electronics, automotive applications |

What Are the Advantages and Disadvantages of Using a Circuit Breaker as an Alternative?

Circuit breakers are a reliable alternative to fuses, designed to interrupt the flow of electricity in the event of an overload or short circuit. Their adjustable trip settings allow for more tailored protection based on specific application needs. However, circuit breakers tend to be more expensive and require a more complex installation process. They may also necessitate periodic testing to ensure functionality, which could lead to additional operational costs.

How Do Polyfuses Compare to the 8A 125V Fuse?

Polyfuses, or resettable fuses, offer an innovative solution by automatically resetting after a fault condition is cleared. This feature makes them particularly appealing for applications where ease of maintenance is a priority. They are often less expensive than circuit breakers, making them a cost-effective option for many users. However, polyfuses can have a slower response time compared to traditional fuses, which may not be ideal for all situations, particularly where immediate protection is critical.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right circuit protection solution requires a careful assessment of specific application requirements, including electrical load, installation complexity, and budget constraints. The 8A 125V fuse is an excellent choice for straightforward applications, while circuit breakers provide more robust options for industrial settings. Polyfuses may serve well in consumer electronics due to their resettable nature. By evaluating these factors, B2B buyers can make informed decisions that align with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for 8a 125v fuse

What Are the Key Technical Properties of an 8A 125V Fuse?

Understanding the technical specifications of an 8A 125V fuse is crucial for B2B buyers, especially those involved in manufacturing, electrical installations, and circuit protection. Here are some essential properties:

-

Current Rating (8 Amps)

The current rating indicates the maximum current the fuse can handle without blowing. For an 8A fuse, it is designed to operate safely at 8 amperes. Selecting a fuse with the correct current rating is critical to prevent circuit damage or equipment failure. Overrated fuses can lead to unsafe conditions, while underrated fuses may blow too frequently, causing operational downtime. -

Voltage Rating (125 Volts AC)

The voltage rating specifies the maximum voltage the fuse can handle without breaking down. An 8A 125V fuse is suitable for applications where the voltage does not exceed 125 volts AC. This rating is vital for ensuring compatibility with the electrical systems in use, as using a fuse with an insufficient voltage rating can lead to catastrophic failures. -

Physical Dimensions (5mm x 20mm)

The physical size of the fuse is important for ensuring it fits the designated fuse holder or circuit protection device. The dimensions of 5mm in diameter and 20mm in length are standard for many applications. Buyers should verify these measurements against their existing systems to avoid mismatches that could disrupt operations. -

Interrupting Rating (150 AIC @ 125 VAC)

The interrupting rating indicates the maximum fault current the fuse can safely interrupt without causing an explosion or fire. For an 8A 125V fuse, this rating is typically 150 AIC (Amperes Interrupting Capacity) at 125 VAC. A higher interrupting rating is especially important in industrial settings where fault conditions may arise, ensuring safety and reliability. -

Response Time (Fast Acting)

Fast-acting fuses are designed to blow quickly under overload conditions, providing immediate protection to circuits and devices. This characteristic is particularly important in sensitive electronic applications where delays in protection can result in damage. Understanding the response time helps buyers select the appropriate fuse for their specific applications. -

Compliance and Certification (UL, CSA)

Certifications from recognized organizations like Underwriters Laboratories (UL) and the Canadian Standards Association (CSA) indicate that the fuse meets specific safety and performance standards. These certifications are crucial for B2B buyers to ensure product quality and compliance with regional regulations.

What Are Common Trade Terminologies Related to Fuses?

In the world of electrical components, certain trade terminologies are essential for effective communication and transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for sourcing quality components, as it often indicates reliability and industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps in budgeting and planning purchases. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotations from suppliers. This process is essential for comparing prices and terms from multiple vendors, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Familiarity with Incoterms is important for B2B transactions to clarify costs, risks, and logistics involved in shipping products. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times is critical for planning and ensuring that projects stay on schedule, especially in industries where delays can be costly. -

Certification

This term refers to the process of verifying that a product meets certain standards or regulations. Certifications such as UL and CSA are essential in the electrical industry, assuring buyers of product safety and compliance.

Understanding these technical properties and trade terminologies enables B2B buyers to make informed decisions when sourcing 8A 125V fuses, ensuring compatibility, safety, and reliability in their operations.

Navigating Market Dynamics and Sourcing Trends in the 8a 125v fuse Sector

What Are the Current Market Dynamics and Key Trends in the 8A 125V Fuse Sector?

The global market for 8A 125V fuses is driven by several factors, including increasing demand for reliable circuit protection in various applications such as consumer electronics, automotive, and industrial machinery. As industries evolve, so do the specifications and standards for electrical components. Emerging markets in Africa, South America, and Asia, particularly countries like Brazil and Vietnam, are experiencing rapid industrial growth, which is resulting in higher consumption of electrical fuses.

Technological advancements also play a crucial role in shaping the market dynamics. The integration of smart technology in electrical systems is pushing manufacturers to innovate and produce fuses that not only meet traditional standards but also cater to modern requirements like enhanced safety features and compatibility with digital circuits. Moreover, the rise of e-commerce platforms is transforming the sourcing landscape, enabling international buyers to access a broader range of products and suppliers, thus facilitating competitive pricing and improved supply chain efficiency.

How Is Sustainability and Ethical Sourcing Transforming the 8A 125V Fuse Market?

Sustainability and ethical sourcing are becoming increasingly important in the procurement of 8A 125V fuses. As global awareness of environmental issues rises, buyers are seeking suppliers who prioritize eco-friendly practices and materials. The production of electrical components, including fuses, often involves processes that can have significant environmental impacts. Therefore, manufacturers are now focusing on reducing waste, optimizing energy consumption, and sourcing materials responsibly.

Additionally, the demand for ‘green’ certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), is influencing sourcing decisions. Buyers are encouraged to collaborate with suppliers who comply with these standards, ensuring that their products are not only efficient but also environmentally friendly. This shift towards sustainability not only enhances brand reputation but also meets the growing consumer expectation for responsible manufacturing practices.

What Is the Historical Context Behind the Development of 8A 125V Fuses?

The evolution of the 8A 125V fuse can be traced back to the early 20th century when electrical safety became a pressing concern due to the increasing use of electricity in homes and industries. Initially, fuses were simple devices designed to protect electrical circuits from overloads. Over time, advancements in materials and technology led to the development of more sophisticated fuses, including glass fuses that offer better visibility and reliability.

The introduction of standards, such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association), further enhanced the credibility and safety of fuses, making them essential components in various electrical applications. Today, the 8A 125V fuse is recognized for its fast-acting characteristics and is widely used across numerous sectors, reflecting its significant evolution from rudimentary designs to modern, efficient solutions tailored to meet complex electrical needs.

In summary, understanding the current market dynamics, embracing sustainability, and acknowledging the historical context of 8A 125V fuses can empower B2B buyers to make informed sourcing decisions that align with both their operational needs and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of 8a 125v fuse

-

How do I select the right 8A 125V fuse for my application?

Selecting the right 8A 125V fuse involves understanding your specific electrical requirements. Consider the type of circuit, the voltage ratings, and whether you need a fast-acting or slow-blow fuse. Fast-acting fuses are ideal for protecting sensitive electronics from short circuits, while slow-blow fuses can handle temporary surges. Always check the manufacturer’s specifications, including the fuse’s interrupting rating and compliance with safety standards like UL and CSA, to ensure compatibility with your equipment. -

What should I consider when sourcing 8A 125V fuses internationally?

When sourcing 8A 125V fuses internationally, consider factors such as supplier reliability, product quality certifications, and shipping logistics. Verify the supplier’s credentials and experience in the industry, as well as their adherence to international standards. It’s also essential to assess lead times, minimum order quantities (MOQ), and shipping options, which can significantly affect your supply chain efficiency. Building a good relationship with a supplier can facilitate smoother transactions and better terms. -

What are common payment terms for purchasing 8A 125V fuses in bulk?

Payment terms for bulk purchases of 8A 125V fuses can vary by supplier and region. Common terms include net 30 or net 60 days, requiring payment within 30 or 60 days after the invoice date. Some suppliers may offer discounts for early payments or require deposits before processing orders. It’s crucial to negotiate terms that align with your cash flow and financial policies, ensuring that both parties are comfortable with the arrangements. -

How can I ensure the quality of 8A 125V fuses from suppliers?

To ensure the quality of 8A 125V fuses, request product samples for testing before placing a bulk order. Verify that the fuses meet relevant safety and performance standards, such as UL and CSA certifications. Additionally, check for reviews and testimonials from other buyers about the supplier’s product quality. Establishing a clear quality assurance protocol with your supplier can help mitigate risks associated with defective products. -

What is the typical lead time for international orders of 8A 125V fuses?

The lead time for international orders of 8A 125V fuses can vary widely depending on factors such as supplier location, shipping method, and order size. Generally, expect lead times of 2-6 weeks for standard shipping methods. For urgent orders, express shipping options may be available, although they can be more expensive. Always confirm lead times with your supplier before placing an order to ensure it aligns with your project timelines. -

What are the implications of minimum order quantities (MOQ) when sourcing fuses?

Minimum order quantities (MOQ) can significantly impact your purchasing strategy. Suppliers often set MOQs to ensure cost-effectiveness and efficient production runs. If the MOQ is higher than your immediate needs, consider negotiating with the supplier or collaborating with other businesses to meet the requirement. Understanding the supplier’s pricing structure in relation to MOQ can help you assess overall costs and budget accordingly. -

Can I customize 8A 125V fuses for specific applications?

Yes, many manufacturers offer customization options for 8A 125V fuses to meet specific application requirements. Customizations may include variations in physical size, breaking capacity, or labeling. When inquiring about customization, provide detailed specifications and intended use cases to the supplier. Keep in mind that custom orders may have longer lead times and higher costs compared to standard products. -

What are the logistics considerations for importing 8A 125V fuses?

When importing 8A 125V fuses, consider logistics aspects such as shipping methods, customs clearance, and import duties. Choose a reliable freight forwarder familiar with your destination country’s regulations. Be aware of potential delays at customs and ensure that all necessary documentation is prepared, including invoices and certificates of origin. Understanding the total landed cost, including shipping and tariffs, will help you make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 8A 125V Fuse Manufacturers & Suppliers List

1. EZLS – Fuse for Christmas Lights 8A 125V

Domain: ezsaleslighting.com

Registered: 2009 (16 years)

Introduction: {“name”:”Fuse for Christmas Lights 8A 125V (20 pack)”,”sku”:”fuse-8a-125v-20pk”,”price”:”$13.99″,”quantity”:”20 pack”,”amps”:”8 Amp”,”voltage”:”125 Volt”,”compatibility”:”Works with C7 & C9 light strings”,”packaging”:”Heavy duty zip lock bag”,”manufacturer”:”EZLS”}

2. Eaton – 8A 125V Glass Fuse

Domain: elliottelectric.com

Registered: 1997 (28 years)

Introduction: {“part_number”: “GMA8R”, “description”: “Eaton 8A 125V Fa 5X20MM Glass Fuse”, “current_rating”: “8A”, “voltage_rating”: “125V”, “type”: “Glass Fuse”, “size”: “5X20MM”}

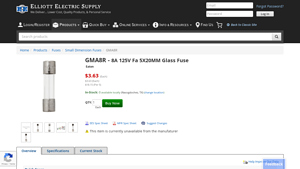

3. Littelfuse – Fast Acting Fuse 312008125V

Domain: tedss.com

Registered: 2004 (21 years)

Introduction: {“part_number”:”312008125V”,”manufacturer”:”LITTELFUSE”,”item_id”:”2026000135″,”fuse_type”:”fast acting”,”current_rating”:”8.000 a”,”voltage_rating”:”125.0 v”,”series”:”312″,”mounting_type”:”holder”,”package”:”BULK”,”item_per_pack”:”1″,”diameter”:”0.25 IN”,”length”:”1.25 IN”,”interrupting_rating”:”10000A @ 125VAC, 35A @ 250VAC”,”minimum_order_quantity”:”80″,”pricing”:{“qty_80″:”0.25″,”qty_100”:”0….

4. Crescent Electric – 8A 125V Glass Fast Acting Fuse

Domain: crescentelectric.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “8A 125V 5mm x 20mm Glass Fast Acting Fuse”, “Manufacturer”: “Crescent Electric Supply Company”, “Amperage”: “8A”, “Voltage”: “125V”, “Size”: “5mm x 20mm”, “Type”: “Glass, Fast Acting”}

5. Mouser – 8 A 125 VDC Fuses

Domain: mouser.com

Registered: 1995 (30 years)

Introduction: This company, Mouser – 8 A 125 VDC Fuses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 8a 125v fuse

The strategic sourcing of 8A 125V fuses is pivotal for businesses aiming to enhance their operational efficiency and reliability in electrical applications. By focusing on quality suppliers such as Bussmann, Littelfuse, and Mersen, international buyers can ensure they are investing in products that meet stringent safety standards, such as UL and CSA certifications. Additionally, understanding the market dynamics and price variations across different regions can help businesses optimize their procurement strategies.

In regions like Africa, South America, the Middle East, and Europe, leveraging local distributors and manufacturers can yield cost advantages and improved supply chain resilience. It’s essential for buyers to engage in thorough market research to identify reputable suppliers, assess inventory levels, and negotiate favorable terms. By prioritizing strategic sourcing, companies can mitigate risks associated with supply disruptions and ensure consistent availability of essential components.

Looking ahead, the demand for reliable electrical components is expected to rise as industries continue to modernize. Buyers are encouraged to proactively explore partnerships with trusted suppliers to secure their supply chains and stay ahead of market trends. By investing in strategic sourcing today, businesses can position themselves for sustainable growth and enhanced operational performance in the future.