The Definitive Guide to Bulk Tomato Cages: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for bulk tomato cages

In the competitive landscape of agricultural supply, sourcing bulk tomato cages presents a significant challenge for international B2B buyers. With the growing demand for efficient plant support systems, businesses in regions such as Africa, South America, the Middle East, and Europe—especially Nigeria and Germany—must navigate a complex marketplace. This guide serves as a comprehensive resource, detailing the various types of tomato cages available, their applications, and the critical factors to consider when selecting suppliers.

From traditional galvanized steel structures to innovative collapsible designs, understanding the nuances of each type can drastically impact crop yield and overall farm productivity. Additionally, we delve into effective supplier vetting processes to ensure quality and reliability, as well as cost considerations that can optimize your purchasing strategy.

This guide empowers B2B buyers to make informed decisions by providing actionable insights into market trends, supplier evaluations, and pricing structures. By equipping your business with the knowledge to navigate the global market for bulk tomato cages, you can enhance your operational efficiency and ensure your agricultural investments yield fruitful results.

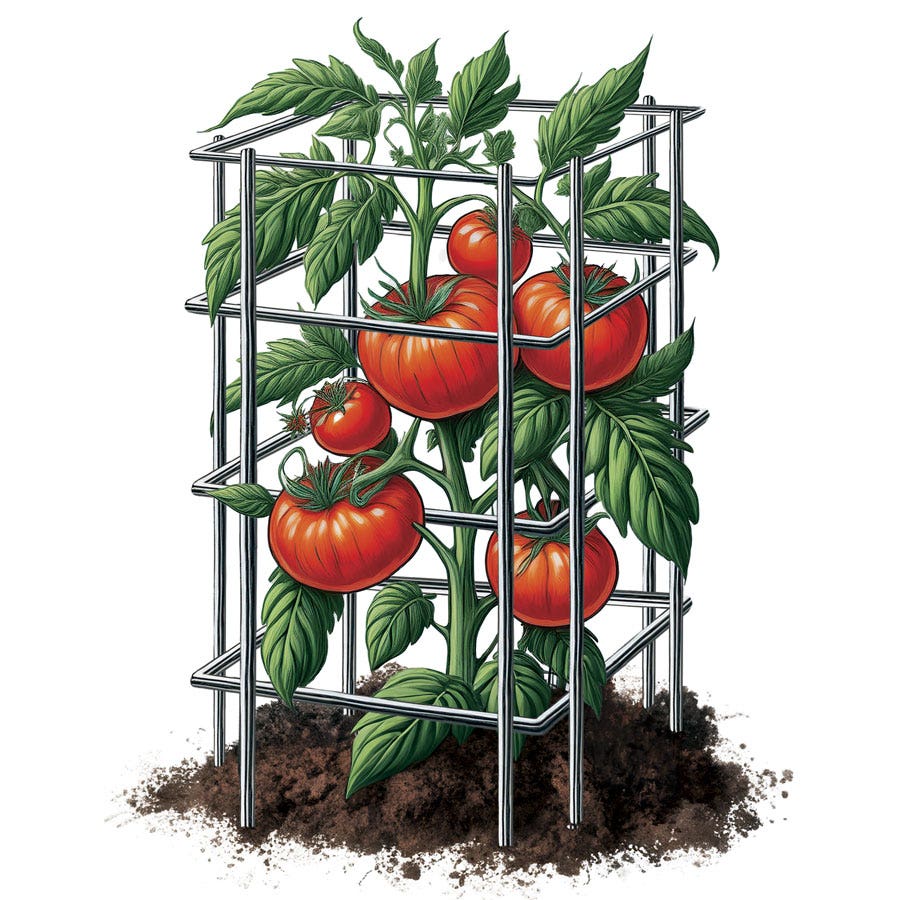

Understanding bulk tomato cages Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Cone Cages | Lightweight, conical shape, often made of wire | Small-scale farms, home gardening | Pros: Easy to store; Cons: Less stability in high winds. |

| Square/Rectangular Cages | Square design with multiple support legs | Commercial agriculture, nurseries | Pros: Enhanced stability; Cons: Bulkier for storage. |

| Heavy-Duty Galvanized Cages | Made from thick galvanized steel, resistant to rust | Large-scale production, export markets | Pros: Long-lasting; Cons: Higher initial cost. |

| Collapsible Cages | Foldable design for easy storage and transport | Retailers, seasonal markets | Pros: Space-efficient; Cons: May require assembly. |

| Tomato Towers | Vertical tower design for maximizing space | Urban gardening, limited-space farms | Pros: Ideal for small areas; Cons: More complex setup. |

What Are Traditional Cone Cages and Their Benefits for B2B Buyers?

Traditional cone cages are lightweight and typically constructed from wire, featuring a conical shape that provides basic support for tomato plants. They are favored by small-scale farmers and home gardeners due to their ease of use and storage. However, their lightweight nature can be a disadvantage in windy conditions, leading to potential plant damage. B2B buyers should consider their target market’s needs, as these cages are ideal for low-budget projects but may not withstand extreme weather.

How Do Square/Rectangular Cages Offer Stability?

Square or rectangular cages are designed with multiple support legs, providing enhanced stability for plants. They are well-suited for commercial agriculture and nurseries, where robust support is essential for high-yield crops. While they offer superior stability compared to cone cages, their bulkier design can make storage more challenging. Buyers focused on long-term agricultural investment should weigh the benefits of durability against the storage constraints.

Why Choose Heavy-Duty Galvanized Cages for Long-Term Use?

Heavy-duty galvanized cages are constructed from thick steel, making them highly resistant to rust and wear over time. These cages cater to large-scale production and export markets, where durability is paramount. Although they come with a higher initial cost, their longevity can lead to lower replacement costs over time. B2B buyers should evaluate the cost-benefit ratio, especially for operations requiring consistent performance under various environmental conditions.

What Are the Advantages of Collapsible Cages in Retail?

Collapsible cages are designed for easy storage and transport, making them an excellent choice for retailers and seasonal markets. Their space-efficient design allows for more manageable inventory, appealing to businesses with limited storage capabilities. However, these cages often require assembly, which could be a drawback for some buyers. Retailers should consider the convenience of transport versus the potential need for assembly when selecting this type of cage.

How Do Tomato Towers Maximize Urban Gardening Space?

Tomato towers utilize a vertical design that maximizes growing space, making them ideal for urban gardens or farms with limited land. They allow for efficient use of vertical space, appealing to urban gardeners looking to maximize yield. However, their setup can be more complex than traditional cages, which may deter some buyers. B2B customers targeting urban agriculture should assess the balance between space efficiency and installation complexity when considering these products.

Key Industrial Applications of bulk tomato cages

| Industry/Sector | Specific Application of bulk tomato cages | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Supporting tomato and vegetable crops in fields | Enhanced crop yield and quality through better support | Durability, material type (galvanized steel preferred), and ease of transport. |

| Horticulture | Use in nurseries for plant growth support | Improved plant health and reduced disease incidence | Sizing options, collapsibility for storage, and UV resistance. |

| Landscaping & Gardening | Decorative plant support in residential projects | Aesthetic appeal while providing functional support | Design variety, material compatibility with landscaping themes, and bulk purchase discounts. |

| Retail Gardening Supplies | Selling bulk tomato cages to consumers | Increased sales volume and customer satisfaction | Supplier reliability, shipping logistics, and product availability. |

| Export & Import | Shipping bulk tomato cages to international markets | Access to diverse markets and enhanced product offerings | Compliance with international shipping regulations and cost-effectiveness. |

How Are Bulk Tomato Cages Used in Agriculture?

In the agriculture sector, bulk tomato cages are essential for supporting tomato and other vegetable crops in large-scale farming operations. They help maintain the structural integrity of plants, allowing for better air circulation and sunlight exposure, which ultimately leads to enhanced crop yield and quality. Buyers from regions like Africa and South America often prioritize durable materials, such as galvanized steel, to withstand diverse climates. Additionally, considerations around transport logistics are critical, as bulk purchases need efficient shipping solutions to minimize costs.

What Role Do Bulk Tomato Cages Play in Horticulture?

Horticulturists utilize bulk tomato cages primarily in nurseries to support young plants, ensuring they grow upright and healthy. This application significantly reduces the incidence of diseases that can arise from plants lying on the ground. For international buyers, particularly in Europe, the ability to source cages that are both robust and collapsible for easy storage is vital. Buyers should also consider UV resistance to ensure longevity in outdoor environments, especially in regions with intense sunlight.

How Are Bulk Tomato Cages Employed in Landscaping?

In landscaping, bulk tomato cages serve both functional and aesthetic purposes. They provide support for climbing plants and can be integrated into decorative garden designs. This dual functionality enhances the visual appeal of residential projects while ensuring plants thrive. When sourcing for landscaping applications, buyers should look for a variety of designs and materials that match their specific landscaping themes. Additionally, bulk purchase options can lead to significant cost savings for landscapers.

Why Are Bulk Tomato Cages Important for Retail Gardening Supplies?

Retail gardening suppliers often stock bulk tomato cages to cater to consumer demand for home gardening solutions. By offering these products in bulk, retailers can increase sales volume and enhance customer satisfaction by providing affordable options for home gardeners. Key sourcing considerations include supplier reliability and the ability to maintain consistent product availability. Retailers must also consider shipping logistics to ensure timely delivery to meet customer needs.

How Do Bulk Tomato Cages Facilitate Export and Import Opportunities?

In the export and import sector, bulk tomato cages provide opportunities to access diverse international markets. Businesses can enhance their product offerings by including these practical gardening solutions in their catalogs. Compliance with international shipping regulations is a crucial consideration for buyers, as is the cost-effectiveness of shipping methods. Understanding the specific requirements of target markets, such as preferred materials and designs, can help businesses successfully penetrate new markets.

3 Common User Pain Points for ‘bulk tomato cages’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Bulk Tomato Cages

The Problem: B2B buyers often struggle with finding reliable suppliers who offer high-quality bulk tomato cages. Many suppliers provide inconsistent product quality, leading to cages that are either too weak to support plants or deteriorate quickly in various weather conditions. This inconsistency can result in significant financial losses for businesses that rely on these products for large-scale agricultural operations. Moreover, with varying international shipping regulations, buyers may face additional hurdles, such as unexpected delays and costs.

The Solution: To ensure the procurement of high-quality bulk tomato cages, buyers should establish long-term relationships with reputable suppliers who specialize in agricultural products. Conduct thorough research by reviewing supplier credentials, customer testimonials, and product certifications. Utilize platforms that aggregate supplier information, allowing for easy comparison of quality and pricing. When placing orders, consider requesting samples before committing to large quantities. Additionally, buyers should inquire about the materials used in the cages, looking for options such as galvanized steel or heavy-duty plastic, which offer better durability and resistance to environmental stressors. Finally, consider suppliers who provide clear shipping policies and support to navigate international logistics efficiently.

Scenario 2: Managing Space and Storage for Bulk Tomato Cages

The Problem: After purchasing bulk tomato cages, many businesses encounter challenges related to storage and space management. Cages, especially those made of metal, can be bulky and difficult to store, leading to clutter and inefficiencies in operational areas. This issue is particularly prevalent in regions where space is at a premium, such as urban agricultural setups or smaller farms.

The Solution: To address storage concerns, buyers should look for collapsible or stackable tomato cage designs. These options not only save space but also simplify transportation and handling. Before purchasing, assess the dimensions of the cages in their collapsed state to ensure they fit within existing storage areas. Implementing an organized storage system, perhaps utilizing shelving or designated bins, can further enhance space utilization. Additionally, consider integrating a rotation system for cage usage, where older cages are used first, preventing overcrowding and ensuring that newer stock remains in good condition. Establishing a clear inventory tracking system can help manage stock levels and facilitate timely reordering.

Scenario 3: Ensuring Proper Support for Growing Tomato Plants

The Problem: A common pain point for buyers is ensuring that tomato cages provide adequate support for growing plants. Many businesses face challenges with cages that are either too short or lack the necessary structure to support heavy fruit-bearing plants. This can lead to plant damage, reduced yields, and wasted resources, causing frustration for growers who depend on healthy crops.

The Solution: To ensure that tomato cages provide sufficient support, buyers should carefully evaluate the height and design of the cages in relation to the specific tomato varieties they plan to cultivate. Opt for taller cages that are at least 54 inches high, particularly for indeterminate varieties that continue to grow throughout the season. Furthermore, consider cages with a wider base and multiple rings for additional stability. It’s essential to educate growers on proper installation techniques, such as burying the legs of the cages deep into the soil for added support. Providing guidance on pruning techniques can also help maximize the effectiveness of the cages, allowing for better airflow and light penetration, ultimately leading to healthier plants and improved yields.

Strategic Material Selection Guide for bulk tomato cages

When selecting materials for bulk tomato cages, it is essential to consider the properties, advantages, and limitations of each material. The choice of material can significantly impact the durability, cost-effectiveness, and overall performance of the cages, particularly in diverse climates and agricultural practices across regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Galvanized Steel for Tomato Cages?

Galvanized steel is a popular choice for bulk tomato cages due to its excellent strength and corrosion resistance. The galvanization process involves coating the steel with zinc, which protects it from rust and degradation, making it suitable for outdoor use. This material can withstand high temperatures and pressures, ensuring that the cages maintain their shape and functionality over time.

Pros and Cons: The primary advantage of galvanized steel is its durability and long lifespan, often exceeding ten years with proper care. However, it can be more expensive than other materials, and the manufacturing process can be complex. Additionally, while it performs well in various climates, extreme conditions may still affect its longevity.

Impact on Application: Galvanized steel cages are compatible with various media, including soil and hydroponic systems, providing robust support for tomato plants.

Considerations for International Buyers: Buyers from regions like Nigeria or Germany should ensure compliance with local standards, such as ASTM or DIN, to guarantee quality and safety. Galvanized steel’s popularity also means that it is widely accepted across different markets.

How Does Plastic Compare as a Material for Tomato Cages?

Plastic, particularly high-density polyethylene (HDPE), is another option for tomato cages. This material is lightweight, resistant to moisture, and does not corrode, making it suitable for humid environments.

Pros and Cons: The key advantage of plastic cages is their affordability and ease of use. They are often collapsible, making storage convenient. However, plastic may not provide the same level of support as metal cages, especially for larger plants. Additionally, prolonged exposure to UV light can degrade plastic over time.

Impact on Application: Plastic cages are ideal for smaller tomato varieties and can be used in raised beds or container gardening. They are less suitable for large-scale agricultural settings where robust support is required.

Considerations for International Buyers: Buyers should look for plastic products that meet international safety and environmental standards. In regions like South America, where UV exposure is high, selecting UV-stabilized plastic can enhance durability.

What are the Benefits of Using Fiberglass for Tomato Cages?

Fiberglass is gaining traction as a material for tomato cages due to its strength and lightweight properties. Fiberglass cages are resistant to corrosion and can withstand various environmental conditions without deteriorating.

Pros and Cons: The main advantage of fiberglass is its strength-to-weight ratio, allowing for easy handling and installation. However, the cost of fiberglass can be higher than both galvanized steel and plastic, and it may require specialized manufacturing techniques.

Impact on Application: Fiberglass cages are particularly effective in high-humidity environments, providing excellent support without rusting. They are suitable for both soil and hydroponic applications.

Considerations for International Buyers: Buyers should ensure that fiberglass products comply with local regulations regarding material safety and environmental impact. In Europe, for instance, adherence to REACH regulations is crucial.

How Does Aluminum Perform as a Material for Tomato Cages?

Aluminum is another viable option for tomato cages, known for its lightweight nature and resistance to rust. Aluminum cages can be designed to be collapsible, making them easy to store and transport.

Pros and Cons: The primary advantage of aluminum is its lightweight, which facilitates easy handling. However, aluminum may not be as strong as galvanized steel, potentially leading to instability for larger plants. Additionally, it can be more expensive than plastic options.

Impact on Application: Aluminum cages are suitable for smaller garden setups and urban gardening, where space and weight are considerations. They perform well in various soil types and can be used in both traditional and modern gardening methods.

Considerations for International Buyers: Buyers should verify that aluminum products meet relevant international standards, such as those set by ASTM or JIS. In regions like the Middle East, where heat can be extreme, ensuring that the aluminum used is of high quality can prevent warping or bending.

Summary Table of Material Selection for Bulk Tomato Cages

| Material | Typical Use Case for bulk tomato cages | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Large-scale agriculture and outdoor use | Excellent durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Container gardening and raised beds | Lightweight and affordable | Less support for larger plants; UV degradation | Low |

| Fiberglass | High-humidity environments and hydroponics | Strong and resistant to corrosion | Higher cost and specialized manufacturing | Med |

| Aluminum | Urban gardening and smaller setups | Lightweight and collapsible | Less strength compared to steel | Med |

This strategic material selection guide provides B2B buyers with essential insights into the properties and implications of various materials for bulk tomato cages, enabling informed purchasing decisions tailored to their specific agricultural needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for bulk tomato cages

What Are the Key Stages in the Manufacturing Process of Bulk Tomato Cages?

The manufacturing process for bulk tomato cages typically involves several critical stages, each designed to ensure the final product meets the necessary quality standards and fulfills market demands. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Tomato Cages?

Material preparation is the foundational step in the manufacturing process. Manufacturers commonly use galvanized steel or high-quality plastic due to their durability and resistance to rust and corrosion. The raw materials undergo a rigorous inspection to ensure they meet specific criteria for strength and flexibility. This initial quality check is essential, as any subpar materials can compromise the integrity of the final product.

What Techniques Are Used in Forming Tomato Cages?

Once the materials are prepared, the forming stage begins. This process often employs techniques such as welding, bending, and cutting. For metal cages, automated machinery is frequently used to ensure precision in dimensions and strength. A common method is the use of CNC (Computer Numerical Control) machines, which provide high accuracy in cutting and shaping the metal components. For plastic cages, extrusion molding is a prevalent technique, allowing for the creation of uniform shapes and sizes.

How Are Tomato Cages Assembled and Finished?

After forming, the assembly process takes place. This may involve manual or automated assembly lines, depending on the manufacturer’s scale of production. Components such as legs, rings, and connectors are brought together, often using additional welding or mechanical fasteners to ensure stability.

The finishing stage includes surface treatments such as powder coating or galvanization, enhancing the product’s durability and aesthetic appeal. These treatments not only protect against environmental factors but also provide resistance against rust, which is particularly important for agricultural products exposed to varying weather conditions.

What Quality Assurance Standards Are Relevant for Tomato Cage Manufacturing?

Quality assurance is a critical aspect of manufacturing bulk tomato cages, ensuring that products meet international and industry-specific standards. For manufacturers targeting international markets, compliance with ISO 9001 is essential. This standard outlines the criteria for a quality management system, focusing on consistent quality and customer satisfaction.

Additionally, compliance with CE marking (Conformité Européenne) is crucial for products sold in European markets, signaling conformity with health, safety, and environmental protection standards. In regions like the Middle East and Africa, certifications from local bodies may also be necessary, depending on the specific market regulations.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically integrated at various stages of the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected upon arrival. Key attributes such as material thickness, tensile strength, and surface integrity are evaluated to ensure compliance with specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are conducted to monitor production consistency. This includes verifying dimensions during the forming stage and ensuring proper assembly techniques are followed.

-

Final Quality Control (FQC): Before shipping, a comprehensive inspection is carried out on the finished products. This may involve testing for structural integrity, rust resistance, and overall quality. Random sampling methods are often employed to assess a representative batch of products.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it is vital to verify a supplier’s quality control measures. Here are several actionable steps:

-

Conduct Supplier Audits: Regular audits allow buyers to assess the supplier’s manufacturing facilities, quality control processes, and adherence to international standards. This can be done through on-site visits or by employing third-party auditing firms.

-

Request Quality Control Reports: Suppliers should provide documentation outlining their QC processes, including inspection reports, compliance certificates, and test results. This transparency is crucial in establishing trust.

-

Utilize Third-Party Inspection Services: Engaging third-party inspection companies can offer an unbiased assessment of the supplier’s products before shipment. These firms can conduct on-site inspections and provide detailed reports on compliance with quality standards.

What Testing Methods Are Commonly Used for Tomato Cages?

Testing methods for bulk tomato cages can vary based on material and design. Common tests include:

-

Load Testing: This assesses the cage’s ability to support the weight of plants and withstand environmental stresses. Load tests can simulate real-life conditions to ensure reliability.

-

Corrosion Resistance Testing: Given the outdoor usage of tomato cages, testing for rust resistance is critical. This may involve accelerated aging tests where cages are exposed to corrosive environments to evaluate durability.

-

Dimensional Verification: Ensuring that the dimensions of the cages adhere to specified tolerances is vital. This is typically done using precision measurement tools to confirm that each unit meets quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers operating across international borders must navigate various nuances when it comes to quality control. Understanding local regulations and compliance requirements is essential. In Europe, for example, CE marking is mandatory, while in African countries, local standards may differ significantly.

Additionally, language barriers and cultural differences can impact communication regarding quality standards. Establishing clear lines of communication and possibly employing local representatives can help mitigate these challenges. Buyers should also consider the implications of logistics and shipping when evaluating product quality, as transportation conditions can affect the integrity of the cages.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for bulk tomato cages can empower B2B buyers to make informed decisions, ensuring they receive high-quality products that meet their specific needs. By leveraging the insights provided in this guide, buyers can enhance their sourcing strategies and build fruitful relationships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bulk tomato cages’

Introduction

This sourcing guide is designed to assist international B2B buyers in procuring bulk tomato cages effectively. With a growing demand for high-quality plant support structures in agriculture, it’s essential to approach the procurement process strategically to ensure you select the right products and suppliers that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating your search for suppliers, clearly outline the specifications for the tomato cages you require. Consider factors such as height, material (e.g., galvanized steel, plastic), and design (e.g., square, round, collapsible).

– Why it matters: Defining specifications helps streamline the sourcing process and ensures that the products align with your agricultural practices.

– Look for: Industry standards that may dictate certain dimensions or materials based on local agricultural conditions.

Step 2: Identify Your Budget

Establish a budget that encompasses not only the cost of the cages but also shipping, customs duties, and potential tariffs. Understanding your financial limits will aid in narrowing down suppliers who can meet your requirements without exceeding your budget.

– Why it matters: A well-defined budget helps prevent overspending and ensures that you can maintain a sustainable sourcing strategy.

– Look for: Suppliers that offer bulk pricing or discounts for larger orders, which can enhance your cost-effectiveness.

Step 3: Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to assess their credibility and reliability. Request company profiles, product catalogs, and references from other businesses in your sector.

– Why it matters: Evaluating suppliers mitigates risks associated with quality issues and delivery delays.

– Look for: Certifications or compliance with international standards, especially if sourcing from different regions, which can impact product quality.

Step 4: Request Samples

Always request samples of the tomato cages before finalizing your order. This allows you to assess the quality, durability, and suitability of the products for your specific needs.

– Why it matters: Testing samples can prevent costly mistakes and ensure that the cages will perform well in your growing conditions.

– Look for: Variations in design and material that could affect the cages’ performance, such as rust resistance or weight capacity.

Step 5: Confirm Shipping and Delivery Terms

Discuss shipping arrangements and delivery timelines with your chosen supplier. Understand the terms of delivery, including lead times, shipping methods, and who bears responsibility for customs clearance.

– Why it matters: Clear shipping terms help you plan your inventory and avoid disruptions in your operations.

– Look for: Suppliers who offer flexible shipping options and have experience in handling international logistics.

Step 6: Negotiate Terms and Conditions

Once you’ve settled on a supplier, negotiate the terms of your purchase, including payment methods, warranties, and return policies. Clear agreements can prevent misunderstandings and protect your investment.

– Why it matters: Strong contractual terms ensure that both parties have a clear understanding of their responsibilities, reducing the risk of disputes.

– Look for: Suppliers who are open to negotiation and demonstrate a willingness to build a long-term partnership.

Step 7: Assess After-Sales Support

Consider the level of after-sales support provided by your supplier, including customer service, technical assistance, and product guarantees. Reliable support can enhance your overall experience and product satisfaction.

– Why it matters: Good after-sales support can assist in troubleshooting and optimizing the use of your tomato cages.

– Look for: Suppliers with a dedicated support team and positive feedback from previous customers regarding their responsiveness and assistance.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing bulk tomato cages, ensuring a successful procurement process that meets their operational needs.

Comprehensive Cost and Pricing Analysis for bulk tomato cages Sourcing

When sourcing bulk tomato cages, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will provide insight into various cost components, price influencers, and practical tips for negotiating the best deals, especially for buyers in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Bulk Tomato Cages?

The total cost of bulk tomato cages can be broken down into several components:

-

Materials: The choice of materials significantly impacts the cost. Common materials include galvanized steel, plastic, and composite materials. Galvanized steel tends to be more expensive due to its durability and rust resistance, making it ideal for long-term use in diverse climates.

-

Labor: Labor costs vary by region and manufacturing practices. In regions with lower labor costs, the overall cost of production may be reduced, but this could also impact the quality of the finished product.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Efficient production processes can help reduce these costs, benefiting buyers in terms of pricing.

-

Tooling: Depending on the design and complexity of the tomato cages, tooling costs can vary. Custom designs may require more sophisticated equipment and setup, increasing initial costs.

-

Quality Control (QC): Ensuring that the cages meet specific standards requires a dedicated QC process, which can add to overall production costs. Certifications like ISO or specific agricultural standards can also impact pricing.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping method, and local customs regulations can significantly influence the final price.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market rates and comparing multiple suppliers can help in negotiating better terms.

How Do Volume and Customization Affect Pricing?

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers typically offer tiered pricing based on order volume, incentivizing larger purchases. Understanding the Minimum Order Quantity (MOQ) is essential for buyers looking to maximize cost efficiency.

Specifications and Customization: Custom features, such as dimensions or additional durability requirements, can increase costs. Buyers should weigh the benefits of customization against the price increase and determine whether standard products meet their needs.

What External Factors Influence Pricing for Tomato Cages?

Quality and Certifications: Products with recognized certifications may command higher prices. Buyers should consider whether these certifications are essential for their market or if lower-cost alternatives suffice.

Supplier Factors: The reliability and reputation of suppliers play a vital role in pricing. Established suppliers might charge more due to their quality assurance processes, while newer entrants may offer lower prices to gain market share.

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms define responsibilities for shipping, insurance, and tariffs, impacting overall costs. For instance, ‘CIF’ (Cost, Insurance, and Freight) includes shipping costs, while ‘FOB’ (Free on Board) may shift more responsibility to the buyer.

What Negotiation Strategies Can Buyers Employ?

-

Research and Comparison: Before negotiating, gather pricing data from multiple suppliers. This helps in establishing a competitive benchmark.

-

Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and favorable terms in future transactions.

-

Highlighting Potential for Bulk Orders: Emphasize your intent for large purchases to leverage better pricing.

-

Understanding Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs such as maintenance, durability, and potential replacements. This perspective can justify a higher upfront cost if the product offers greater longevity.

Conclusion: What Should International Buyers Consider?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the complexities of bulk tomato cage pricing is vital. By analyzing the cost components, recognizing pricing influencers, and employing effective negotiation strategies, buyers can make informed decisions that align with their business goals. It’s essential to remember that prices can vary widely based on specific needs, market conditions, and supplier dynamics, so always request indicative pricing tailored to your requirements.

Alternatives Analysis: Comparing bulk tomato cages With Other Solutions

When considering the optimal support systems for tomato cultivation, bulk tomato cages are often the first option that comes to mind. However, various alternatives can also effectively support plant growth and yield. This analysis will compare bulk tomato cages with two viable alternatives: trellising systems and staking methods. Each solution has unique benefits and challenges that may suit different agricultural contexts and operational needs.

| Comparison Aspect | Bulk Tomato Cages | Trellising Systems | Staking Methods |

|---|---|---|---|

| Performance | High support for vertical growth and fruit protection | Excellent for maximizing space and air circulation | Good for individual plants, limited vertical support |

| Cost | Moderate initial investment; bulk purchasing reduces unit costs | Variable costs depending on materials used | Generally low-cost materials; labor-intensive |

| Ease of Implementation | Simple to set up; can be placed directly into soil | Requires more planning and construction | Quick setup; requires basic tools |

| Maintenance | Low maintenance; durable materials | Moderate; needs regular checks for tension and wear | Low; occasional adjustment needed |

| Best Use Case | Ideal for home gardens and small farms | Best for commercial growers needing space efficiency | Suitable for smaller plots or individual high-value crops |

What are the Advantages and Disadvantages of Trellising Systems?

Trellising systems offer a highly efficient method for supporting tomato plants, particularly in commercial agricultural settings where maximizing space and airflow is crucial. These systems, which often involve horizontal wires or nets, allow plants to grow vertically, reducing disease risk and improving fruit quality. However, the initial setup can be labor-intensive and may require a higher upfront investment in materials compared to bulk tomato cages. Regular maintenance is necessary to ensure that the tension on the wires remains optimal, which may not be feasible for all growers.

How Do Staking Methods Compare for Supporting Tomato Plants?

Staking is a more traditional method where individual plants are supported by inserting stakes into the ground beside them. This approach can be particularly beneficial for high-value crops, allowing for targeted support without the bulkiness of cages. Staking is often more cost-effective, as it can utilize readily available materials. However, it provides less overall support compared to bulk tomato cages, as it does not create a comprehensive structure around the plant, which can lead to issues with fruit protection and plant stability in adverse weather conditions.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right plant support system involves evaluating the specific needs of your agricultural operation. Bulk tomato cages are well-suited for small to medium-sized operations where ease of use and low maintenance are priorities. In contrast, trellising systems may appeal to larger commercial operations looking to maximize space and yield. Staking offers a more economical choice for growers focusing on high-value crops or with limited resources. By considering factors such as cost, implementation ease, maintenance requirements, and the specific growth conditions of the tomatoes, B2B buyers can make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for bulk tomato cages

What Are the Key Technical Properties of Bulk Tomato Cages?

When sourcing bulk tomato cages, understanding the technical specifications is essential for making informed purchasing decisions. Here are the critical properties to consider:

-

Material Grade

The material used in tomato cages significantly affects their durability and resistance to environmental factors. Common materials include galvanized steel, which offers rust resistance, and high-density polyethylene (HDPE) for lightweight applications. Selecting the right material is crucial for ensuring longevity, especially in regions with extreme weather conditions. -

Height and Diameter Specifications

Tomato cages come in various heights and diameters, typically ranging from 36 inches to 54 inches in height. The diameter of the cage affects the amount of support it provides to the plant as it grows. For bulk buyers, ensuring the right dimensions is vital for compatibility with the types of tomatoes and other plants being cultivated. -

Wire Gauge

The wire gauge indicates the thickness of the metal used in the cage. A lower gauge number signifies a thicker wire, which generally offers more strength and support. For instance, a 9-gauge wire is sturdier than a 12-gauge wire. Understanding wire gauge is important for buyers looking for heavy-duty cages capable of supporting larger plants. -

Collapsibility and Storage Features

Bulk tomato cages should ideally be collapsible for easy storage and transportation. Features such as removable panels or foldable designs can significantly reduce shipping costs and storage space requirements. This is especially beneficial for international buyers who may face logistical challenges. -

Environmental Resistance

Cages designed for outdoor use should have properties like UV resistance and weatherproof coatings. These features extend the lifespan of the product, making them a more cost-effective investment for growers in various climates. -

Weight Capacity

Understanding the weight capacity of tomato cages is critical for ensuring that they can support the plant’s growth and the weight of the fruit. This property directly impacts the choice of cage for different tomato varieties, particularly for heavier fruit-bearing types.

What Are Common Trade Terms Related to Bulk Tomato Cages?

Familiarizing yourself with industry terminology can facilitate smoother negotiations and transactions. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

In the context of bulk tomato cages, OEM refers to manufacturers that produce cages for other brands. Buyers can leverage OEM relationships to access custom designs or branded products without the need for extensive in-house manufacturing capabilities. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell per order. Understanding the MOQ is vital for B2B buyers as it affects inventory management and cash flow. Suppliers may set MOQs based on production costs and logistics. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products, in this case, bulk tomato cages. It typically includes details such as specifications, quantities, and delivery timelines. A well-prepared RFQ can lead to competitive pricing and better terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for managing shipping costs, risk, and delivery responsibilities. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). -

Lead Time

Lead time refers to the time taken from placing an order to receiving the products. In agricultural supplies, understanding lead times is critical for planning planting schedules and ensuring timely support for crop growth. -

Freight Forwarding

Freight forwarding involves coordinating the shipment of goods from the manufacturer to the buyer. This term is particularly relevant for international buyers who need to navigate complex logistics and customs regulations. Knowing about freight forwarding can help streamline the importation process and reduce costs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing bulk tomato cages, ultimately enhancing their agricultural operations.

Navigating Market Dynamics and Sourcing Trends in the bulk tomato cages Sector

What Are the Key Market Dynamics and Trends Affecting the Bulk Tomato Cages Sector?

The global market for bulk tomato cages is experiencing a significant transformation driven by various factors. As agricultural practices evolve, the demand for effective plant support systems, including tomato cages, is on the rise. Key drivers include the increasing global population, leading to higher food production needs, and a growing emphasis on sustainable farming practices. Emerging markets in Africa, South America, the Middle East, and Europe are particularly focused on enhancing agricultural productivity, making them prime targets for B2B suppliers of bulk tomato cages.

Technological advancements are also shaping the sourcing landscape. Innovations such as smart agricultural technologies are being integrated into traditional farming methods, allowing for improved crop monitoring and management. This shift necessitates the sourcing of durable and adaptable tomato cages that can withstand varying climatic conditions and support diverse plant types. Additionally, e-commerce platforms are facilitating direct connections between manufacturers and international buyers, streamlining procurement processes and reducing costs.

Another significant trend is the growing interest in customized solutions. Buyers are increasingly seeking tomato cages tailored to specific crop requirements, such as size, material, and design. This demand for customization is pushing manufacturers to innovate and diversify their product offerings, thus enhancing their competitive edge in the market.

How Are Sustainability and Ethical Sourcing Being Integrated into the Bulk Tomato Cages Market?

Sustainability and ethical sourcing have become essential considerations for B2B buyers in the bulk tomato cages sector. The environmental impact of agricultural practices has garnered attention, prompting stakeholders to seek solutions that minimize ecological footprints. Manufacturers are responding by adopting sustainable materials such as recycled plastics and sustainably sourced metals for their tomato cages. This shift not only reduces waste but also appeals to environmentally conscious buyers.

Moreover, the importance of ethical supply chains cannot be overstated. As global awareness of labor practices and environmental standards increases, buyers are prioritizing suppliers who demonstrate a commitment to ethical sourcing. Certifications such as Fair Trade and ISO 14001 for environmental management are becoming crucial in supplier selection. Buyers are encouraged to evaluate their suppliers’ practices to ensure alignment with sustainability goals, thus fostering responsible agricultural practices across the supply chain.

Investing in ‘green’ certifications also enhances marketability, as consumers increasingly favor products that reflect their values. This trend is particularly relevant in regions such as Europe, where stringent regulations and consumer expectations drive demand for sustainable agricultural solutions.

What Is the Historical Context of Bulk Tomato Cages and Their Evolution?

The evolution of bulk tomato cages can be traced back to the early practices of supporting tomato plants to ensure optimal growth and yield. Initially, farmers relied on simple stakes or makeshift supports, which often proved insufficient for larger, more productive tomato varieties. As agricultural knowledge expanded, so did the design of tomato cages, evolving into more robust structures made from materials like wood, wire, and eventually galvanized steel.

The introduction of mass production techniques in the 20th century further transformed the market, allowing for the widespread availability of standardized tomato cages. This accessibility enabled farmers worldwide to adopt improved cultivation practices, leading to increased yields and better-quality produce. Today, the market continues to evolve, with an emphasis on durability, customization, and sustainability, reflecting the changing needs and values of modern agriculture. As B2B buyers navigate this landscape, understanding the historical context can provide valuable insights into current trends and future opportunities in the bulk tomato cages sector.

Frequently Asked Questions (FAQs) for B2B Buyers of bulk tomato cages

-

How do I choose the right tomato cages for my agricultural needs?

Selecting the right tomato cages involves considering several factors, including the type of tomatoes you’re growing, the local climate, and the size of your operation. For larger, indeterminate varieties, opt for sturdy, tall cages that can support heavy fruit loads. Material is also crucial; galvanized steel cages offer durability and resistance to rust, while plastic options may be lighter but less stable. Evaluate your growing conditions and the expected lifespan of the cages to ensure you make a sustainable choice. -

What is the best material for bulk tomato cages?

The best material for bulk tomato cages largely depends on your specific requirements. Galvanized steel is highly recommended for its strength and resistance to corrosion, making it ideal for long-term use in various climates. Alternatively, plastic cages are lightweight and easy to handle but may not provide the same level of support over time. Consider the growing environment and expected wear and tear when deciding on material for optimal plant support. -

What are the minimum order quantities (MOQ) for bulk tomato cages?

Minimum order quantities for bulk tomato cages can vary significantly by supplier. Generally, MOQs may range from 50 to several hundred units, depending on the manufacturer and the customization options requested. It’s advisable to discuss your needs directly with potential suppliers to negotiate terms that suit your business model. Additionally, ordering in bulk often provides cost advantages, so consider consolidating orders with other products if possible. -

How can I ensure the quality of tomato cages from international suppliers?

To ensure quality when sourcing tomato cages from international suppliers, conduct thorough due diligence. Request samples to assess material strength and construction quality. Additionally, verify the supplier’s certifications, such as ISO standards, which can indicate adherence to quality management systems. Engaging third-party inspection services can also provide an extra layer of assurance before shipment. Establishing a solid relationship with your supplier can facilitate ongoing quality checks. -

What payment terms are typical for bulk tomato cage orders?

Payment terms for bulk orders of tomato cages can vary widely based on the supplier’s policies and your negotiation. Common arrangements include a deposit of 30% upfront with the balance due upon delivery or a letter of credit for larger transactions. Some suppliers may also offer net payment terms, allowing you to pay after a specified period post-delivery. Always clarify terms in the contract to avoid misunderstandings and ensure a smooth transaction. -

What are the shipping options for bulk tomato cages to international destinations?

Shipping options for bulk tomato cages typically include sea freight, air freight, and land transport, depending on your location and urgency. Sea freight is the most economical for large orders, though it requires longer transit times. Air freight is faster but significantly more expensive. Ensure that your supplier provides details on shipping costs, estimated delivery times, and whether they handle customs clearance. Familiarize yourself with local regulations and tariffs to avoid unexpected charges. -

Can I customize the size and design of tomato cages for my market?

Yes, many suppliers offer customization options for tomato cages, allowing you to tailor sizes and designs to meet specific market demands. Customization can include variations in height, width, and the number of support rings. When discussing customization, provide clear specifications and consider factors such as transportation and storage of the cages. Collaborating closely with your supplier during the design phase can ensure the final product meets your expectations and market needs. -

What are the best practices for storing bulk tomato cages?

Proper storage of bulk tomato cages is essential for maintaining their integrity and longevity. Store cages in a dry, sheltered location to prevent rust and degradation from moisture. If the cages are collapsible, stack them neatly to save space while ensuring they are not damaged. Regularly inspect stored cages for signs of wear or corrosion, especially if they are made from metal. Implementing these practices can help you maximize the lifespan of your investment in plant support systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Bulk Tomato Cages Manufacturers & Suppliers List

1. Paris Farmers Union – Heavy-Duty Tomato Cages

Domain: parisfarmersunion.com

Registered: 1999 (26 years)

Introduction: This company, Paris Farmers Union – Heavy-Duty Tomato Cages, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Down to Earth Distributors – Wholesale Fertilizers

Domain: downtoearthdistributors.com

Registered: 2001 (24 years)

Introduction: This company, Down to Earth Distributors – Wholesale Fertilizers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Affordable Tomato Cages

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Strong square tomato cages that are affordable; alternatives include using bamboo sticks, Florida weave method with t-posts and bailing twine, or concrete mesh for DIY cages. Suggestions emphasize durability and cost-effectiveness.

4. Johnny’s – 48 Tomato Cages

Domain: johnnyseeds.com

Registered: 1995 (30 years)

Introduction: Tomato Cages – 48″ | Johnny’s Selected Seeds

5. Park Seed – Tomato Cages Pack of 3

6. Facebook – Canning Tomatoes Boxes

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Canning Tomatoes Boxes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for bulk tomato cages

In conclusion, the strategic sourcing of bulk tomato cages presents significant opportunities for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By prioritizing quality, durability, and design—such as opting for galvanized steel or collapsible options—businesses can enhance their crop yields and improve operational efficiency. Engaging with reliable suppliers who offer bulk purchasing options can lead to better pricing and availability, ensuring that your agricultural needs are met without compromising on quality.

As the global demand for fresh produce continues to rise, investing in high-quality tomato cages becomes imperative for optimizing growth conditions and maximizing returns. Buyers should actively seek partnerships with manufacturers that understand regional agricultural practices and can cater to specific market needs.

Looking ahead, the agricultural landscape is evolving, and now is the time for buyers to align their sourcing strategies with emerging trends. By making informed decisions today, businesses can position themselves for success in tomorrow’s competitive market. Engage with trusted suppliers and explore innovative solutions to ensure your operations thrive in the years to come.