Pneumatic Trailer Jack Wheel: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for pneumatic trailer jack wheel

In today’s rapidly evolving global marketplace, sourcing high-quality pneumatic trailer jack wheels presents a significant challenge for B2B buyers. These essential components are crucial for ensuring the stability and mobility of trailers, particularly in regions with diverse terrains such as Africa, South America, the Middle East, and Europe. Understanding the nuances of different types, applications, and the importance of supplier vetting is vital for making informed purchasing decisions that align with operational needs and budget constraints.

This comprehensive guide delves into the various types of pneumatic trailer jack wheels, their applications across multiple industries, and the key factors to consider when selecting the right product for your business. It also addresses critical aspects such as supplier reliability, pricing strategies, and the importance of product specifications to ensure compatibility with existing equipment. By providing actionable insights and expert advice, this guide empowers international B2B buyers—whether from bustling markets in Vietnam or emerging economies in Nigeria—to navigate the complexities of sourcing effectively.

Through this resource, buyers will gain the knowledge necessary to make confident purchasing decisions, ultimately enhancing operational efficiency and reducing downtime. By understanding market trends and supplier dynamics, businesses can secure the best pneumatic trailer jack wheels tailored to their unique requirements, setting the foundation for successful operations in an increasingly competitive landscape.

Understanding pneumatic trailer jack wheel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dual Wheel Pneumatic Caster | Two wheels for enhanced stability and load distribution | Industrial carts, trailers, heavy machinery | Pros: Better stability; Cons: Can be bulkier than single wheels |

| Flat-Free Wheel Kit | Solid construction to prevent punctures, often with swivel feature | Construction sites, rental equipment | Pros: No maintenance; Cons: Limited shock absorption |

| Heavy-Duty Pneumatic Wheel | Larger diameter for rough terrain, high load capacity | Trailers, agricultural equipment | Pros: Handles rough terrain; Cons: Heavier and more expensive |

| Semi-Pneumatic Wheel | Combination of pneumatic and solid design for versatility | Utility trailers, light-duty applications | Pros: Good balance of flexibility and durability; Cons: Limited weight capacity |

| Adjustable Height Jack Wheel | Features a mechanism for height adjustment, often with pneumatic wheels | RVs, boats, and heavy-duty trailers | Pros: Versatile for uneven surfaces; Cons: More complex mechanism can lead to maintenance needs |

What are the Characteristics of Dual Wheel Pneumatic Casters?

Dual wheel pneumatic casters are designed with two wheels that provide enhanced stability and better load distribution. They are particularly useful in industrial settings where equipment and trailers need to navigate uneven surfaces. When considering these casters, buyers should evaluate the weight capacity, wheel diameter, and the type of terrain they will be used on. Their stability makes them ideal for applications where safety and maneuverability are critical.

How Do Flat-Free Wheel Kits Benefit B2B Operations?

Flat-free wheel kits are constructed to eliminate the risk of punctures, making them ideal for high-traffic environments like construction sites. These wheels often come with a swivel feature, enhancing maneuverability when positioning equipment. B2B buyers should consider the operational environment and the expected load to ensure compatibility. While they require no maintenance, their solid construction may provide less shock absorption compared to traditional pneumatic wheels.

Why Choose Heavy-Duty Pneumatic Wheels for Trailers?

Heavy-duty pneumatic wheels are characterized by their larger diameter, which allows them to traverse rough terrain effectively while supporting substantial loads. They are commonly used in trailers and agricultural equipment where durability and performance are paramount. Buyers should assess the weight capacity and the specific applications to ensure they meet operational demands. The investment in these wheels can lead to improved efficiency in challenging environments.

What Advantages Do Semi-Pneumatic Wheels Offer?

Semi-pneumatic wheels combine the advantages of pneumatic and solid wheels, offering a versatile solution for various applications. They provide a good balance between flexibility and durability, making them suitable for utility trailers and light-duty tasks. B2B buyers should consider their specific needs, including weight capacity and terrain types, when selecting these wheels. While they perform well in diverse conditions, their weight capacity is typically lower than that of heavy-duty options.

How Do Adjustable Height Jack Wheels Enhance Versatility?

Adjustable height jack wheels are designed to offer height adjustment capabilities, making them highly versatile for use on uneven surfaces. Commonly found in RVs and heavy-duty trailers, these wheels allow for easy leveling and stabilization. When purchasing, buyers should consider the mechanism’s reliability and ease of use, as well as the maximum height adjustment range. Their adaptability can significantly improve operational efficiency in various applications.

Key Industrial Applications of pneumatic trailer jack wheel

| Industry/Sector | Specific Application of Pneumatic Trailer Jack Wheel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation & Logistics | Used for stabilizing trailers during loading and unloading operations | Enhances safety and efficiency by preventing trailer upending | Ensure compliance with local regulations and weight capacities |

| Construction | Provides support for equipment and materials on job sites | Increases operational stability and prevents equipment damage | Look for durability and resistance to harsh environmental conditions |

| Agriculture | Assists in moving and stabilizing agricultural trailers for equipment transport | Facilitates smoother operations and reduces downtime | Consider compatibility with various trailer types and terrain |

| Event Management | Used for leveling and stabilizing mobile stages and equipment | Ensures safety and stability for events, enhancing guest experience | Assess ease of mobility and setup time for quick event changes |

| Industrial Manufacturing | Supports heavy machinery and tools during maintenance and operation | Reduces risk of accidents and equipment damage | Prioritize high load capacities and reliable performance under stress |

How Are Pneumatic Trailer Jack Wheels Utilized in Transportation & Logistics?

In the transportation and logistics sector, pneumatic trailer jack wheels are essential for stabilizing trailers during loading and unloading. These wheels prevent the trailer from shifting or tipping, especially when not coupled to a tractor. This stability enhances safety and operational efficiency, minimizing the risk of accidents and damage to goods. International buyers, particularly in regions like Africa and South America, should ensure that these jacks comply with local weight regulations and can withstand diverse terrain conditions.

What Role Do Pneumatic Trailer Jack Wheels Play in Construction?

In the construction industry, pneumatic trailer jack wheels are utilized to support equipment and materials on-site. They provide stability for trailers carrying heavy machinery, ensuring that the equipment remains secure during loading and unloading. This stability reduces the risk of accidents and equipment damage, which is critical in construction environments. Buyers should seek out durable options that can resist harsh weather conditions and support significant weight, particularly in regions prone to extreme climates.

How Do Pneumatic Trailer Jack Wheels Benefit Agricultural Operations?

For agricultural applications, pneumatic trailer jack wheels assist in the movement and stabilization of trailers used for transporting equipment and produce. Their ability to level trailers on uneven ground enhances operational efficiency and minimizes downtime caused by equipment instability. Buyers in the agricultural sector should focus on compatibility with various trailer types and the ability to perform well on different terrains, especially in rural areas where road conditions may vary significantly.

Why Are Pneumatic Trailer Jack Wheels Important for Event Management?

In event management, pneumatic trailer jack wheels are crucial for leveling and stabilizing mobile stages and equipment. Their use ensures safety for performers and attendees, as well as a smooth operational flow during events. For B2B buyers in this sector, the ease of mobility and quick setup capabilities are vital considerations, as events often require rapid changes and adjustments. Selecting jacks that can handle various surface types and provide reliable performance is essential for success.

What Advantages Do Pneumatic Trailer Jack Wheels Offer in Industrial Manufacturing?

Within industrial manufacturing, pneumatic trailer jack wheels support heavy machinery and tools during maintenance and operation. They help prevent accidents and equipment damage by providing a stable base for operations. Buyers in this sector should prioritize high load capacities and ensure that the wheels can withstand the stress of continuous use. Additionally, sourcing options that offer reliable performance under various operational conditions is crucial for maintaining productivity in manufacturing environments.

3 Common User Pain Points for ‘pneumatic trailer jack wheel’ & Their Solutions

Scenario 1: Difficulty in Maneuvering Heavy Trailers on Uneven Terrain

The Problem: Many B2B buyers, particularly those in logistics and transportation, face the challenge of maneuvering heavy trailers on uneven or soft ground. Pneumatic trailer jacks often struggle in these conditions, leading to instability and safety concerns during loading or unloading operations. This situation can result in operational delays, increased labor costs, and potential damage to both the trailer and its contents. Buyers may also find that traditional jacks do not provide adequate lift or mobility, leaving them frustrated and seeking alternatives.

The Solution: To address this issue, buyers should consider pneumatic trailer jacks specifically designed for enhanced stability and mobility. Look for models that feature larger wheels, such as 10″ or 16″ pneumatic wheels, which can distribute weight more evenly and prevent sinking into soft ground. Additionally, incorporating stabilizing accessories like heavy-duty jack blocks can provide added support. When sourcing these jacks, ensure they are rated for the load requirements of your specific trailers. Properly training staff on the correct techniques for using pneumatic jacks in challenging environments will also help mitigate risks and improve efficiency.

Scenario 2: Frequent Maintenance and Downtime Due to Wear and Tear

The Problem: B2B companies often experience frequent maintenance issues with their pneumatic trailer jacks due to wear and tear. This is especially true in industries like construction and agriculture, where equipment is used in rugged conditions. Buyers may find that components such as wheels and casters degrade quickly, leading to unplanned downtime and repair costs that can strain budgets. The challenge lies not just in the replacement of parts but also in ensuring that the replacements are durable and compatible with existing equipment.

The Solution: To minimize maintenance and extend the lifespan of pneumatic trailer jacks, buyers should prioritize sourcing high-quality, durable components. Invest in jacks made from heavy-duty materials, and consider options that offer replaceable parts like wheels and casters. Regularly inspect and maintain these components to catch wear before it leads to failure. When purchasing, inquire about warranty options and the availability of replacement parts to ensure quick repairs. Implementing a preventive maintenance schedule can further reduce the risk of downtime, allowing for proactive care rather than reactive fixes.

Scenario 3: Incompatibility with Existing Equipment and Trailers

The Problem: A significant pain point for B2B buyers is the incompatibility of pneumatic trailer jacks with their existing equipment and trailer designs. Buyers may discover after purchase that the jack does not fit properly or does not provide the necessary height adjustment, which can lead to inefficiencies and safety hazards. This issue is often exacerbated in regions with diverse trailer designs, leading to frustration and wasted investment.

The Solution: To prevent compatibility issues, it is crucial for buyers to conduct thorough research before making a purchase. Begin by cataloging the specifications of your existing trailers, including the inner tube diameter and required lift height. When sourcing pneumatic trailer jacks, look for models that offer adjustable heights and various inner tube sizes to ensure versatility. Engaging with suppliers who provide customization options can also be beneficial. Additionally, consider leveraging 3D modeling or CAD software to visualize how the jack will integrate with your trailers, allowing for better-informed purchasing decisions.

Strategic Material Selection Guide for pneumatic trailer jack wheel

What Are the Key Materials Used in Pneumatic Trailer Jack Wheels?

When selecting pneumatic trailer jack wheels, the choice of material is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials used in the construction of these wheels: rubber, polyurethane, steel, and aluminum. Each material offers distinct properties, advantages, and limitations that can significantly impact performance and suitability for various applications.

How Does Rubber Perform in Pneumatic Trailer Jack Wheels?

Rubber is a traditional choice for pneumatic wheels due to its excellent shock absorption and flexibility. It can withstand a wide range of temperatures and offers good traction on various surfaces. Rubber wheels are typically resistant to wear and tear, making them suitable for heavy-duty applications.

Pros: Rubber wheels are durable and provide excellent grip, which is essential for stability during loading and unloading operations. They are also relatively inexpensive to manufacture.

Cons: However, rubber can degrade over time when exposed to UV light and certain chemicals, which may limit their lifespan in harsh environments. Additionally, they may not perform well in extreme temperatures.

Impact on Application: Rubber wheels are compatible with various media, including water and light oils, but may not be suitable for environments with aggressive chemicals.

Considerations for International Buyers: Compliance with local standards, such as ASTM or DIN, is essential. Buyers should ensure that the rubber used meets specific safety and environmental regulations, particularly in regions with stringent guidelines.

What Are the Benefits of Polyurethane in Pneumatic Trailer Jack Wheels?

Polyurethane is increasingly popular for pneumatic trailer jack wheels due to its superior abrasion resistance and load-bearing capabilities. It can withstand higher temperatures and pressures compared to rubber, making it suitable for demanding applications.

Pros: Polyurethane wheels offer excellent durability and resistance to punctures. They also maintain their shape under heavy loads and provide a smoother ride.

Cons: The manufacturing process for polyurethane can be more complex and costly compared to rubber, which may increase the overall price of the wheels.

Impact on Application: Polyurethane wheels are compatible with a broader range of media, including oils and solvents, making them versatile for various industrial applications.

Considerations for International Buyers: Buyers should verify that the polyurethane materials comply with local regulations and standards, especially in industries that require specific certifications.

How Does Steel Contribute to the Performance of Pneumatic Trailer Jack Wheels?

Steel is often used in the construction of the wheel hub or frame rather than the wheel itself. Its high strength and durability make it an excellent choice for supporting heavy loads.

Pros: Steel wheels can withstand extreme conditions and provide excellent stability. They are also resistant to deformation under heavy loads.

Cons: However, steel is prone to corrosion if not properly coated or treated, which can lead to reduced lifespan in outdoor or humid environments.

Impact on Application: Steel wheels are suitable for heavy-duty applications but may not perform well in corrosive environments unless adequately protected.

Considerations for International Buyers: Buyers should ensure that the steel used complies with international standards for strength and corrosion resistance, particularly in regions with high humidity or salt exposure.

What Role Does Aluminum Play in Pneumatic Trailer Jack Wheels?

Aluminum is favored for its lightweight properties and resistance to corrosion, making it suitable for applications where weight reduction is critical.

Pros: Aluminum wheels are easy to handle and install, and they resist rust and corrosion, making them ideal for outdoor use.

Cons: However, aluminum may not have the same load-bearing capacity as steel, which could limit its use in extremely heavy-duty applications.

Impact on Application: Aluminum wheels are compatible with various media and are particularly advantageous in environments where weight is a concern.

Considerations for International Buyers: Buyers should confirm that the aluminum used meets relevant standards for strength and corrosion resistance, especially in regions with significant temperature fluctuations.

Summary Table of Material Selection for Pneumatic Trailer Jack Wheels

| Material | Typical Use Case for pneumatic trailer jack wheel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General-purpose applications | Excellent shock absorption | Degrades under UV exposure | Low |

| Polyurethane | Heavy-duty industrial applications | Superior abrasion resistance | Higher manufacturing cost | Medium |

| Steel | Heavy load support in harsh environments | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight applications | Corrosion-resistant and lightweight | Lower load-bearing capacity | High |

This strategic material selection guide provides international B2B buyers with a comprehensive overview of the materials used in pneumatic trailer jack wheels, enabling informed decisions that align with specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for pneumatic trailer jack wheel

What Are the Main Stages in the Manufacturing Process of Pneumatic Trailer Jack Wheels?

The manufacturing process of pneumatic trailer jack wheels involves several critical stages, ensuring that the final product meets industry standards and customer expectations. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality raw materials, typically steel or composite materials for the wheel, and rubber or polyurethane for the tire. Suppliers must ensure that these materials meet specific mechanical properties and durability standards. Material testing for tensile strength, fatigue resistance, and wear is common at this stage.

-

Forming: The forming stage involves shaping the raw materials into the desired components. For steel wheels, processes such as stamping, forging, or machining are employed to achieve precise dimensions. For rubber or polyurethane tires, molding techniques, including injection molding or compression molding, are used. This stage is crucial for ensuring that all components fit together seamlessly.

-

Assembly: After forming, components are assembled. This includes attaching the tire to the wheel and integrating any necessary hardware, such as bearings or axles. Assembly is often performed in a controlled environment to prevent contamination and ensure accuracy. Automated assembly lines may be used for efficiency, but skilled labor is also essential for quality assurance.

-

Finishing: The finishing stage includes surface treatments such as powder coating or galvanization to enhance corrosion resistance and aesthetics. Quality checks are performed during this stage to ensure that the finish meets specifications. This can involve visual inspections and tests for adhesion and thickness of coatings.

How Is Quality Assurance Integrated into the Manufacturing of Pneumatic Trailer Jack Wheels?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that products meet international standards and customer requirements. Various QA methodologies and checkpoints are integrated throughout the production process.

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines the criteria for a quality management system. Compliance with this standard indicates that a manufacturer has established processes for consistent quality and continuous improvement. Other relevant standards include CE marking for European markets and API standards for products used in the oil and gas industry.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to verify they meet specified requirements. Testing may include dimensional checks and material property assessments.

– In-Process Quality Control (IPQC): During the manufacturing process, IPQC involves ongoing inspections and tests to monitor the quality of products as they are being produced. This can include measuring tolerances, checking assembly accuracy, and ensuring that finishing processes are correctly applied.

– Final Quality Control (FQC): After assembly and finishing, FQC involves comprehensive testing of the completed pneumatic trailer jack wheels. Common tests include load capacity assessments, durability testing, and functional checks to ensure the product performs as intended.

What Common Testing Methods Are Used to Ensure Quality in Pneumatic Trailer Jack Wheels?

To guarantee the reliability and performance of pneumatic trailer jack wheels, manufacturers employ various testing methods:

-

Load Testing: This method assesses the wheel’s ability to bear weight without deforming or failing. It simulates real-world conditions to ensure safety and reliability.

-

Durability Testing: This involves subjecting the wheel to repeated cycles of use to evaluate how it holds up over time. This testing is crucial in identifying potential failure points that may not be apparent through visual inspections.

-

Environmental Testing: Wheels are often tested for performance under various environmental conditions, including extreme temperatures, humidity, and exposure to chemicals. This helps ensure that the product will perform reliably in different climates and conditions.

-

Vibration Testing: This method assesses the wheel’s stability and integrity under dynamic conditions, simulating the stresses it would encounter during transport.

How Can B2B Buyers Verify Supplier Quality Control Processes?

International B2B buyers need to ensure that their suppliers maintain robust quality control processes. Here are some strategies to verify supplier QC:

-

Audits: Conducting on-site audits of suppliers allows buyers to review manufacturing processes and quality control measures firsthand. This includes checking for adherence to international standards and internal QA protocols.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes. These reports should include data from IQC, IPQC, and FQC stages, as well as results from various testing methods.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of supplier quality control measures. These agencies can conduct audits and testing to verify compliance with industry standards.

-

Certifications and Accreditations: Buyers should look for suppliers that hold relevant certifications, such as ISO 9001, and check their validity. These certifications indicate that the supplier has implemented a quality management system and adheres to recognized standards.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential:

-

Regulatory Compliance: Buyers must be aware of the regulatory requirements specific to their region. Different countries may have varying standards for safety, environmental impact, and performance. Ensuring suppliers comply with these regulations is crucial for market entry.

-

Cultural Considerations: Different regions may have distinct approaches to quality control. Understanding these cultural nuances can help buyers communicate effectively with suppliers and align expectations regarding product quality.

-

Supply Chain Transparency: Ensuring transparency in the supply chain is vital for maintaining quality. Buyers should establish clear communication with suppliers about their QC processes and any potential challenges in the supply chain that may affect product quality.

-

Long-Term Partnerships: Building long-term relationships with reliable suppliers can enhance quality assurance. Regular communication and collaboration can lead to continuous improvements in product quality and compliance with international standards.

In summary, the manufacturing processes and quality assurance mechanisms for pneumatic trailer jack wheels are intricate and vital for ensuring product reliability and safety. B2B buyers must engage in thorough verification and due diligence to select suppliers that adhere to stringent quality standards. By understanding the manufacturing stages, quality checkpoints, and testing methods, international buyers can make informed decisions and foster successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pneumatic trailer jack wheel’

In the competitive landscape of B2B procurement, sourcing a pneumatic trailer jack wheel requires a strategic approach. This guide outlines essential steps to ensure you make informed decisions, effectively manage costs, and secure high-quality products tailored to your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s critical to clearly outline your technical requirements for the pneumatic trailer jack wheel. Consider factors such as weight capacity, wheel size, material durability, and compatibility with existing equipment. Establishing these specifications will help streamline the selection process and prevent costly misalignments later on.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing dynamics is vital for effective sourcing. Conduct thorough market research to identify average costs, emerging technologies, and supplier capabilities. Pay attention to regional variations, especially if sourcing from international suppliers, as prices can fluctuate based on local demand and availability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a comprehensive evaluation. Look for established companies with a solid reputation in the industry. Request detailed company profiles, references, and case studies from buyers in similar sectors. This step ensures that you choose a reliable partner who can meet your quality and delivery expectations.

Step 4: Verify Supplier Certifications and Compliance

Ensure that potential suppliers adhere to relevant industry standards and regulations. Request documentation proving compliance with safety and quality certifications, such as ISO or CE markings. This verification process minimizes risks associated with substandard products and guarantees that you are sourcing from reputable manufacturers.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the pneumatic trailer jack wheel from shortlisted suppliers. Testing samples allows you to evaluate performance, durability, and compatibility with your existing equipment. This hands-on approach can highlight potential issues early and save you from costly returns or replacements later.

Step 6: Negotiate Terms and Conditions

Once you have identified a preferred supplier, initiate negotiations on pricing, payment terms, and delivery schedules. Clearly outline your expectations regarding warranty, after-sales service, and support. Effective negotiation can lead to better pricing and improved terms that can enhance your overall procurement strategy.

Step 7: Establish a Quality Control Process

Implementing a quality control process is essential to ensure that the pneumatic trailer jack wheels meet your specifications upon delivery. Develop criteria for inspection and testing upon receipt, and communicate these standards to your supplier. This step helps maintain quality assurance and can prevent future disputes over product quality.

By following this checklist, B2B buyers can navigate the complexities of sourcing pneumatic trailer jack wheels more effectively, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for pneumatic trailer jack wheel Sourcing

What Are the Key Cost Components in Sourcing Pneumatic Trailer Jack Wheels?

When analyzing the cost structure for pneumatic trailer jack wheels, several components contribute to the overall pricing. The primary cost factors include:

-

Materials: The choice of materials significantly affects the cost. High-quality steel or aluminum for durability can increase the price but provides better longevity and performance. Additionally, the type of wheel, such as pneumatic versus semi-pneumatic, influences material costs.

-

Labor: Labor costs vary based on geographic location and the complexity of the manufacturing process. Regions with higher labor costs, such as parts of Europe, may see a higher overall price. Conversely, sourcing from countries with lower labor costs, like Vietnam or certain African nations, can lead to significant savings.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Manufacturers with advanced machinery may have higher overhead costs, but they often achieve better quality and efficiency.

-

Tooling: Initial costs for tooling can be substantial, particularly for custom designs. However, these costs are amortized over larger production runs, making them less significant for bulk orders.

-

Quality Control (QC): Implementing stringent quality control measures adds to the cost but is essential for ensuring product reliability. Certifications like ISO can also increase costs but provide assurance of quality to buyers.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as distance, shipping method (air vs. sea), and customs duties can significantly affect the total cost.

-

Margin: Suppliers will add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on the supplier’s positioning in the market.

How Do Price Influencers Affect the Cost of Pneumatic Trailer Jack Wheels?

Several factors can influence the pricing of pneumatic trailer jack wheels:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts. Understanding the MOQ can help buyers negotiate better pricing, especially for bulk purchases.

-

Specifications and Customization: Custom features, such as specific load capacities or wheel sizes, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and relevant certifications can raise initial costs but may lead to lower maintenance expenses and longer product life, ultimately contributing to a lower Total Cost of Ownership (TCO).

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a track record of quality may charge more, but they offer peace of mind regarding performance and after-sales support.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) affect who bears the shipping costs and risks. Understanding these terms is crucial for calculating the total landed cost of products.

What Are the Best Practices for Negotiating Pneumatic Trailer Jack Wheel Prices?

B2B buyers can adopt several strategies to ensure cost efficiency when sourcing pneumatic trailer jack wheels:

-

Negotiate Based on Volume: Always leverage order size in negotiations. Suppliers are often willing to offer discounts for larger volumes.

-

Evaluate Total Cost of Ownership (TCO): Assess not just the purchase price but also potential costs related to maintenance, replacement, and operational efficiency.

-

Research Market Prices: Familiarize yourself with market rates and competitor pricing to strengthen your negotiation position. Knowledge of the market can help you identify fair pricing and spot overpriced offers.

-

Consider Long-Term Relationships: Building a long-term relationship with a supplier can lead to better pricing and terms over time. Loyalty can also result in priority treatment in inventory shortages or production delays.

-

Be Aware of Pricing Nuances for International Sourcing: Different regions have unique market conditions, regulations, and shipping costs. Buyers from Africa, South America, the Middle East, and Europe should take these factors into account when sourcing to avoid unforeseen expenses.

Conclusion

Navigating the cost and pricing landscape for pneumatic trailer jack wheels requires an understanding of multiple influencing factors. By focusing on the key components, leveraging volume discounts, and understanding the implications of Incoterms, B2B buyers can make informed decisions that lead to cost-effective sourcing. Always remember that the cheapest option may not always be the best in terms of quality and longevity, ultimately affecting the Total Cost of Ownership.

Alternatives Analysis: Comparing pneumatic trailer jack wheel With Other Solutions

Exploring Alternatives to Pneumatic Trailer Jack Wheels

In the realm of trailer handling and stabilization, selecting the right solution can significantly impact operational efficiency and safety. While pneumatic trailer jack wheels are a popular choice due to their adaptability and ease of movement, several alternative solutions also provide viable options for B2B buyers. This section will compare pneumatic trailer jack wheels with traditional hand crank jacks and electric trailer jacks, highlighting their respective strengths and weaknesses.

| Comparison Aspect | Pneumatic Trailer Jack Wheel | Hand Crank Jack | Electric Trailer Jack |

|---|---|---|---|

| Performance | Excellent for maneuverability and stability on uneven surfaces | Good for stability but requires manual effort | High lifting capacity with minimal effort |

| Cost | Moderate ($150-$500) | Low to moderate ($50-$300) | High ($500-$1,500) |

| Ease of Implementation | Easy to attach and use; requires no special training | Simple installation; requires manual operation | Requires electrical setup and may need professional installation |

| Maintenance | Low maintenance; occasional tire inflation needed | Minimal maintenance; check for wear | Higher maintenance; electrical components may require servicing |

| Best Use Case | Ideal for frequent trailer repositioning and leveling on various terrains | Suitable for occasional use in stable environments | Best for heavy-duty applications requiring frequent lifts |

What Are the Pros and Cons of Hand Crank Jacks?

Hand crank jacks are a longstanding alternative to pneumatic trailer jack wheels. They are generally less expensive and straightforward to operate, making them accessible for users with limited budgets or technical skills. However, their manual nature means they require physical effort, which can be a drawback in high-volume operations or for users with mobility issues. Additionally, while they are reliable, hand crank jacks may not provide the same level of maneuverability on uneven terrain compared to pneumatic options.

How Do Electric Trailer Jacks Compare?

Electric trailer jacks represent a modern solution for trailer lifting and stabilization. They offer significant advantages in terms of speed and convenience, allowing operators to lift and lower trailers with the push of a button. This reduces physical strain and increases efficiency, especially in commercial settings where trailers are frequently loaded and unloaded. However, the higher upfront cost and the need for an electrical power source can be limiting factors for some businesses. Additionally, electric systems may require more maintenance due to their complex components.

Conclusion: How to Choose the Right Trailer Jack Solution for Your Business?

Selecting the appropriate trailer jack solution depends on various factors, including budget, operational needs, and the specific environments in which you operate. For businesses requiring high maneuverability and adaptability across diverse terrains, pneumatic trailer jack wheels may be the most suitable choice. Conversely, those seeking cost-effective, low-maintenance solutions for less demanding applications might find hand crank jacks adequate. Meanwhile, electric trailer jacks are ideal for heavy-duty operations where efficiency and ease of use are paramount. Evaluating these aspects will enable B2B buyers to make informed decisions that align with their operational goals and constraints.

Essential Technical Properties and Trade Terminology for pneumatic trailer jack wheel

What Are the Key Technical Properties of Pneumatic Trailer Jack Wheels?

When selecting pneumatic trailer jack wheels, understanding their essential technical properties is crucial for ensuring safety, efficiency, and compatibility with your equipment. Here are several key specifications that every B2B buyer should consider:

-

Material Grade

– Pneumatic trailer jack wheels are typically made from high-grade materials such as steel or durable polymers. Steel offers strength and durability, making it ideal for heavy loads. The choice of material impacts the wheel’s longevity and load-bearing capacity, which is vital for operational safety. -

Load Capacity

– This specification indicates the maximum weight a jack wheel can support. Pneumatic wheels often come with load ratings ranging from a few thousand to over 50,000 lbs. Ensuring that the load capacity matches or exceeds the requirements of your trailers will prevent equipment failure and enhance safety during operation. -

Wheel Diameter

– The size of the wheel significantly influences maneuverability and stability. Common diameters range from 6 to 16 inches. Larger wheels generally provide better traction and stability on uneven surfaces, which is particularly beneficial in varied terrains found in regions like Africa and South America. -

Tread Design

– The tread pattern on pneumatic wheels affects grip and performance. Wheels with deep treads are better suited for off-road conditions, while smoother treads are ideal for paved surfaces. Selecting the right tread design can optimize performance based on your operational environment. -

Pneumatic vs. Semi-Pneumatic

– Pneumatic wheels are filled with air, providing cushioning and shock absorption, which is essential for transporting sensitive equipment. Semi-pneumatic wheels, on the other hand, are solid but designed to mimic the benefits of air-filled wheels. Understanding this distinction helps in selecting the right type for your specific needs. -

Height Adjustment Range

– Some pneumatic trailer jacks offer adjustable height ranges, allowing for better leveling and stability. This feature is particularly useful when dealing with uneven ground or when loading and unloading cargo, ensuring that the trailer remains stable during operations.

What Are Common Trade Terms Related to Pneumatic Trailer Jack Wheels?

Familiarity with industry-specific terminology can streamline the purchasing process and facilitate better communication with suppliers. Here are some common trade terms you should know:

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is critical for ensuring compatibility with existing trailer systems. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ can help in budgeting and inventory management, especially for businesses planning to scale operations. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price bids from suppliers. It is essential for comparing costs and terms from different manufacturers, ensuring that you receive the best value for your investment. -

Incoterms (International Commercial Terms)

– These are pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms can help in negotiating shipping, insurance, and liability terms, ensuring a smoother transaction. -

Lead Time

– This term refers to the time taken from placing an order to receiving it. Understanding lead times is vital for effective project planning and inventory management, especially in regions where logistics can be challenging. -

Static Load Capacity

– This indicates the maximum weight a jack can support without moving. It’s essential for ensuring that the jack can safely hold the trailer in place during loading or unloading operations, especially in high-capacity applications.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when purchasing pneumatic trailer jack wheels, ensuring they meet their operational needs effectively and safely.

Navigating Market Dynamics and Sourcing Trends in the pneumatic trailer jack wheel Sector

Global drivers and trends in the pneumatic trailer jack wheel market reflect a dynamic interplay between technological advancements, evolving consumer demands, and regulatory pressures. One key driver is the growing emphasis on operational efficiency in logistics and transportation sectors across Africa, South America, the Middle East, and Europe. This has led to increased investments in high-quality pneumatic trailer jack wheels, which enhance mobility and stability during loading and unloading operations.

Emerging technologies, such as smart sensors and IoT integration, are transforming traditional pneumatic trailer jack systems into more sophisticated solutions that can monitor performance and provide real-time data to operators. This trend is particularly relevant for B2B buyers looking to optimize their fleet management and reduce downtime. Additionally, automation in manufacturing processes is leading to cost reductions, making pneumatic trailer jack wheels more accessible to a broader range of businesses.

Furthermore, the market is experiencing a shift towards customization and modular designs that cater to specific operational needs, particularly in regions where terrain can vary significantly. This adaptability is crucial for buyers in diverse markets, ensuring they can select solutions that are tailored to their unique challenges, from uneven ground in Nigeria to the infrastructure demands in Vietnam.

How is Sustainability Impacting Sourcing Decisions in the Pneumatic Trailer Jack Wheel Sector?

Sustainability and ethical sourcing are increasingly influencing procurement strategies within the pneumatic trailer jack wheel sector. Environmental impact considerations are prompting businesses to seek suppliers that prioritize eco-friendly manufacturing processes. This includes the use of recycled materials and energy-efficient production methods, which not only reduce the carbon footprint but also align with the growing consumer demand for sustainable products.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are increasingly scrutinizing their suppliers’ practices to ensure compliance with labor standards and environmental regulations. Certifications such as ISO 14001 for environmental management and Fair Trade are becoming critical criteria in supplier selection, enhancing brand reputation and consumer trust.

In this context, manufacturers are responding by investing in ‘green’ certifications and utilizing sustainable materials in their pneumatic trailer jack wheel products. These practices not only meet regulatory requirements but also resonate with environmentally-conscious buyers, creating a competitive edge in the global marketplace.

What is the Historical Context Behind Pneumatic Trailer Jack Wheels?

The evolution of pneumatic trailer jack wheels can be traced back to the early 20th century, when the need for improved mobility and stability in transportation became apparent. Initially, trailer jacks were simple mechanical devices, but as the logistics industry evolved, so did the technology behind these tools. The introduction of pneumatic wheels marked a significant advancement, providing enhanced cushioning and support, particularly on uneven surfaces.

Over the decades, innovations such as adjustable height features and lightweight materials have transformed pneumatic trailer jacks into essential tools for modern transportation and logistics operations. Today, these jacks are integral to the efficiency and safety of loading and unloading processes, reflecting the ongoing demand for reliability and performance in an increasingly competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of pneumatic trailer jack wheel

-

How do I choose the right pneumatic trailer jack wheel for my needs?

Selecting the appropriate pneumatic trailer jack wheel involves considering several factors. First, assess the weight capacity required for your application; options typically range from 2,000 lbs to 50,000 lbs. Next, evaluate the wheel size; larger wheels provide better stability and ease of movement, especially on uneven surfaces. Additionally, consider the material of the wheel, as pneumatic wheels are ideal for soft ground but may require durable materials for heavy-duty use. Finally, check if the design meets your operational needs, such as swivel features for maneuverability. -

What are the advantages of using pneumatic trailer jack wheels over solid wheels?

Pneumatic trailer jack wheels offer several advantages, particularly in terms of mobility and shock absorption. Their air-filled design allows for better traction and smoother movement over rough or uneven terrains, reducing the risk of damage to both the trailer and the surface beneath. They are also less likely to get stuck in soft ground compared to solid wheels, making them ideal for outdoor applications. However, they may require more maintenance due to potential punctures, so consider your operational environment when making a choice. -

What customization options are available for pneumatic trailer jack wheels?

Many suppliers offer customization options for pneumatic trailer jack wheels to meet specific operational needs. Customization can include variations in wheel diameter, tread patterns, load capacities, and materials used in construction. Some manufacturers may also provide options for specific mounting configurations to fit different types of trailers. When considering customization, communicate your requirements clearly with suppliers to ensure they can accommodate your needs effectively. -

What is the minimum order quantity (MOQ) for pneumatic trailer jack wheels?

The minimum order quantity (MOQ) for pneumatic trailer jack wheels can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from as low as 10 units to several hundred. When sourcing, it’s essential to discuss the MOQ upfront with potential suppliers, especially if you are a small or medium-sized business. Some suppliers may offer flexibility in MOQs for first-time buyers or bulk orders, so negotiating terms can be beneficial. -

How can I vet suppliers of pneumatic trailer jack wheels?

To effectively vet suppliers, start by researching their reputation in the industry. Look for reviews and testimonials from other businesses that have sourced similar products. Verify their certifications and compliance with international quality standards, such as ISO. Request samples to assess product quality firsthand. Additionally, check their manufacturing capabilities and lead times to ensure they can meet your demand. Engaging in direct communication and asking specific questions about their processes will also help gauge their reliability. -

What payment terms should I expect when purchasing pneumatic trailer jack wheels internationally?

Payment terms for international purchases of pneumatic trailer jack wheels can vary by supplier and region. Common terms include payment in advance, partial payment upon order confirmation, or net 30/60 days after delivery. It’s crucial to clarify these terms before finalizing any agreements. Utilizing secure payment methods, such as letters of credit or escrow services, can provide additional security for large transactions. Always ensure that payment terms align with your cash flow needs and operational timelines. -

What quality assurance measures should I look for in pneumatic trailer jack wheels?

When sourcing pneumatic trailer jack wheels, inquire about the supplier’s quality assurance (QA) processes. Look for suppliers who conduct regular inspections and testing of their products to ensure they meet specified load capacities and performance standards. Certifications such as ISO 9001 can indicate a commitment to quality management. Additionally, ask about warranty policies and post-sale support, as these can be crucial in addressing any quality-related issues after purchase. -

What logistics considerations should I keep in mind when importing pneumatic trailer jack wheels?

When importing pneumatic trailer jack wheels, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate whether air or sea freight is more cost-effective for your shipment size and urgency. Understand the customs duties and tariffs applicable to your products in your country. Collaborate with a freight forwarder who can help navigate the complexities of international shipping and ensure compliance with import regulations. Proper planning will minimize delays and additional costs, ensuring a smoother supply chain process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Pneumatic Trailer Jack Wheel Manufacturers & Suppliers List

1. Access Casters – Hamilton Dual Wheel Pneumatic Casters

Domain: accesscasters.com

Registered: 2003 (22 years)

Introduction: Hamilton Dual Wheel Pneumatic Casters

2. Croft Trailer – Jack Foot for A-Frame Stability

Domain: crofttrailer.com

Registered: 1997 (28 years)

Introduction: This company, Croft Trailer – Jack Foot for A-Frame Stability, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

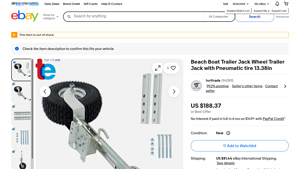

3. turitrade – Beach Boat Trailer Jack Wheel

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”: “Beach Boat Trailer Jack Wheel”, “brand”: “turitrade”, “wheel_diameter”: “13.38in”, “condition”: “New”, “price”: “$188.37”, “shipping”: “Free shipping”, “estimated_delivery”: “Wed, Sep 10 – Sat, Sep 13”, “item_number”: “297472708264”, “UPC”: “Does not apply”}

4. iBoats – Trailer Jack Upgrade

Domain: forums.iboats.com

Registered: 1998 (27 years)

Introduction: This company, iBoats – Trailer Jack Upgrade, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. 4State Trucks – Caster Assembly with 10 Inch Pneumatic Swivel Wheel

Domain: 4statetrucks.com

Registered: 1998 (27 years)

Introduction: Caster Assembly with 10 Inch Pneumatic Swivel Wheel for Premier Trailer Jack 600, 700 Series

Strategic Sourcing Conclusion and Outlook for pneumatic trailer jack wheel

In the dynamic landscape of logistics and transport, the significance of pneumatic trailer jack wheels cannot be overstated. Their ability to enhance mobility, stability, and safety during loading and unloading operations is crucial for international businesses operating in diverse environments. Strategic sourcing of these essential components allows companies to not only secure high-quality products but also to leverage cost efficiencies and build long-term supplier relationships.

As global supply chains evolve, buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers that offer innovative solutions and robust support. Investing in advanced pneumatic trailer jack wheels can lead to significant operational improvements, reducing downtime and increasing productivity.

Looking ahead, the demand for reliable and efficient trailer jacks is expected to grow, driven by expanding trade and logistics requirements. Now is the time for international buyers to engage with trusted suppliers and explore advanced offerings that align with their operational needs. By making informed purchasing decisions, businesses can enhance their competitive edge and drive success in their respective markets.