Top 7 Fresnel Lens For Sale Suppliers (And How to Choose)

Introduction: Navigating the Global Market for fresnel lens for sale

The global market for Fresnel lenses for sale presents unique challenges for B2B buyers, particularly when it comes to sourcing high-quality products that meet specific application requirements. As industries across Africa, South America, the Middle East, and Europe increasingly rely on innovative optical solutions, the demand for versatile Fresnel lenses—used in everything from solar power applications to lighting and projection systems—continues to rise. However, navigating this diverse marketplace can be daunting, given the variety of lens types, materials, and custom options available.

This comprehensive guide aims to empower international B2B buyers by providing actionable insights into the Fresnel lens market. We will explore the different types of Fresnel lenses, such as custom and stock options, and their applications across various industries. Additionally, we will cover essential factors to consider when vetting suppliers, including quality assurance certifications, material specifications, and pricing structures. By equipping buyers with the knowledge needed to make informed purchasing decisions, this guide seeks to streamline the sourcing process and enhance supply chain efficiency.

Whether you are a manufacturer in Saudi Arabia looking to integrate Fresnel lenses into your products, or a retailer in Brazil seeking to offer innovative solutions to your customers, this guide will serve as an invaluable resource for navigating the complexities of the global Fresnel lens market.

Understanding fresnel lens for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Fresnel Lens | Basic design, available in various sizes | Projectors, basic lighting systems | Pros: Cost-effective, lightweight. Cons: Limited optical clarity compared to precision lenses. |

| Precision Fresnel Lens | Tight tolerances, improved surface quality | High-end optical instruments, simulators | Pros: Superior image quality, tailored specifications. Cons: Higher cost, longer lead times. |

| Cylindrical Fresnel Lens | Unique cylindrical shape for specific light distribution | Solar applications, barcode scanners | Pros: Effective for specific applications, customizable sizes. Cons: May require specialized mounting. |

| XL Fresnel Lens | Large area, flexible material, lightweight | Solar cooking, outdoor applications | Pros: Portable, versatile for various uses. Cons: High focal temperature can pose safety risks. |

| Glass Fresnel Lens | Durable, excellent optical clarity | Lighthouses, high-quality projection systems | Pros: Long-lasting, superior performance. Cons: Heavier, more expensive than plastic options. |

What are Standard Fresnel Lenses and Their Applications?

Standard Fresnel lenses are characterized by their basic design and availability in various sizes. These lenses are commonly used in projectors and basic lighting systems where cost-effectiveness and lightweight properties are essential. While they are ideal for general applications, buyers should note that they offer limited optical clarity, making them less suitable for precision tasks.

How Do Precision Fresnel Lenses Stand Out?

Precision Fresnel lenses feature tight tolerances and improved surface quality, making them ideal for high-end optical instruments and simulators. These lenses can be customized to meet specific requirements, ensuring superior image quality. However, buyers should be prepared for a higher cost and potentially longer lead times when ordering these specialized lenses.

What Are the Benefits of Using Cylindrical Fresnel Lenses?

Cylindrical Fresnel lenses are designed for specific light distribution needs, making them particularly useful in solar applications and barcode scanners. Their unique cylindrical shape allows for effective light manipulation, and they can be customized to various sizes. However, buyers may need to consider specialized mounting solutions for optimal performance.

Why Choose XL Fresnel Lenses for Outdoor Applications?

XL Fresnel lenses are notable for their large surface area and lightweight, flexible design. They are particularly popular in solar cooking and outdoor applications due to their portability and versatility. However, caution is advised, as these lenses can reach high focal temperatures, which may pose safety risks if not handled properly.

What Are the Advantages of Glass Fresnel Lenses?

Glass Fresnel lenses are recognized for their durability and excellent optical clarity, making them suitable for critical applications like lighthouses and high-quality projection systems. While they offer superior performance and longevity, buyers must consider that glass lenses are generally heavier and more expensive than their plastic counterparts, which may affect transportation and installation.

Key Industrial Applications of fresnel lens for sale

| Industry/Sector | Specific Application of fresnel lens for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Solar Energy | Concentrating solar power systems | Increased energy efficiency and reduced costs | Material type (glass vs. plastic), focal length, size |

| Lighting Solutions | Theatre and architectural lighting | Enhanced light distribution and control | Customization options, quality assurance, and durability |

| Optical Instruments | Projectors and imaging systems | Improved image clarity and reduced weight | Precision specifications, coatings, and dimensions |

| Consumer Electronics | Magnifiers for electronic devices | Lightweight design for portability and ease of use | Material choice, thickness, and focal distance |

| Safety and Navigation | Lighthouse applications | Long-range visibility and safety for maritime navigation | Compliance with international standards, durability |

How Are Fresnel Lenses Used in Solar Energy Applications?

In the solar energy sector, Fresnel lenses are integral to concentrating solar power (CSP) systems. These lenses focus sunlight onto a small area, significantly improving energy collection efficiency. For international buyers, especially in regions with high solar potential like Africa and South America, sourcing Fresnel lenses requires attention to material durability and the lens’s focal length to ensure optimal performance in varying environmental conditions. Additionally, understanding local regulations regarding solar installations is crucial for compliance.

What Role Do Fresnel Lenses Play in Lighting Solutions?

Fresnel lenses are widely used in theatre and architectural lighting to achieve precise light distribution. Their unique design allows for a compact solution that enhances light control, making them ideal for stage performances and architectural features. B2B buyers in Europe and the Middle East should consider customization options, such as anti-reflective coatings, to enhance performance. Furthermore, the quality assurance processes in lens production are vital to ensure consistent lighting outcomes, which can affect event quality and audience experience.

How Are Fresnel Lenses Beneficial for Optical Instruments?

In the realm of optical instruments, Fresnel lenses are utilized in projectors and imaging systems. Their lightweight and thin profile allow for easier integration into devices while maintaining clarity. Buyers from various regions, including Europe and the Middle East, must prioritize precision specifications and quality assurance to meet stringent optical standards. Additionally, custom coatings can improve performance, making it essential for buyers to engage with suppliers that offer tailored solutions.

What Are the Applications of Fresnel Lenses in Consumer Electronics?

Fresnel lenses are commonly used in magnifiers for electronic devices, providing a lightweight and portable solution for users. Their thin design makes them ideal for handheld devices, enhancing user experience without adding bulk. For international buyers, especially in fast-growing markets in Africa and South America, sourcing options should include considerations for material type and thickness to ensure durability and performance. This is particularly important in regions where devices may be exposed to varying climatic conditions.

How Do Fresnel Lenses Enhance Safety in Navigation?

In maritime navigation, Fresnel lenses are critical components of lighthouses, enhancing visibility over long distances. Their design allows for the efficient projection of light, which is vital for safe navigation. Buyers in the Middle East and Europe should ensure that sourced lenses comply with international standards for safety and durability. Understanding the operational environment and potential weather impacts on lens performance is also essential for maintaining navigational safety.

3 Common User Pain Points for ‘fresnel lens for sale’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Fresnel Lenses

The Problem: B2B buyers, especially those in emerging markets like Africa and South America, often face challenges in sourcing high-quality Fresnel lenses. Many suppliers may not offer the same stringent quality checks or certifications, leading to concerns about the durability and optical performance of the lenses. This lack of consistency can result in project delays and increased costs if lenses fail to meet specifications after purchase.

The Solution: To ensure the procurement of high-quality Fresnel lenses, buyers should prioritize suppliers that are ISO certified and have a robust quality assurance process in place. It’s advisable to request product samples before placing bulk orders, allowing for physical inspection of the lens quality. Additionally, leveraging global suppliers with a proven track record in custom optical solutions can mitigate risks. Buyers should also utilize online platforms to compare specifications, customer reviews, and case studies, which can provide insights into the reliability of different vendors. Establishing long-term relationships with reputable suppliers can facilitate smoother transactions and better pricing over time.

Scenario 2: Uncertainty in Selecting the Right Fresnel Lens Specifications

The Problem: Many B2B buyers struggle with the technical specifications of Fresnel lenses, such as focal length, diameter, and material types. This uncertainty can lead to selecting a lens that is unsuitable for their application, resulting in suboptimal performance and wasted resources. This is particularly critical for industries that require precision optics, such as solar energy or advanced lighting systems.

The Solution: Buyers should engage in a thorough needs assessment before purchasing Fresnel lenses. This involves clearly defining the application requirements, such as light concentration needs, environmental conditions, and weight constraints. Consulting with technical sales teams or optical engineers from suppliers can provide valuable insights into the ideal specifications for their specific use case. Additionally, investing in simulation software or prototyping tools can help buyers visualize how different lenses will perform in their applications. For complex projects, consider requesting custom lens designs that align with precise operational needs, ensuring optimal functionality.

Scenario 3: Managing Costs and Logistics for Fresnel Lens Purchases

The Problem: For international buyers, particularly from regions like the Middle East or Europe, the logistics of importing Fresnel lenses can be daunting. Fluctuating shipping costs, potential customs duties, and lead times can significantly impact project budgets and timelines. Moreover, unforeseen delays can lead to operational bottlenecks and disrupt planned activities.

The Solution: To manage costs and logistics effectively, B2B buyers should explore local suppliers or distributors who can provide Fresnel lenses at competitive prices without the added burden of international shipping. Establishing a clear understanding of shipping terms, including Incoterms, can help buyers anticipate additional costs. Furthermore, negotiating bulk purchasing agreements can lead to better pricing and reduced shipping frequency, which can streamline logistics. Buyers should also consider utilizing supply chain management software to monitor inventory levels and track order statuses, ensuring that they are prepared for any potential delays. Building strategic partnerships with logistics providers can also enhance efficiency, reducing lead times and minimizing disruptions to operations.

Strategic Material Selection Guide for fresnel lens for sale

What Are the Key Materials for Fresnel Lenses in B2B Applications?

Fresnel lenses are engineered from various materials, each offering distinct properties that influence their performance and suitability for specific applications. Understanding these materials is crucial for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, where diverse environmental and regulatory factors come into play.

How Do Acrylic Fresnel Lenses Perform?

Acrylic, or PMMA (Polymethyl Methacrylate), is one of the most common materials used for Fresnel lenses. It is lightweight and offers good optical clarity, making it suitable for applications like solar concentrators and portable magnifiers. Acrylic lenses can typically withstand temperatures up to 80°C and are resistant to UV light, which helps maintain their clarity over time.

Pros: Acrylic lenses are cost-effective, easy to manufacture, and can be produced in large sizes. They are also shatter-resistant, making them ideal for outdoor applications.

Cons: However, acrylic is less durable than glass and can scratch easily. Its lower temperature tolerance may limit its use in high-heat applications.

Impact on Application: Acrylic lenses are often used in solar energy applications due to their lightweight nature, making them easier to handle and install. However, they may not be suitable for high-pressure environments.

Considerations for International Buyers: Compliance with standards such as ASTM and ISO is critical. Buyers should ensure that the acrylic used meets relevant safety and performance specifications, especially in regions with stringent regulations.

What Are the Benefits of Glass Fresnel Lenses?

Glass Fresnel lenses are known for their superior optical clarity and durability. They can withstand higher temperatures (up to 200°C) and are resistant to scratches and chemicals, making them suitable for more demanding applications, such as high-quality projectors and lighthouses.

Pros: Glass lenses provide excellent light transmission and can be manufactured to high precision, which is essential for applications requiring clear and focused light.

Cons: The primary downside is their weight and fragility compared to plastic options. They are also more expensive to produce and transport.

Impact on Application: Glass Fresnel lenses are ideal for applications where optical quality is paramount. However, their weight may pose challenges in portable applications.

Considerations for International Buyers: Buyers must be aware of shipping regulations concerning fragile items and ensure compliance with local standards for safety and performance.

How Do Polycarbonate Fresnel Lenses Compare?

Polycarbonate is another popular material for Fresnel lenses, known for its high impact resistance and lightweight properties. It can withstand temperatures up to 120°C and is often used in applications where durability is critical.

Pros: Polycarbonate lenses are shatterproof and resistant to UV radiation, making them suitable for outdoor applications. They are also more affordable than glass.

Cons: However, polycarbonate lenses can be prone to scratching and may not provide the same level of optical clarity as glass.

Impact on Application: These lenses are commonly used in safety equipment and consumer products due to their robustness. However, their optical performance may limit their use in high-end applications.

Considerations for International Buyers: Buyers should verify that polycarbonate lenses meet relevant safety standards, particularly in industries like automotive and consumer electronics.

What About Specialty Materials for Fresnel Lenses?

Specialty materials, such as silicone or custom-engineered polymers, are also available for specific applications. These materials can offer unique properties such as flexibility or enhanced thermal resistance.

Pros: Specialty materials can be tailored to meet specific application needs, providing innovative solutions for niche markets.

Cons: They often come at a higher cost and may require longer lead times for production.

Impact on Application: These materials are ideal for specialized applications, such as medical devices or advanced optical systems, where standard materials may not suffice.

Considerations for International Buyers: Buyers should engage with suppliers to understand the specific properties of these materials and ensure they meet industry standards.

Summary Table of Fresnel Lens Materials

| Material | Typical Use Case for fresnel lens for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Solar concentrators, portable magnifiers | Lightweight and cost-effective | Scratches easily, lower durability | Low |

| Glass | High-quality projectors, lighthouses | Superior optical clarity | Heavy and fragile | High |

| Polycarbonate | Safety equipment, consumer products | High impact resistance | Prone to scratching | Medium |

| Specialty Materials | Medical devices, advanced optics | Tailored properties | Higher cost and longer lead times | High |

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions regarding the material selection for Fresnel lenses, ensuring compatibility with their specific applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fresnel lens for sale

What Are the Key Stages in the Manufacturing Process of Fresnel Lenses?

The manufacturing of Fresnel lenses is a multi-stage process that requires precision and adherence to quality standards. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers.

1. Material Preparation: What Materials Are Used for Fresnel Lenses?

Fresnel lenses can be constructed from various materials, primarily PMMA (acrylic), polycarbonate, and glass. The choice of material impacts the lens’s optical properties, weight, and durability. The material preparation stage involves sourcing high-quality raw materials that meet specific optical and mechanical standards. This includes ensuring that the materials are free from defects and contaminants, which could affect the final product’s performance.

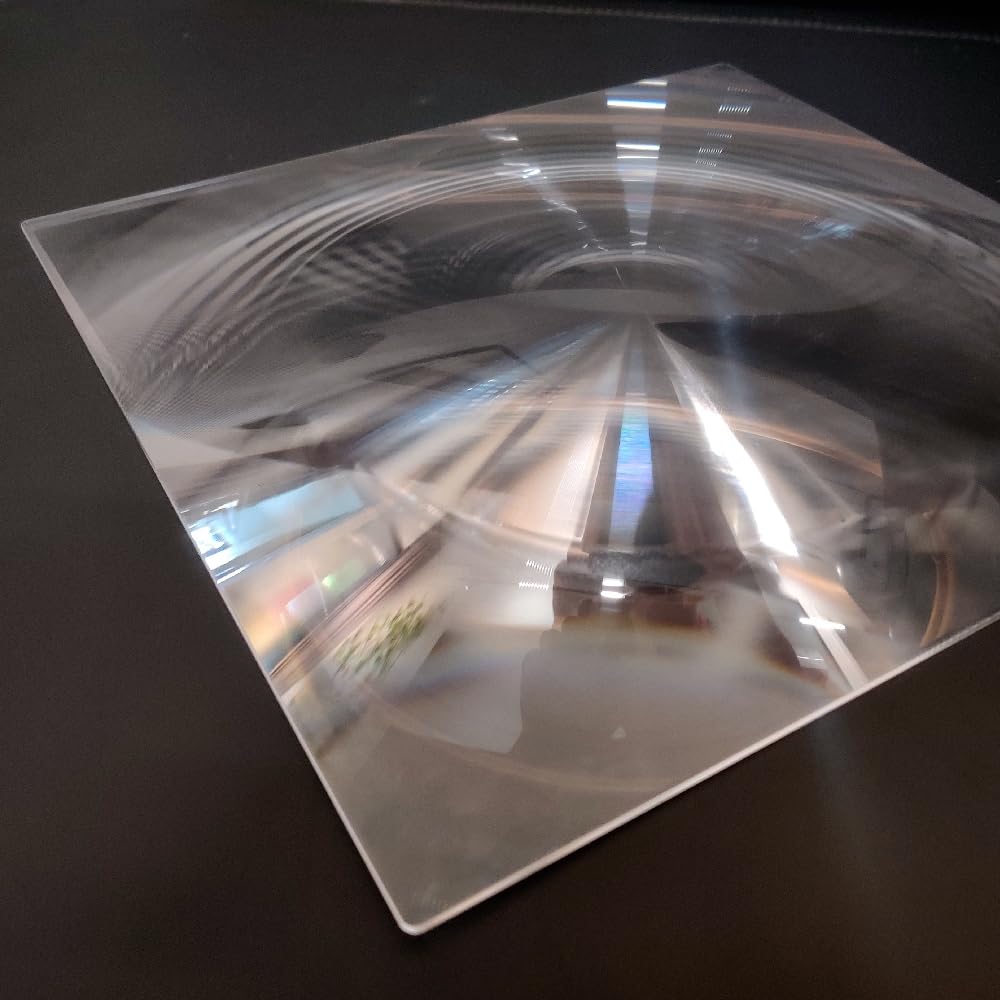

2. Forming: How Are Fresnel Lenses Shaped?

The forming stage utilizes advanced techniques such as injection molding or vacuum forming, particularly for plastic lenses. For glass lenses, processes like precision casting or machining may be employed. During this phase, the materials are shaped into the desired profile, featuring the characteristic concentric grooves that define a Fresnel lens. This stage is critical as it determines the lens’s focal length and overall optical quality.

3. Assembly: What Is Involved in Lens Assembly?

While Fresnel lenses are often produced as single units, some applications may require assembly with additional components, such as frames or protective coatings. This stage ensures that all parts fit together seamlessly and function effectively. If the lens is to be integrated into a larger optical system, alignment and compatibility checks are performed to ensure optimal performance.

4. Finishing: How Is the Final Product Prepared for Sale?

The finishing stage includes polishing and coating processes that enhance the optical properties of the lens. Anti-reflective coatings may be applied to reduce glare and improve light transmission. The lenses are also cleaned and inspected for surface imperfections. This stage ensures that the final product meets the aesthetic and functional requirements of the end-users.

What Quality Assurance Measures Are Essential for Fresnel Lenses?

Quality assurance (QA) is a crucial aspect of Fresnel lens manufacturing, ensuring that products meet international and industry-specific standards.

Relevant International Standards: How Do They Impact Quality?

ISO 9001 is the most recognized international standard for quality management systems. It emphasizes a process-oriented approach to quality assurance, requiring manufacturers to document procedures and continuously improve their processes. For B2B buyers, suppliers with ISO 9001 certification demonstrate a commitment to quality and customer satisfaction.

In addition to ISO 9001, industry-specific certifications such as CE marking for products sold in Europe or API specifications for lenses used in industrial applications may also be relevant. These certifications ensure that the products comply with safety and performance standards specific to their intended use.

What Are the Key Quality Control Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Any materials that do not pass this inspection are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, various tests are conducted at different stages to monitor quality. This may include measurements of lens thickness, refractive index, and surface smoothness.

-

Final Quality Control (FQC): After the lenses are manufactured, a final inspection is conducted. This includes a thorough examination for defects, optical testing, and performance evaluations to ensure that the lenses meet all specifications before they are shipped.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of potential suppliers. Here are some actionable strategies:

Conducting Supplier Audits: What Should Buyers Look For?

Regular audits of suppliers can provide insight into their quality management practices. Buyers should look for evidence of compliance with international standards like ISO 9001 and any industry-specific certifications. Additionally, audits should assess the supplier’s production capabilities, equipment, and quality control processes.

Requesting Quality Reports: What Information Should Be Included?

Buyers should request quality reports that detail the results of IQC, IPQC, and FQC checks. These reports should include data on defect rates, types of defects identified, and corrective actions taken. Comprehensive quality reports provide transparency and build trust between buyers and suppliers.

Utilizing Third-Party Inspection Services: How Can They Help?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These services can conduct independent assessments of manufacturing facilities and product quality, providing B2B buyers with additional assurance regarding the reliability of their suppliers.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers face unique challenges when sourcing Fresnel lenses. Understanding these nuances can help streamline the procurement process:

-

Understanding Regional Standards: Different regions may have varying regulatory requirements and quality standards. Buyers should familiarize themselves with the specific standards applicable to their region to ensure compliance.

-

Cultural Differences in Business Practices: Communication and negotiation styles can vary significantly across cultures. B2B buyers must be aware of these differences to foster effective relationships with suppliers.

-

Logistics and Supply Chain Considerations: International shipping can introduce additional risks, such as damage during transit or delays in delivery. Buyers should work with suppliers who have robust logistics capabilities and can provide clear timelines for production and shipping.

By understanding the manufacturing processes and quality assurance practices behind Fresnel lenses, B2B buyers can make informed decisions and establish strong partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fresnel lens for sale’

When sourcing Fresnel lenses for your business, it’s essential to approach the process with a structured strategy. This checklist will help international B2B buyers effectively navigate their procurement process, ensuring they make informed decisions that align with their specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical requirements for the Fresnel lenses you need. Consider factors such as focal length, diameter, material (glass vs. plastic), and application-specific requirements (e.g., solar concentration, lighting). This clarity will help you communicate effectively with suppliers and ensure that you receive products that meet your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of Fresnel lenses. Look for companies that specialize in optical components and have a proven track record in your region. Utilize online platforms, industry forums, and trade shows to gather information about potential suppliers.

- Key Considerations:

- Supplier reviews and ratings

- Industry certifications (ISO 9001, ISO 14001)

- Product range and customization options

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality assurance processes of your shortlisted suppliers. Certifications such as ISO 9001 indicate that the supplier adheres to international quality management standards, which is crucial for ensuring consistent product quality.

- What to Look For:

- Quality control processes

- Materials used (e.g., PMMA acrylic vs. glass)

- Testing and QA protocols for lenses

Step 4: Request Samples for Testing

Once you have narrowed down your suppliers, request samples of the Fresnel lenses to assess their quality and suitability for your application. Testing samples will allow you to evaluate optical clarity, durability, and performance under real-world conditions.

- Testing Considerations:

- Compatibility with your existing systems

- Performance in relevant applications (e.g., lighting, solar)

- Ease of handling and installation

Step 5: Discuss Customization Options

Engage with suppliers to explore customization options that may be necessary for your specific application. Many suppliers offer bespoke manufacturing services, allowing you to specify dimensions, coatings, and other features that are critical for your needs.

- Customization Factors:

- Size and shape variations

- Surface coatings (e.g., anti-reflective)

- Specific material requirements

Step 6: Compare Pricing and Terms

Once you’ve evaluated samples and customization options, compare pricing and payment terms from different suppliers. Ensure that you consider not just the initial cost but also factors such as shipping fees, import duties, and warranty conditions.

- Pricing Considerations:

- Bulk order discounts

- Payment plans (e.g., installments)

- Return policies and warranty terms

Step 7: Finalize Your Order and Establish Communication

After selecting the supplier that best meets your needs, finalize your order and establish a clear line of communication. Discuss timelines for delivery and any post-purchase support you may require. Building a strong relationship with your supplier can lead to better service and future collaboration.

By following this practical sourcing checklist, B2B buyers can confidently procure Fresnel lenses that align with their operational requirements while ensuring quality and reliability from their suppliers.

Comprehensive Cost and Pricing Analysis for fresnel lens for sale Sourcing

What Are the Key Cost Components in Sourcing Fresnel Lenses?

When analyzing the cost structure for sourcing Fresnel lenses, several components come into play. Materials represent a significant portion of the cost, with options ranging from PMMA acrylic to glass. Acrylic lenses tend to be more cost-effective and lightweight, making them ideal for applications where portability is crucial. Conversely, glass lenses offer superior optical clarity and durability, often justifying a higher price.

Labor costs involve the skilled workforce needed for manufacturing and assembling the lenses. Given the precision required in optics, labor costs can be substantial, especially in regions with higher wage standards. Manufacturing overhead includes expenses related to facility maintenance, equipment depreciation, and utilities. This is particularly relevant for suppliers maintaining high-quality production standards, as adherence to certifications like ISO9001 and ISO14001 can increase operational costs.

Tooling costs are essential for customized orders, as specialized molds and equipment may be necessary to produce bespoke Fresnel lenses. This is especially pertinent for international buyers needing specific dimensions or features. Quality control (QC) processes are critical to ensure that each lens meets the desired specifications, adding another layer of cost. Logistics expenses, including shipping and handling, vary significantly based on the origin and destination of the products, as well as the chosen Incoterms.

Finally, the margin added by suppliers must also be considered. This can fluctuate based on the supplier’s market position, brand reputation, and the level of service they provide.

How Do Price Influencers Impact the Cost of Fresnel Lenses?

Several factors influence the pricing of Fresnel lenses, particularly for international B2B buyers. Volume and minimum order quantities (MOQs) play a crucial role; larger orders typically yield better pricing due to economies of scale. Customization also affects pricing; bespoke lenses require more time and resources to produce, often resulting in higher costs.

The material choice is another pivotal factor. While acrylic lenses are generally less expensive, glass lenses may command a premium price due to their superior performance. The quality and certifications associated with the lenses are also influential; lenses that meet stringent quality standards or are produced by reputable manufacturers may justify higher prices.

Supplier factors, including their location, reputation, and service capabilities, can significantly affect cost. For instance, suppliers in regions with lower production costs may offer more competitive pricing. Additionally, understanding Incoterms is vital for international buyers to avoid unexpected costs related to shipping, duties, and taxes.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

When negotiating prices for Fresnel lenses, international B2B buyers should consider several strategies to enhance cost efficiency. First, establish clear requirements regarding specifications and quantities. This clarity helps suppliers provide accurate quotes and reduces the likelihood of misunderstandings that could lead to additional costs.

Building long-term relationships with suppliers can also yield benefits, as loyal customers often receive better pricing or terms. Buyers should not hesitate to compare quotes from multiple suppliers to ensure competitive pricing. Additionally, inquire about bulk purchase discounts or promotional offers that may not be publicly advertised.

Understanding the Total Cost of Ownership (TCO) is crucial for making informed purchasing decisions. This includes not only the upfront cost but also logistics, maintenance, and potential replacement costs associated with the lenses.

For international transactions, being aware of pricing nuances is essential, particularly in regions like Africa, South America, the Middle East, and Europe. Currency fluctuations, import tariffs, and local regulations can significantly impact the final cost. Therefore, buyers should conduct thorough market research and consider engaging with local representatives or consultants to navigate these complexities effectively.

Disclaimer on Pricing

Prices for Fresnel lenses can vary widely based on the factors discussed. This analysis serves as a guideline for understanding the cost structure and influences affecting pricing. Buyers are encouraged to conduct their due diligence and consult with suppliers for the most accurate and up-to-date pricing information tailored to their specific needs.

Alternatives Analysis: Comparing fresnel lens for sale With Other Solutions

Introduction: Exploring Alternatives to Fresnel Lenses

When considering optical solutions for various applications, it is essential for B2B buyers to evaluate not just the product in question—Fresnel lenses—but also viable alternatives that may meet their specific needs. Each option comes with its unique advantages and limitations, influencing factors such as performance, cost, and ease of implementation. This analysis will compare Fresnel lenses against two notable alternatives: traditional convex lenses and parabolic mirrors.

Comparison Table

| Comparison Aspect | Fresnel Lens For Sale | Traditional Convex Lens | Parabolic Mirror |

|---|---|---|---|

| Performance | Moderate optical clarity; lightweight | High optical clarity; more bulk | Excellent light concentration |

| Cost | Generally lower cost | Higher manufacturing costs | Variable costs depending on size |

| Ease of Implementation | Simple integration into systems | Requires precise mounting | Moderate complexity; precise alignment needed |

| Maintenance | Low maintenance; durable materials | Higher maintenance; fragile | Low maintenance; durable |

| Best Use Case | Solar applications, portable devices | High-end optical instruments | Solar concentrators, telescopes |

Detailed Breakdown of Alternatives

Traditional Convex Lens

Traditional convex lenses offer superior optical clarity compared to Fresnel lenses, making them ideal for applications where image quality is paramount, such as in high-end cameras and optical instruments. However, their bulkier size and weight can be a drawback, especially in portable applications. The higher manufacturing costs associated with traditional convex lenses can also deter budget-conscious buyers. These lenses require precise mounting to ensure optimal performance, which may complicate integration in certain projects.

Parabolic Mirror

Parabolic mirrors excel in applications where high light concentration is necessary, such as solar energy systems and telescopes. They can focus incoming light to a single point, thus maximizing energy capture or enhancing image clarity. While they are generally more versatile, their cost can vary significantly based on the size and material used, potentially making them a more expensive option for some buyers. Additionally, they require careful alignment and maintenance to function optimally, which may not be ideal for all applications, especially in environments with limited resources or expertise.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate optical solution requires a thorough understanding of your specific application requirements. Fresnel lenses are ideal for cost-sensitive projects where weight and size are critical factors, particularly in portable devices and solar applications. In contrast, traditional convex lenses are more suited for high-precision optical tasks, while parabolic mirrors offer unmatched light concentration capabilities but may involve higher costs and maintenance. By carefully assessing these factors, B2B buyers can make informed decisions that align with their operational needs and budget constraints, ensuring optimal performance in their respective applications.

Essential Technical Properties and Trade Terminology for fresnel lens for sale

What Are the Essential Technical Properties of Fresnel Lenses?

When considering the purchase of Fresnel lenses, understanding their technical properties is crucial for making informed decisions. Here are some key specifications:

1. Material Grade

Fresnel lenses can be constructed from various materials, including PMMA acrylic, polycarbonate, and glass. PMMA lenses are lightweight and cost-effective, making them suitable for portable applications like magnifiers and solar concentrators. Glass lenses, while heavier and more expensive, offer superior optical clarity and durability, ideal for high-performance applications like lighthouses and projectors.

2. Focal Length

The focal length (f.l.) of a Fresnel lens determines how effectively it can concentrate light. It is essential for applications ranging from solar energy collection to theatrical lighting. A shorter focal length may be more suitable for applications requiring intense light concentration, while longer focal lengths can provide broader coverage.

3. Aperture Size

The diameter of the lens aperture significantly affects light transmission and focusing capabilities. Larger apertures allow for more light to pass through, improving efficiency in applications such as solar heating or lighting systems. For B2B buyers, selecting the appropriate aperture size can optimize performance based on specific project requirements.

4. Tolerance Levels

Tolerance refers to the permissible deviation from specified dimensions. High tolerance levels are critical for precision applications, such as optical instruments or simulation systems, where alignment and focus are paramount. Buyers should inquire about the manufacturer’s tolerance specifications to ensure compatibility with their systems.

5. Surface Quality

Surface quality is vital for the optical performance of Fresnel lenses. It encompasses factors such as smoothness and the presence of defects. Lenses with high surface quality minimize light scattering and distortion, which is particularly important for applications that demand high fidelity, such as imaging systems.

6. Coating Options

Fresnel lenses can come with various coatings, such as anti-reflective or UV protective layers. These coatings enhance performance by reducing glare and increasing light transmission. For B2B buyers, understanding available coating options can inform decisions about lens longevity and effectiveness in specific environments.

What Are Common Trade Terms Related to Fresnel Lenses?

Familiarizing yourself with industry jargon can streamline communication and negotiations. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Fresnel lenses, understanding whether a supplier is an OEM can indicate the level of customization and quality assurance available.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. For businesses, this is a critical factor in inventory management and budgeting. Buyers must assess their needs against the supplier’s MOQ to avoid excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by potential buyers to solicit price quotes from suppliers for specific products. Submitting an RFQ for Fresnel lenses allows businesses to compare pricing, specifications, and terms from various suppliers, aiding in informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping costs, risks, and delivery obligations associated with Fresnel lens purchases.

5. Lead Time

Lead time is the period between placing an order and receiving the product. For custom Fresnel lenses, lead times can vary significantly based on complexity and supplier capabilities. Buyers should inquire about lead times to align with their project schedules.

6. Quality Assurance (QA)

QA refers to the systematic process of ensuring that products meet specified requirements and standards. For Fresnel lenses, quality assurance is crucial to ensure optical performance and reliability. Buyers should seek suppliers with established QA processes to guarantee product consistency.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make strategic purchasing decisions regarding Fresnel lenses, ensuring they meet their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the fresnel lens for sale Sector

What Are the Key Market Dynamics and Trends Influencing Fresnel Lens Sourcing?

The global market for Fresnel lenses is experiencing significant growth, driven by advancements in optical technology and increasing demand across various sectors. The rise of renewable energy sources, particularly solar power, is a notable driver, as Fresnel lenses are widely used in solar concentrators to enhance energy efficiency. Additionally, industries such as automotive, aerospace, and entertainment are leveraging the lightweight and versatile nature of Fresnel lenses for applications in lighting, projection systems, and visual displays.

Emerging B2B technology trends are reshaping the sourcing landscape. The integration of automation and AI in manufacturing processes is leading to improved production efficiency and quality control. This is particularly relevant for buyers in regions like Africa and South America, where local manufacturing capabilities are growing. Moreover, the increasing importance of e-commerce platforms allows international buyers to access a wider range of suppliers, facilitating competitive pricing and diverse product offerings.

For B2B buyers from the Middle East and Europe, understanding the regional market dynamics is crucial. In markets like Saudi Arabia, where there is a strong push towards sustainable infrastructure, the demand for high-quality, efficient optical components is on the rise. Similarly, in Europe, regulatory frameworks are increasingly favoring suppliers who offer certified and environmentally friendly products.

How Is Sustainability Shaping the Sourcing of Fresnel Lenses?

Sustainability is becoming a critical factor in the sourcing of Fresnel lenses. The environmental impact of materials used in lens production is under scrutiny, prompting buyers to seek out suppliers committed to ethical sourcing practices. For instance, manufacturers that utilize recycled or eco-friendly materials not only reduce waste but also appeal to environmentally conscious buyers.

Certifications such as ISO 14001 (Environmental Management) and the use of green materials in production are increasingly important for buyers evaluating suppliers. This trend aligns with global initiatives to reduce carbon footprints and promote sustainable manufacturing practices.

In regions such as Europe and the Middle East, where consumers are more aware of sustainability issues, B2B buyers are prioritizing suppliers who can demonstrate a commitment to ethical supply chains. By opting for Fresnel lenses produced through sustainable practices, companies can enhance their brand reputation and meet the growing demand for environmentally responsible products.

What Is the Historical Context of Fresnel Lens Development?

The Fresnel lens, invented by Augustin-Jean Fresnel in the early 19th century, revolutionized the field of optics, particularly in lighthouse applications. Its unique design, which employs a series of concentric grooves, allows for the construction of large aperture lenses with minimal material. This innovation not only reduced weight but also improved light transmission efficiency, making it possible to create more powerful and compact lighting solutions.

Over the years, the applications of Fresnel lenses have expanded beyond maritime navigation to include uses in solar energy, automotive lighting, and even consumer electronics. As technology continues to evolve, the Fresnel lens remains a vital component in various industries, demonstrating its enduring significance in the global marketplace.

Understanding this historical context equips B2B buyers with insights into the lens’s development, informing their sourcing decisions and highlighting the importance of selecting high-quality, innovative products that can meet contemporary demands.

Frequently Asked Questions (FAQs) for B2B Buyers of fresnel lens for sale

-

How do I choose the right Fresnel lens for my application?

Choosing the right Fresnel lens involves assessing your specific application needs, including focal length, size, and material. For high-precision applications like projection systems, a glass Fresnel lens may be ideal due to its optical clarity and durability. If weight and cost are critical, consider PMMA acrylic lenses, which are lightweight and versatile. Always evaluate the lens specifications against your project requirements to ensure optimal performance. -

What are the common applications for Fresnel lenses in various industries?

Fresnel lenses are utilized across multiple sectors, including solar energy, lighting, and imaging. In solar applications, they focus sunlight for energy generation, while in lighting, they are used in spotlights and automotive headlights to distribute light evenly. Additionally, they serve in optical devices such as projectors and magnifiers. Understanding your industry’s specific requirements will help you select the most suitable lens. -

What customization options are available for Fresnel lenses?

Many suppliers offer customization options for Fresnel lenses, including size, focal length, and material type. Custom lenses can be tailored to meet specific requirements for applications such as medical devices, solar concentrators, or specialized lighting systems. When considering customization, communicate your exact needs to the supplier to ensure they can meet your specifications while maintaining quality standards. -

What are the minimum order quantities (MOQs) for Fresnel lenses?

Minimum order quantities for Fresnel lenses can vary significantly among suppliers. Some manufacturers may offer low MOQs for standard stock lenses, while custom lenses might require higher MOQs due to production costs. It’s advisable to confirm the MOQ with your supplier upfront and explore options for smaller orders if needed, especially for initial testing or small-scale projects. -

What payment terms should I expect when purchasing Fresnel lenses internationally?

Payment terms for international purchases of Fresnel lenses typically depend on the supplier’s policies and your buyer-seller relationship. Common arrangements include upfront payment, deposits followed by balance on delivery, or payment upon receipt. Be sure to clarify payment terms before finalizing your order to avoid misunderstandings. Additionally, inquire about accepted payment methods, such as bank transfers or credit cards. -

How do I ensure the quality of Fresnel lenses from suppliers?

To ensure quality, look for suppliers who provide detailed product specifications and quality assurance processes. Certifications such as ISO 9001 and ISO 14001 indicate adherence to international quality standards. Request samples before placing a large order, and consider suppliers who offer comprehensive testing and inspection services to verify the optical performance and durability of their lenses. -

What logistics considerations should I keep in mind when importing Fresnel lenses?

When importing Fresnel lenses, consider shipping methods, lead times, and customs regulations. Air freight may be faster but more costly, while sea freight is economical for larger orders. Ensure that your supplier is familiar with international shipping procedures and can provide necessary documentation to facilitate smooth customs clearance. Additionally, evaluate insurance options for your shipment to mitigate risks during transit. -

What are the typical lead times for custom Fresnel lens orders?

Lead times for custom Fresnel lens orders can vary based on complexity and supplier capabilities. Generally, expect a timeframe of 4 to 8 weeks for production after finalizing specifications. It’s essential to discuss lead times with your supplier early in the process, especially if you have specific project deadlines. Planning ahead can help you avoid delays and ensure timely delivery of your lenses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Fresnel Lens For Sale Manufacturers & Suppliers List

1. Knight Optical – Custom Fresnel Lenses

Domain: knightoptical.com

Registered: 2007 (18 years)

Introduction: Knight Optical offers a range of custom Fresnel lenses made from PMMA Acrylic or glass, available in custom specifications. The custom PMMA Fresnel lenses are available in two grades: a standard range starting from 5mm focal length x 5mm diameter aperture up to 254mm focal length x 152mm diameter aperture, and a precision range with tight tolerances starting at 22.2mm focal length x 44.4mm apertur…

2. The Cape Cod Store – Harbour Lights Fresnel Lens

Domain: thecapecodstore.com

Registered: 2004 (21 years)

Introduction: Harbour Lights Fresnel Lens – Limited Edition replicas, retired for many years, guaranteed in perfect condition with original box and Certificate of Authenticity unless otherwise specified. Available models include: HL650 Third 1/2 Order Fresnel Lens Montauk Point, NY – $225; HL651 Third Order Beehive Lens Big Bay Point, MI – $225; HL678 Third Order Fresnel Lens Point Vicente, CA – $275; HL675 Yor…

3. Green Power Science – Solar Products

Domain: greenpowerscience.com

Registered: 2007 (18 years)

Introduction: Green Power Science offers a variety of solar products including Fresnel lenses, parabolic mirrors, solar film, and Stirling engines. Key features of the Fresnel lens include:

– Invented by Augustin-Jean Fresnel for lighthouses, allowing for lighter weight and more efficient light concentration.

– Capable of concentrating sunlight to achieve thermal concentrations exceeding 3233 degrees Fahrenhe…

4. Lighthouse Lens – 2nd Order Fresnel Lens Panel

Domain: lighthouselens.com

Registered: 2004 (21 years)

Introduction: [{‘name’: ‘2nd Order Lighthouse Fresnel Lens Panel’, ‘price’: 75000}, {‘name’: ‘3rd Order Barbier & Bernard Lens Panel’, ‘price’: 7995}, {‘name’: ‘1st Order Sautter Fresnel Lighthouse Lens Panel’, ‘price’: ‘SOLD’}, {‘name’: ‘1900 Chance Brother Lighthouse Fresnel Lens’, ‘price’: 35000}, {‘name’: ‘1st Order Chance Lighthouse Lens Upper Sections’, ‘price’: ‘SOLD’}, {‘name’: ‘800mm, 3rd Order Middle …

5. Reddit – 18×18 Inch Fresnel Lens Sheet

6. CZ Garden – Fresnel Lenses

Domain: czgarden.com

Registered: 2017 (8 years)

Introduction: Fresnel Lenses available in various sizes and configurations. Key products include: 1. 8.3″ X 11.75″ Large 4x Fresnel Lens Full Page Magnifier – Price: $3.99 2. 10 pk Premium Grade Fresnel Lens 4X Magnifier with Orange Pouch – Regular Price: $10.99, Sale Price: $8.99 (Sold Out) 3. Fresnel Lens 4X Magnifier Pocket Wallet Credit Card Size – Unbreakable Plastic (10 Pack Ruler/Magnifier – Yellow) – Re…

7. Edmund Optics – Fresnel Lenses

Domain: edmundoptics.com

Registered: 1999 (26 years)

Introduction: This company, Edmund Optics – Fresnel Lenses, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for fresnel lens for sale

In the dynamic landscape of Fresnel lens sourcing, strategic partnerships and informed decision-making are paramount for international B2B buyers. The versatility of Fresnel lenses—ranging from custom applications in solar technology to traditional uses in lighting—offers significant opportunities across various sectors. Understanding the unique properties of different materials, such as PMMA acrylic versus glass, allows buyers to tailor their selections to specific project needs, enhancing performance while optimizing costs.

Moreover, the importance of quality assurance cannot be overstated. Partnering with ISO-certified suppliers ensures that every lens meets rigorous standards, ultimately leading to improved reliability and efficiency in your applications. As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is an increasing demand for innovative optical solutions that can drive sustainability and technological advancement.

Looking ahead, businesses should actively seek out reliable suppliers who can provide both stock and bespoke solutions, ensuring they remain competitive in an increasingly global marketplace. Engage with expert suppliers today to explore how high-quality Fresnel lenses can elevate your projects and contribute to a more efficient future.