How to Source 12.4X28 Tractor Tire Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for 12.4×28 tractor tire

The global market for 12.4×28 tractor tires presents a unique set of challenges for international B2B buyers, especially those operating in diverse agricultural landscapes across Africa, South America, the Middle East, and Europe. Sourcing the right tires can significantly impact operational efficiency, safety, and overall productivity. This guide aims to demystify the complexities of selecting the ideal 12.4×28 tractor tire by providing a comprehensive overview of types, applications, supplier vetting processes, and cost considerations.

As buyers navigate this intricate landscape, understanding the various tire specifications—including load capacity, ply rating, and tread design—becomes crucial. Additionally, the guide will address how regional factors influence tire performance and availability, helping buyers to make informed decisions tailored to their specific agricultural needs.

By empowering B2B buyers with actionable insights and data-driven recommendations, this resource serves as a valuable tool for enhancing procurement strategies. Whether you are in Vietnam or Saudi Arabia, this guide will equip you with the knowledge to select high-quality tires that meet your operational requirements while optimizing your investment. Together, we will navigate the global market, ensuring that your procurement decisions lead to sustained agricultural success.

Understanding 12.4×28 tractor tire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| R-1 (Agricultural) | Deep tread for optimal traction; tube-type | General farming, tillage | Pros: Excellent grip in soft soil; durable. Cons: May wear faster on hard surfaces. |

| R-1W (Wide) | Wider tread for stability; tubeless options | Row crop farming, heavy machinery | Pros: Enhanced stability; better flotation. Cons: Higher initial cost. |

| R-2 (Rice) | Designed for wet conditions; deep lugs | Rice paddies, wetland farming | Pros: Superior traction in muddy conditions. Cons: Limited use in dry fields. |

| R-3 (Industrial) | Reinforced sidewalls; designed for rough terrain | Construction, logging | Pros: High load capacity; rugged durability. Cons: Heavier weight may affect fuel efficiency. |

| Bias vs. Radial Construction | Bias construction for flexibility; radial for longevity | Versatile farming applications | Pros: Bias offers a softer ride; radial provides longer lifespan. Cons: Bias tires may have lower speed ratings. |

What are the characteristics of R-1 (Agricultural) tires, and when should they be purchased?

R-1 tires are specifically designed for agricultural applications, featuring deep tread patterns that provide excellent traction in soft soil conditions. They are typically tube-type, which can be advantageous for repairs in remote areas. B2B buyers in farming and tillage should consider these tires for their superior grip and durability, although they may wear more quickly on hard surfaces, necessitating careful consideration of the operating environment.

How do R-1W (Wide) tires enhance performance for agricultural machinery?

R-1W tires have a wider tread design that improves stability and flotation, making them ideal for row crop farming and heavy machinery operations. The tubeless design reduces the risk of punctures and allows for easier maintenance. Buyers should weigh the benefits of enhanced stability against the higher initial cost, especially in applications where stability is paramount, such as transporting heavy loads across uneven terrain.

In what scenarios are R-2 (Rice) tires most effective?

R-2 tires are engineered for wetland farming and rice paddies, featuring deep lugs that provide exceptional traction in muddy and waterlogged conditions. These tires are essential for B2B buyers operating in regions where wet farming is prevalent. However, their specialized design limits their effectiveness in dry fields, so buyers should assess their specific agricultural needs before making a purchase.

What advantages do R-3 (Industrial) tires offer for construction applications?

R-3 tires are built with reinforced sidewalls and a rugged tread pattern, making them suitable for industrial applications such as construction and logging. They can carry heavy loads and withstand rough terrains, which is a significant advantage for B2B buyers in these sectors. However, their heavier weight may impact fuel efficiency, so buyers should consider the trade-off between durability and operational costs.

How do bias and radial tire constructions differ in B2B applications?

Bias tires offer a softer ride and are generally more flexible, making them suitable for various farming applications. Conversely, radial tires provide longer lifespan and better fuel efficiency, which can be beneficial for buyers focused on cost-effectiveness over time. When selecting between these constructions, B2B buyers should consider their specific operational needs, including speed ratings and load capacities, to ensure optimal performance.

Key Industrial Applications of 12.4×28 tractor tire

| Industry/Sector | Specific Application of 12.4×28 Tractor Tire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Row Crop Farming | Enhanced traction and stability on varied terrain | Load index and speed rating suitable for local conditions |

| Construction | Earthmoving Equipment | Reliable performance for heavy loads and rough surfaces | Durability against wear and tear, availability of replacement parts |

| Forestry | Logging Operations | Improved grip on uneven ground and slopes | Compatibility with specific logging machinery and local regulations |

| Transportation & Logistics | Hauling Goods on Rural Roads | Efficient movement of agricultural products to market | Consideration of load capacity and inflation pressure for safe transport |

| Landscaping | Turf Management | Minimizes soil compaction while maintaining mobility | Tread design suited for soft ground and local climate conditions |

How is the 12.4×28 Tractor Tire Used in Agriculture?

In the agricultural sector, the 12.4×28 tractor tire is crucial for row crop farming, where it provides superior traction and stability on diverse terrains. This tire size is ideal for tractors engaged in planting, cultivating, and harvesting crops, ensuring efficient power transfer and minimizing soil compaction. Buyers should prioritize tires with a high load index and appropriate speed ratings to match local farming conditions, especially in regions like Africa and South America where field conditions can vary significantly.

What Role Does the 12.4×28 Tire Play in Construction?

In construction, the 12.4×28 tire is employed on earthmoving equipment, such as tractors and backhoes. Its robust design allows for reliable performance under heavy loads and on rough surfaces, making it essential for excavation and grading tasks. Businesses must consider the tire’s durability against wear and tear, particularly in challenging environments, and ensure the availability of replacement parts to minimize downtime.

How is the 12.4×28 Tire Utilized in Forestry?

Forestry operations benefit from the 12.4×28 tractor tire by leveraging its improved grip on uneven ground and slopes, which is vital for logging activities. This tire size supports the safe maneuvering of heavy logging equipment in challenging terrains, enhancing operational efficiency. Buyers in this sector should ensure compatibility with specific logging machinery and be aware of local regulations regarding tire specifications to ensure compliance and safety.

What is the Importance of the 12.4×28 Tire in Transportation & Logistics?

In transportation and logistics, the 12.4×28 tire is utilized for hauling goods on rural roads, where its design allows for efficient movement of agricultural products to market. The tire’s load capacity and inflation pressure are critical factors for ensuring safe transport, particularly in regions with less developed road infrastructure, such as parts of the Middle East and Africa. Buyers should assess these specifications to ensure they meet the demands of their logistics operations.

How Does the 12.4×28 Tire Benefit Landscaping Operations?

In landscaping, the 12.4×28 tire is employed for turf management, where it minimizes soil compaction while maintaining mobility across soft ground. This tire is particularly beneficial in maintaining healthy soil conditions, which is essential for plant growth. When sourcing these tires, businesses should consider tread designs that are suited for local climate conditions to optimize performance and longevity.

3 Common User Pain Points for ‘12.4×28 tractor tire’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Tires at Competitive Prices

The Problem: B2B buyers often struggle to find reliable suppliers for 12.4×28 tractor tires that offer competitive pricing and consistent quality. In regions such as Africa and South America, where agricultural machinery is essential, the lack of accessible information on suppliers can lead to delays in procurement and increased operational costs. Buyers may also face issues with varying tire quality, which can directly impact the performance of agricultural equipment and lead to costly downtime.

The Solution: To effectively source quality 12.4×28 tractor tires, B2B buyers should start by conducting thorough market research to identify reputable suppliers. Utilize online platforms and industry networks to compare prices and read reviews from other businesses. Engaging with local distributors who understand the specific agricultural needs of your region can also provide insights into the best tire options available. Establishing relationships with multiple suppliers can create competitive pricing opportunities and ensure consistent quality through long-term partnerships. Additionally, consider ordering in bulk to leverage discounts and negotiate better terms.

Scenario 2: Navigating Tire Specifications and Compatibility Issues

The Problem: Another common challenge faced by B2B buyers is the complexity of tire specifications and compatibility with existing equipment. The 12.4×28 tractor tire must match specific performance criteria, including load capacity, tread design, and inflation pressure. Misunderstanding these specifications can lead to purchasing tires that do not fit the machinery properly, resulting in safety hazards and inefficiencies in operations.

The Solution: To mitigate compatibility issues, buyers should invest time in understanding the specifications of the 12.4×28 tractor tires relevant to their machinery. Consulting the equipment manufacturer’s manual can provide critical information on load capacities and recommended tire types. When sourcing tires, always cross-reference the tire specifications with the equipment requirements to ensure compatibility. It may also be beneficial to work with a knowledgeable tire dealer who can provide expert advice on matching tires with specific tractor models. Keeping an organized record of tire specifications and past purchases can streamline future procurement processes.

Scenario 3: Managing Tire Maintenance and Longevity

The Problem: Many B2B buyers overlook the importance of tire maintenance, which can lead to premature wear and unexpected expenses. The harsh operating conditions in agricultural settings, such as uneven terrain and exposure to chemicals, can significantly impact the lifespan of 12.4×28 tractor tires. Without a proper maintenance strategy, companies may face frequent replacements, leading to higher operational costs and downtime.

The Solution: To enhance tire longevity and performance, B2B buyers should implement a comprehensive tire maintenance program. This includes regular inspections for wear and tear, monitoring inflation pressure, and ensuring proper alignment of the tires. Establishing a schedule for routine maintenance checks can help identify potential issues before they become serious problems. Buyers should also educate their operators about the correct practices for tire care, such as avoiding overloading machinery and selecting the appropriate tread design for specific tasks. Investing in tire monitoring technology can also provide real-time data on tire conditions, further aiding in proactive maintenance efforts. By prioritizing tire care, businesses can maximize the life of their 12.4×28 tractor tires and reduce overall costs.

Strategic Material Selection Guide for 12.4×28 tractor tire

What Are the Key Materials Used in 12.4×28 Tractor Tires?

Selecting the right materials for 12.4×28 tractor tires is crucial for performance, durability, and cost-effectiveness. Here, we analyze several common materials used in the manufacturing of these tires, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

Natural Rubber: The Traditional Choice

Natural rubber is a primary material used in tire manufacturing, particularly for agricultural applications. It exhibits excellent elasticity, allowing for effective shock absorption and traction on various terrains. Natural rubber also has a high resistance to wear and tear, making it suitable for the demanding conditions faced by tractors.

Pros: Natural rubber is renowned for its durability and flexibility, which enhances ride comfort and traction. It is also relatively cost-effective compared to synthetic alternatives.

Cons: However, natural rubber can be less resistant to extreme temperatures and UV exposure, leading to quicker degradation in harsh climates. This could be a concern for buyers in regions with intense sun exposure or fluctuating temperatures.

Impact on Application: Natural rubber is compatible with a wide range of agricultural tasks, from plowing to hauling.

International Considerations: Buyers should ensure compliance with local regulations regarding rubber sourcing and environmental impact. Standards such as ASTM D2000 can guide material selection.

Synthetic Rubber: Performance and Versatility

Synthetic rubber, such as styrene-butadiene rubber (SBR) or butyl rubber, is increasingly popular in tire production. These materials offer enhanced resistance to heat and aging, making them suitable for high-performance applications.

Pros: Synthetic rubber provides superior durability, chemical resistance, and overall performance in varied environmental conditions. It can be engineered to meet specific performance requirements, such as increased load-bearing capacity.

Cons: The primary downside is the higher cost of synthetic rubber compared to natural rubber. Additionally, the manufacturing process can be more complex, requiring advanced technology and expertise.

Impact on Application: Synthetic rubber tires are ideal for heavy-duty applications, including those in industrial or construction settings.

International Considerations: Buyers must consider the sourcing of synthetic materials and their environmental impact. Compliance with international standards like ISO 14001 for environmental management can be crucial.

Steel Belting: Reinforcement for Strength

Steel belting is often used in the construction of tractor tires to enhance strength and puncture resistance. This material provides structural integrity and helps maintain the tire’s shape under heavy loads.

Pros: The use of steel belting significantly increases tire durability and performance, particularly in challenging terrains. It helps in maintaining tire pressure and reduces the risk of blowouts.

Cons: The main drawback is the added weight, which can affect fuel efficiency. Additionally, steel belting can be more expensive to manufacture.

Impact on Application: Steel-belted tires are particularly suited for applications requiring high load capacities, such as transporting heavy agricultural equipment.

International Considerations: Buyers should ensure compliance with local safety standards and regulations regarding steel use in tire manufacturing, such as those set by the European Union.

Carbon Black: Enhancing Durability and Performance

Carbon black is commonly added to rubber compounds to enhance durability and improve performance. It increases wear resistance and provides UV protection, extending the tire’s lifespan.

Pros: Carbon black enhances the mechanical properties of rubber, improving traction and reducing rolling resistance. This makes it an essential ingredient for tires used in demanding agricultural conditions.

Cons: The environmental impact of carbon black production can be a concern, as it involves significant energy consumption and emissions.

Impact on Application: Tires with carbon black are well-suited for diverse agricultural tasks, providing reliable performance across various soil types.

International Considerations: Buyers should be aware of the environmental regulations related to carbon black production and seek suppliers that adhere to sustainable practices.

Summary Table of Material Selection for 12.4×28 Tractor Tires

| Material | Typical Use Case for 12.4×28 tractor tire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | General agricultural use | Excellent elasticity and durability | Less resistant to extreme conditions | Low |

| Synthetic Rubber | Heavy-duty applications | Superior durability and performance | Higher cost and complex manufacturing | High |

| Steel Belting | High load capacity applications | Increases strength and puncture resistance | Added weight affects fuel efficiency | Medium |

| Carbon Black | Diverse agricultural tasks | Enhances durability and traction | Environmental impact concerns | Medium |

This guide provides valuable insights for B2B buyers in selecting the right materials for 12.4×28 tractor tires, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 12.4×28 tractor tire

What Are the Main Stages in the Manufacturing Process of a 12.4×28 Tractor Tire?

The manufacturing process of a 12.4×28 tractor tire involves several critical stages, each designed to ensure the tire meets the rigorous demands of agricultural use. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

In the initial stage, raw materials such as natural rubber, synthetic rubber, carbon black, and various chemical additives are sourced based on strict quality criteria. These materials are then compounded to create a homogeneous mixture that optimizes performance characteristics like durability, flexibility, and resistance to wear. The compounding process often involves using advanced machinery to ensure consistent quality.

Forming: What Techniques Are Used to Shape the Tire?

Once the materials are prepared, the next step is forming. This stage typically involves creating the tire’s inner and outer layers. Techniques such as extrusion and calendaring are employed to produce rubber sheets and components. The tread pattern is designed to provide optimal traction and performance in various agricultural conditions. The use of specialized molds allows for the precise shaping of tire components, ensuring they meet the specified dimensions.

Assembly: How Are the Components Integrated into a Complete Tire?

The assembly stage is where the tire components come together. This includes layering the inner and outer linings, adding steel belts for strength, and incorporating bead wires to ensure a secure fit on the rim. The assembly process is often carried out using automated machinery, which enhances precision and reduces labor costs. Quality control checkpoints are integrated throughout this stage to ensure that each tire meets the required specifications.

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage involves curing the tire in a mold under heat and pressure, a process known as vulcanization. This step is crucial as it enhances the tire’s strength and elasticity. After curing, the tires undergo a series of inspections, including visual checks for defects and measurements to ensure they conform to the specified dimensions. Additionally, surface treatments may be applied to improve durability and resistance to environmental factors.

What Quality Assurance Standards Are Essential for 12.4×28 Tractor Tires?

Quality assurance in tire manufacturing is vital to ensure safety and performance. International standards such as ISO 9001, which focuses on quality management systems, are commonly implemented. For tires specifically, certifications like CE (Conformité Européenne) and compliance with American Petroleum Institute (API) standards are also essential.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that each tire meets the required specifications. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet quality standards.

- In-Process Quality Control (IPQC): Inspections during the manufacturing process help identify any deviations from specifications early on.

- Final Quality Control (FQC): Comprehensive testing of finished tires includes checking for dimensional accuracy, tread depth, and overall appearance.

What Common Testing Methods Are Used to Ensure Tire Quality?

Various testing methods are employed to validate tire quality, including:

- Performance Testing: Evaluating traction, wear resistance, and heat build-up during operation.

- Durability Testing: Subjecting tires to extreme conditions to assess longevity.

- Pressure Testing: Ensuring that tires can withstand recommended inflation levels without failure.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence when selecting tire suppliers to ensure they adhere to rigorous quality standards. Here are several strategies to verify supplier quality control:

What Are the Best Practices for Conducting Supplier Audits?

Conducting thorough supplier audits is a critical step in quality verification. Buyers should:

- Review Documentation: Ensure that suppliers maintain detailed records of their quality control processes and testing results.

- On-Site Inspections: Visiting manufacturing facilities allows buyers to assess the production process and quality control measures firsthand.

- Request Certifications: Suppliers should provide copies of relevant certifications, such as ISO 9001, CE, and any regional standards applicable to the markets they serve.

How Can Third-Party Inspections Enhance Quality Assurance?

Utilizing third-party inspection services can further enhance quality assurance. Independent inspectors can provide unbiased evaluations of the manufacturing processes and finished products. This is particularly valuable for international buyers who may not have the resources to conduct in-depth audits themselves.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regional Standards Compliance: Different regions may have varying regulations and standards. Buyers should ensure that suppliers comply with local and international standards applicable to their market.

- Cultural Considerations: Understanding cultural differences in business practices can enhance communication and collaboration with suppliers.

- Logistics and Supply Chain Reliability: Quality control doesn’t end at manufacturing; it extends to shipping and delivery. Buyers should ensure that suppliers have reliable logistics partners to minimize the risk of damage during transit.

Conclusion: Why Is Manufacturing and Quality Assurance Critical for 12.4×28 Tractor Tires?

The manufacturing processes and quality assurance measures for 12.4×28 tractor tires are integral to ensuring that these products meet the demanding needs of agricultural operations. By understanding these processes and implementing rigorous quality verification strategies, B2B buyers can make informed decisions, ensuring they procure tires that deliver performance, safety, and reliability in the field.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘12.4×28 tractor tire’

When sourcing 12.4×28 tractor tires, international B2B buyers must navigate a range of considerations to ensure they select the right products for their agricultural needs. This checklist serves as a practical guide to streamline the sourcing process and maximize purchasing efficiency.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the tires you need is crucial. Specify the load index, speed rating, tread type, and whether you require tube-type or tubeless options. For instance, a common choice in the 12.4×28 range includes a load index of 123, which supports a maximum load of approximately 3,417 lbs, essential for heavy-duty agricultural tasks.

Step 2: Identify Your Supplier Sources

Research potential suppliers who specialize in agricultural tires. Look for manufacturers or distributors with a proven track record in your target market regions, such as Africa, South America, the Middle East, and Europe. Verify their credibility through online reviews, industry recognition, and recommendations from other businesses in your network.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Ensure they have experience with international shipping and understand the logistical challenges specific to your location. This step helps mitigate risks associated with supplier reliability.

Step 4: Request Detailed Product Information

When engaging with suppliers, ask for comprehensive product specifications and certifications. This includes tread depth, inflation pressure, and any warranties offered. Confirm that the products meet international safety and quality standards, which can differ significantly between regions.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing effectively. Pay attention not just to the base price of the tires, but also to shipping costs, potential discounts for bulk purchases, and payment terms. Some suppliers may offer financing options or flexible payment schedules that can ease cash flow concerns.

Step 6: Assess After-Sales Support and Services

Evaluate the level of after-sales support offered by potential suppliers. Reliable customer service can be invaluable, especially in addressing issues like tire performance or warranty claims. Inquire about return policies and whether they provide technical support to help you with installation or maintenance.

Step 7: Finalize Your Order and Logistics

Once you select a supplier, finalize your order by confirming all details, including specifications, pricing, and delivery timelines. Discuss shipping methods and ensure that logistics are in place to handle potential customs issues. Clear communication during this phase can prevent costly delays and misunderstandings.

By following this structured approach, you can streamline your sourcing process for 12.4×28 tractor tires, ensuring that you secure the best products for your agricultural needs while minimizing risks associated with international procurement.

Comprehensive Cost and Pricing Analysis for 12.4×28 tractor tire Sourcing

Understanding the cost structure and pricing for 12.4×28 tractor tires is critical for international B2B buyers aiming to optimize their procurement strategies. This analysis delves into the key components of tire costs, the factors influencing pricing, and provides actionable insights for effective negotiation and sourcing.

What Are the Key Cost Components in 12.4×28 Tractor Tire Pricing?

The cost structure for 12.4×28 tractor tires comprises several critical components:

-

Materials: The primary raw materials include rubber, steel belts, and fabric. The quality of these materials significantly affects durability and performance. Prices can fluctuate based on global commodity rates, impacting the final tire cost.

-

Labor: Labor costs vary by region and are influenced by local wage standards. Manufacturers in countries with lower labor costs may provide more competitive pricing, but this can come at the expense of quality.

-

Manufacturing Overhead: This encompasses factory expenses such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead and, in turn, lower prices.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, especially for customized tire specifications. These costs are often amortized over large production runs, making bulk purchases more economical.

-

Quality Control (QC): Rigorous QC processes are essential to ensure product reliability. While investing in high-quality control measures may increase initial costs, they ultimately reduce long-term costs associated with warranty claims and replacements.

-

Logistics: Shipping and handling costs vary based on the distance from the manufacturer to the buyer, the mode of transport, and any customs duties involved. Efficient logistics can minimize these expenses significantly.

-

Margin: The profit margin applied by manufacturers and distributors also plays a vital role in pricing. Understanding typical margins in the industry can help buyers identify fair pricing.

How Do Price Influencers Affect the Cost of 12.4×28 Tractor Tires?

Several factors can influence the pricing of 12.4×28 tractor tires:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Manufacturers typically offer discounts based on minimum order quantities (MOQs), making it advantageous for buyers to plan ahead.

-

Specifications and Customization: Tires with specialized features or custom specifications (e.g., tread patterns, load ratings) may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Tires made from higher-quality materials or those that meet international certifications (e.g., ISO, DOT) often command higher prices. However, these products can offer better performance and longevity, contributing to a lower total cost of ownership.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their brand value and service quality, but they also tend to offer better support and warranty options.

-

Incoterms: The terms of trade defined by Incoterms can affect overall costs. Buyers should clarify who is responsible for shipping, insurance, and customs clearance to avoid unexpected expenses.

What Are Effective Buyer Tips for Negotiating Prices on 12.4×28 Tractor Tires?

To maximize cost-efficiency when sourcing 12.4×28 tractor tires, buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, MOQ, and payment terms. Leveraging multiple supplier quotes can provide leverage in negotiations.

-

Evaluate Total Cost of Ownership: Consider not just the initial purchase price but also factors like durability, warranty, and replacement costs. A higher upfront cost may yield savings in the long run if the tires last longer.

-

Stay Informed About Pricing Nuances: Be aware of regional market trends, currency fluctuations, and seasonal demands that may affect pricing. This knowledge can provide a competitive edge in negotiations.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, priority service, and access to exclusive deals. Regular communication and feedback can foster mutual benefits.

Conclusion

In summary, understanding the intricate cost structure and the various factors influencing pricing for 12.4×28 tractor tires is essential for B2B buyers. By focusing on the total cost of ownership, leveraging negotiation strategies, and remaining informed about market dynamics, buyers can make more strategic purchasing decisions that align with their operational needs. Always remember that the prices indicated in this analysis are subject to market fluctuations and should be viewed as indicative rather than fixed.

Alternatives Analysis: Comparing 12.4×28 tractor tire With Other Solutions

Exploring Alternatives to the 12.4×28 Tractor Tire: What Are Your Options?

In the agricultural sector, selecting the right tire for tractors is crucial for optimizing performance, cost-efficiency, and overall productivity. While the 12.4×28 tractor tire is a popular choice due to its robust specifications and reliability, exploring alternative solutions can provide businesses with additional options that may better suit their specific needs. Below, we compare the 12.4×28 tractor tire against two viable alternatives: the 12.4-24 tractor tire and the use of tracks instead of tires.

| Comparison Aspect | 12.4×28 Tractor Tire | 12.4-24 Tractor Tire | Tracks (Rubber or Metal) |

|---|---|---|---|

| Performance | Excellent traction in diverse terrains; suitable for heavy loads. | Good performance, but slightly lower load capacity. | Superior traction and stability, especially on soft or uneven ground. |

| Cost | Generally higher price point, ranging from $434 to $706. | More affordable, typically between $400 and $600. | Higher upfront cost; installation and maintenance can be expensive. |

| Ease of Implementation | Easy to install on compatible tractors. | Similarly easy to implement; requires compatible rim sizes. | More complex installation process; requires specialized equipment. |

| Maintenance | Moderate maintenance; regular checks recommended. | Similar maintenance requirements as 12.4×28 tires. | Higher maintenance due to wear and tear; may require specialized service. |

| Best Use Case | Ideal for general farming applications and moderate terrain. | Suitable for lighter machinery or smaller tractors in less demanding conditions. | Best for heavy-duty applications, especially in wet or muddy environments. |

What Are the Benefits and Drawbacks of the 12.4-24 Tractor Tire?

The 12.4-24 tractor tire serves as a cost-effective alternative to the 12.4×28 tire. While it offers good traction and performance, its load capacity is slightly lower, making it less suitable for heavy-duty applications. The initial cost is generally lower, which can be appealing for budget-conscious buyers. However, businesses should consider whether the reduced capacity aligns with their operational needs, particularly if they frequently handle heavy loads.

How Do Tracks Compare to Traditional Tires for Agricultural Use?

Using tracks, whether rubber or metal, can significantly enhance traction and stability, especially on challenging terrains such as mud or soft soil. Tracks distribute weight more evenly, reducing soil compaction and improving overall field health. However, the higher upfront cost and more complex installation process can be a deterrent for some buyers. Additionally, maintenance can be more intensive, requiring specialized knowledge and tools. Tracks are best suited for heavy-duty applications where superior traction is necessary.

How Can B2B Buyers Decide on the Right Tire or Alternative for Their Needs?

Choosing the right tire or alternative solution requires a thorough understanding of operational needs, terrain types, and budget constraints. B2B buyers should assess the specific requirements of their agricultural applications, including load capacity and terrain challenges. If the primary concern is cost and lighter loads, the 12.4-24 tractor tire may suffice. For operations demanding high traction and stability, particularly in adverse conditions, tracks could be the best investment despite the higher costs. Ultimately, aligning the choice with operational goals and financial considerations will lead to the most effective solution.

Essential Technical Properties and Trade Terminology for 12.4×28 tractor tire

What Are the Essential Technical Properties of a 12.4×28 Tractor Tire?

Understanding the key technical specifications of a 12.4×28 tractor tire is crucial for B2B buyers to make informed purchasing decisions. Here are the most critical properties:

-

Load Index

The load index indicates the maximum weight the tire can safely support. For the 12.4×28 tire, common load indices range from 113 to 123, equating to maximum loads of approximately 2,535 to 3,417 lbs. This specification is vital for ensuring that the tire can handle the demands of agricultural machinery, particularly in diverse terrains common in regions like Africa and South America. -

Speed Rating

Speed ratings (e.g., A6, A8) signify the maximum speed the tire can maintain safely. For instance, an A6 rating allows for speeds up to 19 MPH, while an A8 rating permits speeds up to 25 MPH. Selecting the correct speed rating is essential for operational efficiency and safety in various agricultural tasks. -

Tread Depth

Tread depth is measured in 32nds of an inch and affects traction and performance. Typical tread depths for 12.4×28 tires range from 38 to 64/32nds. A deeper tread provides better grip in muddy or uneven conditions, which is particularly important in regions prone to heavy rainfall or challenging agricultural landscapes. -

Ply Rating

The ply rating indicates the tire’s strength and load capacity. A common rating for 12.4×28 tires is 6 or 8 ply, which reflects the tire’s ability to withstand heavy loads and impacts. For B2B buyers, understanding ply ratings helps in assessing durability, which translates to lower replacement costs and increased productivity. -

Inflation Pressure

Recommended inflation pressure, typically around 24-33 PSI for 12.4×28 tires, directly impacts performance, fuel efficiency, and tire life. Proper inflation ensures optimal contact with the ground, reducing wear and tear and enhancing overall operational efficiency, which is crucial for agricultural businesses. -

Construction Type

Most 12.4×28 tractor tires are bias or radial construction. Bias tires provide a flexible sidewall for better traction, while radial tires offer improved stability and fuel efficiency. Knowing the construction type helps buyers choose the right tire for their specific agricultural applications.

What Are Common Trade Terms Related to 12.4×28 Tractor Tires?

Familiarity with industry jargon is essential for B2B buyers in navigating tire procurement effectively. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to tires produced by the original manufacturer of the tractor or agricultural equipment. Purchasing OEM tires can ensure compatibility and performance, making it a preferred choice for many businesses. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers as it can affect inventory management and cash flow, especially for businesses operating in regions with fluctuating demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific tire models. Submitting an RFQ can help buyers obtain competitive pricing and ensure they receive the best value for their purchases. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and delivery points. Familiarity with these terms helps businesses mitigate risks and streamline logistics. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for inventory planning and ensuring that agricultural operations remain uninterrupted. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the tire’s performance and durability. Knowing the warranty terms can offer buyers peace of mind and protect their investment against defects or premature wear.

In summary, understanding both the technical properties and trade terminology associated with 12.4×28 tractor tires is essential for B2B buyers to make informed decisions that enhance operational efficiency and reduce costs.

Navigating Market Dynamics and Sourcing Trends in the 12.4×28 tractor tire Sector

The market for 12.4×28 tractor tires is influenced by several global drivers, including the increasing demand for agricultural productivity, advancements in tire technology, and the rising adoption of precision farming techniques. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking durable and efficient solutions to meet their agricultural needs. Key trends impacting the sector include the integration of digital technologies for inventory management and procurement processes, such as e-commerce platforms that allow buyers to compare prices, specifications, and reviews easily. Additionally, the shift towards online marketplaces is enabling buyers to access a broader range of suppliers, enhancing competition and driving down prices.

Emerging sourcing trends are also noteworthy. Buyers are focusing on local sourcing to reduce lead times and logistics costs, particularly in developing regions where transportation can be a challenge. Furthermore, there is a growing interest in purchasing tires that offer better fuel efficiency and lower rolling resistance, as these attributes can significantly impact operational costs. As the market evolves, B2B buyers are encouraged to stay informed about innovations in tire technology that enhance performance and longevity, ensuring they make well-informed purchasing decisions.

How Does Sustainability Influence the Sourcing of 12.4×28 Tractor Tires?

The environmental impact of tire production and disposal has become a significant concern in the agricultural sector. B2B buyers are increasingly prioritizing sustainability in their sourcing decisions. This shift is driven by both regulatory requirements and consumer preferences for environmentally friendly products. Ethical supply chains are essential, as they not only ensure compliance with local and international standards but also enhance the reputation of businesses committed to sustainable practices.

Sourcing tires that incorporate recycled materials or are manufactured with eco-friendly processes can help minimize the carbon footprint. Moreover, certifications such as ISO 14001 for environmental management systems and certifications for sustainable rubber sourcing are becoming crucial for suppliers to demonstrate their commitment to sustainability. B2B buyers should consider these factors when evaluating potential suppliers, as choosing partners who prioritize sustainability can lead to long-term benefits, including improved brand loyalty and reduced operational risks.

What is the Historical Context of the 12.4×28 Tractor Tire Market?

The evolution of the 12.4×28 tractor tire market reflects broader trends in agricultural mechanization and tire technology. Initially, tractor tires were predominantly made from natural rubber and lacked the durability required for intensive agricultural use. Over the decades, advancements in materials science led to the introduction of synthetic rubber compounds, improving tire strength and performance.

The introduction of radial tires in the late 20th century revolutionized the sector, providing better fuel efficiency and enhanced traction on various terrains. This evolution has continued with innovations in tread design, which now cater to specific agricultural applications, such as tillage and harvesting. As the agricultural landscape evolves, so too does the demand for specialized tires like the 12.4×28, reflecting the ongoing commitment to improving agricultural productivity and efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of 12.4×28 tractor tire

-

How do I choose the right 12.4×28 tractor tire for my equipment?

Choosing the right 12.4×28 tractor tire involves understanding your equipment’s specifications, including load capacity, speed rating, and terrain type. Consider the tire’s construction type (bias vs. radial) and tread design, as these factors significantly influence performance. Additionally, assess the tire’s ply rating, which indicates its strength and durability under heavy loads. Consulting with suppliers about your specific operational needs can also provide tailored recommendations for optimal performance. -

What factors should I consider when sourcing 12.4×28 tractor tires internationally?

When sourcing 12.4×28 tractor tires internationally, consider factors such as supplier reliability, product quality, and compliance with local regulations. It’s crucial to assess shipping costs, lead times, and the supplier’s ability to provide after-sales support. Additionally, verify the tire’s specifications against your requirements, and ensure that the supplier can handle customs clearance and any potential import duties that may apply. -

What are common payment terms for purchasing tractor tires in bulk?

Payment terms for purchasing tractor tires can vary widely depending on the supplier and the buyer’s relationship. Common terms include a deposit upfront (often 30-50%) with the balance due upon delivery or within a specified period after receipt of goods. Some suppliers may offer financing options or discounts for early payment. It’s essential to clarify payment methods (e.g., wire transfer, letter of credit) and ensure that they align with your financial capabilities and risk management strategies. -

How can I vet suppliers for 12.4×28 tractor tires?

To vet suppliers for 12.4×28 tractor tires, start by researching their reputation in the industry through reviews and testimonials. Request references from previous clients, especially those in your region, to gauge their experience. Evaluate the supplier’s certifications, such as ISO standards, and inquire about their quality control processes. Additionally, assess their ability to provide timely shipping and customer service support to ensure they can meet your business needs. -

What is the minimum order quantity (MOQ) for 12.4×28 tractor tires?

Minimum order quantities (MOQ) for 12.4×28 tractor tires can vary by supplier, typically ranging from a single tire to several dozen. Many suppliers have flexible MOQs based on your purchasing power and the specific tire model. When negotiating, consider discussing bulk discounts or combined orders with other products to meet MOQ requirements while optimizing your purchasing strategy. -

What should I do if I receive defective 12.4×28 tractor tires?

If you receive defective 12.4×28 tractor tires, promptly contact the supplier to report the issue. Document the defects with photographs and keep records of all communications. Most reputable suppliers offer warranties or return policies that allow for the exchange or refund of defective products. Ensure you understand the return process, including shipping arrangements and any documentation required for claims. -

How can I customize my 12.4×28 tractor tires?

Customization options for 12.4×28 tractor tires may include specific tread patterns, sidewall markings, or ply ratings tailored to your operational needs. Discuss your requirements with potential suppliers, as some manufacturers may offer bespoke solutions. Be prepared to provide detailed specifications, including expected load capacities and environmental conditions, to ensure that the customized tires meet your performance expectations. -

What logistics considerations should I keep in mind when importing tractor tires?

When importing 12.4×28 tractor tires, consider logistics factors such as shipping methods (air vs. sea), transit times, and potential customs clearance procedures. Ensure your supplier provides clear shipping documentation, including invoices and certificates of origin. Familiarize yourself with local import regulations and tariffs to avoid unexpected costs. Partnering with a reliable freight forwarder can help streamline the logistics process and ensure timely delivery to your location.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 12.4X28 Tractor Tire Manufacturers & Suppliers List

1. SimpleTire – 12.4/28 Tires

Domain: simpletire.com

Registered: 2009 (16 years)

Introduction: 12.4/28 Tires available online at SimpleTire. Key details include:

– Rims not included with tire purchase.

– Various brands and models available, including BKT, Galaxy, Titan, Firestone, and more.

– Load Index ranges from 113 to 123, with maximum loads from 2535 lbs to 3417 lbs.

– Load Range options include C (6 Ply) and D (8 Ply).

– Maximum speeds vary by model, ranging from 19 MPH to 56 MPH.

– T…

2. Titan – Agra Vantage R-1 TL Tire

Domain: gallaghertire.com

Registered: 2000 (25 years)

Introduction: [{“item”:”TITAN AGRA VANTAGE R-1 TL 12.4-24 D TIRE ONLY”,”item_number”:”4AV8AD”,”availability”:”24 AVAILABLE IN GALLAGHER INVENTORY, 25+ AVAILABLE IN SUPPLIER WAREHOUSE INVENTORY”,”max_load_capacity_lbs”:2830,”max_psi”:32,”rim_diameter”:24,”rim_size”:”24X10″,”section_width”:12,”speed_rating”:”A8/25″,”weight_lbs”:113},{“item”:”ALLIANCE 324 FARM PRO R1 TL 12.4-24 D TIRE ONLY”,”item_number”:”32405301…

3. Your Next Tire – 12.4-28 Tractor Tire

4. Ford – Tractors and Backhoes

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Ford 501, 600, 601, 700, 701, 800, 801, 900, 901 tractors/backhoes; Wanted: Good 12.4×28 tire on rim.

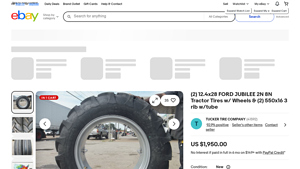

5. FORD – 12.4×28 Tractor Tires with Wheels

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: (2) 12.4×28 FORD JUBILEE 2N 8N Tractor Tires with Wheels & (2) 550×16 3 rib with tube; Condition: New; Price: US $1,950.00; Quantity available: 3; Shipping: Free Standard Shipping; Location: Dyersburg, Tennessee, United States; Returns: 30 days returns, buyer pays for return shipping; Seller: T TUCKER TIRE COMPANY, 92.9% positive feedback; Model: FORD JUBILEE 2N 8N; Brand: Unbranded; Compatible Eq…

6. Yesterday’s Tractors – 12.4 x 28 Tires Discussion

Domain: forums.yesterdaystractors.com

Registered: 1997 (28 years)

Introduction: 12.4 x 28 tires; commonly discussed in relation to Ford 8N and 3000 tractors; users express mixed opinions on suitability for 8N; some prefer 11.2 x 28 tires for better performance; 12.4 tires provide good traction, especially in winter; some users have filled tires with fluid for added weight; compatibility with different rim sizes mentioned; overall satisfaction with appearance and performance n…

7. BKT – 12.4-28 Tyres for Sale

Domain: tractorpool.com

Registered: 2002 (23 years)

Introduction: Used 12.4 28 for sale on tractorpool.com. Available from machinery dealers or private sellers. Offers on high-quality agricultural machinery. Active search filters include category: Tractors, model/designation: 12.4 28. Tyres available include BKT TR-135 12.4-28 8PR 120A8 and Alliance Farmpro 324 12.4-28. Prices on request.

Strategic Sourcing Conclusion and Outlook for 12.4×28 tractor tire

In navigating the complexities of sourcing 12.4×28 tractor tires, international B2B buyers must prioritize value-driven decisions that align with their operational needs. The diversity of tire options, ranging from load capacities to tread depths, highlights the importance of understanding specific agricultural applications and environmental conditions. By leveraging strategic sourcing practices, buyers can secure competitive pricing, optimize inventory management, and ensure product availability.

Additionally, considering partnerships with reputable suppliers who offer financing options and favorable shipping terms can enhance procurement efficiency. With a growing emphasis on sustainability and performance, selecting high-quality tires that meet rigorous standards will contribute to enhanced operational productivity and reduced downtime.

As you look ahead, now is the time to act. Assess your sourcing strategies, explore supplier options, and engage with manufacturers that understand your regional requirements. The future of your agricultural operations depends on the tires you choose today. Embrace this opportunity to elevate your sourcing practices and position your business for long-term success in the global marketplace.