Choosing Your Knotty Pine Vinyl Plank Flooring: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for knotty pine vinyl plank flooring

In today’s dynamic global market, sourcing high-quality knotty pine vinyl plank flooring presents a unique challenge for international B2B buyers. With its combination of aesthetic appeal and practical benefits, knotty pine vinyl flooring has gained traction across diverse regions, including Africa, South America, the Middle East, and Europe. However, navigating the complexities of product specifications, supplier reliability, and cost-effectiveness can be daunting.

This comprehensive guide delves into the various types of knotty pine vinyl plank flooring, highlighting their applications in residential and commercial settings. It also covers essential aspects such as supplier vetting processes, competitive pricing strategies, and installation considerations, ensuring that buyers are well-equipped to make informed decisions. By providing actionable insights and industry best practices, this guide empowers B2B buyers to confidently navigate the market landscape and select flooring solutions that align with their specific needs and objectives.

Whether you are looking to enhance the aesthetic of a hospitality space in Nigeria or seeking durable flooring for a retail outlet in Vietnam, understanding the nuances of knotty pine vinyl plank flooring will position your business for success. This resource is designed to streamline your purchasing process, enabling you to optimize both value and quality in your flooring investments.

Understanding knotty pine vinyl plank flooring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof Luxury Vinyl Plank | High durability, 100% waterproof, various thickness options | Commercial spaces, residential properties | Pros: Long-lasting, easy to maintain. Cons: Initial cost higher than standard vinyl. |

| Wide Plank Knotty Pine Vinyl | Wider planks for a rustic look, enhanced grain detail | High-end residential, boutique hotels | Pros: Aesthetic appeal, unique character. Cons: Limited availability, higher price point. |

| Antique Pine Vinyl WPC | Vintage appearance, 20mil wear layer, click/lock installation | Retail stores, restaurants | Pros: Easy installation, cost-effective. Cons: May require more frequent replacements. |

| Select Knotty Pine Vinyl Plank | Custom milling options, various lengths, and widths available | Custom homes, upscale renovations | Pros: Customizable, high-quality finish. Cons: Longer lead times for custom orders. |

| Standard Knotty Pine Vinyl Plank | Cost-effective, traditional design, available in multiple colors | Budget-friendly projects, rental spaces | Pros: Affordable, widely available. Cons: Less durability compared to luxury options. |

What Are the Characteristics of Waterproof Luxury Vinyl Plank Flooring?

Waterproof luxury vinyl plank flooring is designed for high durability and resilience, making it ideal for areas prone to moisture, such as kitchens and bathrooms. This type features a robust wear layer, typically around 12 mils, and is available in various thicknesses to suit different applications. B2B buyers should consider its long-term cost-effectiveness due to reduced maintenance and replacement needs, despite a higher initial investment compared to standard vinyl options.

How Does Wide Plank Knotty Pine Vinyl Differ from Other Variants?

Wide plank knotty pine vinyl flooring offers a rustic aesthetic with wider planks that enhance the visual impact of any space. Its detailed grain patterns evoke a traditional wood look, making it suitable for high-end residential projects and boutique hotels. B2B buyers should note that while this option adds significant character, its availability may be limited and typically comes at a premium price, necessitating careful budgeting for procurement.

What Makes Antique Pine Vinyl WPC a Popular Choice?

Antique pine vinyl WPC (Wood Plastic Composite) flooring combines a vintage look with modern durability. With a 20 mil wear layer and a simple click/lock installation method, it is particularly well-suited for retail spaces and restaurants where aesthetics and functionality are paramount. Buyers should weigh its cost-effectiveness against the potential for more frequent replacements in high-traffic areas, making it a strategic choice for budget-conscious projects.

Why Choose Select Knotty Pine Vinyl Plank for Custom Projects?

Select knotty pine vinyl plank flooring stands out for its customizable options, allowing buyers to select specific lengths and widths to meet project requirements. Ideal for upscale renovations and custom homes, this flooring type offers a high-quality finish that can be stained or coated to match design preferences. B2B buyers should be prepared for longer lead times associated with custom orders but can expect a product that enhances the overall aesthetic and value of their projects.

What Are the Advantages of Standard Knotty Pine Vinyl Plank Flooring?

Standard knotty pine vinyl plank flooring provides a cost-effective solution for budget-friendly projects. Available in various colors and styles, it is widely used in rental spaces and less formal commercial environments. While it offers affordability and ease of availability, buyers should consider its lower durability compared to more premium options, which may lead to increased maintenance or replacement costs over time.

Key Industrial Applications of knotty pine vinyl plank flooring

| Industry/Sector | Specific Application of knotty pine vinyl plank flooring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Flooring for hotels and resorts | Enhances aesthetic appeal while being durable and easy to maintain | Look for waterproof and stain-resistant options to handle high foot traffic |

| Retail | Showroom and retail space flooring | Provides a warm, inviting atmosphere that can enhance customer experience | Consider the cost-effectiveness and ease of installation for quick renovations |

| Education | Classrooms and common areas | Offers comfort and noise reduction, promoting a better learning environment | Ensure compliance with safety standards and durability for high-traffic areas |

| Healthcare | Flooring in clinics and hospitals | Easy to clean and maintain, promoting hygiene and safety | Select options that are antimicrobial and resistant to spills |

| Residential Developments | Flooring for apartments and housing projects | Cost-effective and stylish, appealing to potential buyers or renters | Seek options with long warranties and low maintenance requirements |

How is Knotty Pine Vinyl Plank Flooring Used in Hospitality Settings?

In the hospitality sector, knotty pine vinyl plank flooring is frequently used in hotels and resorts to create a warm and inviting atmosphere. This flooring option not only enhances the aesthetic appeal of lobbies, guest rooms, and dining areas but also withstands the rigors of high foot traffic. Its waterproof and stain-resistant properties make it ideal for areas prone to spills, ensuring that maintenance is straightforward and cost-effective. International buyers should prioritize suppliers that offer a variety of styles and colors to cater to diverse customer preferences.

What Benefits Does Knotty Pine Vinyl Plank Flooring Provide for Retail Spaces?

In retail environments, knotty pine vinyl plank flooring can be utilized in showrooms and sales floors to create an inviting ambiance that encourages customer engagement. This flooring solution is not only durable but also easy to install, allowing for quick renovations that minimize downtime. Additionally, its cost-effectiveness helps businesses maintain a budget while achieving a high-end look. Buyers should consider sourcing from manufacturers who provide samples and detailed specifications to ensure the flooring meets their design and functional needs.

Why is Knotty Pine Vinyl Plank Flooring Ideal for Educational Institutions?

Educational institutions, such as schools and universities, often utilize knotty pine vinyl plank flooring in classrooms and common areas. The flooring’s noise reduction capabilities contribute to a conducive learning environment, while its comfortable surface makes it suitable for long hours of use. Furthermore, the ease of cleaning and maintenance ensures that these spaces remain hygienic. Buyers in this sector should look for flooring options that comply with safety standards and can endure the wear and tear of daily student activity.

How Does Knotty Pine Vinyl Plank Flooring Enhance Healthcare Facilities?

In healthcare settings, knotty pine vinyl plank flooring is employed in clinics and hospitals due to its easy-to-clean nature, which promotes hygiene and safety. Its resistance to spills and stains is particularly beneficial in environments where cleanliness is paramount. The comfort of the flooring also aids in patient recovery areas and waiting rooms. Healthcare buyers should prioritize sourcing flooring that is antimicrobial and designed for heavy foot traffic to ensure longevity and safety.

What Makes Knotty Pine Vinyl Plank Flooring Suitable for Residential Developments?

Knotty pine vinyl plank flooring is an excellent choice for residential developments, including apartments and housing projects, due to its cost-effectiveness and stylish appearance. This flooring option appeals to potential buyers or renters by providing a rustic yet modern aesthetic. Its long-lasting durability and low maintenance requirements make it an attractive investment for property developers. Buyers should seek options with extensive warranties to ensure they are making a wise long-term investment.

3 Common User Pain Points for ‘knotty pine vinyl plank flooring’ & Their Solutions

Scenario 1: Quality Concerns in Product Sourcing

The Problem: B2B buyers often face the challenge of ensuring the quality of knotty pine vinyl plank flooring when sourcing from various suppliers. Inconsistent quality across batches can lead to issues such as mismatched colors, variations in texture, and durability concerns. This is particularly critical for businesses in the flooring installation sector, as poor-quality materials can result in customer dissatisfaction, increased returns, and damage to reputation.

The Solution: To mitigate quality concerns, buyers should establish strong relationships with reputable manufacturers and suppliers who offer detailed product specifications and samples. Implement a robust vetting process that includes requesting certifications, warranty information, and customer reviews. Additionally, conducting periodic quality checks and audits of the suppliers’ production facilities can help ensure that the flooring meets industry standards. When specifying products, clearly communicate your quality requirements, including acceptable tolerance levels for color and texture, to minimize discrepancies.

Scenario 2: Installation Challenges for Knotty Pine Vinyl Plank Flooring

The Problem: Another common issue faced by B2B buyers is the complexity of installing knotty pine vinyl plank flooring, especially in commercial spaces with unique layouts or high foot traffic. Inexperienced installers may struggle with the interlocking mechanism or miscalculate the amount of flooring needed, leading to wasted materials and increased labor costs.

The Solution: To address installation challenges, it is essential to provide comprehensive training and resources to installers. Consider partnering with suppliers who offer training sessions or detailed installation guides that cover best practices for laying knotty pine vinyl planks. Additionally, emphasize the importance of proper subfloor preparation and acclimatization of the planks before installation. Providing tools like online calculators for material estimation can also assist installers in accurately determining the quantity needed, reducing waste and ensuring a smoother installation process.

Scenario 3: Misalignment with Customer Expectations

The Problem: B2B buyers often encounter difficulties in aligning the final product with the expectations of their customers, particularly when it comes to aesthetics and functionality. For instance, customers may anticipate the warm, rustic charm of natural wood, but if the vinyl planks do not replicate this effectively, it can lead to dissatisfaction and requests for refunds or exchanges.

The Solution: To bridge the gap between customer expectations and the actual product, B2B buyers should prioritize transparent communication and provide realistic samples of knotty pine vinyl plank flooring. Offering visual aids, such as high-quality images and videos that showcase the flooring in various settings, can help customers visualize the final outcome. Additionally, consider using augmented reality tools that allow customers to see how the flooring would look in their space before making a decision. By managing expectations through education about the product’s features and limitations, buyers can foster greater customer satisfaction and loyalty.

Strategic Material Selection Guide for knotty pine vinyl plank flooring

What Are the Key Materials Used in Knotty Pine Vinyl Plank Flooring?

Knotty pine vinyl plank flooring is an innovative solution that combines aesthetic appeal with durability. The materials used in its construction significantly influence its performance, cost-effectiveness, and suitability for various applications. Here, we analyze four common materials utilized in knotty pine vinyl plank flooring from a B2B perspective.

What Are the Key Properties of PVC in Knotty Pine Vinyl Plank Flooring?

Polyvinyl Chloride (PVC) is a primary material used in vinyl flooring. It offers excellent durability, with a temperature rating that can withstand a wide range of conditions. PVC is inherently resistant to moisture, making it suitable for areas prone to spills or humidity. However, it can be sensitive to extreme temperatures, which may cause expansion or contraction.

Pros: PVC flooring is cost-effective and easy to install. It is also available in various designs, allowing for customization to mimic natural wood finishes.

Cons: While PVC is durable, it can be prone to scratching and may not have the same lifespan as higher-end materials. Additionally, environmental concerns regarding PVC production may affect its acceptability in certain markets.

How Does WPC (Wood Plastic Composite) Perform in Knotty Pine Vinyl Plank Flooring?

WPC combines wood fibers and plastic, offering a unique blend of aesthetics and functionality. It boasts excellent temperature and pressure ratings, making it suitable for high-traffic areas. WPC is also waterproof, contributing to its longevity and ease of maintenance.

Pros: The composite nature of WPC provides superior comfort underfoot and excellent sound absorption, making it ideal for residential and commercial applications. Its resistance to moisture makes it a popular choice in regions with high humidity.

Cons: The manufacturing process for WPC can be more complex, leading to higher costs compared to traditional vinyl. Additionally, while WPC is durable, it may not be as scratch-resistant as pure vinyl options.

What Role Does Rigid Core Technology Play in Knotty Pine Vinyl Plank Flooring?

Rigid core technology involves a multi-layer construction that enhances stability and durability. This type of flooring is designed to withstand heavy foot traffic and impacts, making it suitable for commercial environments. It also offers excellent sound insulation and is resistant to moisture.

Pros: Rigid core flooring is easy to install and can be placed over existing floors without the need for additional underlayment. Its durability ensures a longer lifespan, reducing the need for frequent replacements.

Cons: The initial cost of rigid core products can be higher than traditional vinyl. Additionally, while it is durable, it may be heavier, complicating transportation and installation.

How Do Natural Wood Veneers Enhance Knotty Pine Vinyl Plank Flooring?

Natural wood veneers are often used in luxury vinyl plank flooring to provide an authentic wood appearance. They enhance the aesthetic appeal while maintaining the benefits of vinyl’s durability and ease of maintenance.

Pros: Wood veneers offer a realistic look and feel, making them attractive for high-end residential and commercial projects. They are also easier to maintain than solid wood, as they resist stains and moisture.

Cons: The use of natural wood veneers can increase costs significantly. Additionally, they may require more careful handling during installation to avoid damage.

Summary Table of Materials for Knotty Pine Vinyl Plank Flooring

| Material | Typical Use Case for knotty pine vinyl plank flooring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Residential and light commercial areas | Cost-effective and easy to install | Prone to scratching and environmental concerns | Low |

| WPC | High-traffic residential and commercial environments | Superior comfort and moisture resistance | Higher manufacturing costs | Medium |

| Rigid Core | Commercial spaces and high-traffic areas | Long-lasting durability and easy installation | Higher initial cost and heavier weight | High |

| Natural Wood Veneer | Luxury residential and high-end commercial projects | Authentic wood appearance | Increased cost and requires careful handling | High |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions regarding knotty pine vinyl plank flooring. Understanding the properties, advantages, and limitations of each material can facilitate compliance with regional standards and preferences, ensuring successful procurement and application.

In-depth Look: Manufacturing Processes and Quality Assurance for knotty pine vinyl plank flooring

What Are the Main Stages in the Manufacturing Process of Knotty Pine Vinyl Plank Flooring?

The manufacturing process for knotty pine vinyl plank flooring involves several critical stages that ensure high-quality and durable products suitable for various applications. Understanding these stages can help B2B buyers evaluate suppliers effectively.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage begins with the selection of high-quality raw materials, primarily vinyl and stabilizers, which are essential for producing resilient flooring. Manufacturers often source vinyl from reputable suppliers to ensure consistency and reliability. Once sourced, the materials undergo a cleaning and conditioning process to remove impurities that could affect the final product’s quality.

In the case of knotty pine aesthetics, manufacturers may also incorporate wood grain patterns into the vinyl layer, often using advanced printing techniques. This preparation stage is crucial, as it lays the groundwork for the quality and appearance of the finished flooring.

Forming: What Techniques Are Used to Create Vinyl Planks?

During the forming stage, the prepared materials are combined and heated to form a homogenous mixture. This mixture is then extruded into sheets or planks through specialized machinery. Various techniques, such as embossing, are employed to create textures that mimic the look of real wood, enhancing the visual appeal of the flooring.

The dimensions of the planks, including width and thickness, are precisely controlled during this process to ensure uniformity across batches. This attention to detail is vital for B2B buyers who require consistent products for large-scale installations.

Assembly: How Are Planks Constructed and Prepped for Finishing?

After forming, the planks undergo an assembly process where additional layers are added. This may include a backing layer for stability and a wear layer that enhances durability and resistance to scratches and stains. The assembly process often employs advanced bonding techniques to ensure that the layers adhere well without delaminating over time.

Quality control checkpoints are established at this stage to verify the integrity of the assembly. This includes visual inspections and mechanical tests to ensure that the planks can withstand the demands of high-traffic environments.

Finishing: What Steps Are Involved in Finalizing the Product?

The finishing stage is where the planks receive their final coatings and treatments. This may involve applying a protective layer that enhances water resistance and durability. Manufacturers may also use UV coating to protect against fading from sunlight.

Once finished, the planks are subjected to additional quality checks to ensure they meet the required specifications. These checks often include measuring thickness, weight, and appearance to ensure that the planks conform to industry standards.

What Quality Assurance Standards Are Relevant for Knotty Pine Vinyl Plank Flooring?

Quality assurance is paramount in the production of knotty pine vinyl plank flooring. International and industry-specific standards provide a framework for ensuring that products meet customer expectations and regulatory requirements.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized international standards is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 demonstrates a manufacturer’s commitment to quality and continuous improvement. For B2B buyers, this certification can serve as a reliable indicator of a supplier’s quality assurance practices.

Additionally, CE marking is essential for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards. Buyers in Europe should prioritize suppliers with CE certification to ensure regulatory compliance.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Inspects raw materials for quality before production begins.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early and ensure adherence to specifications.

- Final Quality Control (FQC): Conducts comprehensive checks on finished products, including dimensional accuracy and surface quality.

Implementing these checkpoints ensures that any potential issues are identified and addressed promptly, reducing the risk of defects in the final product.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

What Audits and Reports Should Buyers Request?

Buyers should request documentation such as quality assurance reports and audit records. This may include internal audit findings and third-party inspection reports, which provide insights into the supplier’s quality management practices.

Additionally, suppliers should be open to third-party audits conducted by recognized organizations. These audits can provide an unbiased assessment of the supplier’s processes and compliance with relevant standards.

How Can Buyers Ensure Compliance with Specific Quality Standards?

For B2B buyers, understanding the nuances of quality control certifications is essential. Different regions may have varying requirements, and ensuring compliance with these standards can be complex. Buyers should familiarize themselves with the specific certifications required in their target markets and verify that their suppliers meet these criteria.

Engaging with local industry associations can also provide valuable insights into best practices and standards specific to different regions. Networking with other businesses in the same industry can help buyers share information about reliable suppliers and their quality assurance practices.

Conclusion: What Should B2B Buyers Consider When Sourcing Knotty Pine Vinyl Plank Flooring?

When sourcing knotty pine vinyl plank flooring, B2B buyers should prioritize suppliers that demonstrate a commitment to quality through robust manufacturing processes and adherence to international standards. Understanding the stages of manufacturing and the importance of quality control can aid buyers in making informed decisions.

By verifying supplier practices through audits and quality certifications, buyers can mitigate risks and ensure that they are investing in high-quality flooring solutions that meet their specific needs. As the market for vinyl flooring continues to grow globally, informed purchasing decisions will be essential for success in this competitive landscape.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘knotty pine vinyl plank flooring’

Introduction

This practical sourcing guide provides a comprehensive checklist for B2B buyers looking to procure knotty pine vinyl plank flooring. By following these steps, businesses can ensure they make informed decisions that align with their project requirements, budget, and long-term goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, outline the specific requirements for your knotty pine vinyl plank flooring. Consider factors such as thickness, wear layer, dimensions, and installation method (e.g., click-lock or glue-down). Clearly defined specifications help streamline supplier selection and ensure the product meets your operational needs.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing is crucial for making competitive purchasing decisions. Analyze regional pricing variations, especially in target markets like Africa, South America, the Middle East, and Europe. Monitor fluctuations in material costs and emerging trends, such as sustainability in flooring options, to enhance negotiation leverage with suppliers.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and product quality. Request detailed company profiles, product catalogs, and references from other businesses within your industry. Pay attention to reviews and case studies that highlight the supplier’s experience and customer satisfaction levels. This research mitigates risks associated with subpar products and service.

- Check for Certifications: Ensure suppliers hold necessary certifications (e.g., ISO, CE) that validate their compliance with international quality standards.

Step 4: Request Samples for Assessment

Before finalizing a purchase, request samples of the knotty pine vinyl plank flooring. Evaluating physical samples allows you to assess the product’s appearance, texture, and overall quality firsthand. This step is vital to confirm that the flooring meets your aesthetic and functional requirements.

Step 5: Review Warranty and Return Policies

Examine the warranty and return policies offered by suppliers. A robust warranty indicates confidence in product durability and quality. Ensure that return policies are flexible enough to accommodate potential issues, such as damage during shipping or dissatisfaction with the product once received.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms. Discuss pricing, payment terms, delivery schedules, and bulk order discounts. Effective negotiation can significantly impact your overall project budget and cash flow management.

Step 7: Finalize Logistics and Installation Plans

After securing your order, plan the logistics for delivery and installation. Coordinate with suppliers to confirm shipping timelines and ensure that flooring arrives on schedule. Additionally, consider whether to use professional installation services or if the flooring can be installed using a DIY approach, which may impact your overall costs.

By following these steps, B2B buyers can effectively navigate the procurement process for knotty pine vinyl plank flooring, ensuring a successful and satisfactory purchase experience.

Comprehensive Cost and Pricing Analysis for knotty pine vinyl plank flooring Sourcing

What Are the Key Cost Components for Knotty Pine Vinyl Plank Flooring?

When sourcing knotty pine vinyl plank flooring, understanding the cost structure is essential for effective budgeting and procurement. The main cost components include:

-

Materials: The primary material in vinyl flooring is polyvinyl chloride (PVC), with varying qualities affecting the price. Higher-quality materials, like those with enhanced durability or waterproof features, typically command higher prices. Additionally, aesthetic finishes or textures can influence material costs.

-

Labor: Installation costs can vary significantly based on the region and complexity of the job. In many markets, skilled labor is a significant part of the total expenditure, especially for intricate designs or large-scale installations.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and workforce management. Manufacturers with advanced technology or eco-friendly processes may have higher overhead, which can translate to higher pricing.

-

Tooling and Equipment: Initial costs for tools and machinery are factored into the pricing of flooring products. Manufacturers who invest in high-quality equipment may produce superior products, affecting the overall cost.

-

Quality Control (QC): Rigorous QC processes ensure that the flooring meets industry standards. This can add to the cost, but it ultimately assures buyers of the product’s longevity and performance.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, transportation mode, and fuel prices can significantly influence logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. The margin can vary based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Affect the Cost of Knotty Pine Vinyl Plank Flooring?

Several factors can influence the pricing of knotty pine vinyl plank flooring:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Buyers looking to source large quantities should negotiate for better rates based on their volume needs.

-

Specifications and Customization: Custom designs or specific finishes can increase costs. Buyers should balance their aesthetic preferences with budget constraints, as high customization can significantly impact pricing.

-

Material Quality and Certifications: Flooring with certifications for sustainability or enhanced durability may have a higher initial cost but can provide better long-term value. It’s advisable to consider these certifications when evaluating suppliers.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their brand equity and service quality, while less-known suppliers may offer lower prices but come with risks.

-

Incoterms: Understanding the shipping terms (Incoterms) is vital for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the flooring.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Knotty Pine Vinyl Plank Flooring?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, adopting strategic sourcing practices can lead to substantial savings:

-

Negotiation: Engage in proactive negotiation with suppliers. Highlighting potential for bulk purchases or long-term partnerships may encourage suppliers to offer more competitive pricing.

-

Consider Total Cost of Ownership (TCO): While the upfront cost is crucial, evaluating the TCO—including installation, maintenance, and longevity—can provide a clearer picture of overall value. Higher-quality products may have a higher upfront cost but can save money in the long run through reduced maintenance and replacement needs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import tariffs that can affect pricing. Engaging local representatives or consultants familiar with regional market dynamics can provide insights into fair pricing and help navigate potential pitfalls.

-

Sourcing from Local Manufacturers: Whenever possible, consider sourcing from local manufacturers to reduce logistics costs and lead times. This can also minimize the risks associated with international shipping delays.

Disclaimer on Indicative Prices

Prices for knotty pine vinyl plank flooring can vary widely based on the aforementioned factors. The figures mentioned in various sources are indicative and may not reflect current market conditions. Always consult with suppliers for the most accurate and up-to-date pricing tailored to your specific requirements.

Alternatives Analysis: Comparing knotty pine vinyl plank flooring With Other Solutions

Understanding Alternatives to Knotty Pine Vinyl Plank Flooring

In the competitive flooring market, knotty pine vinyl plank flooring stands out for its aesthetic appeal and practical benefits. However, B2B buyers often need to evaluate various flooring options to find the best fit for their specific requirements. This section explores alternatives to knotty pine vinyl plank flooring, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Knotty Pine Vinyl Plank Flooring | Laminate Flooring | Solid Hardwood Flooring |

|---|---|---|---|

| Performance | Waterproof, durable, and soft underfoot | Scratch-resistant, less moisture-resistant | Highly durable, can be refinished |

| Cost | $3.00 – $5.00 per sq. ft. | $1.50 – $3.50 per sq. ft. | $5.00 – $12.00 per sq. ft. |

| Ease of Implementation | DIY-friendly, click-lock installation | Easy to install, requires underlayment | Requires professional installation |

| Maintenance | Easy to clean, resistant to stains | Moderate; requires regular cleaning | Needs periodic refinishing and maintenance |

| Best Use Case | High-traffic commercial areas, residential spaces | Budget-friendly options for homes and rentals | High-end residential spaces, long-term investment |

What are the Pros and Cons of Laminate Flooring Compared to Knotty Pine Vinyl Plank Flooring?

Laminate flooring is often chosen for its affordability and ease of installation. It offers a wide variety of designs, including wood-like finishes that can mimic the appearance of knotty pine. However, while laminate is scratch-resistant, it is less effective in moisture-prone areas compared to vinyl. Additionally, laminate cannot be refinished, which may limit its longevity in high-traffic environments.

What Benefits Does Solid Hardwood Flooring Offer Over Knotty Pine Vinyl Plank Flooring?

Solid hardwood flooring is a classic choice known for its durability and timeless appeal. It can be refinished multiple times, allowing it to maintain its appearance over decades. However, the installation process can be complex and often requires professional help, driving up costs significantly. Solid hardwood is also more susceptible to moisture damage, making it less suitable for areas like kitchens or bathrooms.

Conclusion: How to Choose the Right Flooring Solution for Your Needs

When selecting a flooring solution, B2B buyers should carefully consider their specific use case, budget constraints, and the desired aesthetic. Knotty pine vinyl plank flooring excels in high-traffic and moisture-prone areas due to its durability and easy maintenance. In contrast, laminate flooring may serve budget-conscious projects well, while solid hardwood is ideal for high-end applications where longevity and refinishing are priorities. By analyzing these alternatives, buyers can make informed decisions that align with their operational needs and financial objectives.

Essential Technical Properties and Trade Terminology for knotty pine vinyl plank flooring

What Are the Key Technical Properties of Knotty Pine Vinyl Plank Flooring?

Knotty pine vinyl plank flooring is a popular choice for both residential and commercial spaces due to its aesthetic appeal and practical benefits. Understanding its technical properties is crucial for B2B buyers to make informed purchasing decisions.

-

Material Composition

Knotty pine vinyl plank flooring is typically made from polyvinyl chloride (PVC) and other additives that enhance durability and flexibility. The vinyl core is designed to mimic the appearance of real wood while providing a more cost-effective and water-resistant alternative. This composition is essential for buyers seeking longevity and low maintenance in high-traffic areas. -

Wear Layer Thickness

The wear layer is a protective coating that determines the flooring’s resistance to scratches, stains, and general wear. Common thicknesses range from 12 mil to 30 mil, with thicker layers offering better durability. For B2B buyers, understanding wear layer specifications is vital to match the flooring with the intended use, especially in commercial environments where foot traffic is high. -

Dimensions and Format

Knotty pine vinyl planks come in various sizes, typically ranging from 5 to 7 inches in width and 36 to 48 inches in length. The dimensions affect both installation methods and aesthetic appeal. Buyers should consider the scale of their projects and the look they want to achieve when selecting plank sizes. -

Installation Method

Vinyl plank flooring can be installed using various methods, including click-lock and glue-down systems. Click-lock installations are favored for their ease and speed, making them ideal for DIY projects. Understanding installation options helps B2B buyers evaluate labor costs and project timelines. -

Water Resistance and Warranty

Many knotty pine vinyl planks are 100% waterproof, making them suitable for areas prone to moisture, such as bathrooms and kitchens. A warranty typically spans 10 years for commercial use and a lifetime for residential applications. These factors are crucial for B2B buyers to assess the flooring’s suitability for different environments and to ensure long-term performance.

What Are Common Trade Terms Used in the Knotty Pine Vinyl Plank Flooring Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common trade terms associated with knotty pine vinyl plank flooring:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that are sold under another company’s brand. For B2B buyers, knowing the OEM of the flooring can provide insights into quality standards and manufacturing practices. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for buyers to manage inventory costs and ensure they meet their project requirements without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. B2B buyers should utilize RFQs to gather competitive pricing and ensure they understand the terms of sale, including shipping and delivery. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms helps B2B buyers navigate international transactions effectively and understand their obligations. -

SPC (Stone Plastic Composite)

This refers to a type of rigid core vinyl flooring that offers enhanced durability and stability. Understanding SPC is valuable for buyers looking for high-performance flooring solutions in challenging environments. -

WPC (Wood Plastic Composite)

WPC is another type of vinyl flooring that combines wood fibers with plastic for a more natural feel. Knowing the differences between WPC and SPC can help buyers make informed choices based on performance needs and aesthetic preferences.

By grasping these technical properties and trade terms, B2B buyers can better navigate the complexities of sourcing knotty pine vinyl plank flooring and ensure they select the most suitable products for their projects.

Navigating Market Dynamics and Sourcing Trends in the knotty pine vinyl plank flooring Sector

What Are the Current Market Dynamics and Key Trends for Knotty Pine Vinyl Plank Flooring?

The global market for knotty pine vinyl plank flooring is experiencing significant growth driven by various factors. Increasing demand for cost-effective, durable, and aesthetically pleasing flooring options is at the forefront. Key trends include a shift towards waterproof and easy-to-install products, which are particularly appealing to both residential and commercial sectors. Innovations in manufacturing technology have led to the production of more realistic wood grain appearances, catering to consumer preferences for natural aesthetics without the associated maintenance of traditional wood.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, it’s crucial to stay updated on regional market dynamics. For example, in emerging markets, the trend towards urbanization is driving the demand for affordable yet stylish flooring solutions. Buyers should also be aware of the growing emphasis on e-commerce platforms, which streamline sourcing processes and provide access to a wider range of products. Moreover, the integration of digital tools in inventory management and order tracking enhances efficiency and transparency in the supply chain.

How Is Sustainability and Ethical Sourcing Impacting the Knotty Pine Vinyl Plank Flooring Sector?

Sustainability is becoming a critical consideration for B2B buyers in the flooring sector. The environmental impact of flooring materials is under scrutiny, leading to a preference for products that demonstrate a commitment to sustainability. Knotty pine vinyl plank flooring, often made from recycled materials or with low-VOC emissions, aligns with these eco-friendly trends.

Buyers should prioritize suppliers that maintain ethical supply chains and adhere to certifications such as FloorScore or GreenGuard, which ensure products meet strict environmental standards. Additionally, opting for flooring that is durable and easy to maintain not only reduces waste but also supports sustainable building practices. By sourcing sustainable products, B2B buyers can enhance their brand reputation and appeal to an increasingly eco-conscious consumer base.

What Is the Brief History and Evolution of Knotty Pine Vinyl Plank Flooring?

The evolution of vinyl flooring dates back to the early 20th century, but its rise to prominence occurred post-World War II, when the need for affordable and durable flooring options surged. Knotty pine vinyl plank flooring emerged as a favored choice due to its rustic aesthetic and practicality. Over the decades, advancements in manufacturing techniques have transformed vinyl flooring into a sophisticated option, combining the elegance of natural wood with the benefits of modern materials.

Today, knotty pine vinyl plank flooring stands out for its resilience and versatility, making it suitable for diverse applications ranging from residential homes to high-traffic commercial spaces. As global markets continue to evolve, this flooring solution is poised to remain a popular choice among B2B buyers looking for style, sustainability, and cost-effectiveness.

Frequently Asked Questions (FAQs) for B2B Buyers of knotty pine vinyl plank flooring

-

How do I determine the right knotty pine vinyl plank flooring for my business needs?

When selecting knotty pine vinyl plank flooring, consider factors such as durability, moisture resistance, and design preferences. Evaluate the wear layer thickness; a thicker layer (20 mil or more) is ideal for high-traffic areas. Additionally, assess the aesthetic appeal, including color variations and textures that align with your brand. It’s also beneficial to request samples to ensure the flooring meets your expectations before placing a bulk order. -

What are the benefits of using knotty pine vinyl plank flooring for commercial spaces?

Knotty pine vinyl plank flooring offers numerous advantages for commercial environments, including durability, water resistance, and ease of maintenance. It provides a cost-effective alternative to traditional wood flooring while delivering a similar aesthetic. Its noise reduction properties make it suitable for busy settings, and its DIY installation capabilities can significantly reduce labor costs. Moreover, vinyl flooring is resistant to scratches and stains, ensuring longevity even in high-traffic areas. -

What should I consider when vetting suppliers for knotty pine vinyl plank flooring?

When vetting suppliers, prioritize their experience in the flooring industry and seek those with a proven track record in international trade. Check for certifications and quality standards, such as ISO or CE markings. Request references from previous clients to gauge their reliability and customer service. Additionally, inquire about their production capabilities, lead times, and whether they offer customization options to meet your specific requirements. -

What are the typical minimum order quantities (MOQ) for knotty pine vinyl plank flooring?

Minimum order quantities can vary significantly among suppliers, but they typically range from 500 to 1,000 square feet for knotty pine vinyl plank flooring. Understanding MOQs is crucial for budgeting and inventory management. Some suppliers may be flexible with smaller orders, especially for new customers or samples, so it’s advisable to communicate your needs directly to negotiate favorable terms. -

What payment terms should I expect when sourcing flooring internationally?

Payment terms can differ based on supplier policies and your negotiating leverage. Common terms include a 30% deposit upon order confirmation, with the balance due before shipping. Some suppliers may offer letters of credit or escrow services to ensure security for both parties. It’s essential to clarify payment methods accepted (e.g., wire transfer, credit card) and any applicable fees to avoid unexpected costs. -

How can I ensure quality assurance (QA) for my flooring order?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Consider conducting a pre-shipment inspection through a third-party service to verify that the flooring meets your quality standards. Establish clear communication regarding your expectations, including tolerance levels for defects. Additionally, inquire about the supplier’s return policy in case the delivered products do not meet agreed-upon specifications. -

What logistics considerations should I keep in mind when importing knotty pine vinyl plank flooring?

Logistics are critical when importing flooring. Assess the shipping methods available, including sea freight or air freight, considering factors like cost and delivery time. Understand customs regulations and duties applicable in your country to avoid delays. Collaborate with a reliable freight forwarder to facilitate the import process, and ensure you have the necessary documentation, such as bills of lading and customs clearance forms. -

Can I customize knotty pine vinyl plank flooring to fit my specific design needs?

Yes, many suppliers offer customization options for knotty pine vinyl plank flooring, including color, texture, and size variations. Discuss your design vision with potential suppliers to determine their capabilities. Customization may involve additional costs and longer lead times, so it’s essential to plan accordingly. Request samples of custom designs to evaluate how they align with your overall aesthetic before finalizing your order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Knotty Pine Vinyl Plank Flooring Manufacturers & Suppliers List

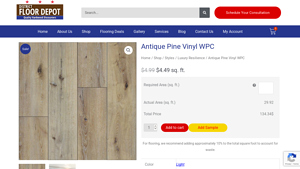

1. Resilienta – Antique Pine Vinyl WPC

Domain: districtfloordepot.com

Registered: 2017 (8 years)

Introduction: Product Name: Antique Pine Vinyl WPC

Brand: Resilienta

Price: $4.49 per sq. ft. (original price $4.99)

SKU: RW-ANTIQUEPINE-WPC

Categories: Luxury Resilience, Waterproof Flooring

Color: Light

Construction: Vinyl

Style: Luxury Resilience, WPC

Wear Layer: 20 mil

Width: 9″

Warranty: 10 Year Commercial, Lifetime Residential

Installation Method: Click/Lock, Glue

Features:

– Elegant, life-like appearanc…

2. Southern Wood Specialties – Select Knotty Pine Flooring

Domain: southernwoodspecialties.com

Registered: 2011 (14 years)

Introduction: {“product_name”: “Select Knotty Pine Flooring”, “categories”: [“Flooring”, “Southern Pine”], “sku”: “N/A”, “available_sizes”: [“1×6”, “1×4”, “1×8”], “thickness”: “¾ inch”, “coverage”: “5-1/8 inches”, “lengths_available”: [“8 feet”, “10 feet”], “pricing”: {“min_order_sq_ft”: 500, “price_range_sq_ft”: “$1.62 – $2.50”, “best_value_price_sq_ft”: “$1.78”}, “features”: [“Matches best-selling Select Knot…

3. Carlisle – Wide Plank Knotty Pine Flooring

Domain: wideplankflooring.com

Registered: 1997 (28 years)

Introduction: Wide Plank Knotty Pine Flooring from Carlisle Wide Plank Floors adds rustic charm and comfortable elegance to any room. Made from Eastern White Pine and Longleaf Heart Pine, this flooring recreates the warmth and character of traditional floors. Options include Original Grade (more character with knots and variations), Heirloom Grade (consistent appearance), and Signature Blend (balance of both). …

4. Houzz – Flooring Options

Domain: houzz.com

Registered: 2006 (19 years)

Introduction: This company, Houzz – Flooring Options, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for knotty pine vinyl plank flooring

In navigating the dynamic landscape of knotty pine vinyl plank flooring, strategic sourcing emerges as a critical advantage for international buyers. The versatility and durability of vinyl planks, coupled with their aesthetic appeal, position them as an ideal choice for various markets, particularly in Africa, South America, the Middle East, and Europe. By prioritizing suppliers who offer high-quality products—such as those with waterproof features, easy installation methods, and a range of designs—businesses can enhance their value proposition and meet diverse consumer demands.

Moreover, the cost-effectiveness of knotty pine vinyl flooring can significantly reduce long-term expenses, making it an attractive option for both residential and commercial applications. Engaging directly with manufacturers can also yield better pricing and more reliable supply chains, ensuring that your business remains competitive.

Looking ahead, the trend towards sustainable and resilient flooring solutions is set to grow. International buyers should seize this opportunity to align with innovative suppliers that prioritize eco-friendly practices. By investing in knotty pine vinyl plank flooring, you not only elevate your product offerings but also contribute to a more sustainable future. Embrace this opportunity to redefine your sourcing strategy and position your business for success in the evolving flooring market.