Field Bar Cooler: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for field bar cooler

In today’s competitive landscape, sourcing high-quality field bar coolers can pose significant challenges for international B2B buyers. With the increasing demand for portable and stylish cooling solutions for outdoor events, businesses must navigate a complex market filled with varied options. This comprehensive guide aims to simplify the process by exploring the diverse types of field bar coolers available, their applications across different sectors, and essential considerations for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Saudi Arabia—will find invaluable insights into cost structures, material quality, and design features that influence purchasing decisions. By equipping buyers with the knowledge to evaluate and compare products effectively, this guide empowers them to make informed choices that align with their unique business needs and expectations.

Additionally, it addresses key factors such as sustainability, craftsmanship, and functionality, which are increasingly important in today’s eco-conscious market. Whether you are looking to enhance your outdoor offerings or simply improve your inventory, understanding the nuances of the field bar cooler market will position your business for success.

Understanding field bar cooler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hardcase Coolers | Durable, waterproof, and insulated construction | Outdoor events, festivals, catering | Pros: Exceptional durability; Cons: Heavier to transport. |

| Portable Mini Bars | Compact design with integrated storage for drinks | Private events, corporate gatherings | Pros: Space-efficient; Cons: Limited capacity. |

| Multi-Compartment Coolers | Multiple sections for different beverage types | Catering services, outdoor adventures | Pros: Versatile storage; Cons: More complex to manage. |

| Luxury Coolers | High-end materials, stylish designs, and branding potential | Corporate gifts, premium events | Pros: Enhances brand image; Cons: Higher price point. |

| Eco-Friendly Coolers | Made from sustainable materials and designed for longevity | Environmentally conscious businesses | Pros: Appeals to eco-friendly brands; Cons: May have limited designs. |

What Are the Key Characteristics of Hardcase Coolers?

Hardcase coolers are designed for rugged outdoor use, often featuring a waterproof and insulated construction. These coolers are ideal for businesses that need reliable storage for beverages during outdoor events, festivals, or catering services. When considering a purchase, B2B buyers should assess the cooler’s weight versus its durability, as heavier models may be more challenging to transport but offer superior protection.

How Do Portable Mini Bars Stand Out in the Market?

Portable mini bars are compact and designed for easy transport, often featuring integrated storage for various drinks. Their space-efficient design makes them perfect for private events or corporate gatherings where space is limited. Buyers should evaluate the storage capacity and ease of assembly when selecting a mini bar, as these factors will impact usability during events.

What Are the Advantages of Multi-Compartment Coolers?

Multi-compartment coolers provide versatile storage options, allowing businesses to separate different types of beverages. This feature is particularly useful for catering services and outdoor adventures where diverse drink offerings are essential. Buyers should consider the complexity of managing multiple compartments and ensure that the cooler aligns with their specific storage needs.

Why Choose Luxury Coolers for Corporate Events?

Luxury coolers are crafted from high-end materials and often feature stylish designs that can enhance a brand’s image. They are ideal for corporate gifts or premium events where presentation matters. However, the higher price point may be a consideration for buyers, who should weigh the benefits of brand enhancement against their budget constraints.

How Do Eco-Friendly Coolers Meet Business Needs?

Eco-friendly coolers are constructed from sustainable materials and are designed for longevity, appealing to environmentally conscious businesses. They are an excellent choice for companies looking to promote their commitment to sustainability. Buyers should consider the design options available, as eco-friendly models may have more limited aesthetics compared to traditional coolers.

Key Industrial Applications of field bar cooler

| Industry/Sector | Specific Application of field bar cooler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Events | Outdoor catering and mobile bars | Enhances guest experience with stylish cooling solutions | Durability, portability, and aesthetic appeal are crucial. |

| Tourism & Recreation | Safari and adventure tourism | Provides reliable beverage storage in remote locations | Must withstand harsh conditions and maintain ice retention. |

| Food & Beverage Distribution | Mobile beverage distribution for events | Facilitates easy transport of chilled products | Capacity, insulation efficiency, and ease of cleaning are key. |

| Retail & E-commerce | Promotional events and pop-up shops | Attracts customers with visually appealing displays | Customization options and brand visibility are important. |

| Outdoor Sports & Recreation | Sporting events and tailgating | Keeps beverages cold, enhancing the spectator experience | Lightweight design and ease of transport are essential. |

How Does the Field Bar Cooler Serve the Hospitality & Events Sector?

In the hospitality and events sector, field bar coolers are essential for outdoor catering and mobile bars. They provide a stylish solution for keeping beverages cold, enhancing the overall guest experience. Businesses benefit from the cooler’s durability and portability, allowing them to serve clients in various locations. International buyers should consider sourcing coolers that not only meet aesthetic requirements but also offer robust insulation capabilities to ensure optimal cooling performance throughout events.

What Role Does the Field Bar Cooler Play in Tourism & Recreation?

Field bar coolers are indispensable in safari and adventure tourism, where reliable beverage storage is crucial. These coolers allow operators to provide chilled drinks in remote areas, enhancing the experience for tourists. The key requirements for buyers in this sector include the cooler’s ability to withstand harsh environmental conditions while maintaining ice retention over extended periods. Additionally, portability is essential for easy transport between locations.

How is the Field Bar Cooler Used in Food & Beverage Distribution?

In food and beverage distribution, field bar coolers are utilized for mobile beverage distribution at events and festivals. They facilitate the easy transport of chilled products, ensuring that beverages are served at optimal temperatures. Businesses benefit from the coolers’ insulation efficiency and large capacity, which can accommodate high volumes of drinks. Buyers should prioritize coolers that are easy to clean and maintain, as hygiene is paramount in the food and beverage industry.

Why is the Field Bar Cooler Valuable for Retail & E-commerce?

Retailers and e-commerce businesses leverage field bar coolers during promotional events and pop-up shops. These coolers attract customers with their stylish designs and functionality, making them an effective marketing tool. The value lies in their ability to keep products chilled while enhancing brand visibility. When sourcing, businesses should look for customization options that allow for branding and marketing, along with features that ensure durability and ease of transport.

How Does the Field Bar Cooler Enhance Outdoor Sports & Recreation?

Field bar coolers are vital for sporting events and tailgating activities, where keeping beverages cold is essential for enhancing the spectator experience. They provide a convenient solution for fans who want to enjoy chilled drinks while supporting their teams. Key considerations for buyers include the cooler’s lightweight design and ease of transport, as these features are critical for mobility during events. Additionally, the coolers should have excellent insulation properties to ensure beverages remain cold for extended periods.

3 Common User Pain Points for ‘field bar cooler’ & Their Solutions

Scenario 1: Navigating Harsh Climate Conditions with Field Bar Coolers

The Problem: In regions with extreme temperatures, such as parts of Africa and the Middle East, maintaining the temperature of beverages in field bar coolers poses a significant challenge. B2B buyers often find that traditional coolers fail to keep drinks cold for extended periods, leading to customer dissatisfaction during outdoor events or excursions. This issue not only affects the quality of the beverages but can also damage the brand’s reputation among clients who expect a premium experience.

The Solution: To effectively tackle this problem, buyers should invest in field bar coolers that are specifically engineered for superior insulation and ice retention. When sourcing, look for products that highlight their thermal efficiency and use high-quality materials designed for extreme conditions. It’s also wise to evaluate user testimonials and performance metrics that confirm prolonged cooling capabilities. Additionally, consider bulk purchasing arrangements that include a warranty, ensuring that the investment is protected and that you receive quality assurance. Proper usage includes pre-chilling the cooler before filling it with beverages, using high-quality ice or ice packs, and limiting the cooler’s exposure to direct sunlight to enhance its performance.

Scenario 2: Ensuring Portability and Convenience for Outdoor Events

The Problem: Organizing outdoor events often requires transporting equipment over uneven terrains. B2B buyers frequently report struggles with the weight and bulkiness of traditional coolers, which can hinder mobility and complicate logistics. This can be especially problematic for businesses involved in catering, event planning, or outdoor adventures, where time and efficiency are critical.

The Solution: Buyers should prioritize field bar coolers that are designed for portability without compromising on capacity or performance. When evaluating options, look for features like integrated wheels, lightweight materials, and ergonomic handles that enhance transportability. Additionally, consider coolers that offer modular designs, allowing for easy stacking or attachment to other equipment. This adaptability can streamline logistics and improve efficiency during events. Training staff on proper loading techniques can also help maximize space and minimize the risk of damage during transport.

Scenario 3: Balancing Aesthetic Appeal with Functional Design

The Problem: In the competitive landscape of B2B services, particularly in the hospitality and luxury event sectors, aesthetics play a crucial role in client satisfaction. Buyers often struggle to find coolers that not only perform well but also align with the brand’s image and appeal to discerning customers. A cooler that looks out of place can detract from the overall experience, impacting customer perceptions and repeat business.

The Solution: To address this issue, buyers should explore field bar coolers that offer a blend of functionality and stylish design. Conduct thorough research to identify brands that focus on craftsmanship and aesthetic appeal, such as those offering customizable options or unique finishes that can complement various event themes. Collaborate with suppliers who understand your brand’s vision and can provide samples or mock-ups to ensure that the cooler aligns with your aesthetic requirements. Investing in high-quality, visually appealing coolers can serve as both a practical tool and a marketing asset, enhancing the overall customer experience while promoting brand identity.

Strategic Material Selection Guide for field bar cooler

What Are the Key Materials Used in Field Bar Coolers?

When selecting materials for field bar coolers, several factors come into play, including performance, durability, cost, and compliance with international standards. Below are four common materials used in the manufacturing of field bar coolers, along with their properties, advantages, disadvantages, and considerations for international buyers.

How Does Polyethylene Benefit Field Bar Coolers?

Polyethylene is a widely used plastic in cooler manufacturing due to its excellent durability and resistance to impact and moisture. It typically has a temperature rating of -50°C to 80°C, making it suitable for a variety of climates.

Pros: Polyethylene is lightweight, cost-effective, and resistant to corrosion and UV radiation. Its manufacturing process is relatively straightforward, allowing for mass production.

Cons: While durable, polyethylene can become brittle over time, especially under extreme temperatures. It may also not provide the same level of insulation as other materials, which can impact cooling efficiency.

Impact on Application: Polyethylene coolers are compatible with most beverages and food items. However, they may not be suitable for high-pressure applications.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local environmental regulations regarding plastic use. Understanding ASTM standards for plastic materials can also guide procurement decisions.

What Advantages Does Stainless Steel Offer for Coolers?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a popular choice for high-end coolers. It can withstand extreme temperatures and is often used in marine environments.

Pros: Stainless steel offers superior durability and a long lifespan. Its resistance to rust and staining makes it ideal for outdoor use, and it is easy to clean.

Cons: The primary drawback is the higher cost compared to plastic materials. Additionally, stainless steel can be heavier, which may affect portability.

Impact on Application: Stainless steel is compatible with a wide range of beverages and can maintain temperature effectively. However, it may require additional insulation to optimize performance.

Considerations for International Buyers: Buyers should look for compliance with international standards such as ASTM A240 for stainless steel. Markets in Europe may have specific regulations regarding food safety and material composition.

Why Is Foam Insulation Important in Cooler Design?

Foam insulation, often made from polyurethane or polystyrene, is critical for maintaining temperature in coolers. It provides excellent thermal resistance, typically rated at R-5 to R-7 per inch.

Pros: Foam insulation is lightweight and provides superior thermal performance, which enhances the cooler’s ability to maintain low temperatures over extended periods.

Cons: Foam can be sensitive to moisture and may degrade if exposed to water over time. Additionally, its manufacturing process can be more complex, potentially increasing costs.

Impact on Application: Foam insulation is essential for coolers designed for long outdoor events. However, it may not be suitable for environments with high humidity.

Considerations for International Buyers: Buyers should ensure that foam insulation meets local fire safety and environmental standards. Understanding the differences between JIS and ASTM standards for insulation can also be beneficial.

How Does Aluminum Compare as a Cooler Material?

Aluminum is lightweight and offers good thermal conductivity, making it a viable option for cooler exteriors. It can be anodized for additional corrosion resistance.

Pros: Aluminum is lightweight and can be easily molded into complex shapes. It provides good thermal performance and is recyclable, which appeals to environmentally conscious buyers.

Cons: Aluminum can be prone to denting and scratching, which may affect aesthetics and durability. It also has a lower resistance to corrosion compared to stainless steel unless treated.

Impact on Application: Aluminum is suitable for a variety of beverages but may not hold up as well in harsh environments without protective coatings.

Considerations for International Buyers: Buyers should check for compliance with local recycling regulations and standards for aluminum products, particularly in Europe, where sustainability is a significant concern.

Summary Table of Material Selection for Field Bar Coolers

| Material | Typical Use Case for Field Bar Cooler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Budget-friendly coolers | Lightweight and cost-effective | Can become brittle over time | Low |

| Stainless Steel | High-end, durable coolers | Superior durability and corrosion resistance | Higher cost and weight | High |

| Foam Insulation | Long-term outdoor use | Excellent thermal performance | Sensitive to moisture | Medium |

| Aluminum | Lightweight, portable coolers | Good thermal conductivity | Prone to denting and scratching | Medium |

This guide provides a comprehensive overview of material options for field bar coolers, enabling international B2B buyers to make informed decisions tailored to their specific market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for field bar cooler

What Are the Key Stages in the Manufacturing Process of a Field Bar Cooler?

The manufacturing process of a field bar cooler involves several critical stages, each essential to ensuring the final product meets quality standards and fulfills customer expectations.

Material Preparation: What Materials Are Used?

The foundation of any durable cooler lies in its materials. High-density polyethylene (HDPE) and aluminum are commonly utilized due to their lightweight yet robust nature. HDPE offers excellent insulation properties, making it ideal for maintaining temperature, while aluminum provides structural integrity and corrosion resistance. The preparation phase involves sourcing these materials from reliable suppliers, ensuring they meet international quality standards.

How Is the Forming Process Conducted?

The forming process typically includes molding and shaping the materials into the desired cooler design. For HDPE, this often involves rotational molding, which creates seamless, hollow components. This technique minimizes the risk of leaks and enhances the cooler’s insulation capabilities. For metal components, processes such as stamping or cutting are employed to achieve precise dimensions and shapes. The use of advanced machinery ensures accuracy and reduces production time.

What Does the Assembly Process Look Like?

Once the individual components are formed, they proceed to the assembly stage. This involves the careful integration of the cooler’s body, lid, insulation, and any additional features such as handles or wheels. Skilled technicians utilize both automated and manual assembly techniques to ensure that each cooler is constructed to specifications. Quality control checkpoints are integrated throughout this stage to catch any potential defects early in the process.

How Is the Finishing Process Completed?

The finishing stage involves surface treatment, painting, and branding. Coolers may undergo processes like powder coating or UV treatment to enhance durability and aesthetic appeal. Branding is often applied through screen printing or decals, ensuring that the final product not only performs well but also meets branding requirements. This stage is crucial for creating a visually appealing product that stands out in the market.

What Quality Assurance Measures Are Typically Implemented?

Quality assurance (QA) is vital in the manufacturing of field bar coolers, ensuring that each product meets established standards and customer expectations.

Which International Standards Are Relevant for Field Bar Coolers?

Manufacturers often adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards not only enhances product quality but also boosts credibility in the global market. Additionally, certifications like CE mark (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards may apply depending on the cooler’s intended use.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around three main checkpoints:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials before they enter the production line. Materials must meet specific quality criteria to ensure the durability and performance of the final product.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor production quality. This includes verifying dimensions, checking for defects, and ensuring that assembly procedures are followed correctly.

-

Final Quality Control (FQC): Once assembly is complete, a final inspection ensures that each cooler meets design specifications and quality standards. This may involve performance testing, such as checking insulation effectiveness and verifying that all components function as intended.

What Common Testing Methods Are Used?

Testing methods can vary but often include:

- Thermal Performance Testing: Evaluating the cooler’s ability to maintain temperature over specified periods.

- Leak Testing: Ensuring that the cooler is watertight and free from leaks.

- Durability Testing: Subjecting the cooler to various environmental conditions to assess its robustness and longevity.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers have several options to verify the quality control measures of their suppliers, particularly when sourcing field bar coolers internationally.

What Steps Can Buyers Take for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. This includes on-site inspections where buyers can evaluate the manufacturing environment, equipment, and overall adherence to quality standards. Buyers should request detailed documentation of the supplier’s quality management system and past audit results.

How Important Are Quality Reports and Certifications?

Requesting quality reports and certifications is crucial for verification. These documents provide insights into the manufacturer’s compliance with international standards and their internal QC processes. Certifications from recognized bodies can serve as additional assurance of the manufacturer’s commitment to quality.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process. These services can conduct random inspections during production and pre-shipment, ensuring that products meet the specified quality standards before they leave the manufacturer. This step is particularly important for B2B buyers from regions like Africa, South America, and the Middle East, where local regulations may differ significantly.

How Do Quality Control Nuances Affect International B2B Transactions?

Understanding the nuances of quality control in international transactions is vital for B2B buyers. Different regions may have varying standards and expectations regarding product quality. For instance, European buyers may prioritize CE certification, while Middle Eastern clients may focus on compliance with local health and safety regulations.

In conclusion, the manufacturing processes and quality assurance measures for field bar coolers are comprehensive and critical for ensuring product reliability and customer satisfaction. By understanding these processes, B2B buyers can make informed decisions and establish fruitful partnerships with manufacturers that prioritize quality and durability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘field bar cooler’

Introduction

Sourcing a field bar cooler requires careful consideration to ensure you select a product that meets your specific needs while also providing quality and durability. This guide serves as a checklist for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, helping you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the key features you need in a field bar cooler. Consider factors such as size, insulation capabilities, material, and portability.

– Insulation Performance: Look for coolers that maintain temperature for extended periods.

– Material Quality: Choose durable materials that can withstand outdoor conditions.

Step 2: Set Your Budget and Pricing Expectations

Establish a budget that reflects both your financial constraints and the quality you desire. Understanding the price range for different types of coolers can help you avoid overspending or settling for inferior products.

– Market Research: Compare prices from various suppliers to identify competitive offers.

– Cost vs. Value: Assess whether the cooler’s features justify its price, ensuring long-term value.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure reliability and quality. Request detailed company profiles, product specifications, and references from previous clients.

– Supplier Experience: Check how long the supplier has been in the industry and their reputation.

– Customer Feedback: Look for reviews and testimonials to gauge product performance and service quality.

Step 4: Verify Certifications and Compliance

Ensure that the coolers meet international standards and certifications relevant to your region. Compliance with safety and environmental regulations is crucial for avoiding potential liabilities.

– Quality Standards: Look for certifications such as ISO or equivalent to ensure product quality.

– Sustainability Practices: Verify if the supplier follows sustainable manufacturing practices, which can be an important factor for many businesses today.

Step 5: Request Samples for Testing

Before making a bulk purchase, request samples of the cooler to evaluate their performance firsthand. Testing the product can reveal its strengths and weaknesses in real-world conditions.

– Performance Evaluation: Assess insulation effectiveness, durability, and ease of use.

– User Experience: Consider how the cooler fits into your intended use cases, such as outdoor events or commercial applications.

Step 6: Understand Warranty and After-Sales Support

Review the warranty terms and after-sales support offered by the supplier. A solid warranty can provide peace of mind and indicate the manufacturer’s confidence in their product.

– Warranty Duration: Look for warranties that cover a reasonable period and include conditions for repairs or replacements.

– Customer Service: Ensure that the supplier provides accessible customer support for any inquiries or issues that may arise.

Step 7: Finalize Your Purchase Agreement

Once you are satisfied with the product and supplier, finalize your purchase agreement. Pay attention to delivery timelines, payment terms, and any potential bulk order discounts.

– Contract Clarity: Ensure all terms are clearly defined to avoid misunderstandings later.

– Payment Flexibility: Discuss payment options that suit your financial flow, which can be especially important for larger orders.

By following this checklist, you can make informed decisions while sourcing field bar coolers that align with your business needs and values.

Comprehensive Cost and Pricing Analysis for field bar cooler Sourcing

What Are the Key Cost Components in Sourcing Field Bar Coolers?

When considering the sourcing of field bar coolers, understanding the cost structure is essential for effective budgeting and price negotiation. The primary cost components include:

-

Materials: The quality of materials significantly influences the cooler’s durability and performance. High-grade insulation, weather-resistant fabrics, and premium finishes can elevate costs but are vital for longevity and functionality.

-

Labor: Labor costs vary based on geographical location and production methods. Handcrafted items, like those from Fieldbar, often incur higher labor costs due to the skilled artisanship involved, impacting the final price.

-

Manufacturing Overhead: This encompasses expenses related to the production facility, utilities, and indirect labor. Efficient manufacturing processes can help minimize overhead, thus reducing overall costs.

-

Tooling: Initial tooling costs for specialized molds and equipment can be significant, especially for custom designs. These costs are usually amortized over a larger production run, making it crucial to assess minimum order quantities (MOQs).

-

Quality Control (QC): Rigorous QC processes ensure that coolers meet specified standards, which can add to production costs. However, investing in quality control can reduce returns and enhance customer satisfaction.

-

Logistics: Transportation and handling costs are particularly relevant for international buyers. Factors such as shipping method, distance, and customs duties can significantly affect the final price.

-

Margin: Suppliers will typically add a profit margin based on their cost structure and market positioning. This margin can vary widely based on competition, brand reputation, and product uniqueness.

How Do Price Influencers Affect Field Bar Cooler Pricing?

Several factors can influence the pricing of field bar coolers, particularly for international B2B buyers:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs. Negotiating for bulk purchases can provide significant savings.

-

Specifications and Customization: Custom designs or specific features (such as branding or unique color options) may increase costs. Buyers should weigh the benefits of customization against the associated price increase.

-

Materials: The choice of materials directly impacts the cooler’s durability and effectiveness. Premium materials will come at a higher cost but can justify the price through enhanced performance and longevity.

-

Quality and Certifications: Certifications (such as ISO or environmental standards) can add credibility but may increase production costs. Buyers should consider whether the added costs align with their market needs.

-

Supplier Factors: The supplier’s reputation, reliability, and location can affect pricing. Sourcing from established suppliers may come at a premium but can reduce risks associated with quality and delivery.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms define responsibilities for shipping, insurance, and tariffs, which can significantly affect total costs.

What Are the Best Buyer Tips for Negotiating Cooler Prices?

B2B buyers should adopt several strategies to enhance cost-efficiency when sourcing field bar coolers:

-

Leverage Negotiation: Engage in discussions about pricing, especially for larger orders. Suppliers may be willing to offer discounts for bulk purchases or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also maintenance, durability, and operational costs. Investing in higher-quality coolers may yield lower TCO over time.

-

Understand Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from diverse markets like Africa, South America, the Middle East, and Europe. Currency fluctuations and local economic conditions can impact pricing strategies.

-

Research and Compare Suppliers: Conduct thorough market research to compare pricing structures, quality, and service levels among different suppliers. This information can empower buyers during negotiations.

-

Stay Informed About Trends: Keeping up with industry trends can provide insights into pricing shifts, new materials, and innovative designs, helping buyers make informed decisions.

Disclaimer on Indicative Prices

It is important to note that prices for field bar coolers can vary significantly based on the factors discussed above. Buyers should conduct thorough research and consult with multiple suppliers to obtain accurate pricing relevant to their specific needs and market conditions.

Alternatives Analysis: Comparing field bar cooler With Other Solutions

Understanding Alternatives in Cooler Solutions

When evaluating cooler solutions for outdoor events or field activities, it’s essential for B2B buyers to consider various options available in the market. While the Field Bar Cooler is a premium choice known for its craftsmanship and aesthetic appeal, there are other alternatives that may suit different needs, budgets, or use cases. This analysis will compare the Field Bar Cooler with two viable alternatives: traditional hard-sided coolers and portable electric coolers.

Comparison Table

| Comparison Aspect | Field Bar Cooler | Traditional Hard-Sided Cooler | Portable Electric Cooler |

|---|---|---|---|

| Performance | Superior ice retention, stylish design | Good insulation, bulkier | Quick cooling, varies by power source |

| Cost | Premium pricing (£179 – £349) | Mid-range (£50 – £200) | Higher initial cost (£200 – £600) |

| Ease of Implementation | Ready to use, no setup required | Simple to use, but heavy | Requires power source, setup needed |

| Maintenance | Low, durable materials | Moderate, cleaning needed | Higher, requires electrical upkeep |

| Best Use Case | Luxury events, outdoor leisure | General outdoor use | Camping, tailgating, and long trips |

Detailed Breakdown of Alternatives

Traditional Hard-Sided Cooler

Traditional hard-sided coolers, such as those made by brands like Igloo or Coleman, offer solid insulation and are generally more affordable. They are built to last and can handle rough outdoor conditions. However, they tend to be bulkier and heavier, making them less portable. While their ice retention capabilities are generally good, they may not match the stylish aesthetic and premium feel of the Field Bar Cooler, which can be a deciding factor for luxury events.

Portable Electric Cooler

Portable electric coolers, such as the Dometic CFX series, provide rapid cooling capabilities and can maintain consistent temperatures for extended periods. They are perfect for events where quick access to chilled items is necessary, but they require a power source, which can limit their usability in remote locations. Additionally, they typically come with a higher price tag and may require more maintenance due to electrical components. Their versatility makes them ideal for camping or long road trips, but they may not offer the same level of elegance that a Field Bar Cooler does for formal gatherings.

How to Choose the Right Cooler for Your Needs

In selecting the most suitable cooler solution, B2B buyers should assess their specific requirements, including the intended use case, budget constraints, and desired aesthetic. The Field Bar Cooler excels in design and ice retention, making it a top choice for high-end events. However, if cost and portability are more critical, traditional hard-sided coolers present a practical option. For scenarios where quick cooling is paramount, portable electric coolers are the best fit. Understanding these nuances will enable buyers to make informed decisions that align with their operational needs and brand image.

Essential Technical Properties and Trade Terminology for field bar cooler

What Are the Key Technical Properties of a Field Bar Cooler?

When evaluating a field bar cooler for B2B procurement, understanding its technical properties is crucial for ensuring product quality and performance. Here are some essential specifications to consider:

1. Material Grade

The material grade refers to the type and quality of materials used in the cooler’s construction, such as high-density polyethylene (HDPE) or stainless steel. High-quality materials enhance durability and resistance to environmental factors, which is critical for outdoor use. A cooler made from premium materials can withstand rough handling, extreme temperatures, and exposure to moisture, reducing the likelihood of product failure.

2. Insulation Thickness

Insulation thickness is a key factor affecting the cooler’s ability to retain temperature. A thicker insulation layer generally offers better thermal performance, keeping beverages cold for extended periods. This property is essential for businesses that require reliable cooling solutions during outdoor events or extended trips, ensuring customer satisfaction and reducing the need for frequent replenishment of ice.

3. Weight Capacity

Weight capacity indicates the maximum load the cooler can handle without compromising its structural integrity. Understanding this specification is vital for businesses that plan to transport heavy items or large quantities of beverages. A cooler with a higher weight capacity can accommodate more products, making it a more versatile option for various applications, from catering to corporate events.

4. Portability Features

Portability features include handles, wheels, and overall design that facilitate easy transport. For B2B buyers, these features are crucial for ensuring that the cooler can be moved effortlessly across various terrains, from beaches to outdoor venues. Investing in a cooler with effective portability features can improve operational efficiency and reduce labor costs.

5. Warranty and Repairability

A warranty period signifies the manufacturer’s confidence in the product’s durability. Additionally, repairability refers to the ability to replace parts, which can significantly extend the cooler’s lifespan. For businesses, this means lower long-term costs and less waste, aligning with sustainable practices that are increasingly important in today’s market.

What Are Common Trade Terms Used in the Field Bar Cooler Industry?

Understanding industry terminology can significantly enhance communication and negotiation in B2B transactions. Here are some essential terms to familiarize yourself with:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the field bar cooler industry, buyers might engage with OEMs for customized designs or specific features that align with their brand requirements. Knowing about OEM relationships can help buyers make informed decisions regarding sourcing and quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ is essential for budgeting and inventory management. It can also impact pricing, as larger orders often qualify for better rates, making it a critical factor in procurement strategy.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. Including detailed specifications in an RFQ can lead to more accurate quotes and better supplier responses. This term is vital for streamlining the purchasing process and ensuring competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is crucial for B2B transactions involving international suppliers, as they outline who bears the risk and costs during transit, helping to avoid disputes and ensure smooth logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. For businesses, understanding lead times is essential for planning and managing inventory effectively. Longer lead times can affect sales and customer satisfaction, making it a critical consideration in supplier selection.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing field bar coolers, ensuring they select products that meet their operational needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the field bar cooler Sector

What Are the Key Market Drivers and Trends Affecting the Field Bar Cooler Sector?

The field bar cooler market is experiencing robust growth due to several global drivers. Increasing outdoor recreational activities, such as camping, picnicking, and tailgating, are prompting a surge in demand for portable cooling solutions. Emerging markets in Africa, South America, the Middle East, and parts of Europe are particularly ripe for expansion, with a growing middle class seeking quality outdoor experiences. Technological advancements in materials and insulation techniques are enhancing product performance, making coolers more efficient and durable. Additionally, e-commerce platforms are streamlining the procurement process for B2B buyers, enabling easy access to a wider variety of products.

Current sourcing trends indicate a shift towards customizable and branded cooler solutions. Businesses are keen to invest in products that not only serve a functional purpose but also enhance brand visibility. Eco-friendly materials are gaining traction, driven by consumer preferences for sustainable products. In regions like Saudi Arabia and Vietnam, where outdoor leisure activities are becoming increasingly popular, the demand for stylish and functional coolers is on the rise, indicating a lucrative market for international B2B buyers.

How Important Is Sustainability and Ethical Sourcing in the Field Bar Cooler Market?

Sustainability and ethical sourcing are paramount in the field bar cooler market. As environmental concerns grow, B2B buyers are increasingly prioritizing products that minimize ecological impact. This includes the use of recycled materials, energy-efficient manufacturing processes, and sustainable packaging. Companies that adopt eco-friendly practices not only appeal to environmentally conscious consumers but also enhance their brand reputation and marketability.

Ethical supply chains are critical in ensuring that products are made responsibly. This involves transparency in sourcing raw materials, fair labor practices, and adherence to environmental regulations. Certifications such as ISO 14001 for environmental management and FSC (Forest Stewardship Council) for sustainable wood sourcing are becoming essential for businesses aiming to demonstrate their commitment to sustainability. By prioritizing these factors, international B2B buyers can align their procurement strategies with global sustainability goals and consumer expectations.

What Is the Brief Evolution and History of the Field Bar Cooler Industry?

The evolution of the field bar cooler industry can be traced back to the early 20th century when portable iceboxes emerged as essential tools for outdoor activities. Over the decades, innovations in insulation technology and materials have transformed these products from simple containers into highly efficient, stylish coolers. The introduction of hard-shell designs provided enhanced durability, while advancements in thermoregulation have significantly improved ice retention.

In recent years, the focus has shifted towards not only functionality but also aesthetics, with manufacturers crafting coolers that serve as stylish accessories for outdoor leisure. As consumer preferences evolve, the industry continues to innovate, emphasizing quality, sustainability, and design. This historical context is crucial for B2B buyers, as it underscores the importance of selecting products that reflect current trends while maintaining a legacy of performance and reliability.

Frequently Asked Questions (FAQs) for B2B Buyers of field bar cooler

-

How do I ensure the quality of field bar coolers when sourcing?

To ensure quality when sourcing field bar coolers, it’s vital to conduct thorough supplier vetting. Look for manufacturers with a proven track record and positive reviews. Request samples to evaluate craftsmanship and performance, focusing on durability, insulation effectiveness, and overall design. Additionally, consider suppliers who offer warranties or guarantees, as this reflects their confidence in product quality. Engaging in direct communication can also clarify any concerns and ensure that the supplier understands your specific requirements. -

What is the best way to customize field bar coolers for my brand?

Customizing field bar coolers can significantly enhance brand visibility. Work with suppliers who offer customization options such as color choices, branding with logos, and unique packaging. Discuss your vision and requirements upfront to ensure they can accommodate your requests. Also, inquire about minimum order quantities (MOQs) for customized products, as this varies by supplier. A well-defined customization process can help create a product that resonates with your target market while reinforcing your brand identity. -

What are the typical minimum order quantities (MOQs) for field bar coolers?

Minimum order quantities for field bar coolers can vary significantly based on the manufacturer and the specifics of your order. Generally, MOQs can range from 50 to several hundred units. When negotiating with suppliers, discuss your needs and see if they can offer flexibility, especially for first-time orders. Understanding the MOQ helps in planning your inventory and ensuring that you can meet market demand without overcommitting resources. -

What payment terms should I expect when sourcing field bar coolers internationally?

Payment terms can vary widely depending on the supplier and the nature of the transaction. Typically, you might encounter terms such as 30% deposit upfront and 70% upon shipment. Some suppliers may also offer payment through letters of credit or escrow services to ensure transaction security. It’s essential to clarify these terms early in negotiations and ensure they align with your cash flow and financial planning. -

How can I manage logistics and shipping for international orders of field bar coolers?

Managing logistics for international orders involves understanding shipping options, costs, and timelines. Work closely with your supplier to determine the best shipping methods (air freight vs. sea freight) based on urgency and budget. Additionally, consider customs regulations and import duties in your country, as these can impact overall costs. Partnering with a reliable freight forwarder can streamline the process, ensuring timely delivery while minimizing potential issues. -

What quality assurance processes should I look for in a field bar cooler supplier?

When sourcing field bar coolers, inquire about the supplier’s quality assurance processes. Look for manufacturers who implement rigorous testing and inspection protocols during production. This can include material quality checks, performance testing for insulation, and final product inspections. A supplier with certified quality management systems (like ISO 9001) demonstrates a commitment to maintaining high standards, which is crucial for ensuring the reliability of your products. -

Are there specific certifications I should look for when sourcing field bar coolers?

Certifications can provide reassurance regarding the quality and safety of field bar coolers. Look for suppliers that comply with international standards such as ISO, CE, or FDA certifications, particularly if you plan to market these coolers in regions with strict regulations. Certifications related to sustainability and environmental impact, such as FSC or Green Seal, can also enhance your brand’s appeal to eco-conscious consumers. -

What are the most common issues faced when sourcing field bar coolers internationally?

Common issues when sourcing field bar coolers internationally include communication barriers, varying quality standards, and delays in production or shipping. Misunderstandings regarding product specifications can lead to unsatisfactory outcomes. To mitigate these risks, establish clear communication channels with your supplier, utilize comprehensive contracts, and maintain regular updates throughout the production process. Additionally, consider working with suppliers who have experience exporting to your region to navigate potential regulatory hurdles effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Field Bar Cooler Manufacturers & Suppliers List

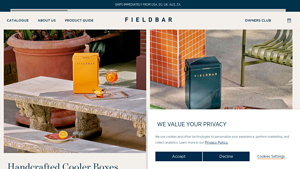

1. Fieldbar Co. – Handcrafted Cooler Boxes

Domain: fieldbar.com

Registered: 2008 (17 years)

Introduction: Fieldbar Co. offers handcrafted cooler boxes designed for outdoor leisure. Key products include the Drinks Box (10.5 qt) and Gin Trunk (25.5 qt), available in various colors such as Sea Boat Blue, Orchard Orange, Bazaruto Blue, Parisian Green, Safari White, and Oyster Grey, all priced at $229. Accessories like the Drinks Box Sling are available for $39. The coolers are made in Cape Town, engineere…

2. Fieldbar – Handcrafted Cooler Boxes

Domain: fieldbar.co.za

Registered: 2020 (5 years)

Introduction: Fieldbar offers a range of handcrafted cooler boxes and outdoor goods. Key products include: 1. Mini Bar – 4L, available in Bazaruto Blue for R 1,799. 2. Drinks Box – 10L, available in Orchard Orange for R 2,499. 3. Gin Trunk – 24L, available in Safari White for R 4,599. 4. Field Bottle – 750ML, available in Parisian Green and Orchard Orange for R 899. 5. Seabed Towels – 600GSM, available in Nelli…

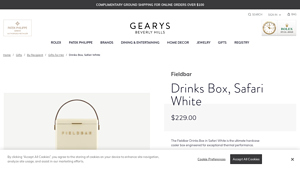

3. Geary’s – Fieldbar Drinks Box

Domain: gearys.com

Registered: 1999 (26 years)

Introduction: This company, Geary’s – Fieldbar Drinks Box, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Accio – Fieldbar Drinks Box

Domain: accio.com

Registered: 1997 (28 years)

Introduction: {‘B2C_Product_Name’: ‘Fieldbar Drinks Box’, ‘Price_Range_USD’: ‘$229 – $320’, ‘Key_Features’: [‘5-year warranty’, ‘ABS plastic’, ‘removable insulation’, ‘stylish color options’], ‘Availability_Platforms’: [‘Amazon’, ‘The Magnum Company’, ‘Yuppiechef’], ‘Durability’: ‘Made with impact-resistant ABS plastic and reinforced hinges’, ‘Aesthetic_Appeal’: ‘Available in six vibrant colors (e.g., Parisian …

Strategic Sourcing Conclusion and Outlook for field bar cooler

What Are the Key Takeaways for Sourcing Field Bar Coolers?

In the competitive market of field bar coolers, strategic sourcing plays a pivotal role in ensuring that international buyers secure high-quality products that meet their specific needs. Prioritizing craftsmanship, durability, and sustainability can significantly enhance the value proposition of these coolers. Buyers should focus on manufacturers that offer both aesthetic appeal and superior functionality, ensuring that their investments not only attract customers but also withstand the rigors of outdoor use.

How Can International Buyers Leverage Strategic Sourcing?

By engaging directly with reputable suppliers and authorized retailers, businesses can mitigate risks associated with counterfeit products and establish trust in their purchasing decisions. Additionally, exploring partnerships with brands that emphasize repairability and longevity aligns with the growing global demand for sustainable solutions, enhancing brand reputation and customer loyalty.

What’s Next for B2B Buyers in the Field Bar Cooler Market?

As the demand for outdoor leisure products continues to rise, now is the time for international buyers—particularly from Africa, South America, the Middle East, and Europe—to capitalize on this trend. By adopting a proactive approach to sourcing, businesses can not only meet the expectations of a discerning consumer base but also position themselves as leaders in a rapidly evolving market. Invest in quality today to ensure lasting returns in the outdoor leisure space.