A B2B Buyer’s Guide to Brc 18650 Battery: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for brc 18650 battery

In the fast-paced world of technology, sourcing reliable BRC 18650 batteries presents a significant challenge for international B2B buyers. As the demand for high-capacity, rechargeable lithium-ion batteries continues to rise across various sectors—from consumer electronics to renewable energy—the pressure to find quality suppliers can be overwhelming. This guide aims to demystify the complexities of the global market for BRC 18650 batteries, offering valuable insights into the different types available, their applications, and key considerations for supplier vetting.

Within these pages, we will explore the diverse landscape of BRC 18650 batteries, including specifications, performance metrics, and safety features. Buyers will gain a comprehensive understanding of how these batteries can enhance the performance of high-drain devices such as flashlights, cameras, and medical equipment. Additionally, we will provide actionable strategies for evaluating suppliers, assessing costs, and negotiating contracts that ensure both quality and value.

This guide is designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including Brazil and Vietnam. By equipping you with the knowledge and tools needed to make informed purchasing decisions, we empower your business to navigate the complexities of the battery market confidently, ultimately driving operational success and sustainability.

Understanding brc 18650 battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Protected Button Top | Built-in safety circuit; prevents overcharge/discharge | Flashlights, toys, high-drain devices | Pros: Enhanced safety; versatile use. Cons: Slightly higher cost than unprotected types. |

| Flat Top | No protruding button; often used in specific devices | E-cigarettes, some flashlights | Pros: Compact design; good for devices requiring flat contact. Cons: Limited applications compared to button tops. |

| High Capacity (3500-4200mAh) | Larger energy storage; suitable for extended use | Electric vehicles, portable electronics | Pros: Longer usage time; fewer replacements. Cons: Higher initial investment; may require specialized chargers. |

| High Discharge (20A+) | Designed for high-drain applications; rapid discharge | Power tools, drones, high-performance devices | Pros: Excellent performance under load; reliable for demanding tasks. Cons: Shorter lifespan under extreme use conditions. |

| Low Self-Discharge | Retains charge for longer periods; ideal for standby use | Emergency equipment, backup systems | Pros: Ready to use when needed; less frequent charging. Cons: Generally lower capacity; may not meet high-drain needs. |

What Are the Characteristics of Protected Button Top Batteries?

Protected button top batteries are equipped with built-in safety circuits that guard against overcharging, overheating, and short circuits. These features make them particularly suitable for high-drain devices like flashlights and toys, where reliability is crucial. When purchasing, B2B buyers should consider the balance between safety features and cost, as these batteries often come at a premium due to their added protection.

How Do Flat Top Batteries Differ in Use?

Flat top batteries lack a protruding button, making them ideal for devices that require a flush connection, such as certain e-cigarettes. They are generally less versatile than their button-top counterparts but can be a cost-effective choice for specific applications. Buyers should ensure compatibility with their devices before selecting flat top batteries, as their unique design limits their usage.

What Advantages Do High Capacity Batteries Offer?

High-capacity batteries, ranging from 3500mAh to 4200mAh, are designed for extended use in applications like electric vehicles and portable electronics. They provide longer run times and reduce the frequency of replacements, which can be a significant advantage for businesses looking to minimize operational downtime. However, buyers should be aware of the higher initial costs and ensure they have the appropriate charging infrastructure to support these batteries.

Why Choose High Discharge Batteries for Performance?

High discharge batteries are engineered to deliver power quickly, making them perfect for demanding applications such as power tools and drones. Their ability to sustain high currents ensures reliable performance during intensive tasks. While they offer excellent performance, buyers must consider the trade-off of a potentially shorter lifespan when used under extreme conditions, which may affect long-term cost-effectiveness.

What Are the Benefits of Low Self-Discharge Batteries?

Low self-discharge batteries are designed to retain their charge for extended periods, making them ideal for emergency equipment and backup systems. This feature ensures that devices are ready to use when needed, enhancing reliability. However, these batteries typically have a lower capacity than others, which may not satisfy high-drain applications. B2B buyers should assess their specific needs to determine if the benefits of low self-discharge outweigh the limitations in capacity.

Key Industrial Applications of brc 18650 battery

| Industry/Sector | Specific Application of brc 18650 battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Power supply for laptops and portable devices | Enhanced performance and extended usage time | Ensure compatibility with device specifications and safety standards. |

| Renewable Energy | Energy storage in solar power systems | Efficient energy utilization and reduced operational costs | Verify capacity and discharge rates to match energy needs. |

| Medical Devices | Backup power for medical equipment | Reliability in critical situations, ensuring patient safety | Compliance with medical regulations and battery lifespan requirements. |

| Automotive | Power for electric bicycles and scooters | Improved performance and range for electric vehicles | Assess weight and size constraints for integration into vehicles. |

| Security & Surveillance | Power source for LED flashlights and security cameras | Reliable operation and longer battery life in critical applications | Evaluate environmental conditions and battery protection features. |

How is the BRC 18650 Battery Used in Consumer Electronics?

In the consumer electronics sector, the BRC 18650 battery serves as a primary power source for laptops, tablets, and other portable devices. Its high capacity (up to 3000mAh) allows for longer usage times, addressing the common issue of rapid battery depletion. B2B buyers in this sector must consider compatibility with device specifications, including voltage and physical dimensions, as well as safety certifications to ensure reliable performance.

What Role Does the BRC 18650 Battery Play in Renewable Energy Solutions?

The BRC 18650 battery is integral to energy storage solutions in solar power systems, where it stores energy generated during peak sunlight hours for later use. This application enhances energy efficiency and reduces overall operational costs. International buyers should focus on the battery’s capacity and discharge rates to ensure they meet the energy demands of their systems, while also considering environmental certifications to comply with local regulations.

How is the BRC 18650 Battery Critical for Medical Devices?

In the medical sector, the BRC 18650 battery provides backup power for essential medical equipment, such as portable ultrasound machines and defibrillators. Its reliability is crucial in ensuring patient safety during emergencies. Buyers in this industry must prioritize compliance with medical regulations and standards, as well as the battery’s lifespan and performance metrics to guarantee uninterrupted service in critical situations.

In What Ways Does the BRC 18650 Battery Enhance Automotive Applications?

The automotive industry utilizes the BRC 18650 battery as a power source for electric bicycles and scooters, contributing to their enhanced performance and extended range. This application is particularly relevant as the demand for eco-friendly transportation solutions grows. B2B buyers should assess the battery’s weight and size constraints to ensure seamless integration into various vehicle models, alongside evaluating the discharge rates to support the required performance levels.

How is the BRC 18650 Battery Used in Security and Surveillance Systems?

In security and surveillance applications, the BRC 18650 battery powers LED flashlights and security cameras, ensuring reliable operation in critical situations. Its long lifespan and rechargeability reduce the frequency of replacements, providing cost savings. Buyers in this sector should evaluate the battery’s protection features against environmental conditions, such as temperature extremes and humidity, to ensure optimal performance in diverse settings.

3 Common User Pain Points for ‘brc 18650 battery’ & Their Solutions

Scenario 1: Inconsistent Battery Performance Leads to Operational Delays

The Problem: B2B buyers often face the issue of inconsistent battery performance in high-drain devices such as flashlights or medical equipment. For example, a company in the Middle East that relies on 18650 batteries for portable lighting may find that some batteries do not hold a charge as expected, leading to unexpected outages during critical operations. This inconsistency can disrupt workflows, cause safety hazards, and ultimately impact customer satisfaction.

The Solution: To mitigate this problem, it is crucial to source BRC 18650 batteries from reputable manufacturers who adhere to stringent quality control measures. Buyers should look for batteries with high cycle performance and internal protection mechanisms, such as PCB protection, which safeguards against overcharging and discharging. Furthermore, implementing a rigorous testing protocol upon receipt of batteries can help identify underperforming units. By maintaining a reliable inventory of quality batteries and regularly cycling through stock, buyers can ensure optimal performance and minimize operational disruptions.

Scenario 2: Difficulty in Selecting the Right Battery Type

The Problem: In diverse markets, buyers often struggle to select the appropriate type of BRC 18650 battery for their specific applications. For instance, a company in South America might need batteries for various devices, ranging from high-drain tools to low-power gadgets, but may not be aware of the differences between button top and flat top designs. This lack of clarity can lead to purchasing errors and wasted resources.

The Solution: To resolve this issue, it is essential to develop a comprehensive understanding of battery specifications and their applications. Buyers should invest time in training their procurement teams on the differences between battery types, including voltage, capacity, and physical design. Creating a decision matrix that aligns battery specifications with device requirements can streamline the selection process. Additionally, collaborating with suppliers who provide detailed product information and support can further aid in making informed decisions, ensuring that the right batteries are sourced for each application.

Scenario 3: Concerns About Battery Safety and Environmental Compliance

The Problem: With increasing regulatory scrutiny around battery safety and environmental impact, B2B buyers often encounter challenges in ensuring compliance with international standards. A European company sourcing BRC 18650 batteries may be particularly concerned about issues such as hazardous materials, recycling processes, and the longevity of battery life cycles, which can affect both safety and sustainability initiatives.

The Solution: To address these concerns, buyers should prioritize sourcing from manufacturers who comply with international safety standards, such as ISO certifications, and who provide clear documentation regarding their batteries’ environmental impact. Establishing relationships with suppliers who are transparent about their manufacturing processes and materials can help ensure compliance. Additionally, integrating a robust recycling program for used batteries can significantly reduce environmental impact and enhance corporate responsibility. By focusing on these measures, buyers can not only safeguard their operations but also contribute positively to sustainability efforts in their industries.

Strategic Material Selection Guide for brc 18650 battery

What Materials Are Commonly Used in BRC 18650 Batteries?

The BRC 18650 battery is a popular choice in various applications, including consumer electronics, power tools, and electric vehicles. The performance and reliability of these batteries largely depend on the materials used in their construction. Below is an analysis of four common materials used in BRC 18650 batteries, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Lithium Cobalt Oxide (LiCoO2)

Key Properties:

Lithium cobalt oxide is known for its high energy density and excellent thermal stability. It operates effectively at temperatures ranging from -20°C to 60°C and has a nominal voltage of 3.7V.

Pros & Cons:

The main advantage of LiCoO2 is its high capacity, making it suitable for applications requiring long run times. However, it is relatively expensive and can be prone to overheating if not managed properly, which may lead to safety concerns.

Impact on Application:

LiCoO2 is ideal for high-drain devices like smartphones and laptops. Its performance can be compromised in extreme temperatures, making it less suitable for regions with harsh climates.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider compliance with safety standards such as IEC 62133 and UN 38.3 for transport. Additionally, sourcing from reputable manufacturers who adhere to international quality certifications is crucial.

2. Lithium Iron Phosphate (LiFePO4)

Key Properties:

Lithium iron phosphate offers excellent thermal stability and a lower risk of thermal runaway, with a temperature rating of up to 70°C.

Pros & Cons:

This material is known for its long cycle life and safety, making it a preferred choice for applications requiring high reliability. However, it has a lower energy density compared to other lithium compounds, which may limit its use in compact devices.

Impact on Application:

LiFePO4 is particularly well-suited for electric vehicles and energy storage systems where safety and longevity are paramount. Its performance remains stable across a wide range of temperatures.

Considerations for International Buyers:

B2B buyers in Europe and the Middle East should ensure that their suppliers comply with EU RoHS directives and other environmental regulations. The growing emphasis on sustainability may also favor LiFePO4 over other materials.

3. Nickel Manganese Cobalt (NMC)

Key Properties:

NMC combines the properties of nickel, manganese, and cobalt, resulting in a balanced performance with good thermal stability and energy density.

Pros & Cons:

The primary advantage of NMC is its versatility, offering a good compromise between capacity, lifespan, and cost. However, the complexity of manufacturing NMC batteries can lead to higher production costs.

Impact on Application:

NMC batteries are widely used in electric vehicles and power tools due to their high energy density and efficiency. They perform well in various environmental conditions, making them suitable for diverse applications.

Considerations for International Buyers:

Buyers should be aware of the supply chain dynamics of cobalt and nickel, particularly concerning ethical sourcing. Compliance with international standards such as ISO 9001 can also be a significant factor in supplier selection.

4. Graphite Anode Material

Key Properties:

Graphite is commonly used as an anode material in lithium-ion batteries due to its excellent conductivity and stability.

Pros & Cons:

Graphite anodes provide good cycling performance and are cost-effective. However, they have a lower capacity compared to silicon-based alternatives, which may limit their performance in high-capacity applications.

Impact on Application:

Graphite anodes are suitable for a wide range of applications, including consumer electronics and electric vehicles. Their performance can be affected by temperature fluctuations, which is a consideration for buyers in hotter climates.

Considerations for International Buyers:

B2B buyers should consider the environmental regulations related to mining and processing graphite, especially in regions with strict environmental laws. Ensuring that suppliers adhere to sustainability practices can enhance brand reputation.

Summary Table of Material Selection for BRC 18650 Batteries

| Material | Typical Use Case for brc 18650 battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium Cobalt Oxide (LiCoO2) | Smartphones, laptops | High energy density | Expensive, risk of overheating | High |

| Lithium Iron Phosphate (LiFePO4) | Electric vehicles, energy storage | Excellent thermal stability and safety | Lower energy density | Medium |

| Nickel Manganese Cobalt (NMC) | Electric vehicles, power tools | Balanced performance | Higher production costs | Medium |

| Graphite Anode Material | Consumer electronics, electric vehicles | Good cycling performance | Lower capacity than silicon alternatives | Low |

This strategic material selection guide provides valuable insights for B2B buyers, helping them make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for brc 18650 battery

What Are the Key Stages in the Manufacturing Process of BRC 18650 Batteries?

The production of BRC 18650 batteries involves several critical stages that ensure high performance and safety. Understanding these stages is vital for B2B buyers looking for reliable suppliers.

Material Preparation: What Raw Materials Are Used?

The first stage in battery manufacturing is material preparation, which involves sourcing high-quality raw materials. Typically, this includes lithium cobalt oxide or lithium iron phosphate for the cathode, graphite for the anode, and a polymer separator. The choice of materials significantly influences the battery’s performance, capacity, and lifespan. Suppliers often use premium-grade materials to enhance the battery’s energy density and ensure safety during operation.

How Is the Battery Formed?

Once the materials are prepared, the next step is the formation of the battery cells. This process includes the mixing of active materials with a binder and solvent to create a slurry, which is then coated onto metal foils. These foils are dried and cut into specific sizes, followed by stacking or winding to form the electrodes. The cells are then filled with electrolyte, which facilitates ion movement during charging and discharging.

What Does the Assembly Process Involve?

After forming the cells, the assembly stage begins. Here, the individual cells are integrated into battery packs, which may involve multiple cells connected in series or parallel to achieve desired voltage and capacity. During this stage, manufacturers pay close attention to the arrangement of cells to optimize performance and ensure thermal management.

What Are the Finishing Touches?

The final stage of manufacturing involves finishing processes, including the installation of protective circuits and casing. These protective circuits help prevent overcharging, overheating, and short-circuiting, ensuring user safety. The batteries are then subjected to various tests before packaging, confirming that they meet stringent quality standards.

What Quality Assurance Standards Are Relevant for BRC 18650 Batteries?

Quality assurance is critical in battery manufacturing, particularly for B2B transactions. Buyers should be aware of international standards and certifications that ensure product reliability and safety.

Which International Standards Should B2B Buyers Look For?

Manufacturers of BRC 18650 batteries typically adhere to international quality standards such as ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer consistently meets customer and regulatory requirements. Other relevant certifications include CE marking, which signifies conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

How Are Quality Control Checkpoints Integrated?

Quality control (QC) is embedded throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that each production stage adheres to quality standards.

- Final Quality Control (FQC): The finished products undergo rigorous testing to verify performance metrics such as capacity, voltage, and safety features.

What Testing Methods Are Commonly Used in BRC 18650 Battery Production?

Various testing methods ensure that BRC 18650 batteries meet quality and safety standards. These tests may include:

- Charge and Discharge Testing: Evaluating the battery’s performance under various load conditions.

- Cycle Life Testing: Measuring how many charge/discharge cycles the battery can endure before its capacity significantly diminishes.

- Thermal Stability Testing: Assessing the battery’s performance under high-temperature conditions to prevent thermal runaway.

- Short-Circuit and Overcharge Testing: Ensuring that protective circuits function correctly to mitigate risks.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure reliability and safety.

What Steps Can Buyers Take to Audit Suppliers?

Buyers can conduct audits to assess a supplier’s manufacturing processes and quality control systems. This may include:

- Factory Audits: Visiting the manufacturing facility to observe processes and quality control measures firsthand.

- Documentation Review: Evaluating quality control records, testing results, and compliance certificates to ensure adherence to international standards.

- Third-party Inspections: Engaging independent inspection agencies to perform quality assessments and provide unbiased reports.

What Nuances Should Buyers Be Aware Of in Different Regions?

Different regions may have varying regulatory requirements and quality expectations. For instance, suppliers from Europe may be subject to stricter environmental regulations compared to those in other regions. Buyers from Africa and South America should pay close attention to these nuances and ensure that their suppliers are compliant with local regulations while also adhering to international standards.

Conclusion: Why Is Quality Assurance Critical for BRC 18650 Battery Suppliers?

In the competitive landscape of battery manufacturing, maintaining high-quality standards is essential for meeting customer expectations and ensuring safety. B2B buyers must prioritize suppliers that demonstrate robust quality assurance processes, adhere to international standards, and are transparent about their manufacturing practices. By doing so, they can mitigate risks and ensure the reliability of their battery products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brc 18650 battery’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring BRC 18650 batteries effectively. As the demand for high-capacity rechargeable batteries continues to rise, understanding the nuances of sourcing can lead to better purchasing decisions and improved operational efficiency. Follow this step-by-step checklist to ensure that you find the right supplier and product for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for sourcing the right BRC 18650 battery. Consider factors such as capacity (mAh), voltage (typically 3.7V), size (18mm x 65mm), and discharge rates. Knowing these details will help you communicate your needs effectively and avoid purchasing batteries that do not meet your requirements.

Step 2: Research Market Trends and Pricing

Before engaging with suppliers, conduct thorough market research to understand current pricing and trends for BRC 18650 batteries. This knowledge will empower you to negotiate better deals and identify competitive suppliers. Pay attention to bulk pricing options, as larger orders often come with significant discounts.

Step 3: Evaluate Potential Suppliers

Vet suppliers meticulously to ensure reliability and quality. Request company profiles, production capabilities, and references from other businesses in your industry. Look for suppliers with certifications such as ISO 9001 and adherence to international safety standards, which indicate a commitment to quality and safety.

Step 4: Request Product Samples

Always request samples of the BRC 18650 batteries before making a bulk purchase. Testing samples allows you to evaluate performance, compatibility with your devices, and overall quality. Ensure the samples meet your technical specifications and perform well under your expected usage conditions.

Step 5: Assess Warranty and Return Policies

Understanding the warranty and return policies is crucial for mitigating risks associated with battery procurement. Check if the supplier offers a warranty period and what it covers. This information is vital in case of defects or performance issues, ensuring you have recourse if the products do not meet your expectations.

Step 6: Confirm Compliance with Regulations

Ensure that the batteries comply with international regulations and standards relevant to your market. This includes safety certifications and environmental regulations, which are particularly important when importing products. Compliance reduces the risk of legal issues and enhances product safety for end-users.

Step 7: Finalize Payment and Shipping Arrangements

Once you have selected a supplier, finalize the payment terms and shipping arrangements. Discuss options for shipping methods, lead times, and costs. Clear communication regarding these details will help avoid unexpected delays and ensure that your batteries arrive on time and in good condition.

By following this checklist, B2B buyers can streamline the sourcing process for BRC 18650 batteries and make informed decisions that enhance their supply chain efficiency.

Comprehensive Cost and Pricing Analysis for brc 18650 battery Sourcing

What are the Key Cost Components in Sourcing BRC 18650 Batteries?

When sourcing BRC 18650 batteries, understanding the cost structure is crucial for effective budgeting and pricing negotiations. The primary components influencing costs include:

-

Materials: The cost of raw materials, particularly lithium-ion components, can vary significantly based on market fluctuations. High-quality materials increase battery performance and longevity but also raise the overall cost.

-

Labor: Labor costs are influenced by the manufacturing location. Regions with higher wages, such as parts of Europe, will see increased costs compared to lower-wage areas in Asia.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and facility costs. Efficient production lines can reduce overhead, impacting the final price.

-

Tooling: Initial costs for molds and production equipment can be substantial but are amortized over large production runs. Custom tooling for specific battery configurations will further influence this cost.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability, particularly important in high-stakes applications. This adds to labor and overhead costs but is essential for maintaining brand reputation.

-

Logistics: Shipping costs are determined by the weight and volume of batteries, as well as the chosen transportation method. International shipping can introduce additional tariffs and fees, affecting the total cost.

-

Margin: Supplier profit margins vary widely based on market positioning, brand reputation, and the level of service provided. Understanding a supplier’s margin can provide leverage during negotiations.

How Do Price Influencers Affect BRC 18650 Battery Costs?

Several factors can influence the pricing of BRC 18650 batteries:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often come with significant discounts. Buyers should assess their inventory needs to negotiate better prices based on anticipated demand.

-

Specifications/Customization: Custom battery designs or specific performance characteristics can increase costs. Buyers should balance the need for customization against budget constraints.

-

Materials and Quality Certifications: Batteries that meet international safety and quality standards (e.g., CE, RoHS) may command higher prices. Buyers should weigh the benefits of certified products against their cost.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more but offer better warranty terms and customer service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is critical for budgeting. Different terms can shift the responsibility and costs of transportation, affecting the total landed cost.

What Tips Can Help Buyers Optimize BRC 18650 Battery Sourcing Costs?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost efficiency:

-

Negotiation: Leverage volume commitments or long-term contracts to negotiate better pricing. Suppliers may be willing to reduce costs for guaranteed business.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the lifecycle costs, including charging, maintenance, and disposal. High-quality batteries may have a higher upfront cost but lower TCO due to longer life cycles.

-

Understand Pricing Nuances: Prices can fluctuate based on global market conditions, particularly in raw material sourcing. Stay informed about market trends to time purchases effectively.

-

Build Relationships with Suppliers: Establishing strong partnerships can lead to preferential pricing and priority during shortages.

-

Explore Local Suppliers: For buyers in regions like Africa or South America, local suppliers may offer competitive pricing and reduced shipping costs, enhancing overall supply chain efficiency.

Conclusion

Sourcing BRC 18650 batteries requires a nuanced understanding of cost structures and pricing influencers. By considering these factors and employing strategic sourcing practices, international B2B buyers can optimize their procurement processes and achieve better pricing outcomes. Always remember that prices can vary significantly, so conducting thorough market research and maintaining flexibility in negotiations will yield the best results.

Alternatives Analysis: Comparing brc 18650 battery With Other Solutions

Exploring Alternative Solutions to the BRC 18650 Battery

In the rapidly evolving world of battery technology, businesses often seek alternatives to the BRC 18650 battery to meet specific operational needs. Understanding the strengths and weaknesses of various options is crucial for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Below, we compare the BRC 18650 battery with two viable alternatives: lithium polymer (LiPo) batteries and nickel-metal hydride (NiMH) batteries.

| Comparison Aspect | BRC 18650 Battery | Lithium Polymer Battery (LiPo) | Nickel-Metal Hydride Battery (NiMH) |

|---|---|---|---|

| Performance | High capacity (3000mAh) and stable voltage (3.7V) | High energy density, lightweight | Moderate capacity (up to 3000mAh) but lower energy density |

| Cost | Typically ranges from $8.99 to $10.74 per unit | Generally higher due to advanced technology | More affordable, usually around $5-$8 per unit |

| Ease of Implementation | Widely compatible with devices; requires a compatible charger | Requires careful handling and specific charging equipment | Easy to use with standard chargers; less sensitive |

| Maintenance | Low maintenance with proper usage; needs occasional reconditioning | Requires careful monitoring to avoid swelling and damage | Moderate maintenance; self-discharge can be a concern |

| Best Use Case | Ideal for high-drain devices like flashlights and laptops | Excellent for drones, RC devices, and portable electronics | Suitable for less demanding applications like remote controls and lower-drain devices |

What Are the Advantages and Disadvantages of Lithium Polymer Batteries Compared to BRC 18650 Batteries?

Lithium polymer (LiPo) batteries are renowned for their lightweight design and high energy density, making them suitable for applications where weight is a critical factor, such as in drones and RC devices. They typically offer a more compact form factor than the cylindrical BRC 18650 batteries, which can be an advantage in space-constrained applications. However, LiPo batteries require more careful handling and specific charging equipment due to their sensitivity to overcharging and potential for swelling or catching fire if mishandled. This can lead to increased operational costs and complexity.

How Do Nickel-Metal Hydride Batteries Stack Up Against the BRC 18650 Battery?

Nickel-metal hydride (NiMH) batteries are often considered a more affordable alternative to lithium-ion solutions like the BRC 18650. They are easier to handle and charge, making them a popular choice for consumer electronics, such as remote controls and basic electronic devices. However, NiMH batteries generally have a lower energy density and capacity compared to lithium-ion batteries, which means they may not be suitable for high-drain applications. Additionally, they tend to self-discharge more quickly, which can be a disadvantage in applications requiring long-term storage or infrequent use.

How Can B2B Buyers Choose the Right Battery Solution?

When selecting the most appropriate battery solution, B2B buyers should carefully assess their specific needs, including the types of devices they will power, the importance of weight and size, budget constraints, and maintenance capabilities. The BRC 18650 battery excels in high-drain applications where reliability and performance are paramount. In contrast, if weight and compactness are critical, LiPo batteries may be the ideal choice. For cost-sensitive applications with less demanding power requirements, NiMH batteries could be the best fit. By understanding the distinct advantages and drawbacks of each option, businesses can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for brc 18650 battery

What Are the Key Technical Properties of BRC 18650 Batteries?

Understanding the technical specifications of BRC 18650 batteries is crucial for B2B buyers in industries such as electronics, renewable energy, and consumer goods. Here are some essential properties:

-

Capacity (mAh)

The capacity of a battery, measured in milliamp hours (mAh), indicates how much charge it can hold. For example, a BRC 18650 battery typically has a capacity ranging from 2600mAh to 4200mAh. A higher capacity means longer usage time, which is vital for high-drain devices like flashlights and power tools. Buyers should consider their application needs to select the appropriate capacity. -

Nominal Voltage (V)

The nominal voltage of a BRC 18650 battery is generally 3.7V. This standard voltage is important as it affects compatibility with devices. Devices designed for a specific voltage range will only operate efficiently within that range. Understanding nominal voltage helps buyers avoid purchasing batteries that may not work with their equipment. -

Discharge Current (A)

This specification indicates the maximum current the battery can deliver continuously. For instance, a BRC 18650 battery may support a discharge current of up to 30A. High discharge rates are essential for applications requiring quick bursts of energy, such as in electric vehicles or power-hungry tools. Buyers need to match the discharge current with their device’s requirements to ensure performance and safety. -

Internal Resistance (mΩ)

Internal resistance affects how well a battery can perform under load. Lower resistance typically means better efficiency and less heat generation during operation. For BRC 18650 batteries, internal resistance values can range from 30mΩ to 180mΩ. Buyers should look for batteries with low internal resistance for applications demanding high efficiency. -

Cycle Life

Cycle life refers to the number of charge and discharge cycles a battery can undergo before its capacity drops below 80% of the original. BRC 18650 batteries often support around 500 cycles. Understanding cycle life is critical for cost-effectiveness; batteries with longer cycle lives reduce replacement costs and waste, making them more sustainable.

What Are Common Trade Terms Related to BRC 18650 Batteries?

Familiarity with industry jargon can empower B2B buyers to negotiate better and make informed purchasing decisions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of BRC 18650 batteries, buyers often seek OEM partners to ensure that the batteries meet specific standards and integrate seamlessly into their products. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs that align with their demand forecasts to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers. For B2B buyers, issuing an RFQ for BRC 18650 batteries can help in comparing prices, understanding lead times, and assessing supplier capabilities. A well-structured RFQ can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Understanding these terms can help B2B buyers manage shipping costs and risks effectively when importing BRC 18650 batteries from different regions. -

PCB (Printed Circuit Board) Protection

PCB protection refers to a built-in safety feature in many lithium-ion batteries, including BRC 18650 types. It regulates the battery’s output and prevents issues such as overcharging or overheating. Buyers should prioritize batteries with PCB protection for enhanced safety and reliability in their applications.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the brc 18650 battery Sector

What Are the Global Drivers Influencing the BRC 18650 Battery Market?

The BRC 18650 battery sector is witnessing a surge driven by several global trends. The increasing demand for portable electronic devices and electric vehicles (EVs) has heightened the need for efficient, high-capacity lithium-ion batteries. In regions such as Africa and South America, the rise of renewable energy solutions is further propelling the demand for energy storage systems, where BRC 18650 batteries play a crucial role. Additionally, advancements in battery technology, including enhanced energy density and faster charging capabilities, are attracting international buyers looking for innovative solutions.

Emerging B2B trends highlight a shift towards bulk purchasing and long-term partnerships with manufacturers. Buyers are increasingly seeking suppliers that can offer not only competitive pricing but also reliability in supply chains and product quality. Furthermore, the rise of e-commerce platforms has simplified sourcing processes, enabling buyers from diverse geographical locations to access a broader range of products. This trend is particularly significant in markets like Brazil and Vietnam, where digital infrastructure is rapidly developing.

How Is Sustainability and Ethical Sourcing Reshaping the BRC 18650 Battery Market?

Sustainability and ethical sourcing have become paramount in the BRC 18650 battery industry. The environmental impact of battery production, particularly concerning resource extraction and waste management, is garnering attention from international buyers. Ethical sourcing practices involve ensuring that raw materials, such as lithium and cobalt, are obtained responsibly, minimizing ecological degradation and promoting fair labor practices.

Buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainability through certifications and eco-friendly manufacturing processes. Green certifications, such as ISO 14001 for environmental management, can provide assurance of a supplier’s dedication to reducing their carbon footprint. Moreover, innovations in recycling technologies are enabling the recovery of valuable materials from used batteries, contributing to a circular economy. This shift not only enhances brand reputation but also aligns with the growing consumer demand for environmentally responsible products.

What Is the Brief Evolution and History of the BRC 18650 Battery?

The BRC 18650 battery has evolved significantly since its inception in the early 1990s. Initially developed for consumer electronics, its application has expanded to include electric vehicles, renewable energy storage, and various high-drain devices. As technology advanced, manufacturers improved the energy density and safety features of these batteries, leading to the introduction of protective circuits that prevent overheating and overcharging.

The global shift towards renewable energy and electric mobility has further accelerated the development of the BRC 18650 battery, establishing it as a cornerstone in the transition to sustainable energy solutions. Today, it represents a critical component in various industries, reflecting its adaptability and the growing demand for efficient energy storage systems worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of brc 18650 battery

-

How do I ensure the quality of BRC 18650 batteries before purchasing?

To ensure quality, request samples from potential suppliers before making bulk purchases. Verify that the batteries meet international standards such as IEC or UL certifications. Additionally, inquire about the manufacturing process, including quality control measures and testing protocols. It’s also beneficial to review customer testimonials and seek third-party audits of the supplier’s facilities to assess reliability and performance. -

What is the best BRC 18650 battery for high-drain devices?

For high-drain devices, the BRC 18650 batteries with a capacity of 3000mAh or higher are ideal. Look for batteries that provide high discharge rates (at least 10A) to ensure optimal performance. Brands like UltraFire and EBL offer reliable options with built-in protection features that enhance safety and longevity. Always check the specifications to match the battery’s discharge capabilities with your device’s requirements. -

What are the minimum order quantities (MOQs) for BRC 18650 batteries?

MOQs vary by supplier and can range from as few as 10 units to several thousand, depending on the manufacturer and pricing structure. When sourcing, clarify the MOQ and negotiate if necessary, especially if you are a small business. Some suppliers may offer flexibility for first-time buyers or bulk discounts, so it’s worth discussing your specific needs to find a suitable arrangement. -

What payment terms should I expect when sourcing BRC 18650 batteries internationally?

Payment terms can differ significantly based on the supplier and your negotiation. Common terms include upfront payment, a 30% deposit with the balance due before shipment, or payment upon delivery. It’s advisable to use secure payment methods such as letters of credit or escrow services to protect your investment. Always clarify payment terms and ensure they are documented in your purchase agreement. -

How can I vet suppliers of BRC 18650 batteries?

To vet suppliers, start by researching their reputation through online reviews and industry forums. Request references from previous customers and verify their business licenses and certifications. Additionally, consider conducting factory visits or utilizing third-party inspection services to assess manufacturing capabilities and quality control practices. Establishing a trustworthy relationship with suppliers is crucial for long-term success. -

What customization options are available for BRC 18650 batteries?

Many manufacturers offer customization options such as branding, packaging, and specific technical specifications like capacity and discharge rates. When discussing your needs, provide detailed requirements to ensure the supplier can meet them. Customization can also include protective features or specific labeling, so it’s essential to communicate clearly and confirm all details in writing. -

What logistics considerations should I keep in mind when importing BRC 18650 batteries?

When importing batteries, consider shipping regulations, especially regarding hazardous materials. Ensure compliance with international shipping laws and customs requirements in your destination country. Collaborate with a logistics provider experienced in handling battery shipments to navigate potential challenges. Additionally, factor in lead times for production and shipping to avoid delays in your supply chain. -

What are the warranty and return policies for BRC 18650 batteries?

Warranty and return policies vary by supplier, but most reputable manufacturers offer warranties ranging from 6 months to 2 years. Clarify the terms of the warranty, including what it covers (e.g., defects, performance issues) and the process for returns or exchanges. Make sure these policies are clearly outlined in your purchase agreement to protect your investment and ensure accountability from the supplier.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Brc 18650 Battery Manufacturers & Suppliers List

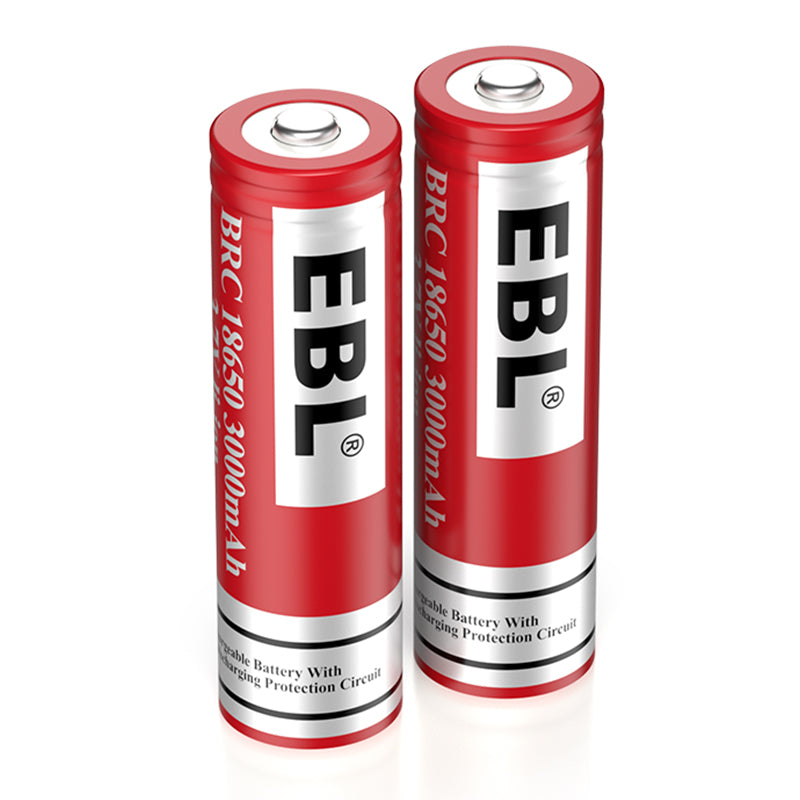

1. EBL – BRC 18650 Battery

Domain: eblofficial.com

Registered: 2019 (6 years)

Introduction: EBL BRC 18650 Battery – High Capacity 18650 Lithium Battery. 12-Month Warranty. 30-Day Money-Back Guarantee.

2. UltraFire – FLB 18650 3000mAh Battery

Domain: batteryjunction.com

Registered: 2004 (21 years)

Introduction: {“Product Name”: “UltraFire FLB 18650 3000mAh 3.7V High-Capacity Protected Lithium Ion (Li-ion) Button Top Battery”, “Item Number”: “ULTRAFIRE-BRC-18650-3000”, “Brand”: “UltraFire”, “Capacity”: “3000mAh”, “Nominal Voltage”: “3.7V”, “Cut-off Voltage”: “2.5V”, “Internal Impedance”: “≤ 180 Milli-Ohms”, “Cycle Performance”: “90% of initial capacity at 400 cycles”, “Charge Cycles”: “500”, “Charging Cur…

3. UltraFire – BRC 18650 3600mAh Li-ion Battery

Domain: lightmalls.com

Registered: 2011 (14 years)

Introduction: {“Product Name”:”Ultrafire BRC 18650 3600mAh 3.7V Protected Li-ion Battery (2Pcs)”,”Brand”:”UltraFire”,”Type”:”Rechargeable lithium battery”,”Model”:”BRC18650″,”Rechargeable Times”:”Up to 500 times”,”Charge Time”:”2-4hrs”,”Voltage”:”3.7V”,”Capacity”:”3600mAh”,”Protected”:”YES”,”Cell Type”:”Li-ion”,”Rechargeable”:”Yes”,”Over Discharge Warning”:”Full voltage is not higher than the recommended 4.2V, …

4. EBL – BRC 18650 Rechargeable Battery

Domain: kenleephotography.wordpress.com

Registered: 2000 (25 years)

Introduction: Product Name: EBL BRC 18650 Rechargeable Battery 3000mAh – Protected Button Top

Capacity: 3000mAh

Nominal Voltage: 3.7V

Rechargeable: Yes

Charge Current: Standard: 400mA | Max: 2200mA

Discharge Current: Standard: 440mA | Max: 6000mA

Discharge Cut-off Voltage: 3V

Internal Resistance: ≦80mΩ

Weight: 1.55oz (per cell)

Dimensions: 0.71*2.66 inch (18.5*67.5mm)

Operating Temperature Range: -40 to 140 Fah…

5. UltraFire – 18650 Li-ion Battery

Domain: ultrafire.com

Registered: 1999 (26 years)

Introduction: {‘Brand’: ‘UltraFire’, ‘Battery Type’: ‘18650’, ‘Material’: ‘Li-ion’, ‘Capacity’: ‘3000mAh’, ‘Rated Voltage’: ‘3.7V’, ‘Charge Termination Voltage’: ‘4.2V’, ‘Discharge Termination Voltage’: ‘2.75V’, ‘Maximum Discharge Current’: ‘1.8A-3.6A’, ‘Size’: ‘2.62″ (L) x 0.72″ (W) x 0.72″ (H)’, ‘Weight’: ‘46.5g’, ‘Chargeable’: ‘Yes’, ‘Protective Case’: ‘Yes’}

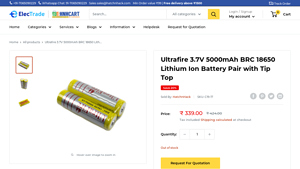

6. Ultrafire – 3.7V 5000mAh BRC 18650 Lithium Ion Battery Pair

Domain: hnhcart.com

Registered: 2019 (6 years)

Introduction: Ultrafire 3.7V 5000mAh BRC 18650 Lithium Ion Battery Pair with Tip Top

Strategic Sourcing Conclusion and Outlook for brc 18650 battery

What Are the Key Benefits of Strategic Sourcing for BRC 18650 Batteries?

In today’s competitive landscape, strategic sourcing of BRC 18650 batteries is crucial for international B2B buyers. The high-capacity options, such as the 3000mAh and 4200mAh variants, deliver exceptional performance for demanding applications, ensuring that your products remain reliable and efficient. By focusing on reputable suppliers who prioritize quality and safety—such as those with built-in protection circuits—you can minimize risks associated with battery performance and customer satisfaction.

How Can International Buyers Leverage Trends in Battery Technology?

The growing trend towards high-capacity, environmentally friendly batteries presents a significant opportunity for buyers across Africa, South America, the Middle East, and Europe. As demand for portable power solutions increases, aligning your sourcing strategy with suppliers who offer innovative technology and competitive pricing can enhance your market position. Additionally, considering bulk purchasing options can lead to substantial cost savings, making it a smart strategy for forward-thinking businesses.

What’s Next for Your Sourcing Strategy?

As you navigate the future of battery sourcing, it’s essential to stay informed about technological advancements and market trends. Engage with suppliers who demonstrate a commitment to quality and compliance with international standards. By prioritizing strategic sourcing now, you can ensure a sustainable supply chain that meets your operational needs. Embrace the opportunities that lie ahead and position your business for success in the evolving landscape of battery technology.