Choosing Your Vintage Coffee Grinder Parts: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for vintage coffee grinder parts

In the dynamic landscape of the global market, sourcing vintage coffee grinder parts presents a unique challenge for B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Brazil. The intricate nature of antique machinery, combined with the scarcity of authentic components, makes it essential for businesses to navigate this niche market with expertise and foresight. This guide aims to demystify the process, providing comprehensive insights into various types of vintage coffee grinder parts, their applications, and effective supplier vetting strategies.

From identifying essential components like grinder mechanisms and handles to understanding the nuances of pricing and shipping logistics, this guide serves as a valuable resource for informed purchasing decisions. Buyers will gain a deeper understanding of market trends, ensuring they can make strategic investments that not only enhance their product offerings but also cater to the growing demand for quality vintage items.

By equipping international B2B buyers with actionable insights and best practices, this guide empowers them to confidently approach their sourcing challenges. Whether you’re a retailer seeking to expand your inventory or a repair service looking for specific parts, the information provided here will facilitate a more streamlined and successful purchasing experience in the global marketplace for vintage coffee grinder parts.

Understanding vintage coffee grinder parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Hand Grinders | Typically made of wood or cast iron; hand-cranked | Specialty coffee shops, artisan roasters | Pros: Low maintenance, authentic experience. Cons: Labor-intensive, slower production rate. |

| Electric Burr Grinders | Electric-powered, uses burrs for consistent grind | Large-scale coffee producers, cafes | Pros: Fast, consistent results. Cons: Higher initial investment, requires electricity. |

| Wall-Mounted Grinders | Mounted on walls, often with decorative designs | Cafés, restaurants with limited counter space | Pros: Space-saving, vintage aesthetic. Cons: Less versatile, installation required. |

| Vintage Grinder Parts | Replacement components for various models; often hard-to-find | Restoration specialists, collectors | Pros: Essential for maintaining vintage equipment. Cons: Limited availability, can be costly. |

| Specialty Accessories | Includes lids, handles, and grind containers | Custom coffee shops, restoration projects | Pros: Enhances functionality and aesthetics. Cons: May not fit all models, requires compatibility checks. |

What Are Manual Hand Grinders and Their B2B Suitability?

Manual hand grinders are characterized by their traditional design, often crafted from wood or cast iron, and operated through a hand-cranking mechanism. These grinders are ideal for specialty coffee shops and artisan roasters that emphasize craftsmanship and an authentic coffee experience. When considering a purchase, B2B buyers should evaluate the grinder’s durability and the ease of sourcing replacement parts, as manual grinders may require more frequent maintenance than electric models.

How Do Electric Burr Grinders Benefit Large-Scale Coffee Producers?

Electric burr grinders utilize a motorized mechanism to produce a consistent grind, making them a staple in large-scale coffee production and café settings. Their efficiency allows for high-volume grinding, catering to businesses that serve a significant customer base. Buyers should assess the grinder’s capacity, grind size options, and compatibility with existing equipment to ensure it meets their operational needs while also considering the upfront investment cost.

What Are the Advantages of Wall-Mounted Grinders for Cafés?

Wall-mounted grinders offer a unique blend of functionality and vintage charm, making them suitable for cafés and restaurants with limited counter space. They are designed to be both practical and decorative, often enhancing the aesthetic appeal of the establishment. B2B buyers should consider installation requirements and the grinder’s ability to handle different grind sizes, as well as its maintenance needs to ensure long-term usability.

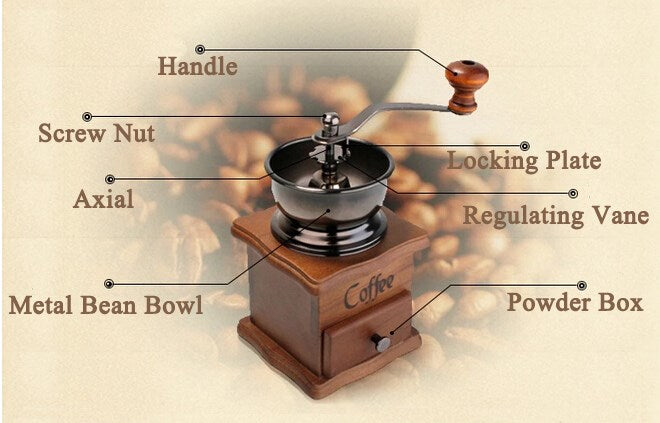

Why Are Vintage Grinder Parts Important for Restoration Specialists?

Vintage grinder parts are essential for businesses focused on restoring antique coffee equipment. These components, which include anything from handles to internal mechanisms, can be challenging to source, making them invaluable for restoration specialists and collectors. Buyers need to be diligent in verifying the compatibility of parts with specific grinder models, as well as being prepared for potential higher costs due to their rarity.

How Do Specialty Accessories Enhance the Functionality of Coffee Grinders?

Specialty accessories for coffee grinders, such as lids, handles, and grind containers, can significantly enhance both functionality and aesthetic appeal. These components are particularly beneficial for custom coffee shops and restoration projects where unique designs are desired. When purchasing, B2B buyers should ensure that the accessories are compatible with their existing grinders and assess the potential for customization to meet specific branding or operational needs.

Key Industrial Applications of vintage coffee grinder parts

| Industry/Sector | Specific Application of Vintage Coffee Grinder Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Specialty Coffee Shops | Restoration of Antique Grinders | Enhances brand authenticity and customer experience | Authenticity of parts, compatibility, and sourcing reliability |

| Antique Restoration | Repair and refurbishment of collectible items | Increases resale value and market appeal | Availability of original parts, quality assurance, and provenance |

| Home Decor Retailers | Display and functional use in vintage-themed decor | Attracts niche customers and enhances product offerings | Unique design elements, sourcing from reputable suppliers |

| Culinary Schools | Educational demonstrations using vintage equipment | Provides hands-on learning experiences for students | Availability of operational parts, instructional materials |

| Export and Import Businesses | Sourcing and selling vintage parts internationally | Expands market reach and diversifies product portfolio | Compliance with import/export regulations, shipping logistics |

How Are Vintage Coffee Grinder Parts Utilized in Specialty Coffee Shops?

Specialty coffee shops often seek to restore vintage coffee grinders to maintain authenticity in their offerings. These shops use vintage grinders not just for their aesthetic value but also for the unique flavor profiles they can produce. By sourcing authentic parts, businesses can ensure that the grinders operate effectively, providing high-quality coffee that meets customer expectations. Buyers must consider the authenticity and compatibility of parts to ensure seamless integration into their operations.

In What Ways Do Antique Restoration Professionals Use Vintage Coffee Grinder Parts?

Antique restoration professionals utilize vintage coffee grinder parts to repair and refurbish collectible items. This practice enhances the resale value and market appeal of restored items, attracting collectors and enthusiasts. Sourcing original parts is critical, as it maintains the historical integrity of the piece. Buyers must prioritize quality assurance and provenance when sourcing these parts to guarantee authenticity and craftsmanship.

How Do Home Decor Retailers Benefit from Vintage Coffee Grinder Parts?

Home decor retailers incorporate vintage coffee grinders into their product offerings, either as functional items or decorative pieces. By showcasing these unique items, retailers can attract niche customers who appreciate vintage aesthetics. The value lies in the distinctiveness of each piece, which can enhance the overall appeal of their inventory. Retailers should focus on sourcing unique design elements and ensuring that suppliers can provide reliable stock to meet customer demand.

What Role Do Vintage Coffee Grinder Parts Play in Culinary Schools?

Culinary schools use vintage coffee grinders for educational demonstrations, offering students hands-on experiences with historical equipment. This approach not only teaches students about coffee preparation but also emphasizes the importance of traditional methods. Availability of operational parts is crucial for maintaining these grinders in working condition. Schools should also seek instructional materials to accompany these demonstrations, ensuring that students gain comprehensive knowledge about the equipment.

How Can Export and Import Businesses Leverage Vintage Coffee Grinder Parts?

Export and import businesses can capitalize on the growing interest in vintage coffee grinder parts by sourcing and selling these items internationally. This expands market reach and diversifies product portfolios, appealing to collectors and coffee enthusiasts alike. Compliance with import/export regulations is essential, as is an understanding of shipping logistics to ensure timely delivery. Businesses should also establish relationships with reliable suppliers to maintain a consistent inventory of sought-after parts.

3 Common User Pain Points for ‘vintage coffee grinder parts’ & Their Solutions

Scenario 1: Difficulty in Finding Authentic Replacement Parts

The Problem: B2B buyers often struggle to locate authentic replacement parts for vintage coffee grinders. This is particularly true for businesses specializing in restoration or resale of antique coffee equipment. Many suppliers do not carry specific parts due to the rarity and age of these grinders, leading to frustration and potential project delays. Moreover, counterfeit parts can mislead buyers, damaging their credibility and customer trust.

The Solution: To effectively source authentic vintage coffee grinder parts, buyers should engage with specialized communities and associations, such as the Association of Coffee Mill Enthusiasts (ACME). These organizations can provide valuable resources and networks that connect buyers with reputable sellers who stock genuine parts. Buyers should also consider leveraging online platforms that specialize in antique parts, ensuring they verify the seller’s credibility through reviews and testimonials. Additionally, documenting the specific parts needed with detailed photos can facilitate better communication with suppliers. This proactive approach minimizes the risk of acquiring counterfeit components and ensures the integrity of restoration projects.

Scenario 2: Understanding Compatibility Issues with Vintage Parts

The Problem: Compatibility is a significant concern for businesses looking to replace parts in vintage coffee grinders. Each model may have unique specifications, and mismatched parts can lead to functionality issues, resulting in additional costs and time lost on repairs. Buyers often find it challenging to ascertain whether a part is suitable for their specific grinder model, especially when dealing with older or less common brands.

The Solution: To navigate compatibility challenges, buyers should maintain a comprehensive inventory of grinder models and their respective specifications. This includes noting dimensions, material types, and unique design features. Before purchasing parts, they should consult with suppliers who offer expert guidance on compatibility and can provide detailed specifications for each component. Establishing a relationship with knowledgeable sellers can also prove beneficial; they can assist in identifying the right parts and even offer customization services if necessary. Furthermore, utilizing online forums and community groups for advice on specific models can provide insights from other experienced restorers who have faced similar challenges.

Scenario 3: High Shipping Costs and International Sourcing Hurdles

The Problem: International B2B buyers often encounter high shipping costs and logistical challenges when sourcing vintage coffee grinder parts from different countries. The costs associated with shipping fragile or heavy items can significantly impact overall project budgets. Additionally, customs regulations and potential delays can complicate the purchasing process, leading to uncertainty and frustration.

The Solution: To mitigate high shipping costs, buyers should explore bulk purchasing options or establish partnerships with local suppliers who can source parts from international vendors. Collaborating with other businesses in similar markets can create opportunities for shared shipping costs and reduce individual expenses. Buyers can also investigate regional suppliers who specialize in vintage parts, as they may offer competitive pricing and faster delivery times. Utilizing freight forwarders experienced in handling antique items can streamline the shipping process and help navigate customs more effectively. Lastly, staying informed about shipping regulations and potential tariffs can assist in budgeting for overall costs, allowing for more accurate project planning.

Strategic Material Selection Guide for vintage coffee grinder parts

What Are the Key Materials Used in Vintage Coffee Grinder Parts?

When selecting materials for vintage coffee grinder parts, it is essential to consider their properties, advantages, and limitations. The choice of material not only affects the performance and durability of the grinder but also influences the overall cost and manufacturing complexity. Here, we analyze four common materials used in vintage coffee grinder parts: cast iron, brass, stainless steel, and wood.

How Does Cast Iron Perform in Vintage Coffee Grinder Parts?

Cast iron is a traditional material widely used in vintage coffee grinders, particularly for the body and grinding mechanisms. It boasts excellent durability and can withstand high temperatures, making it suitable for long-term use. However, it is prone to corrosion if not properly maintained, especially in humid environments.

Pros: Cast iron offers high durability and a classic aesthetic that appeals to collectors. It provides a stable grinding surface, which is crucial for consistent coffee grounds.

Cons: The weight of cast iron can complicate shipping and handling, increasing costs for international buyers. Additionally, its susceptibility to rust requires careful maintenance, which may not be feasible for all users.

Impact on Application: Cast iron is compatible with various coffee beans and grinding methods, but its heavy nature may not be suitable for portable grinders.

What Are the Benefits of Using Brass in Vintage Coffee Grinder Parts?

Brass is often used for components such as handles and decorative elements. It is known for its resistance to corrosion and excellent machinability, making it easy to manufacture intricate designs.

Pros: Brass parts add aesthetic value and are less likely to corrode compared to iron. They can also be polished to a high shine, enhancing the visual appeal of the grinder.

Cons: The cost of brass is generally higher than that of cast iron, which can affect the overall pricing of the product. Additionally, brass is softer than iron, making it less suitable for high-stress components.

Impact on Application: Brass is ideal for decorative parts but may not withstand heavy usage in grinding mechanisms.

Why Choose Stainless Steel for Vintage Coffee Grinder Parts?

Stainless steel is increasingly popular for grinder parts due to its excellent corrosion resistance and strength. It is particularly favored for grinding burrs and internal mechanisms.

Pros: Stainless steel is durable and easy to clean, making it ideal for food-related applications. It does not rust or tarnish, ensuring long-lasting performance.

Cons: The manufacturing process for stainless steel can be more complex and costly. Additionally, its higher density compared to other materials may impact the weight of the final product.

Impact on Application: Stainless steel is compatible with all types of coffee beans and is suitable for both manual and electric grinders.

What Role Does Wood Play in Vintage Coffee Grinder Parts?

Wood is a traditional material used primarily for the exterior casing and decorative elements of vintage coffee grinders. It provides a warm, classic appearance and can be sourced sustainably.

Pros: Wood offers aesthetic appeal and can be easily shaped and finished. It is lightweight, which makes shipping more economical.

Cons: Wood is susceptible to warping and damage from moisture, which can limit its longevity. It also requires regular maintenance to preserve its appearance and functionality.

Impact on Application: While wood enhances the visual appeal of the grinder, it may not be suitable for parts that experience high mechanical stress.

Summary of Material Selection for Vintage Coffee Grinder Parts

| Material | Typical Use Case for Vintage Coffee Grinder Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Body and grinding mechanisms | High durability and stability | Prone to corrosion and heavy | Medium |

| Brass | Handles and decorative elements | Corrosion-resistant and aesthetic | Higher cost and softer material | High |

| Stainless Steel | Grinding burrs and internal mechanisms | Corrosion-resistant and durable | Complex manufacturing and heavier | High |

| Wood | Exterior casing and decorative parts | Aesthetic appeal and lightweight | Susceptible to moisture and damage | Medium |

This guide provides a comprehensive overview of the materials used in vintage coffee grinder parts, helping international B2B buyers make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for vintage coffee grinder parts

What Are the Key Stages in the Manufacturing Process of Vintage Coffee Grinder Parts?

Manufacturing vintage coffee grinder parts involves several critical stages that ensure quality and authenticity. The process typically includes material preparation, forming, assembly, and finishing.

-

Material Preparation: The choice of materials is vital in producing durable and authentic parts. Common materials include cast iron, wood, and brass, which are often sourced from suppliers specializing in vintage-style components. Initial steps involve inspecting raw materials for defects and ensuring they meet the necessary specifications for strength and durability.

-

Forming: This stage involves shaping the materials into the desired parts. Techniques such as casting and machining are prevalent. For example, cast iron parts are created using molds, while machined components may require CNC (Computer Numerical Control) technology for precision. This stage is crucial for maintaining the vintage aesthetic while ensuring functionality.

-

Assembly: Once the individual components are formed, they are assembled into complete parts. Skilled labor is often required to ensure that each part fits perfectly, particularly when dealing with intricate designs typical of vintage grinders. Attention to detail during assembly helps prevent misalignment and ensures smooth operation.

-

Finishing: The final stage involves various treatments to enhance the appearance and longevity of the parts. This may include polishing, painting, or applying protective coatings. Finishing not only improves aesthetics but also adds a layer of protection against wear and corrosion, ensuring that the parts maintain their functionality over time.

How Is Quality Assurance Implemented in the Production of Vintage Coffee Grinder Parts?

Quality assurance (QA) in manufacturing vintage coffee grinder parts is crucial for maintaining standards that meet international and industry-specific requirements. Various checkpoints and testing methods are employed throughout the manufacturing process.

-

Relevant International Standards: Compliance with international standards such as ISO 9001 is essential for quality management systems. This certification ensures that suppliers adhere to systematic processes that enhance product quality and customer satisfaction. Additionally, CE marking may be required for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Effective quality control often involves several checkpoints, including:

– Incoming Quality Control (IQC): This stage inspects raw materials upon arrival to ensure they meet predetermined standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, reducing waste and rework.

– Final Quality Control (FQC): A comprehensive evaluation is conducted on finished parts to confirm they meet specifications before shipping. -

Common Testing Methods: Various testing methods are utilized to ensure quality. These may include dimensional checks, functional tests, and material property evaluations (e.g., hardness tests for metal components). Visual inspections for aesthetic qualities and defects are also standard practice.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital for ensuring reliable procurement.

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to assess a supplier’s quality control measures. During an audit, buyers can evaluate the manufacturing environment, processes, and adherence to quality standards firsthand.

-

Requesting Quality Reports: Buyers should request documentation related to quality control processes, including test reports and compliance certificates. These documents can provide insights into the supplier’s commitment to quality and adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality practices. These services can verify compliance with required standards and provide detailed reports on the findings, giving buyers additional assurance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control, particularly in sourcing vintage coffee grinder parts.

-

Cultural and Regulatory Differences: Buyers must navigate different cultural attitudes towards quality and varying regulatory environments. Understanding local practices can aid in establishing effective communication and expectations regarding quality standards.

-

Logistics and Shipping Considerations: The logistics of transporting parts internationally can affect quality. Buyers should ensure that suppliers have robust packaging and handling processes to prevent damage during transit.

-

Traceability and Documentation: Buyers should prioritize suppliers who maintain thorough documentation and traceability of their parts. This is particularly important for vintage components, where authenticity and provenance play a significant role in value.

Conclusion: How Can Buyers Ensure They Receive Quality Vintage Coffee Grinder Parts?

In summary, B2B buyers looking for vintage coffee grinder parts should focus on understanding the manufacturing processes and quality assurance practices of potential suppliers. By evaluating material preparation, forming techniques, assembly methods, and finishing processes, buyers can gauge the quality of the parts. Furthermore, verifying compliance with international standards, conducting audits, and ensuring effective logistics can significantly enhance the procurement experience. With careful consideration and due diligence, buyers can secure high-quality vintage coffee grinder parts that meet their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vintage coffee grinder parts’

The procurement of vintage coffee grinder parts requires careful planning and execution to ensure quality, authenticity, and timely delivery. This guide provides a step-by-step checklist tailored for B2B buyers, particularly those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the specific parts you need for vintage coffee grinders. This includes identifying the model, brand, and condition (new or used) of the parts required. Precise specifications will help you communicate effectively with suppliers and minimize misunderstandings regarding your order.

- Considerations:

- Model numbers and year of manufacture.

- Material preferences (e.g., wood, metal).

- Functional requirements (e.g., compatibility with existing grinders).

Step 2: Conduct Market Research

Explore various marketplaces and platforms where vintage coffee grinder parts are sold. Research potential suppliers, their offerings, and the reputation of their products. A thorough understanding of market options will empower you to make informed decisions and find competitive pricing.

- Focus Areas:

- Online platforms like PicClick and specialized antique parts websites.

- Regional suppliers that may have unique inventory.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform a detailed evaluation. Request company profiles, product samples, and references from other buyers. This step is vital to ensure that the supplier can meet your quality standards and delivery timelines.

- Key Actions:

- Check for customer reviews and testimonials.

- Ask for information about their sourcing practices and part authenticity.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers adhere to relevant industry standards and regulations. This may include certifications related to quality assurance or environmental compliance. Suppliers that are transparent about their practices are likely to provide better quality products.

- Important Documents:

- Quality assurance certifications.

- Import/export compliance documents, particularly for international orders.

Step 5: Negotiate Terms and Conditions

Once you’ve identified potential suppliers, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements will help mitigate risks and ensure both parties have aligned expectations.

- Negotiation Points:

- Bulk order discounts.

- Warranty and return policies for defective parts.

Step 6: Establish Communication Channels

Set up reliable communication channels with your chosen supplier. Regular communication can prevent misunderstandings and ensure that any issues are addressed promptly.

- Recommended Practices:

- Use professional communication tools (e.g., email, video calls).

- Document all agreements and discussions for future reference.

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics of transporting the parts from the supplier to your location. Assess shipping options, costs, and potential customs duties for international shipments. A well-planned logistics strategy can save time and reduce unexpected costs.

- Logistics Considerations:

- Choose reputable shipping carriers.

- Factor in lead times for international shipping.

By following this comprehensive checklist, B2B buyers can streamline their sourcing process for vintage coffee grinder parts, ensuring they obtain high-quality products while minimizing risks.

Comprehensive Cost and Pricing Analysis for vintage coffee grinder parts Sourcing

What Are the Key Cost Components for Vintage Coffee Grinder Parts?

Sourcing vintage coffee grinder parts involves several cost components that significantly affect the overall pricing structure. Understanding these elements can empower B2B buyers to make informed purchasing decisions.

Materials: The primary cost driver in vintage coffee grinder parts is the raw materials used. Common materials include cast iron, brass, wood, and glass. Vintage parts often require high-quality materials to maintain authenticity, which can inflate costs.

Labor: Skilled craftsmanship is essential when producing or refurbishing vintage parts. Labor costs may vary significantly based on geographic location, with regions known for artisanal work, such as parts of Europe and South America, typically commanding higher rates.

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and equipment maintenance. For small-scale or artisanal manufacturers, overhead costs can be substantial relative to production volume.

Tooling: Custom tooling may be required for unique parts, particularly for restoration projects. This upfront investment can add to the overall cost but is often necessary for achieving precise specifications.

Quality Control (QC): Ensuring that parts meet quality standards is critical, especially for international buyers who may have specific certifications in mind. QC processes involve additional labor and testing costs that can influence final pricing.

Logistics: Shipping vintage parts across borders involves various logistics costs, including freight, insurance, and potential customs duties. Understanding Incoterms is crucial, as they determine who is responsible for shipping costs and risks.

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on the uniqueness and demand for specific parts. High-demand or rare parts may attract a premium margin.

How Do Price Influencers Affect the Cost of Vintage Coffee Grinder Parts?

Several factors can influence the pricing of vintage coffee grinder parts, making it essential for buyers to be aware of these variables.

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for bulk purchases. Understanding the MOQ can help buyers negotiate lower prices by consolidating orders.

Specifications and Customization: Custom parts or those with specific design requirements can lead to higher costs. Buyers should be clear about their needs upfront to avoid unexpected expenses.

Materials and Quality Certifications: The choice of materials and certifications can significantly impact pricing. Parts made from high-quality, certified materials may come at a premium but offer better durability and performance.

Supplier Factors: The reputation and reliability of suppliers can also influence prices. Established suppliers with a proven track record may charge more due to their perceived value, while newer suppliers might offer lower prices to gain market share.

What Buyer Tips Can Help Optimize Costs in Vintage Coffee Grinder Parts Sourcing?

Navigating the sourcing landscape for vintage coffee grinder parts can be complex, especially for international buyers. Here are some actionable tips to optimize costs.

Negotiation: Always approach negotiations with a clear understanding of your requirements and market prices. Building relationships with suppliers can lead to better terms and pricing over time.

Cost-Efficiency: Evaluate the total cost of ownership (TCO) instead of just the purchase price. Consider factors like durability, maintenance, and potential replacement costs over time to make more informed decisions.

Pricing Nuances for International Buyers: International buyers, particularly from regions like Africa and South America, should be aware of additional costs such as tariffs, shipping, and exchange rates. Understanding local market dynamics can also aid in negotiating better prices.

Disclaimer for Indicative Prices: Due to the nature of vintage parts, prices can fluctuate based on availability and condition. It’s advisable to request quotes and conduct thorough market research to ensure competitive pricing.

By understanding these cost components and pricing influencers, B2B buyers can navigate the vintage coffee grinder parts market more effectively, ensuring they make informed decisions that align with their business needs.

Alternatives Analysis: Comparing vintage coffee grinder parts With Other Solutions

Understanding Alternatives in the Vintage Coffee Grinder Parts Market

When evaluating options for sourcing vintage coffee grinder parts, it’s essential to consider alternative solutions that can meet similar needs. This analysis will compare vintage coffee grinder parts against two viable alternatives: modern electric coffee grinders and refurbished vintage grinders. Each option presents unique benefits and challenges for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Vintage Coffee Grinder Parts | Modern Electric Coffee Grinders | Refurbished Vintage Grinders |

|---|---|---|---|

| Performance | High, authentic grinding quality | Consistent grind speed and quality | Varies, depends on restoration quality |

| Cost | Often high due to rarity and demand | Generally affordable, $20-$200 | Moderate, $50-$150 depending on condition |

| Ease of Implementation | Requires knowledge for sourcing and fitting | Plug-and-play functionality | May require some setup, depending on restoration |

| Maintenance | Regular upkeep needed; parts may be scarce | Minimal; generally low maintenance | Regular maintenance needed, parts may be scarce |

| Best Use Case | Collectors and enthusiasts seeking authenticity | High-volume coffee businesses needing efficiency | Coffee shops wanting character and vintage appeal |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Modern Electric Coffee Grinders?

Modern electric coffee grinders provide a user-friendly experience, allowing for quick and consistent grinding. They are designed for efficiency, making them ideal for high-volume operations such as coffee shops or restaurants. With prices ranging from $20 to $200, they are generally accessible for most buyers. However, while they offer convenience, they lack the historical charm and craftsmanship found in vintage grinders. Furthermore, their reliance on electricity may not suit all environments, particularly in regions with unstable power supply.

How Do Refurbished Vintage Grinders Compare to Original Parts?

Refurbished vintage grinders are an attractive alternative for businesses looking to retain the aesthetic of vintage equipment while benefiting from some restoration. These grinders can deliver the authentic grinding experience that coffee enthusiasts seek. Costs are typically moderate, ranging from $50 to $150, making them a reasonable option for those wanting vintage flair without the high investment of sourcing original parts. However, the performance can vary significantly based on the quality of restoration work, and maintenance can be a concern due to the availability of parts. Buyers should ensure that the refurbishment includes quality checks and guarantees.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between vintage coffee grinder parts, modern electric grinders, or refurbished vintage options, B2B buyers should carefully assess their specific requirements. Considerations such as budget, intended use, and maintenance capabilities are crucial. For those prioritizing authenticity and craftsmanship, vintage parts may be the best choice despite potential sourcing challenges. Conversely, businesses needing consistent performance and low maintenance might find modern electric grinders more suitable. Refurbished vintage grinders offer a middle ground, combining aesthetic appeal with functional reliability, making them an excellent option for cafes and restaurants looking to enhance their brand image while maintaining operational efficiency.

Essential Technical Properties and Trade Terminology for vintage coffee grinder parts

What are the Key Technical Properties of Vintage Coffee Grinder Parts?

When sourcing vintage coffee grinder parts, understanding the essential technical properties is crucial for ensuring compatibility, durability, and optimal performance. Here are some critical specifications to consider:

-

Material Grade

– Vintage coffee grinder parts are typically made from materials like cast iron, brass, and wood. The material grade affects not only the grinder’s aesthetic appeal but also its longevity and functionality. For instance, cast iron provides durability and resistance to wear, making it suitable for long-term use. Buyers should ensure that the materials meet their specific requirements for quality and sustainability. -

Tolerance Levels

– Tolerance refers to the allowable deviation in dimensions and performance of parts. For vintage grinders, precise tolerances are vital, especially for components like burrs and gears, which directly impact grinding efficiency and consistency. A close tolerance ensures that parts fit together seamlessly, preventing issues such as jamming or uneven grinding. -

Finish Type

– The finish type, which can range from polished to matte, plays a significant role in both aesthetics and maintenance. A quality finish not only enhances the visual appeal but also protects the material from rust and wear. For B2B buyers, selecting parts with a suitable finish can reduce maintenance costs and extend the lifespan of the grinders. -

Compatibility Specifications

– Understanding compatibility specifications is essential for sourcing parts that fit specific grinder models. This includes knowing the dimensions, thread sizes, and connector types. Providing clear compatibility information reduces the likelihood of returns and enhances customer satisfaction. -

Weight and Dimensions

– The weight and dimensions of parts affect shipping costs and handling. For international buyers, understanding these specifications can facilitate logistics planning and ensure that parts are suitable for their intended use. Lighter parts may reduce shipping costs, while precise dimensions ensure they fit within existing setups.

What are Common Trade Terms in the Vintage Coffee Grinder Parts Industry?

Navigating the trade terminology in the vintage coffee grinder parts market can streamline procurement and enhance communication. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to parts that are produced by the original manufacturer of the coffee grinder. OEM parts are often preferred for their guaranteed compatibility and quality. B2B buyers should consider OEM options for repairs or restorations to maintain authenticity and performance. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers looking to manage inventory costs effectively. By knowing the MOQ, businesses can negotiate better terms or assess whether they can meet the supplier’s requirements. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific parts. This process helps buyers compare options and make informed purchasing decisions. Including detailed specifications in an RFQ can yield more accurate quotes and foster competitive pricing. -

Incoterms (International Commercial Terms)

– These are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help B2B buyers understand their obligations and negotiate better shipping arrangements, particularly when importing parts from different regions. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the product. Knowing the lead time is essential for planning inventory and ensuring timely repairs or restorations. Buyers should ask suppliers for their typical lead times to align their purchasing strategy with operational needs. -

Aftermarket Parts

– These are parts made by third-party manufacturers rather than the original manufacturer. Aftermarket parts can offer cost-effective alternatives for vintage coffee grinders, but buyers should assess their quality and compatibility before making a purchase.

By understanding these technical properties and trade terms, B2B buyers in the vintage coffee grinder parts market can make informed decisions that enhance their procurement processes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the vintage coffee grinder parts Sector

What Are the Current Trends Driving the Vintage Coffee Grinder Parts Market?

The vintage coffee grinder parts market is witnessing a resurgence driven by a growing appreciation for artisanal coffee and the nostalgia associated with vintage appliances. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly interested in sourcing authentic parts for restoration and resale purposes. Key drivers include the rise in coffee culture, with consumers seeking unique brewing experiences and the aesthetic appeal of vintage grinders, which often serve as decorative pieces in cafés and homes alike.

Emerging trends in B2B technology are facilitating more efficient sourcing processes. Digital marketplaces and platforms that specialize in vintage parts are gaining traction, enabling buyers to connect directly with suppliers worldwide. This trend is particularly significant for buyers in regions like Vietnam and Brazil, where local sourcing options may be limited. Additionally, the use of social media and online communities, such as the Association of Coffee Mill Enthusiasts (A.C.M.E.), fosters collaboration and knowledge sharing among collectors and restorers, enhancing the overall market dynamics.

Another notable trend is the increasing demand for customization and personalization in vintage coffee grinders. Buyers are looking for specific components that align with their restoration projects, which drives suppliers to maintain diverse inventories. As competition intensifies, suppliers that offer comprehensive catalogs and quick identification assistance will likely gain a competitive edge.

How Is Sustainability Shaping the Sourcing of Vintage Coffee Grinder Parts?

Sustainability is becoming a focal point in the sourcing of vintage coffee grinder parts, as international buyers are increasingly mindful of the environmental impact of their purchases. The demand for ethically sourced and sustainably produced materials is influencing buyer preferences, particularly in Europe and the Middle East. Suppliers that can demonstrate adherence to sustainable practices and provide transparency in their supply chains are likely to attract more business.

The use of recycled materials in the production of replacement parts is gaining popularity. B2B buyers are seeking suppliers who can offer ‘green’ certifications or materials that minimize environmental footprints. This trend not only appeals to eco-conscious consumers but also aligns with global efforts to reduce waste and promote circular economies.

Moreover, ethical sourcing practices are becoming essential as buyers increasingly consider the social implications of their purchases. Suppliers who prioritize fair labor practices and community engagement in their operations are more likely to build trust and foster long-term relationships with international buyers. As sustainability continues to shape market dynamics, businesses that embrace these principles will find themselves better positioned in the competitive landscape.

What Is the Historical Context of Vintage Coffee Grinder Parts?

The history of vintage coffee grinder parts dates back to the late 19th and early 20th centuries, when coffee mills became essential household items in North America and Europe. Early grinders were often crafted from durable materials like cast iron and wood, designed to last for generations. As coffee culture expanded, these grinders evolved in both design and function, leading to a diverse range of styles and mechanisms.

During the mid-20th century, the introduction of electric coffee grinders shifted consumer preferences toward more modern appliances. However, the charm and craftsmanship of vintage models have led to a revival in interest, particularly among collectors and specialty coffee enthusiasts. This historical appreciation fuels the current market for vintage grinder parts, as buyers seek authentic components for restoration projects. Understanding this evolution provides valuable context for B2B buyers, highlighting the importance of quality and authenticity in sourcing vintage coffee grinder parts today.

Frequently Asked Questions (FAQs) for B2B Buyers of vintage coffee grinder parts

-

How do I identify the correct vintage coffee grinder parts for my model?

Identifying the right parts for your vintage coffee grinder involves a few key steps. First, check the manufacturer’s name and model number, which are often located on the grinder itself. Next, consult online resources or forums dedicated to antique coffee grinders, where enthusiasts and experts can provide insights. If available, take clear photographs of the grinder and the specific parts you need, as this can greatly assist suppliers in locating the exact replacements. Additionally, some suppliers may offer identification services, so don’t hesitate to reach out for assistance. -

What is the best way to ensure quality when sourcing vintage coffee grinder parts?

To ensure quality when sourcing vintage coffee grinder parts, start by selecting reputable suppliers with positive reviews and a proven track record in the industry. Look for suppliers who specialize in antique or vintage items, as they are more likely to understand the nuances of these products. Request detailed descriptions and photographs of the parts before purchasing. Additionally, inquire about their quality assurance processes, return policies, and whether they offer warranties on their products. Establishing a good line of communication with the supplier can also help ensure you receive high-quality parts. -

What are typical minimum order quantities (MOQs) for vintage coffee grinder parts?

Minimum order quantities (MOQs) for vintage coffee grinder parts can vary significantly based on the supplier and the type of parts being ordered. Generally, MOQs may range from a single piece for common parts to larger quantities for specialized or rare components. When negotiating with suppliers, be clear about your needs and explore whether they can accommodate smaller orders, especially if you’re testing a new supplier. Additionally, some suppliers may offer discounts for larger orders, so it’s beneficial to assess your long-term needs. -

What payment terms should I expect when purchasing vintage coffee grinder parts internationally?

When purchasing vintage coffee grinder parts internationally, payment terms can vary widely among suppliers. Many suppliers prefer secure payment methods such as PayPal or bank transfers, which offer buyer protection. It’s common for suppliers to require payment upfront, especially for custom or rare parts. Always clarify payment terms before finalizing your order, including any deposits, payment schedules, and accepted currencies. Additionally, inquire about any potential customs duties or taxes that may apply to international transactions, as these can impact your overall costs. -

How can I verify the legitimacy of a supplier for vintage coffee grinder parts?

To verify the legitimacy of a supplier for vintage coffee grinder parts, conduct thorough research before making a purchase. Check their website for contact information, customer reviews, and testimonials. Utilize platforms like LinkedIn or industry-specific forums to find feedback from other buyers. Request references from the supplier and follow up to ensure they are trustworthy. Additionally, look for suppliers who are members of relevant associations, as this can indicate a commitment to quality and ethical practices. -

What logistics considerations should I be aware of when importing vintage coffee grinder parts?

When importing vintage coffee grinder parts, consider logistics factors such as shipping costs, delivery times, and customs regulations. Research shipping options that best fit your budget and timeline; express shipping may be faster but more expensive. Be aware of any import restrictions or duties that could apply to antique items in your country. It’s advisable to work with suppliers who provide clear shipping policies and tracking information, ensuring you can monitor your shipment’s progress. -

Can I request customization for vintage coffee grinder parts?

Yes, many suppliers of vintage coffee grinder parts may offer customization options, especially for parts that are no longer in production. If you have specific requirements, such as size, material, or design modifications, communicate these clearly to the supplier. Be prepared to provide detailed specifications or drawings to facilitate the customization process. Keep in mind that custom orders may have longer lead times and higher costs, so it’s important to discuss these factors upfront. -

What should I do if I receive the wrong parts for my vintage coffee grinder?

If you receive the wrong parts for your vintage coffee grinder, promptly contact the supplier to report the issue. Provide clear details about the order, including order numbers and photographs of the incorrect parts. Most reputable suppliers have return and exchange policies in place, so inquire about the process for returning the wrong items and obtaining the correct ones. Document all communications and keep records of your order to facilitate a smooth resolution. If the supplier is unresponsive, consider escalating the issue through payment protection services or consumer protection agencies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Vintage Coffee Grinder Parts Manufacturers & Suppliers List

1. eBay – Coffee Grinder Parts

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: coffee grinder parts, vintage coffee grinder parts, Capresso coffee grinder parts, coffee grinder replacement blade, grinder parts, Kitchenaid coffee grinder parts, Cuisinart coffee grinder parts, stainless steel coffee grinder, antique coffee grinder, Breville coffee grinder parts, Ditting coffee grinder parts, replacement parts for Cuisinart electric automatic coffee grinder, Breville grinder as…

2. Etsy – Vintage Working Coffee Grinder-Wheel Crank

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Coffee Grinder Parts available on Etsy include over 1,000 items with options for free shipping and delivery within 7 days. Key products include: 1. Vintage Working Coffee Grinder-Wheel Crank with Wood Base – $49.99, ships from NC. 2. Coffee Grinder Bellows – $27.99, ships from GA. 3. Wall Coffee Grinder Drip Tray – Vintage Glass – $39.82. 4. Retro manual coffee grinder – $68.85, free shipping. 5. …

3. PEDE – Coffee Grinder & Parts

Domain: antiquedutchclockparts.nl

Registered: 2015 (10 years)

Introduction: Product Name: PEDE coffeegrinder & parts

Product Description: Our archives of PEDE coffeegrinder & parts products showcasing what we have to offer.

Product Categories: Complete grinders (4), Glass grind bucket (3), Bean containers (15), New lids (4), Used lids (3), Back boards (5), Grinder mechanism (5), Handle parts (13), Lids & handle combo (1)

4. PicClick – Antique Coffee Grinder Parts

Domain: picclick.com

Registered: 2003 (22 years)

Introduction: Antique Coffee Grinder Parts for Sale; Types: Antique Coffee Grinder (36), Coffee Grinder (67), Hand Grinder (1), Vintage Coffee Grinder (13), Wall-Mounted Coffee Mill (1); Condition: Used (101), Unspecified (5); Price Range: Various; Item Location: USA & International; Ships to: North America, Worldwide; Power Source: Electrical (2), Manual (25), Not Specified (66); Time Period Manufactured: 1850…

5. Kofio – Replacement Parts for Coffee Grinders

Domain: kofio.co

Registered: 2020 (5 years)

Introduction: Replacement parts for manual coffee grinders available at Kofio.co include: 1. Hario plastic inner stone pin (PI-MSS-1-EX) – €4.49 (Last 3 left in stock) 2. Comandante Bean Jar Large – coffee container – smoke – €15.99 (In stock > 5) 3. Hario Skerton PLUS spare grinding stone with axis – €11.99 (Only 1 left in stock) 4. Hario spare handle for Hario Mini Mill Slim PLUS – €11.99 (Only 2 left in stoc…

6. Zassenhaus – Conical Burrs for Vintage Grinders

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Replacement burrs for vintage manual grinders, specifically looking for conical burrs. User is interested in brands like Zassenhaus and Grulet, and is inquiring about the availability and compatibility of high-quality burrs for older grinders.

7. Zassenhaus – Coffee Grinders

Domain: zassenhaus-brandshop.com

Registered: 2016 (9 years)

Introduction: {“spare_parts”: [{“name”: “Zassenhaus – Coffee grinder/espresso grinder BARISTA 2.0”, “price”: “€99.99*”}, {“name”: “Zassenhaus – Coffee grinder/espresso grinder MANO”, “price”: “€79.99*”}, {“name”: “Zassenhaus – Collecting container for coffee grinder Kingston”, “description”: “Fits to electric coffee grinder ‘Kingston’ Art. 043006”, “price”: “€14.99*”}, {“name”: “Zassenhaus – Collecting containe…

8. Old Coffee Grinders – Replacement Parts

Domain: oldcoffeegrinders.com

Registered: 2003 (22 years)

Introduction: Replacement Parts: 1. Glass Hoppers for Wall Mount Coffee Mills – Rarely available, high value. 2. Reproduction Landers Frary and Clark Universal No. 24 Wall Mounting Bracket – Cast alloy copy, temporarily out of stock. 3. Reproduction Arcade Crystal No. 3 Hopper – Thick, wavy glass, $65.00 (Includes Shipping), limited stock. 4. Catch Cups (Glass) – Horseshoe and star design, good replacement for …

9. JavaPresse – Antique Coffee Grinders

Domain: javapresse.com

Registered: 2015 (10 years)

Introduction: Antique coffee grinders are vintage pieces that may require restoration. Key assessment points include checking for missing parts (grinding handle, burrs, screws, ground catcher drawer, grind size mechanism), feeling the burrs for sharpness, and inspecting for mold or rust. Restoration steps involve disassembling the grinder, soaking parts in cleaner, cleaning the grounds drawer and grinder body, …

Strategic Sourcing Conclusion and Outlook for vintage coffee grinder parts

In the ever-evolving landscape of vintage coffee grinder parts, strategic sourcing emerges as a critical component for international buyers looking to enhance their collections or restore antique machines. By leveraging global networks and specialized suppliers, businesses can access authentic and rare components that are essential for maintaining the integrity of these cherished items. Engaging with organizations like the Association of Coffee Mill Enthusiasts (A.C.M.E.) can provide valuable insights and support in identifying parts, thus streamlining the sourcing process.

Additionally, the growing online marketplaces present an opportunity for B2B buyers from Africa, South America, the Middle East, and Europe to connect with suppliers who offer a wide range of products, from complete grinders to specific replacement parts. This accessibility not only simplifies procurement but also fosters a community of enthusiasts dedicated to preserving coffee grinding heritage.

As the demand for vintage coffee grinder parts continues to rise, it is crucial for international buyers to stay informed about market trends and emerging suppliers. Embrace the journey of strategic sourcing—by building relationships with reliable partners, you can ensure the longevity and functionality of vintage coffee grinders while celebrating the craftsmanship behind them. Start exploring these opportunities today to enhance your sourcing strategy and enrich your offerings in the global marketplace.