The Definitive Guide to 400 Gsm: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for 400 gsm

Navigating the global market for 400 gsm (grams per square meter) fabrics presents a unique challenge for international B2B buyers, particularly those focused on sourcing high-quality apparel such as hoodies and crewneck sweatshirts. As businesses seek to provide their customers with durable and comfortable products, understanding the intricacies of fabric weight becomes crucial. This guide delves into the various types of 400 gsm materials, their applications in the apparel industry, and essential considerations for supplier vetting and cost analysis.

With a comprehensive scope, this resource empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—specifically markets like Saudi Arabia and Brazil—to make informed purchasing decisions. By exploring the benefits of 400 gsm fabrics, including their longevity and suitability for different climates, buyers can align their sourcing strategies with their target audience’s needs.

Moreover, the guide addresses key factors such as market trends, pricing structures, and best practices for engaging with suppliers. Through this exploration, businesses can enhance their product offerings and ensure they are equipped to meet the demands of a competitive landscape. By leveraging the insights provided, B2B buyers will be well-positioned to navigate the complexities of the global fabric market with confidence and clarity.

Understanding 400 gsm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 400 GSM Fleece Hoodies | Soft, warm, and durable fleece material | Promotional apparel, workwear, casual wear | Pros: High warmth and comfort; Cons: Heavier weight may not be suitable for warmer climates. |

| 400 GSM Crewneck Sweatshirts | Classic design, versatile for layering | Retail, corporate branding, team uniforms | Pros: Easy to customize; Cons: Limited ventilation compared to lighter fabrics. |

| 400 GSM Heavyweight T-Shirts | Thick cotton blend, excellent for screen printing | Merchandise, events, company giveaways | Pros: Durability and print quality; Cons: Higher cost compared to lighter options. |

| 400 GSM Relaxed Fit Sweatshirts | Loose fit, often with added features like pockets | Casual retail, lifestyle brands | Pros: Trendy and comfortable; Cons: May not appeal to all demographics. |

| 400 GSM Eco-Friendly Fabrics | Made from recycled materials, sustainable production | Eco-conscious brands, corporate responsibility initiatives | Pros: Appeals to sustainability-focused buyers; Cons: May have higher production costs. |

What are the Characteristics of 400 GSM Fleece Hoodies?

400 GSM fleece hoodies are characterized by their soft texture and excellent insulation properties. They are particularly suitable for colder climates or outdoor activities, making them a popular choice for promotional apparel and workwear. When purchasing, consider the potential for customization, as many suppliers offer embroidery or screen printing options. Buyers should also evaluate the fabric’s durability, especially if the product will be used frequently.

How Do 400 GSM Crewneck Sweatshirts Stand Out?

Crewneck sweatshirts at 400 GSM provide a classic and versatile option for businesses looking to enhance their branding. Their thicker fabric makes them ideal for layering, which is beneficial in both retail settings and corporate environments. When sourcing these sweatshirts, businesses should focus on fabric quality and the range of available sizes. While they are easy to customize, the limited breathability may not be suitable for all climates.

Why Choose 400 GSM Heavyweight T-Shirts for Your Business?

Heavyweight t-shirts made from 400 GSM fabric are ideal for businesses that prioritize durability and print quality. They are particularly effective for merchandise and promotional giveaways, as their substantial weight ensures longevity. Buyers should consider the cost versus the expected lifespan of the t-shirts. While they tend to be pricier than lighter alternatives, their ability to withstand frequent washing makes them a worthwhile investment.

What Are the Benefits of 400 GSM Relaxed Fit Sweatshirts?

Relaxed fit sweatshirts at 400 GSM offer a contemporary style that appeals to a diverse demographic, making them a great addition to casual retail lines. Their loose fit enhances comfort, and features like pockets can add functionality. When purchasing, businesses should assess the target market’s preferences, as this style may not appeal universally. Additionally, while they are trendy, the relaxed fit may not be suitable for formal settings.

How Do Eco-Friendly 400 GSM Fabrics Impact B2B Purchasing Decisions?

Eco-friendly fabrics at 400 GSM are increasingly sought after by brands committed to sustainability. These materials, often made from recycled substances, align with corporate responsibility initiatives and appeal to environmentally conscious consumers. Buyers should weigh the benefits of promoting sustainability against potentially higher production costs. Additionally, ensuring that suppliers can provide certifications for eco-friendly claims is crucial for maintaining credibility in the market.

Key Industrial Applications of 400 gsm

| Industry/Sector | Specific Application of 400 gsm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel Manufacturing | Production of Hoodies and Sweatshirts | High durability and warmth, ideal for winter wear | Ensure fabric meets international quality standards |

| Sportswear | Athletic Wear for Outdoor Activities | Enhanced comfort and thermal regulation | Look for moisture-wicking properties in the fabric |

| Corporate Branding | Custom Branded Merchandise | Strong brand visibility and customer loyalty | Consider customization options and bulk pricing |

| Hospitality | Staff Uniforms and Promotional Apparel | Professional appearance and employee comfort | Ensure compliance with industry-specific regulations |

| Retail Fashion | High-End Casual Wear | Appeals to premium market segments | Check for sustainable sourcing and ethical production |

How is 400 GSM Utilized in Apparel Manufacturing, and What Benefits Does It Offer?

In the apparel manufacturing sector, 400 gsm is primarily used for producing high-quality hoodies and sweatshirts. This fabric weight provides significant durability and warmth, making it ideal for winter collections. Manufacturers can create garments that withstand frequent wear and washing, appealing to consumers seeking long-lasting products. For international buyers, particularly in colder regions, sourcing 400 gsm fabric ensures that the final product meets customer expectations for warmth and quality, while also aligning with local market trends.

What Role Does 400 GSM Play in Sportswear for Outdoor Activities?

In the sportswear industry, 400 gsm fabric is utilized for creating athletic wear designed for outdoor activities. This weight offers enhanced comfort and thermal regulation, crucial for athletes who require flexibility and warmth during colder months. The fabric’s breathability and ability to wick moisture away from the body are essential features that can significantly improve performance. Buyers from regions with diverse climates should prioritize sourcing options that emphasize these properties, ensuring their products cater to both functionality and comfort.

How is 400 GSM Applied in Corporate Branding and Custom Merchandise?

Corporate branding often leverages 400 gsm fabric for producing custom-branded merchandise, such as hoodies and sweatshirts. The substantial weight of the fabric ensures that logos and branding elements are prominently displayed while maintaining a professional appearance. Businesses benefit from using durable materials that foster customer loyalty and brand recognition. For buyers, it is essential to consider the customization options available and the minimum order quantities, as these factors can impact cost-effectiveness and inventory management.

Why is 400 GSM Important for Hospitality Staff Uniforms?

In the hospitality sector, 400 gsm fabric is commonly used for staff uniforms and promotional apparel. The heavy weight of the fabric not only provides a professional appearance but also ensures employee comfort during long shifts. Uniforms made from this material can withstand the rigors of daily use while maintaining their shape and look. Buyers in this industry should consider sourcing from manufacturers who comply with industry-specific regulations regarding uniform standards and comfort features.

How Does 400 GSM Enhance Retail Fashion Offerings?

In retail fashion, 400 gsm is increasingly used for high-end casual wear, catering to consumers looking for quality and comfort. This fabric weight appeals to premium market segments that prioritize durability and style. Retailers can leverage 400 gsm garments to differentiate themselves in a competitive market, offering products that justify a higher price point due to their quality. Buyers should focus on sourcing sustainable and ethically produced fabrics, as these factors are becoming increasingly important to consumers in many regions, including Europe and South America.

3 Common User Pain Points for ‘400 gsm’ & Their Solutions

Scenario 1: Difficulty in Assessing Fabric Quality for Bulk Purchases

The Problem: When purchasing 400 gsm fabric, B2B buyers often struggle to accurately assess the quality of the material without physically inspecting it. This is particularly challenging for international buyers who may rely on online catalogs and supplier descriptions. Misjudging the fabric quality can lead to significant financial losses, as the final products may not meet customer expectations, resulting in returns or diminished brand reputation.

The Solution: To effectively evaluate the quality of 400 gsm fabric before purchasing, buyers should request physical samples from suppliers. This allows them to assess the texture, weight, and overall feel of the material firsthand. Additionally, buyers should inquire about the supplier’s manufacturing processes and quality control measures to understand the durability and longevity of the fabric. Establishing a relationship with reputable suppliers who can provide detailed information and transparency about their products can also mitigate risks associated with quality assessments.

Scenario 2: Confusion Over Fabric Weight and Intended Use

The Problem: B2B buyers frequently encounter confusion regarding the appropriate applications for 400 gsm fabric, especially when considering the range of garments it can produce. Some buyers may assume that heavier fabric is universally suitable for all types of clothing, leading to mismatches between fabric weight and intended use, such as using 400 gsm for summer apparel where lighter fabrics are more appropriate.

The Solution: To navigate this issue, buyers should conduct thorough research on the specific applications of 400 gsm fabric. They can consult industry guides or expert opinions on fabric weights and their suitable uses. For instance, 400 gsm is ideal for winter apparel, such as hoodies and crewneck sweatshirts, where warmth and durability are priorities. Buyers should also engage with suppliers who can offer insights into the best practices for fabric selection based on the end-use of the garments. This proactive approach ensures that they choose the right fabric for their specific needs, minimizing the risk of product mismatches.

Scenario 3: Challenges in Pricing and Budgeting for High GSM Fabrics

The Problem: The cost of 400 gsm fabrics can be significantly higher than lighter alternatives, creating budgetary concerns for B2B buyers. This financial strain can lead to tough decisions between quality and cost, especially for businesses operating on tight margins. Buyers may also face challenges when negotiating prices with suppliers, particularly in regions where the fabric is not locally sourced.

The Solution: To address pricing concerns, buyers should take a strategic approach to sourcing. This includes comparing prices from multiple suppliers and considering bulk purchasing options, which can often lead to discounts. Establishing long-term relationships with suppliers can also facilitate better pricing negotiations over time. Additionally, buyers should consider the total cost of ownership by evaluating the long-term benefits of investing in higher-quality fabrics, such as reduced returns and increased customer satisfaction. By presenting a well-researched case to suppliers, buyers can advocate for better pricing that reflects their commitment to quality and durability in their products.

Strategic Material Selection Guide for 400 gsm

When selecting materials for 400 GSM products, particularly in the context of hoodies and crewneck sweatshirts, it is essential to consider various fabric types that meet specific performance and market needs. Below is an analysis of four common materials used in 400 GSM applications, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What are the Key Properties of Cotton-Polyester Blends for 400 GSM?

Cotton-polyester blends are a popular choice for 400 GSM garments due to their balanced properties. Typically, these fabrics offer excellent breathability from cotton while benefiting from the durability and wrinkle resistance of polyester. The temperature rating is generally suitable for moderate climates, making them versatile for various regions.

Pros: The blend provides comfort and durability, making it suitable for everyday wear. It also retains color well and is less prone to shrinking compared to 100% cotton.

Cons: The cost can be higher than pure cotton, and the fabric may not be as breathable as 100% cotton, which could be a concern in hotter climates.

Impact on Application: This material is well-suited for casual wear and can handle regular washing without significant wear, making it ideal for promotional items or uniforms.

Considerations for International Buyers: Compliance with local textile regulations is crucial. For example, buyers in Europe may require adherence to Oeko-Tex standards, while those in the Middle East might prioritize moisture-wicking properties for comfort in hot climates.

How Does Fleece Perform as a 400 GSM Material?

Fleece, particularly made from polyester, is another widely used material for 400 GSM apparel. It is known for its warmth and softness, making it ideal for cooler climates.

Pros: Fleece is lightweight yet provides excellent insulation. It is also quick-drying and resistant to moisture, making it suitable for outdoor activities.

Cons: While fleece is durable, it can be prone to pilling over time. Additionally, it may not be as environmentally friendly if sourced from non-recycled polyester.

Impact on Application: Fleece garments are excellent for outdoor wear and active lifestyles, providing comfort and warmth without excessive weight.

Considerations for International Buyers: Buyers should be aware of the environmental impact of polyester fleece and may prefer products made from recycled materials, especially in regions with strong sustainability initiatives like Europe.

What are the Benefits of Using Heavyweight Cotton for 400 GSM?

Heavyweight cotton is a traditional choice for 400 GSM garments, offering a natural feel and breathability.

Pros: This material is highly durable and comfortable, making it suitable for long-term wear. It also has a premium feel that can enhance brand perception.

Cons: The cost of heavyweight cotton can be significantly higher, and it may require more care during washing to prevent shrinkage.

Impact on Application: Heavyweight cotton is particularly suited for high-end fashion or branded merchandise where quality is paramount.

Considerations for International Buyers: Buyers should ensure compliance with cotton sourcing standards, particularly in regions like Africa, where sustainable sourcing practices are increasingly important.

How Do Blends of Wool and Synthetic Fibers Function in 400 GSM Products?

Wool blends, often mixed with synthetic fibers, are used in some 400 GSM applications, especially for premium offerings.

Pros: Wool provides excellent insulation and moisture-wicking properties, while synthetic fibers enhance durability and reduce care requirements.

Cons: Wool blends can be more expensive and may require special care to maintain their quality.

Impact on Application: These blends are ideal for premium outerwear and can cater to markets that prioritize both style and functionality.

Considerations for International Buyers: Buyers should verify the sourcing of wool to ensure compliance with ethical standards, particularly in regions with strict animal welfare regulations.

Summary Table of Material Selection for 400 GSM

| Material | Typical Use Case for 400 gsm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton-Polyester Blend | Casual wear, uniforms | Comfortable and durable | Less breathable than pure cotton | Medium |

| Fleece | Outdoor apparel, activewear | Lightweight and warm | Prone to pilling | Medium |

| Heavyweight Cotton | High-end fashion, branded merchandise | Premium feel and durability | Higher cost and care requirements | High |

| Wool-Synthetic Blend | Premium outerwear | Excellent insulation and style | Expensive and requires special care | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to source 400 GSM products effectively, ensuring they meet both performance and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for 400 gsm

What Are the Main Stages in the Manufacturing Process for 400 GSM Fabrics?

The production of 400 GSM fabric, commonly used for hoodies and sweatshirts, involves several critical stages that ensure high quality and durability. Understanding these stages can help B2B buyers assess the capabilities of their suppliers.

Material Preparation: How is Raw Fabric Processed for 400 GSM?

The manufacturing process begins with the selection of high-quality raw materials, typically cotton and polyester blends, which provide the desired weight and comfort. The fabric is then processed through several steps:

- Spinning: Fibers are spun into yarn, with attention to fiber quality and length, which directly impacts the final fabric’s texture.

- Dyeing: Pre-dyed yarn or fabric is often preferred to ensure color consistency. The dyeing process must adhere to eco-friendly practices, particularly for international buyers concerned about sustainability.

- Weaving: The yarn is woven into fabric using specific techniques, such as circular knitting, which is common for fleece materials. This stage determines the fabric’s elasticity and softness.

What Techniques Are Commonly Used in Forming 400 GSM Fabrics?

After preparation, the fabric undergoes forming techniques that shape it into usable materials.

- Cutting: The fabric is cut into patterns based on the intended garment design. Precision in this stage is critical to minimize waste and ensure a proper fit.

- Sewing: Pieces are assembled using industrial sewing machines. Techniques like overlocking and flatlock stitching are used to enhance durability and comfort, particularly in high-stress areas like seams and cuffs.

What Finishing Processes Enhance the Quality of 400 GSM Products?

The finishing stage adds the final touches to the fabric, improving both aesthetics and functionality.

- Brushing: This technique raises the fibers on the fabric’s surface, creating a soft, fuzzy texture that enhances comfort.

- Sanforizing: This pre-shrinking process minimizes further shrinkage after washing, ensuring that the final product maintains its shape and size.

- Quality Coatings: Some manufacturers apply water-repellent or stain-resistant coatings, adding value for buyers who require functional garments for specific environments.

What International Quality Assurance Standards Should B2B Buyers Know?

Quality assurance (QA) is paramount in the manufacturing process of 400 GSM fabrics. Understanding international standards can help B2B buyers ensure they are partnering with reliable suppliers.

Which International Standards Are Relevant for 400 GSM Fabric?

- ISO 9001: This standard focuses on quality management systems (QMS) and is crucial for manufacturers aiming for consistency and customer satisfaction. Suppliers certified under ISO 9001 have demonstrated their ability to meet customer and regulatory requirements effectively.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- OEKO-TEX Standard 100: This certification assures that the textiles are free from harmful substances, an important consideration for environmentally conscious buyers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integral to maintaining the standards expected in 400 GSM fabric manufacturing. Understanding these checkpoints can help B2B buyers assess supplier reliability.

What Are the Different QC Checkpoints?

- Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the production line. Key metrics include fiber quality, dye consistency, and compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, regular checks ensure that the production processes adhere to established standards. This may involve monitoring machine settings, seam integrity, and fabric weight.

- Final Quality Control (FQC): Before shipment, finished products undergo thorough inspections. This includes checking for defects, colorfastness, and overall garment construction.

What Common Testing Methods Are Employed for Quality Assurance?

Quality assurance is further supported by various testing methods designed to evaluate the fabric’s performance characteristics.

- Physical Testing: This includes tensile strength tests, pilling tests, and abrasion resistance tests to ensure the fabric can withstand regular use.

- Chemical Testing: Assessing the fabric for harmful substances and ensuring compliance with safety standards is crucial for global markets.

- Wash Testing: Conducting wash tests to evaluate shrinkage and colorfastness ensures that the fabric maintains its quality through multiple washes.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some recommended actions:

- Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into the quality management practices in place. This includes evaluating production processes and staff training.

- Request Quality Reports: Suppliers should be able to provide detailed QC reports that outline inspection results and compliance with international standards.

- Utilize Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased evaluation of the supplier’s quality control measures, providing additional assurance.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, may face unique challenges regarding quality control and certification.

- Regulatory Compliance: Different regions may have varying regulations regarding textile imports. Understanding these regulations is crucial to avoid delays and penalties.

- Cultural Expectations: Buyers should be aware of cultural nuances that may affect product preferences and quality expectations. For example, the Middle Eastern market may prioritize modesty and fabric weight differently than South American buyers.

- Sustainability Considerations: Increasingly, international buyers are seeking suppliers that adhere to sustainable practices. Certifications such as GOTS (Global Organic Textile Standard) or Fair Trade can be significant differentiators.

In conclusion, understanding the manufacturing processes and quality assurance measures for 400 GSM fabrics is essential for B2B buyers. By focusing on supplier capabilities, international standards, and rigorous quality control, buyers can make informed decisions that align with their operational needs and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘400 gsm’

Introduction

When sourcing 400 gsm (grams per square meter) fabrics, particularly for hoodies and sweatshirts, B2B buyers must navigate a range of considerations to ensure quality, compliance, and cost-effectiveness. This guide provides a practical checklist that will help you make informed decisions and streamline your procurement process.

1. Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the fabric meets your project requirements. Consider factors such as weight, fabric composition (e.g., cotton-polyester blends), and intended use (e.g., winter wear versus all-season apparel). This clarity will guide your supplier discussions and product evaluations.

2. ✅ Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in 400 gsm fabrics. Use platforms like Alibaba, trade fairs, and industry directories to create a shortlist. Prioritize suppliers with a proven track record in your target markets, as they will be more familiar with regional compliance and customer preferences.

3. ✅ Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with international quality standards. Look for certifications such as OEKO-TEX or GOTS, which indicate adherence to environmental and safety standards. This step reduces the risk of sourcing subpar materials and ensures that your products are market-ready.

4. ✅ Request Samples for Testing

Always request fabric samples before placing a bulk order. Assess the samples for weight, texture, and durability to ensure they align with your specifications. Testing should also include washability and colorfastness, as these factors significantly affect the garment’s longevity and customer satisfaction.

5. ✅ Confirm Pricing and Terms of Sale

Engage suppliers in discussions about pricing structures, including bulk discounts, payment terms, and shipping costs. Be clear about your budget and negotiate terms that protect your interests. Understanding the total cost of procurement will help you make a more informed decision and avoid unexpected expenses.

6. ✅ Assess Lead Times and Production Capacity

Inquire about lead times and the supplier’s production capacity to ensure they can meet your delivery schedule. Understanding their capabilities will allow you to plan your inventory and marketing strategies effectively. A reliable supplier should provide clear timelines for production and shipping.

7. ✅ Establish Communication Protocols

Effective communication is vital for a successful sourcing relationship. Establish clear channels for updates and inquiries, and consider setting up regular check-ins to monitor progress. This proactive approach helps to address any issues early and fosters a strong partnership with your supplier.

By following this checklist, B2B buyers can enhance their sourcing strategy for 400 gsm fabrics, ensuring they select the right materials and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for 400 gsm Sourcing

What Are the Key Cost Components of 400 GSM Sourcing?

When sourcing 400 GSM (grams per square meter) products, particularly fleece garments like hoodies and crewneck sweatshirts, it’s essential to understand the cost structure involved. The primary cost components include:

-

Materials: The fabric composition significantly affects the price. Higher GSM typically means more raw materials are used, resulting in higher costs. For instance, a 400 GSM fleece may require more premium fibers, which can increase the base material cost.

-

Labor: Labor costs can vary widely based on the region of production. Skilled labor is needed for cutting, sewing, and finishing high-quality garments, particularly when intricate designs or customizations are involved.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, equipment maintenance, and factory management. Higher overheads are often found in regions with stringent labor laws and safety regulations.

-

Tooling: This refers to the costs associated with machinery and tools used in production. Custom tools for unique designs can add to the initial investment.

-

Quality Control (QC): Ensuring that the final product meets specific standards can incur additional costs. Implementing rigorous QC processes may require dedicated staff and testing equipment.

-

Logistics: Shipping and handling costs can fluctuate based on geographical distance, shipping method, and the terms of delivery. International shipments often incur customs fees and tariffs, which need to be factored into the overall cost.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin can vary based on market demand, competition, and brand positioning.

How Do Price Influencers Affect 400 GSM Product Costs?

Several factors influence the pricing of 400 GSM products, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for larger orders, making it advantageous for buyers to negotiate favorable terms.

-

Specifications and Customization: Custom designs, colors, or features can lead to increased costs. Buyers should assess whether the added value justifies the higher price.

-

Material Quality and Certifications: The source and quality of materials impact pricing. Certifications for organic or sustainable materials may also command higher prices but can appeal to environmentally conscious markets.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for pricing. Different terms dictate who bears the cost of transportation, insurance, and tariffs, affecting the overall cost structure.

What Are the Best Practices for International Buyers Sourcing 400 GSM Products?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to maximize cost efficiency:

-

Negotiate Effectively: Always negotiate prices and payment terms. Building a strong relationship with suppliers can lead to better deals and potential long-term partnerships.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider all associated costs, including shipping, customs duties, and potential wastage during production. This holistic view can lead to better financial decisions.

-

Understand Pricing Nuances: Familiarize yourself with local market conditions and currency fluctuations that could impact pricing. Being aware of seasonal demand changes can also provide leverage during negotiations.

-

Request Samples: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure the product meets your specifications.

-

Stay Informed About Regulations: Each country may have different import regulations affecting product pricing. Understanding these can help avoid unexpected costs during the sourcing process.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market dynamics, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and seek updated quotes directly from suppliers.

Alternatives Analysis: Comparing 400 gsm With Other Solutions

Introduction to Alternatives in Fabric Weight Solutions

In the realm of textile selection, the weight of fabric, measured in grams per square meter (GSM), plays a pivotal role in determining the performance, durability, and cost-effectiveness of garments. While 400 GSM fleece is celebrated for its thickness and warmth, it is essential to consider alternative options that may better suit specific business needs. This section explores two viable alternatives to 400 GSM fleece, providing a comparative analysis to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | 400 GSM | 300 GSM Fleece | 250 GSM Fleece |

|---|---|---|---|

| Performance | Excellent warmth; suitable for colder climates | Good warmth; versatile for transitional weather | Moderate warmth; ideal for mild conditions |

| Cost | Higher price point due to material weight | Mid-range pricing; offers balance between cost and quality | Lower price point; budget-friendly option |

| Ease of Implementation | Requires specific manufacturing processes; may have longer lead times | More common and easier to source | Widely available and quick to produce |

| Maintenance | High durability; withstands frequent washing | Durable but may wear faster than 400 GSM | Less durable; may require more frequent replacement |

| Best Use Case | Winter wear, outdoor activities in cold environments | Layering for transitional seasons, casual wear | Summer wear, promotional items |

Detailed Breakdown of Alternatives

300 GSM Fleece

300 GSM fleece is a popular choice for businesses seeking a balance between warmth and cost. It provides adequate insulation for cooler weather without being excessively heavy. The moderate weight makes it easier to manufacture and source, which can result in shorter lead times for orders. However, while it is durable, it may not last as long under heavy use compared to 400 GSM options, which could lead to higher replacement costs over time. Businesses looking for versatile solutions that cater to a variety of climates might find 300 GSM fleece to be an ideal compromise.

250 GSM Fleece

For companies focused on budget-friendly options, 250 GSM fleece is an attractive alternative. This lighter fabric is suitable for warmer climates and is often used for promotional items or casual wear. While it is significantly less expensive than its heavier counterparts, it offers only moderate warmth and durability, making it less ideal for colder environments. Additionally, the frequent need for replacement due to wear and tear can offset initial cost savings. Therefore, it is best suited for businesses prioritizing cost over longevity and performance.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate fabric weight for your business, consider the specific requirements of your target market. If you cater to colder climates or require durable, long-lasting garments, 400 GSM fleece remains the superior choice despite its higher cost. Conversely, if your focus is on versatility and budget, alternatives like 300 GSM or 250 GSM fleece could better meet your needs. By carefully evaluating performance, cost, ease of implementation, maintenance, and the best use case, B2B buyers can strategically choose the fabric solution that aligns with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for 400 gsm

What Are the Key Technical Properties of 400 GSM Fabric?

When evaluating 400 GSM fabric, understanding its technical specifications is crucial for making informed purchasing decisions. Here are several critical properties that B2B buyers should consider:

-

Material Composition

The fabric composition significantly influences the performance and durability of 400 GSM garments. Common materials include cotton, polyester, or blends. For instance, a 400 GSM cotton-polyester blend offers both breathability and moisture-wicking properties, making it ideal for activewear. Buyers should assess the material based on their target market’s preferences and the intended use of the apparel. -

Weight and Thickness

GSM stands for grams per square meter, and a weight of 400 GSM indicates a heavy fabric, often used for winter wear such as hoodies and sweatshirts. This weight offers excellent insulation and durability, making it suitable for colder climates. Understanding the weight helps buyers predict how the fabric will perform in various conditions, impacting customer satisfaction and retention. -

Shrinkage Rate

Fabric shrinkage is a vital consideration, especially for garments intended for regular wear. 400 GSM fabrics typically experience some shrinkage after the first wash. Buyers should inquire about the manufacturer’s pre-shrinking processes to mitigate this issue, ensuring that the final product maintains its size and fit after laundering. -

Durability and Lifespan

Heavier fabrics like those with a GSM of 400 are generally more durable, meaning they can withstand frequent washing and wear without significant degradation. This property is particularly important for B2B buyers who prioritize long-lasting products, as it influences customer loyalty and repeat business. -

Color Fastness

The ability of the fabric to retain its color after washing and exposure to sunlight is another critical property. High-quality 400 GSM fabrics usually have excellent color fastness, making them suitable for printed or dyed apparel. Buyers should seek manufacturers that provide color fastness certifications to ensure product quality.

What Are Common Trade Terms Related to 400 GSM Fabrics?

Understanding the terminology used in the textile industry is essential for effective communication and negotiation. Here are several common trade terms relevant to B2B buyers of 400 GSM fabrics:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of 400 GSM garments, an OEM may create custom designs for brands seeking to offer unique products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For 400 GSM fabrics, MOQs can vary widely based on the manufacturer and the specific fabric types. Understanding MOQ helps buyers assess their purchasing power and plan inventory accordingly. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products. When sourcing 400 GSM fabrics, buyers should prepare an RFQ that outlines their specifications, desired quantities, and delivery timelines to receive competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined international sales terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers engaging in cross-border trade of 400 GSM fabrics. -

Lead Time

This term refers to the amount of time it takes from placing an order until it is fulfilled. For 400 GSM fabrics, lead times can be influenced by factors such as production schedules and shipping methods. Understanding lead times helps buyers plan their inventory and meet customer demands effectively. -

Sample Approval

Before finalizing a large order, buyers often request samples to evaluate quality, color, and texture. Sample approval is crucial in the textile industry, as it ensures that the final product meets the specified standards and reduces the risk of costly returns or dissatisfaction.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right 400 GSM fabric for their business needs while fostering strong supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the 400 gsm Sector

What Are the Current Market Dynamics and Key Trends in the 400 GSM Sector?

The global demand for 400 GSM fabrics is being driven by the rising popularity of heavy-duty apparel such as hoodies and sweatshirts, particularly in colder climates. In regions like Europe and North America, the trend towards casual and athleisure wear has led to increased production and sourcing of thicker fabrics. For international B2B buyers in Africa, South America, and the Middle East, understanding these dynamics is crucial. Emerging markets are witnessing a shift towards higher quality, durable materials, as consumer preferences evolve. Moreover, the online marketplace for textiles is expanding, enabling buyers to access a broader range of suppliers.

Technological advancements are shaping the sourcing landscape, with digital platforms facilitating easier supplier discovery and comparison. Innovations in textile manufacturing, such as automated weaving techniques, are enhancing the quality and consistency of 400 GSM fabrics. Additionally, data analytics is playing a key role in inventory management and demand forecasting, helping businesses optimize their supply chains. Buyers should also be aware of the competitive pricing strategies that are emerging due to increased competition among manufacturers, particularly those based in developing countries.

How Is Sustainability and Ethical Sourcing Influencing the 400 GSM Fabric Sector?

Sustainability is becoming a pivotal consideration for B2B buyers in the 400 GSM sector. The environmental impact of textile production is substantial, and there is growing pressure on manufacturers to adopt eco-friendly practices. This includes using organic cotton, recycled polyester, and other sustainable materials that reduce the carbon footprint of the production process. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainability, as consumers demand transparency and responsibility in their purchasing choices.

Certification schemes such as Global Organic Textile Standard (GOTS) and OEKO-TEX® provide buyers with the assurance that their products meet stringent environmental and social standards. These certifications not only enhance the credibility of suppliers but also serve as a marketing advantage in a competitive landscape. For international buyers, particularly those in regions like the Middle East and South America, aligning with suppliers who adhere to these standards can enhance brand reputation and appeal to environmentally conscious consumers.

What Is the Historical Context of 400 GSM Fabric Usage in B2B?

The concept of fabric weight, measured in GSM (grams per square meter), has been a critical factor in the textile industry for decades. The evolution of 400 GSM fabrics can be traced back to the need for heavier, more durable garments that can withstand wear and tear. Historically, these fabrics gained popularity in the late 20th century as casual wear became mainstream. The 400 GSM category emerged as a preferred choice for winter apparel, offering both warmth and comfort.

Over the years, advancements in textile technology have enhanced the quality and versatility of 400 GSM fabrics, making them suitable for various applications beyond traditional clothing. The introduction of blends and innovative finishes has allowed manufacturers to cater to diverse consumer preferences while maintaining the essential qualities of durability and comfort. Understanding this evolution can help B2B buyers appreciate the value and applications of 400 GSM fabrics in today’s market.

Frequently Asked Questions (FAQs) for B2B Buyers of 400 gsm

-

How do I determine the right GSM for my apparel needs?

To determine the appropriate GSM for your apparel, consider the intended use of the garment. For heavier items like hoodies and sweatshirts, 400 GSM is ideal for colder climates or for customers seeking durability. If your target market includes warmer regions, you might opt for lighter fabrics between 200-300 GSM. Always align GSM with the expected wear frequency; heavier garments generally last longer under frequent use. -

What are the advantages of sourcing 400 GSM fabrics?

Sourcing 400 GSM fabrics offers several advantages, including increased durability and warmth, making them suitable for winter apparel. These fabrics provide a premium feel, which can enhance brand perception among consumers. Additionally, the weight helps in maintaining shape and structure, ensuring that garments do not sag or lose form after multiple washes. -

What should I consider when vetting suppliers for 400 GSM products?

When vetting suppliers, check for their experience in producing 400 GSM fabrics and their compliance with international quality standards. Request samples to assess fabric quality and durability. Additionally, consider their production capacity, lead times, and ability to handle custom orders. Reviews and testimonials from previous clients can provide insights into their reliability and service quality. -

What are the common payment terms for international B2B transactions?

Common payment terms include upfront deposits (typically 30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer net 30 or net 60 terms, allowing buyers to pay within 30 or 60 days post-delivery. It’s crucial to clarify these terms upfront and consider using secure payment methods like letters of credit or escrow services to mitigate risks. -

What is the minimum order quantity (MOQ) for 400 GSM fabrics?

MOQs for 400 GSM fabrics can vary significantly among suppliers, typically ranging from 100 to 1,000 units depending on the manufacturer’s production capabilities. When negotiating, consider your inventory needs and whether the supplier can accommodate smaller orders, especially for new or seasonal products. Discussing flexibility in MOQs can help establish a long-term partnership. -

How can I customize 400 GSM products to suit my brand?

Customization options for 400 GSM products may include fabric color, design patterns, and branding elements such as logos or labels. Many suppliers offer services like screen printing, embroidery, or sublimation. Ensure you communicate your specific requirements clearly and ask for samples to review before finalizing orders. Discussing customization options upfront can help align expectations and lead to successful branding. -

What quality assurance measures should I expect from suppliers?

Suppliers should have stringent quality assurance processes in place, including fabric testing for weight, durability, and colorfastness. Request certifications that verify their compliance with international quality standards. Additionally, consider conducting third-party inspections before shipment to ensure that the products meet your specifications and reduce the risk of defects. -

What logistics considerations should I keep in mind when importing 400 GSM fabrics?

When importing 400 GSM fabrics, consider shipping methods, customs regulations, and potential tariffs. Ensure your supplier provides necessary documentation for smooth customs clearance. Evaluate shipping costs and delivery timelines to optimize your supply chain. Collaborating with a reliable logistics partner can facilitate tracking and handling, ensuring timely delivery to your location.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

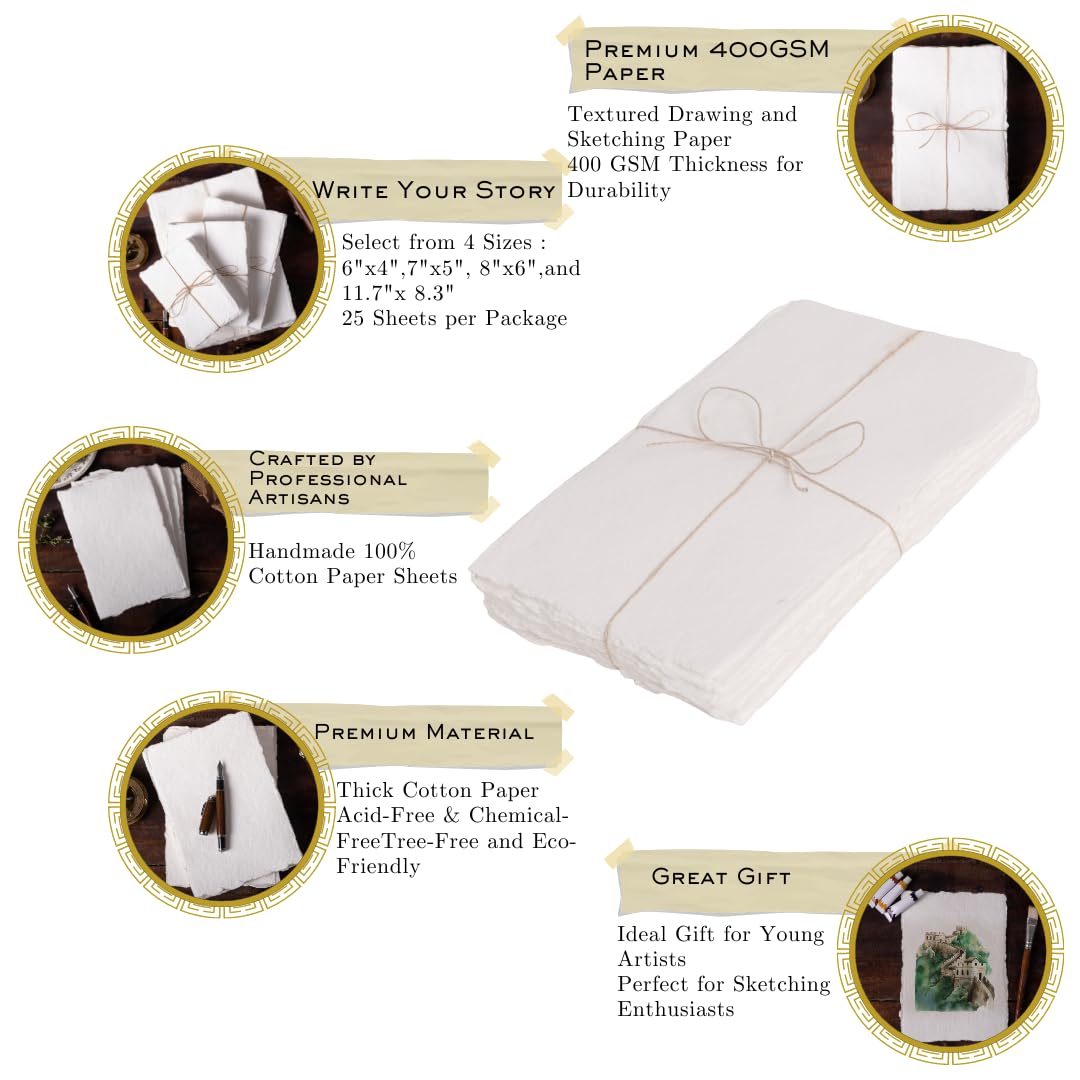

Top 5 400 Gsm Manufacturers & Suppliers List

1. House of Blanks – 400 GSM Hoodies & Crewneck Sweatshirts

Domain: houseofblanks.com

Registered: 2008 (17 years)

Introduction: 400 GSM Hoodies and Crewneck Sweatshirts

2. Nature’s Fabrics – Bamboo Fleece 400 GSM Tubular

Domain: naturesfabrics.com

Registered: 2009 (16 years)

Introduction: Bamboo Fleece Fabric – 400 GSM – Tubular

3. Etsy – 400gsm Cotton Sweatshirt Fabric

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: 400gsm Sweatshirt Fabric, 100% Cotton, 60″ Wide, Sold by the Yard, Suitable for Hoodies, Pullovers, Sweatshirts, and Sweatpants, Sale Price $8.50 (Original Price $8.95), Free Shipping.

4. eBay – Men’s Heavyweight Pullover Hoodie

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”Men’s Heavyweight Pullover Hoodie”,”Material”:”Cotton/Poly Blend (45% Cotton, 55% Polyester)”,”Weight”:”400 GSM”,”Sizes Available”:”S-3XL”,”Colors Available”:[“Apricot”,”Black”,”Camel”,”Dark Gray”,”Green”,”Light Gray”,”Navy Blue”,”Orange”,”Pink”,”Purple”,”Red”,”Blue”,”White”,”Wine Red”,”Yellow”],”Condition”:”New with tags”,”Price”:”$48.44 (Was $56.99, 15% off)”,”Shipping”:”Free”,”…

5. Scraping Dog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

Strategic Sourcing Conclusion and Outlook for 400 gsm

In conclusion, the strategic sourcing of 400 gsm fabrics presents a significant opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The higher GSM weight not only signifies a robust and durable product but also aligns with consumer preferences for quality and longevity. As international buyers navigate this market, understanding the implications of fabric weight on pricing, quality, and end-use will be crucial in making informed procurement decisions.

Investing in 400 gsm apparel, such as hoodies and sweatshirts, can enhance brand reputation by delivering premium products that meet customer expectations. Furthermore, suppliers who prioritize quality and transparency in their offerings will stand out in a competitive landscape.

As we look ahead, the demand for high-quality garments is poised to grow, driven by consumer awareness and sustainability trends. Buyers are encouraged to forge strategic partnerships with reliable manufacturers to ensure a consistent supply of 400 gsm fabrics that meet market needs. Now is the time to leverage these insights and strengthen your sourcing strategies to capitalize on emerging opportunities in the global marketplace.