A Deep Dive into Grommet Belts Solution

Introduction: Navigating the Global Market for grommet belts

In an increasingly competitive global market, sourcing high-quality grommet belts can pose significant challenges for B2B buyers. With diverse styles and material options available, it’s essential for businesses, especially in regions like Africa, South America, the Middle East, and Europe, to navigate this landscape effectively. This guide serves as a comprehensive resource that delves into various types of grommet belts, their applications across different industries, and key considerations for supplier vetting.

Understanding the nuances of pricing, material quality, and design variations will empower international buyers to make informed purchasing decisions that align with their market demands. Whether you are looking for fashion-forward options for retail or durable belts for industrial applications, our guide provides insights into cost structures, supplier reliability, and emerging trends in the grommet belt sector.

By equipping B2B buyers with actionable insights and expert recommendations, we aim to facilitate seamless procurement processes and foster successful partnerships with suppliers. This resource is tailored to meet the specific needs of businesses in Brazil, Nigeria, and other key markets, ensuring that you can confidently source grommet belts that enhance your product offerings and meet customer expectations.

Understanding grommet belts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Grommet Belt | Single row of grommets, often in leather | Retail fashion, uniform supplies | Pros: Versatile, timeless design. Cons: Limited style options. |

| Studded Grommet Belt | Features metal studs along with grommets | Fashion retail, costume supply | Pros: Trendy, eye-catching. Cons: May not appeal to all demographics. |

| Double and Triple Row Grommet | Multiple rows of grommets for enhanced design | Specialty fashion, promotional items | Pros: Unique aesthetic, customizable. Cons: Higher price point. |

| Wide Grommet Belt | Broader belt width, often with oversized grommets | Casual wear, niche markets | Pros: Statement piece, durable. Cons: May not fit all styles. |

| Biker Grommet Belt | Rugged design, often made from heavy leather | Motorcycle apparel, outdoor gear retailers | Pros: Strong, functional. Cons: Limited appeal outside niche markets. |

What Are the Characteristics of Classic Grommet Belts?

Classic grommet belts are typically made from leather and feature a single row of evenly spaced grommets. This style is widely recognized for its versatility and timeless appeal, making it suitable for various applications in retail fashion and uniform supplies. When considering a bulk purchase, B2B buyers should focus on the quality of leather, as well as potential customization options for branding purposes. While they offer a classic look, options may be limited in terms of design variations.

How Do Studded Grommet Belts Stand Out?

Studded grommet belts incorporate metal studs alongside grommets, adding a trendy and edgy flair. They are particularly popular in fashion retail and costume supply sectors, appealing to a younger demographic. B2B buyers should evaluate the durability of the studs and the overall construction of the belt, as these factors significantly impact customer satisfaction. While these belts can attract attention, they may not resonate with all customer segments, posing a risk for broader market appeal.

What Are the Advantages of Double and Triple Row Grommet Belts?

Double and triple row grommet belts are characterized by their multiple rows of grommets, which create a more intricate and unique design. These belts are often used in specialty fashion and promotional items, allowing for a customizable aesthetic. B2B buyers should consider the potential for branding opportunities, as these belts can be tailored to reflect a company’s identity. However, the higher price point may deter budget-conscious buyers, making it essential to highlight the unique selling propositions during the purchasing process.

What Makes Wide Grommet Belts a Good Choice?

Wide grommet belts feature a broader design and oversized grommets, making them a statement accessory. They are commonly found in casual wear and niche markets, appealing to consumers looking for distinctive styles. B2B buyers should assess the durability and comfort of these belts, as they need to withstand regular use. While they serve as a bold fashion statement, their fit may not suit all styles, which could limit their marketability in more conservative segments.

In What Contexts Are Biker Grommet Belts Used?

Biker grommet belts are designed with a rugged aesthetic, often crafted from heavy-duty leather to withstand the demands of motorcycle riding. These belts are primarily marketed through motorcycle apparel and outdoor gear retailers. B2B buyers should focus on the strength and functionality of these belts, ensuring they meet the needs of their target audience. While they offer durability and a unique style, their appeal is largely confined to niche markets, which may limit broader consumer interest.

Key Industrial Applications of grommet belts

| Industry/Sector | Specific Application of grommet belts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Customized grommet belts for fashion collections | Enhances brand identity and product uniqueness | Material quality, design flexibility, and pricing |

| Manufacturing | Industrial grommet belts for machinery and tools | Improves equipment efficiency and durability | Load capacity, material resistance, and compliance |

| Automotive | Grommet belts in automotive accessories | Offers customization options for vehicle interiors | Compatibility with vehicle models and safety standards |

| Entertainment | Grommet belts for costumes and performance wear | Adds aesthetic appeal for theatrical productions | Design intricacy, material durability, and cost-effectiveness |

| Sports and Recreation | Grommet belts for sports gear and uniforms | Enhances functionality and style for athletes | Breathability, adjustability, and branding options |

How Are Grommet Belts Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, grommet belts are often customized for specific collections, providing a unique touch to clothing lines. Designers leverage these belts to enhance brand identity, making them a critical component for attracting customers. Buyers in this industry should consider material quality and design flexibility, ensuring that the grommet belts align with current fashion trends while remaining cost-effective.

What Role Do Grommet Belts Play in Manufacturing?

Within manufacturing, grommet belts are utilized in various machinery and tools to facilitate movement and power transmission. They are essential for improving equipment efficiency and durability, which can significantly reduce downtime and maintenance costs. Buyers need to evaluate load capacity and material resistance, ensuring compliance with industry standards for safety and performance, particularly in demanding environments.

How Are Grommet Belts Applied in the Automotive Sector?

In the automotive industry, grommet belts are incorporated into various accessories, including seat covers and interior decorations. They provide customization options that enhance the aesthetic appeal of vehicles, appealing to consumers seeking personalized touches. When sourcing grommet belts, businesses must ensure compatibility with different vehicle models and adhere to safety standards to maintain quality and reliability.

Why Are Grommet Belts Important in Entertainment?

For the entertainment industry, grommet belts are crucial components in costumes and performance wear, adding both functionality and style. These belts are designed to withstand the rigors of performances while providing an aesthetic appeal that complements the overall costume. Buyers should focus on design intricacy and material durability, balancing cost with the need for high-quality, visually appealing products.

How Do Grommet Belts Enhance Sports Gear?

In the sports and recreation sector, grommet belts are integrated into sports gear and uniforms, enhancing both functionality and style. They provide athletes with adjustable fits and can feature breathable materials for added comfort during physical activities. Key considerations for buyers include breathability, adjustability, and the potential for branding, ensuring that the belts not only perform well but also represent the team or brand effectively.

3 Common User Pain Points for ‘grommet belts’ & Their Solutions

Scenario 1: Sizing and Fit Issues with Grommet Belts

The Problem: A common challenge faced by B2B buyers, especially when purchasing grommet belts for retail or promotional purposes, is ensuring the right sizing and fit for their target audience. Many suppliers provide belts in standard sizes without taking into account the diverse body shapes and sizes across different regions, particularly in international markets such as Africa and South America. This can lead to high return rates and dissatisfied customers, which ultimately affects the bottom line and the brand’s reputation.

The Solution: To mitigate sizing issues, B2B buyers should prioritize sourcing grommet belts from manufacturers that offer a wide range of sizes and customizable options. When placing orders, it’s beneficial to request detailed sizing charts and fit guides that cater to different demographics. Additionally, consider implementing a sample program where buyers can test various sizes before committing to larger orders. Providing clear product descriptions and size recommendations based on customer demographics can also enhance customer satisfaction and reduce returns.

Scenario 2: Durability and Quality Concerns of Grommet Belts

The Problem: Another prevalent pain point is the inconsistency in the quality and durability of grommet belts. Buyers may encounter products that wear out quickly or do not meet the promised specifications, leading to customer complaints and potential loss of business. This is particularly concerning for retailers who wish to maintain a strong reputation for quality in competitive markets.

The Solution: To ensure high quality and durability, B2B buyers should focus on establishing relationships with reputable manufacturers known for their craftsmanship and use of premium materials. Requesting product samples before making bulk purchases can help assess the durability of the belts. Buyers should also inquire about the materials used, such as full-grain leather or reinforced stitching, as these factors contribute significantly to longevity. Additionally, consider sourcing belts that come with a warranty or satisfaction guarantee, which can provide peace of mind and bolster customer confidence in the product.

Scenario 3: Limited Design Options for Grommet Belts

The Problem: Many B2B buyers find that the available design options for grommet belts are often limited, making it difficult to cater to the diverse fashion preferences of consumers across different regions. This lack of variety can lead to stagnant inventory and missed opportunities in the market, especially in vibrant fashion markets like Brazil or Nigeria where unique styles are highly sought after.

The Solution: To address this issue, buyers should actively seek manufacturers that offer a wide array of designs, colors, and customizations. Engaging in collaborative designs with manufacturers can also lead to unique products that resonate with local markets. Buyers should conduct market research to identify trends and consumer preferences in their specific regions and use this data to guide their purchasing decisions. Furthermore, consider introducing limited edition designs or seasonal collections to keep the inventory fresh and appealing to a diverse customer base. This strategy not only enhances sales potential but also establishes the brand as a trendsetter in the market.

Strategic Material Selection Guide for grommet belts

What Are the Key Materials Used in Grommet Belts?

When selecting grommet belts for diverse applications, understanding the materials used is crucial for ensuring performance, durability, and compliance with industry standards. Here, we analyze four common materials: leather, synthetic leather, nylon, and cotton. Each material presents unique properties, advantages, and limitations that can impact the end product’s suitability for various markets.

How Does Leather Perform in Grommet Belts?

Leather is a traditional choice for grommet belts, prized for its durability and aesthetic appeal. Full-grain leather, in particular, offers exceptional strength, temperature resistance, and a natural finish that enhances style. It can withstand high levels of stress without tearing, making it suitable for heavy-duty applications.

Pros: Leather belts provide superior durability and a premium look, appealing to high-end markets. They are also resistant to wear and tear, which is beneficial for long-term use.

Cons: The cost of high-quality leather can be significant, and sourcing may be challenging in certain regions. Additionally, leather requires specific care to maintain its appearance and longevity.

For international buyers, compliance with environmental standards related to leather tanning processes is essential, particularly in Europe, where regulations may be stricter. Understanding local preferences for leather quality can also influence purchasing decisions.

What Are the Benefits of Synthetic Leather for Grommet Belts?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is increasingly popular for grommet belts due to its cost-effectiveness and versatility. It mimics the appearance of real leather while offering additional benefits like easier maintenance and water resistance.

Pros: Synthetic leather is generally less expensive than genuine leather and can be produced in various colors and textures. It is also easier to clean and maintain, making it suitable for everyday wear.

Cons: While synthetic leather can offer good durability, it may not match the longevity of high-quality leather. Additionally, it can be less breathable, which might affect comfort in hot climates.

Buyers from regions with high humidity, such as parts of Africa and South America, may prefer synthetic leather for its moisture resistance. However, they should also consider the environmental impact of synthetic materials and seek suppliers who adhere to sustainability practices.

How Does Nylon Compare for Grommet Belts?

Nylon is a synthetic fabric known for its strength, elasticity, and resistance to abrasion. It is lightweight and can be easily dyed, making it a popular choice for casual and sporty grommet belts.

Pros: Nylon belts are highly durable and resistant to wear, making them ideal for active lifestyles. They are also less expensive than leather options, appealing to budget-conscious consumers.

Cons: Nylon may not provide the same level of aesthetic appeal as leather, which could limit its market reach. Additionally, nylon belts can be less comfortable in extreme temperatures, as they may not breathe as well.

International buyers should consider the specific applications of nylon belts, especially in regions with varying climates. Compliance with standards related to fabric safety and durability is also important, particularly in Europe and the Middle East.

What Role Does Cotton Play in Grommet Belts?

Cotton is a natural fiber known for its softness and breathability, making it suitable for casual grommet belts. It is often blended with other materials to enhance durability and performance.

Pros: Cotton belts are comfortable to wear and easy to clean, making them suitable for everyday use. They are also biodegradable, appealing to environmentally conscious consumers.

Cons: Cotton is less durable than synthetic options and may not withstand heavy use as effectively. It can also absorb moisture, which may lead to quicker wear in humid conditions.

For international buyers, understanding local preferences for natural fibers versus synthetic materials is crucial. Compliance with organic certification standards may also be relevant for buyers in Europe and North America.

Summary Table of Material Selection for Grommet Belts

| Material | Typical Use Case for grommet belts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Fashion, heavy-duty applications | Superior durability and style | High cost and maintenance required | High |

| Synthetic Leather | Everyday wear, budget-friendly | Cost-effective and easy care | Less durable than genuine leather | Medium |

| Nylon | Active lifestyle, casual wear | Lightweight and abrasion-resistant | Limited aesthetic appeal | Low |

| Cotton | Casual use, comfort-focused | Soft, breathable, biodegradable | Less durable, moisture-absorbent | Low |

This guide provides a comprehensive overview of material options for grommet belts, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for grommet belts

What Are the Key Stages in the Manufacturing Process of Grommet Belts?

The manufacturing process for grommet belts involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages can help B2B buyers identify reliable suppliers and ensure that the belts meet their specific requirements.

Material Preparation: What Materials Are Used in Grommet Belts?

The first stage involves selecting the right materials, which typically include leather, synthetic fabrics, or a combination of both. High-quality leather, such as full-grain or top-grain leather, is often preferred for its durability and aesthetic appeal. Synthetic materials may be chosen for their cost-effectiveness and versatility.

Once the materials are selected, they undergo a preparation process that includes cutting them into the desired shapes and sizes. This step is crucial, as precise measurements will affect the fit and functionality of the grommet belt.

How Are Grommet Belts Formed?

The forming stage involves creating the grommet holes and any decorative elements. Grommet holes are typically made using specialized die-cutting tools or grommet presses. This process ensures that the holes are uniform and correctly positioned, which is essential for the belt’s functionality and appearance.

In this stage, manufacturers may also apply treatments to enhance the material’s properties, such as waterproofing or stain resistance. This step is particularly important for grommet belts that are intended for outdoor or heavy-duty use.

What Does the Assembly Process Entail?

Once the materials have been prepared and formed, the next step is assembly. This involves stitching the belt together, attaching the buckle, and inserting the grommets. The stitching must be robust to withstand daily wear and tear, and various techniques, such as double-stitching or reinforced stitching, may be employed to enhance durability.

Quality control checkpoints are often integrated during the assembly process. For instance, an In-Process Quality Control (IPQC) review might ensure that the stitching meets the specified standards before proceeding to the next stage.

How Are Grommet Belts Finished?

The finishing stage includes any additional treatments, such as dyeing, polishing, or coating. For leather belts, this may involve applying conditioners or sealants to enhance the leather’s appearance and longevity. Synthetic belts may undergo heat treatment or lamination for added durability.

Quality assurance checks, known as Final Quality Control (FQC), are conducted at this stage to ensure that the product meets all specifications before it is packaged for shipment.

What International Standards and Quality Assurance Practices Are Relevant for Grommet Belts?

B2B buyers must be aware of the various international standards and quality assurance practices that apply to grommet belts. Adherence to these standards not only ensures product quality but also facilitates smoother international trade.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a widely recognized standard for quality management systems. Suppliers that comply with ISO 9001 demonstrate a commitment to quality processes, which can enhance buyer confidence.

Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe can indicate compliance with health, safety, and environmental protection standards. Buyers from regions like Africa, South America, and the Middle East should also be aware of local regulations that may affect product acceptance in their markets.

How Are Quality Control Checkpoints Implemented?

Quality control checkpoints are critical in ensuring that grommet belts meet specified quality standards. The typical checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet quality specifications before production begins.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks ensure that each stage adheres to quality standards.

-

Final Quality Control (FQC): A comprehensive review of the finished product to ensure it meets all specifications before shipping.

These checkpoints help identify and rectify issues early in the production process, minimizing the risk of defective products reaching the market.

What Testing Methods Are Commonly Used in Grommet Belt Manufacturing?

Testing methods are essential for ensuring the durability and functionality of grommet belts. Various approaches may be employed, including:

- Tensile Strength Testing: To measure the belt’s ability to withstand pulling forces without breaking.

- Abrasion Testing: To assess how well the belt material can resist wear and tear over time.

- Colorfastness Testing: To ensure that dye does not fade or bleed when exposed to moisture or sunlight.

These tests provide valuable insights into the performance and longevity of the grommet belts, helping B2B buyers make informed purchasing decisions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

-

Supplier Audits: Conducting on-site audits can provide firsthand insights into the supplier’s manufacturing processes and quality control practices. This is particularly useful for buyers from regions like Africa or South America, where quality may vary significantly.

-

Quality Reports: Requesting documentation of quality control practices, including results from IQC, IPQC, and FQC, can help buyers assess the reliability of a supplier.

-

Third-Party Inspections: Engaging independent inspection agencies can add an extra layer of assurance. These agencies can conduct thorough evaluations of the manufacturing process and product quality before shipment.

-

Certification Verification: Buyers should verify any claims of compliance with international standards, such as ISO or CE, by checking certification documents.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate a complex landscape of quality assurance that can vary by region. For instance, buyers in Europe may have stricter compliance requirements compared to those in Africa or South America. Additionally, understanding local regulations and standards is crucial to ensure that products meet market expectations.

Moreover, cultural differences in quality perception may influence buyer-supplier relationships. Establishing clear communication and expectations regarding quality can help bridge these gaps and foster long-term partnerships.

In conclusion, understanding the manufacturing processes and quality assurance practices for grommet belts is crucial for B2B buyers aiming to make informed purchasing decisions. By focusing on supplier quality, international standards, and verification methods, buyers can enhance their procurement strategies and ensure they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘grommet belts’

Introduction

This sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure grommet belts. With the increasing popularity of these fashionable accessories across various markets, understanding the procurement process is essential. This guide will outline key steps to ensure you select the best suppliers and products that meet your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications of the grommet belts you wish to source. Consider factors such as materials (e.g., leather, synthetic), size variations, grommet styles, and durability requirements. Defining these specifications helps streamline the sourcing process and ensures that you receive products that meet your quality standards.

Step 2: Research Market Trends and Demand

Understanding current market trends is crucial for making informed purchasing decisions. Analyze which styles, colors, and materials are trending in your target regions, such as Africa, South America, and Europe. Utilize market reports, social media insights, and competitor analysis to gauge consumer preferences, which can guide your sourcing strategy and inventory management.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet potential suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in producing high-quality grommet belts and ensure they can meet your volume requirements.

- Check for Certifications: Verify that suppliers comply with international quality standards, such as ISO certifications, which indicate reliability and adherence to industry norms.

- Assess Production Capabilities: Understand their production capacity and lead times to ensure they can fulfill your orders in a timely manner.

Step 4: Request Product Samples

Once you have shortlisted potential suppliers, request samples of the grommet belts. This step is essential to evaluate the quality, craftsmanship, and overall aesthetic of the products. Inspect the materials used, the durability of grommets, and the overall finish to ensure they align with your brand’s standards.

Step 5: Negotiate Pricing and Terms

Engage in discussions about pricing, payment terms, and minimum order quantities. Understanding the total cost of procurement, including shipping and customs duties, will help you assess the financial feasibility of your sourcing decisions. Don’t hesitate to negotiate terms that provide the best value while maintaining quality.

Step 6: Verify Shipping and Logistics Capabilities

Assess the shipping and logistics capabilities of your chosen supplier. Ensure they can deliver products to your specified locations efficiently and cost-effectively. Consider potential shipping times, customs regulations, and whether the supplier has experience exporting to your target markets.

Step 7: Establish a Quality Control Process

Before finalizing your order, establish a quality control process to ensure that the grommet belts meet your specifications. This may include setting up inspections at different stages of production and before shipment. Implementing a robust quality control system mitigates risks and helps maintain product consistency, ultimately leading to greater customer satisfaction.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for grommet belts, ensuring they procure high-quality products that meet market demand.

Comprehensive Cost and Pricing Analysis for grommet belts Sourcing

What Are the Key Cost Components for Sourcing Grommet Belts?

Understanding the cost structure for sourcing grommet belts is essential for international B2B buyers, especially when considering the diverse markets in Africa, South America, the Middle East, and Europe. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Grommet belts are often made from leather, synthetic materials, or a combination of both. Full-grain leather tends to be more expensive due to its quality and durability, while synthetic options may lower costs but could compromise longevity.

-

Labor: Labor costs vary by region and can be influenced by the complexity of the manufacturing process. Skilled craftsmanship, particularly for handmade grommet belts, can increase labor costs.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: The initial investment in tools and machinery for creating grommet belts can be substantial. Custom tooling for specific designs may add to the upfront costs but can lead to better margins over time.

-

Quality Control (QC): Ensuring the quality of grommet belts is crucial, especially for B2B transactions. Implementing rigorous QC processes may increase production costs but is vital for maintaining brand reputation and reducing returns.

-

Logistics: Shipping and handling costs are significant, particularly for international shipments. Factors such as distance, shipping method, and volume can greatly influence these expenses.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary based on competition, brand positioning, and market demand.

How Do Price Influencers Affect Grommet Belt Sourcing?

Several factors can influence the pricing of grommet belts, impacting the total cost for B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better prices and optimize inventory levels.

-

Specifications and Customization: Unique designs, custom sizes, and specific materials can lead to higher costs. Buyers should consider whether customization is necessary or if standard products will suffice.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., eco-friendly, fair trade) can increase costs but may appeal to certain markets and consumer bases.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their reliability and quality assurance, while newer suppliers might offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate responsibilities in shipping and logistics. Understanding these can help buyers avoid unexpected costs and delays.

What Are Effective Buyer Tips for Cost-Efficiency in Grommet Belt Sourcing?

For international B2B buyers, particularly those operating in diverse and emerging markets, several strategies can enhance cost-efficiency:

-

Negotiation: Always negotiate pricing, especially when dealing with larger quantities. Suppliers may have room for discounts that can significantly impact overall costs.

-

Total Cost of Ownership (TCO): Consider the TCO beyond just the purchase price. This includes logistics, potential returns, and long-term durability. Investing in higher-quality belts may reduce replacement costs over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect pricing. Establishing relationships with local suppliers may mitigate these costs.

-

Research and Compare Suppliers: Evaluate multiple suppliers based on quality, price, and service. Engaging with suppliers who have experience in your target market can provide insights into regional preferences and pricing trends.

Disclaimer

Prices for grommet belts can vary widely based on the factors outlined above. The examples provided are indicative and may not reflect current market conditions or specific supplier pricing. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing grommet belts With Other Solutions

Exploring Alternatives to Grommet Belts for Your Business Needs

In the competitive landscape of fashion accessories, particularly in the belt segment, grommet belts stand out for their unique design and durability. However, it is essential for B2B buyers to explore alternative solutions that may better meet their specific requirements. This analysis will compare grommet belts with two viable alternatives: studded belts and traditional leather belts, focusing on key performance metrics.

| Comparison Aspect | Grommet Belts | Studded Belts | Traditional Leather Belts |

|---|---|---|---|

| Performance | High durability; stylish | Very durable; edgy look | Classic durability; versatile |

| Cost | Moderate ($60 – $200) | Moderate to high ($50 – $250) | Varies widely ($30 – $300) |

| Ease of Implementation | Simple production process | Simple production process | More complex due to variety of styles |

| Maintenance | Low; easy to clean | Low; easy to clean | Low; regular cleaning needed |

| Best Use Case | Casual and edgy outfits | Casual, punk, or rock styles | Formal and casual settings |

What Are the Advantages and Disadvantages of Studded Belts?

Studded belts offer a robust alternative to grommet belts, featuring metal studs embedded along the belt’s length. This design can create a bold, punk-inspired look that appeals to specific demographics, especially among younger consumers. The key advantages of studded belts include their durability and the ability to make a fashion statement. However, they may not be as versatile as grommet belts, limiting their appeal in formal or business settings. Additionally, the cost can vary significantly based on the material and stud design, potentially affecting bulk purchasing decisions.

How Do Traditional Leather Belts Compare?

Traditional leather belts are a timeless choice that can adapt to both formal and casual attire. They are often made from high-quality leather, which can be beneficial for companies looking to project a sophisticated image. The primary advantage of traditional leather belts is their versatility; they can be worn in various settings, from business meetings to casual outings. However, the cost can vary widely, and certain styles may require more intricate production processes. This complexity can affect lead times and availability for international buyers.

Conclusion: How to Choose the Right Belt Solution for Your Business?

When selecting the right belt solution for your business, consider your target audience and the specific context in which the belts will be used. Grommet belts are ideal for trendy, casual applications, while studded belts may attract a niche market with a penchant for edgy fashion. Traditional leather belts, on the other hand, provide a classic option that can cater to a broader audience. Assess factors like performance, cost, ease of implementation, and maintenance to determine the best fit for your needs. Ultimately, aligning your choice with your brand’s identity and customer preferences will lead to more effective purchasing decisions.

Essential Technical Properties and Trade Terminology for grommet belts

What Are the Key Technical Properties of Grommet Belts?

When sourcing grommet belts, understanding the essential technical specifications is crucial for making informed purchasing decisions. Here are several critical properties to consider:

-

Material Composition

Grommet belts are typically made from materials such as leather, synthetic fabrics, or canvas. Leather belts are often favored for their durability and aesthetic appeal, while synthetic options can offer weather resistance and lower costs. The choice of material impacts not only the product’s lifespan but also its suitability for specific applications, such as fashion or workwear. -

Belt Width

The width of grommet belts can vary, commonly ranging from 1 inch to 2 inches. A wider belt may provide better support and durability, making it ideal for heavy-duty use. In contrast, narrower belts can be more fashion-oriented, appealing to different market segments. Buyers should align the width with the intended use and consumer preferences. -

Grommet Size and Spacing

The size and spacing of grommets play a significant role in both functionality and aesthetics. Grommets can vary in diameter, typically ranging from 0.5 to 1.5 inches, and can be spaced closely or widely apart. This affects the belt’s adjustability and style. Understanding these dimensions is vital for meeting customer expectations and ensuring product compatibility with existing apparel. -

Buckle Type

The buckle mechanism can significantly impact user experience. Common types include prong, snap, and ratchet buckles. Each type offers different levels of adjustability and ease of use. For example, ratchet buckles provide a more customizable fit, which can enhance consumer satisfaction. -

Thickness and Tolerance

The thickness of the belt material can range from 1/8 inch to 1/4 inch. Tolerance levels indicate how much variation is acceptable in the manufacturing process. Maintaining strict tolerances ensures consistency in product quality, which is vital for bulk orders and brand reputation. -

Color and Finish Options

Grommet belts come in various colors and finishes, including matte, glossy, and distressed looks. Offering a range of colors can cater to diverse consumer tastes, especially in fashion markets. Understanding color trends can help businesses position their products effectively.

What Are Common Trade Terms Related to Grommet Belts?

Navigating the grommet belt market requires familiarity with specific industry jargon. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are sold by another company under its brand name. In the context of grommet belts, OEM manufacturers often provide customized designs or specifications to meet the needs of brand owners. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers to manage inventory and production costs effectively. Lower MOQs can be beneficial for new businesses or those testing market demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. B2B buyers should prepare detailed RFQs that specify desired properties, quantities, and any other relevant information to receive accurate pricing and terms. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms is vital for negotiating shipping and delivery terms, which can affect total landed costs. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. It encompasses manufacturing, shipping, and any other processing time. Knowing the lead time helps businesses plan inventory and meet customer demand without delays. -

Quality Assurance (QA)

QA refers to the systematic processes in place to ensure that products meet specified standards before they reach the market. Establishing clear QA protocols is crucial for maintaining product integrity and customer satisfaction, especially in bulk orders.

By familiarizing yourself with these technical properties and trade terms, you can better navigate the grommet belt market, ensuring that your purchasing decisions align with your business needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the grommet belts Sector

What Are the Key Market Dynamics and Trends Influencing Grommet Belts?

The grommet belts sector is experiencing a transformative phase, driven by a blend of fashion trends, consumer preferences, and technological advancements. Globally, there is a growing inclination towards personalized and unique accessories, leading to an increased demand for grommet belts that offer both style and functionality. In regions like Africa and South America, the market is influenced by vibrant local cultures that favor bold designs and expressive accessories. Additionally, the rise of e-commerce platforms has expanded market access, enabling international B2B buyers to source products from various regions, including Europe and the Middle East.

Emerging B2B tech trends are reshaping the sourcing landscape for grommet belts. Advanced analytics and artificial intelligence are being utilized to predict fashion trends and optimize inventory management. This allows suppliers to respond quickly to market demands, reducing lead times and minimizing stockouts. Furthermore, the integration of augmented reality (AR) in online shopping experiences is enhancing customer engagement, providing buyers the ability to visualize how grommet belts will complement their outfits before making a purchase.

Sustainability considerations are also influencing purchasing decisions. B2B buyers are increasingly seeking suppliers that prioritize eco-friendly practices and materials, reflecting a broader trend towards responsible consumption. As the market evolves, understanding these dynamics will be crucial for international buyers looking to capitalize on the opportunities within the grommet belts sector.

How Important Are Sustainability and Ethical Sourcing in the Grommet Belts Industry?

Sustainability and ethical sourcing have become paramount in the grommet belts industry, driven by increasing consumer awareness and regulatory pressures. The environmental impact of traditional manufacturing processes raises concerns about waste, pollution, and resource depletion. As a response, many manufacturers are adopting sustainable practices, such as using recycled materials or implementing energy-efficient production methods. For international B2B buyers, aligning with suppliers who prioritize sustainability can enhance brand reputation and meet the demands of environmentally conscious consumers.

Ethical supply chains are equally critical. Buyers are increasingly scrutinizing the labor practices of their suppliers, seeking those that ensure fair wages and safe working conditions. Certifications such as Fair Trade and Global Organic Textile Standard (GOTS) can serve as indicators of ethical practices, providing assurance to buyers about the integrity of their sourcing decisions. Additionally, the incorporation of biodegradable materials in grommet belt production is gaining traction, appealing to eco-conscious markets.

In conclusion, prioritizing sustainability and ethical sourcing is not only beneficial for the environment but also offers a competitive advantage in an increasingly conscientious marketplace.

What Is the Historical Context of Grommet Belts and Their Evolution in the B2B Space?

Grommet belts have a rich history that dates back to the early 20th century when they were primarily associated with military and workwear. Initially designed for functionality, these belts incorporated metal grommets for durability and ease of adjustment. Over the decades, grommet belts transitioned into fashion statements, particularly within punk and alternative subcultures during the late 20th century.

As fashion trends evolved, so did the designs and materials used in grommet belts. Today, they are crafted from a variety of materials, including leather, synthetic fabrics, and eco-friendly alternatives, appealing to a diverse range of consumers. For B2B buyers, understanding this evolution is essential, as it highlights the shifting preferences and demands of the market. By recognizing the historical significance and contemporary relevance of grommet belts, buyers can make informed sourcing decisions that resonate with current consumer trends.

Frequently Asked Questions (FAQs) for B2B Buyers of grommet belts

-

How do I select the right grommet belts for my business needs?

To select the right grommet belts, consider factors such as material, design, and intended market. Assess the durability of materials like leather versus synthetic options based on your customer base’s preferences. Additionally, evaluate the styles and colors that resonate with your target demographic. If you cater to diverse markets, offering a variety of sizes and designs can enhance your appeal. Finally, review supplier catalogs to ensure that they can meet your product quality standards and customization needs. -

What are the customization options available for grommet belts?

Customization options for grommet belts can include color, material, size, and design features such as the number and type of grommets. Many suppliers offer bespoke services, allowing you to create unique products tailored to your brand identity. It is advisable to discuss your specific requirements with potential suppliers to understand their capabilities. Be sure to inquire about minimum order quantities (MOQs) for customized designs, as this can vary widely among manufacturers. -

What are the minimum order quantities (MOQs) for grommet belts?

Minimum order quantities for grommet belts can vary significantly based on the supplier and customization level. Typically, MOQs range from 100 to 500 units, especially for customized products. It’s essential to clarify these details during initial discussions with suppliers. Additionally, some manufacturers may offer flexibility in MOQs for established customers or larger orders, so it’s worth negotiating terms that suit your business model. -

How can I vet suppliers for grommet belts?

To effectively vet suppliers for grommet belts, conduct thorough research including checking references, reading reviews, and verifying their business credentials. Request samples of products to assess quality firsthand. Additionally, evaluate their production capabilities, lead times, and communication practices. Consider visiting their facilities if feasible, or utilizing third-party inspection services to ensure compliance with your quality standards. Establishing a reliable partnership is crucial for long-term success. -

What payment terms are commonly offered by grommet belt suppliers?

Payment terms can vary widely among grommet belt suppliers, often influenced by factors such as order size and relationship history. Common terms include upfront deposits (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer credit terms after establishing a solid relationship. It’s important to negotiate terms that align with your cash flow and risk management strategies while ensuring clarity on potential penalties for late payments. -

What quality assurance measures should I implement when sourcing grommet belts?

Implementing quality assurance measures is essential for maintaining product standards. Start by defining clear specifications for materials, craftsmanship, and packaging. Conduct regular quality inspections throughout the production process, including pre-production samples and in-line checks. Collaborate with suppliers to establish quality control protocols and utilize third-party inspection services when necessary. Documenting these processes can help mitigate risks and ensure that products meet your market’s expectations. -

How do logistics and shipping impact the sourcing of grommet belts?

Logistics and shipping play a critical role in the sourcing of grommet belts, affecting delivery times and costs. Factors such as the supplier’s location, shipping methods, and customs regulations in your country can significantly impact your overall supply chain efficiency. It’s advisable to work with logistics partners who have experience in international shipping and can navigate customs processes effectively. Establishing a clear timeline for delivery and understanding potential delays can help in planning your inventory management. -

What are the trends in the grommet belt market that I should be aware of?

Staying informed about market trends is crucial for competitive advantage. Currently, there is a growing demand for eco-friendly materials and sustainable production practices in the grommet belt market. Additionally, fashion trends are shifting towards unique designs, including statement pieces with bold colors and patterns. Monitoring consumer preferences through market research and industry reports can help you adapt your product offerings. Engaging with fashion influencers or participating in trade shows can also provide insights into emerging styles.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Grommet Belts Manufacturers & Suppliers List

1. Leather Belts Online – Grommet Belts for Men

Domain: leatherbeltsonline.com

Registered: 2015 (10 years)

Introduction: Labor Day SALE – 30% OFF! Free Shipping on Orders $100 and Up! Grommet Belts for Men available in various sizes and colors. Sizes range from 28″ to 46″. Belt widths include 3.0 cm, 3.5 cm, 3.8 cm, 4.0 cm, and 4.5 cm. Buckle colors available in Black, Gold, and Silver. Leather types include Cow, Full Grain, Smooth, and Vegan. Multiple products listed with discounts, including: 1. Black Studded Belt…

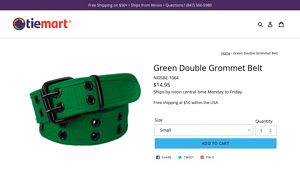

2. Tiemart – Green Double Grommet Belt

Domain: tiemart.com

Registered: 2001 (24 years)

Introduction: {‘product_name’: ‘Green Double Grommet Belt’, ‘sku’: ‘NI0SBE-1064’, ‘price’: ‘$14.95’, ‘sizes_available’: [‘Small (29″ to 31″)’, ‘Medium (32″ to 34″)’, ‘Large (34″ to 36″)’, ‘Extra Large (37″ to 38″)’], ‘color’: ‘green’, ‘material’: ‘100% Cotton’, ‘features’: ‘Two rows of black tone metal grommets and roller buckle, 1.5 inches wide, unisex design’, ‘shipping_info’: ‘Ships from Illinois, free shipp…

3. Hot Topic – Two-Row Black Grommet Belt

4. Leatherpunk – Pyramid Studded Leather Belts

Domain: leatherpunk.com

Registered: 2002 (23 years)

Introduction: Leatherpunk offers a variety of pyramid studded leather belts and punk style studded leather belts. Key features include:

– Made from strong single ply full grain leather

– Fitted with heavy hardware

– Designed for both men and women

– Guaranteed never to split apart

– Most belts feature strong snap fastener fittings for easy buckle removal

– Only maker of belts using real chrome plated pyra…

5. Target – Grommet Belts Collection

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Grommet Belts Collection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Love Strength – Eden Grommet Belt

Domain: lovestrength.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “Eden Grommet Belt”, “color”: “Black”, “price”: “$114”, “description”: “Grommets for when you’re feeling a little edgy meet our signature sleek slim leather belt. Eden is made to elevate the everyday.”, “features”: [“Edgy grommet details”, “Sleek finish”, “Genuine leather”, “Metal hardware”], “available_sizes”: [“One Size – 40″ buckle bar to the point”], “measurement”: “Measuremen…

Strategic Sourcing Conclusion and Outlook for grommet belts

As the demand for grommet belts continues to grow globally, especially in markets across Africa, South America, the Middle East, and Europe, strategic sourcing becomes essential for B2B buyers looking to capitalize on this trend. By prioritizing quality materials and reliable suppliers, businesses can enhance their product offerings while ensuring customer satisfaction. The diversity in styles, from classic leather to trendy studded designs, presents numerous opportunities for importers to cater to varying consumer preferences.

Investing in strategic sourcing practices not only streamlines procurement processes but also fosters long-term relationships with manufacturers, which is vital for maintaining a competitive edge. Buyers are encouraged to conduct thorough market research, evaluate suppliers based on their production capabilities, and negotiate favorable terms that align with their business goals.

Looking ahead, the grommet belt market is poised for continued expansion, driven by evolving fashion trends and consumer demands. International B2B buyers should seize this moment to strengthen their sourcing strategies and explore innovative ways to introduce grommet belts into their product lines. By doing so, they can not only meet market demands but also position themselves as leaders in this dynamic sector.